A Deep Dive into 20 Gallon Drum Solution

Introduction: Navigating the Global Market for 20 gallon drum

In the complex landscape of international trade, sourcing the right 20-gallon drum can present a significant challenge for B2B buyers. Whether you are in Nigeria, Brazil, or Germany, understanding the nuances of different drum types, materials, and their specific applications is crucial to ensuring that your supply chain remains efficient and compliant with safety regulations. This guide serves as a comprehensive resource for navigating the global market for 20-gallon drums, offering insights into the various types available—such as plastic, steel, and fiber drums—as well as their applications in industries ranging from food and beverage to hazardous waste management.

Buyers will benefit from a thorough exploration of supplier vetting processes, which are essential for establishing reliable partnerships. We will address key considerations like cost, durability, and regulatory compliance, enabling you to make informed purchasing decisions. By understanding the dimensions and weight capacities of different drum options, you can optimize your storage and transport solutions, ensuring that your operations run smoothly.

This guide empowers international B2B buyers by providing actionable insights tailored to specific regional challenges and market dynamics. With a focus on practical solutions, you can confidently select the right 20-gallon drum for your business needs, ensuring safety, efficiency, and cost-effectiveness in your operations.

Understanding 20 gallon drum Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Drums | Durable, corrosion-resistant, often lined for specific contents | Chemicals, oils, food products | Pros: High strength, suitable for hazardous materials. Cons: Heavier and may be more expensive. |

| Plastic Drums | Lightweight, weather-resistant, often UV protected | Chemicals, food storage, waste disposal | Pros: Cost-effective, easy to handle. Cons: May not withstand extreme temperatures. |

| Fiber Drums | Made from composite materials, often recyclable | Packaging, non-hazardous materials | Pros: Lightweight, eco-friendly. Cons: Less durable than metal or plastic. |

| Lab Pack Drums | Designed for hazardous materials with secure closures | Laboratory waste, hazardous material transport | Pros: Ensures safe containment, compliant with regulations. Cons: Limited to smaller, non-leaking items. |

| Reconditioned Drums | Previously used drums that have been cleaned and refurbished | Cost-effective option for bulk storage | Pros: Environmentally friendly, lower cost. Cons: May have limited availability and varied quality. |

What are the Characteristics of Steel Drums and Their Suitability for B2B Buyers?

Steel drums are renowned for their durability and strength, making them a preferred choice for storing hazardous materials, chemicals, and food products. These drums can be coated internally to prevent corrosion, which enhances their suitability for various applications. When purchasing steel drums, B2B buyers should consider weight capacity, compatibility with stored materials, and whether the drum requires additional protective linings. Their robust nature makes them ideal for long-term storage and transportation, but they may come at a higher cost and weight compared to other options.

How Do Plastic Drums Compare in Terms of Cost-Effectiveness and Applications?

Plastic drums are constructed from high-density polyethylene (HDPE) and are known for their lightweight and cost-effective nature. They are resistant to weather and impact, making them suitable for a range of applications, including food storage, chemicals, and waste disposal. B2B buyers should evaluate the specific chemical compatibility and temperature tolerance when selecting plastic drums. While they offer significant advantages in handling and price, it’s crucial to ensure they meet the necessary safety standards for hazardous materials.

What Makes Fiber Drums an Eco-Friendly Option for Packaging?

Fiber drums are made from composite materials and are often recyclable, appealing to environmentally conscious businesses. They are lightweight and typically used for packaging non-hazardous materials. While fiber drums are less durable than their metal or plastic counterparts, they are suitable for products that do not require heavy-duty containment. B2B buyers should consider the intended use and whether the drum will be exposed to moisture or heavy handling, as these factors can impact performance.

Why Choose Lab Pack Drums for Hazardous Materials?

Lab pack drums are specifically designed for the safe transport and storage of hazardous materials. They feature secure closures and are made to contain smaller, non-leaking items. This makes them essential in laboratory settings and for companies handling hazardous waste. When purchasing lab pack drums, B2B buyers must ensure compliance with relevant safety regulations and consider the volume of materials being stored. While they provide excellent safety features, their use is limited to specific types of materials.

What are the Benefits and Considerations for Purchasing Reconditioned Drums?

Reconditioned drums offer a sustainable and cost-effective solution for businesses looking to minimize waste and reduce expenses. These drums have been cleaned and refurbished for reuse, making them an eco-friendly choice. However, B2B buyers should be cautious about the quality and consistency of reconditioned drums, as their condition can vary. It’s essential to verify the supplier’s reputation and ensure that the drums meet required safety standards for the intended application.

