Choosing Your Diagram Centrifuge: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for diagram centrifuge

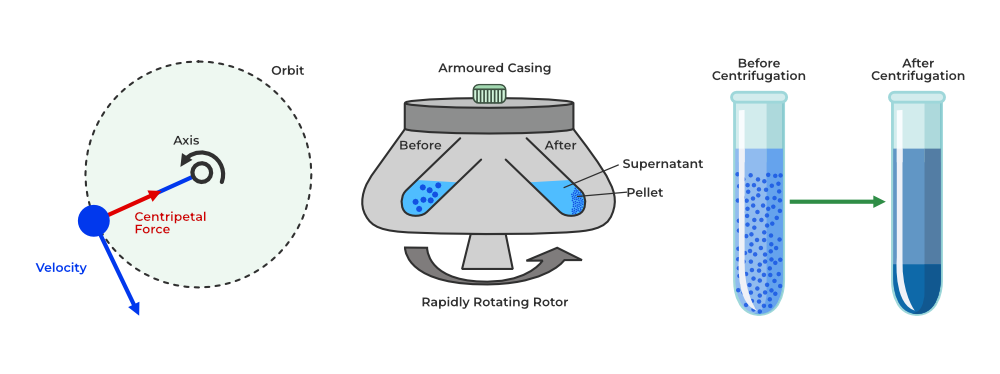

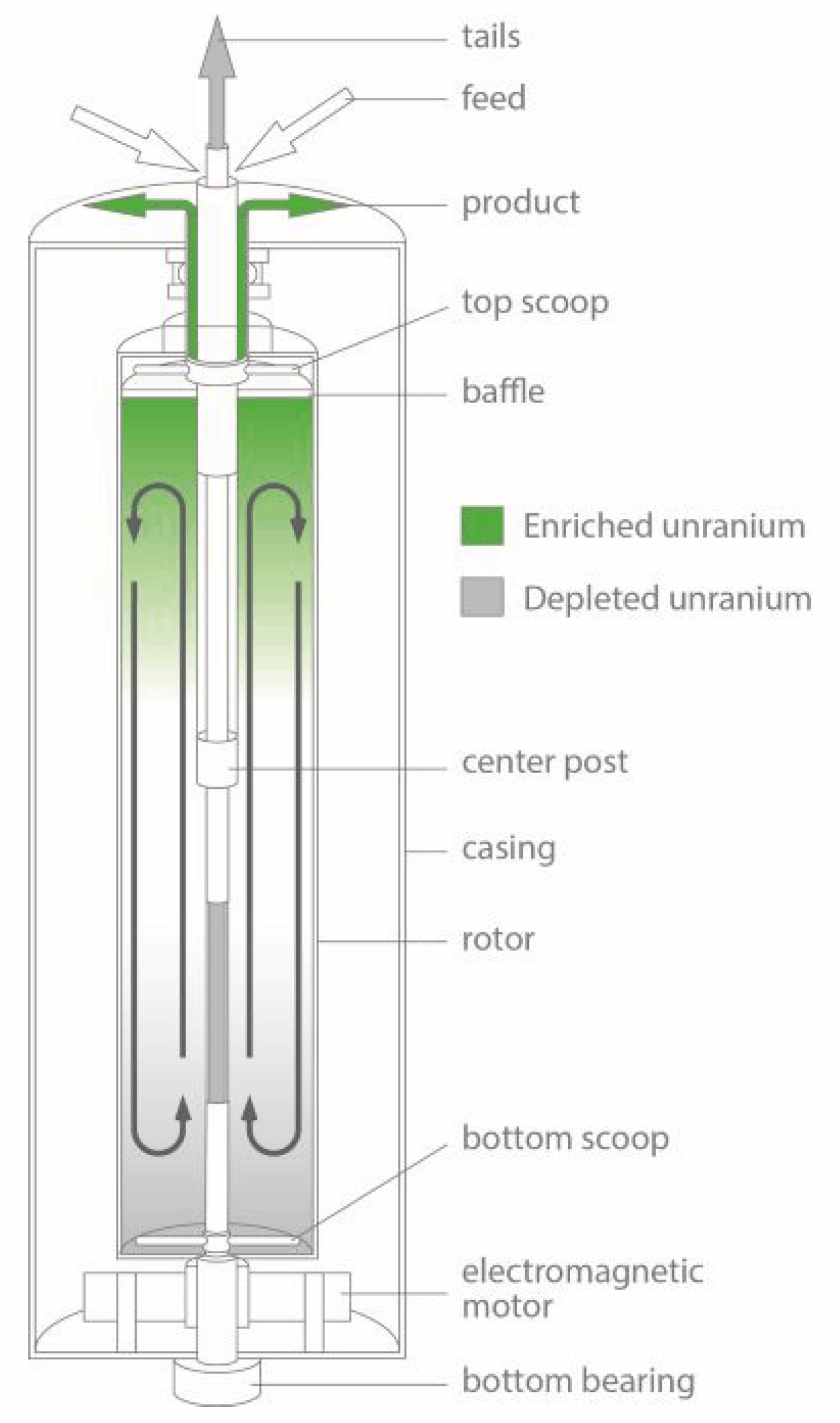

In today’s rapidly evolving industrial landscape, sourcing the right diagram centrifuge can present significant challenges for B2B buyers across diverse markets, particularly in regions such as Africa, South America, the Middle East, and Europe. With an increasing demand for efficient separation and purification processes, understanding the nuances of different centrifuge types, their applications, and supplier reliability is crucial for successful procurement. This guide serves as a comprehensive resource, delving into the various types of diagram centrifuges, their operational principles, and the critical factors influencing their performance.

By exploring essential aspects such as supplier vetting, cost considerations, and application-specific requirements, this guide equips international buyers with the insights needed to make informed purchasing decisions. Whether you are in the pharmaceutical, biotechnology, or food processing sectors, understanding the intricacies of centrifuge technology will enable you to optimize your operations and enhance product quality. The guide also emphasizes best practices for evaluating suppliers, ensuring that your investments yield the highest returns.

As you navigate the global market for diagram centrifuges, this resource will empower you to overcome common challenges and leverage opportunities for growth, ultimately driving your business success in a competitive landscape.

Understanding diagram centrifuge Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Benchtop Centrifuge | Compact design, suitable for small labs | Clinical diagnostics, research labs | Pros: Space-saving, user-friendly. Cons: Limited capacity compared to larger models. |

| High-Speed Centrifuge | Operates at 15,000-30,000 RPM, versatile rotor options | Biochemical analysis, protein purification | Pros: Efficient for delicate samples. Cons: Higher cost, requires careful handling. |

| Refrigerated Centrifuge | Maintains low temperatures (-20 to -40°C) during operation | DNA/RNA analysis, sensitive biological samples | Pros: Preserves sample integrity. Cons: More expensive due to cooling mechanisms. |

