Vehicle Plate Flipper: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for vehicle plate flipper

In today’s evolving automotive landscape, sourcing vehicle plate flippers has become a critical consideration for businesses across diverse markets. These innovative devices enable users to easily switch or conceal license plates, providing not only aesthetic benefits for car enthusiasts at shows but also practical applications in various industries. However, navigating the complexities surrounding the purchase and usage of these products—especially in regions such as Africa, South America, the Middle East, and Europe—poses unique challenges.

This comprehensive guide delves into the multifaceted world of vehicle plate flippers, covering key aspects such as types, applications, legal implications, and supplier vetting processes. With insights into regional market demands and compliance requirements, B2B buyers can make informed decisions tailored to their specific needs.

By addressing common concerns related to functionality, durability, and cost, this guide empowers international buyers, particularly from countries like Nigeria and Saudi Arabia, to confidently engage with suppliers. Whether you are looking to enhance your vehicle fleet’s versatility or cater to niche markets, understanding the dynamics of vehicle plate flippers will enable you to capitalize on this growing segment effectively. Armed with the right knowledge, you can navigate the global market landscape and optimize your purchasing strategy.

Understanding vehicle plate flipper Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Plate Flippers | Operated by a lever or knob; simple mechanics. | Automotive shows, car customization shops. | Pros: Cost-effective, easy to install. Cons: Requires manual operation, less durable. |

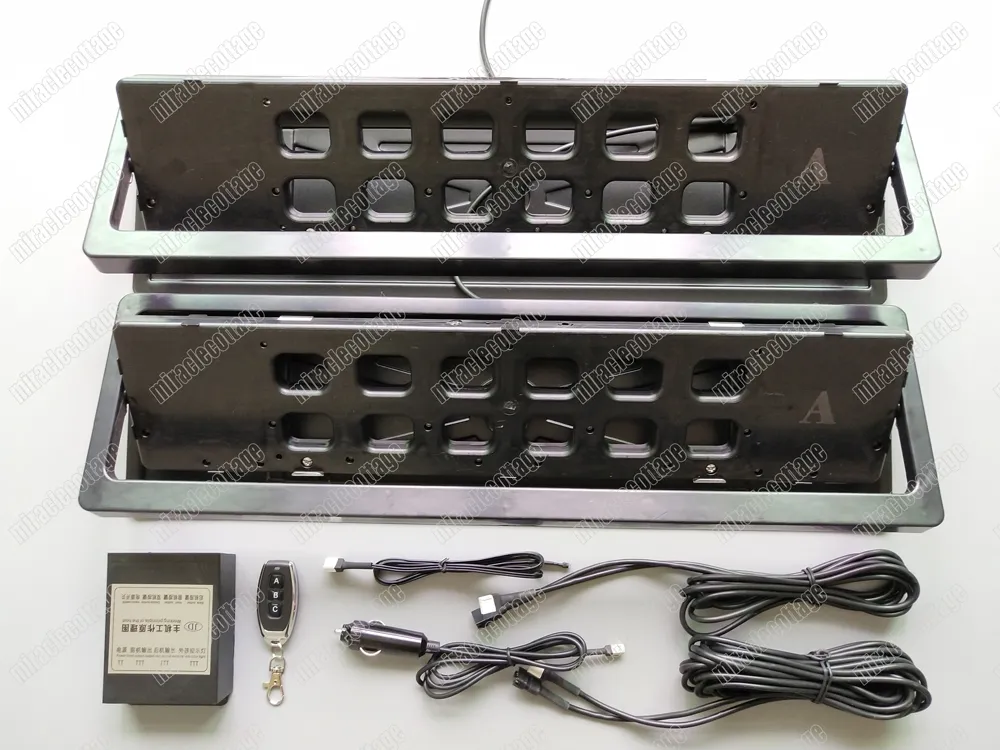

| Remote-Controlled Flippers | Allows plate flipping at the push of a button; typically wireless. | Car dealerships, luxury vehicle markets, event organizers. | Pros: Convenient, enhances user experience. Cons: Higher cost, potential for electronic failure. |

| Automated Flipping Systems | Integrated with vehicle systems; flips based on conditions (e.g., speed). | Fleet management, law enforcement. | Pros: Highly efficient, reduces manual intervention. Cons: Complex installation, higher initial investment. |

| Customizable Flippers | Offers aesthetic variations and branding options. | Marketing agencies, automotive accessory retailers. | Pros: Enhances vehicle appeal, promotes branding. Cons: May require more frequent updates or changes. |

| Stealth Plate Systems | Designed for concealment; often used in high-security applications. | Security firms, luxury car owners. | Pros: Enhanced security, discreet design. Cons: Legal concerns in various jurisdictions, higher regulatory scrutiny. |

What are Manual Plate Flippers and Their B2B Applications?

Manual plate flippers are straightforward devices that allow users to switch plates through a lever or knob mechanism. They are particularly suitable for automotive shows and customization shops where aesthetic appeal is key. Buyers should consider the simplicity and cost-effectiveness of these systems, but also recognize that they require manual operation, which may not be ideal for all applications.