Key Industrial Applications of 20 gallon drum

| Industry/Sector | Specific Application of 20 Gallon Drum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Manufacturing | Storage of hazardous chemicals | Ensures safe containment and compliance | UN/DOT ratings, material compatibility, durability |

| Food and Beverage | Transport of liquid food products | Maintains product integrity and safety | Food-grade certification, ease of cleaning, sealing |

| Waste Management | Collection and transport of hazardous waste | Facilitates safe disposal and regulatory compliance | Leak-proof design, proper labeling, size specifications |

| Agriculture | Storage of fertilizers and pesticides | Protects against contamination and environmental impact | UV resistance, material type (plastic vs. steel) |

| Pharmaceuticals | Transport of bulk pharmaceutical ingredients | Ensures safe handling and storage standards | Compliance with health regulations, tamper-proof seals |

How Are 20 Gallon Drums Used in Chemical Manufacturing?

In the chemical manufacturing sector, 20-gallon drums are essential for the safe storage and transport of hazardous materials. These drums are designed to meet stringent safety standards, ensuring compliance with regulations regarding hazardous materials. Buyers in this industry must prioritize sourcing drums with appropriate UN/DOT ratings to guarantee safe containment. Additionally, the material of the drum—whether plastic or steel—should be compatible with the chemicals being stored to prevent leaks or reactions.

What Role Do 20 Gallon Drums Play in the Food and Beverage Industry?

In the food and beverage industry, 20-gallon drums are commonly used for transporting liquid products such as oils, syrups, and sauces. These drums help maintain product integrity by providing a secure and stable environment for storage. For international buyers, it’s crucial to ensure that the drums are food-grade certified, allowing for safe contact with consumable goods. Additionally, ease of cleaning and effective sealing mechanisms are essential to prevent contamination and spoilage during transport.

How Are 20 Gallon Drums Utilized in Waste Management?

Waste management companies often rely on 20-gallon drums for the safe collection and transport of hazardous waste. These drums are designed to contain potentially harmful materials, helping businesses comply with environmental regulations. Buyers should focus on sourcing leak-proof designs that include proper labeling for hazardous materials. The size of the drum is also a consideration, as it must align with the volume of waste being managed to optimize efficiency in collection and disposal processes.

In What Ways Do Agriculture Businesses Use 20 Gallon Drums?

In agriculture, 20-gallon drums are frequently employed for storing fertilizers and pesticides. These drums protect against contamination from environmental factors, ensuring that agricultural inputs remain effective. Buyers in this sector need to consider the UV resistance of the drums, especially in regions with high sunlight exposure. Additionally, the choice between plastic and steel drums can impact durability and cost, making it vital to assess the specific needs of the agricultural application.

How Are 20 Gallon Drums Important for the Pharmaceutical Sector?

The pharmaceutical industry utilizes 20-gallon drums for transporting bulk ingredients safely. These drums must meet strict health regulations to ensure that the contents remain uncontaminated and secure. Key sourcing considerations include compliance with health standards, tamper-proof seals, and the ability to withstand various temperatures during transport. For international buyers, understanding regional regulations is crucial to ensure that the drums meet local compliance requirements, thereby safeguarding product quality and safety.

3 Common User Pain Points for ’20 gallon drum’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Material for Specific Applications

The Problem: B2B buyers often grapple with the challenge of selecting the appropriate material for their 20-gallon drums, especially when dealing with hazardous or sensitive substances. For instance, a company in the chemical industry might need to store corrosive liquids. However, if they choose a drum made from the wrong material, such as untreated steel, they risk contamination or even leakage, which can lead to safety hazards, regulatory fines, and financial losses.

The Solution: To mitigate this issue, it is crucial for buyers to conduct a thorough analysis of the substances they intend to store. They should consider factors such as the chemical compatibility of the drum material, the expected temperature ranges, and the potential for physical impact. For hazardous materials, opting for high-density polyethylene (HDPE) drums with appropriate UN/DOT ratings is advisable due to their chemical resistance and lightweight nature. Additionally, buyers should consult with suppliers who can provide detailed specifications and recommendations based on the specific materials they handle, ensuring compliance with safety regulations and industry standards.

Scenario 2: Managing Logistics and Transportation Challenges

The Problem: Logistics present a significant pain point for B2B buyers using 20-gallon drums. Transporting these drums safely and efficiently can be complicated, especially when dealing with international shipping or varying regulations across countries. For instance, a business in Brazil might face stringent customs regulations regarding the transport of hazardous materials, leading to delays and increased costs if not properly addressed.

The Solution: To streamline logistics, buyers should engage with experienced freight forwarders who specialize in hazardous materials. It is essential to understand the specific regulations of both the origin and destination countries. Buyers should ensure that their drums are compliant with international shipping standards, including proper labeling and documentation. Additionally, employing robust packaging solutions, such as using drum pallets or spill containment measures, can enhance safety during transport. By investing in training for staff on the logistics of handling 20-gallon drums, companies can minimize errors and ensure timely deliveries.

Scenario 3: Ensuring Compliance with Safety and Environmental Regulations

The Problem: Compliance with safety and environmental regulations can be a daunting task for B2B buyers managing 20-gallon drums, particularly when it comes to hazardous materials. A manufacturing company in Nigeria, for example, might struggle to meet the local environmental protection standards when storing and disposing of chemical waste, leading to potential legal issues and reputational damage.