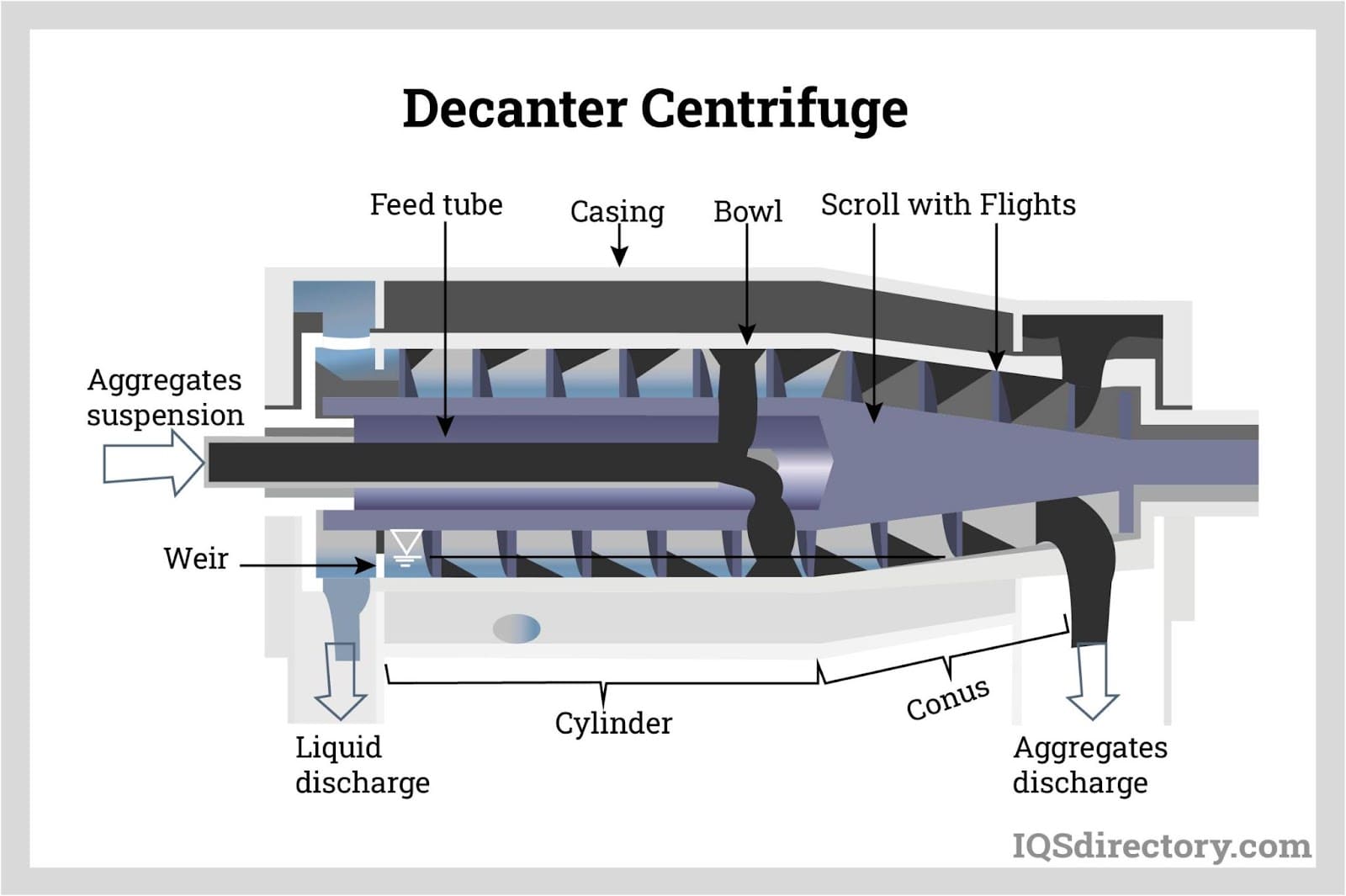

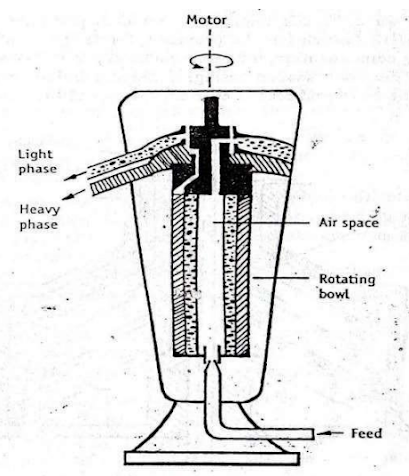

| Continuous Flow Centrifuge | Processes large volumes continuously without affecting sedimentation | Blood fractionation, wastewater treatment | Pros: High throughput. Cons: More complex setup, higher initial investment. |

| Microcentrifuge | Designed for small tubes (up to 2.0 ml), compact footprint | Molecular biology, small sample processing | Pros: Ideal for limited samples. Cons: Not suitable for larger volumes. |

What Are the Key Characteristics of Benchtop Centrifuges?

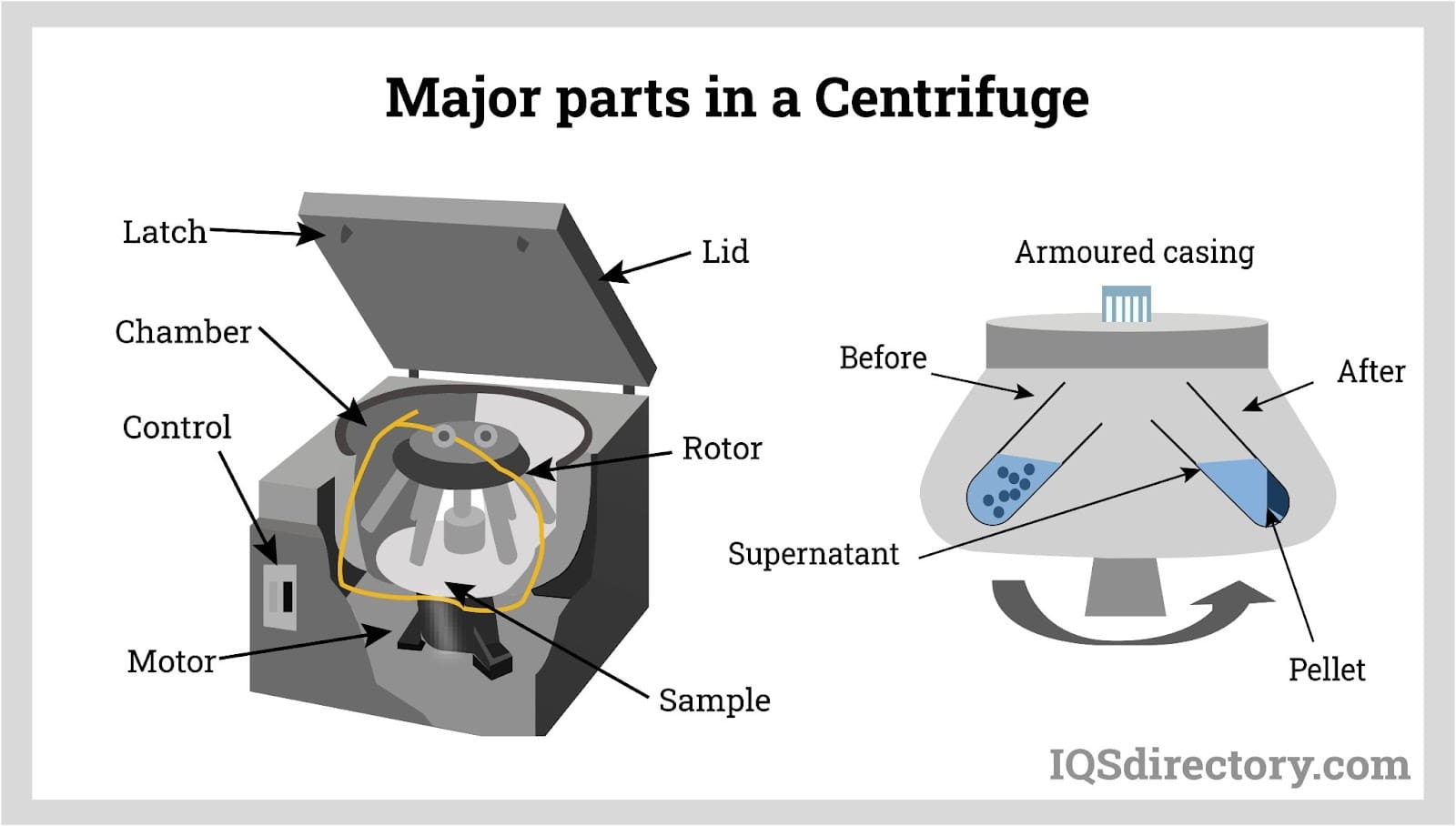

Benchtop centrifuges are compact, making them ideal for laboratories with limited space. They typically feature a lid that secures the rotor, allowing for safe operation. These centrifuges are versatile and can be used for various applications, including clinical diagnostics and routine laboratory procedures. When purchasing, buyers should consider the maximum speed, capacity, and ease of use, as these factors significantly influence operational efficiency.

How Do High-Speed Centrifuges Stand Out in B2B Applications?

High-speed centrifuges are characterized by their ability to reach speeds between 15,000 and 30,000 RPM. This capability makes them particularly effective in biochemical analysis and protein purification, where rapid sedimentation is crucial. Buyers should evaluate the rotor types available, as different configurations can impact the effectiveness of the separation process. While they offer significant efficiency, the higher cost and need for careful handling are essential considerations.

Why Choose Refrigerated Centrifuges for Sensitive Samples?