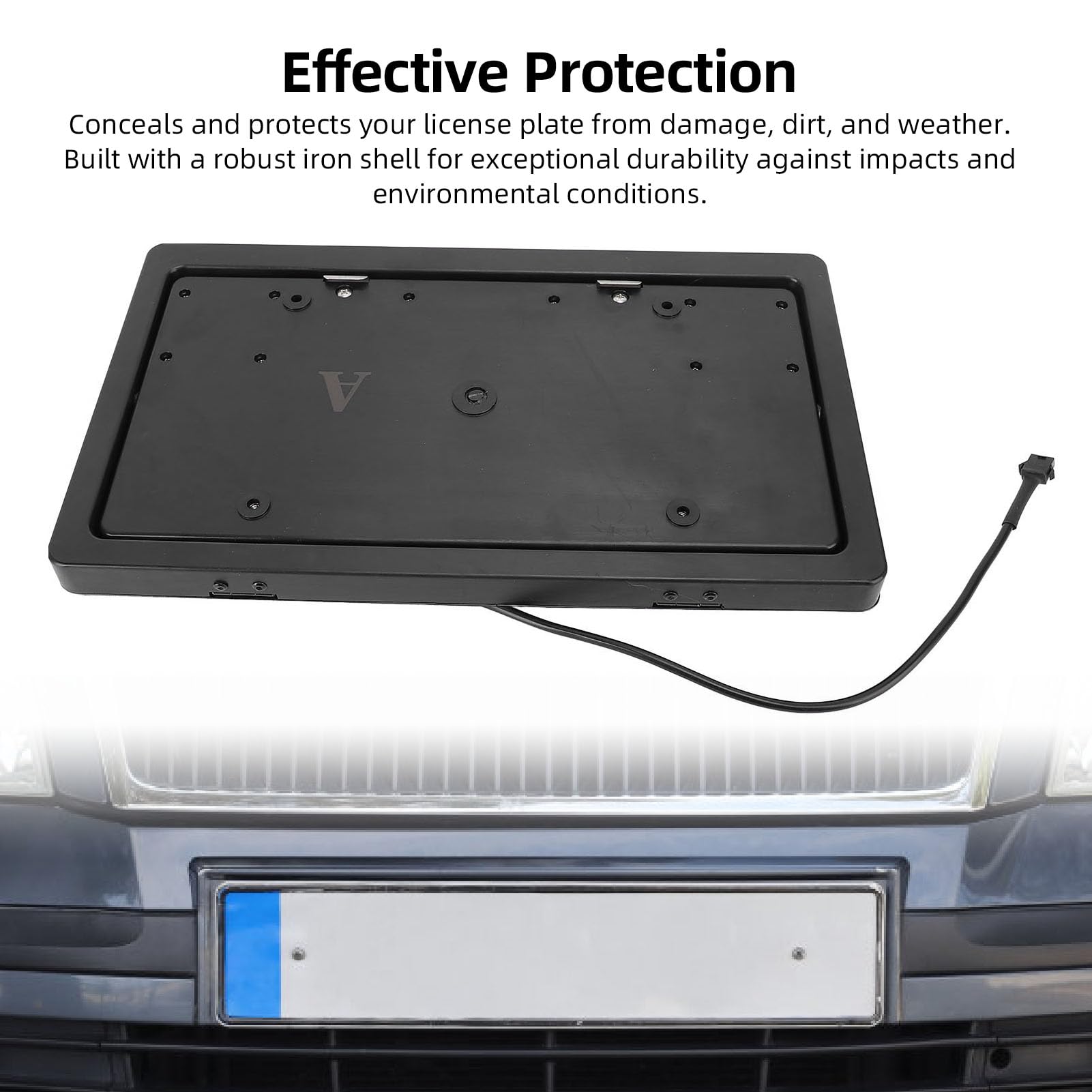

Illustrative image related to vehicle plate flipper

How Do Remote-Controlled Flippers Enhance User Experience?

Remote-controlled flippers offer convenience by allowing users to change their plates with a simple button press. This feature is especially appealing to car dealerships and luxury vehicle markets where user experience is paramount. While these systems add a layer of convenience, potential buyers should weigh the higher cost and risk of electronic failure against the benefits of ease of use.

What Makes Automated Flipping Systems Ideal for Fleet Management?

Automated flipping systems are integrated with vehicle electronics and can flip plates based on various conditions, such as vehicle speed. This technology is particularly beneficial for fleet management and law enforcement, where efficiency and real-time responsiveness are crucial. However, the complexity of installation and higher upfront costs may deter some buyers, making it essential to evaluate long-term operational benefits.

Why Choose Customizable Flippers for Marketing Purposes?

Customizable flippers allow for aesthetic variations and branding opportunities, making them an excellent choice for marketing agencies and automotive accessory retailers. These systems can enhance vehicle appeal and promote brand visibility. However, businesses must consider the potential need for frequent updates or changes to maintain their marketing edge.

Illustrative image related to vehicle plate flipper

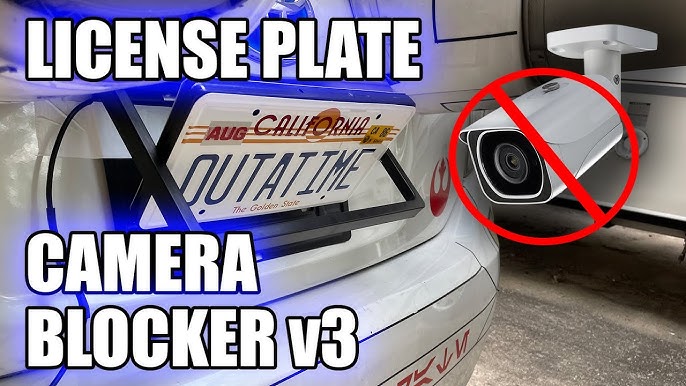

What Are the Advantages and Legal Considerations of Stealth Plate Systems?

Stealth plate systems are designed for concealment, making them popular among security firms and luxury car owners looking for added protection. Their discreet design can enhance security, but buyers must be cautious about legal implications, as the use of such devices is subject to varying regulations across jurisdictions. Understanding the legal landscape is crucial for potential buyers considering these systems.

Key Industrial Applications of vehicle plate flipper

| Industry/Sector | Specific Application of Vehicle Plate Flipper | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Accessories | Customization for Car Shows and Exhibitions | Enhances vehicle appeal and brand visibility at events | Durability, ease of installation, compatibility with various plate sizes |

| Law Enforcement & Security | Concealment during Operations | Protects operational integrity during undercover missions | Compliance with local laws, reliability under various conditions |

| Fleet Management | Quick Switching for Diverse Operations | Reduces downtime and enhances operational efficiency | Compatibility with fleet vehicles, remote control features |

| Event Management | Aesthetic Enhancement for Promotional Vehicles | Attracts customer attention and boosts brand image | Customization options, ease of use, and security features |

| International Shipping | Adaptation to Local Regulations | Ensures compliance with varying international vehicle laws | Understanding of local regulations, customization for specific markets |

How is Vehicle Plate Flipper Used in Automotive Accessories?