The Solution: To address compliance challenges, companies should develop a comprehensive understanding of both local and international regulations that pertain to their specific materials. This includes adhering to guidelines for the storage, labeling, and disposal of hazardous substances. Collaborating with environmental consultants can provide valuable insights into best practices and regulatory updates. Furthermore, buyers should consider investing in drums that feature built-in safety mechanisms, such as leak-proof seals and secondary containment options, which not only enhance safety but also demonstrate a commitment to environmental stewardship. Regular training sessions for employees on compliance and safety procedures are also vital to maintaining standards and reducing risks.

Strategic Material Selection Guide for 20 gallon drum

What Are the Key Properties of Steel Drums for 20 Gallon Applications?

Steel drums are a robust option for a variety of applications, particularly in the storage and transportation of hazardous materials. They typically feature a temperature rating that can withstand high pressures, making them suitable for various chemical substances. Corrosion resistance can be enhanced through coatings, such as epoxy or phenolic linings, which protect the drum’s interior from reactive materials.

Pros and Cons of Steel Drums:

Steel drums offer superior durability and strength, making them ideal for heavy-duty applications. However, they tend to be heavier and more expensive than their plastic counterparts. The manufacturing complexity is higher due to the need for welding and coating processes. For international buyers, especially in regions like Africa and South America, compliance with local and international standards such as ASTM and UN certifications is crucial, as is the availability of reconditioning options.

How Do Plastic Drums Compare for 20 Gallon Storage Solutions?

Plastic drums, particularly those made from high-density polyethylene (HDPE), are lightweight and resistant to impact and weathering. They are typically rated for lower pressure applications but excel in chemical resistance, making them suitable for a wide range of liquids, including corrosive substances.

Pros and Cons of Plastic Drums:

The primary advantage of plastic drums is their cost-effectiveness and lower weight, which simplifies handling and transportation. However, they may not be suitable for high-pressure applications and can be less durable compared to steel. International buyers should consider the specific chemical compatibility of plastic drums with the substances they intend to store, as well as compliance with local regulations regarding hazardous materials.

What Are the Benefits of Fiber Drums in 20 Gallon Formats?

Fiber drums, often made from recycled materials, provide a sustainable option for storage and transport. They are lightweight and can be designed to meet specific requirements for various applications, including food storage or hazardous waste.

Pros and Cons of Fiber Drums:

Fiber drums are environmentally friendly and cost-effective, making them attractive for businesses looking to reduce their carbon footprint. However, they generally offer less durability than steel or plastic drums and are not suitable for all types of liquids, particularly those that are hazardous or corrosive. International buyers should ensure that fiber drums meet relevant standards for their intended use, particularly in food and pharmaceutical applications.

Illustrative image related to 20 gallon drum

What Should International Buyers Consider When Selecting Materials for 20 Gallon Drums?

When selecting materials for 20-gallon drums, international buyers must consider various factors, including local regulations, compliance with standards such as ASTM, DIN, or JIS, and the specific needs of their applications. For instance, buyers in regions like the Middle East may prioritize UV resistance due to harsh climates, while those in Europe might focus on sustainability and recyclability. Understanding these regional preferences can significantly impact purchasing decisions.

| Material | Typical Use Case for 20 Gallon Drum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Storing hazardous materials | High durability and strength | Heavier and more expensive | High |

| Plastic | Storing chemicals and liquids | Lightweight and cost-effective | Limited pressure tolerance | Medium |

| Fiber | Food storage and non-hazardous waste | Environmentally friendly | Less durable for hazardous use | Low |

| Stainless Steel | Food and pharmaceutical applications | Excellent corrosion resistance | Higher cost and weight | High |

In-depth Look: Manufacturing Processes and Quality Assurance for 20 gallon drum

What Are the Main Stages of the Manufacturing Process for 20 Gallon Drums?

The manufacturing process of 20-gallon drums involves several critical stages that ensure the final product meets industry standards for safety and durability. Understanding these stages can help B2B buyers make informed decisions regarding their procurement processes.

Material Preparation: What Materials Are Used in 20 Gallon Drum Production?

The first stage in the manufacturing of 20-gallon drums involves selecting appropriate materials. Common materials include:

- Steel: Known for its strength and durability, steel drums are often used for hazardous materials. They can be lined to prevent corrosion.

- Plastic: High-density polyethylene (HDPE) is frequently used due to its lightweight nature and resistance to chemicals. Plastic drums are ideal for non-hazardous materials and offer cost advantages.

- Fiber: Fiber drums are made from composite materials and are often used for dry goods and non-hazardous substances.

Material selection is crucial, as it affects the drum’s performance, safety, and compliance with international regulations.

How Are 20 Gallon Drums Formed?