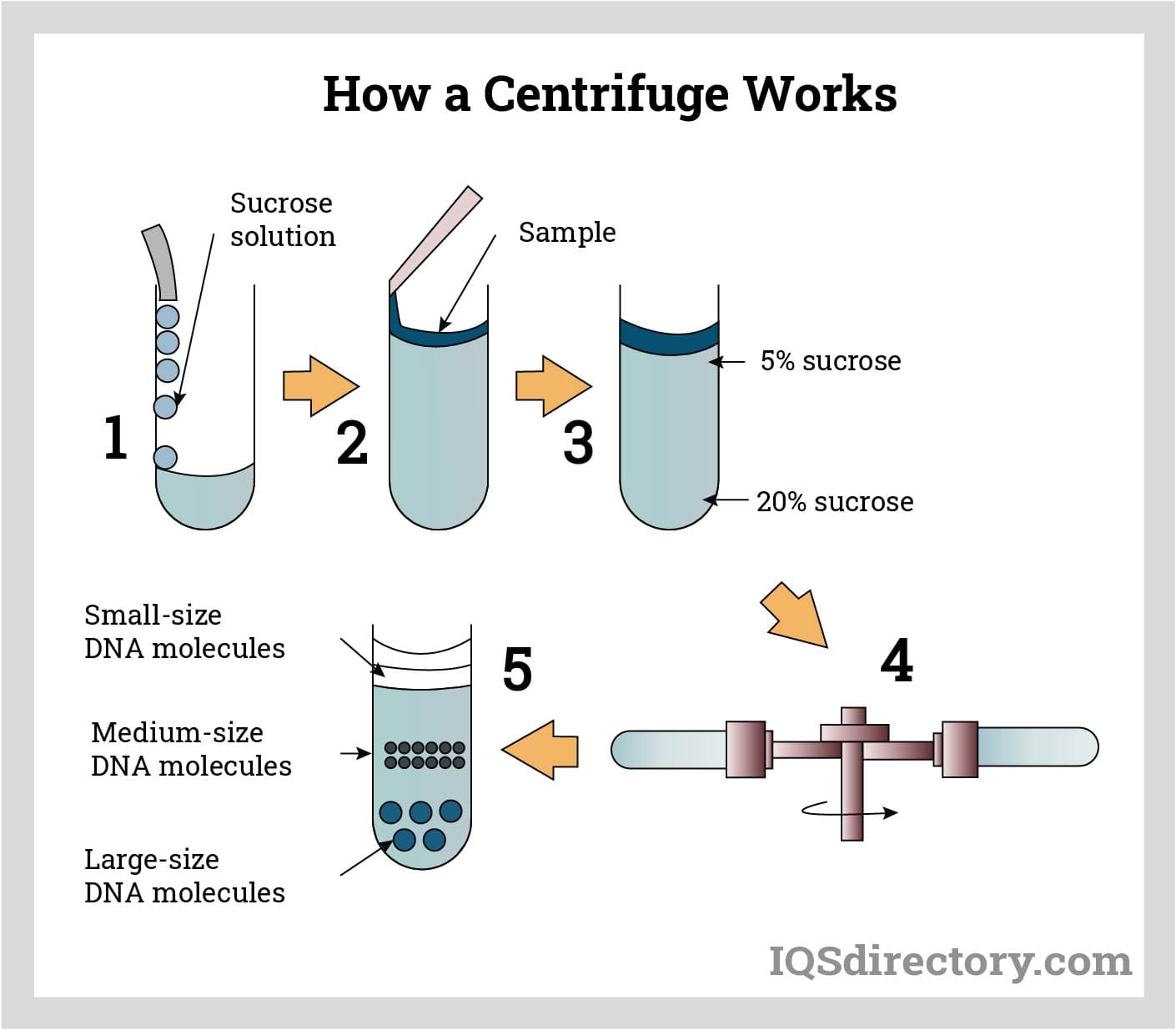

Refrigerated centrifuges are designed to operate within a temperature range of -20 to -40°C, making them suitable for DNA and RNA analysis, where sample integrity is paramount. They are equipped with advanced cooling systems that preserve sensitive biological materials during centrifugation. When considering a purchase, businesses should assess cooling efficiency, maximum speed, and capacity, as these elements affect both performance and budget.

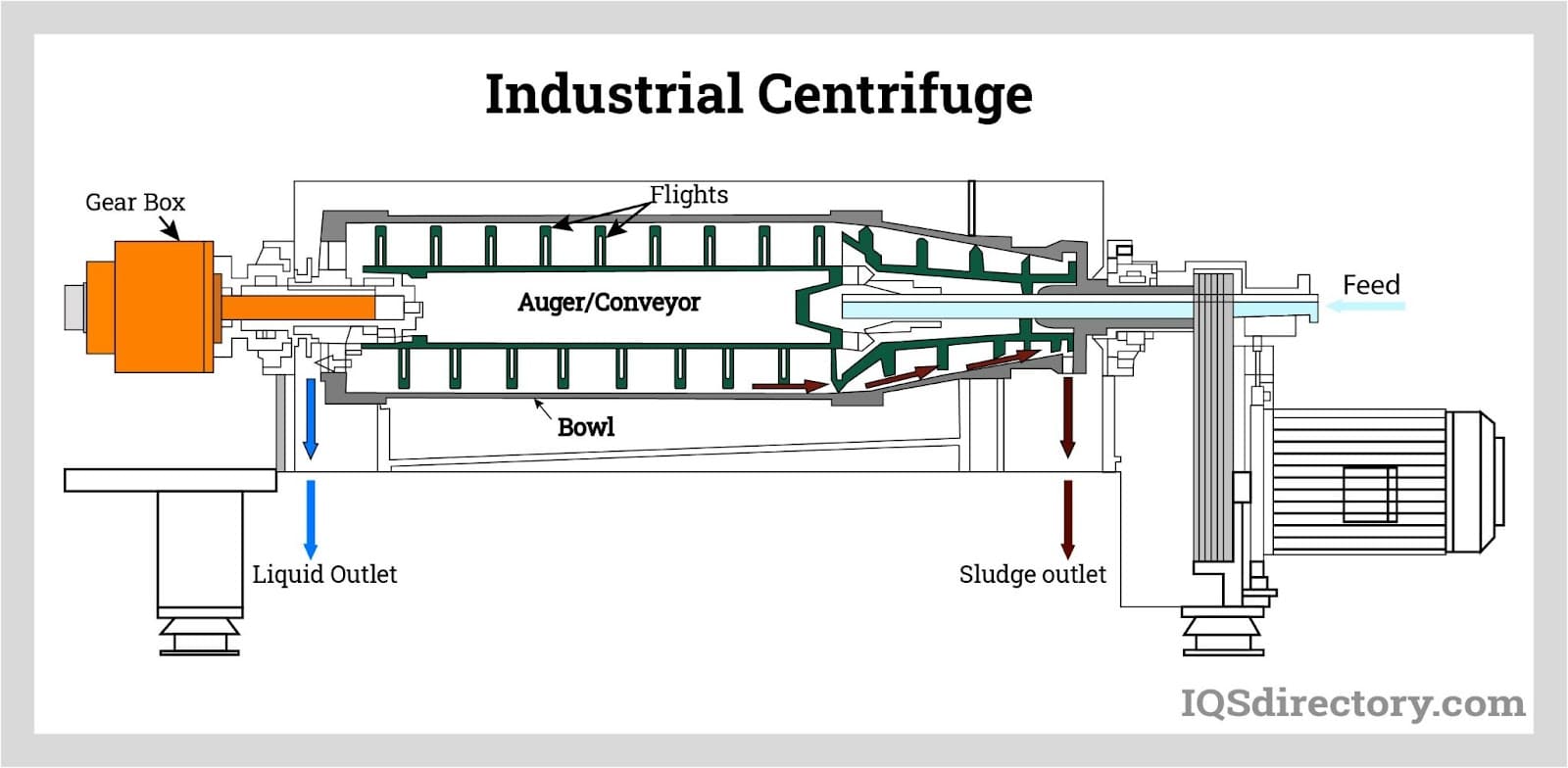

Illustrative image related to diagram centrifuge

What Are the Advantages of Continuous Flow Centrifuges?

Continuous flow centrifuges allow for the uninterrupted processing of large sample volumes, making them ideal for applications like blood fractionation and wastewater treatment. Their design enables efficient sedimentation without compromising separation quality. Buyers should focus on the throughput capacity and the complexity of setup when evaluating these systems, as they often require a higher initial investment but yield significant operational benefits.

How Can Microcentrifuges Benefit Small-Scale Operations?