In the automotive accessories sector, vehicle plate flippers are primarily utilized to enhance the aesthetic appeal of cars during car shows and exhibitions. By allowing quick switching between standard and custom license plates, businesses can significantly boost their brand visibility. International buyers, particularly from regions like Africa and South America, should consider the durability and ease of installation of these devices, ensuring they can withstand varied weather conditions while fitting standard plate sizes.

What Role Does Vehicle Plate Flipper Play in Law Enforcement and Security?

For law enforcement and security operations, vehicle plate flippers serve a crucial role in concealing license plates during undercover missions. This functionality protects the operational integrity of law enforcement vehicles, enabling officers to perform their duties without exposing their identity. B2B buyers in this sector must ensure that the devices comply with local regulations, as misuse can lead to legal repercussions. Reliability under various environmental conditions is also essential to maintain operational effectiveness.

How Does Vehicle Plate Flipper Benefit Fleet Management?

In fleet management, vehicle plate flippers provide a practical solution for companies that operate diverse vehicle types across different jurisdictions. The ability to quickly switch license plates minimizes downtime during transitions between operations, enhancing overall efficiency. When sourcing for fleet applications, businesses should prioritize compatibility with various vehicle models and the inclusion of remote control features for ease of use, particularly in larger fleets.

Why is Vehicle Plate Flipper Important for Event Management?

Event management firms use vehicle plate flippers to enhance the aesthetic appeal of promotional vehicles at events and exhibitions. By allowing for the display of custom plates, these devices attract customer attention and enhance brand image. International B2B buyers should seek customization options that align with their marketing strategies and ensure the devices are easy to use and secure to prevent theft or misuse.

How Does Vehicle Plate Flipper Adapt to International Shipping Needs?

In the realm of international shipping, vehicle plate flippers must be adaptable to comply with various local regulations regarding license plates. This adaptability is crucial for businesses that operate across borders, ensuring that they remain compliant with regional laws while transporting goods. Buyers in this sector should focus on understanding local regulations and seek flippers that offer customization for specific markets, helping to streamline their operations in diverse environments.

3 Common User Pain Points for ‘vehicle plate flipper’ & Their Solutions

Scenario 1: Navigating Legal Compliance for Vehicle Plate Flippers

The Problem:

B2B buyers in regions with stringent automotive regulations face the challenge of ensuring that vehicle plate flippers comply with local laws. In countries like Nigeria or Saudi Arabia, where law enforcement is increasingly vigilant about vehicle modifications, businesses risk legal repercussions if they inadvertently procure flippers that are deemed illegal. Additionally, the ambiguity surrounding regulations can lead to confusion, resulting in potential financial losses or damaged reputations for companies that fail to adhere to the law.

Illustrative image related to vehicle plate flipper

The Solution:

To mitigate compliance risks, B2B buyers should conduct thorough market research and engage with legal experts familiar with automotive regulations in their target markets. It’s essential to source vehicle plate flippers from manufacturers who provide clear documentation regarding compliance with local laws. Buyers should also consider investing in flippers designed specifically for aesthetic use, as these are generally more accepted in auto shows and exhibitions. Establishing a partnership with local automotive associations can provide valuable insights into regulatory updates and best practices, ensuring that your business remains compliant while utilizing vehicle plate flippers.

Scenario 2: Addressing Installation Challenges for Vehicle Plate Flippers

The Problem:

Another common pain point for B2B buyers is the complexity involved in the installation of vehicle plate flippers. Many businesses, especially those operating fleets of vehicles, may not have the technical expertise required to install these devices correctly. Improper installation can lead to malfunctioning units, which not only impacts the aesthetic benefits but also heightens safety concerns and could potentially lead to legal issues if plates are not visible as required by law.

The Solution:

To overcome installation challenges, B2B buyers should prioritize purchasing vehicle plate flippers from manufacturers that offer comprehensive installation guides and customer support. Opt for suppliers who provide video tutorials or live chat assistance to help with the installation process. Additionally, consider partnering with local automotive service providers who are experienced with these devices; they can offer installation services and ongoing maintenance. Investing in training sessions for in-house technicians can also ensure that your team is well-equipped to handle installations and troubleshoot any issues that may arise.

Scenario 3: Managing Customer Perceptions and Brand Image

The Problem:

For businesses in the automotive sector, the use of vehicle plate flippers can sometimes lead to negative perceptions from customers. In regions where these devices are associated with illegal activities, such as evading tolls or law enforcement, companies may find themselves struggling to maintain a positive brand image. This perception can deter potential customers who may view the use of such devices as unethical, affecting overall sales and customer loyalty.

The Solution:

To manage customer perceptions effectively, B2B buyers should focus on transparent marketing strategies that highlight the legitimate uses of vehicle plate flippers, such as for aesthetic purposes at car shows or exhibitions. Creating educational content that informs customers about the legal and safe use of these devices can help alleviate concerns. Engaging in community outreach and participating in local automotive events can further enhance brand visibility and position your company as a responsible player in the market. Collaborating with influencers or industry experts to advocate for the positive aspects of vehicle plate flippers can also help reshape public perception and foster trust in your brand.

Illustrative image related to vehicle plate flipper

Strategic Material Selection Guide for vehicle plate flipper

What Materials Are Commonly Used in Vehicle Plate Flippers?

When selecting materials for vehicle plate flippers, several factors must be considered, including durability, cost, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of vehicle plate flippers: aluminum, stainless steel, plastic, and composite materials.

How Does Aluminum Perform in Vehicle Plate Flipper Applications?

Aluminum is a widely used material in vehicle plate flippers due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of around -50°C to 150°C, making it suitable for various climates. The main advantages of aluminum include its high strength-to-weight ratio and ease of machining, which simplifies manufacturing processes. However, it can be more expensive than other materials and may require additional coatings to enhance its durability against scratches and impacts.