Once the materials are prepared, the next step is the forming process. This can vary based on the type of drum being produced:

- For Steel Drums: Steel sheets are cut into predetermined sizes and then formed into cylindrical shapes using processes such as roll forming or stamping. The edges are then welded or seam-joined to create a leak-proof structure.

- For Plastic Drums: HDPE is typically blow-molded or injection-molded into the desired shape. The process allows for uniform wall thickness and ensures that the drum can withstand the intended pressures.

- For Fiber Drums: Layers of fiberboard are glued together and formed into a cylindrical shape. This method provides a lightweight option for transporting dry goods.

What Is the Assembly Process for 20 Gallon Drums?

After forming, the next step is assembly, which includes adding components such as lids, seals, and closures.

- Lids and Closures: Depending on the drum type, lids may feature screw tops, lever-locks, or other closure mechanisms. These are crucial for maintaining the integrity of the contents.

- Seals: Proper sealing is essential for preventing leaks, especially in drums used for hazardous materials. Gaskets or O-rings are often used to enhance sealing capabilities.

What Quality Assurance Measures Are Implemented During Drum Production?

Quality assurance (QA) is paramount in drum manufacturing, particularly for B2B buyers who require reliable products. Various international standards guide the QA processes.

Which International Standards Are Relevant for 20 Gallon Drums?

International standards such as ISO 9001 provide frameworks for quality management systems. Compliance with these standards indicates that a manufacturer has established processes for consistent quality. Other relevant certifications include:

- CE Marking: Required for products sold in the European Economic Area, ensuring compliance with safety, health, and environmental protection standards.

- UN/DOT Regulations: For drums intended to store or transport hazardous materials, compliance with United Nations (UN) and Department of Transportation (DOT) regulations is mandatory.

What Are the Key Quality Control Checkpoints in Drum Manufacturing?

Throughout the manufacturing process, several quality control (QC) checkpoints are implemented:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, various parameters such as dimensions, weight, and material integrity are monitored.

- Final Quality Control (FQC): The finished drums undergo comprehensive testing, including pressure tests and leak tests, to verify their integrity before being shipped.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are some effective strategies:

What Auditing Practices Should Buyers Employ?

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures in place. This includes reviewing documentation, inspecting production lines, and checking compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality assurance practices. These inspections often include random sampling and testing of drums to ensure compliance with specifications.

What Documentation and Reports Should Buyers Request?

Buyers should request:

- Certificates of Compliance: Documentation proving adherence to relevant standards.

- Quality Control Reports: Detailed reports summarizing QC processes, including any deviations and corrective actions taken.

- Test Results: Results from any tests conducted on the drums, such as weight capacity tests or chemical resistance assessments.

What Are the Common Testing Methods for Quality Assurance?

Several common testing methods are utilized to ensure the quality of 20-gallon drums:

- Hydrostatic Testing: This method checks for leaks by filling the drum with water and applying pressure. It helps verify that the drum can withstand the pressure of its intended contents.

- Drop Tests: To evaluate durability, drums may be subjected to drop tests from specified heights to ensure they can withstand impacts during transport.

- Chemical Compatibility Testing: For drums intended for chemical storage, compatibility tests confirm that the material of the drum does not react adversely with the stored substances.

Conclusion: Why Is Quality Assurance Crucial for International Buyers?

For B2B buyers, particularly those in emerging markets, understanding the manufacturing processes and quality assurance measures for 20-gallon drums is essential. It not only ensures that the products will meet their specific needs but also helps mitigate risks associated with substandard materials or manufacturing practices. By emphasizing the importance of quality control and adhering to international standards, buyers can make informed decisions that enhance the reliability and safety of their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ’20 gallon drum’

When sourcing a 20-gallon drum for your business needs, it’s essential to follow a structured approach to ensure you select the right product for your specific applications. This guide provides a step-by-step checklist to streamline your procurement process, helping you make informed decisions while engaging with suppliers.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your 20-gallon drum. Consider the materials you need the drum to be made from—options include steel, plastic, or fiber—each with unique properties suitable for different applications. Determine the intended use, whether for hazardous materials, food storage, or general warehousing, as this will influence your selection criteria.

- Material Considerations: Ensure the drum material aligns with the nature of the contents, such as corrosive chemicals or food products.

- Compliance Requirements: Identify any industry-specific regulations that the drum must meet, such as UN/DOT ratings for hazardous materials.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in 20-gallon drums. Look for reputable companies with a solid track record in your region, particularly in Africa, South America, the Middle East, and Europe.

- Supplier Reviews: Read testimonials and reviews from other B2B buyers to gauge the reliability and quality of the supplier’s products.

- Product Range: Evaluate whether the supplier offers various types of drums to meet diverse needs, including reconditioned options for sustainability.

Step 3: Request Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request detailed quotes. Comparing pricing is crucial, but don’t overlook the importance of quality and service.

- Inclusions in Quotes: Ensure that quotes include all costs, such as shipping, handling, and any necessary accessories.