Microcentrifuges are specifically designed for handling small sample volumes (up to 2.0 ml) and are known for their compact size. They are particularly useful in molecular biology labs for applications like nucleic acid purification. When choosing a microcentrifuge, businesses should consider the maximum speed and compatibility with various tube sizes. While they excel in small-scale operations, their limited capacity may not meet the needs of larger experiments.

Key Industrial Applications of diagram centrifuge

| Industry/Sector | Specific Application of Diagram Centrifuge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Biotechnology | Isolation of DNA and RNA from samples | Enhanced research accuracy and efficiency | Quality of materials, compatibility with existing lab setups |

| Pharmaceuticals | Purification of active pharmaceutical ingredients (APIs) | Improved drug efficacy and safety | Regulatory compliance, scalability, and maintenance support |

| Food and Beverage | Separation of cream from milk or juice extraction | Increased product quality and yield | Hygiene standards, energy efficiency, and operational costs |

| Environmental Science | Treatment of wastewater through solid-liquid separation | Compliance with environmental regulations | Robustness, capacity, and ease of operation |

| Clinical Laboratories | Centrifugation for blood sample analysis | Rapid and accurate diagnostic results | Speed, temperature control, and reliability |

How is the Diagram Centrifuge Used in Biotechnology?

In the biotechnology sector, diagram centrifuges are essential for isolating DNA and RNA from biological samples. This application is crucial for genetic research, diagnostics, and biopharmaceutical development. The centrifuge efficiently separates nucleic acids from proteins and other cellular debris, ensuring high purity levels. Buyers in this sector should consider the centrifuge’s capacity, compatibility with different tube sizes, and the quality of materials used to ensure reliable results.

What Role Does the Diagram Centrifuge Play in Pharmaceuticals?

In pharmaceuticals, diagram centrifuges are employed to purify active pharmaceutical ingredients (APIs) during drug formulation. This process enhances the efficacy and safety of medications by ensuring that impurities are effectively removed. For international buyers, especially in regions like Africa and South America, sourcing centrifuges that meet stringent regulatory standards is critical. Additionally, the ability to scale operations and provide maintenance support is essential for long-term investment.

How is the Diagram Centrifuge Applied in Food and Beverage Industries?

The food and beverage industry utilizes diagram centrifuges for processes such as cream separation in dairy production and juice extraction. This application enhances product quality by ensuring that unwanted solids are removed, resulting in a smoother final product. Buyers should focus on sourcing centrifuges that adhere to hygiene standards and are energy-efficient to minimize operational costs while maximizing yield.

Illustrative image related to diagram centrifuge

How Does the Diagram Centrifuge Contribute to Environmental Science?

In environmental science, diagram centrifuges are vital for treating wastewater through solid-liquid separation. This application aids in meeting environmental regulations by ensuring that contaminants are effectively removed from water before discharge. Buyers should prioritize centrifuges that are robust and have a high capacity to handle large volumes, as well as those that are easy to operate to facilitate compliance with regulatory standards.

What is the Importance of the Diagram Centrifuge in Clinical Laboratories?

In clinical laboratories, diagram centrifuges are indispensable for blood sample analysis. They allow for the rapid separation of plasma and serum, leading to quicker and more accurate diagnostic results. For international B2B buyers, factors such as speed, temperature control, and reliability are paramount to ensure high-quality testing. Investing in a dependable centrifuge can significantly enhance laboratory efficiency and patient care.

3 Common User Pain Points for ‘diagram centrifuge’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Centrifuge Type for Specific Applications

The Problem: Many B2B buyers face the challenge of selecting the appropriate type of centrifuge for their specific applications. With various models available—such as benchtop, microcentrifuge, and high-speed centrifuges—buyers often struggle to determine which features align best with their operational needs. For instance, a laboratory focusing on DNA analysis may need a refrigerated centrifuge, while a facility processing blood samples might require a hematocrit centrifuge. The wrong choice can lead to suboptimal results, increased operational costs, and frustration among lab personnel.

The Solution: To effectively navigate this decision, buyers should start by conducting a thorough needs assessment. Identify the specific applications and types of samples that will be processed. Create a checklist of essential features such as speed range (RPM), temperature control capabilities, and rotor types that suit your needs. Consulting with manufacturers or suppliers who specialize in centrifuges can provide valuable insights. Furthermore, requesting demonstrations or trials can help evaluate how well a particular centrifuge performs in your specific setting. This hands-on approach ensures you select a model that not only meets your requirements but also enhances your lab’s efficiency and productivity.

Scenario 2: Overcoming Maintenance Challenges and Downtime

The Problem: Regular maintenance is critical for the longevity and performance of diagram centrifuges, yet many buyers underestimate this necessity. Without appropriate maintenance, equipment can break down unexpectedly, leading to costly downtime and disruptions in laboratory workflows. This challenge is particularly pronounced in regions where service technicians may not be readily available, leaving buyers with limited options for prompt repairs.

The Solution: Establishing a proactive maintenance schedule is essential for keeping centrifuges in optimal condition. Buyers should engage with manufacturers to understand the recommended maintenance procedures and intervals specific to their centrifuge model. This could include routine checks of the rotor, seals, and motor, along with regular calibration of speed and temperature settings. Furthermore, investing in training for lab personnel on basic maintenance can help identify potential issues before they escalate. For regions with limited access to service technicians, consider forming partnerships with local technicians or exploring remote diagnostic services offered by manufacturers. This strategy not only minimizes downtime but also extends the lifespan of your equipment.

Scenario 3: Ensuring Compliance with Regulatory Standards

The Problem: Compliance with regulatory standards is a significant concern for many B2B buyers, particularly in industries such as pharmaceuticals and biotechnology. Buyers often struggle to ensure that their centrifuge operations meet the necessary local and international regulations regarding safety and quality control. Non-compliance can lead to costly fines, product recalls, and damage to the company’s reputation.

The Solution: To navigate compliance effectively, buyers should familiarize themselves with the relevant regulations that apply to their industry and region. This includes understanding guidelines from organizations such as the FDA, WHO, or local health authorities. Working closely with suppliers can provide insights into how specific centrifuge models are designed to meet these standards. Additionally, implementing a robust quality management system (QMS) that documents procedures, training, and maintenance can significantly aid in compliance efforts. Regular audits and assessments of centrifuge operations should be conducted to identify areas for improvement and ensure adherence to regulations. By prioritizing compliance from the outset, buyers can safeguard their operations and enhance their credibility in the market.

Strategic Material Selection Guide for diagram centrifuge

What Are the Key Properties of Common Materials Used in Diagram Centrifuges?

When selecting materials for diagram centrifuges, several factors must be considered to ensure optimal performance and compliance with international standards. The most common materials include stainless steel, aluminum, plastics (such as polycarbonate), and carbon fiber. Each material has unique properties that influence its suitability for different applications in varying environments.

Stainless Steel: A Durable Choice for Centrifuge Components

Stainless steel is renowned for its excellent corrosion resistance, strength, and durability, making it ideal for high-performance centrifuge components. Its temperature and pressure ratings are typically high, allowing it to withstand extreme operational conditions.

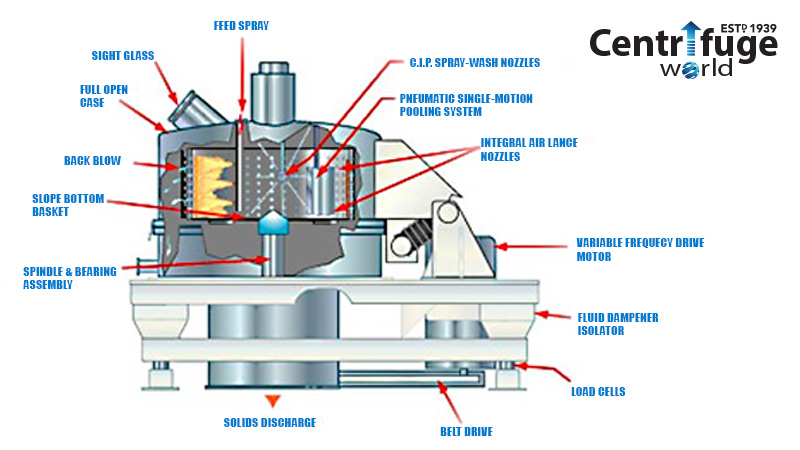

Illustrative image related to diagram centrifuge

Pros: Stainless steel is highly durable and can endure repeated use without significant wear. It is also easy to clean and sterilize, which is crucial in laboratory settings.

