A B2B Buyer’s Guide to Conveyor Belt Elevator: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for conveyor belt elevator

As industries across the globe strive for efficiency and productivity, the sourcing of conveyor belt elevators has emerged as a critical challenge for B2B buyers. These systems, designed to facilitate the vertical transfer of goods, are indispensable in sectors such as manufacturing, agriculture, and food processing. However, navigating the complexities of selecting the right conveyor belt elevator involves more than just understanding its basic functions; it requires an in-depth knowledge of types, applications, and supplier capabilities.

This comprehensive guide aims to empower international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Nigeria. We delve into various conveyor belt elevator configurations—ranging from simple two-axle systems to complex multi-section designs—and their specific applications across different industries. Additionally, we provide actionable insights on supplier vetting, critical design considerations, and cost implications, ensuring that you make informed purchasing decisions.

By equipping you with the necessary knowledge and tools, this guide not only simplifies the sourcing process but also enhances your competitive edge in the global marketplace. Whether you are looking to optimize your existing operations or expand into new territories, understanding the intricacies of conveyor belt elevators is essential for sustainable growth and success.

Understanding conveyor belt elevator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cleated Belt Elevators | Features vertical cleats that prevent product slippage | Food processing, packaging, and material handling | Pros: Excellent for steep inclines; minimizes product loss. Cons: May require more maintenance due to wear on cleats. |

| Bucket Elevators | Utilizes buckets attached to a belt for vertical lifting | Grain handling, mining, and bulk material transport | Pros: Efficient for large volumes; versatile in handling various materials. Cons: Higher initial costs; complex installation. |

| Z-Shape Elevators | Incorporates horizontal and vertical sections in a Z configuration | Warehousing, logistics, and distribution centers | Pros: Space-efficient design; suitable for limited floor space. Cons: More intricate design can lead to higher maintenance. |

| SuperDrive™ Elevators | Positive drive system that eliminates slippage and off-tracking | Bakery, confectionery, and other food industries | Pros: Reduces downtime; lowers operational costs. Cons: Initial investment can be higher than traditional systems. |

| Spiral Elevators | Features a continuous spiral design for compact vertical transport | Food processing, pharmaceuticals, and packaging | Pros: Space-saving; allows for high throughput. Cons: More complex maintenance and potential for higher energy consumption. |

What are Cleated Belt Elevators and When Should You Use Them?

Cleated belt elevators are designed with vertical cleats that effectively prevent product slippage during the vertical transport process. They are particularly suitable for applications in food processing and packaging, where maintaining product integrity is crucial. When considering this type, buyers should evaluate the incline angle, as steeper angles may require more robust cleat designs. Additionally, while they minimize product loss, the cleats may wear down over time, necessitating regular maintenance.

How Do Bucket Elevators Function and What Are Their Advantages?

Bucket elevators use a series of buckets attached to a belt to lift bulk materials vertically. This design is particularly effective in grain handling, mining, and bulk material transport applications. Buyers should consider the volume of material to be handled and the specific material characteristics, as different bucket shapes and sizes can accommodate various products. Although bucket elevators can be more costly to install, their efficiency in handling large volumes often justifies the investment.

What Makes Z-Shape Elevators Unique for Space-Constrained Environments?

Z-shape elevators are characterized by their ability to transition between horizontal and vertical sections, making them ideal for environments with limited floor space, such as warehousing and distribution centers. Their design allows for efficient use of vertical space while maintaining a compact footprint. Buyers should assess the layout of their facility to determine the practicality of this elevator type. While they offer significant space-saving advantages, the complexity of their design may lead to increased maintenance needs.

Why Choose SuperDrive™ Elevators for Your Production Needs?

SuperDrive™ elevators incorporate a positive drive system that prevents slippage and off-tracking, making them ideal for industries such as baking and confectionery. This technology enhances operational efficiency and reduces downtime, appealing to businesses focused on minimizing costs. When considering this type, buyers should weigh the initial investment against long-term savings in operational costs. While the upfront cost may be higher, the reduction in maintenance and increased productivity can provide significant returns.

How Do Spiral Elevators Enhance Vertical Transport Efficiency?

Spiral elevators feature a continuous spiral design that allows for compact vertical transport, making them suitable for food processing, pharmaceuticals, and packaging applications. Their space-saving design enables high throughput, but buyers should consider the complexity of maintenance and the potential for higher energy consumption. Assessing the specific throughput requirements and available space will help determine whether a spiral elevator meets operational needs effectively.

Key Industrial Applications of conveyor belt elevator

| Industry/Sector | Specific Application of conveyor belt elevator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Elevating products in bakeries and food factories | Increases efficiency and reduces manual handling costs | Ensure compliance with food safety regulations; choose durable, easy-to-clean materials |

| Agriculture | Grain handling in elevators and storage facilities | Enhances material flow and reduces spoilage | Select belts resistant to abrasion and moisture; consider local climate factors |

| Mining and Minerals | Transporting bulk materials in processing plants | Improves operational efficiency and reduces downtime | Look for belts that can withstand heavy loads and harsh conditions; prioritize maintenance requirements |

| Recycling and Waste Management | Elevating recyclables in sorting facilities | Streamlines sorting processes and boosts throughput | Focus on belts that can handle varied materials and are easy to maintain; consider sourcing from local manufacturers |

| Construction | Moving heavy materials on construction sites | Increases safety and productivity, minimizes labor costs | Assess load capacities and flexibility; ensure compliance with local safety standards |

How Are Conveyor Belt Elevators Used in Food Processing?

In the food processing industry, conveyor belt elevators are crucial for elevating products like dough, packaged goods, or bulk ingredients. These systems minimize manual handling, thus reducing labor costs and the risk of contamination. Buyers in this sector should prioritize belts that meet stringent food safety regulations, such as FDA approvals, and are constructed from materials that are easy to clean and maintain. Additionally, durability is essential to withstand high operational demands in bakeries and food factories.

