How to Source Heat Exchanger Images Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for heat exchanger images

In today’s competitive global landscape, sourcing high-quality heat exchanger images can be a daunting challenge for international B2B buyers. Whether you are looking to enhance your marketing materials or require precise visuals for technical documentation, finding the right images to represent various types of heat exchangers—from air-to-air and tube heat exchangers to plate and coil designs—can significantly impact your purchasing decisions. This comprehensive guide addresses the key aspects of navigating the global market for heat exchanger images, covering essential topics such as types of heat exchangers, their applications across various industries, and strategies for vetting suppliers effectively.

By exploring the diverse range of available heat exchanger images, buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—can make informed decisions that align with their specific needs. The guide empowers you with actionable insights on pricing structures, quality standards, and best practices for sourcing images that not only meet aesthetic requirements but also comply with industrial standards. Ultimately, this resource aims to simplify the procurement process, enabling you to select the most suitable visual assets that resonate with your brand and enhance your operational efficiency in a global marketplace.

Understanding heat exchanger images Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Air to Air Heat Exchangers | Transfers heat between two air streams; often compact and lightweight. | HVAC systems, industrial ventilation. | Pros: Energy-efficient, space-saving. Cons: Limited to air applications, may require regular maintenance. |

| Tube Heat Exchangers | Consists of bundles of tubes; suitable for high-pressure applications. | Chemical processing, oil refining, power plants. | Pros: High thermal efficiency, durable under extreme conditions. Cons: More complex to clean and maintain. |

| Plate Heat Exchangers | Composed of thin plates stacked together; compact and efficient. | Food processing, pharmaceuticals, HVAC. | Pros: High heat transfer efficiency, easy to clean. Cons: Sensitive to pressure variations, potential for leaks. |

| Coil Heat Exchangers | Uses coiled tubes; ideal for compact spaces. | Refrigeration, air conditioning. | Pros: Space-efficient, versatile. Cons: Limited capacity, may have lower heat transfer efficiency compared to other types. |

| Double Pipe Heat Exchangers | Simple design with two concentric pipes; cost-effective. | Water heating, oil cooling. | Pros: Low manufacturing cost, easy to install. Cons: Less efficient for large-scale applications, limited heat transfer area. |

What Are the Characteristics of Air to Air Heat Exchangers?

Air to air heat exchangers are designed to transfer heat between two air streams without mixing them. They are typically compact and lightweight, making them ideal for HVAC systems and industrial ventilation applications. B2B buyers should consider their energy efficiency and space-saving capabilities, especially in environments where air quality and temperature control are critical. However, they may require regular maintenance to ensure optimal performance and longevity.

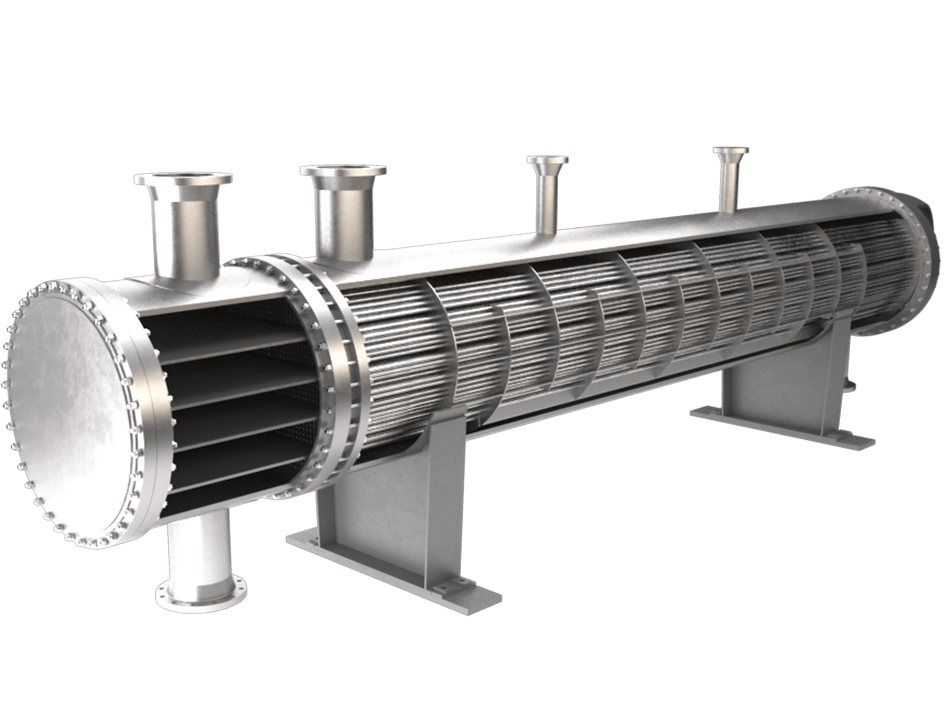

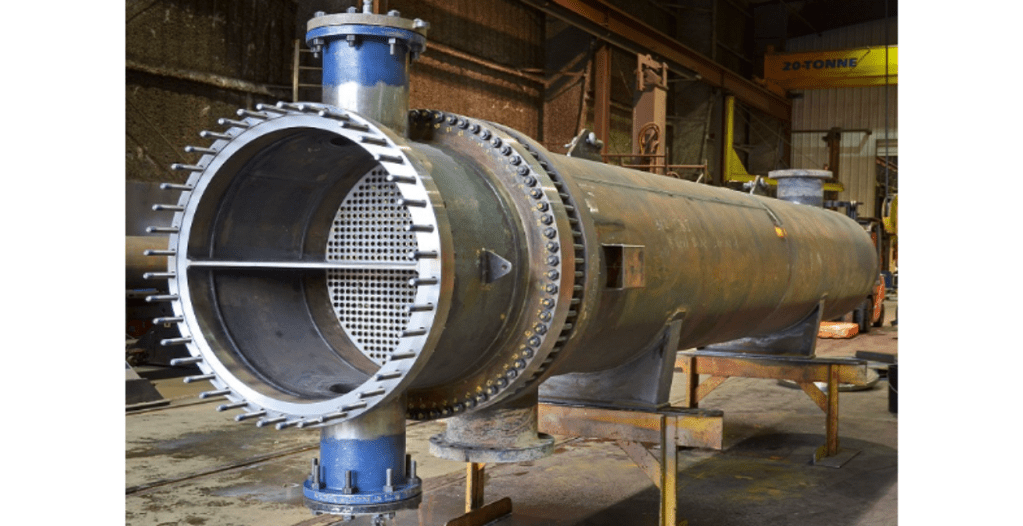

How Do Tube Heat Exchangers Function in Industrial Settings?