Cons: The primary drawback is its cost, as stainless steel can be more expensive than other materials. Additionally, the manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances. However, it may not be suitable for applications involving highly reactive chemicals, which can lead to pitting corrosion.

Considerations for International Buyers: Buyers from regions such as Africa, South America, and the Middle East should ensure that the stainless steel used meets international standards like ASTM A240 or DIN 1.4401 to guarantee quality and performance.

Aluminum: Lightweight and Cost-Effective

Aluminum is another popular material for centrifuge rotors and components due to its lightweight nature and good strength-to-weight ratio. It is often used in applications where weight savings are crucial.

Pros: Aluminum is generally less expensive than stainless steel and offers good thermal conductivity, which can be beneficial in temperature-sensitive applications.

Cons: While aluminum has decent corrosion resistance, it is not as robust as stainless steel. It may require protective coatings when used with aggressive chemicals.

Impact on Application: Aluminum is suitable for low to moderate-speed centrifuges and is compatible with many biological samples. However, its use in high-speed applications is limited due to potential deformation under extreme conditions.

Considerations for International Buyers: Buyers should verify that aluminum components comply with relevant standards such as ASTM B221 to ensure quality. In regions like Brazil, where cost sensitivity is high, aluminum may be preferred for budget-conscious projects.

Plastics (Polycarbonate): Versatile and Affordable

Polycarbonate is a common plastic used in centrifuge applications, particularly for components like tubes and lids. It is known for its impact resistance and clarity.

Pros: Polycarbonate is lightweight, cost-effective, and offers good chemical resistance, making it suitable for various laboratory applications.

Cons: While it performs well under normal conditions, polycarbonate may not withstand high temperatures or aggressive solvents, limiting its use in certain environments.

Impact on Application: It is often used in applications requiring transparency for visual inspection of samples. However, its limitations in temperature and chemical compatibility must be considered.

Considerations for International Buyers: Buyers should check for compliance with safety standards like ISO 13485, especially in medical applications. In regions like the Middle East, where temperature extremes can occur, ensuring the material can handle local conditions is vital.

Carbon Fiber: High Strength with Low Weight

Carbon fiber is increasingly being used in high-end centrifuge applications due to its exceptional strength-to-weight ratio and stiffness.

Pros: Carbon fiber is incredibly strong yet lightweight, making it ideal for high-speed centrifuges. It also has excellent fatigue resistance.

Cons: The primary limitation is its high cost and complex manufacturing processes, which can make it less accessible for budget-sensitive buyers.

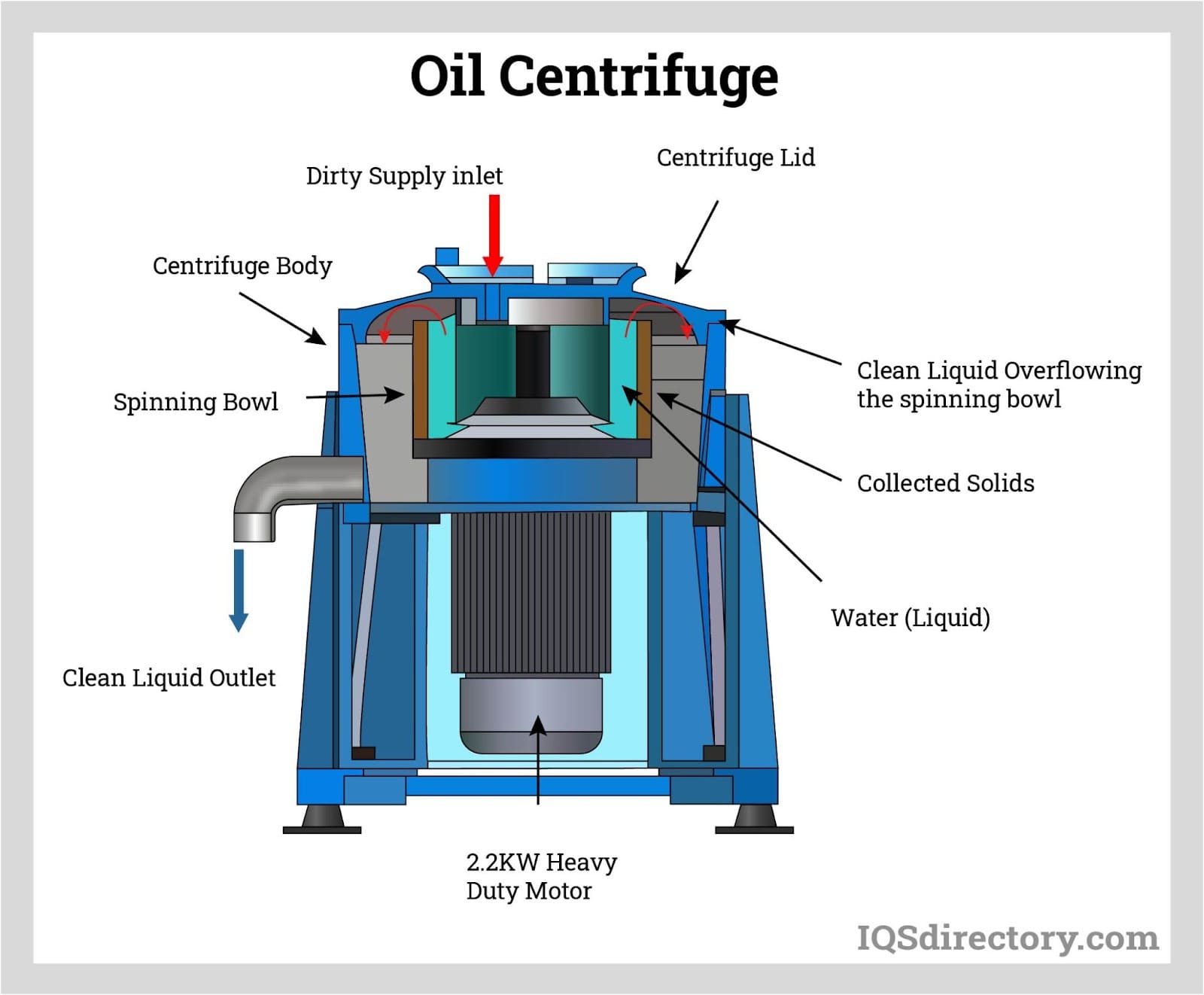

Illustrative image related to diagram centrifuge

Impact on Application: Carbon fiber is suitable for high-performance applications where weight reduction is critical. However, its compatibility with certain chemicals should be evaluated to prevent degradation.

Considerations for International Buyers: Buyers should ensure that carbon fiber components meet international standards such as ASTM D7264. In Europe, where advanced technology is prevalent, carbon fiber may be favored for cutting-edge applications.

Summary Table of Material Selection for Diagram Centrifuge

| Material | Typical Use Case for diagram centrifuge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-performance rotors and components | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Low to moderate-speed centrifuges | Lightweight and cost-effective | Limited corrosion resistance | Medium |

| Plastics (Polycarbonate) | Tubes and lids | Lightweight and good chemical resistance | Limited high-temperature performance | Low |

| Carbon Fiber | High-speed centrifuges | Exceptional strength-to-weight ratio | High cost and complex manufacturing | High |

This guide provides a comprehensive overview of material selection for diagram centrifuges, helping international B2B buyers make informed decisions based on performance, cost, and regional considerations.

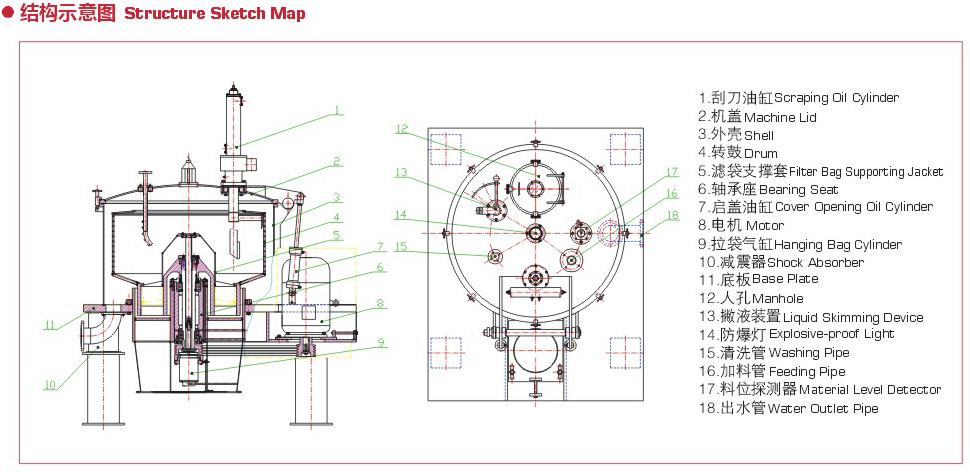

In-depth Look: Manufacturing Processes and Quality Assurance for diagram centrifuge

The manufacturing process of diagram centrifuges is intricate and involves several key stages, each critical to ensuring high performance and reliability. Understanding these stages is vital for B2B buyers looking to source centrifuges that meet their specific needs. Here, we break down the manufacturing processes and quality assurance measures that are essential for producing high-quality centrifuges.

