Loop Latch: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for loop latch

In the fast-evolving global marketplace, sourcing the right loop latch can present significant challenges for international B2B buyers. With a myriad of options available, from various materials and designs to differing functionalities, understanding how to navigate this complex landscape is crucial. This guide aims to simplify the sourcing process by providing an in-depth exploration of loop latches, covering types, applications, supplier vetting, and cost considerations.

Loop latches are essential components in a variety of industries, serving purposes from securing gates in agricultural settings to enhancing privacy in residential applications. As buyers from regions such as Africa, South America, the Middle East, and Europe—countries like Brazil and Vietnam—seek reliable suppliers, this guide empowers them to make informed purchasing decisions. By outlining the features and benefits of different loop latch designs, alongside practical advice for evaluating suppliers, we aim to enhance your procurement strategy.

Furthermore, understanding regional market trends and pricing structures will enable you to optimize your supply chain effectively. Whether you are looking for durable latches for fencing, gates, or industrial applications, this comprehensive resource will equip you with the insights needed to confidently source the ideal loop latch for your business needs. Embrace the opportunity to streamline your purchasing process and secure the best products for your projects.

Understanding loop latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight Loop Latch | Simple design, available in various sizes and finishes | Gates, doors, and fencing | Pros: Cost-effective, versatile. Cons: May require frequent maintenance in harsh environments. |

| Split Rail Round Loop Latch | Designed for split rail fences, round rail compatibility | Agricultural fencing, residential gates | Pros: Easy installation, durable. Cons: Limited to specific rail types. |

| Wood Hardware® Loop Latch | Heavy-duty, zinc-plated for corrosion resistance | Wood gates, privacy gates | Pros: Strong and durable, reversible. Cons: Installation may require specific tools. |

| Aluminum Loop Latch | Lightweight, rust-resistant, often used in window frames | Windows, light-duty applications | Pros: Easy to handle, low maintenance. Cons: Less robust for heavy-duty use. |

| Gate Latch Loop and Hook Style | Versatile hook design, suitable for various gate types | Agricultural, commercial, and residential gates | Pros: Flexible application, secure. Cons: Can be complex to install without proper guidance. |

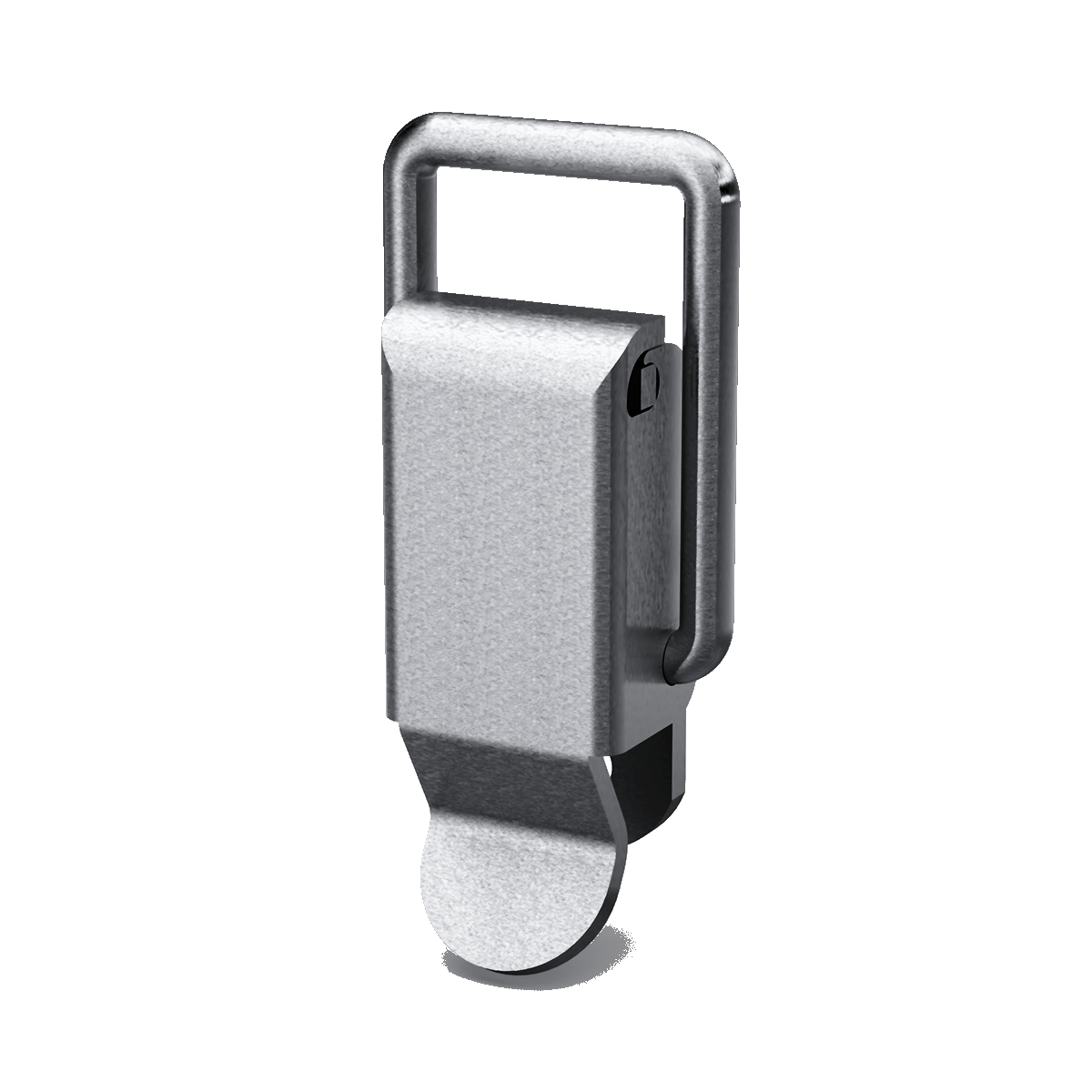

What Are the Characteristics of Straight Loop Latches?

Straight loop latches are characterized by their straightforward design, typically consisting of a latch that engages with a strike plate. These latches are available in various sizes and finishes, making them adaptable for multiple applications, including gates, doors, and fencing. For B2B buyers, the primary considerations include the cost-effectiveness and versatility of these latches. However, in harsh environments, they may require more frequent maintenance due to exposure to elements.