- Bulk Discounts: Inquire about bulk purchasing options or discounts for long-term contracts, as this can significantly impact your overall costs.

Step 4: Verify Supplier Certifications

Before finalizing your order, verify that the supplier holds the necessary certifications for quality and safety. This step helps ensure that the products meet international standards and your specific industry requirements.

- ISO Certifications: Look for ISO certifications that demonstrate a commitment to quality management.

- Safety and Compliance: Ensure the supplier complies with local and international safety regulations, particularly if dealing with hazardous materials.

Step 5: Review Delivery Options and Lead Times

Discuss the delivery options and lead times with your chosen supplier. Understanding these logistics is critical for planning your operations.

- Shipping Methods: Inquire about the available shipping methods and their respective costs, especially for international shipments.

- Lead Time: Confirm the expected lead time for order fulfillment to avoid disruptions in your supply chain.

Step 6: Establish Payment Terms and Conditions

Negotiate payment terms that are favorable to your business while ensuring they align with the supplier’s policies. Clear payment agreements can help avoid misunderstandings later on.

- Payment Methods: Discuss acceptable payment methods, such as credit terms, upfront payments, or escrow services.

- Invoicing Procedures: Clarify invoicing processes to ensure smooth transactions.

Step 7: Conduct a Final Quality Check

Before accepting the delivery of your 20-gallon drums, conduct a final quality check upon arrival. Inspect the drums for any signs of damage or non-compliance with your specifications.

- Documentation Verification: Ensure that all received items match the order specifications and that relevant documentation, such as certificates of compliance, is included.

- Return Policy Awareness: Familiarize yourself with the supplier’s return policy in case any issues arise.

By following these steps, you can effectively navigate the sourcing process for 20-gallon drums, ensuring that you select a product that meets your operational needs while partnering with a reliable supplier.

Comprehensive Cost and Pricing Analysis for 20 gallon drum Sourcing

What Are the Key Cost Components in Sourcing 20 Gallon Drums?

When evaluating the total cost of sourcing 20-gallon drums, understanding the various cost components is essential. The main cost factors include:

-

Materials: The choice of materials significantly impacts the cost. Steel drums tend to be more expensive due to their durability and ability to withstand harsh environments, while plastic drums offer a lighter and often more economical alternative. The specific material used (e.g., high-density polyethylene vs. carbon steel) can also affect pricing.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing, assembly, and quality control. Regions with lower labor costs can offer more competitive pricing, but it’s vital to assess the quality of craftsmanship and adherence to safety standards.

-

Manufacturing Overhead: This includes all indirect costs related to production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, thus lowering the overall price of the drums.

-

Tooling: The initial investment in molds and equipment for drum production is a crucial factor. Custom designs or variations in drum specifications may require additional tooling costs, which can be amortized over larger production runs to achieve cost savings.

-

Quality Control (QC): Ensuring that drums meet safety and regulatory standards involves additional costs for testing and inspections. Certifications (such as UN/DOT ratings) also play a role in pricing, as compliant products typically command higher prices.

-

Logistics: Shipping and handling costs vary based on the origin and destination of the drums. Factors such as transportation mode, distance, and fuel prices can affect logistics expenses. Additionally, the choice of Incoterms can influence who bears these costs.

-

Margin: Suppliers will include a profit margin in their pricing. This margin can vary based on market demand, competition, and the supplier’s brand reputation.

How Do Price Influencers Affect the Sourcing of 20 Gallon Drums?

Several factors can influence the price of 20-gallon drums, particularly for international buyers:

-

Volume/MOQ: Purchasing in larger quantities often results in lower per-unit costs. Suppliers may offer discounts for bulk orders, which can be beneficial for companies with high storage or shipping needs.

-

Specifications and Customization: Custom designs or specific features (such as UV resistance or specialized closures) can increase costs. Buyers should weigh the need for customization against budget constraints.

-

Material Quality and Certifications: Drums that meet higher quality standards and certifications typically cost more. This is crucial for industries dealing with hazardous materials, where compliance is non-negotiable.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their products but often provide better service and quality assurance.

-

Incoterms: Understanding Incoterms is essential for calculating total landed costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) can significantly influence the final price, especially for international transactions.

What Buyer Tips Can Enhance Cost Efficiency in 20 Gallon Drum Procurement?

B2B buyers should consider the following strategies to enhance cost efficiency:

-

Negotiate: Leverage volume purchases to negotiate better terms or discounts. Building a long-term relationship with suppliers can also lead to favorable pricing and more flexible terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as durability, maintenance, and compliance costs that can affect the overall expenditure over time.

-

Understand Pricing Nuances for International Sourcing: Different regions may have varying cost structures due to labor, materials, and logistics. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to compare prices and quality across suppliers.

-

Keep an Eye on Market Trends: Pricing for raw materials can fluctuate. Being aware of these trends can help in timing purchases to secure better rates.