Illustrative image related to diagram centrifuge

What Are the Main Stages of Manufacturing Diagram Centrifuges?

How is Material Prepared for Centrifuge Production?

Material preparation is the foundational step in the manufacturing process. The primary materials used in centrifuge manufacturing include high-grade stainless steel, aluminum, and various polymers, chosen for their strength, durability, and resistance to corrosion. Suppliers must conduct rigorous quality checks on incoming materials to ensure they meet specified standards.

Material testing often includes tensile strength assessments and corrosion resistance evaluations. This initial scrutiny is critical as it directly impacts the centrifuge’s performance and lifespan. For instance, stainless steel components must be free from impurities to avoid weakening during high-speed operations.

What Forming Techniques Are Commonly Used in Centrifuge Manufacturing?

Once materials are approved, the next stage is forming. This involves shaping the materials into the necessary components of the centrifuge, such as the rotor, motor casing, and housing. Common techniques include:

- CNC Machining: Computer Numerical Control (CNC) machining is used to achieve precise dimensions and tolerances for critical components.

- Injection Molding: This method is often employed for producing polymer parts, ensuring uniformity and scalability.

- Die Casting: For aluminum components, die casting provides a cost-effective solution with high precision.

Each forming technique is selected based on the specific requirements of the component and its role in the centrifuge’s functionality.

How is the Assembly Process Conducted for Centrifuges?

The assembly phase involves integrating all the formed components into a complete centrifuge. This process typically follows a systematic approach to ensure consistency and quality. Key steps include:

- Component Verification: Each part is inspected for defects and compatibility before assembly.

- Sub-assembly: Smaller assemblies, such as the rotor and drive shaft, are pre-assembled to streamline the final assembly.

- Final Assembly: The complete unit is assembled, ensuring that all components fit correctly and function as intended.

During this phase, manufacturers often employ automated assembly lines to enhance efficiency and reduce human error, ensuring a consistent product.

What Finishing Techniques Are Applied to Enhance Centrifuge Quality?

Finishing is the final stage of manufacturing, which enhances both the aesthetic and functional qualities of the centrifuge. Common finishing techniques include:

- Surface Treatment: Processes such as anodizing or passivation are applied to metal parts to improve corrosion resistance and surface hardness.

- Painting and Coating: Aesthetic finishes and protective coatings are added to components to enhance durability and visual appeal.

- Quality Polishing: Critical surfaces, especially on rotors, are polished to reduce friction and wear during operation.

These finishing touches not only improve the longevity of the equipment but also contribute to its overall performance and reliability.

What Quality Assurance Measures Are Essential for Centrifuge Manufacturing?

Which International Standards Should B2B Buyers Be Aware of?

Quality assurance in centrifuge manufacturing is paramount, particularly for international buyers. Adhering to recognized international standards such as ISO 9001 ensures that the manufacturing processes are consistent and meet global quality benchmarks. Additional certifications like CE marking signify compliance with European safety and health regulations, while API standards may apply for specific applications in the oil and gas sector.

What Are the Key Quality Control Checkpoints in Centrifuge Production?

Quality control (QC) is integrated throughout the manufacturing process and typically includes several critical checkpoints:

- Incoming Quality Control (IQC): This stage assesses raw materials for compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): Conducted during various stages of assembly, IPQC ensures that each component meets quality standards before proceeding to the next stage.

- Final Quality Control (FQC): The completed centrifuge undergoes rigorous testing, including operational tests, to verify functionality and performance before shipping.

Each checkpoint serves as a safeguard against defects, ensuring only the highest quality products reach the market.

What Common Testing Methods Are Used to Ensure Centrifuge Quality?

Several testing methods are employed to validate the quality and safety of centrifuges, including:

- Performance Testing: Verifying the centrifuge’s operational efficiency and effectiveness under various conditions.

- Durability Testing: Assessing the centrifuge’s ability to withstand prolonged use and extreme conditions.

- Safety Testing: Ensuring that the centrifuge meets all safety regulations, including emergency shut-off features and lid locking mechanisms.

These tests are critical for ensuring that the centrifuge performs reliably in demanding environments.

How Can B2B Buyers Verify Supplier Quality Control Processes?

What Steps Can Buyers Take to Ensure Their Suppliers Meet Quality Standards?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers. Here are some actionable strategies:

- Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes, quality management systems, and adherence to international standards.

- Requesting Documentation: Buyers should request quality assurance documentation, including certificates of conformity, test reports, and compliance with relevant standards.

- Engaging Third-Party Inspectors: Hiring independent inspectors to evaluate the manufacturing process and conduct product testing can provide an unbiased assessment of quality.

These measures help ensure that suppliers not only claim adherence to quality standards but also practice them consistently.

What Nuances Should International Buyers Consider Regarding Quality Certification?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality certification is crucial. Different regions may have specific regulatory requirements or standards that must be met.

Buyers should familiarize themselves with local regulations and ensure that the suppliers can provide the necessary certifications and documentation to comply with these standards. Additionally, understanding the logistics of importing certified products can prevent delays and ensure compliance with local laws.

In summary, the manufacturing processes and quality assurance measures for diagram centrifuges are complex yet crucial for ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions when sourcing centrifuges that meet their specific operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diagram centrifuge’

To ensure a successful procurement process for a diagram centrifuge, follow this comprehensive checklist. This guide is designed to aid B2B buyers in navigating the complexities of sourcing the right equipment for their needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial as it directly influences the performance and suitability of the centrifuge for your applications. Consider factors such as maximum speed (rpm), rotor types (fixed-angle, swinging-bucket, or vertical), and the capacity of sample tubes. Additionally, evaluate the intended use—whether for cell separation, protein purification, or other specific applications.

Step 2: Assess Your Budget Constraints

Understanding your budget is fundamental to narrowing down your options. Determine not only the purchase price but also the total cost of ownership, which includes maintenance, potential upgrades, and operational costs. Research typical price ranges for different models and consider any additional features that might justify a higher price point.

Step 3: Evaluate Potential Suppliers

Before making a purchase, it’s essential to thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and client testimonials, particularly from businesses in similar industries or regions. Look for suppliers with a proven track record in providing high-quality centrifuges and consider their after-sales support and warranty options.

Illustrative image related to diagram centrifuge

Step 4: Check Compliance and Certifications

Ensuring that the centrifuge meets relevant industry standards and certifications is vital for operational safety and compliance. Verify if the equipment adheres to international standards such as ISO or CE marking. This compliance can be crucial for laboratory accreditation and can enhance the reliability of your results.

Step 5: Inquire About Customization Options

Many suppliers offer customization options to better suit specific laboratory needs. Inquire whether the centrifuge can be tailored to accommodate unique sample types or operational workflows. Custom features may include specialized rotors, temperature control systems, or software integration for data management.

Step 6: Request Demonstrations or Trials

Whenever possible, request a demonstration or trial period for the centrifuge before finalizing the purchase. This allows you to assess the equipment’s performance in real-world conditions and ensures it meets your operational requirements. Pay attention to ease of use, noise levels, and the efficiency of sample processing.

Step 7: Plan for Training and Support

Once you’ve selected a supplier, ensure that training and ongoing support are included in the procurement process. Proper training for your team can enhance the efficient use of the centrifuge and minimize the risk of operational errors. Discuss the availability of technical support and the response times for service requests.

Illustrative image related to diagram centrifuge

By following this structured approach, B2B buyers can make informed decisions when sourcing a diagram centrifuge, ensuring that their investment meets both current and future laboratory needs.