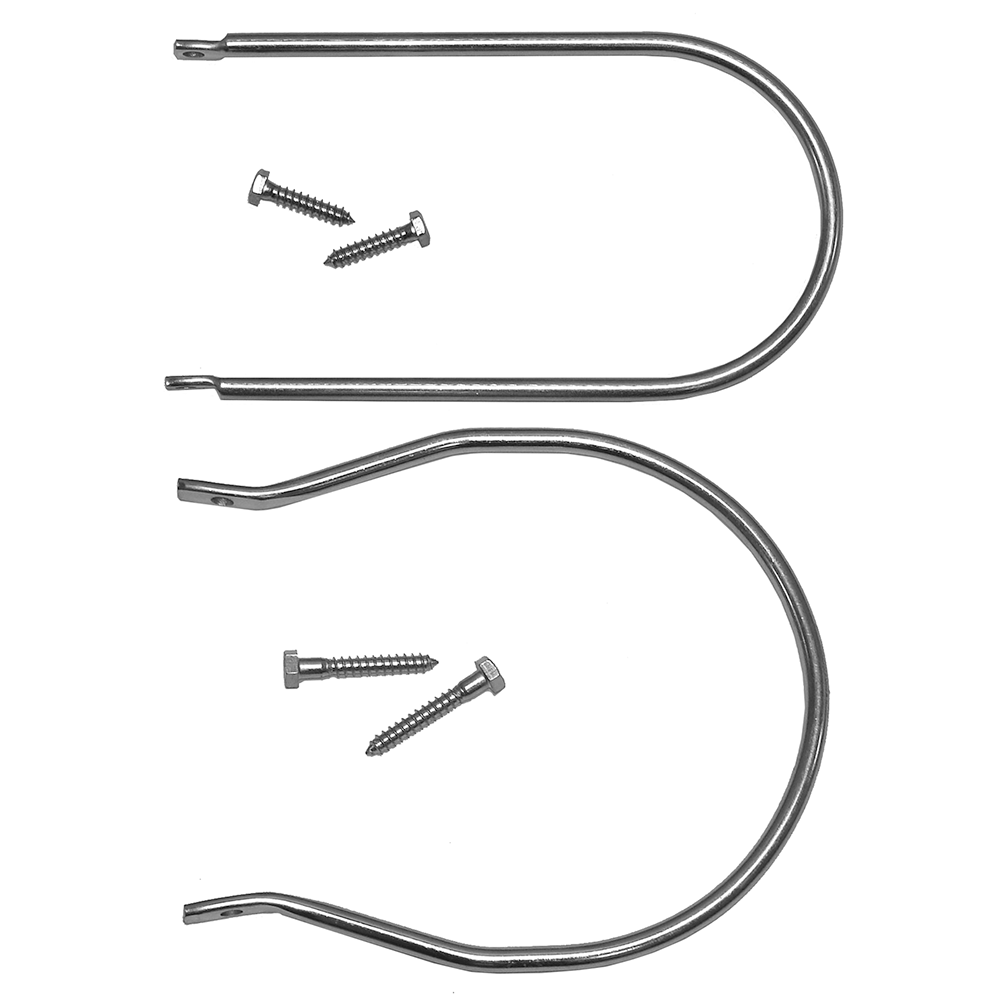

How Do Split Rail Round Loop Latches Differ?

Split rail round loop latches are specifically designed for use with split rail fencing. Their round design allows them to secure gates effectively while accommodating the unique shape of split rail systems. They are commonly used in agricultural settings and residential properties. Buyers should consider the ease of installation and durability of these latches. However, their use is limited to specific rail types, which may restrict their application in some projects.

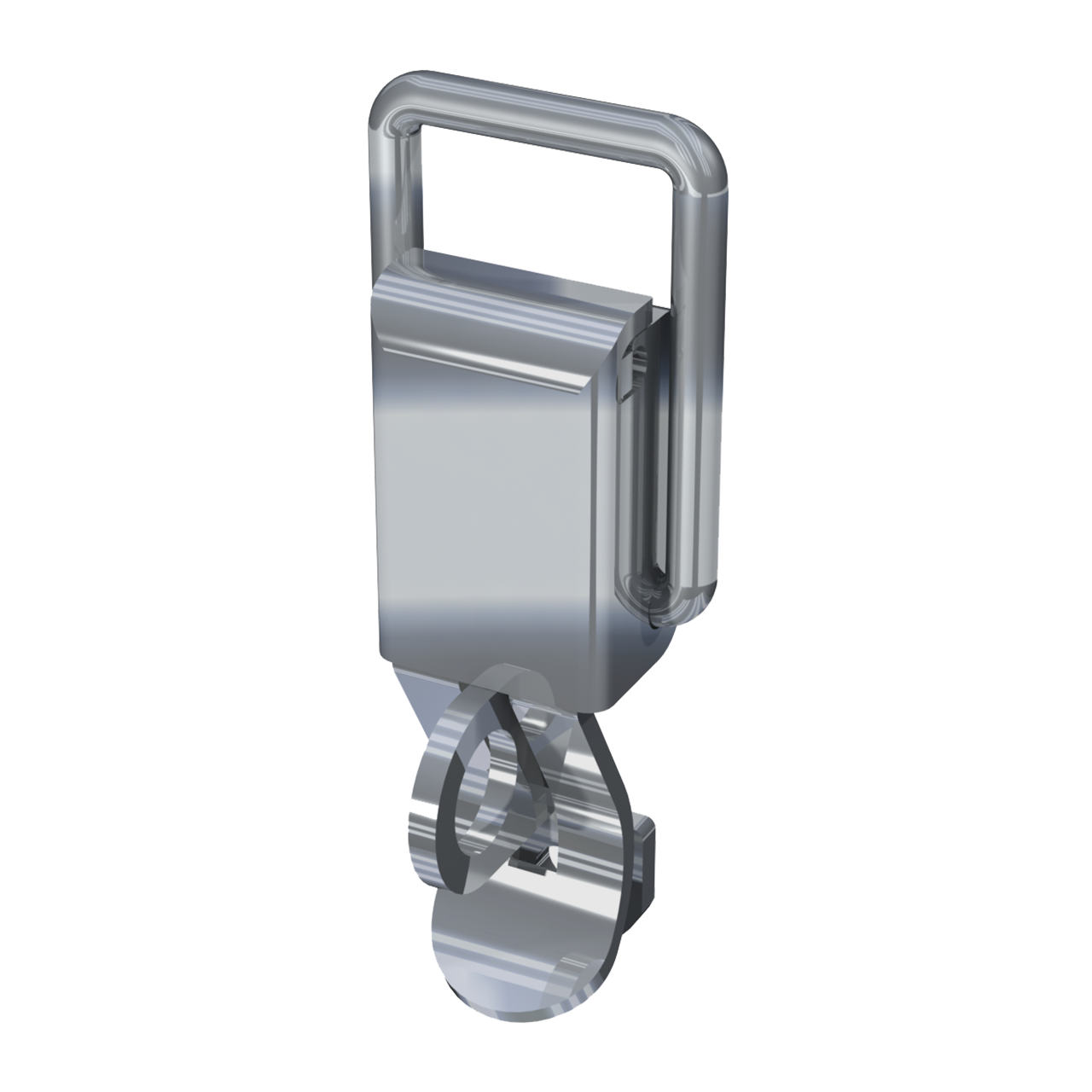

Illustrative image related to loop latch

What Advantages Do Wood Hardware® Loop Latches Offer?

Wood Hardware® loop latches are made from heavy-duty materials and feature a zinc plating that offers excellent corrosion resistance. These latches are particularly suitable for wooden gates and privacy barriers, providing a reliable locking mechanism. B2B buyers value their strength and durability, especially in outdoor applications. The reversible design adds to their flexibility. However, installation may require specific tools, which could be a consideration for some buyers.

Why Choose Aluminum Loop Latches for Light-Duty Applications?