For international buyers, particularly in regions like Africa and the Middle East, aluminum’s lightweight properties can be beneficial for shipping and handling. Compliance with standards such as ASTM B209 for aluminum alloys is crucial to ensure quality and performance.

Illustrative image related to vehicle plate flipper

What Are the Benefits of Using Stainless Steel in Vehicle Plate Flippers?

Stainless steel is another popular choice for vehicle plate flippers, known for its exceptional strength and durability. It offers excellent resistance to corrosion, particularly in environments with high humidity or exposure to road salts. The material can withstand temperatures from -200°C to 800°C, making it suitable for extreme conditions. However, stainless steel is heavier than aluminum and can be more expensive, which may impact overall production costs.

For B2B buyers in Europe and South America, adhering to standards like ASTM A240 for stainless steel is essential. The material’s longevity and resistance to wear make it an attractive option for products intended for long-term use.

How Do Plastics Compare for Vehicle Plate Flipper Applications?

Plastic materials, such as ABS (Acrylonitrile Butadiene Styrene) and polypropylene, are often chosen for vehicle plate flippers due to their low cost and lightweight characteristics. They provide decent resistance to impacts and can be molded into complex shapes, offering design flexibility. However, plastics typically have lower temperature resistance, generally around -20°C to 80°C, and may degrade over time when exposed to UV light.

Illustrative image related to vehicle plate flipper

For international buyers, especially in regions like Nigeria and Saudi Arabia, it is crucial to consider the environmental impact and compliance with local regulations regarding plastic use. Standards such as ISO 9001 for quality management can help ensure that the products meet necessary safety and performance criteria.

What Role Do Composite Materials Play in Vehicle Plate Flippers?

Composite materials, which combine different materials to enhance performance, are gaining traction in the vehicle plate flipper market. They offer a unique blend of strength, lightweight properties, and resistance to corrosion. Composites can withstand a wide temperature range, typically from -40°C to 120°C, making them versatile for various applications. However, the manufacturing process can be complex and costly, which may deter some manufacturers.

For B2B buyers in Europe and the Middle East, understanding the specific composite material standards, such as ASTM D3039 for tensile properties, is essential for ensuring product reliability and safety. The initial investment may be higher, but the long-term benefits in durability and performance can justify the cost.

Illustrative image related to vehicle plate flipper

Summary Table of Material Selection for Vehicle Plate Flippers

| Material | Typical Use Case for vehicle plate flipper | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight flippers for car shows | Excellent corrosion resistance | Higher cost than some alternatives | Medium |

| Stainless Steel | Durable flippers for long-term use | Exceptional strength and durability | Heavier and more expensive | High |

| Plastic | Cost-effective flippers for casual use | Low cost and design flexibility | Limited temperature resistance | Low |

| Composite | High-performance flippers for varied climates | Strong and lightweight | Complex manufacturing process | High |

By carefully considering these materials and their properties, B2B buyers can make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for vehicle plate flipper

What Are the Key Stages in the Manufacturing Process of Vehicle Plate Flippers?

The manufacturing process of vehicle plate flippers involves several critical stages, each designed to ensure the final product meets quality and performance standards. Understanding these stages is essential for B2B buyers looking for reliable suppliers.

Material Preparation: What Materials Are Used and How Are They Processed?

The first step in the manufacturing process is material preparation. Typically, high-grade metals such as aluminum or stainless steel are selected due to their durability and resistance to corrosion. These materials are sourced from reputable suppliers who provide certifications for quality assurance.

Once the materials are procured, they undergo cutting and shaping. Laser cutting and CNC machining are common techniques used to ensure precision in dimensions, which is vital for the proper fit of license plates. After cutting, the metal pieces are deburred to remove any sharp edges that could compromise safety during handling or installation.

How Are Vehicle Plate Flippers Formed?

Following material preparation, the next stage is forming. This involves bending and molding the metal components into the desired shapes for the plate flipper mechanism. Techniques such as stamping and deep drawing are often employed to create the necessary parts, including the frame and mounting brackets.

The forming process must be executed with precision, as any misalignment can lead to functional issues, such as improper flipping or mechanical failure. Quality control measures are typically integrated at this stage, where samples are tested for dimensional accuracy.

What Does the Assembly Process Entail?

Assembly is a critical phase where all components are brought together to create the final product. This includes the integration of the flipping mechanism, remote control unit, and electrical components like wiring and motors.

The assembly process may involve both manual labor and automated machinery, depending on the scale of production. Each assembly line is designed to optimize efficiency while maintaining high standards of craftsmanship.

To ensure reliability, each unit is tested for functionality before it leaves the assembly line. This includes checking the remote control operation, the mechanical flipping action, and overall durability under simulated conditions.

What Finishing Techniques Are Commonly Used?

The finishing stage involves surface treatments to enhance both aesthetics and performance. Common techniques include powder coating, anodizing, or galvanizing, which provide a protective layer against environmental factors like moisture and UV radiation.

The finishing process not only improves the product’s appearance but also extends its lifespan. Quality assurance checks at this stage often include visual inspections and adhesion tests to ensure that coatings are applied uniformly and effectively.

Illustrative image related to vehicle plate flipper

What Quality Assurance Practices Should B2B Buyers Consider?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that vehicle plate flippers meet both international and industry-specific standards. Understanding these practices can help B2B buyers make informed decisions when selecting suppliers.

Which International Standards Apply to Vehicle Plate Flippers?

For manufacturers aiming to compete in international markets, compliance with standards such as ISO 9001 is essential. This standard focuses on quality management systems and is widely recognized across industries.

Additionally, CE marking is crucial for products sold in the European market, indicating compliance with health, safety, and environmental protection standards. For buyers in the Middle East and Africa, suppliers should also be familiar with regional standards and certifications that may apply.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically segmented into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, periodic checks are conducted to monitor the quality of the work in progress. This includes checking dimensions, assembly accuracy, and functionality of the flipping mechanism.