Comprehensive Cost and Pricing Analysis for diagram centrifuge Sourcing

What Are the Key Cost Components in Sourcing Diagram Centrifuges?

When sourcing diagram centrifuges, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The quality and type of materials used significantly affect pricing. High-grade stainless steel and specialized plastics may increase costs but are essential for durability and performance.

-

Labor: Labor costs vary by region and depend on the complexity of the manufacturing process. Skilled labor is often required for assembly and quality control, impacting the overall price.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overheads, thereby lowering prices.

-

Tooling: Custom tooling for unique designs or specifications can add to the initial investment. However, once established, these costs may be amortized over larger production runs.

-

Quality Control (QC): Rigorous QC processes ensure that the centrifuges meet international standards, which may increase costs but are essential for reliability and compliance.

-

Logistics: Transportation, warehousing, and customs duties can significantly influence total costs, especially for international buyers. Understanding Incoterms is vital to managing these expenses effectively.

-

Margin: Suppliers will typically include a profit margin in their pricing. This can vary based on market demand, competition, and the supplier’s positioning.

How Do Price Influencers Affect the Sourcing of Diagram Centrifuges?

Several factors influence the pricing of diagram centrifuges, particularly in international markets:

-

Volume/MOQ: Pricing can be more favorable when purchasing in bulk due to economies of scale. Minimum order quantities (MOQ) may also affect unit costs.

-

Specifications and Customization: Custom features or specific technical requirements can lead to increased costs. Buyers should assess whether the added features justify the price increase.

-

Materials Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) often come at a premium but can enhance performance and reliability, especially in regulated industries.

-

Supplier Factors: The supplier’s reputation, experience, and location can impact pricing. Established suppliers may charge more for their expertise and reliability.

-

Incoterms: Understanding shipping terms and responsibilities can help buyers negotiate better deals and avoid unexpected costs. Incoterms dictate who bears shipping costs and risks at various stages of transport.

What Buyer Tips Can Help Negotiate Better Prices for Diagram Centrifuges?

To optimize sourcing strategies and achieve cost efficiencies, international B2B buyers should consider the following tips:

-

Negotiate Effectively: Leverage volume commitments and long-term contracts to negotiate better pricing and terms. Building a relationship with suppliers can also yield favorable conditions.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront cost but also operational and maintenance expenses over the centrifuge’s lifecycle. A lower initial price may lead to higher long-term costs if quality is compromised.

-

Understand Pricing Nuances in Different Regions: Prices can vary significantly across regions due to economic factors, import duties, and local manufacturing capabilities. Buyers in Africa, South America, the Middle East, and Europe should research local markets for competitive pricing.

-

Stay Informed on Market Trends: Keep abreast of technological advancements and shifts in demand that could influence pricing. Being informed allows buyers to make timely purchasing decisions.

Disclaimer Regarding Indicative Prices

It’s important to note that prices for diagram centrifuges can fluctuate based on various factors, including market conditions and supplier pricing strategies. Therefore, buyers should seek multiple quotes and conduct thorough market research to ensure they receive competitive pricing tailored to their specific needs.

Illustrative image related to diagram centrifuge

Alternatives Analysis: Comparing diagram centrifuge With Other Solutions

Introduction: Understanding Alternatives to Diagram Centrifuge

In the realm of laboratory equipment, the diagram centrifuge is recognized for its efficiency in separating mixtures based on density through centrifugal force. However, various alternatives exist that can also achieve similar separation goals, each with its unique advantages and disadvantages. This analysis will compare the diagram centrifuge with two notable alternatives: filtration systems and sedimentation processes, providing insights for B2B buyers looking to optimize their laboratory operations.

Comparison Table

| Comparison Aspect | Diagram Centrifuge | Filtration System | Sedimentation Process |

|---|---|---|---|

| Performance | High efficiency in separating particles based on density | Moderate efficiency, depending on filter size | Low efficiency, relies on gravity |

| Cost | Moderate to high initial investment | Low to moderate, depending on filter type | Low initial cost, but slow process |

| Ease of Implementation | Requires trained personnel for setup and operation | Simple installation, minimal training required | Very simple, can be done with basic equipment |

| Maintenance | Requires regular calibration and cleaning | Low maintenance, mostly filter replacement | Minimal maintenance, mainly monitoring |

| Best Use Case | Ideal for biological and chemical applications needing precise separation | Suitable for large volume liquid filtration | Effective for larger particles in lower volume applications |

Detailed Breakdown of Alternatives

Filtration Systems

Filtration systems utilize porous materials to separate particles from liquids based on size. They can vary in complexity, from simple mesh filters to advanced microfiltration systems. The primary advantage of filtration is its low cost and ease of implementation, making it accessible for many laboratories. However, it may not provide the same level of efficiency as a diagram centrifuge, especially when dealing with very fine particles or specific density separations. Filtration is best suited for applications where speed and volume are more critical than the precision of particle separation.

Sedimentation Process

Sedimentation is a natural separation technique that relies on gravity to settle particles out of a fluid. This method is cost-effective since it requires minimal equipment and can be easily performed in various settings. However, the efficiency of sedimentation is significantly lower than that of a diagram centrifuge, as it depends on the size and density of the particles and the duration of the process. Sedimentation is particularly useful for larger particles or when high precision is not a priority, making it ideal for preliminary separation in large-scale operations.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between a diagram centrifuge and its alternatives, B2B buyers should carefully consider their specific operational needs, including the required separation efficiency, budget constraints, and the complexity of implementation. The diagram centrifuge offers high-performance capabilities suitable for precise scientific applications, while filtration systems and sedimentation processes provide cost-effective solutions for less demanding separations. Ultimately, the right choice will depend on balancing performance requirements with operational capabilities and financial considerations.

Essential Technical Properties and Trade Terminology for diagram centrifuge

What Are the Key Technical Properties of a Diagram Centrifuge?

Understanding the technical specifications of a diagram centrifuge is crucial for B2B buyers looking to make informed purchasing decisions. Here are some essential properties to consider:

1. Rotor Speed (RPM)

The rotor speed, measured in revolutions per minute (RPM), indicates how quickly the centrifuge can spin. Higher speeds result in greater centrifugal force, enabling effective separation of particles. For B2B buyers, selecting a centrifuge with the appropriate RPM for specific applications ensures optimal performance and efficiency, especially in industries like pharmaceuticals and biotechnology.

2. Maximum Capacity

The maximum capacity refers to the amount of sample material the centrifuge can accommodate, usually expressed in liters or the number of tubes. Understanding capacity is vital for businesses that handle large volumes of samples, as it directly affects throughput and productivity. A centrifuge with a higher capacity can save time and reduce operational costs.

3. Temperature Control Range

Temperature control is critical in many centrifugation applications, particularly for sensitive biological samples. Centrifuges may offer a temperature control range from -20°C to +40°C. Buyers should prioritize temperature-controlled models to prevent sample degradation, especially in research and clinical settings where precision is paramount.

4. Material Grade

The material used in the construction of the centrifuge, such as stainless steel or high-grade plastics, determines its durability and resistance to chemical corrosion. High-quality materials can enhance the longevity of the equipment, making it a more valuable investment for businesses. Buyers should consider the types of samples they will process to ensure compatibility with the centrifuge’s materials.

5. Noise Level

Noise level, measured in decibels (dB), is an often-overlooked specification that can impact the work environment. Centrifuges that operate quietly contribute to a better workspace, particularly in laboratories where concentration is essential. Buyers should inquire about the noise level to ensure it meets their operational needs.

What Are Common Trade Terms Related to Diagram Centrifuges?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. When purchasing centrifuges, understanding OEM relationships can help buyers identify quality standards and potential warranty options. Buyers may choose OEM products for reliability and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products that a supplier is willing to sell. This is an essential consideration for B2B buyers, as it can affect budgeting and inventory management. Understanding MOQ helps businesses plan their purchases and avoid overstocking or running out of essential equipment.

3. RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. For B2B buyers, issuing an RFQ can streamline procurement by ensuring they receive competitive pricing and clear terms from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, delivery responsibilities, and risk management. This knowledge is crucial for international B2B transactions involving centrifuges, particularly for buyers in emerging markets.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the product. It is a critical factor in supply chain management, as extended lead times can impact project timelines. Buyers should communicate lead time expectations with suppliers to align procurement processes with operational needs.

By understanding these technical properties and trade terminology, B2B buyers can make more informed decisions when investing in diagram centrifuges, ensuring they select equipment that meets their operational requirements and budgetary constraints.