Aluminum loop latches are lightweight and rust-resistant, making them ideal for lighter-duty applications such as window frames. They are easy to handle and require minimal maintenance, appealing to buyers looking for straightforward solutions. However, their lightweight nature means they may not be suitable for heavy-duty applications, which should be considered when making purchasing decisions.

What Makes Gate Latch Loop and Hook Style a Versatile Option?

The gate latch loop and hook style is notable for its versatile design, allowing it to be used across various gate types, including agricultural, commercial, and residential applications. This flexibility makes it a popular choice among B2B buyers. While it offers secure locking capabilities, the installation process can be complex without proper guidance, which is a potential drawback for some users.

Key Industrial Applications of loop latch

| Industry/Sector | Specific Application of loop latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Securing gates in livestock enclosures | Enhances security and prevents livestock escape | Durability against weather conditions; ease of installation; rust resistance |

| Construction | Use in temporary fencing for construction sites | Provides quick access control and safety on-site | Compliance with local regulations; load-bearing capacity; material strength |

| Manufacturing | Gate latches for secure access to restricted areas | Improves safety and protects sensitive equipment | Compatibility with gate types; corrosion resistance; ease of operation |

| Landscaping & Fencing | Latching mechanisms for garden and pool gates | Ensures safety and privacy while enhancing aesthetics | Versatility with different materials; aesthetic options; ease of maintenance |

| Industrial Warehousing | Loop latches for securing storage areas and containers | Prevents unauthorized access and enhances security | Strength and durability; compatibility with various gate designs; cost-effectiveness |

How is Loop Latch Used in Agriculture for Securing Livestock?

In the agriculture sector, loop latches are critical for securing gates in livestock enclosures. They provide a reliable way to keep animals contained while allowing for easy access for farmers. These latches solve the common problem of gates being left open or unlatched, which can lead to livestock escaping and potential losses. Buyers in this sector should consider the durability of materials, particularly resistance to rust and corrosion, as these latches are often exposed to harsh weather conditions.

What Role Does Loop Latch Play in Construction Sites?

Loop latches find extensive application in temporary fencing around construction sites. They facilitate quick access control, allowing workers to enter and exit securely while deterring unauthorized personnel. This not only enhances safety but also protects valuable equipment from theft or vandalism. When sourcing loop latches for this application, businesses should focus on compliance with local regulations regarding safety and security, as well as ensuring the latches can withstand the demands of a busy construction environment.

How Does Loop Latch Enhance Security in Manufacturing Facilities?

In manufacturing, loop latches are essential for securing access points to restricted areas, such as machinery rooms or hazardous materials storage. They provide an added layer of security, ensuring that only authorized personnel can enter sensitive zones. This application helps mitigate risks associated with workplace accidents and theft. Buyers should prioritize latches that are compatible with various gate types and have a proven track record of durability and corrosion resistance, given the industrial environment.

Why are Loop Latches Important in Landscaping and Fencing?

Loop latches are commonly used in landscaping and fencing applications, particularly for garden and pool gates. They ensure safety and privacy while enhancing the aesthetic appeal of outdoor spaces. The ability to easily secure gates helps prevent unauthorized access to pools or gardens, making them safer for children and pets. When sourcing these latches, buyers should look for versatility with different materials, aesthetic options, and ease of maintenance, ensuring that the latches complement the overall design of the landscape.

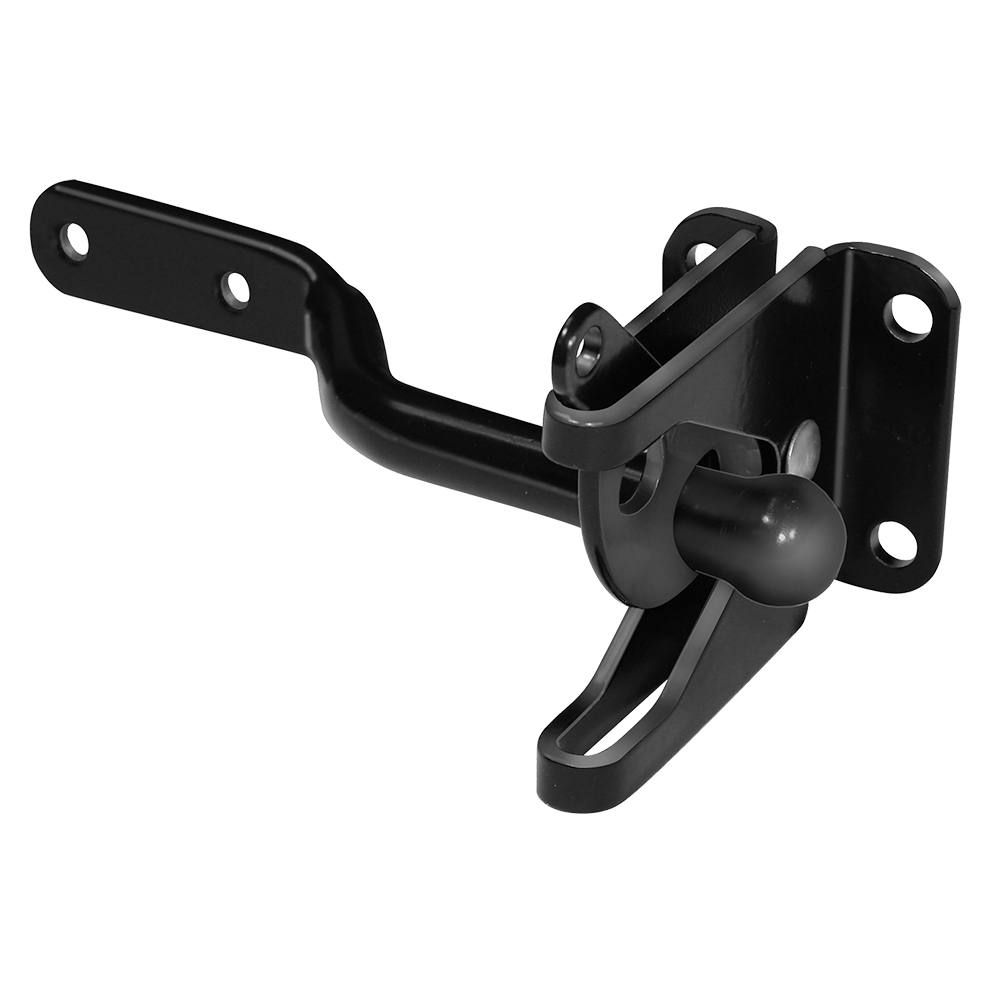

Illustrative image related to loop latch

How Do Loop Latches Secure Industrial Warehousing?

In industrial warehousing, loop latches are employed to secure storage areas and containers, preventing unauthorized access and enhancing overall security. This application is particularly important for protecting valuable inventory and sensitive materials. Buyers should consider the strength and durability of the latches to withstand heavy usage, compatibility with various gate designs, and cost-effectiveness, as these factors can significantly impact operational efficiency and security in a warehousing environment.

3 Common User Pain Points for ‘loop latch’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Loop Latch for Specific Applications

The Problem: B2B buyers often face challenges in determining which loop latch is suitable for their specific application, especially when dealing with diverse materials and gate types. For example, a company that manufactures fencing may need loop latches for both wooden and vinyl gates. Without a clear understanding of the differences in latch construction, material compatibility, and operational mechanics, buyers risk purchasing latches that either fail to function effectively or require costly modifications. This can lead to delays in project timelines and increased operational costs.

