The Definitive Guide to Paper Burn Barrel: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for paper burn barrel

In the evolving landscape of waste management, sourcing effective solutions like paper burn barrels has become a pressing challenge for businesses worldwide. As organizations grapple with the secure disposal of sensitive documents, the demand for reliable and efficient burning systems has surged, especially in regions like Africa, South America, the Middle East, and Europe. This comprehensive guide delves into the multifaceted world of paper burn barrels, exploring their various types, applications, and the pivotal role they play in ensuring compliance with environmental regulations.

Within these pages, B2B buyers will discover essential insights into the nuances of selecting the right burn barrel for their specific needs. From understanding the technical specifications that enhance burning efficiency to evaluating suppliers based on reliability and cost-effectiveness, this guide aims to equip decision-makers with the knowledge necessary for informed purchasing. By addressing critical factors such as regulatory compliance, operational efficiency, and supplier vetting processes, we empower businesses to make strategic choices that align with their sustainability goals.

Whether you are a facility manager in Saudi Arabia seeking to optimize waste disposal or a procurement officer in Nigeria looking for cost-effective solutions, this guide serves as your roadmap to navigating the global market for paper burn barrels. Embrace the opportunity to enhance your waste management practices while ensuring the security of your confidential information.

Understanding paper burn barrel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Steel Barrel | 55-gallon capacity, durable steel construction | Small to medium businesses, offices | Pros: Cost-effective, easy to use. Cons: Limited airflow can slow burning. |

| Enhanced Airflow Barrel | Designed with ventilation holes for airflow | Warehouses, large offices | Pros: Faster burning, reduces smoke. Cons: Higher initial investment. |

| Mobile Incinerator | Trailer-mounted, equipped with forced air | Industrial sectors, waste management | Pros: High capacity, efficient for large volumes. Cons: Requires transportation and setup. |

| Shredding Burn Unit | Combines shredding and burning capabilities | Data destruction services, banks | Pros: Ensures complete destruction, secure. Cons: More complex, higher maintenance. |

| Eco-Friendly Incinerator | Uses advanced technology to minimize emissions | Corporations focused on sustainability | Pros: Environmentally friendly, compliant with regulations. Cons: Higher cost, may require special permits. |

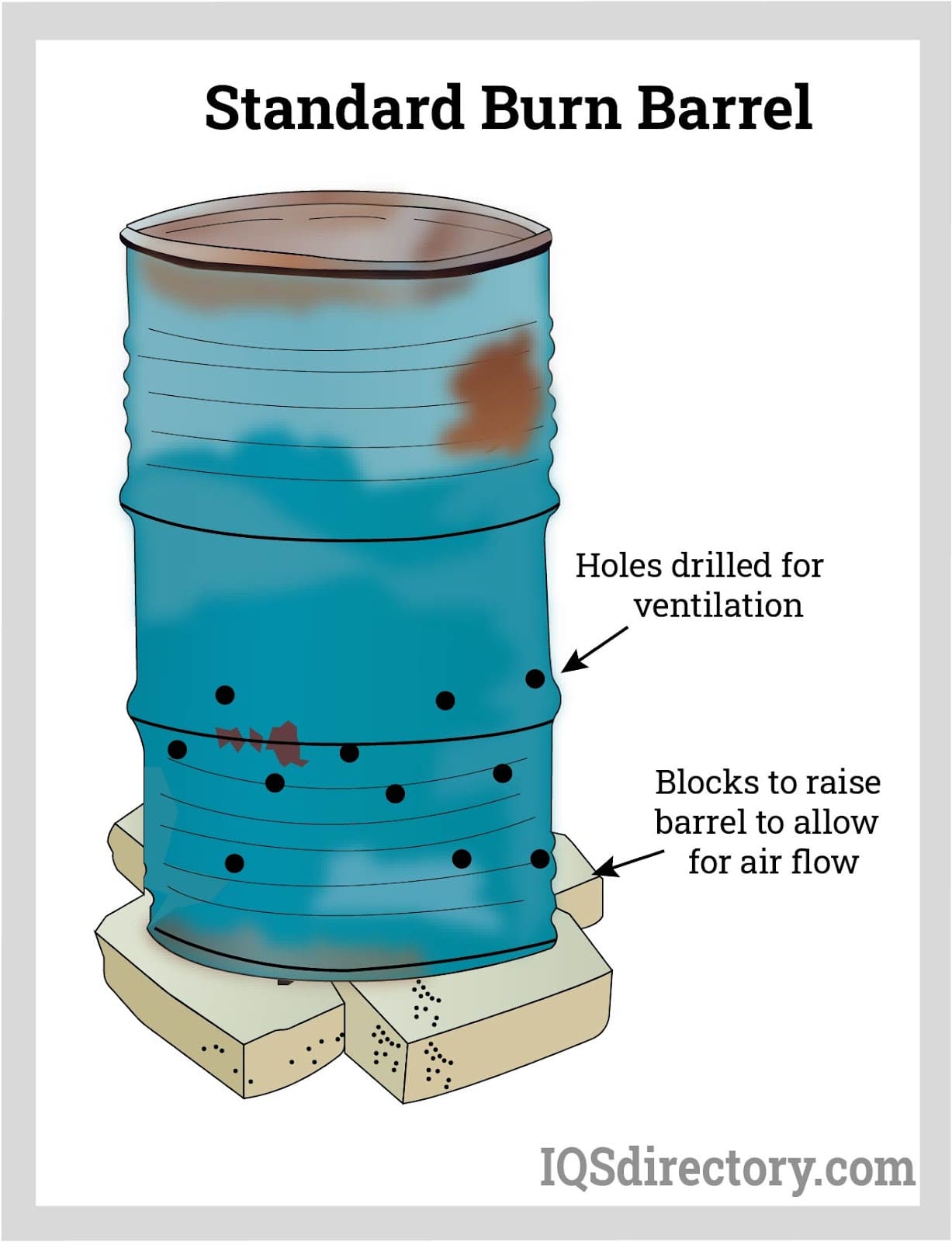

What Are the Characteristics of a Standard Steel Barrel?