-

Final Quality Control (FQC): Once the product is fully assembled, a comprehensive inspection is performed. This includes functional testing of the entire unit, ensuring that it operates as intended, and that all components are secure.

These checkpoints are essential for identifying defects early in the process, reducing waste, and ensuring that the final product adheres to quality standards.

Illustrative image related to vehicle plate flipper

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring the reliability of vehicle plate flippers. Here are several methods to achieve this:

What Role Do Audits and Reports Play in Quality Verification?

Conducting regular audits of potential suppliers can provide insight into their manufacturing practices and quality assurance measures. An audit may include reviewing documentation related to quality management systems, production processes, and compliance with international standards.

Buyers should request quality reports that detail the results of internal audits, quality control checks, and any corrective actions taken in response to identified issues. This transparency helps build trust and ensures that suppliers are committed to maintaining high-quality standards.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can further validate a supplier’s quality control processes. These independent organizations can conduct audits, perform product testing, and certify compliance with relevant standards.

Third-party inspections offer an unbiased assessment of the supplier’s capabilities, helping buyers mitigate risks associated with subpar products or manufacturing practices.

Illustrative image related to vehicle plate flipper

What Are the Unique Quality Control Considerations for International Buyers?

B2B buyers in regions such as Africa, South America, the Middle East, and Europe should be aware of specific quality control nuances when dealing with international suppliers.

How Do Regional Regulations Affect Quality Standards?

Each region may have different regulatory requirements impacting quality assurance practices. For instance, buyers in Europe must ensure that products comply with CE marking, while buyers in the Middle East might require adherence to specific local certifications.

Understanding these regional differences is crucial for ensuring that products not only meet the buyer’s expectations but also comply with local laws and regulations.

What Should Buyers Know About Supply Chain Transparency?

Finally, transparency in the supply chain is vital for maintaining quality. Buyers should seek suppliers who are open about their sourcing practices, manufacturing processes, and quality control measures. This transparency can significantly reduce the risk of encountering quality issues down the line.

In conclusion, understanding the manufacturing processes and quality assurance practices of vehicle plate flippers is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they partner with reliable suppliers who prioritize quality and compliance.

Illustrative image related to vehicle plate flipper

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vehicle plate flipper’

When sourcing vehicle plate flippers, it is essential to approach the process systematically to ensure you select the right product that meets your specific needs. This guide provides a step-by-step checklist designed for B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline the technical requirements for the vehicle plate flipper. Consider the dimensions, materials, and operational voltage.

– Key Considerations: Ensure compatibility with standard license plate sizes in your target market, such as 12” x 6” (305mm x 152mm), and evaluate the durability of materials, especially if the product will be used in varying weather conditions.

Step 2: Research Legal Compliance in Target Markets

Understand the legal status of vehicle plate flippers in your intended regions of sale. Regulations vary significantly, and some areas may have strict prohibitions against these devices.

– Important Details: Investigate any recent legislation affecting the use of plate flippers, especially in markets like the USA, where some states have enacted bans. This will help you avoid legal pitfalls and potential fines.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they meet industry standards and have a reliable track record. Request company profiles, case studies, and references from previous clients.

– Assessment Criteria: Look for suppliers who provide warranties and have experience in international shipping, especially to your target regions. It’s also beneficial to check customer reviews and feedback to gauge product quality and service reliability.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the vehicle plate flippers to evaluate their functionality and quality firsthand.

– Testing Focus: Assess the ease of installation, operational efficiency, and durability under various conditions. This step is crucial to ensure that the product performs as expected and meets customer satisfaction.

Step 5: Negotiate Pricing and Terms

Once you have identified suitable suppliers and tested their products, negotiate pricing and delivery terms. This is a critical step to ensure you achieve a competitive advantage in your market.

– Negotiation Points: Discuss bulk order discounts, payment terms, and shipping logistics. Ensure that all agreements are documented to avoid misunderstandings later.

Step 6: Verify After-Sales Support and Warranty

Confirm that the supplier offers robust after-sales support and clear warranty terms. This is vital for maintaining customer satisfaction and addressing any potential issues that may arise post-purchase.

– Support Evaluation: Look for suppliers who provide technical assistance and have a straightforward warranty process. A good support system can enhance your brand’s reputation and customer loyalty.

Step 7: Plan for Regulatory Changes

Stay informed about potential changes in regulations regarding vehicle plate flippers in your target markets. This will help you adapt your sourcing strategy proactively.

– Ongoing Monitoring: Establish a system for monitoring legal developments and industry trends. Engaging with industry associations can provide valuable insights and updates.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing vehicle plate flippers, ensuring compliance, quality, and competitiveness in their markets.

Comprehensive Cost and Pricing Analysis for vehicle plate flipper Sourcing

What Are the Key Cost Components of Vehicle Plate Flipper Manufacturing?

When sourcing vehicle plate flippers, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The quality of materials significantly impacts the cost. Typically, metal frames are preferred for durability and aesthetics, while electronic components (e.g., motors, control units) are vital for functionality. The use of high-grade materials can lead to a higher initial investment but often results in lower maintenance costs over time.

-

Labor: Labor costs vary based on the region of production. Countries with lower labor costs may offer more competitive pricing, but this can also affect the quality of workmanship. Skilled labor is necessary for assembly and quality control, influencing overall production costs.

-

Manufacturing Overhead: This includes utilities, facility costs, and indirect labor. Efficient manufacturing processes can reduce overhead costs, making it essential to assess potential suppliers’ operational efficiencies.

-

Tooling: Custom tooling for unique designs or specifications can be a significant upfront cost. Buyers should consider whether standard designs can meet their needs to avoid unnecessary expenses.

-

Quality Control (QC): Ensuring that products meet required standards incurs additional costs. Comprehensive QC processes can prevent defects and returns, ultimately saving money in the long run.