The Solution: To effectively navigate this issue, buyers should conduct thorough research into the specifications of various loop latches available on the market. Key factors to consider include the material of the latch (e.g., zinc-plated steel for corrosion resistance), the type of gate it will be used with (wooden vs. vinyl), and the specific locking mechanism required (self-closing vs. manual). Partnering with reputable manufacturers who provide detailed product specifications, installation guides, and customer support can greatly simplify this process. Additionally, leveraging sample orders to evaluate the latch’s compatibility with existing products can further mitigate risks associated with incorrect purchases.

Scenario 2: Ensuring Longevity and Durability of Loop Latches in Harsh Environments

The Problem: Many B2B buyers operate in regions where environmental conditions can severely impact the performance of hardware, including loop latches. For instance, buyers in coastal areas may experience rapid corrosion of metal latches due to saltwater exposure, while those in regions with extreme temperatures may find that standard latches warp or become brittle. These issues can lead to frequent replacements and increased maintenance costs, ultimately affecting the bottom line.

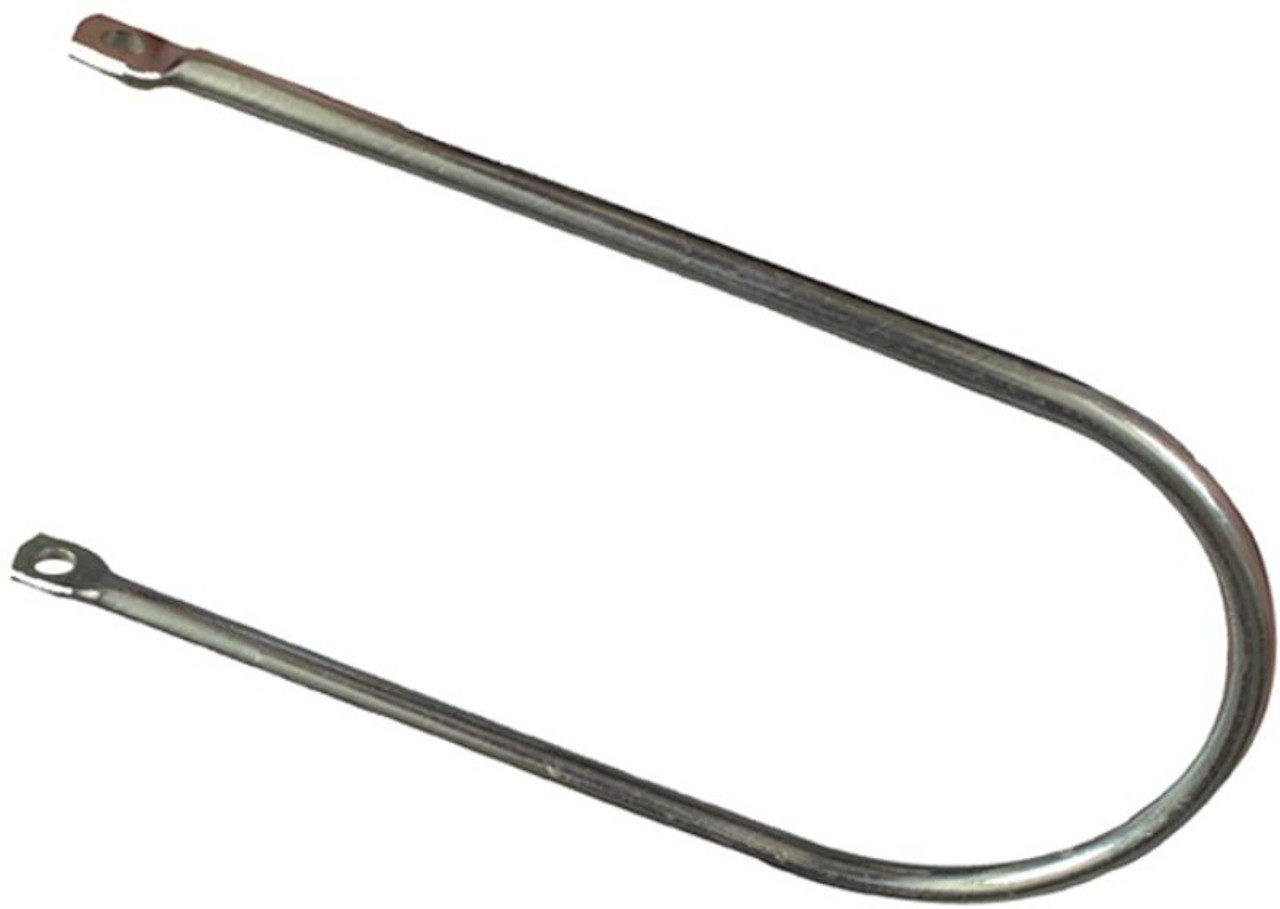

Illustrative image related to loop latch

The Solution: Buyers should prioritize sourcing loop latches that are specifically designed for durability in harsh environments. This includes selecting latches made from high-quality materials such as stainless steel or those with advanced coatings that provide additional corrosion resistance. Furthermore, it’s crucial to consider the latch’s design features that enhance durability, such as thicker gauge materials and weatherproof seals. Establishing relationships with manufacturers that offer warranties and guarantees can provide additional assurance regarding the product’s longevity. Regular maintenance checks should also be scheduled to identify any signs of wear or damage early on.

Scenario 3: Complications in Installation and Adjustment of Loop Latches

The Problem: Installation can be a significant pain point for B2B buyers, particularly when loop latches do not align properly with gate frames or require adjustments post-installation. Poor installation can lead to operational failures, such as gates that don’t close securely or latches that are difficult to operate. This not only affects the functionality of the gate but also raises safety concerns, especially in commercial settings.

The Solution: To streamline the installation process, buyers should invest in loop latches that come with comprehensive installation instructions and all necessary hardware. Some manufacturers provide video tutorials or on-site support to ensure proper installation techniques are followed. It’s also beneficial to use adjustable latches, which can accommodate variations in gate alignment. Training staff on best practices for installation and adjustment can further enhance efficiency. Finally, creating a checklist for installation can help ensure that all steps are followed and that any adjustments needed are identified and addressed immediately. By focusing on proper installation, buyers can reduce the likelihood of future issues and enhance the overall reliability of their gate systems.

Strategic Material Selection Guide for loop latch

What Are the Key Properties of Common Materials Used for Loop Latches?

When selecting materials for loop latches, it is essential to consider various properties that affect product performance. Common materials include stainless steel, aluminum, zinc-plated steel, and plastic. Each material has unique characteristics that influence its application, durability, and suitability for different environments.

Illustrative image related to loop latch

How Does Stainless Steel Perform in Loop Latch Applications?

Stainless steel is renowned for its exceptional corrosion resistance, making it ideal for outdoor applications and environments exposed to moisture. Its high tensile strength allows it to withstand significant pressure, ensuring reliability in demanding conditions. However, the cost of stainless steel is typically higher than other materials, which may impact budget considerations for large-scale projects.