Tube heat exchangers feature bundles of tubes that facilitate heat transfer between fluids. Their robust construction allows them to withstand high pressures and temperatures, making them suitable for demanding applications in chemical processing, oil refining, and power generation. Buyers should evaluate the thermal efficiency and durability of these systems, as well as the complexity involved in cleaning and maintenance, which can impact operational costs.

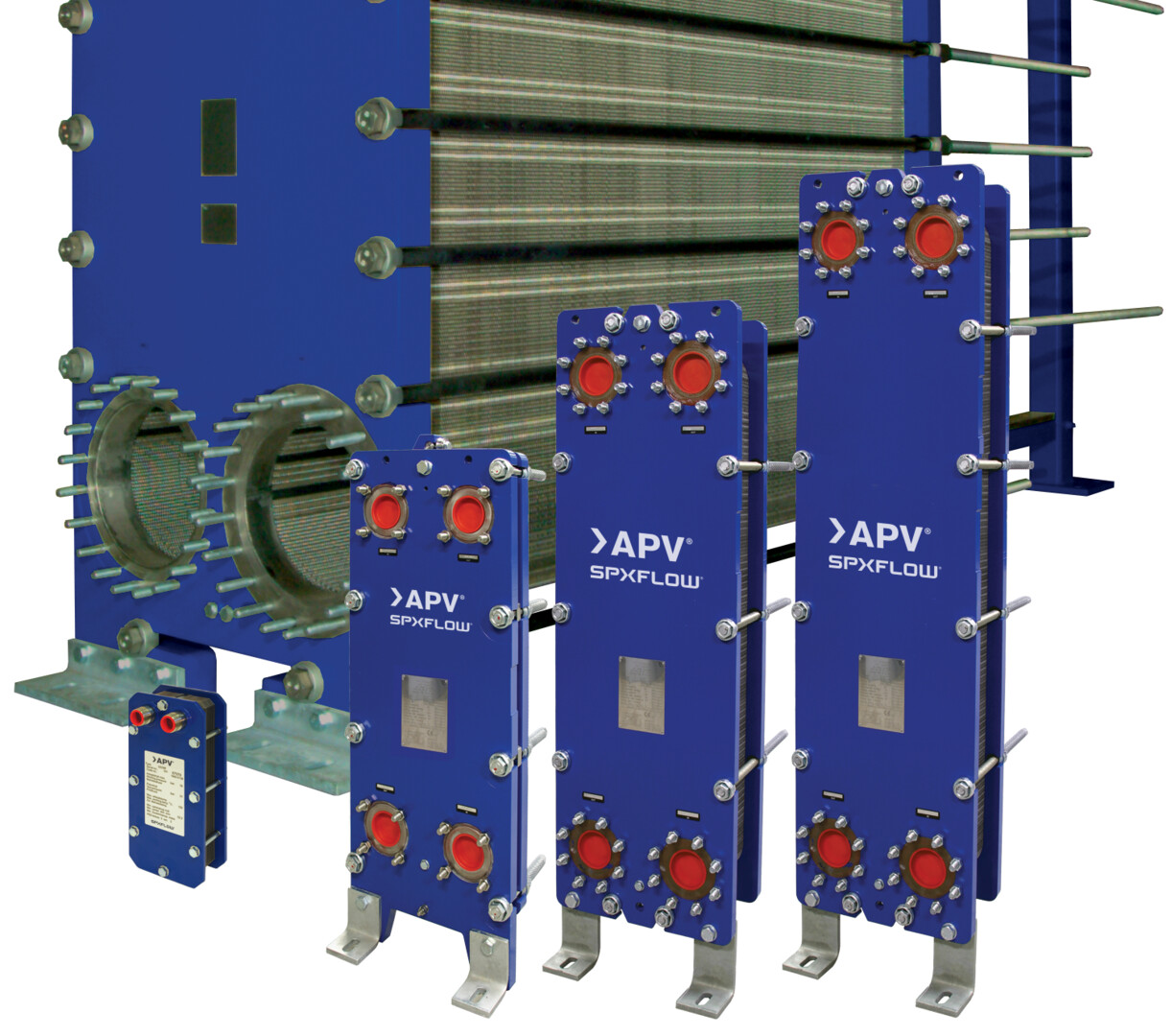

What Makes Plate Heat Exchangers Efficient?

Plate heat exchangers consist of a series of thin plates stacked together, creating multiple channels for fluid flow. This design maximizes the surface area for heat transfer, making them highly efficient for applications in food processing and pharmaceuticals. B2B buyers appreciate their compact size and ease of cleaning, although they should be aware of their sensitivity to pressure changes and the potential for leaks, which can affect system reliability.

What Are the Advantages of Coil Heat Exchangers?

Coil heat exchangers utilize coiled tubes to transfer heat, making them an excellent choice for compact installations in refrigeration and air conditioning systems. Their versatility allows them to adapt to various applications while maintaining a space-efficient design. However, buyers should note that while they are suitable for smaller systems, they may have limited capacity and lower heat transfer efficiency compared to other types of heat exchangers.

Illustrative image related to heat exchanger images

Why Choose Double Pipe Heat Exchangers for Cost-Effective Solutions?

Double pipe heat exchangers consist of two concentric pipes, providing a straightforward and cost-effective solution for heat transfer needs, such as water heating and oil cooling. Their simple design makes them easy to install and maintain, appealing to budget-conscious buyers. However, their efficiency is limited for large-scale applications due to the reduced heat transfer area, which should be considered when evaluating potential purchases.