-

Logistics: Shipping costs, especially for international buyers, can be substantial. Factors such as distance, weight, and shipping method impact logistics costs. Understanding Incoterms is crucial for clarifying responsibilities and costs related to shipping.

-

Margin: Manufacturers typically add a margin to cover their costs and profit. This margin can vary widely depending on the supplier’s market positioning, brand reputation, and product uniqueness.

How Do Price Influencers Affect Vehicle Plate Flipper Costs?

Several factors can influence the pricing of vehicle plate flippers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounts. Buyers should negotiate volume pricing to lower per-unit costs. However, it’s essential to ensure that the order size aligns with demand to avoid excess inventory.

-

Specifications and Customization: Custom designs or features can increase costs. Buyers should weigh the benefits of customization against the additional expenses it incurs. Standardized options may be more cost-effective.

-

Materials and Quality Certifications: The use of certified materials (e.g., weather-resistant metals) adds to the cost but may be necessary for compliance with local regulations. Buyers should inquire about certifications relevant to their markets.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record, while new entrants may offer lower prices to gain market share. Assessing supplier stability and quality history is crucial.

-

Incoterms: Understanding Incoterms helps buyers clarify shipping responsibilities and costs. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can significantly impact total landed costs.

What Tips Can Help B2B Buyers Optimize Costs When Sourcing Vehicle Plate Flippers?

-

Negotiate Effectively: Utilize volume commitments and long-term partnerships to negotiate better pricing. Building relationships with suppliers can lead to favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, potential defects, and logistics costs over the product’s lifecycle. A higher upfront cost may be justified by lower long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can affect total costs. Researching local regulations in target markets (like Nigeria or Saudi Arabia) can provide insights into additional costs.

-

Evaluate Supplier Locations: Sourcing from nearby suppliers may reduce shipping costs and lead times, enhancing responsiveness to market changes.

-

Stay Informed on Market Trends: Keeping abreast of industry developments can help buyers anticipate price changes and better time their purchases.

Disclaimer on Pricing

Prices for vehicle plate flippers can fluctuate based on market conditions, supplier pricing strategies, and raw material costs. The prices discussed herein are indicative and should be confirmed with suppliers for accuracy in specific negotiations.

Alternatives Analysis: Comparing vehicle plate flipper With Other Solutions

Introduction: Exploring Alternatives to Vehicle Plate Flippers

In the automotive industry, vehicle plate flippers are gaining traction for their ability to provide aesthetic flexibility and convenience for car enthusiasts and event participants. However, various alternative solutions exist that cater to similar needs, each with its unique advantages and drawbacks. This section aims to compare the vehicle plate flipper against alternative technologies, helping B2B buyers make informed decisions based on performance, cost, implementation ease, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Vehicle Plate Flipper | Alternative 1: License Plate Covers | Alternative 2: Digital License Plate |

|---|---|---|---|

| Performance | Instant flipping; aesthetic enhancement | Obscures plate visibility; static | Dynamic display; customizable |

| Cost | $200 – $300 USD | $20 – $100 USD | $300 – $600 USD |

| Ease of Implementation | Moderate (requires installation) | Easy (self-adhesive options available) | Moderate to high (wiring required) |

| Maintenance | Low (durability concerns in harsh conditions) | Low (replaceable if damaged) | Medium (software updates required) |

| Best Use Case | Car shows, photo shoots | Everyday use, aesthetic customization | Fleet management, advanced tracking |

Detailed Breakdown of Alternatives

License Plate Covers

License plate covers serve as a straightforward alternative to vehicle plate flippers. They are designed to obscure the license plate’s visibility from certain angles, offering a degree of customization. The primary advantages include low cost and ease of installation, making them accessible for everyday users. However, their static nature means they do not offer the flexibility of switching plates for different occasions. Furthermore, many jurisdictions consider these covers illegal if they obstruct plate visibility, which could lead to legal complications.

Digital License Plate

Digital license plates represent a high-tech alternative, featuring customizable displays that can show various messages and vehicle information. While they provide significant aesthetic and functional advantages, such as real-time tracking and notifications, the cost and installation complexity are higher. Digital plates require wiring into the vehicle’s electrical system, which may necessitate professional installation. Maintenance is also a consideration, as updates and potential repairs can add to ongoing costs. They are particularly beneficial for fleet management, where tracking and communication are crucial.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate solution for vehicle plate management, B2B buyers should carefully assess their specific requirements and operational contexts. Vehicle plate flippers offer unique advantages for events and aesthetic enhancements, while license plate covers and digital license plates provide alternatives that may better suit everyday use or advanced fleet management. Evaluating factors such as budget, ease of installation, and intended use will empower buyers to choose a solution that aligns with their operational goals and legal considerations in their respective markets.

Essential Technical Properties and Trade Terminology for vehicle plate flipper

What are the Key Technical Properties of Vehicle Plate Flippers?

Understanding the technical specifications of vehicle plate flippers is crucial for B2B buyers, as these details can significantly impact product performance, compatibility, and compliance with local regulations. Here are some essential properties to consider:

1. Material Composition

Vehicle plate flippers are typically made from high-grade metal, which ensures durability and resistance to environmental factors such as rain, snow, and sunlight. The choice of material affects the product’s longevity and ability to withstand various weather conditions, which is particularly important for buyers in regions with extreme climates.

2. Voltage and Power Specifications

Most vehicle plate flippers operate on a DC 12V power supply, drawing a power rate of around 2W. This specification is critical because it determines compatibility with standard vehicle electrical systems. Buyers should ensure that the flipper’s voltage requirements align with their vehicle models to avoid installation issues.

3. Control Distance

The effective control distance for these devices is typically around 50 meters. This specification is essential for users who may require remote operation from a distance, such as during car shows or exhibitions. A longer control range enhances usability and convenience for the end user.

Illustrative image related to vehicle plate flipper

4. Plate Compatibility

Vehicle plate flippers are designed to accommodate standard plate sizes, commonly 12” x 6” (305mm x 152mm). Compatibility with various international plate sizes is vital for B2B buyers operating in different markets, ensuring that the product meets regional licensing requirements without the need for modifications.