Pros: Durable, corrosion-resistant, high strength.

Cons: Higher cost, potential for galling in threaded applications.

Impact on Application: Suitable for industrial and commercial settings, particularly in coastal regions where saltwater exposure is a concern.

Considerations for International Buyers: Compliance with ASTM standards is crucial, and buyers should verify local regulations regarding stainless steel grades.

What Advantages Does Aluminum Offer for Loop Latches?

Aluminum is lightweight and resistant to rust, making it a popular choice for loop latches in residential and light commercial applications. Its ease of fabrication allows for intricate designs, and it can be anodized for enhanced surface protection. However, aluminum may not provide the same strength as steel, which could be a limitation in high-stress applications.

Pros: Lightweight, corrosion-resistant, cost-effective.

Cons: Lower strength compared to steel, potential for bending under heavy loads.

Impact on Application: Ideal for gates and doors in residential settings, particularly in regions with moderate climates.

Considerations for International Buyers: Compliance with JIS standards is often preferred in Asian markets, while European buyers may look for EN standards.

Why Choose Zinc-Plated Steel for Loop Latches?

Zinc-plated steel offers a balance of strength and corrosion resistance at a lower cost than stainless steel. The zinc coating provides a protective layer that helps prevent rust, making it suitable for outdoor applications. However, the durability of the coating can vary, and exposure to harsh environments may lead to corrosion over time.

Pros: Cost-effective, strong, good corrosion resistance.

Cons: Coating may wear off, leading to rust; not as durable as stainless steel.

Impact on Application: Suitable for agricultural and industrial applications, particularly in regions with moderate weather.

Considerations for International Buyers: Buyers should ensure that the zinc plating meets local standards for corrosion resistance.

What Role Does Plastic Play in Loop Latch Design?

Plastic loop latches are lightweight and resistant to corrosion, making them an excellent choice for specific applications such as screen doors and lightweight gates. They are typically less expensive and can be molded into various shapes. However, plastic may not withstand heavy loads or extreme temperatures, limiting its use in more demanding environments.

Illustrative image related to loop latch

Pros: Lightweight, cost-effective, corrosion-resistant.

Cons: Limited strength, potential for degradation under UV exposure.

Impact on Application: Best suited for indoor applications or regions with mild climates.

Considerations for International Buyers: Compliance with local safety standards is important, especially for applications involving children or pets.

Summary Table of Material Selection for Loop Latches

| Material | Typical Use Case for loop latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial gates, coastal applications | Exceptional corrosion resistance | Higher cost, potential galling | High |

| Aluminum | Residential gates, light commercial | Lightweight, rust-resistant | Lower strength, may bend under load | Medium |

| Zinc-Plated Steel | Agricultural and industrial settings | Cost-effective, strong | Coating may wear off | Low |

| Plastic | Screen doors, lightweight gates | Lightweight, cost-effective | Limited strength, UV degradation risk | Low |

This material selection guide aims to assist international B2B buyers in making informed decisions based on performance characteristics, application suitability, and compliance with local standards. Understanding these factors will help ensure that the selected loop latch meets the specific needs of various projects across different regions.

In-depth Look: Manufacturing Processes and Quality Assurance for loop latch

Manufacturing processes and quality assurance (QA) are critical components in the production of loop latches, which are essential for securing gates, doors, and screens across various applications. For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, understanding these processes can significantly impact procurement decisions.

What Are the Main Stages in the Manufacturing Process of Loop Latches?

The manufacturing process of loop latches typically involves several key stages, including material preparation, forming, assembly, and finishing.

-

Material Preparation

The initial step involves selecting high-quality materials, such as stainless steel, aluminum, or zinc-plated steel, which provide durability and resistance to corrosion. The chosen material is sourced from reputable suppliers who comply with international standards. Once procured, the materials undergo cutting and shaping to prepare them for forming. -

Forming Techniques

During this phase, various forming techniques are employed, depending on the design specifications of the loop latch. Common methods include stamping, forging, and machining. Stamping is often used for mass production, allowing for the quick creation of consistent shapes, while forging enhances the strength of components through controlled deformation. Precision machining may be employed for intricate designs or custom components, ensuring tight tolerances are met. -

Assembly Process

After forming, the components are assembled. This can involve manual assembly or automated processes, depending on production scale and complexity. For instance, loop latches may require the integration of springs or locking mechanisms, which necessitates careful assembly to ensure proper functionality. Quality checks are often performed at this stage to catch any defects early in the process. -

Finishing Techniques

The final stage involves finishing processes that enhance both aesthetic appeal and functional performance. Common techniques include powder coating, anodizing, or electroplating, which provide additional protection against rust and wear. This stage also includes cleaning and inspecting the latches to ensure they meet quality standards before packaging.

How Is Quality Assurance Implemented in Loop Latch Production?

Quality assurance in the manufacturing of loop latches is crucial to ensure reliability and safety. International and industry-specific standards guide these QA processes.

Illustrative image related to loop latch

-

What Are the Relevant International Standards?

Many manufacturers adhere to ISO 9001, a globally recognized standard for quality management systems. This certification demonstrates a commitment to consistent quality and customer satisfaction. Additionally, CE marking is essential for products sold in the European market, indicating compliance with health, safety, and environmental protection standards. -

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial stage inspects raw materials to ensure they meet specified requirements before production begins.

– In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help identify and rectify issues in real-time, minimizing defects.

– Final Quality Control (FQC): A thorough inspection occurs before products are packaged and shipped, verifying that the loop latches meet all specifications and standards. -

What Testing Methods Are Commonly Used?

Loop latches undergo various testing methods to ensure their durability and functionality. Common tests include tensile strength tests, corrosion resistance tests, and operational tests to assess the latch’s performance under different conditions. Manufacturers may also conduct fatigue testing to evaluate how well the latches withstand repeated use.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those operating in diverse regulatory environments, verifying a supplier’s quality control processes is essential.

-

What Should Buyers Look for in Supplier Audits?

Buyers should request detailed quality assurance reports, including results from IQC, IPQC, and FQC. Conducting on-site audits can provide insight into the supplier’s manufacturing processes and adherence to quality standards. Additionally, third-party inspections can validate the supplier’s claims regarding quality and compliance with international standards. -

How Do Certifications Affect Supplier Selection?

Certifications such as ISO 9001, CE marking, and other industry-specific certifications should be a priority when selecting suppliers. These certifications indicate that a manufacturer has established quality management systems and adheres to best practices in production. Buyers should request copies of these certifications and verify their validity. -

What Nuances Should International Buyers Be Aware Of?

Different regions may have varying standards and regulations concerning quality assurance. For example, European buyers may prioritize CE marking, while buyers in Africa or South America might focus on local compliance standards. Understanding these nuances is vital for successful procurement and ensuring that products meet local legal requirements.

Conclusion

The manufacturing processes and quality assurance practices for loop latches are integral to ensuring product reliability and safety. For B2B buyers, particularly in diverse international markets, a thorough understanding of these processes aids in making informed purchasing decisions. By prioritizing suppliers who adhere to established quality standards and conducting due diligence through audits and inspections, buyers can secure reliable loop latches that meet their specific needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘loop latch’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure loop latches. Loop latches are essential components in various applications, including gates, doors, and screens, providing security and ease of use. Understanding the critical steps in sourcing these products will help ensure you make informed decisions that meet your specific requirements.