What Role Do Conveyor Belt Elevators Play in Agriculture?

In agriculture, conveyor belt elevators are extensively used for handling grains in storage facilities and during transport. These elevators facilitate the efficient movement of grains from ground level to storage silos, reducing spoilage and improving overall material flow. Buyers should consider belts that are resistant to moisture and abrasion, as these factors are critical in agricultural environments. Furthermore, sourcing from local suppliers may provide additional insights into material performance under regional climate conditions, enhancing operational reliability.

How Are Conveyor Belt Elevators Beneficial in Mining and Minerals?

In the mining and minerals sector, conveyor belt elevators are employed to transport bulk materials from extraction sites to processing plants. These systems enhance operational efficiency by reducing the time and labor involved in moving heavy materials. Buyers should look for belts designed to handle extreme loads and harsh operating conditions, ensuring they can endure the rigors of mining environments. Additionally, maintenance requirements should be factored in, as minimizing downtime is crucial for productivity in this industry.

Why Are Conveyor Belt Elevators Important in Recycling and Waste Management?

Conveyor belt elevators are vital in recycling and waste management facilities, where they are used to elevate recyclables for sorting and processing. These systems streamline operations, increasing throughput and reducing manual sorting labor. When sourcing for this application, businesses should focus on durable belts that can handle various materials, from plastics to metals, and are easy to maintain. Local sourcing may also provide advantages in terms of logistical efficiency and support.

How Do Conveyor Belt Elevators Enhance Construction Operations?

In the construction sector, conveyor belt elevators are utilized to move heavy materials such as concrete, bricks, and aggregates on-site. This application significantly increases safety and productivity by reducing manual lifting and transportation efforts. Buyers should assess the load capacities and flexibility of the belts to ensure they meet specific construction needs. Compliance with local safety standards is also essential to ensure worker safety and operational integrity on construction sites.

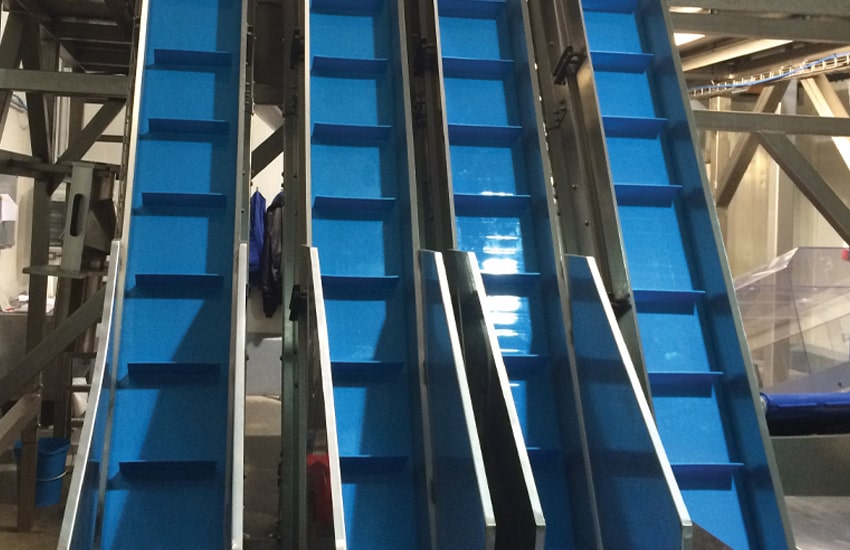

Illustrative image related to conveyor belt elevator

3 Common User Pain Points for ‘conveyor belt elevator’ & Their Solutions

Scenario 1: Inefficient Product Transfers Leading to Downtime

The Problem: B2B buyers often encounter the challenge of product transfers that are not optimized for their specific operations. For example, a manufacturing facility may experience significant downtime due to frequent belt slippage or off-tracking in their conveyor belt elevators. This inefficiency can lead to delays in production schedules, increased labor costs for manual adjustments, and potential safety hazards from malfunctioning equipment. Buyers in industries such as food processing or heavy manufacturing may find their operations severely hampered by these issues, leading to lost revenue and dissatisfied customers.

The Solution: To address this pain point, B2B buyers should consider investing in high-quality, specially designed conveyor belt elevators that minimize slippage and off-tracking. Utilizing belts with advanced features such as cleats or sidewalls can help secure products during elevation, especially in steep inclines. Additionally, integrating Positive Drive belts, like Volta’s SuperDrive™, can significantly reduce slippage and ensure consistent performance. Buyers should engage with suppliers to conduct a thorough evaluation of their operational requirements, including load types, incline angles, and environmental conditions, which can help in selecting the right belt design and configuration. Regular maintenance schedules should also be established to ensure that all components, including pulleys and transitions, are functioning optimally to avoid future downtimes.

Scenario 2: Inadequate Compliance with Safety Standards

The Problem: Compliance with safety regulations is a critical concern for B2B buyers, especially in industries like grain handling and food processing. Buyers often face the challenge of ensuring that their conveyor belt elevators meet stringent OSHA and MSHA standards for static conductivity and flame resistance. Failure to comply can lead to costly fines and, more importantly, jeopardize the safety of workers and the integrity of operations. Buyers may feel overwhelmed by the complexity of regulatory requirements, leading to hesitation in their purchasing decisions.

The Solution: To navigate compliance effectively, B2B buyers should prioritize sourcing conveyor belt elevators that are certified and meet industry-specific safety standards. Working with trusted suppliers who provide certifications for their products can significantly reduce compliance-related risks. Buyers should also request documentation that outlines the safety features of the elevator systems, such as flame-retardant materials or static-conductive belts. Conducting a thorough risk assessment of the facility’s operations can help identify potential hazards and ensure that the chosen elevator systems are adequately equipped to mitigate these risks. Regular training and audits should be implemented to keep staff informed about safety protocols and ensure ongoing compliance.