5. Installation Requirements

Buyers should consider the installation complexity of vehicle plate flippers. Some models may require specific mounting hardware or slight modifications depending on vehicle design. Clear installation guidelines can facilitate smoother integration and reduce the need for technical support.

6. Warranty and Compliance

A standard warranty, often around one year, provides buyers with assurance regarding product quality and performance. Additionally, understanding compliance with local laws is crucial, as the use of plate flippers may be restricted in certain jurisdictions. Buyers must be informed about the legal implications of using these devices in their respective regions.

Which Trade Terminology Should B2B Buyers Understand?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some key terms relevant to vehicle plate flippers:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of vehicle plate flippers, understanding OEM relationships can be crucial for buyers looking for quality assurance and compatibility with specific vehicle brands.

Illustrative image related to vehicle plate flipper

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. For B2B buyers, knowing the MOQ can help in budget planning and inventory management, particularly when entering new markets or testing product demand.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to suppliers to request pricing and terms for specific products. For vehicle plate flippers, submitting an RFQ can facilitate competitive pricing and help in assessing supplier capabilities.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to clarify shipping responsibilities, cost allocations, and risk management when importing vehicle plate flippers.

Illustrative image related to vehicle plate flipper

5. SKU (Stock Keeping Unit)

SKU is a unique identifier for a specific product, which helps in inventory management. For businesses dealing with vehicle plate flippers, proper SKU management is vital for tracking sales and managing stock levels efficiently.

6. Lead Time

Lead time refers to the time taken from placing an order to the product’s delivery. Understanding lead times for vehicle plate flippers can help businesses plan their inventory and ensure timely availability for customers, particularly in competitive markets.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they select the right vehicle plate flipper products that meet their operational needs and compliance requirements.

Illustrative image related to vehicle plate flipper

Navigating Market Dynamics and Sourcing Trends in the vehicle plate flipper Sector

What Are the Key Market Dynamics and Trends Impacting the Vehicle Plate Flipper Sector?

The global vehicle plate flipper market is witnessing significant growth driven by increasing demand for vehicle customization, enhanced aesthetics, and the growing popularity of automotive events. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly interested in these products as they enhance vehicle appeal while also providing functional benefits. In particular, the versatility of plate flippers, which can accommodate various license plate sizes and styles, makes them attractive for international markets.

Emerging trends in the sector include the integration of advanced technology, such as remote control systems that allow for seamless operation. The rise of e-commerce platforms has also transformed sourcing practices, enabling B2B buyers to access a wider range of products from international suppliers. Furthermore, the trend towards online customization tools allows consumers to visualize their vehicle modifications before purchase, influencing sourcing decisions. However, regulatory challenges are emerging, as some jurisdictions impose restrictions on the use of these devices due to concerns over their potential misuse in evading law enforcement. This regulatory landscape creates both challenges and opportunities for suppliers looking to navigate compliance while meeting customer demand.

How Is Sustainability and Ethical Sourcing Addressed in the Vehicle Plate Flipper Industry?

Sustainability has become a critical focus in the vehicle plate flipper sector, driven by increasing awareness of environmental impacts and the importance of ethical supply chains. B2B buyers are increasingly looking for suppliers who prioritize eco-friendly materials and manufacturing processes. The use of recycled metals and environmentally friendly coatings can significantly reduce the carbon footprint associated with producing plate flippers, appealing to environmentally conscious businesses.

Moreover, ethical sourcing practices that ensure fair labor conditions and responsible production are gaining traction among international buyers. Suppliers who can demonstrate commitment to sustainability through certifications or environmentally friendly practices are likely to gain a competitive edge. Additionally, transparency in the supply chain, including the ability to trace materials back to their sources, is becoming a key factor in procurement decisions. As regulatory pressures around sustainability increase, businesses in this sector must adapt to align with global standards and meet the expectations of their B2B partners.

How Has the Vehicle Plate Flipper Market Evolved Over Time?

The vehicle plate flipper market has evolved significantly over the years, transitioning from simple mechanical devices to sophisticated electronic systems. Initially, these products were primarily used for aesthetic purposes at car shows and events, allowing enthusiasts to showcase custom plates without the constraints of legal requirements. As technology advanced, remote-controlled plate flippers emerged, offering greater convenience and functionality.

Illustrative image related to vehicle plate flipper

However, the rise in their use for illicit purposes—such as evading tolls and law enforcement—has prompted regulatory scrutiny in several regions, particularly in the United States. Legislative measures targeting the sale and use of these devices are becoming more common, impacting market dynamics and sourcing strategies. As a result, manufacturers and suppliers are adapting their offerings to comply with evolving laws while continuing to meet the needs of legitimate customers who seek to enhance their vehicles. This evolution reflects the broader trends in the automotive accessory market, where innovation and compliance must go hand in hand.

Frequently Asked Questions (FAQs) for B2B Buyers of vehicle plate flipper

-

How do I choose the right vehicle plate flipper for my market?

Selecting the right vehicle plate flipper involves understanding local regulations and customer preferences. Research the legality of plate flippers in your target countries, as some regions impose strict restrictions. Consider the dimensions and compatibility with standard license plates in your area. Engaging with local automotive enthusiasts and businesses can provide insights into popular styles and functionalities. Additionally, analyze competitors to identify unique selling points that can differentiate your offering. -

What are the common uses for vehicle plate flippers in different markets?

Vehicle plate flippers are primarily used for aesthetic purposes at car shows, allowing users to switch between custom plates seamlessly. In some regions, they are utilized for practical applications, such as displaying promotional plates for businesses. However, it’s essential to note that in certain markets, they may be misused to evade law enforcement. Understanding these varied uses can help you tailor your marketing strategies and product features to align with legitimate customer needs. -

What customization options are available for vehicle plate flippers?