Key Industrial Applications of heat exchanger images

| Industry/Sector | Specific Application of heat exchanger images | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Visual documentation of heat exchangers in refineries | Enhances operational safety and maintenance efficiency | Consider corrosion resistance and specific thermal requirements |

| Chemical Processing | Illustrative examples for heat exchangers in chemical reactors | Aids in optimizing heat transfer processes | Ensure compatibility with various chemicals and pressure ratings |

| HVAC Systems | Design and layout images for commercial HVAC heat exchangers | Improves system efficiency and energy savings | Look for energy ratings and compliance with international standards |

| Food and Beverage | Showcasing sanitary heat exchangers for food processing | Ensures compliance with health regulations | Focus on materials that prevent contamination and facilitate cleaning |

| Power Generation | Images of heat exchangers in power plants | Supports efficiency improvements in energy production | Verify thermal performance and adaptability to varying fuel types |

How Are Heat Exchanger Images Utilized in the Oil and Gas Sector?

In the oil and gas industry, heat exchanger images serve as vital tools for visual documentation and training. These images help in identifying the layout and condition of exchangers in refineries, enhancing safety protocols during maintenance and inspections. Buyers from regions like the Middle East and Africa need to consider the specific corrosion resistance of materials used, as well as the thermal performance required for high-pressure environments.

What Role Do Heat Exchanger Images Play in Chemical Processing?

Chemical processing facilities often rely on heat exchanger images to illustrate various designs and configurations used in reactors. These visuals assist engineers in optimizing heat transfer processes, ensuring that the systems meet stringent operational standards. For B2B buyers in South America, understanding compatibility with different chemicals and pressure ratings is crucial when sourcing heat exchangers.

How Are Heat Exchanger Images Applied in HVAC Systems?

In HVAC systems, heat exchanger images are essential for showcasing designs that maximize energy efficiency and comfort in commercial buildings. These images help stakeholders visualize the integration of heat exchangers into existing systems, facilitating better decision-making. European buyers should prioritize sourcing heat exchangers that meet energy efficiency ratings and comply with local regulations to ensure optimal performance.

Why Are Heat Exchanger Images Important in the Food and Beverage Industry?

In the food and beverage sector, heat exchanger images highlight sanitary designs necessary for compliance with health and safety regulations. These visuals support the selection of equipment that minimizes contamination risks during processing. Buyers should focus on sourcing materials that are easy to clean and maintain, ensuring a safe production environment, particularly in regions with strict food safety standards.

Illustrative image related to heat exchanger images

How Do Heat Exchanger Images Enhance Power Generation Efficiency?

In power generation, heat exchanger images illustrate the critical role these components play in improving overall system efficiency. By visually representing the installation and operation of heat exchangers, these images aid in training and operational assessments. Buyers from various regions need to verify the thermal performance of heat exchangers and their adaptability to different fuel types to optimize energy production.

3 Common User Pain Points for ‘heat exchanger images’ & Their Solutions

Scenario 1: Difficulty in Visualizing Heat Exchanger Specifications

The Problem: B2B buyers often struggle to find images that accurately represent the specifications of various heat exchanger models. This challenge can lead to confusion when attempting to compare products or communicate requirements to suppliers. For instance, a buyer from a petrochemical company in Saudi Arabia may need specific visuals of shell and tube heat exchangers to ensure they meet their operational standards. Without clear, detailed images, buyers risk making misinformed purchasing decisions that could impact system efficiency and operational safety.

The Solution: To effectively overcome this issue, buyers should leverage comprehensive online galleries and manufacturer websites that provide high-resolution images of heat exchangers. Look for platforms that categorize images based on design type—such as air-to-air, tube, and plate heat exchangers—allowing for easier navigation. Additionally, requesting images that include dimensions and material specifications can enhance understanding. Buyers should also consider using 3D models or virtual reality tools if available, as these can provide a more immersive understanding of how different designs will fit into existing systems. Engaging directly with manufacturers for additional visuals or product datasheets can further clarify specifications and ensure alignment with operational needs.

Scenario 2: Inadequate Image Quality for Marketing Materials

The Problem: When creating marketing materials or technical documentation, B2B buyers often encounter low-quality or generic images that fail to represent the sophistication of heat exchangers. This can be particularly detrimental for companies in Europe, where visual quality directly impacts brand perception and trust. Poor images can undermine the credibility of marketing efforts, making it difficult to convey the value and technical superiority of the products being offered.

The Solution: To enhance the quality of marketing materials, buyers should prioritize sourcing images from reputable stock photo agencies or directly from manufacturers that offer high-definition visuals. Utilizing platforms like Adobe Stock or iStock allows buyers to access a wide range of professionally captured images tailored to their specific needs. It’s essential to ensure that the images selected are relevant to the target market and showcase the heat exchanger’s features, such as size, material, and application. Additionally, buyers should consider hiring a professional photographer to capture custom images of their own products in operation, as this can provide unique content that resonates with potential customers.

Scenario 3: Misalignment Between Image and Product Functionality

The Problem: Another prevalent issue is the misalignment between the images of heat exchangers and their actual functionality. B2B buyers may find visually appealing images that do not accurately reflect how the products operate or fit within a specific application. For instance, a buyer in South America may select a heat exchanger based on a beautiful image, only to discover later that it doesn’t meet their technical needs for a chemical processing application. This disconnect can lead to costly project delays and increased operational risks.

The Solution: To address this challenge, buyers should adopt a systematic approach to vetting images against product specifications and functionality. It is advisable to request detailed product descriptions alongside images, focusing on operational parameters such as temperature ranges, pressure capacities, and material compatibility. Engaging in discussions with suppliers to clarify how the images correlate with real-world applications can also help mitigate this risk. Additionally, seeking case studies or testimonials that illustrate the successful use of particular heat exchangers in similar applications can provide buyers with a clearer understanding of how the product performs in practice. This thorough vetting process ensures that the selected heat exchanger not only looks good but also meets the necessary functional requirements for the buyer’s specific needs.

Illustrative image related to heat exchanger images

Strategic Material Selection Guide for heat exchanger images

What Are the Common Materials Used in Heat Exchanger Images?

When selecting materials for heat exchangers, several factors influence performance, durability, and suitability for specific applications. Below are analyses of four common materials used in heat exchangers, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Do Stainless Steel Properties Affect Heat Exchanger Performance?