Scenario 3: High Operating Costs Due to Frequent Maintenance

The Problem: Frequent maintenance and repairs can significantly inflate the operating costs of conveyor belt elevators. B2B buyers may find that their existing systems require constant attention due to wear and tear, particularly in environments that handle abrasive or heavy materials. This not only affects the bottom line but also diverts valuable resources away from core operations. Companies may struggle to balance the need for reliability with the financial implications of maintaining outdated or subpar systems.

The Solution: To reduce operating costs, buyers should invest in durable, high-performance conveyor belt elevators designed for their specific applications. For instance, belts made from robust materials that resist abrasion, oil, and weather exposure can extend the lifespan of the equipment and minimize the frequency of repairs. Furthermore, opting for custom fabrication options that cater to specific operational needs—such as belts with unique patterns or profiles—can enhance efficiency and reduce wear. Buyers should also consider implementing a predictive maintenance program, leveraging technology to monitor belt performance in real-time. This proactive approach allows for timely interventions before minor issues escalate into costly repairs, ultimately leading to lower total cost of ownership.

Strategic Material Selection Guide for conveyor belt elevator

What are the Key Properties of Rubber Materials for Conveyor Belt Elevators?

Rubber is one of the most commonly used materials for conveyor belt elevators due to its excellent elasticity and durability. It can withstand a range of temperatures, typically from -40°C to 120°C, depending on the specific formulation. Additionally, rubber exhibits good resistance to abrasion, making it suitable for handling bulk materials like grains and aggregates.

Illustrative image related to conveyor belt elevator

Pros: Rubber belts are generally cost-effective and provide good traction, which is essential for incline applications. They can also be manufactured with various profiles, such as chevron or rough-top, enhancing their ability to transport materials at steep angles.

Cons: However, rubber is susceptible to degradation from UV exposure and certain chemicals, which may limit its use in specific environments. Moreover, the manufacturing process can be complex, requiring specialized equipment and expertise.

For international buyers, especially in regions like Africa and South America, it is crucial to consider compliance with local standards such as ASTM and ISO certifications, as well as the availability of rubber materials that meet these requirements.

How Does PVC Compare as a Material for Conveyor Belt Elevators?

Polyvinyl Chloride (PVC) is another popular choice for conveyor belt elevators, particularly in food-grade applications. PVC belts are known for their chemical resistance and can operate effectively in temperature ranges between -10°C and 60°C.

Pros: They are lightweight, cost-effective, and easy to clean, making them ideal for food processing and packaging industries. Furthermore, PVC can be manufactured in various colors and patterns, allowing for customization based on specific operational needs.

Illustrative image related to conveyor belt elevator

Cons: On the downside, PVC belts may not offer the same level of durability as rubber belts, particularly in high-abrasion environments. They can also be less flexible, which might limit their application in certain configurations.

For buyers in the Middle East and Europe, ensuring that PVC belts comply with food safety regulations (such as FDA or EU standards) is essential. Additionally, understanding the local climate and its impact on PVC performance is crucial for optimal material selection.

What Advantages Do Steel Reinforced Belts Offer for Heavy-Duty Applications?

Steel reinforced belts are often used in heavy-duty conveyor belt elevators, particularly in mining and construction applications. These belts are designed to handle extreme loads and can operate effectively in high-pressure environments.

Pros: The key advantage of steel reinforced belts is their exceptional strength and durability, making them suitable for transporting heavy materials like ores and aggregates. They also exhibit excellent resistance to tearing and puncturing.

Illustrative image related to conveyor belt elevator

Cons: However, the cost of steel reinforced belts is significantly higher than rubber or PVC options. Additionally, their weight can increase the operational costs related to energy consumption and equipment wear.

For international buyers, particularly in regions with stringent mining regulations, ensuring compliance with standards such as MSHA in the U.S. or similar local regulations is vital. Buyers should also consider logistical factors, such as the availability of replacement parts and service support in their region.

How Do Thermoplastic Elastomers (TPE) Enhance Conveyor Belt Performance?

Thermoplastic elastomers (TPE) are increasingly being used in conveyor belt elevators due to their unique properties that combine the benefits of rubber and plastic. TPE belts can operate in a temperature range of -30°C to 80°C and provide excellent chemical resistance.

Pros: TPE belts are highly durable, flexible, and can be customized for various applications, including food processing and packaging. They also offer a lower environmental impact, as they can be recycled.

Cons: The main limitation of TPE belts is their higher initial cost compared to traditional rubber or PVC options. Additionally, their performance in extremely high-temperature applications may be limited.

For B2B buyers in Europe and the Middle East, TPE belts may align well with sustainability initiatives and compliance with environmental regulations, making them an attractive option for companies looking to enhance their green credentials.

Summary Table of Material Selection for Conveyor Belt Elevators

| Material | Typical Use Case for conveyor belt elevator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Bulk material handling (grains, aggregates) | Excellent elasticity and durability | Susceptible to UV degradation | Medium |

| PVC | Food processing and packaging | Lightweight and easy to clean | Less durable in high-abrasion environments | Low |

| Steel Reinforced | Heavy-duty applications (mining, construction) | Exceptional strength and durability | High cost and increased operational weight | High |

| Thermoplastic Elastomers | Food processing, packaging | Durable, flexible, and recyclable | Higher initial cost | Medium to High |

This guide provides a strategic overview of material selection for conveyor belt elevators, helping international B2B buyers make informed decisions tailored to their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor belt elevator

What Are the Main Stages in the Manufacturing Process of Conveyor Belt Elevators?