The standard steel burn barrel is a widely recognized option, typically featuring a 55-gallon capacity made from durable steel. This type is ideal for small to medium businesses looking for a straightforward solution to dispose of paper waste. However, its design may restrict airflow, leading to slower burning rates. Buyers should consider the ease of use and affordability, but also be aware of the potential need for additional airflow enhancements to optimize performance.

How Does an Enhanced Airflow Barrel Improve Burning Efficiency?

Enhanced airflow barrels are designed with strategically placed ventilation holes that facilitate better air circulation, promoting faster combustion of paper waste. These barrels are particularly suitable for larger offices and warehouses where higher volumes of waste are generated. While they offer the advantage of quicker burning and reduced smoke output, the initial investment is typically higher than standard barrels. Businesses prioritizing efficiency in waste disposal may find this option appealing.

What Are the Benefits of a Mobile Incinerator for Large-Scale Waste?

Mobile incinerators are trailer-mounted units equipped with forced air systems that allow for the efficient burning of large quantities of paper waste. This type is particularly beneficial for industrial sectors and waste management services that require high-capacity solutions. While they provide the advantage of mobility and efficiency, buyers must consider the logistics of transportation and setup, which can add complexity to their waste management strategy.

Why Choose a Shredding Burn Unit for Secure Document Disposal?

Shredding burn units combine the processes of shredding and burning, making them ideal for businesses such as banks and data destruction services that require secure disposal of sensitive documents. This type ensures complete destruction of paper materials, significantly reducing the risk of data breaches. However, these units are more complex and may involve higher maintenance costs. B2B buyers should weigh the importance of security against the operational challenges of these systems.

What Makes an Eco-Friendly Incinerator a Sustainable Choice?

Eco-friendly incinerators utilize advanced technology to minimize emissions and comply with environmental regulations. These units are increasingly favored by corporations that are committed to sustainability and reducing their carbon footprint. While they offer significant benefits in terms of environmental impact, the higher initial cost and potential requirement for special permits can be a consideration for buyers. Organizations focused on corporate responsibility may find this type aligns well with their values and operational goals.

Key Industrial Applications of paper burn barrel

| Industry/Sector | Specific Application of paper burn barrel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Waste Management | Disposal of confidential documents and paper waste | Ensures secure destruction of sensitive information | Compliance with local regulations and environmental standards |

| Healthcare | Destruction of patient records and medical documents | Protects patient privacy and meets regulatory requirements | Need for fire safety features and proper ventilation |

| Financial Services | Secure disposal of financial records and statements | Mitigates risk of data breaches and fraud | Sourcing from certified manufacturers for quality assurance |

| Construction & Engineering | Disposal of construction site paperwork and blueprints | Streamlines site management and compliance | Durability and capacity to handle large volumes of paper |

| Education | Disposal of old student records and administrative paperwork | Facilitates compliance with data protection laws | Consideration for size and ease of use in school settings |

How is the Paper Burn Barrel Used in Waste Management?

In the waste management sector, paper burn barrels are instrumental in the secure disposal of confidential documents and paper waste. These barrels allow companies to incinerate sensitive materials on-site, ensuring that information does not fall into the wrong hands. For international buyers, especially in regions like Africa and South America, compliance with local environmental regulations is crucial. Therefore, sourcing barrels that meet these standards can enhance operational efficiency while minimizing legal risks.

What Role Does a Paper Burn Barrel Play in Healthcare?

Healthcare facilities often generate a significant amount of paper waste, including patient records and medical documents. Utilizing a paper burn barrel enables these institutions to securely destroy sensitive information, thus protecting patient privacy and adhering to strict regulatory requirements. Buyers in the Middle East should consider burn barrels equipped with fire safety features and proper ventilation systems to ensure compliance with health and safety regulations in their regions.

Why is a Paper Burn Barrel Essential for Financial Services?

In the financial services sector, the secure disposal of documents such as client statements and financial records is paramount. A paper burn barrel provides a reliable method for mitigating the risks associated with data breaches and fraud. When sourcing these products, companies should prioritize barrels from certified manufacturers to ensure quality and compliance with industry standards, particularly in Europe where data protection laws are stringent.

How Can Construction and Engineering Industries Benefit from Paper Burn Barrels?

Construction and engineering firms often deal with a large volume of paperwork, including contracts and blueprints, which must be disposed of securely. A paper burn barrel streamlines the disposal process, ensuring compliance with waste management regulations while keeping the site organized. Buyers in this sector should consider the durability and capacity of the barrels to handle substantial amounts of paper waste efficiently.

What is the Importance of Paper Burn Barrels in Education?