Stainless steel is a popular choice for heat exchangers due to its excellent corrosion resistance and ability to withstand high temperatures and pressures. Key properties include a temperature rating of up to 800°C (1472°F) and a pressure rating that can exceed 1000 psi, depending on the specific grade.

Pros: Its durability and resistance to oxidation make it suitable for various media, including aggressive chemicals and steam. Stainless steel is also relatively easy to fabricate and can be welded without compromising its integrity.

Cons: The primary drawback is its cost, which is higher than carbon steel. Additionally, while it performs well in many environments, it may not be suitable for certain chloride-containing media, which can lead to pitting corrosion.

Impact on Application: Stainless steel heat exchangers are commonly used in food processing, pharmaceuticals, and chemical industries due to their hygienic properties and resistance to corrosion.

Illustrative image related to heat exchanger images

Considerations for International Buyers: Compliance with international standards such as ASTM A312 for piping and DIN 17440 for stainless steel is crucial. Buyers from regions like Europe and the Middle East may prefer specific grades like 316L for enhanced corrosion resistance.

What Advantages Do Copper Alloys Offer in Heat Exchanger Applications?

Copper and its alloys are known for their excellent thermal conductivity, making them ideal for heat exchangers where efficient heat transfer is critical. They can typically handle temperatures up to 250°C (482°F) and pressures around 300 psi.

Pros: Copper’s high thermal efficiency allows for smaller designs, reducing material costs. It also possesses inherent antimicrobial properties, making it suitable for applications in healthcare and food processing.

Cons: However, copper is susceptible to corrosion in certain environments, particularly in the presence of ammonia or chlorides. Additionally, its cost can be a limiting factor for large-scale applications.

Impact on Application: Copper heat exchangers are often used in HVAC systems and refrigeration due to their superior heat transfer capabilities.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards, such as ASTM B280 for copper tubing. In regions like South America, where humidity can be high, additional corrosion protection may be necessary.

Why Is Carbon Steel a Common Choice for Heat Exchanger Manufacturing?

Carbon steel is frequently used in heat exchanger construction due to its strength and affordability. It typically supports temperatures up to 400°C (752°F) and pressures around 1500 psi, making it suitable for many industrial applications.

Pros: Its lower cost compared to stainless steel and copper makes it an attractive option for large-scale projects. Carbon steel also offers good mechanical properties and can be easily welded.

Cons: The major downside is its susceptibility to corrosion, especially in moist or acidic environments. This often necessitates additional coatings or treatments, which can increase overall costs.

Illustrative image related to heat exchanger images

Impact on Application: Carbon steel heat exchangers are widely used in oil and gas, power generation, and chemical processing industries.

Considerations for International Buyers: Compliance with standards such as ASTM A106 for seamless carbon steel pipes is essential. Buyers in regions like Africa and the Middle East should consider the local environmental conditions that may affect corrosion rates.

How Do Titanium Alloys Enhance Heat Exchanger Durability?

Titanium is increasingly being used in heat exchangers due to its exceptional corrosion resistance and strength-to-weight ratio. It can handle temperatures up to 600°C (1112°F) and pressures exceeding 2000 psi.

Pros: Titanium’s resistance to a wide range of corrosive environments makes it ideal for applications involving seawater or aggressive chemicals. Its lightweight nature also allows for easier installation and reduced structural support requirements.

Cons: The primary disadvantage is its high cost and manufacturing complexity, which can limit its use to specialized applications.

Impact on Application: Titanium heat exchangers are often found in marine applications, chemical processing, and aerospace, where performance and durability are critical.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM B338 for titanium pipes. In Europe, specific grades may be preferred due to regulatory requirements.

Illustrative image related to heat exchanger images

Summary Table of Material Selection for Heat Exchanger Images

| Material | Typical Use Case for heat exchanger images | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost than carbon steel | High |

| Copper Alloys | HVAC systems, refrigeration | Superior thermal conductivity | Susceptible to corrosion in certain environments | Med |

| Carbon Steel | Oil and gas, power generation | Cost-effective and strong | Prone to corrosion | Low |

| Titanium | Marine applications, aerospace | Exceptional corrosion resistance | High cost and manufacturing complexity | High |

This strategic material selection guide provides essential insights for B2B buyers in selecting the appropriate materials for heat exchangers, ensuring optimal performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for heat exchanger images

What Are the Key Stages in the Manufacturing Process of Heat Exchangers?

The manufacturing process of heat exchangers is a multifaceted operation that involves several critical stages, ensuring that the final product meets stringent performance and safety standards. Understanding these stages is essential for B2B buyers, especially those from diverse regions, including Africa, South America, the Middle East, and Europe.

Material Preparation: What Are the Essential Steps?

The first stage in heat exchanger manufacturing involves material selection and preparation. Common materials include stainless steel, titanium, and other corrosion-resistant alloys, chosen based on the specific application, operating conditions, and required thermal conductivity. The selected materials undergo cutting, machining, and surface treatment to prepare them for the next phases.

Specialized techniques such as laser cutting and CNC machining ensure precision in dimensions, which is crucial for the efficiency of the heat exchanger. Proper material preparation not only enhances performance but also ensures durability under varying operational conditions.

How Are Heat Exchangers Formed?

Forming is a critical stage where the prepared materials are shaped into the required configurations. This may involve processes like bending, rolling, or stamping, depending on the type of heat exchanger being produced (e.g., shell and tube, plate, or coil designs).

Illustrative image related to heat exchanger images

For shell and tube heat exchangers, for instance, tubes are formed and then arranged within a shell. Advanced techniques such as hydroforming may also be employed to create complex shapes while maintaining structural integrity. This stage is vital as it influences the overall efficiency and functionality of the heat exchanger.

What Does the Assembly Process Entail?

Once the components are formed, assembly begins. This stage typically involves welding, brazing, or mechanically fastening the parts together to create a complete unit. The choice of assembly method is influenced by factors like the type of heat exchanger and the materials used.

Quality control is paramount during assembly, as improper techniques can lead to leaks or failures. Automated welding processes may be used to ensure consistency, while skilled technicians conduct inspections to verify that assembly standards are met.

What Finishing Techniques Are Employed in Heat Exchanger Manufacturing?