The manufacturing process of conveyor belt elevators involves several critical stages, each designed to ensure the product meets the rigorous demands of various industries. These stages include material preparation, forming, assembly, and finishing.

1. Material Preparation

The first step in manufacturing conveyor belt elevators is selecting the appropriate materials. Depending on the application, materials can range from rubber and PVC to specialized compounds that offer resistance to oil, abrasion, and flame. Suppliers often conduct a thorough assessment of the material properties, ensuring compliance with international standards such as ISO 9001 for quality management systems.

Once the materials are selected, they undergo preparation processes such as cutting and treating to ensure they meet specific tolerances. This stage is critical as the quality of the raw materials directly impacts the performance and durability of the final product.

2. Forming

The forming stage involves shaping the prepared materials into the desired configurations. This can include molding, extrusion, or weaving, depending on the type of belt being produced. For instance, cleated belts may require specialized molds to create the necessary profiles that will grip products effectively during elevation.

Advanced techniques like hot and cold vulcanization are employed to bond layers of materials, enhancing strength and flexibility. Precision in this stage is paramount, as the wrong dimensions or inconsistencies can lead to operational failures in the field.

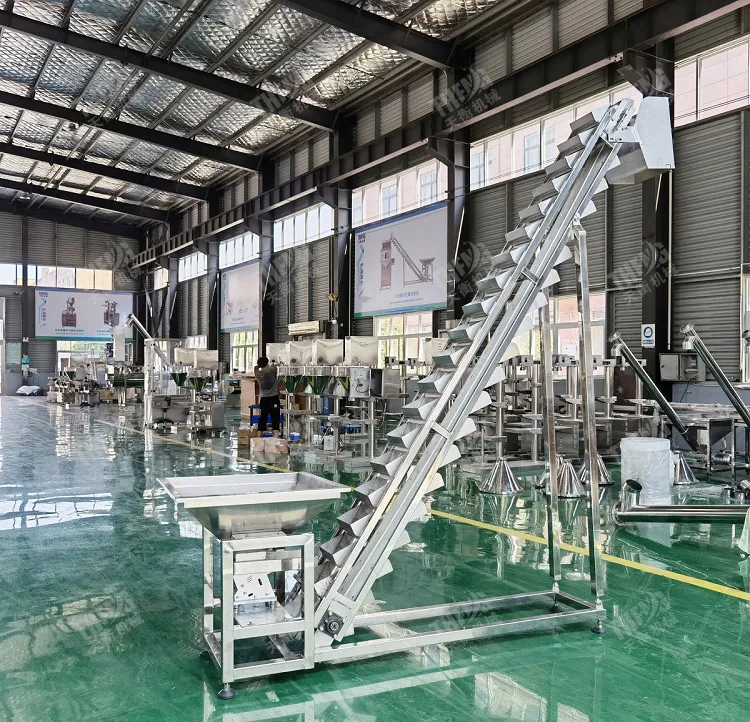

Illustrative image related to conveyor belt elevator

3. Assembly

After forming, the belts are assembled into the complete conveyor elevator systems. This stage includes attaching components such as pulleys, frames, and drive systems. Proper alignment and tensioning of belts are critical to prevent slippage and ensure smooth operation.

Manufacturers often utilize automated assembly lines to enhance efficiency and reduce human error. However, skilled technicians are also involved to oversee the assembly process, ensuring that each unit meets the required specifications and standards.

4. Finishing

The final stage of manufacturing is finishing, which includes surface treatments, inspections, and packaging. Surface treatments may involve coating the belts to improve resistance to wear and environmental factors.

Quality checks are conducted at this stage to ensure that every component adheres to the specified standards. This may include testing for durability, flexibility, and load capacity. Proper packaging is also crucial, as it protects the product during transport and ensures it arrives at the client’s location in optimal condition.

Illustrative image related to conveyor belt elevator

How is Quality Assurance Integrated into the Manufacturing of Conveyor Belt Elevators?

Quality assurance (QA) is integral to the manufacturing process, ensuring that conveyor belt elevators not only meet but exceed industry standards. Various international and industry-specific certifications play a vital role in this process.

1. What Are the Key International Standards for Conveyor Belt Elevators?

Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards is essential for B2B buyers, as it indicates that the manufacturer consistently delivers quality products.

In addition to ISO standards, industry-specific certifications such as CE marking for products sold in Europe and API specifications for oil and gas applications can significantly impact a supplier’s credibility. These certifications assure buyers that the products have undergone rigorous testing and meet stringent safety and performance criteria.

2. What QC Checkpoints Should Buyers Be Aware Of?

Quality control checkpoints throughout the manufacturing process include:

- Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production process, ensuring they meet specified criteria.

- In-Process Quality Control (IPQC): This stage includes real-time monitoring of the manufacturing process, allowing for immediate corrective actions if deviations occur.

- Final Quality Control (FQC): Conducted post-assembly, this ensures the finished product adheres to all specifications and is ready for shipment.

These checkpoints are crucial for maintaining product integrity and minimizing defects.

3. What Common Testing Methods Are Used in Quality Assurance?

Testing methods for conveyor belt elevators include tensile strength tests, abrasion resistance tests, and dynamic flex tests. Each test assesses a different aspect of the belt’s performance, ensuring it can withstand the operational demands it will face in various applications.

For example, tensile strength tests evaluate the maximum load the belt can handle, while abrasion tests assess how well the material resists wear over time. Documented results from these tests can provide valuable insights for B2B buyers seeking reliable suppliers.

Illustrative image related to conveyor belt elevator

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

B2B buyers must be proactive in verifying the quality assurance practices of their suppliers to ensure they receive high-quality products. Here are effective strategies for doing so:

1. Conducting Audits

Regular audits are a vital tool for assessing a supplier’s adherence to quality standards. Buyers can request audits of the manufacturing facility to evaluate processes and compliance with international and industry standards. This can include reviewing documentation of past quality control measures and certifications.