Conclusion

Sourcing 20-gallon drums involves a comprehensive understanding of cost components and price influencers. By strategically negotiating and considering total cost ownership, international B2B buyers can make informed decisions that align with their operational needs while optimizing their procurement budgets. Always remember that indicative prices can vary based on market conditions and specific supplier offerings.

Alternatives Analysis: Comparing 20 gallon drum With Other Solutions

When considering storage and transportation solutions for liquids, chemicals, or hazardous materials, the 20-gallon drum is a common choice. However, various alternatives exist that may better suit specific needs based on performance, cost, and usage requirements. Understanding these alternatives can help businesses optimize their operations and comply with regulations.

| Comparison Aspect | 20 Gallon Drum | IBC Tote (Intermediate Bulk Container) | 5 Gallon Pail |

|---|---|---|---|

| Performance | High durability; suitable for both solids and liquids; can withstand pressure | Excellent for bulk liquids; larger capacity (typically 275-330 gallons); easy to transport | Lightweight; good for small quantities; easy to handle |

| Cost | Moderate initial cost; reconditioning available | Higher upfront investment but cost-effective for large volumes | Lower cost per unit; economical for small volumes |

| Ease of Implementation | Standardized dimensions; requires proper handling equipment | Requires additional space; may need specialized equipment for filling and emptying | Simple to use; no special equipment needed |

| Maintenance | Requires regular inspection; can rust if not properly maintained | Durable but may require cleaning between uses; needs proper handling | Minimal maintenance; easy to clean |

| Best Use Case | Ideal for transporting and storing hazardous materials; versatile for various industries | Best for bulk storage and transportation of liquids; suitable for chemical and food industries | Perfect for small batches of products; good for consumer goods |

What Are the Benefits and Drawbacks of Using IBC Totes as an Alternative?

IBC totes offer a larger capacity, making them ideal for businesses that deal with bulk liquids. Their design allows for efficient stacking and storage, maximizing warehouse space. However, they require more initial investment and might necessitate specialized handling equipment. Additionally, if not properly maintained, they can develop leaks, which poses a risk for hazardous materials.

How Does the 5 Gallon Pail Compare as a Smaller Alternative?

The 5-gallon pail is a practical solution for businesses needing to store smaller quantities. Its lightweight design allows for easy handling and transportation, making it a favorite for consumer goods and small batch products. However, its limited capacity means that frequent replenishment may be necessary for larger operations, leading to increased labor and transportation costs over time.

Conclusion: How Can B2B Buyers Choose the Right Storage Solution?

When selecting the right storage solution, B2B buyers should consider their specific operational needs, including the volume of materials to be stored, budget constraints, and regulatory compliance. The 20-gallon drum is versatile and durable, making it suitable for a range of applications. However, for businesses dealing with bulk quantities or smaller product lines, IBC totes or 5-gallon pails may provide more cost-effective and efficient alternatives. Assessing the unique requirements of your operation will ensure that you choose the most appropriate storage solution to optimize efficiency and compliance.

Essential Technical Properties and Trade Terminology for 20 gallon drum

What Are the Key Technical Properties of a 20 Gallon Drum?

When considering the procurement of 20-gallon drums, understanding their technical properties is crucial for ensuring they meet your operational needs. Here are some key specifications to consider:

1. Material Grade

The most common materials for 20-gallon drums are high-density polyethylene (HDPE), steel, and fiber. HDPE drums are lightweight and resistant to chemicals, making them suitable for hazardous materials. Steel drums offer durability and protection against punctures, while fiber drums are often used for dry goods. Selecting the appropriate material can significantly impact the drum’s longevity and suitability for your specific application.

2. Weight Capacity

Typically, a 20-gallon drum has a weight capacity of up to 440 pounds (199.58 kg). This capacity may vary based on the drum’s material and design. Understanding the weight limits is essential for safe transportation and storage, as exceeding these limits can lead to structural failure or safety hazards.

3. Closure Type

The closure mechanism can vary among drums, with options including lever-lock, screw-top, and plain lids. Lever-lock closures provide an added layer of security against leaks, especially for hazardous materials, while screw-top lids offer ease of access. The choice of closure can affect the efficiency of your operations and compliance with safety regulations.

4. UN/DOT Rating

Many 20-gallon drums come with United Nations (UN) and Department of Transportation (DOT) ratings, which indicate their suitability for transporting hazardous materials. A drum with a UN rating, such as 1H2/Y100/S, signifies that it meets specific standards for safety and durability during transport. Understanding these ratings is vital for compliance with international shipping regulations.

5. Dimensions

Standard exterior dimensions for a 20-gallon drum are approximately 21.75 inches in height and 18.75 inches in diameter. These measurements are crucial for compatibility with storage systems and transportation methods. Knowing the dimensions helps businesses optimize space and logistics, leading to cost savings.