Educational institutions frequently accumulate outdated student records and administrative paperwork that require secure disposal. By employing a paper burn barrel, schools can effectively manage their data protection obligations while maintaining a clutter-free environment. When sourcing for educational use, considerations should include the size of the barrel and its ease of use to accommodate various administrative needs across different school settings.

3 Common User Pain Points for ‘paper burn barrel’ & Their Solutions

Scenario 1: Inefficient Burning Process for Large Quantities of Paper

The Problem: Many businesses, especially in sectors like finance, healthcare, and legal, often need to dispose of sensitive documents safely. When using a paper burn barrel, buyers quickly discover that burning large volumes of stacked papers can be inefficient. Papers tend to smolder rather than burn completely, requiring constant attention and frequent stirring to achieve proper combustion. This not only wastes time but can also pose a risk of non-compliance with data protection regulations if documents are not destroyed thoroughly.

The Solution: To improve the efficiency of burning operations, businesses should invest in burn barrels designed with airflow optimization features. Look for models that include a double-walled structure or strategically placed air holes to enhance oxygen flow, facilitating a hotter and more complete burn. Prior to disposal, shredding or crumpling papers can also help; this increases surface area and allows for better combustion. Additionally, consider using a commercial-grade paper burn barrel with a forced air system, which can significantly reduce burn time and enhance safety by minimizing smoke emissions. These barrels are often equipped with a fan or blower to maintain high temperatures, ensuring that sensitive documents are destroyed in compliance with security standards.

Scenario 2: Environmental Concerns and Compliance Issues

The Problem: Environmental regulations regarding open burning vary significantly across regions, making it challenging for B2B buyers to ensure compliance while disposing of paper waste. In some areas, burning paper can lead to air quality issues or violations of local laws, resulting in hefty fines and damage to a company’s reputation. Buyers may feel overwhelmed trying to navigate these regulations while still needing to manage their waste efficiently.

The Solution: Businesses should first consult local environmental agencies to understand the specific regulations related to paper burning in their area. Seeking out burn barrels that are EPA-certified or compliant with local laws can provide peace of mind. Additionally, consider implementing a waste management plan that includes alternative disposal methods, such as partnering with certified shredding services that offer environmentally friendly destruction. These services can often provide on-site shredding, ensuring compliance while allowing companies to maintain security. Leveraging these partnerships not only helps mitigate environmental impact but also enhances corporate social responsibility initiatives.

Scenario 3: Safety Risks Associated with Manual Burning

The Problem: Burning paper can pose several safety risks, particularly in industrial or commercial settings where flammable materials are present. Without proper protocols, there is a risk of fire spreading beyond the burn barrel, leading to property damage or personal injury. B2B buyers often struggle with finding effective ways to ensure safe operations while managing paper disposal.

The Solution: To enhance safety during the burning process, it’s crucial to establish clear safety protocols and utilize the right equipment. Invest in burn barrels made from fire-resistant materials and ensure they are placed in a controlled environment away from flammable substances. Implementing a designated burning area with proper clearance can significantly reduce fire hazards. Additionally, training employees on fire safety procedures, including the use of fire extinguishers and emergency protocols, is essential. Consider integrating technology solutions like temperature sensors or automated ignition systems that can help monitor conditions and minimize manual involvement. This not only protects staff but also safeguards the organization’s assets, aligning with best practices in workplace safety.

Strategic Material Selection Guide for paper burn barrel

When selecting materials for paper burn barrels, it is crucial for B2B buyers to consider the specific properties, advantages, and limitations of each material. The choice of material can significantly impact the performance, durability, and compliance of the burn barrel, especially in diverse international markets such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Steel for Paper Burn Barrels?

Steel is one of the most common materials used in the construction of paper burn barrels. Its high-temperature resistance makes it suitable for burning operations, as it can withstand the intense heat generated during combustion. Additionally, steel has good structural integrity, which allows it to maintain its shape and functionality over time.

Pros and Cons of Steel

The primary advantage of steel is its durability; it can last for many years with proper maintenance. However, it is susceptible to corrosion if not adequately treated or coated, which can lead to premature failure. The manufacturing complexity is moderate, as steel barrels require welding and finishing processes. For international buyers, compliance with standards such as ASTM A36 for structural steel is essential, especially in regions where regulations are stringent.

How Does Aluminum Compare as a Material for Paper Burn Barrels?

Aluminum is another viable option for burn barrels due to its lightweight nature and excellent corrosion resistance. It can withstand high temperatures, albeit not as effectively as steel, making it suitable for less intense burning applications.

Pros and Cons of Aluminum

The key advantage of aluminum is its resistance to rust, which is particularly beneficial in humid climates or areas with high rainfall. However, its lower melting point compared to steel can be a limitation in high-temperature applications. The cost of aluminum is generally higher than that of steel, which may be a consideration for budget-conscious buyers. Buyers in regions like Saudi Arabia or Nigeria should ensure compliance with local standards regarding aluminum products.

What Role Does Stainless Steel Play in Paper Burn Barrel Manufacturing?

Stainless steel, known for its exceptional corrosion resistance and aesthetic appeal, is an excellent choice for burn barrels that require both durability and a clean appearance. Its ability to withstand high temperatures without degrading makes it suitable for intensive burning operations.