The finishing stage includes processes that enhance the heat exchanger’s performance and longevity. This may involve surface treatments such as passivation, painting, or coating to prevent corrosion and improve heat transfer efficiency.

Illustrative image related to heat exchanger images

Additionally, the units may undergo pressure testing to ensure that they can withstand the operational pressures they will encounter. These finishing touches are crucial for ensuring that the heat exchangers perform reliably in demanding environments.

What Quality Assurance Measures Are Essential for Heat Exchanger Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, especially for products like heat exchangers that operate under high pressure and temperature. Adhering to international standards and implementing stringent QA protocols helps ensure product reliability and safety.

Which International Standards Should B2B Buyers Be Aware Of?

For manufacturers targeting international markets, compliance with standards such as ISO 9001 is essential. This standard focuses on quality management systems and ensures that products consistently meet customer and regulatory requirements.

Illustrative image related to heat exchanger images

Additionally, industry-specific certifications like CE marking (for compliance with European standards) and API (American Petroleum Institute) specifications are important, particularly for heat exchangers used in oil and gas applications. These certifications signify that the products meet rigorous performance and safety criteria.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early. The primary checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for compliance with specifications before they are used in production.

-

In-Process Quality Control (IPQC): Conducted during manufacturing, this phase involves monitoring processes and product dimensions to ensure they conform to quality standards.

-

Final Quality Control (FQC): The final stage of inspection, FQC involves comprehensive testing of the completed heat exchanger, including pressure tests, leak tests, and thermal efficiency evaluations.

These checkpoints help maintain high quality throughout the production process and reduce the likelihood of defects reaching the customer.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures of their suppliers. Here are some actionable insights:

Illustrative image related to heat exchanger images

What Are the Best Practices for Conducting Supplier Audits?

Regular audits of suppliers can provide invaluable insights into their quality control processes. Buyers should consider:

-

On-Site Audits: Visiting the manufacturing facility allows buyers to assess the production processes, equipment, and quality management systems in place.

-

Documentation Review: Evaluating quality control records, inspection reports, and compliance certificates can help verify adherence to international standards.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s quality assurance measures.

How Can Buyers Navigate Quality Control Nuances in Different Regions?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of regional nuances in quality standards and certifications.

-

Understanding Local Regulations: Different countries may have varying requirements for heat exchangers, particularly regarding safety and environmental standards. Buyers should familiarize themselves with these regulations to ensure compliance.

-

Cultural Sensitivity in Quality Expectations: Recognizing that perceptions of quality may differ across cultures can help buyers communicate their expectations effectively and build stronger supplier relationships.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures is crucial for B2B buyers of heat exchangers. By focusing on material preparation, forming, assembly, and finishing, along with rigorous quality control standards, buyers can ensure they select reliable suppliers capable of meeting their operational needs.

Illustrative image related to heat exchanger images

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heat exchanger images’

When sourcing heat exchanger images for your business needs, it is vital to have a structured approach to ensure you acquire the right visuals that align with your specifications and brand requirements. This guide provides a step-by-step checklist to help you efficiently navigate the procurement process.

Step 1: Identify Your Specific Needs

Before starting your search, define the types of heat exchanger images you require. Consider the applications, designs, and industries relevant to your business, such as air to air, tube, plate, or coil heat exchangers. This clarity will help you focus your efforts and streamline the sourcing process.

Step 2: Research Reputable Image Sources

Investigate various platforms that specialize in industrial images, such as Adobe Stock, Shutterstock, and industry-specific galleries like those from TITAN Metal Fabricators. Look for sources that provide high-resolution images and comprehensive galleries showcasing different types of heat exchangers, ensuring a diverse selection for your needs.

Step 3: Evaluate Image Quality and Licensing

When selecting images, pay close attention to their quality and licensing agreements. Ensure the images are high-resolution and suitable for your intended use—be it for marketing materials, technical documentation, or presentations. Check the licensing terms to avoid legal issues; some images may have restrictions on commercial use.

Step 4: Consider Custom Image Solutions

If standard images do not meet your specifications, explore options for custom photography. This approach allows you to showcase your products or projects in a way that reflects your brand identity. Engage with photographers or firms that have experience in industrial photography to capture the unique aspects of your heat exchangers.

Step 5: Request Samples and Verify Authenticity

Before finalizing your order, request sample images to assess their relevance and quality. Additionally, verify the authenticity of the images, especially if they are sourced from stock libraries. Look for images that provide context, such as installation settings or operational environments, to enhance their applicability.

Step 6: Check for Supplier Reviews and Testimonials

Research the reputation of the image providers by checking reviews and testimonials from previous clients. This feedback can provide insights into their reliability, customer service, and the quality of their image collections. Favor suppliers who have demonstrated experience in the industrial sector and positive feedback from similar businesses.

Illustrative image related to heat exchanger images

Step 7: Finalize Your Purchase and Keep Records

Once you have selected the images that meet your criteria, proceed with the purchase. Ensure that you keep accurate records of your transactions, including licenses and usage rights. This documentation will be valuable for compliance and future reference, especially if you plan to use the images across multiple platforms or projects.

By following these steps, you can effectively source high-quality heat exchanger images that meet your business objectives while minimizing risks associated with image use and supplier selection.

Comprehensive Cost and Pricing Analysis for heat exchanger images Sourcing

When sourcing heat exchanger images for B2B applications, understanding the comprehensive cost structure and pricing dynamics is essential for making informed purchasing decisions. This guide provides insights into the key components influencing costs, pricing strategies, and practical tips for international buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Sourcing Heat Exchanger Images?

The cost structure for heat exchanger images typically includes several components:

-

Materials: The quality of images can vary based on the type of heat exchanger being depicted (e.g., tube, plate, or coil). High-resolution images that showcase intricate designs and details may command higher prices due to the need for specialized photography equipment and techniques.

-

Labor: This includes the costs associated with professional photographers, graphic designers, and editors who ensure that images meet industry standards. Labor costs can significantly influence the final price, especially if custom images are requested.

-

Manufacturing Overhead: While not directly applicable to images, overhead can encompass the costs of maintaining a photo gallery or stock image service. This might include website maintenance, storage fees, and administrative costs.