What Are Common Trade Terms Related to 20 Gallon Drums?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several common terms you should know:

1. OEM (Original Equipment Manufacturer)

In the context of drums, an OEM is a company that produces the drums or parts that are then marketed by another company. Understanding OEM relationships can help you identify quality manufacturers and ensure that you are sourcing reliable products.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. This term is important for budgeting and inventory planning, as suppliers may set MOQs based on production costs and demand.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific quantities of products. Utilizing RFQs effectively can help you obtain competitive pricing and ensure that all potential suppliers are evaluated on the same criteria.

4. Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Knowing Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), helps ensure clarity in shipping responsibilities and costs, which is crucial for international B2B dealings.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times is crucial for supply chain management, ensuring that you have the necessary materials when needed to avoid production delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding the procurement of 20-gallon drums, ultimately enhancing operational efficiency and compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the 20 gallon drum Sector

What Are the Key Market Trends in the 20 Gallon Drum Sector?

The 20-gallon drum sector is experiencing significant transformation driven by global demand for versatile storage solutions. Key market drivers include the rise in manufacturing activities in emerging economies, particularly in Africa and South America, where industrialization is accelerating. Additionally, the increasing need for compliance with stringent regulations on hazardous materials is pushing businesses to invest in durable and compliant storage options.

Emerging technologies such as smart tracking systems and IoT-enabled solutions are becoming prevalent in the sourcing of 20-gallon drums. These technologies enhance inventory management and provide real-time data on usage patterns, ensuring better resource allocation for international buyers. Furthermore, the trend toward online procurement is reshaping how businesses source these products, allowing for competitive pricing and improved supplier transparency.

For buyers in regions like Nigeria and Brazil, understanding the local supply chain dynamics is crucial. Factors such as import tariffs, transportation costs, and regional regulations can significantly impact sourcing strategies. Cultivating relationships with local suppliers who understand the nuances of the market can enhance reliability and cost-effectiveness.

How Is Sustainability Shaping the 20 Gallon Drum Industry?

Sustainability is becoming a cornerstone in the 20-gallon drum sector. As industries worldwide strive to reduce their environmental impact, ethical sourcing and sustainable materials are gaining prominence. Buyers are increasingly prioritizing drums made from recyclable materials or those that come with certifications that affirm their environmental credentials.

Plastic drums, for instance, are often made from high-density polyethylene (HDPE), which is recyclable and lightweight, reducing the carbon footprint during transportation. Steel drums, on the other hand, can be reconditioned and reused, offering an eco-friendly alternative to single-use packaging.

Moreover, companies are focusing on establishing ethical supply chains that emphasize fair labor practices and minimize environmental degradation. By choosing suppliers committed to sustainable practices, businesses can enhance their brand reputation and appeal to environmentally conscious consumers. Certifications like ISO 14001, which focuses on effective environmental management systems, can serve as a benchmark for selecting suppliers.

What Is the Historical Context of 20 Gallon Drums in B2B Markets?

The 20-gallon drum has evolved significantly since its inception in the mid-20th century. Initially designed for the storage and transportation of liquids, these drums have adapted to meet the changing demands of various industries, including chemicals, food processing, and pharmaceuticals.

Historically, drums were predominantly made from metal, which provided durability but posed challenges in weight and corrosion. The introduction of plastic drums offered a lightweight alternative that is resistant to chemicals and easier to handle. Over the years, innovations in design and materials have led to the creation of specialized drums, such as lab pack drums for hazardous materials, catering to specific industry needs.

This evolution reflects broader trends in manufacturing and logistics, highlighting the importance of adaptability in the B2B sector. As markets continue to shift, the 20-gallon drum will likely remain a vital component in effective supply chain management, embodying both functionality and compliance in an ever-evolving regulatory landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of 20 gallon drum

-

How do I choose the right type of 20-gallon drum for my needs?

Choosing the right type of 20-gallon drum depends on the materials you plan to store or transport. Steel drums are ideal for hazardous materials due to their durability and resistance to corrosion. Plastic drums are lighter and suitable for non-hazardous liquids or solids, while fiber drums are often used for dry goods. Assess the chemical compatibility, weight capacity, and environmental conditions of your materials to ensure you select the most appropriate drum. -

What are the key specifications I should consider when sourcing 20-gallon drums?

When sourcing 20-gallon drums, key specifications include material type (steel, plastic, or fiber), dimensions (height and diameter), weight capacity, and closure type. It’s also essential to consider any certifications required for your industry, such as UN/DOT ratings for hazardous materials. Understanding these specifications helps ensure compliance with safety regulations and compatibility with your operational needs. -

How can I verify the credibility of a 20-gallon drum supplier?

To verify a supplier’s credibility, check for industry certifications, customer testimonials, and product reviews. Request samples to assess quality and ensure that the supplier adheres to international standards. Additionally, investigate their history in the market and their compliance with safety regulations. Engaging in direct communication can also provide insights into their customer service and responsiveness. -

What is the typical minimum order quantity (MOQ) for 20-gallon drums?