2. Reviewing Quality Reports

Suppliers should provide detailed quality reports that outline testing results, compliance with standards, and any corrective actions taken in response to non-conformities. Buyers should scrutinize these reports for transparency and consistency.

3. Engaging Third-Party Inspectors

Employing independent third-party inspectors can provide an unbiased assessment of the manufacturing processes and quality control measures. These inspectors can conduct thorough evaluations and ensure that the supplier meets the necessary standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control.

1. Understanding Regional Standards

Different regions may have varying standards and regulations that impact the quality of conveyor belt elevators. For instance, compliance with local safety regulations in Saudi Arabia may differ from those in Nigeria. Buyers should familiarize themselves with these standards to ensure their suppliers are compliant.

2. Supply Chain Considerations

International logistics can pose challenges related to product quality. Factors such as temperature fluctuations during transport can affect the integrity of materials. Buyers should work with suppliers who have robust logistics strategies to mitigate these risks.

3. Cultural and Language Barriers

Cultural differences and language barriers can impact communication regarding quality expectations. Buyers should establish clear lines of communication and possibly consider hiring local representatives to facilitate interactions with suppliers.

In summary, understanding the manufacturing processes and quality assurance practices for conveyor belt elevators is essential for B2B buyers. By prioritizing quality standards, conducting thorough evaluations, and navigating international nuances, buyers can make informed decisions that enhance their operational efficiency and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor belt elevator’

In the competitive landscape of industrial operations, selecting the right conveyor belt elevator is crucial for optimizing production efficiency and ensuring safe material handling. This guide provides a structured checklist to assist B2B buyers in making informed procurement decisions for conveyor belt elevators.

Step 1: Define Your Technical Specifications

Establish clear technical requirements based on your operational needs. Consider factors such as load capacity, height of elevation, and the type of materials being transported. This step is vital to ensure that the selected conveyor belt elevator meets your specific operational demands and avoids costly modifications later.

- Load Capacity: Determine the maximum weight your elevator will need to handle.

- Material Type: Different materials may require different belt compositions (e.g., rubber vs. PVC).

Step 2: Research and Compare Available Types

Investigate the various types of conveyor belt elevators available in the market, such as bucket elevators, cleated conveyors, and modular designs. Understanding the advantages and limitations of each type will help you select the most suitable option for your application.

- Bucket Elevators: Ideal for vertical lifting of bulk materials.

- Cleated Conveyors: Effective for transporting materials at steep angles.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and quality. Look for suppliers with a strong reputation in your industry, and request case studies or testimonials from similar businesses.

- Company Background: Assess their experience and expertise in conveyor solutions.

- Customer References: Speak with previous clients to gauge satisfaction and performance.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers comply with relevant industry standards and certifications. Certifications can indicate a commitment to quality and safety, which is crucial for operational integrity.

- Safety Standards: Look for compliance with OSHA and MSHA regulations.

- Quality Assurance: Check for ISO certifications that demonstrate adherence to international quality standards.

Step 5: Request Customization Options

Discuss potential customization options with suppliers to tailor the conveyor belt elevator to your specific needs. Custom features may include belt profiles, material composition, and operational integration.

- Belt Profiles: Options like Chevron or V-Cleat can enhance material handling efficiency.

- Material Choices: Choose based on factors like abrasion resistance or food-grade requirements.

Step 6: Assess Maintenance and Support Services

Evaluate the maintenance and support services offered by the supplier. A good support system can significantly impact the longevity and performance of your conveyor belt elevator.

Illustrative image related to conveyor belt elevator

- Service Agreements: Look for suppliers offering robust maintenance packages.

- Technical Support: Ensure they provide timely assistance for any operational issues.

Step 7: Compare Costs and Total Cost of Ownership

Finally, analyze the total cost of ownership, including initial purchase price, installation, maintenance, and operational costs. A lower upfront cost may not always translate to savings in the long run.

- Installation Fees: Consider any additional costs for professional installation.

- Energy Efficiency: Assess the energy consumption of the equipment to project ongoing costs.

By following this structured checklist, B2B buyers can confidently navigate the sourcing process for conveyor belt elevators, ensuring they make informed and strategic purchasing decisions that align with their operational goals.

Comprehensive Cost and Pricing Analysis for conveyor belt elevator Sourcing

What Are the Key Cost Components in Conveyor Belt Elevator Sourcing?

When sourcing conveyor belt elevators, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The choice of materials significantly influences costs. Conveyor belts are typically made from rubber, PVC, or specialized compounds, each varying in durability and application suitability. For example, food-grade belts incur higher costs due to stringent regulations and certifications.

-

Labor: Labor costs encompass both direct manufacturing labor and indirect labor involved in design, engineering, and support services. Skilled labor is essential for ensuring quality and efficiency, particularly in custom orders.

-

Manufacturing Overhead: This includes costs associated with production facilities, utilities, and equipment depreciation. Efficient manufacturing processes can help minimize overhead, thus lowering overall costs.

-

Tooling: Depending on the design complexity, tooling costs can vary widely. Custom molds and dies for specialized belt profiles can represent a significant upfront investment.

-

Quality Control (QC): Implementing robust QC measures is essential for maintaining product standards and preventing costly defects. This can involve both in-house testing and third-party certifications, adding to overall costs.

-

Logistics: Transportation and handling costs are critical, particularly for international shipments. Factors such as shipping distance, freight method, and customs duties can significantly impact the total cost.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can fluctuate based on market conditions and competition.

How Do Price Influencers Affect Conveyor Belt Elevator Costs?

Several factors can influence pricing strategies in the conveyor belt elevator market, especially for international buyers.