Pros and Cons of Stainless Steel

The primary advantage of stainless steel is its longevity and low maintenance requirements, as it does not rust or corrode easily. However, it is significantly more expensive than both carbon steel and aluminum, which can be a deterrent for some buyers. Furthermore, the manufacturing process is more complex due to the need for specialized welding techniques. Buyers in Europe may prefer stainless steel due to its compliance with EU regulations regarding environmental safety.

Are Composite Materials a Viable Option for Paper Burn Barrels?

Composite materials, such as fiberglass or reinforced plastics, are increasingly being explored for burn barrel applications. These materials offer a unique combination of lightweight properties and resistance to corrosion.

Pros and Cons of Composite Materials

The main advantage of composites is their resistance to chemical degradation and low weight, which facilitates easier transport and handling. However, they may not withstand the same high temperatures as metals, limiting their application in more intense burning scenarios. The cost of composites can vary widely, but they are often more expensive than traditional materials like steel. International buyers should consider local regulations regarding the use of composite materials in waste management.

Summary of Material Selection for Paper Burn Barrels

| Material | Typical Use Case for paper burn barrel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General burning applications | High durability and temperature resistance | Susceptible to corrosion | Medium |

| Aluminum | Lightweight burning needs | Excellent corrosion resistance | Lower melting point | High |

| Stainless Steel | Intensive burning operations | Long-lasting and low maintenance | Higher cost and complex manufacturing | High |

| Composite | Lightweight and corrosion-resistant use | Chemical resistance and low weight | Limited high-temperature resistance | Medium to High |

In conclusion, the selection of materials for paper burn barrels is critical for ensuring compliance, durability, and performance. Understanding the unique properties and market requirements will enable international buyers to make informed decisions that align with their operational needs and regulatory standards.

In-depth Look: Manufacturing Processes and Quality Assurance for paper burn barrel

What Are the Key Manufacturing Processes for Paper Burn Barrels?

Manufacturing paper burn barrels involves several critical stages that ensure the final product meets safety and performance standards. The primary stages of manufacturing include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Paper Burn Barrels?

The manufacturing process begins with selecting the right materials, typically high-quality steel or heavy-duty galvanized metal. The choice of material is essential as it directly impacts the durability and heat resistance of the burn barrel. Once the materials are sourced, they undergo a thorough inspection to ensure they meet the specified standards for thickness and corrosion resistance.

After inspection, the materials are cut into appropriate sizes for the barrel components. This process often employs advanced cutting techniques such as laser cutting or plasma cutting to achieve precise dimensions. Additionally, the edges are deburred to eliminate sharp edges that could pose safety risks during handling.

Illustrative image related to paper burn barrel

What Forming Techniques Are Used in Burn Barrel Production?

Forming is the next stage, where the cut metal sheets are shaped into the cylindrical form of the burn barrel. This is usually achieved through processes like rolling and welding. The rolling process involves bending the metal sheets into a cylindrical shape, which is then welded to create a seamless barrel.

Welding techniques may include MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding, both of which provide strong joints capable of withstanding high temperatures. Quality welds are crucial for ensuring the structural integrity of the barrel, particularly under the stress of high heat during operation.

How Are Paper Burn Barrels Assembled?

Once the individual components are formed, assembly begins. This includes attaching any necessary features such as air holes, lids, and handles. Air holes are strategically placed to facilitate airflow, which enhances combustion efficiency and minimizes smoke production.

During assembly, the manufacturer ensures that all components fit snugly and securely, which is vital for both safety and performance. Any additional features, such as protective coatings or insulation, may also be applied at this stage to enhance durability and heat resistance.

What Finishing Processes Are Essential for Quality?

The finishing process is crucial for enhancing the appearance and longevity of the burn barrel. Common finishing techniques include powder coating or galvanizing. Powder coating provides a protective layer that resists corrosion, while galvanizing offers a zinc coating that protects against rust.

After finishing, the barrels undergo a final inspection to ensure that the surface treatment is uniform and that there are no defects. This inspection is essential for meeting international standards and ensuring the product’s longevity under various environmental conditions.

What Quality Assurance Measures Are Implemented in Burn Barrel Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of paper burn barrels, ensuring that products meet established standards and customer expectations. Key quality assurance measures include adherence to international standards such as ISO 9001 and industry-specific certifications like CE and API.

Which International Standards Are Relevant for Burn Barrel Manufacturing?

ISO 9001 is a widely recognized standard that sets out the criteria for a quality management system. It focuses on continuous improvement and customer satisfaction, making it essential for manufacturers looking to export products internationally. Compliance with CE marking indicates that the product meets EU safety, health, and environmental protection requirements, which is crucial for buyers in Europe.

API (American Petroleum Institute) standards may also be relevant, particularly for manufacturers targeting sectors that require high-temperature applications. Compliance with these standards demonstrates a commitment to quality and safety, which can significantly influence purchasing decisions among B2B buyers.

What Are the Key Quality Control Checkpoints in Production?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure product integrity. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Regular inspections during the manufacturing process assess whether production is adhering to established quality standards.

- Final Quality Control (FQC): A comprehensive assessment of the finished product ensures that all specifications have been met before shipment.

What Testing Methods Are Commonly Used for Paper Burn Barrels?

Several testing methods are employed to validate the quality and performance of paper burn barrels. These include:

- Pressure Testing: Ensures that the barrel can withstand high internal pressures without failure.

- Heat Resistance Testing: Assesses the barrel’s ability to endure high temperatures during operation.