Minimum order quantities for 20-gallon drums can vary significantly by supplier and region. Generally, MOQs may range from 50 to 500 units, depending on the manufacturer’s production capabilities and your specific requirements. It’s advisable to negotiate terms with suppliers and consider bulk ordering for better pricing while ensuring that your inventory needs are met. -

What payment terms should I expect when sourcing 20-gallon drums internationally?

Payment terms for international orders can vary widely but often include options such as advance payment, letter of credit, or payment upon receipt. Be sure to discuss payment methods and terms before finalizing your order to avoid any misunderstandings. Consider using escrow services for larger transactions to protect both parties until the drums are delivered and inspected. -

How do I ensure quality assurance when purchasing 20-gallon drums?

To ensure quality assurance, request detailed product specifications and certifications from the supplier. Consider conducting factory audits or third-party inspections to verify compliance with quality standards. Establishing a clear return policy and quality control measures will also help mitigate risks associated with defective products. Regular communication with the supplier during the production process can further enhance quality assurance. -

What logistics considerations should I keep in mind for shipping 20-gallon drums?

Logistics considerations for shipping 20-gallon drums include selecting the right mode of transport (sea, air, or land), understanding customs regulations, and ensuring proper packaging for safe transit. Factor in lead times for production and shipping, as well as any potential delays at customs. Collaborating with a logistics provider experienced in handling hazardous materials can streamline the shipping process and reduce risks. -

Can I customize the design or branding on my 20-gallon drums?

Yes, many suppliers offer customization options for 20-gallon drums, including color choices, labeling, and branding. Customization can enhance brand visibility and ensure compliance with regulatory requirements. Discuss your specific needs with potential suppliers, as minimum order quantities for customized drums may differ from standard products. Be sure to review proofs or samples before production to ensure accuracy.

Top 5 20 Gallon Drum Manufacturers & Suppliers List

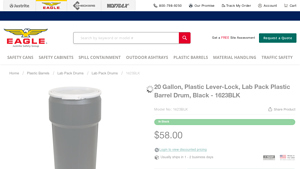

1. Eagle – 1623BLK High-Density Polyethylene Container

Domain: eagle.justrite.com

Registered: 1997 (28 years)

Introduction: {“Model No”: “1623BLK”, “Color”: “Black”, “Brand”: “Eagle”, “Material”: “High-Density Polyethylene (HDPE)”, “Net Weight (lbs)”: “10.25”, “Net Weight (kgs)”: “4.65”, “UN/DOT Rating”: “1H2/X75/S, 1H2/Y100/S”, “DOT 49 CFR 173.12”: “Yes”, “Exterior Dimensions (inches)”: “15.75D x 30.5H”, “Interior Dimensions (inches)”: “15.4 (Top) x 12.88 (Bottom) x 29.88 (Height)”, “Gallon Capacity”: “20”, “Closure T…

2. McMaster – 20 Gallon Drums

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – 20 Gallon Drums, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Skolnik – Compact 20 Gallon Drum

Domain: skolnik.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Compact 20 Gallon Drum”, “Material Options”: [“salvage steel”, “stainless steel”, “carbon steel”, “7A Type A”, “seamless crevice-free”, “process”, “UN-rated”, “Leverlock”], “Key Features”: {“Versatile Configurations”: “Available in multiple configurations to meet specific needs.”, “Space-Saving Design”: “Compact size optimizes storage and transport, ideal for crowded environments…

4. eBay – 20 Gallon Drum

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 20 Gallon Drum, available in various materials including plastic and steel, with options for new and used conditions. Common features include removable tops, quick installation, and suitability for garden irrigation and water storage. Color options include black, blue, brown, and more. Price range varies, with listings under $75 and up to $150 or more. Shipping options include free delivery and lo…

5. Illing Company – 20 Gallon White Steel Drum

Domain: illingcompany.com

Registered: 2002 (23 years)

Introduction: 20 Gallon White Tight Head Unlined Steel Drum

Strategic Sourcing Conclusion and Outlook for 20 gallon drum

In the competitive landscape of international trade, strategic sourcing of 20-gallon drums offers significant advantages for B2B buyers. By understanding the diverse types of drums—such as steel, plastic, and fiber—and their specific applications, businesses can make informed choices that align with their operational needs. This insight is crucial for industries ranging from manufacturing to food and hazardous waste management, where the right drum can enhance efficiency and safety.

Moreover, leveraging supplier relationships and exploring bulk purchasing options can yield cost savings and ensure consistent supply, particularly in emerging markets like Nigeria and Brazil, where demand is on the rise. As environmental regulations tighten, selecting drums that meet compliance standards will not only safeguard your operations but also enhance your brand’s reputation.

Looking ahead, international buyers are encouraged to stay abreast of innovations in drum design and material technology that can improve sustainability and functionality. By proactively engaging with suppliers and investing in quality products, businesses can position themselves for success in an evolving marketplace. Now is the time to optimize your sourcing strategy and secure reliable solutions for your operations.

Illustrative image related to 20 gallon drum

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.