-

Volume/MOQ: Bulk orders often lead to significant cost reductions. Suppliers are more willing to negotiate better rates for larger quantities, impacting the overall cost per unit.

-

Specifications and Customization: Custom designs tailored to specific applications can increase costs. Buyers should balance the need for unique features with their budget constraints.

-

Material Quality and Certifications: Higher-quality materials and compliance with international standards (e.g., FDA, OSHA) typically raise costs. These factors are particularly relevant for industries like food processing and pharmaceuticals.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products, but they often provide better support and quality assurance.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) used in transactions is vital. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect the final pricing.

What Are the Buyer Tips for Cost-Efficiency in Conveyor Belt Elevator Sourcing?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider several strategies to enhance cost-efficiency in their sourcing efforts.

-

Negotiation: Effective negotiation can lead to significant savings. Buyers should be prepared with market data and competitor pricing to leverage during discussions.

-

Total Cost of Ownership (TCO): Assessing the TCO, which includes initial costs, maintenance, and operational efficiency, can provide a clearer picture of long-term value. This approach can justify higher upfront costs if the product leads to lower operational expenses.

-

Leverage Local Suppliers: Whenever possible, consider local suppliers to reduce logistics costs and simplify customs processes. This is particularly beneficial for regions with complex import regulations.

-

Research and Benchmarking: Conduct thorough research on market prices and supplier performance. Benchmarking against industry standards can help identify competitive pricing and potential cost-saving opportunities.

-

Stay Informed on Pricing Nuances: International markets can be volatile, and currency fluctuations may impact pricing. Staying informed about economic conditions in both the buyer’s and supplier’s countries can help in making timely purchasing decisions.

Conclusion

While the costs associated with sourcing conveyor belt elevators can vary widely based on multiple factors, a strategic approach to understanding these components and influencers can lead to more informed purchasing decisions. Buyers should always keep in mind the importance of negotiating effectively and considering the total cost of ownership to ensure they achieve the best value for their investment.

Alternatives Analysis: Comparing conveyor belt elevator With Other Solutions

Introduction

When considering solutions for vertical product transfer, the conveyor belt elevator is a widely accepted choice. However, various alternatives exist that may offer specific advantages depending on operational requirements, industry standards, and budget constraints. In this analysis, we will compare conveyor belt elevators with two viable alternatives: bucket elevators and pneumatic conveying systems. This comparison will provide insights into the strengths and weaknesses of each option, helping international B2B buyers make informed decisions.

| Comparison Aspect | Conveyor Belt Elevator | Bucket Elevator | Pneumatic Conveying System |

|---|---|---|---|

| Performance | High efficiency for bulk materials; handles steep angles well. | Excellent for high-capacity transport; ideal for granular materials. | Versatile; can handle various materials, including powders and granules. |

| Cost | Moderate initial investment; low long-term maintenance costs. | Higher initial cost; durable and long-lasting, but may have higher maintenance. | Variable costs depending on system complexity; may require specialized equipment. |

| Ease of Implementation | Requires careful design for transitions; generally straightforward installation. | Installation can be complex due to height; requires precise engineering. | Often requires extensive planning and customization; installation can be labor-intensive. |

| Maintenance | Low maintenance; regular checks needed for belt wear. | Moderate to high maintenance; requires attention to bucket integrity and chain. | Can be high maintenance; system components may need frequent servicing. |

| Best Use Case | Ideal for food processing, packaging, and bulk material handling. | Best for grain handling, construction materials, and heavy loads. | Suitable for fragile materials, powders, and applications requiring high flexibility. |

What Are the Advantages and Disadvantages of Bucket Elevators?

Bucket elevators are designed to lift bulk materials vertically using buckets attached to a belt or chain. One significant advantage of bucket elevators is their ability to handle large volumes of material efficiently, making them ideal for industries such as agriculture and construction. However, they can be more expensive to install and maintain due to their mechanical complexity and the need for regular inspections of the buckets and chains. Bucket elevators also have limitations regarding the types of materials they can handle, as they are primarily suited for granular materials.

How Do Pneumatic Conveying Systems Compare?

Pneumatic conveying systems utilize air pressure to transport materials through pipelines. This method offers remarkable versatility, allowing for the movement of a wide range of materials, including powders and fragile goods. The primary advantage of pneumatic systems is their ability to minimize material degradation during transport. However, they can be more costly to set up and maintain, especially if specialized equipment is required. Additionally, pneumatic systems often demand extensive planning and can be labor-intensive to install, making them less appealing for some buyers.

Conclusion

Selecting the right vertical transfer solution depends on various factors, including the type of material being transported, budget constraints, and operational requirements. Conveyor belt elevators offer a balanced approach with moderate costs and low maintenance, making them suitable for many industries. Bucket elevators excel in high-capacity scenarios but come with higher initial costs and maintenance needs. Pneumatic conveying systems provide flexibility and material protection but can be expensive and complex to implement. B2B buyers should carefully assess their specific needs and operational contexts to choose the most effective solution for their vertical transport challenges.

Essential Technical Properties and Trade Terminology for conveyor belt elevator

What Are the Essential Technical Properties of Conveyor Belt Elevators?