-

Tooling: In the context of images, tooling can refer to the technology used to capture and process images. Advanced cameras and editing software contribute to the overall cost.

-

Quality Control (QC): Ensuring that images meet specific quality standards can add to the cost. This might involve additional rounds of editing or verification processes to ensure clarity and relevance.

-

Logistics: For digital images, logistics costs are generally minimal but can include the distribution of files and server costs associated with hosting large image libraries.

-

Margin: Suppliers will typically add a margin to cover their costs and generate profit. This margin can vary widely depending on the supplier’s pricing strategy and market positioning.

How Do Price Influencers Affect Heat Exchanger Image Costs?

Several factors can influence the pricing of heat exchanger images:

-

Volume/MOQ (Minimum Order Quantity): Suppliers may offer discounts for bulk purchases. If a buyer requires a large number of images, negotiating for volume pricing can lead to significant savings.

-

Specifications and Customization: Custom images that cater to specific needs or showcase unique designs will generally be priced higher than standard images. Buyers should clearly communicate their requirements to avoid unexpected costs.

-

Materials and Quality Certifications: The quality of the images, including resolution and detail, can affect pricing. Images that are certified for use in professional publications or marketing may also come at a premium.

-

Supplier Factors: Established suppliers with a strong reputation may charge more for their services compared to lesser-known providers. It’s essential to assess the supplier’s portfolio and client reviews.

-

Incoterms: Understanding the terms of trade can help buyers manage costs effectively. Different Incoterms can affect shipping and handling costs, especially if physical prints or specialized formats are required.

What Are Practical Tips for Negotiating Costs and Ensuring Cost-Efficiency?

-

Negotiate Wisely: Engage suppliers in discussions about pricing, particularly if you plan to make a substantial purchase. Leverage your position as a recurring buyer to negotiate better terms.

-

Consider Total Cost of Ownership (TCO): When evaluating options, consider not just the upfront costs but the long-term value. High-quality images may reduce the need for frequent replacements or additional editing costs.

-

Understand Pricing Nuances for International Buyers: Be aware of potential currency fluctuations and import duties that could impact overall costs. Establishing a clear understanding of these factors can lead to better budgeting.

-

Utilize Free Trials: Many stock image services offer free trials. Use these to assess the quality of images before committing to a purchase. This can also help in understanding the different types of images available and their relevance to your needs.

-

Leverage Regional Supplier Relationships: For buyers in Africa, South America, the Middle East, and Europe, establishing relationships with local suppliers can minimize shipping costs and lead to better communication.

Disclaimer on Indicative Prices

Pricing for heat exchanger images can vary significantly based on the factors discussed above. It is advisable for buyers to request quotes from multiple suppliers to ensure competitive pricing and to consider the specific context of their purchase to achieve the best value.

Alternatives Analysis: Comparing heat exchanger images With Other Solutions

Exploring Alternatives to Heat Exchanger Images in Industrial Applications

When considering visual representations of heat exchangers, it’s essential to understand how these images compare to other methods of conveying information about heat transfer technologies. This section provides a comparative analysis of heat exchanger images against alternative solutions, helping B2B buyers make informed decisions based on their specific needs.

Illustrative image related to heat exchanger images

| Comparison Aspect | Heat Exchanger Images | CAD Models | Interactive 3D Simulations |

|---|---|---|---|

| Performance | Effective for visual identification and marketing | High precision in design and specifications | Real-time interaction, dynamic adjustments |

| Cost | Generally low cost for stock images | Moderate cost for software and skilled personnel | High cost due to advanced technology and development |

| Ease of Implementation | Quick and easy to source | Requires training for users | Requires significant investment and expertise |

| Maintenance | No maintenance required | Updates needed for accuracy | Requires ongoing software support and updates |

| Best Use Case | Marketing materials, product catalogs | Engineering design and prototype development | Training, simulation, and complex design evaluations |

What are the Benefits of Using CAD Models as an Alternative?

Computer-Aided Design (CAD) models serve as a robust alternative to heat exchanger images, offering detailed specifications and dimensions that enhance understanding during the design phase. CAD models enable engineers to visualize complex systems, allowing for precise calculations and modifications. However, this approach requires a moderate investment in software and skilled personnel. While CAD models can be time-consuming to create, they are invaluable in industries where exact specifications are crucial, such as oil and gas or pharmaceuticals.

How Do Interactive 3D Simulations Enhance Understanding of Heat Exchangers?

Interactive 3D simulations provide an immersive experience that allows users to manipulate and explore the components of heat exchangers in real-time. This method excels in training environments, where users can engage with the product dynamically, leading to better retention of information and a deeper understanding of the operational principles. However, the cost of developing these simulations can be significant, and they require ongoing maintenance and updates to remain relevant and functional. While they are an excellent tool for educational purposes, their complexity may not be necessary for every application.

Why Choose Heat Exchanger Images for Your Marketing Needs?

Heat exchanger images are a highly effective way to visually communicate the product’s features and benefits in marketing materials. They are easily accessible and can be quickly integrated into brochures, websites, and presentations. The low cost of acquiring stock images makes them an attractive option for businesses looking to enhance their visual marketing without the need for extensive resources. However, heat exchanger images lack the detailed technical specifications found in CAD models or the interactive capabilities of 3D simulations, which may limit their effectiveness in technical discussions.

How Can B2B Buyers Select the Right Solution for Their Needs?

When choosing the right solution for conveying information about heat exchangers, B2B buyers should consider their specific objectives. If the goal is to create engaging marketing materials, heat exchanger images are a suitable choice. For engineering-focused tasks requiring precision, CAD models are more appropriate. Meanwhile, for training and educational purposes, interactive 3D simulations provide a unique and effective learning experience. Ultimately, the decision should align with the buyer’s budget, the complexity of the information being conveyed, and the intended audience’s needs. By evaluating these factors, buyers can select the most effective method for their business objectives.

Illustrative image related to heat exchanger images

Essential Technical Properties and Trade Terminology for heat exchanger images

What Are the Key Technical Properties of Heat Exchanger Images?

When evaluating heat exchanger images for purchase or specification, several critical technical properties should be considered. Understanding these properties helps B2B buyers ensure that they select the right equipment for their operational needs.