- Corrosion Testing: Evaluates the effectiveness of protective coatings and the material’s resistance to rust and degradation over time.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Buyers can adopt several strategies:

- Supplier Audits: Conducting regular audits of manufacturing facilities can provide insights into the supplier’s adherence to quality standards.

- Quality Reports: Requesting detailed quality reports can help buyers assess the supplier’s performance in meeting quality benchmarks over time.

- Third-Party Inspections: Engaging independent inspectors to evaluate product quality before shipment can add an extra layer of assurance.

What Are the QC and Certification Nuances for International Buyers?

International buyers must navigate various regulations and standards that may differ by region. Understanding local regulations regarding product safety and environmental compliance is crucial. Additionally, buyers should ensure that suppliers are familiar with export requirements and can provide necessary documentation to facilitate smooth transactions across borders.

In conclusion, the manufacturing processes and quality assurance measures for paper burn barrels are complex but vital for ensuring product reliability and safety. By understanding these processes and implementing thorough verification strategies, B2B buyers can make informed purchasing decisions that align with their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘paper burn barrel’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure paper burn barrels, which are essential for efficient and environmentally responsible disposal of confidential documents. By following these steps, you can ensure that you select a high-quality product that meets your operational needs and complies with local regulations.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in the sourcing process. Consider the size, material, and design of the burn barrel, as these factors will impact its efficiency and safety. For instance, a barrel made from heavy-gauge steel will be more durable and able to withstand high temperatures compared to lighter alternatives.

Step 2: Research Local Regulations

Understanding local laws and regulations regarding burning materials is crucial. Different regions may have specific guidelines governing the use of burn barrels, especially concerning emissions and safety. Ensure you have the necessary permits and comply with environmental standards to avoid legal issues.

Illustrative image related to paper burn barrel

Step 3: Evaluate Potential Suppliers

Before making a purchase, it’s important to thoroughly vet potential suppliers. Request detailed company profiles, product specifications, and customer references. Look for suppliers with a proven track record in your region, as local expertise can be invaluable in navigating regulatory requirements.

- Check for Compliance: Ensure that the supplier adheres to local and international safety standards.

- Assess Reputation: Read reviews and testimonials from other businesses in similar sectors.

Step 4: Request Samples or Prototypes

If possible, request samples or prototypes of the burn barrels you are considering. This allows you to evaluate the quality and functionality of the products before making a bulk purchase. Assess factors such as airflow design, ease of use, and overall build quality.

Step 5: Negotiate Pricing and Terms

Once you have identified suitable suppliers, initiate negotiations on pricing, delivery timelines, and payment terms. Be transparent about your budget and expectations to foster a mutually beneficial agreement. Also, inquire about bulk discounts or long-term contracts that can reduce costs.

Illustrative image related to paper burn barrel

Step 6: Verify Supplier Certifications

Confirm that the supplier holds the necessary certifications for manufacturing and selling burn barrels. This includes compliance with safety standards, environmental regulations, and quality management systems. Certifications can serve as a mark of credibility and assurance of product quality.

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics involved in transporting the burn barrels to your location. Discuss shipping options, delivery times, and any potential customs requirements if you are importing from another country. Having a clear logistics plan will help ensure a smooth procurement process and timely delivery.

By following this step-by-step checklist, B2B buyers can navigate the procurement process for paper burn barrels effectively, ensuring compliance, quality, and cost-efficiency in their sourcing decisions.

Illustrative image related to paper burn barrel

Comprehensive Cost and Pricing Analysis for paper burn barrel Sourcing

What Are the Key Cost Components in Sourcing Paper Burn Barrels?

When sourcing paper burn barrels, understanding the cost structure is essential for B2B buyers. The primary components include:

-

Materials: The most significant cost factor is the raw materials, typically steel or heavy-duty metal for durability. Prices can fluctuate based on global steel market trends, which are influenced by supply chain disruptions, tariffs, and trade policies.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with lower labor costs can provide significant savings. However, buyers must also consider labor skill levels, as experienced workers may yield higher quality products.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility expenses. Efficient manufacturing processes can minimize these overhead costs.

-

Tooling: Customization of burn barrels may require specialized tooling, which can add to initial costs but may lead to better product specifications.

-

Quality Control (QC): Implementing strict QC measures ensures that the barrels meet safety and performance standards. This can be a necessary investment to avoid costly returns or compliance issues.

-

Logistics: Shipping costs are often underestimated. Factors such as distance, mode of transport, and international tariffs can significantly impact the total cost. Incoterms play a crucial role in defining responsibilities and can affect pricing.

-

Margin: Suppliers will apply a markup to cover their costs and profit. Understanding the typical margins in the industry can help buyers negotiate better.

How Do Volume and Customization Affect Pricing for Paper Burn Barrels?

Volume and specifications are critical price influencers. Higher order volumes typically yield lower per-unit prices due to economies of scale. Suppliers may offer discounts for bulk purchases, making it advantageous for businesses with high consumption rates.

Customization can also affect pricing significantly. Standard burn barrels will generally be less expensive than those tailored to specific needs, such as size, additional features (like ventilation systems), or branding. Buyers should assess whether the benefits of customization justify the additional costs.

Illustrative image related to paper burn barrel

What Role Do Quality Certifications and Supplier Factors Play in Pricing?