Navigating Market Dynamics and Sourcing Trends in the diagram centrifuge Sector

What Are the Current Market Dynamics and Key Trends in the Diagram Centrifuge Sector?

The global diagram centrifuge market is witnessing significant growth, fueled by advancements in laboratory automation and increasing demand for precise separation techniques across various industries, including healthcare, pharmaceuticals, and environmental testing. Key drivers include the rising prevalence of chronic diseases, which necessitates extensive laboratory testing, and the growing emphasis on research and development in the life sciences sector. Additionally, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking centrifuge solutions that offer enhanced efficiency, reliability, and automation capabilities.

Emerging trends include the integration of IoT technology, which enables real-time monitoring and data analysis, thus improving operational efficiency and reducing downtime. Furthermore, the shift towards compact and multifunctional centrifuges is gaining traction, particularly among smaller laboratories that require versatile equipment without compromising on performance. As global supply chains adapt, buyers are encouraged to consider suppliers who are not only innovative but also responsive to the specific needs of diverse markets.

How Does Sustainability and Ethical Sourcing Impact the Diagram Centrifuge Industry?

Sustainability and ethical sourcing are becoming pivotal considerations for B2B buyers in the diagram centrifuge sector. The environmental impact of manufacturing processes and product lifecycle management is under scrutiny, prompting companies to adopt greener practices. This includes sourcing materials that are recyclable or have a lower carbon footprint, as well as implementing energy-efficient manufacturing processes.

Ethical supply chains are increasingly important, as buyers are more inclined to partner with manufacturers who demonstrate social responsibility and compliance with environmental regulations. Certifications such as ISO 14001 for environmental management and RoHS for hazardous substances are becoming essential indicators of a supplier’s commitment to sustainability. By prioritizing suppliers who adhere to these standards, international buyers can not only enhance their brand reputation but also contribute to a more sustainable future for the industry.

What is the Brief Evolution and History of Diagram Centrifuges Relevant to B2B Buyers?

The evolution of diagram centrifuges can be traced back to the late 18th century when the principles of centrifugal force were first explored. The initial designs were rudimentary, primarily aimed at separating substances based on density. The advancements made by the Prandtl brothers in the 19th century laid the groundwork for practical applications in the dairy industry, notably for cream separation.

As scientific research progressed throughout the 20th century, centrifuges became integral to various fields, including molecular biology and clinical diagnostics. The introduction of high-speed and refrigerated centrifuges revolutionized laboratory capabilities, enabling the purification of delicate biological materials. Today, the focus has shifted towards digital integration and user-friendly designs, reflecting the needs of modern laboratories. Understanding this historical context allows B2B buyers to appreciate the technological advancements that have shaped the current offerings in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of diagram centrifuge

-

How do I choose the right diagram centrifuge for my laboratory?

Selecting the appropriate diagram centrifuge involves assessing your specific application needs. Consider factors such as sample types, required speeds (RPM), and centrifugation techniques (e.g., preparative or analytical). Evaluate the volume of samples you process, as this will dictate the rotor size and capacity. Additionally, check for features like temperature control, which is crucial for sensitive samples. Always consult with suppliers to gain insights on the best centrifuge models suited for your laboratory requirements. -

What are the key features to look for in a diagram centrifuge?

Essential features to consider include rotor type (fixed-angle, swinging-bucket, or vertical), speed range, and temperature control capabilities. Safety features, such as a locking lid and imbalance detection, are crucial for safe operation. Assess the ease of use and maintenance requirements, as well as the availability of replacement parts. Lastly, consider the manufacturer’s reputation and support services to ensure long-term reliability and assistance when needed. -

What is the typical lead time for ordering a diagram centrifuge internationally?

Lead times can vary significantly depending on the manufacturer, model, and customization options. Generally, expect a lead time of 4 to 12 weeks for standard models. Customizations may extend this period, potentially adding several weeks. It’s advisable to communicate directly with suppliers to obtain accurate timelines based on your specific order details and shipping requirements, especially considering potential delays due to customs and logistics. -

What payment terms should I expect when purchasing a diagram centrifuge?

Payment terms can vary widely between suppliers, but common practices include a deposit (usually 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer payment upon delivery or even financing options. Be sure to discuss terms upfront and clarify any additional costs, such as shipping, taxes, or duties. Understanding the payment structure will help you budget effectively for your purchase. -

How can I verify the quality of a diagram centrifuge supplier?

To vet a supplier, start by checking their certifications and industry standards, such as ISO 9001 for quality management systems. Request references or case studies from other clients to gauge satisfaction levels. Additionally, look for reviews and feedback on platforms like LinkedIn or industry-specific forums. A reputable supplier should be transparent about their manufacturing processes, warranty policies, and customer support services. -

What are the minimum order quantities (MOQ) for diagram centrifuges?

MOQs can vary based on the supplier and the type of centrifuge. Some manufacturers may allow single-unit purchases, while others may set an MOQ of 5-10 units, especially for customized models. Always clarify this aspect during your initial discussions to avoid misunderstandings. If you are a smaller laboratory, consider negotiating terms or looking for suppliers that cater to smaller orders. -

What logistics considerations should I be aware of when importing a diagram centrifuge?

Logistics considerations include shipping methods (air vs. sea), customs regulations, and potential tariffs or duties applicable to your region. Ensure you have the correct import licenses and understand the shipping timelines. Work closely with your supplier and a reliable freight forwarder to navigate these complexities and ensure timely delivery. Additionally, consider insurance options to protect your investment during transit. -

Can I customize a diagram centrifuge to meet my specific requirements?

Yes, many manufacturers offer customization options to tailor centrifuges for specific applications. Customizations may include rotor types, speed settings, and additional features like temperature control or specialized software for data analysis. Discuss your specific needs with potential suppliers to explore available options. Keep in mind that customizations may affect lead times and costs, so factor this into your planning.

Top 4 Diagram Centrifuge Manufacturers & Suppliers List

1. Microbioz India – Centrifuge Diagrams

Domain: microbiozindia.com

Registered: 2014 (11 years)

Introduction: Centrifuge diagrams are essential for optimizing processes in industries such as biotechnology, chemistry, and food production. Key components include the rotor, which supports sample containers, and the motor that spins the rotor. Sample tubes hold the mixtures to be separated, and centrifugal force pushes particles outward as the rotor spins. Diagrams may depict density gradients, separation zon…

2. LabIcons – Centrifuge Icons

Domain: labicons.net

Registered: 2018 (7 years)

Introduction: This company, LabIcons – Centrifuge Icons, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. MicrobeNotes – Centrifuge

Domain: microbenotes.com

Registered: 2018 (7 years)

Introduction: Centrifuge: A lab instrument for density-based separation of fluids, gases, or liquids. Key components include: Motor (creates spin), Rotor assembly (supports rotor components), Containers (test tubes, blood bags, etc.), Control Panel (controls parameters like temperature and speed), Latch (keeps lid closed during operation), and Lid (must be closed for operation). Types of centrifuges include Ben…

4. Adobe Stock – Centrifuge Tube Collection

Domain: stock.adobe.com

Registered: 1986 (39 years)

Introduction: Centrifuge Tube Images – Browse 13,360 Stock Photos, Vectors, and Video | Adobe Stock. Includes 2,238 videos related to centrifuge tubes. Offers a free trial for 10 images or 1 video, and access to over 200 million assets in the full collection.

Strategic Sourcing Conclusion and Outlook for diagram centrifuge

In conclusion, strategic sourcing for diagram centrifuges presents a critical opportunity for international buyers to enhance operational efficiency and innovation. By understanding the diverse types and applications of centrifuges, businesses can better match their specific needs with the right equipment. This approach not only ensures optimal performance but also promotes cost-effectiveness through informed procurement decisions.

Engaging with reliable suppliers and manufacturers allows buyers to access cutting-edge technology while negotiating favorable terms that can lead to long-term partnerships. It is essential for businesses in regions such as Africa, South America, the Middle East, and Europe to leverage these strategic sourcing insights, as they can significantly impact productivity and research outcomes.

Illustrative image related to diagram centrifuge

As the demand for advanced laboratory equipment continues to rise, now is the time to act. Prioritize your sourcing strategy to not only meet current needs but also to position your organization for future growth and success in a competitive landscape. Embrace the opportunity to explore innovative solutions that can propel your business forward in the evolving market of diagram centrifuges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to diagram centrifuge