-

Material Grade

Heat exchangers are typically constructed from various materials, including stainless steel, carbon steel, and specialized alloys like titanium or high-nickel alloys. The material grade is crucial as it determines corrosion resistance, thermal conductivity, and durability. For instance, stainless steel is commonly used in food and pharmaceutical applications due to its non-reactive nature. Buyers must select a material that aligns with the operational environment and fluid characteristics. -

Design Type

Heat exchangers come in several designs, including shell and tube, plate, and air-to-air configurations. Each design serves different applications and efficiency requirements. For example, shell and tube heat exchangers are favored in high-pressure environments, while plate heat exchangers are ideal for space-constrained applications. Understanding the design type helps buyers match the heat exchanger to their specific process needs. -

Thermal Efficiency

This property measures how effectively a heat exchanger transfers heat between fluids. It is often expressed as a heat transfer coefficient (U-value). Higher thermal efficiency can lead to reduced energy consumption and operational costs, making it a vital specification for buyers. Evaluating thermal efficiency through images can also provide insight into the design features that enhance performance. -

Pressure Rating

The pressure rating indicates the maximum pressure the heat exchanger can withstand during operation. This is essential for ensuring safety and reliability in high-pressure applications, such as oil refining or chemical processing. Buyers should verify that the pressure rating aligns with their system’s operational parameters to avoid potential failures. -

Fouling Resistance

Fouling refers to the buildup of unwanted materials on heat exchanger surfaces, which can significantly reduce efficiency. Images showcasing features like smooth surfaces or specialized coatings can indicate a design that minimizes fouling. B2B buyers need to consider fouling resistance in environments where fluid composition may lead to deposits, ensuring longer operational intervals and reduced maintenance costs. -

Size and Dimensions

The physical dimensions of the heat exchanger are critical for installation and operation. Images should clearly depict size specifications, including length, width, and height. Buyers must ensure that the selected heat exchanger fits within existing infrastructure while meeting performance requirements.

What Common Trade Terms Should B2B Buyers Know About Heat Exchangers?

Understanding trade terminology is essential for effective communication and negotiation in the heat exchanger market. Here are several key terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Buyers often prefer OEM products due to their reliability and quality assurance. Knowing the OEM of a heat exchanger can provide confidence in the product’s performance and compatibility. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers looking to negotiate orders, especially when entering new markets or testing products. Understanding MOQ can help buyers manage inventory and cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is a formal process that helps buyers gather competitive offers. Crafting a detailed RFQ can lead to better pricing and service terms, making it an essential part of procurement strategies. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping, insurance, and liability aspects, ensuring smooth logistics and compliance. -

Lead Time

This term refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times is crucial for project planning and inventory management, especially in industries where equipment downtime can lead to significant losses. -

Certification Standards

Certifications, such as ASME (American Society of Mechanical Engineers) or ISO (International Organization for Standardization), indicate that a heat exchanger meets specific safety and quality standards. Familiarity with these standards helps buyers ensure compliance and reliability in their operations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing heat exchangers, ultimately enhancing operational efficiency and reliability.

Navigating Market Dynamics and Sourcing Trends in the heat exchanger images Sector

What Are the Current Market Dynamics and Key Trends Affecting Heat Exchanger Images?

The global market for heat exchanger images is witnessing significant growth, driven by increasing industrialization, the need for energy efficiency, and stringent environmental regulations. As industries such as oil and gas, power generation, and food processing expand, the demand for high-quality visual content representing heat exchanger systems has surged. B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe (notably Saudi Arabia and Germany), are increasingly seeking detailed and accurate images to aid in decision-making, product development, and marketing.

Emerging trends in this sector include the integration of advanced technologies like 3D modeling and augmented reality (AR) to enhance the visual representation of heat exchangers. These technologies allow manufacturers and suppliers to present their products more effectively, showcasing intricate details and operational capabilities that traditional images may not convey. Furthermore, the rise of e-commerce and digital marketing platforms has necessitated a higher quality of visual content, leading businesses to invest in professional image galleries and stock photo services.

International buyers are also looking for suppliers that offer customizable solutions, reflecting the unique requirements of their industries. This shift towards tailored products is prompting manufacturers to produce a diverse range of heat exchanger types, including shell and tube, plate, and coil designs, each suited to specific applications. As a result, B2B buyers are encouraged to explore comprehensive photo galleries that provide a broad spectrum of heat exchanger images to facilitate informed purchasing decisions.

Illustrative image related to heat exchanger images

How Can Sustainability and Ethical Sourcing Impact the Heat Exchanger Images Sector?

Sustainability is increasingly becoming a priority in the global market, influencing how heat exchangers are manufactured, marketed, and visualized. B2B buyers are now placing greater emphasis on the environmental impact of products, including the materials used in heat exchangers and their associated images. For heat exchanger images, this translates into a demand for visuals that highlight sustainable practices, such as the use of recycled materials or energy-efficient designs.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing the sourcing practices of suppliers, looking for certifications that demonstrate compliance with environmental standards. Images that reflect ‘green’ certifications and sustainable materials not only resonate with eco-conscious consumers but also enhance the credibility of manufacturers in the eyes of potential clients. For instance, showcasing heat exchangers made from eco-friendly materials or highlighting energy-efficient operations through compelling imagery can significantly impact buyer perceptions and purchasing decisions.

Moreover, as global regulations on emissions and waste become more stringent, suppliers that adopt sustainable practices are likely to gain a competitive edge. B2B buyers should prioritize partnerships with manufacturers that align with these values, ensuring that their sourcing decisions contribute to a more sustainable future.

Illustrative image related to heat exchanger images

What Is the Evolution of Heat Exchanger Images in the B2B Market?

The evolution of heat exchanger images reflects the broader trends in industrial marketing and technology. Initially, visual representations were limited to basic photographs, often lacking detail and context. However, as industries began to recognize the importance of high-quality imagery in conveying technical specifications and operational efficiency, the demand for more sophisticated visuals grew.

With the advent of digital photography and advanced imaging techniques, heat exchanger images evolved to include detailed close-ups, 3D renderings, and context-rich environments. This shift has enabled B2B buyers to gain a deeper understanding of product functionality and applications. Today, the integration of AR and virtual reality is set to further revolutionize the market, allowing buyers to interact with heat exchanger designs in an immersive manner.