Step 1: Define Your Technical Specifications

Before beginning your sourcing process, it’s vital to clearly define the technical specifications of the loop latches you need. Consider factors such as material (e.g., aluminum, stainless steel), size, load capacity, and finish. This clarity will streamline your search and help you communicate effectively with potential suppliers.

Illustrative image related to loop latch

Step 2: Research Market Trends and Applications

Understanding the current market trends and applications for loop latches is essential for making informed purchasing decisions. Explore how different industries utilize loop latches, from fencing and gate hardware to industrial applications. Pay attention to emerging materials or technologies that might enhance the functionality and durability of the latches.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and quality standards. Request company profiles, product catalogs, and references from other buyers in similar industries or regions. Look for suppliers with a proven track record in delivering quality products and excellent customer service.

- Assess Certifications: Verify that suppliers hold relevant certifications such as ISO or CE, which indicate adherence to industry standards.

Step 4: Request Samples for Quality Assessment

Before making a bulk purchase, request samples of the loop latches to assess their quality and performance. This step is crucial for evaluating the latch’s durability, ease of installation, and overall functionality. Testing samples will help you identify any potential issues before committing to a larger order.

Step 5: Review Pricing and Payment Terms

Compare pricing from multiple suppliers while considering the overall value, not just the cost. Look for hidden costs such as shipping fees, taxes, and potential duties. Additionally, evaluate the payment terms offered by suppliers, as favorable terms can impact your cash flow and overall project budget.

Step 6: Confirm Warranty and After-Sales Support

Ensure that the loop latches come with a warranty that covers defects and issues arising from normal use. This warranty is a crucial indicator of the manufacturer’s confidence in their product. Additionally, inquire about after-sales support, as having access to technical assistance can be beneficial for installation and maintenance.

Step 7: Establish a Long-Term Relationship

Once you’ve identified a reliable supplier, work towards establishing a long-term relationship. Building rapport can lead to better pricing, priority service, and insights into new products and innovations. Regular communication will also help you stay informed about changes in the market and supplier capabilities.

By following this checklist, B2B buyers can navigate the complexities of sourcing loop latches effectively, ensuring they select the best products for their specific needs.

Comprehensive Cost and Pricing Analysis for loop latch Sourcing

What Are the Key Cost Components in Loop Latch Production?

When sourcing loop latches, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common materials include stainless steel, aluminum, and zinc-plated steel, with prices varying based on quality and sourcing location. For example, stainless steel latches generally have a higher cost due to their corrosion resistance and durability.

-

Labor: Labor costs can fluctuate based on the region of production. In areas with higher wage standards, such as Europe, labor costs will be more substantial compared to regions like South America or certain parts of Asia.

-

Manufacturing Overhead: This encompasses the indirect costs of production, including utilities, facility maintenance, and administrative expenses. Efficient production processes can help keep these costs low.

-

Tooling: The initial investment in tooling for custom designs can be significant. If your order requires specialized latches, be prepared for higher upfront costs associated with the creation of molds or dies.

-

Quality Control (QC): Ensuring the latches meet industry standards and certifications (like ISO) can add to the cost, but it is a necessary investment to avoid costly defects and ensure safety.

-

Logistics: Shipping costs will vary depending on the distance and mode of transport. International buyers must consider customs duties and tariffs, which can significantly affect the overall cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary widely based on the supplier’s positioning in the market.

How Do Price Influencers Affect Loop Latch Costs?

Several factors can influence the pricing of loop latches, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Ordering in bulk often leads to lower per-unit costs. Suppliers may offer discounts for larger orders, making it advantageous for buyers to consolidate their purchases.

-

Specifications and Customization: Custom latches that meet specific requirements (e.g., unique sizes or finishes) usually cost more than standard models. Buyers should assess whether customization is necessary or if standard options can suffice.

-

Material Quality and Certifications: Higher-quality materials and certified products (e.g., for safety or environmental standards) command higher prices. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The supplier’s reputation, reliability, and location can impact pricing. Established suppliers may charge more for their products due to perceived quality and service levels.

-

Incoterms: Understanding the Incoterms agreed upon in the purchase contract is crucial, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This can influence the total landed cost of the latches.

What Buyer Tips Can Enhance Cost-Efficiency in Loop Latch Sourcing?

International B2B buyers can leverage several strategies to enhance cost-efficiency:

-

Negotiation: Don’t hesitate to negotiate pricing, especially for larger orders. Suppliers are often open to discussions, particularly if you can demonstrate a long-term purchasing commitment.

-

Total Cost of Ownership (TCO): Assess the TCO rather than just the upfront price. Consider factors like durability, maintenance, and warranty when evaluating the value of a latch.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in exchange rates and local economic conditions that may affect pricing. Conduct market research to understand regional pricing trends.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and more favorable payment terms. Regular communication fosters trust and can result in more advantageous deals.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific order requirements. Always request updated quotes from suppliers to ensure accurate budgeting.

Illustrative image related to loop latch

Alternatives Analysis: Comparing loop latch With Other Solutions

Introduction to Alternative Solutions for Loop Latches

In the realm of securing gates and doors, loop latches are a popular choice due to their straightforward design and ease of use. However, various alternative solutions can also provide effective locking mechanisms. Understanding these options allows B2B buyers to make informed decisions tailored to their specific needs, particularly when considering performance, cost, and application.

Comparison of Loop Latch with Alternative Solutions

| Comparison Aspect | Loop Latch | Magnetic Gate Latch | Slide Bolt Latch |

|---|---|---|---|

| Performance | Simple and effective for light to moderate use | High security with automatic engagement | Reliable for heavy-duty applications |

| Cost | Low-cost, typically $1.40 – $8.87 per unit | Moderate cost, around $40 – $75 | Low to moderate, typically $5 – $15 |

| Ease of Implementation | Easy to install with basic tools | Moderate; may require precise alignment | Simple installation with screws |

| Maintenance | Low maintenance, durable materials | Low maintenance, robust design | Moderate; may need periodic adjustments |

| Best Use Case | Residential gates, screens, and lightweight doors | Security-sensitive areas like commercial gates | Heavy-duty gates in agricultural or industrial settings |

In-Depth Look at Alternative Solutions

Magnetic Gate Latch

Magnetic gate latches are designed to provide a secure and automatic locking mechanism. These latches engage when the gate closes, making them ideal for high-traffic areas where users may not always remember to latch the gate manually. The primary advantage is their robust security; however, they typically come at a higher price point. Installation can be slightly more complex, requiring precise alignment to ensure functionality. They are particularly suited for commercial applications where security is paramount.

Slide Bolt Latch

Slide bolt latches offer a reliable locking mechanism suitable for heavier gates and doors. Their design allows for easy locking and unlocking by sliding a bolt into place. While generally more affordable than magnetic latches, they do require more maintenance as the mechanism can become misaligned over time, especially in high-use scenarios. Slide bolts are often favored in agricultural and industrial settings due to their strength and reliability, making them ideal for securing larger gates against intruders or livestock.