Quality certifications, such as ISO or safety compliance, can influence pricing. Suppliers that invest in certifications often charge higher prices, reflecting the assurance of product quality and safety. When sourcing from international suppliers, it’s crucial to verify that they meet the required standards for your region, as this can impact both legal compliance and product performance.

Supplier factors, including reputation and reliability, can also affect costs. Established suppliers may charge more due to their track record of quality and service, while newer or less established companies might offer lower prices to gain market share.

How Can Buyers Negotiate and Achieve Cost Efficiency in International Sourcing?

Effective negotiation is key to achieving cost efficiency. B2B buyers should:

-

Research Market Prices: Understanding the market landscape helps in negotiating better deals. Utilize platforms and industry reports to gather pricing information.

-

Leverage Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, maintenance, and disposal costs over the product’s lifespan. This holistic view can justify higher upfront costs if they lead to lower overall expenses.

-

Be Cautious with Incoterms: Familiarize yourself with Incoterms to clearly define shipping responsibilities and costs. This clarity can prevent unexpected charges and enhance negotiation leverage.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of potential pricing nuances:

-

Currency Fluctuations: Exchange rates can significantly affect final costs. Locking in prices when the currency is favorable can be advantageous.

-

Import Duties and Taxes: Different countries have varying tariffs and taxes that can impact the total price. Conduct thorough research or consult with a trade expert to understand these implications.

-

Cultural Differences in Negotiation: Be aware of cultural nuances in negotiation practices. In some regions, building relationships may be as important as pricing, impacting your overall sourcing strategy.

Disclaimer on Indicative Prices

Prices for paper burn barrels can vary widely based on location, specifications, and market conditions. It is advisable to request quotes from multiple suppliers to ensure competitive pricing and to factor in all associated costs for a comprehensive budget evaluation.

Alternatives Analysis: Comparing paper burn barrel With Other Solutions

Introduction: Exploring Alternatives to Paper Burn Barrels

As businesses across various sectors seek efficient and secure methods for disposing of sensitive documents, understanding alternative solutions to traditional paper burn barrels becomes essential. Each method offers distinct advantages and drawbacks, which can significantly impact operations, costs, and compliance with environmental regulations. This analysis compares the paper burn barrel to two viable alternatives: industrial shredders and document destruction services, helping B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Paper Burn Barrel | Industrial Shredder | Document Destruction Service |

|---|---|---|---|

| Performance | Moderate; requires manual feeding | High; continuous operation | Very high; on-site shredding |

| Cost | Low initial cost | Moderate to high | Variable; often pay-per-use |

| Ease of Implementation | Simple setup; requires permits | Requires space and power source | Minimal setup; service provided |

| Maintenance | Low; occasional cleaning | Moderate; requires regular upkeep | None; managed by service provider |

| Best Use Case | Rural areas with limited options | Large volumes of paper needing destruction | Offices needing secure disposal |

Detailed Breakdown of Alternatives

1. Industrial Shredders

Industrial shredders are powerful machines designed for high-volume document destruction. They can process large quantities of paper quickly and efficiently, ensuring that sensitive information is irretrievable. The key advantages include high performance and the ability to handle various materials beyond paper. However, they require a significant initial investment and ongoing maintenance, including regular blade sharpening and motor checks. These machines also demand adequate space and power supply, making them less ideal for smaller businesses or those with limited resources.

2. Document Destruction Services

Document destruction services provide a convenient and secure option for businesses needing to dispose of sensitive materials. These services often include on-site shredding, allowing companies to witness the destruction of their documents, which enhances trust and compliance with data protection regulations. While the cost can vary based on volume and frequency of service, many find the peace of mind and convenience worth the investment. However, relying on an external service may not be feasible for businesses in remote locations or those with urgent disposal needs.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate method for document disposal depends on various factors, including business size, volume of documents, and budget. For organizations in rural areas or with limited resources, a paper burn barrel may still be the most viable option. However, for businesses with higher volumes of sensitive information, industrial shredders or document destruction services may offer more efficient and secure alternatives. B2B buyers should evaluate their specific needs, regulatory requirements, and long-term operational goals to make the best choice for their document disposal strategy.

Essential Technical Properties and Trade Terminology for paper burn barrel

When considering the procurement of paper burn barrels, it is essential to understand their technical properties and the terminology commonly used in the industry. This knowledge not only aids in making informed purchasing decisions but also enhances negotiations and collaborations with suppliers.

Illustrative image related to paper burn barrel

What Are the Key Technical Properties of a Paper Burn Barrel?

1. Material Grade

The most common material used for paper burn barrels is heavy-duty steel, typically with a gauge of 16 to 18. This thickness ensures durability and resistance to high temperatures. High-grade materials are critical in ensuring the longevity of the burn barrel, especially in industrial settings where frequent use is expected. Selecting barrels made from quality materials reduces the risk of structural failure and enhances safety.

2. Capacity

The standard capacity for paper burn barrels is usually around 55 gallons. This specification is vital for businesses that need to dispose of large volumes of paper waste efficiently. Understanding the capacity helps companies plan their waste management processes effectively and ensures compliance with local disposal regulations.

3. Ventilation Features

Effective burn barrels are designed with proper ventilation, often featuring strategically placed holes or a mesh lid. This design promotes airflow, facilitating more efficient combustion of paper materials. For B2B buyers, choosing a barrel with adequate ventilation is crucial as it ensures complete burning, reducing smoke and harmful emissions, which is particularly important in regions with strict environmental regulations.