When selecting conveyor belt elevators, understanding key technical properties is vital for ensuring operational efficiency and product handling. Here are some critical specifications to consider:

Illustrative image related to conveyor belt elevator

-

Material Grade

The material grade of the conveyor belt is fundamental. Common materials include rubber and PVC, each offering varying degrees of oil resistance, flame retardancy, and durability against wear and tear. For example, rubber belts are ideal for heavy-duty applications in harsh environments, while PVC belts may be more suitable for lighter loads. Selecting the right material impacts the longevity and reliability of the elevator, ultimately affecting maintenance costs and operational downtime. -

Load Capacity

Load capacity indicates the maximum weight the conveyor belt can handle. This specification is often expressed in Pounds per Inch of Width (PIW). Choosing a belt with the appropriate load capacity is crucial for preventing premature wear and potential failure. For B2B buyers, understanding load capacity ensures that the elevator can meet production demands without compromising safety or efficiency. -

Belt Width and Length

The dimensions of the conveyor belt, including its width and length, are critical for compatibility with existing systems and for meeting specific application requirements. Wider belts can accommodate larger volumes of material, while the length determines the height and reach of the elevator system. These dimensions must be tailored to your operational setup to optimize performance and minimize the risk of material spillage. -

Cleat Design

Cleats are raised sections on the conveyor belt that help contain materials during elevation. The design and height of cleats are vital for maintaining material stability, especially at steep angles. Various cleat designs, such as scoop, chevron, or V-cleat, can significantly enhance efficiency by reducing slippage and ensuring that materials are transported safely. Selecting the right cleat design can improve throughput and reduce operational disruptions. -

Tensioning and Tracking Mechanism

The tensioning system maintains the proper tension in the conveyor belt, which is essential for preventing slippage and ensuring smooth operation. Additionally, a well-designed tracking mechanism ensures that the belt remains aligned throughout its operation. Both factors are vital for reducing wear and tear, thus extending the lifespan of the conveyor system and minimizing maintenance costs.

What Are the Key Trade Terminology Terms for Conveyor Belt Elevators?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of conveyor belt elevators, understanding whether you are dealing with an OEM can help in assessing product quality and compatibility with your existing systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, especially for businesses in regions with fluctuating demand. It ensures that you can procure the necessary quantities without incurring excess costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. Submitting an RFQ allows businesses to compare prices and negotiate better terms, making it a critical step in the procurement process. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping contracts. Familiarity with these terms helps businesses understand shipping costs, risks, and responsibilities, which is particularly important for international transactions. -

Lead Time

Lead time is the period between placing an order and receiving the product. Understanding lead times is essential for planning production schedules and managing inventory, particularly in industries where timely delivery is critical.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when investing in conveyor belt elevators, ensuring efficiency and compliance with operational needs.

Navigating Market Dynamics and Sourcing Trends in the conveyor belt elevator Sector

What Are the Current Market Dynamics and Key Trends Affecting Conveyor Belt Elevators?

The conveyor belt elevator sector is experiencing significant transformations driven by technological advancements and evolving market demands. Globally, the increasing automation in manufacturing processes is a key driver, particularly in sectors such as food processing, agriculture, and mining. Companies are increasingly investing in conveyor systems that can enhance efficiency, reduce labor costs, and ensure precise material handling. In regions like Africa and South America, the demand for reliable and efficient conveyor belt elevators is surging, fueled by infrastructure development and the expansion of agricultural exports.

Illustrative image related to conveyor belt elevator

Emerging technologies, such as IoT and AI, are also reshaping the landscape. These technologies provide real-time monitoring and predictive maintenance capabilities, allowing businesses to optimize performance and reduce downtime. For international B2B buyers, this trend represents an opportunity to enhance operational efficiency and minimize lifecycle costs. Additionally, the demand for custom solutions is rising, as businesses seek to tailor conveyor systems to specific applications, such as high-incline transport or handling abrasive materials.

Furthermore, sustainability is becoming a paramount consideration. Companies are increasingly prioritizing suppliers that demonstrate environmental responsibility and offer products made from eco-friendly materials. This shift is particularly evident in Europe and the Middle East, where regulatory frameworks encourage green practices. B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with market demands and sustainability goals.

How Does Sustainability and Ethical Sourcing Impact the Conveyor Belt Elevator Industry?

In the current global market, sustainability and ethical sourcing have become crucial factors for B2B buyers in the conveyor belt elevator sector. The environmental impact of manufacturing processes, including waste generation and resource depletion, necessitates a shift towards greener practices. Companies are now seeking suppliers that prioritize eco-friendly materials and sustainable production methods.

Certifications such as ISO 14001 for environmental management and compliance with REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations can provide assurance to buyers about a supplier’s commitment to sustainability. Additionally, the use of recycled materials in conveyor belt production not only reduces environmental impact but can also lead to cost savings.

Illustrative image related to conveyor belt elevator

Ethical supply chains are equally important, particularly in regions where labor practices may vary significantly. Buyers are increasingly scrutinizing their suppliers’ labor conditions, pushing for transparency and fair treatment of workers. By prioritizing suppliers that adhere to ethical sourcing standards, businesses can enhance their brand reputation and appeal to a growing base of environmentally and socially conscious consumers.

How Has the Conveyor Belt Elevator Industry Evolved Over Time?

The evolution of the conveyor belt elevator industry has been marked by significant technological advancements and changing market needs. Initially, conveyor belts were primarily used for horizontal transportation, but as industries evolved, the demand for vertical transportation solutions grew. This led to the development of specialized conveyor belt elevators designed to handle materials at various angles, enhancing efficiency and productivity in industries such as agriculture, mining, and food processing.

Throughout the decades, innovations such as cleated belts and positive drive systems have emerged, addressing issues related to slippage and off-tracking. These advancements have made conveyor belt elevators more reliable and easier to maintain, significantly reducing operational costs. As industries continue to prioritize automation and efficiency, the conveyor belt elevator sector is expected to further innovate, offering B2B buyers increasingly sophisticated solutions tailored to their specific operational needs.

In summary, understanding the market dynamics, sustainability considerations, and historical context of conveyor belt elevators can empower international B2B buyers to make informed sourcing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor belt elevator

-

How do I solve issues with conveyor belt slippage?