Conclusion: Choosing the Right Latch for Your Needs

When selecting between a loop latch and its alternatives, B2B buyers should carefully consider the specific requirements of their application. Factors such as security needs, the weight of the gate, environmental conditions, and budget constraints will influence the best choice. Loop latches are excellent for low-security applications and offer cost-effective solutions, while magnetic and slide bolt latches cater to higher security and durability needs. By aligning the choice of latch with the intended use case, businesses can ensure a secure and efficient locking solution.

Essential Technical Properties and Trade Terminology for loop latch

What Are the Essential Technical Properties of a Loop Latch?

Understanding the technical properties of loop latches is crucial for B2B buyers who prioritize quality, durability, and functionality in their procurement processes. Below are several key specifications that should be considered when evaluating loop latches:

-

Material Grade

Loop latches are often made from various materials, including steel, aluminum, and zinc-plated steel. The material grade affects the latch’s strength, corrosion resistance, and overall durability. For example, zinc-plated steel offers enhanced rust protection, making it suitable for outdoor applications. Selecting the right material is vital to ensure longevity and performance, especially in harsh environments. -

Finish Type

The finish of a loop latch plays a significant role in its resistance to environmental factors. Common finishes include powder coating and galvanization. A durable finish not only enhances aesthetics but also protects against wear and tear, thus extending the product’s lifespan. Buyers should consider the environmental conditions where the latch will be used, as this can dictate the most suitable finish. -

Load Capacity

Each loop latch is rated for a specific load capacity, which indicates the maximum weight it can securely hold. This specification is critical for applications in gates and doors, where safety is paramount. Overloading a latch can lead to failure, compromising security and functionality. Understanding the load requirements for your application ensures that you select a latch capable of meeting those needs. -

Installation Method

Loop latches can be installed using various methods, including screw-on or snap-in designs. The choice of installation method impacts the ease of setup and maintenance. A straightforward installation process can save time and labor costs, making it an important consideration for contractors and project managers. -

Compatibility with Gate Types

Different loop latches are designed to work with specific types of gates, such as wooden, vinyl, or metal gates. Knowing the compatibility of a latch with the intended gate type ensures optimal performance and security. This consideration is essential for buyers to avoid mismatches that could lead to operational issues. -

Reversible Design

Many loop latches feature a reversible design, allowing them to be installed on either the left or right side of a gate. This versatility is advantageous in various applications and simplifies inventory management for distributors and retailers.

What Are Common Trade Terms Related to Loop Latches?

Navigating the procurement landscape requires familiarity with specific industry jargon. Here are some common trade terms that are relevant to loop latches:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are sold under another brand’s name. In the context of loop latches, understanding OEM relationships can help buyers identify trusted manufacturers who ensure product quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and purchasing strategy. Knowing the MOQ can help businesses plan their procurement more effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products, such as loop latches. This process allows buyers to compare offers from different manufacturers and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is essential for international buyers to clarify who is responsible for costs, risks, and logistics during the transportation of loop latches. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. In the context of loop latches, shorter lead times can be critical for projects with tight deadlines. Buyers should inquire about lead times when negotiating with suppliers to ensure timely delivery. -

Certification Standards

Certification standards refer to the compliance of products with specific quality and safety regulations. Loop latches may need to meet local or international standards, such as ISO or ANSI, depending on the market. Buyers should verify these certifications to ensure that the products they are purchasing adhere to required safety and quality benchmarks.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing loop latches, ensuring that they meet their specific application needs while maintaining compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the loop latch Sector

What Are the Current Market Trends Shaping the Loop Latch Sector?

The loop latch market is witnessing significant growth driven by several global factors. Increased urbanization and infrastructure development across Africa, South America, the Middle East, and Europe are propelling demand for secure and reliable fastening solutions. The construction and fencing industries are particularly strong drivers, as loop latches are essential for securing gates and fences in residential and commercial applications. Furthermore, the rise of e-commerce has made it easier for international B2B buyers to source loop latches from various suppliers, enhancing competition and pricing strategies.

Emerging technologies are also reshaping the sourcing landscape. Innovations in manufacturing processes, such as automated production lines and advanced materials, are leading to cost-effective and high-quality loop latch solutions. Additionally, buyers are increasingly utilizing digital platforms for procurement, enabling them to compare products and prices more efficiently. Sustainability is becoming a key purchasing criterion, with buyers favoring suppliers that demonstrate environmentally responsible practices and products.

How Is Sustainability Influencing the Loop Latch Supply Chain?

Sustainability is a crucial consideration for international B2B buyers in the loop latch sector. As environmental concerns gain traction globally, there is a growing emphasis on ethical sourcing and the environmental impact of materials used in manufacturing loop latches. Buyers are increasingly seeking suppliers that adhere to strict environmental standards and offer products made from recycled or eco-friendly materials.

Illustrative image related to loop latch

The importance of transparent supply chains cannot be overstated. Companies are now more accountable for their sourcing practices, and buyers are looking for certifications such as ISO 14001 or LEED to ensure that their suppliers maintain sustainable operations. By prioritizing sustainability, businesses can not only reduce their ecological footprint but also enhance their brand reputation among environmentally conscious consumers. This trend is particularly relevant in regions like Europe, where regulatory frameworks for sustainable practices are becoming increasingly stringent.

What Is the Historical Context of Loop Latches in B2B Markets?

The evolution of loop latches dates back several decades, with their design and functionality improving significantly over time. Initially, loop latches were simple mechanical devices made from basic metals, primarily used for securing gates and doors. As industries evolved, the demand for more robust and durable latching solutions led to advancements in materials and manufacturing techniques.

In the modern context, loop latches are available in a variety of materials, including aluminum, stainless steel, and zinc-plated options, which enhance their durability and resistance to corrosion. This evolution has allowed loop latches to be utilized in a broader range of applications, from residential fencing to industrial gates. Today, the market is characterized by a diverse range of products, catering to the specific needs of different sectors, including construction, agriculture, and security. Understanding this historical context can help B2B buyers make informed decisions when sourcing loop latches for their projects.

Frequently Asked Questions (FAQs) for B2B Buyers of loop latch

-

How do I select the right loop latch for my application?

Choosing the right loop latch involves assessing the specific needs of your project. Consider factors like the material of your gate or door, the required durability, and whether you need a self-closing option. Evaluate the latch’s compatibility with your existing hardware and check if it meets local regulations. Additionally, inspect the latch’s corrosion resistance and ease of installation. Collaborating with a knowledgeable supplier can provide insights into the best options tailored to your operational requirements. -

What are the key features to look for in a high-quality loop latch?

When sourcing a loop latch, prioritize features such as material quality, corrosion resistance, and design versatility. Look for latches made from heavy-duty materials like stainless steel or zinc-plated steel for enhanced durability. Ensure the latch can accommodate various gate types and sizes, and consider ease of installation and maintenance. A good latch should also offer reliable locking mechanisms and a smooth operational experience to enhance security and functionality. -

What is the minimum order quantity (MOQ) for loop latches?