Many suppliers offer customization options, including design, color, and branding opportunities. Customization can enhance your product’s appeal and allow you to target specific demographics effectively. When sourcing, inquire about available modifications, such as remote control designs or frame materials. Collaborating with manufacturers who provide tailored solutions can also help you meet unique market demands, ensuring you stand out from competitors. -

What is the minimum order quantity (MOQ) for vehicle plate flippers?

Minimum order quantities can vary significantly between manufacturers. Generally, MOQs may range from 50 to 500 units, depending on the supplier’s production capabilities and your customization requests. It’s advisable to negotiate terms to find a balance that meets your budget and inventory needs. Some manufacturers might offer lower MOQs for first-time buyers or sample orders, allowing you to test the market before committing to larger quantities. -

What payment terms should I expect when sourcing vehicle plate flippers?

Payment terms can differ among suppliers and may include options such as upfront payment, net 30, or letter of credit arrangements. Commonly, B2B transactions require a deposit (often 30% to 50%) before production begins, with the balance due upon shipment or delivery. Always clarify payment methods accepted (e.g., bank transfer, credit card) and ensure all terms are documented in your contract to avoid misunderstandings. -

How can I ensure quality assurance (QA) for vehicle plate flippers?

To maintain quality standards, collaborate with manufacturers that adhere to international quality certifications, such as ISO 9001. Request samples before placing large orders to assess material quality and functionality. Establish a QA process that includes regular inspections during production and prior to shipment. Additionally, consider third-party inspection services to verify compliance with safety and performance standards, particularly if exporting to regions with strict regulations. -

What logistics considerations should I keep in mind when importing vehicle plate flippers?

Logistics play a crucial role in the successful importation of vehicle plate flippers. Evaluate shipping options based on cost, speed, and reliability, considering both air and sea freight. Familiarize yourself with import duties and taxes in your target market, as these can significantly impact your overall costs. Partnering with experienced freight forwarders can streamline the process, ensuring compliance with local customs regulations and timely delivery. -

How do I vet suppliers for vehicle plate flippers effectively?

Vetting suppliers involves assessing their credibility, production capacity, and compliance with industry standards. Start by reviewing their business history, client testimonials, and product certifications. Engage in direct communication to gauge their responsiveness and willingness to accommodate your specific needs. Additionally, consider visiting their manufacturing facilities, if possible, to observe their production processes firsthand. Utilizing platforms that offer supplier ratings and reviews can also enhance your selection process.

Top 6 Vehicle Plate Flipper Manufacturers & Suppliers List

1. 510 Auto Group – License Plate Flippers

Domain: 510autogroup.com

Registered: 2017 (8 years)

Introduction: License Plate Flippers (USA Style) | Remote Plate Switcher

2. PlateVanish – Stealth License Plate Flipper Kit

Domain: platevanish.com

Registered: 2023 (2 years)

Introduction: Stealth License Plate Flipper Double Plate Kit (Front & Rear USA/Canada)\n- Regular Price: $210.00 USD\n- Sale Price: $169.99 USD\n- Warranty: 1-year warranty from the date of receipt\n- Material: High-grade Iron with anti-rust properties\n- Input Voltage: DC 12V\n- Power Consumption: 2W\n- Control Distance: 50 meters\n- Frame Dimensions: 190.5mm x 340mm (7.5″ x 13.4″), depth: 25mm (1″)\n- Designe…

3. Stellantis – Deployable Front License Plate Bracket

Domain: americancarsandracing.com

Registered: 2021 (4 years)

Introduction: Stellantis has applied for a patent on a “Deployable Front License Plate Bracket” designed for Jeep SUVs. The feature includes a telescoping arm that can extend the license plate away from the body, flip it to a horizontal position, and retract it into a slot in the front fascia. This design aims to improve airflow and cooling by preventing the front license plate from blocking air intake, which c…

4. eBay – Plate Flipper Products

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Plate Flipper products available on eBay include various types such as license plate flippers, body kit flippers, and flipper mounts. Prices range from approximately ILS 20.00 to ILS 2,726.22, with options for both new and pre-owned items. Delivery fees vary based on location, with some items offering free returns. Notable listings include a brand new license plate flipper for ILS 217.77, a pre-ow…

5. Landline Media – License Plate Flippers

Domain: landline.media

Introduction: License plate flippers are manual, electric, or mechanical devices installed on vehicles to switch between license plates or obscure them. They are used to avoid tolls, evade law enforcement, and engage in criminal activities. Five states have outlawed these devices, including Florida, Tennessee, Pennsylvania, Texas, and Washington. Florida’s new law makes it a misdemeanor to manufacture, purchase…

6. Nissan – Hinged License Plate Bracket

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Older Nissan vehicles often come with a rear license plate mounted on a hinged bracket, allowing the plate to fold down. This design was intended to facilitate the removal of the rear bumper without needing to detach the license plate. However, police may mistake this feature for an illegal plate flipper, leading to fines for owners who explain that it is a factory-installed feature.

Strategic Sourcing Conclusion and Outlook for vehicle plate flipper

As the demand for vehicle plate flippers continues to rise, international B2B buyers must navigate a complex landscape marked by both opportunities and challenges. Strategic sourcing plays a pivotal role in ensuring that businesses acquire high-quality products while adhering to regional regulations and market trends. Buyers should prioritize suppliers who demonstrate compliance with local laws, particularly given the increasing scrutiny on the use of such devices in various jurisdictions.

By leveraging strategic sourcing, businesses can not only enhance their product offerings but also build a reputation for reliability and integrity in a competitive market. This is particularly crucial in regions like Africa, South America, the Middle East, and Europe, where the regulatory environment around vehicle modifications is evolving.

Looking ahead, international buyers are encouraged to engage with reputable manufacturers and distributors who can provide both innovative solutions and the necessary support for navigating compliance issues. As consumer preferences shift towards customization and personalization, investing in quality vehicle plate flippers can position your business for long-term success. Explore your sourcing options today to stay ahead in this dynamic industry.

Illustrative image related to vehicle plate flipper

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.