To mitigate conveyor belt slippage, consider using belts with specialized cleat designs or profiles that enhance grip and prevent material from sliding back. Additionally, ensure that the belt tension is properly adjusted and that pulleys are adequately sized to facilitate smooth transitions. Regular maintenance checks on the belt and conveyor system can help identify wear or misalignment that contributes to slippage. If slippage persists, consulting with your supplier for tailored solutions or upgrades may be necessary. -

What is the best type of conveyor belt elevator for grain handling?

For grain handling, a robust rubber or PVC conveyor belt designed to withstand abrasion and static is ideal. Look for belts with features like oil resistance and flame retardancy, as they enhance safety and durability in harsh environments. Custom profiles, such as Chevron or V-Cleat patterns, can optimize incline efficiency and minimize material slippage. Ensure the selected belt meets industry certifications (like OSHA or MSHA) for peace of mind in compliance. -

What are the common customization options available for conveyor belt elevators?

Customization options for conveyor belt elevators include varying belt widths, lengths, and profiles to match specific operational needs. You can choose from different cleat heights and shapes, as well as materials that cater to environmental conditions (e.g., food-grade or fire-retardant). Additionally, some suppliers offer custom fabrications such as slitting and punching to fit unique machinery specifications, thereby enhancing operational efficiency and performance. -

What are the minimum order quantities (MOQs) for conveyor belt elevators?

Minimum order quantities can vary significantly among suppliers and depend on factors such as belt type, customization options, and production capabilities. Generally, MOQs range from a few units for standard belts to larger quantities for custom or specialized products. It’s advisable to discuss your needs with potential suppliers to understand their policies, as many are willing to accommodate smaller orders for new customers or ongoing partnerships. -

What payment terms should I expect when sourcing conveyor belt elevators internationally?

Payment terms in international transactions typically range from upfront payment to net 30, 60, or 90 days, depending on the supplier’s policies and your negotiation. Common methods include wire transfers, letters of credit, and online payment platforms. Always clarify payment terms during negotiations to avoid misunderstandings. Additionally, consider factoring in currency fluctuations and international transaction fees when budgeting for your purchase. -

How can I ensure quality assurance (QA) for my conveyor belt elevators?

To ensure quality assurance, request detailed product specifications, certifications, and testing reports from suppliers. Establish a clear QA process that includes inspection upon receipt, regular audits during production, and adherence to industry standards. Consider suppliers that offer warranties and customer support services, as these can be indicators of their commitment to quality. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations. -

What logistics considerations should I keep in mind when importing conveyor belt elevators?

Logistics considerations include understanding shipping methods, transit times, and customs regulations for your destination country. Collaborate with your supplier to determine the best shipping options, whether air freight for speed or ocean freight for cost-effectiveness. Ensure all documentation is prepared to facilitate smooth customs clearance. It’s also essential to factor in potential duties and taxes when calculating total landed costs. -

What are the key factors to consider when vetting suppliers for conveyor belt elevators?

When vetting suppliers, consider their experience in the industry, production capabilities, and customer reviews. Assess their compliance with international standards and certifications relevant to your needs. Evaluate their responsiveness and willingness to provide technical support and customization options. Finally, check their financial stability and ability to meet delivery timelines, as these factors significantly impact your operational efficiency and reliability.

Top 4 Conveyor Belt Elevator Manufacturers & Suppliers List

1. Volta Belting – Conveyor Belt Elevators

Domain: voltabelting.com

Registered: 1999 (26 years)

Introduction: Volta Belting offers conveyor belt elevators designed for vertical transfers, utilizing cleated or sidewall belts for effective product elevation or decline. Key features include:

– Options for inclined sections and horizontal transitions (L-shaped, Z, swan-neck, goose-neck)

– Critical design for transition areas to prevent belt failure

– Larger pulleys for belt flexing with cleats, sidewalls, …

2. The Belt Man – Belt Lift System

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The Belt Man Lift is a rubber belt with pads bolted to it that continuously moves. It allows a person to step onto the moving platform as it descends through the floor. It has been described as potentially unsafe, with a user reporting an incident where their foot got stuck, leading to a near-fall from several stories.

3. WSJ – The Paternoster Elevator

Domain: wsj.com

Registered: 1994 (31 years)

Introduction: The Paternoster is a unique, doorless elevator system commonly found in Europe. It operates continuously in a loop, allowing passengers to step on and off at any floor without waiting for doors to open or close. This elevator design is notable for its efficiency and space-saving characteristics, making it a distinctive feature in various buildings.

4. Dodman – Flighted Belt Conveyor

Domain: dodman.com

Registered: 1999 (26 years)

Introduction: Flighted Belt Conveyor by Dodman Ltd is designed for gently and quickly elevating products in a clean and safe manner. Key features include:

– Available in plastic, polyurethane, and rubber materials.

– Customizable sizes to meet specific requirements.

– Options for swan neck and goose neck configurations to optimize space.

– Gentle transition between levels, ideal for fragile food products.

– Hyg…

Strategic Sourcing Conclusion and Outlook for conveyor belt elevator

In the realm of conveyor belt elevators, strategic sourcing stands as a pivotal element for optimizing operational efficiency and reducing total cost of ownership. Key takeaways from our exploration emphasize the importance of selecting the right materials and designs tailored to specific industry needs, whether in grain handling, food production, or other applications. Robust options, such as cleated belts and custom profiles, enhance performance and minimize maintenance, while compliance with safety standards ensures peace of mind for international buyers.

As global supply chains evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the emphasis on reliable, high-performance solutions becomes ever more critical. Investing in quality conveyor belt elevators not only boosts productivity but also fosters long-term partnerships with suppliers committed to innovation and customer satisfaction.

Looking ahead, now is the time for international B2B buyers to evaluate their sourcing strategies. Embrace the opportunity to collaborate with industry leaders to harness cutting-edge technology and customized solutions. By prioritizing strategic sourcing, you can position your operations for sustainable growth and competitive advantage in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to conveyor belt elevator