Minimum order quantities (MOQs) for loop latches can vary significantly depending on the supplier and product type. Typically, MOQs can range from as low as 100 pieces to several thousand. It’s essential to communicate your requirements with potential suppliers to negotiate favorable terms, especially if you are a smaller business or testing a new product line. Some suppliers may offer flexibility in MOQs for first-time buyers or bulk orders. -

How can I ensure the quality of loop latches from international suppliers?

To ensure quality when sourcing loop latches internationally, conduct thorough due diligence on potential suppliers. Request product samples and certifications that indicate compliance with international standards. Establish clear quality assurance protocols, including inspections during production and before shipment. Additionally, consider using third-party inspection services to verify quality before acceptance. Building strong relationships with suppliers can also help maintain quality control over time. -

What are the common payment terms for sourcing loop latches internationally?

Payment terms for international purchases of loop latches generally include options such as upfront payment, letters of credit, or payment upon delivery. Common practices include a 30% deposit with the balance due before shipping or upon receipt of goods. It’s crucial to discuss and agree on payment terms before placing an order to avoid misunderstandings. Be aware of any additional fees associated with currency conversion and international wire transfers. -

How do I manage logistics and shipping for loop latch orders?

Effective logistics management for loop latch orders involves selecting reliable shipping partners and understanding customs regulations in your destination country. Coordinate with suppliers to determine the best shipping methods based on cost, speed, and reliability. Ensure that all necessary documentation, such as commercial invoices and packing lists, is prepared to facilitate smooth customs clearance. Additionally, track shipments regularly and maintain open communication with your supplier and shipping company to address any potential issues promptly. -

What customization options are available for loop latches?

Many manufacturers offer customization options for loop latches, allowing you to tailor products to your specific needs. Customization may include variations in size, finish, and materials, as well as branding options such as logo engraving. When discussing customization with suppliers, clearly outline your requirements, including volume, lead times, and any regulatory standards that must be met. This can enhance your product’s compatibility with existing systems and improve overall customer satisfaction. -

What are the best practices for installing loop latches?

To ensure optimal performance, follow best practices when installing loop latches. Begin by reading the manufacturer’s installation instructions thoroughly. Use appropriate tools and ensure that the latch aligns correctly with the gate or door frame. Pre-drill holes for screws to avoid damaging the latch or the material. Regularly check the latch’s functionality post-installation and make adjustments as necessary to maintain security and ease of use. Proper installation not only enhances performance but also extends the lifespan of the latch.

Top 7 Loop Latch Manufacturers & Suppliers List

1. Nationwide Industries – Round Loop Latch

Domain: pennfence.com

Registered: 1999 (26 years)

Introduction: Product Name: Round Loop Latch

Brand: Nationwide Industries

Price: $5.00

Features:

– Wide selection for various gate types (vinyl, steel, aluminum, wood, pool)

– Trusted quality from a leading name in gate hardware

– Innovative design for safe, dependable, and efficient function

– Complete kits with screws and installation instructions

– Durable hinges sold in pairs for strength and long-lasting …

2. Nielsen Hardware – Straight Loop Latches

Domain: nielsenhardware.com

Registered: 2003 (22 years)

Introduction: Straight Loop Latches are over-center latches featuring a high strength wire loop for maximum holding power. They are available in various styles, including options for padlockable eyes. Materials include steel with multiple finishes and stainless steel for durability in harsh environments. They can be supplied with or without holes and with weld projections to accommodate different mounting requi…

3. Metro Screenworks – Loop Latch 100 Pcs

Domain: metroscreenworks.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Loop Latch 100 Pcs”, “brand”: “Metro Screenworks”, “material”: “Aluminum”, “finish”: “Silver”, “sku”: “”, “upc”: “”, “price”: “$79.95”, “availability”: “in-stock”, “description”: “These loop latches are made of aluminum and available in a silver finish. Loop Latches will hold the bottom of the screen in the window frame. This loop latch hooks over a screw which you will put in th…

4. TCH – Loop Latches

Domain: us.tchweb.com

Registered: 1998 (27 years)

Introduction: Loop Latches – TCH

1. Pad lockable Over Center Drawlatch and Strike

– Price: $3.10 USD

– SKU: 501-527800

2. Heavy Duty large Adjustable Lever Catch with Padlock loop

– Price: Quote Only

3. Stainless Steel Miniature Strike

– Price: $1.18 USD

– SKU: 501-9201805

4. Stainless Steel Miniature Straight Loop Drawlatch

– Price: $5.42 USD

– SKU: 501-9200805

5. Compact Bent Loop Dr…

5. Big D Web – Gate Latch Loop and Hook Style

Domain: bigdweb.com

Registered: 1997 (28 years)

Introduction: Gate Latch Loop and Hook Style

– Price: $3.99

– SKU: 1524

– In stock: Yes

– Description: This gate latch can be used as a gate latch or as a bucket hook. It features a ring with a hook underneath attached to a strong metal piece that mounts to the wall. A piece of chain hooks around to keep the gate in place.

– Product Details: 5″ chain, screw eye and plate with ring and hook.

– UPC Code: 76583968…

6. Nationwide Industries – Split Rail Loop Latches for Wood Gates

Domain: hooverfence.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Split Rail Loop Latches for Wood Gates”, “brand”: “Nationwide Industries”, “item_number”: “NW38302Q-P”, “price_range”: “$6.30 – $6.99”, “finish”: “Zinc plated steel”, “features”: [“Used on split rail fences, split rail, and post and rail fences”, “Not self-closing”, “Mounts on top of the gate and loops over the fence post”, “Rust resistant zinc coated for long life”, “Ideal for u…

7. Nationwide Industries – Split Rail Loop Latch

Domain: nationwideindustries.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Split Rail Loop Latch”, “part_number”: “NW38302Q”, “material”: “Zinc”, “screws”: “Hot dipped galvanized screws”, “hardware_type”: [“Accessories”, “Brackets”, “Drop Rods”, “Finials”, “Gate Handles”, “Hinges”, “Latches”, “Pool & Patio Post Caps”], “application”: [“Chain Link”, “Ornamental”, “Pool & Patio”, “Vinyl”, “Wood”], “specialty”: [“Million Cycle Warranty”, “Innovative Produc…

Strategic Sourcing Conclusion and Outlook for loop latch

As the demand for loop latches continues to grow across various industries, international B2B buyers must prioritize strategic sourcing to maximize value and ensure product reliability. Loop latches, available in diverse materials and designs, cater to a wide range of applications—from fencing to window security—making them essential components for numerous projects. Understanding pricing dynamics, such as the variations found in straight loop latches from Nielsen Hardware and split rail options from Penn Fencing, allows buyers to negotiate better deals and select the best products for their needs.

Furthermore, leveraging relationships with reputable suppliers can enhance procurement efficiency. Buyers should seek manufacturers that offer quality assurance, innovative designs, and comprehensive support, ensuring that their investments lead to long-term operational success. As markets evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, staying informed about emerging trends and technologies in gate hardware will be crucial.

Looking ahead, buyers are encouraged to explore partnerships that align with their strategic objectives, fostering growth and resilience in their operations. Embrace the opportunity to enhance your sourcing strategies today, and position your business for a competitive advantage in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.