Illustrative image related to paper burn barrel

4. Weight Tolerance

Burn barrels should have a weight tolerance that accommodates the maximum expected load of paper waste. A barrel with a higher weight tolerance minimizes the risk of deformation or collapse under pressure. This specification is especially significant for businesses that handle a variety of materials and need assurance that their equipment can withstand operational demands.

5. Safety Features

Many paper burn barrels come equipped with safety features such as locking lids or spark guards. These features are essential for preventing accidental fires and ensuring compliance with fire safety regulations. Businesses must prioritize these safety elements to protect personnel and property, particularly in areas where fire hazards are a concern.

What Are Common Trade Terminology and Jargon Related to Paper Burn Barrels?

1. OEM (Original Equipment Manufacturer)

In the context of paper burn barrels, OEM refers to manufacturers that produce the barrels according to specifications provided by other companies. Understanding OEM relationships can help buyers identify reputable suppliers and ensure they are sourcing quality products that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For businesses, knowing the MOQ is crucial for budgeting and inventory management. It can also affect negotiations, as larger orders may yield discounts, making it important for buyers to assess their needs carefully.

Illustrative image related to paper burn barrel

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. This process allows businesses to compare pricing, terms, and conditions from multiple suppliers, facilitating informed decision-making. Understanding how to craft an effective RFQ can lead to better pricing and service agreements.

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of sellers and buyers in the shipping process. Familiarity with Incoterms can help businesses navigate logistics more efficiently, ensuring clarity on who bears the risk and cost at various stages of the delivery process.

5. Lead Time

Lead time refers to the time taken from placing an order until it is delivered. For B2B buyers, understanding lead times is essential for planning and operational efficiency. Longer lead times can impact project timelines, so it is critical to negotiate terms that align with business needs.

Understanding these technical specifications and industry terms equips B2B buyers with the necessary insights to make strategic decisions when sourcing paper burn barrels. By focusing on quality, capacity, safety, and effective communication with suppliers, businesses can optimize their waste management solutions.

Illustrative image related to paper burn barrel

Navigating Market Dynamics and Sourcing Trends in the paper burn barrel Sector

What Are the Current Market Dynamics and Key Trends in the Paper Burn Barrel Sector?

The paper burn barrel market is experiencing transformative changes driven by several global factors. The demand for efficient waste management solutions has surged, especially in regions where traditional disposal methods are limited or costly. Countries in Africa, South America, the Middle East, and Europe are increasingly adopting burn barrels as practical alternatives for disposing of sensitive documents and other paper waste. Notably, the rise in data privacy concerns has also heightened the need for secure disposal methods, propelling the market forward.

Emerging technologies play a pivotal role in this sector, with innovations in design and materials improving the efficiency and safety of burn barrels. For instance, advancements in combustion technology are enabling manufacturers to produce barrels that burn more effectively while minimizing smoke and emissions. Furthermore, the integration of smart technologies, such as temperature sensors and automated air flow systems, is beginning to enter the market, appealing to tech-savvy B2B buyers looking for modern solutions.

Market dynamics are also influenced by regional regulations regarding waste disposal. In countries like Saudi Arabia and Nigeria, regulatory frameworks are evolving to address environmental concerns, prompting businesses to seek compliant and efficient disposal methods. B2B buyers are advised to stay informed about local regulations and industry standards to ensure their sourcing decisions align with legal requirements.

Illustrative image related to paper burn barrel

How Is Sustainability and Ethical Sourcing Impacting the Paper Burn Barrel Market?

Sustainability is becoming a cornerstone of the paper burn barrel sector, reflecting a broader trend across industries. Environmental impact considerations are prompting buyers to prioritize products that minimize carbon footprints and adhere to sustainable practices. The sourcing of raw materials for burn barrels is increasingly scrutinized, with buyers seeking suppliers who demonstrate ethical practices and transparency in their supply chains.

The importance of ethical sourcing cannot be overstated, particularly for international buyers. Companies are increasingly inclined to work with manufacturers that utilize recycled materials or sustainably sourced components in their burn barrels. Certifications such as Forest Stewardship Council (FSC) and Eco-Label are gaining traction as indicators of environmentally responsible products. Buyers are encouraged to verify these certifications when sourcing to ensure they are making environmentally conscious choices.

Moreover, the push for ‘green’ certifications is affecting procurement strategies. B2B buyers are not only looking for functional products but also for those that align with their corporate social responsibility (CSR) goals. As sustainability becomes a competitive differentiator, businesses that adopt environmentally friendly practices in their sourcing strategies are likely to gain a favorable market position.

What Is the Historical Context of the Paper Burn Barrel Industry?

The concept of burning waste has been around for centuries, but the paper burn barrel as a defined product has evolved significantly over time. Initially, makeshift burn barrels were created using repurposed metal containers, primarily for residential use. However, as environmental regulations became more stringent, particularly in the late 20th century, the need for more efficient and compliant burn solutions emerged.

Manufacturers began developing specialized burn barrels designed to optimize combustion efficiency and reduce harmful emissions. Today, the industry is characterized by a focus on safety, efficiency, and sustainability, with new designs incorporating advanced materials and features that cater to both residential and commercial needs.

In conclusion, understanding the market dynamics, trends, and historical context of the paper burn barrel sector is crucial for international B2B buyers. By aligning sourcing strategies with sustainability and ethical practices, businesses can not only meet regulatory requirements but also enhance their brand reputation and competitiveness in a rapidly evolving market.