As the market continues to evolve, B2B buyers are encouraged to stay abreast of technological advancements that can enhance their sourcing processes, ensuring they leverage the best available visual content to support their business objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of heat exchanger images

-

How do I source high-quality heat exchanger images for my business?

To source high-quality heat exchanger images, start by exploring reputable stock photo websites like Adobe Stock, Shutterstock, or iStock. These platforms offer a wide range of images and often allow you to filter by resolution, licensing, and specific types of heat exchangers. Additionally, consider reaching out to manufacturers or industry-specific galleries that may have exclusive images showcasing their products in real-world applications. Always ensure that the images are properly licensed for your intended use to avoid any copyright issues. -

What types of heat exchanger images should I look for?

When sourcing heat exchanger images, focus on various types such as air-to-air, tube, plate, and coil heat exchangers. Each type serves different applications and industries, so it’s important to select images that accurately represent your specific needs. Additionally, consider images that highlight unique features, such as corrosion resistance or custom designs, which can be particularly appealing to B2B buyers interested in specialized equipment. -

How can I verify the credibility of a heat exchanger image supplier?

To verify the credibility of a heat exchanger image supplier, check for reviews and testimonials from previous clients. Investigate their portfolio to assess the quality and relevance of their images to your industry. Additionally, consider their licensing agreements to ensure they provide clear usage rights. Engaging in direct communication can also help gauge their professionalism and responsiveness, which are critical factors in establishing a reliable partnership. -

What are the typical payment terms when purchasing heat exchanger images?

Payment terms for heat exchanger images can vary significantly by supplier. Many stock photo platforms offer flexible payment options, including one-time purchases or subscription models. In B2B transactions, it’s common to negotiate terms, especially for bulk purchases or exclusive rights. Always review the payment policies, including any potential discounts for long-term contracts or large orders, to ensure they align with your budget and cash flow requirements. -

What customization options are available for heat exchanger images?

Customization options for heat exchanger images may include the ability to request specific angles, contexts, or branding elements. Some suppliers may allow you to commission unique images tailored to your business needs, ensuring that they align with your marketing strategy. It’s advisable to discuss your requirements upfront and confirm any additional costs associated with creating custom images. -

What is the minimum order quantity (MOQ) for purchasing heat exchanger images?

The minimum order quantity (MOQ) for heat exchanger images largely depends on the supplier. Stock photo websites typically do not have an MOQ, as images can be purchased individually. However, for custom images or bulk orders from manufacturers, there may be a minimum number of images required to fulfill an order. Always clarify the MOQ during negotiations to avoid any misunderstandings. -

How do logistics and delivery work for sourcing heat exchanger images internationally?

Logistics for sourcing heat exchanger images internationally often involve digital delivery, which is typically instantaneous through online platforms. However, if you’re ordering custom images, discuss timelines and delivery methods with your supplier. Ensure that they can accommodate international transactions and that you understand any potential customs or import duties if physical products are involved, such as printed materials. -

What quality assurance measures should I expect when sourcing heat exchanger images?

Quality assurance measures can include the provision of high-resolution images, clear licensing agreements, and the option for revisions if you are commissioning custom images. Reputable suppliers often have established quality control processes to ensure that the images meet industry standards and your specific requirements. Always ask for sample images or portfolios to assess quality before making a purchase.

Top 4 Heat Exchanger Images Manufacturers & Suppliers List

1. Adobe Stock – Heat Exchanger Visuals

Domain: stock.adobe.com

Registered: 1986 (39 years)

Introduction: Heat Exchanger Images – Browse 17,714 Stock Photos, Vectors, and Video | Adobe Stock. Includes 1925 videos related to heat exchangers. Options for free trials to access images and videos. Various formats available: images, videos, audio, templates, 3D assets. License terms and support available. Region selection may affect language and promotional content.

2. TITAN – Heat Exchangers

Domain: titanmf.com

Registered: 1999 (26 years)

Introduction: TITAN’s Heat Exchanger product line includes various Shell and Tube Heat Exchanger designs and TEMA designs such as Fixed Tube Sheet, U-Bundle, Packed Head, Floating Tube Sheet, Kettle Reboilers, Falling Film Evaporators / Absorbers, Bayonet, Helical Coil, Immersion Coil, and Double Pipe. Designs can incorporate loose-lined, solid, and explosion-clad tube sheet options. All head and closure design…

3. iStock – Heat Exchanger Images

Domain: istockphoto.com

Registered: 2000 (25 years)

Introduction: 1,200+ Heat Exchanger Stock Photos, Pictures & Royalty-Free Images

4. Heat Exchanger Manufacturers – Tube Heat Exchangers

Domain: heatexchangermanufacturers.com

Registered: 2001 (24 years)

Introduction: Tube heat exchangers are designed with bundles of tubes to efficiently transfer heat between two fluids. They are constructed to be sturdy and pressure-resistant, making them ideal for industrial systems requiring long-term thermal performance and durability. Types include shell and tube, U-tube, and straight-tube designs, each serving different performance needs. Common applications are in chemic…

Strategic Sourcing Conclusion and Outlook for heat exchanger images

In conclusion, the strategic sourcing of heat exchanger images is pivotal for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. High-quality images facilitate informed decision-making by showcasing various types of heat exchangers, from tube to plate designs, which are essential for numerous industrial applications. By leveraging comprehensive galleries and stock image platforms, buyers can visualize the specifications and capabilities of different models, enhancing their procurement processes.

Furthermore, understanding the nuances of heat exchanger designs, such as those fabricated from corrosion-resistant materials, can lead to significant long-term operational efficiencies and cost savings. As industries increasingly prioritize sustainability and efficiency, the demand for innovative heat exchanger solutions will continue to rise.

Illustrative image related to heat exchanger images

As you consider your sourcing strategies, take advantage of the vast resources available online to ensure your selections align with both your operational needs and market trends. Stay ahead of the competition by integrating high-quality visuals into your procurement strategy, enabling better communication with stakeholders and enhancing your overall project outcomes. Explore the available options today and empower your business with the right tools for success in the evolving industrial landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.