Frequently Asked Questions (FAQs) for B2B Buyers of paper burn barrel

-

How do I ensure compliance with local regulations when using paper burn barrels?

Ensuring compliance with local regulations is crucial before implementing a paper burn barrel system. Start by researching the environmental laws and waste management regulations in your region, as they can vary significantly. Consult local authorities or environmental agencies to obtain necessary permits. In some regions, burning waste might be strictly prohibited or require specific safety measures. Additionally, consider engaging with local waste management experts who can provide insights into best practices and compliance requirements tailored to your area. -

What is the best material for constructing a paper burn barrel?

The best material for constructing a paper burn barrel is typically a heavy-duty steel drum, preferably one that is 55 gallons in capacity. Steel offers durability and resistance to high temperatures, ensuring safe and effective burning. Look for barrels that are designed specifically for burning purposes, as they often include ventilation features to enhance airflow. Avoid using barrels that previously contained hazardous materials, as residues can compromise safety and lead to harmful emissions during combustion. -

How can I optimize the burning process for efficiency?

To optimize the burning process in a paper burn barrel, ensure that the paper is crumpled or shredded to increase surface area, allowing it to catch fire more easily. Arrange the paper loosely to facilitate airflow, which is crucial for combustion. Consider adding dry kindling or small wooden pieces to help ignite the paper quickly. Additionally, avoid overloading the barrel; burning in smaller batches can improve efficiency and reduce smoke emissions, making the process more environmentally friendly. -

What factors should I consider when selecting a supplier for paper burn barrels?

When selecting a supplier for paper burn barrels, assess their experience and reputation in the market. Look for suppliers who specialize in industrial waste management products and have a proven track record. Evaluate the quality of their products by requesting samples or customer testimonials. Additionally, inquire about customization options, minimum order quantities (MOQs), lead times, and after-sales support. Establishing a strong relationship with a reliable supplier can ensure consistent product availability and support. -

What are the typical payment terms in international B2B transactions for paper burn barrels?

Payment terms in international B2B transactions can vary widely, but common practices include upfront deposits (often 30-50%) with the balance paid upon delivery or after inspection. Some suppliers may offer letters of credit or trade financing options to secure the transaction. It’s essential to clearly outline payment terms in the purchase agreement to avoid misunderstandings. Additionally, consider discussing currency exchange rates and potential transaction fees, as these can impact overall costs. -

How can I verify the quality of paper burn barrels before purchasing?

To verify the quality of paper burn barrels before purchasing, request product specifications and certifications from the supplier. Look for compliance with international standards such as ISO or local regulatory approvals. If possible, arrange for a factory visit or request third-party inspection services to assess product quality firsthand. Additionally, seek references or reviews from other businesses that have purchased from the supplier to gain insights into their reliability and product performance. -

What logistics considerations should I keep in mind when importing paper burn barrels?

When importing paper burn barrels, logistics considerations include shipping methods, customs regulations, and import duties. Determine the most cost-effective shipping option (e.g., sea freight vs. air freight) based on your timeline and budget. Familiarize yourself with the customs clearance process in your country, as this can vary significantly. Collaborate with a logistics provider experienced in international shipping to navigate any potential challenges and ensure timely delivery of your products. -

Can I customize paper burn barrels to meet specific operational needs?

Yes, many suppliers offer customization options for paper burn barrels to cater to specific operational needs. Customizations may include size variations, additional ventilation features, or modifications for easy handling and transportation. When discussing customization, provide detailed specifications and requirements to the supplier to ensure they can meet your expectations. Keep in mind that custom orders may have different lead times and minimum order quantities, so plan accordingly to avoid delays in your operations.

Top 2 Paper Burn Barrel Manufacturers & Suppliers List

1. SoloStove – Smoke Output Comparison

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the SoloStove product, specifically regarding its size and smoke output when burning shredded paper. Users are curious if a smaller SoloStove would produce less smoke compared to a Bonfire-sized pit. The consensus suggests that a hotter fire results in less smoke, but burning shredded paper still generates significant smoke and embers. Recommendations include using a…

2. Do It Yourself – Industrial Paper Burners

Domain: doityourself.com

Registered: 1995 (30 years)

Introduction: burn barrel, 1 1/2″ holes for air flow, designed for burning paper files, requires faster burning method for stacked files, suggestions for industrial paper burners with sealed burn area and forced air.

Strategic Sourcing Conclusion and Outlook for paper burn barrel

In summary, the effective strategic sourcing of paper burn barrels is essential for businesses seeking efficient waste management solutions. By understanding the various options available—ranging from DIY setups to industrial-grade incinerators—buyers can select the right solution tailored to their operational needs. Key takeaways include the importance of considering local regulations, evaluating the environmental impact of burning versus shredding, and understanding the logistics involved in transporting and maintaining these units.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, investing in high-quality burn barrels not only enhances compliance with waste disposal regulations but also promotes a sustainable approach to waste management. As industries evolve and prioritize eco-friendly practices, the demand for innovative waste solutions will continue to rise.

Illustrative image related to paper burn barrel

Looking ahead, businesses should actively seek partnerships with reputable suppliers who can provide not only the products but also insights into best practices for usage and maintenance. By taking proactive steps now, you can position your organization as a leader in responsible waste management, ultimately driving efficiency and sustainability in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to paper burn barrel