Unlocking Value: A Strategic Analysis of the Loudspeaker Voice Coil Market

Introduction: Navigating the Global Market for loudspeaker voice coil

The global market for loudspeaker voice coils presents significant challenges for B2B buyers, particularly when it comes to sourcing high-quality components that meet specific performance criteria. With a diverse array of options available, from different sizes and configurations to various material types, selecting the right voice coil can be a daunting task. This guide aims to demystify the complexities of the loudspeaker voice coil market by providing a comprehensive overview of the types, applications, and key factors to consider in your procurement process.

In this resource, we delve into the intricacies of voice coil specifications, including winding techniques, wire materials, and insulation types. Additionally, we provide actionable insights on how to effectively vet suppliers, ensuring you partner with reputable manufacturers who can deliver both quality and consistency. Understanding the cost implications associated with various voice coil options will also empower you to make informed purchasing decisions that align with your budgetary constraints.

This guide is tailored for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including markets like Nigeria and Vietnam. By equipping you with the knowledge to navigate the global landscape of loudspeaker voice coils, we aim to enhance your confidence in sourcing decisions, ultimately driving the success of your audio projects and business ventures.

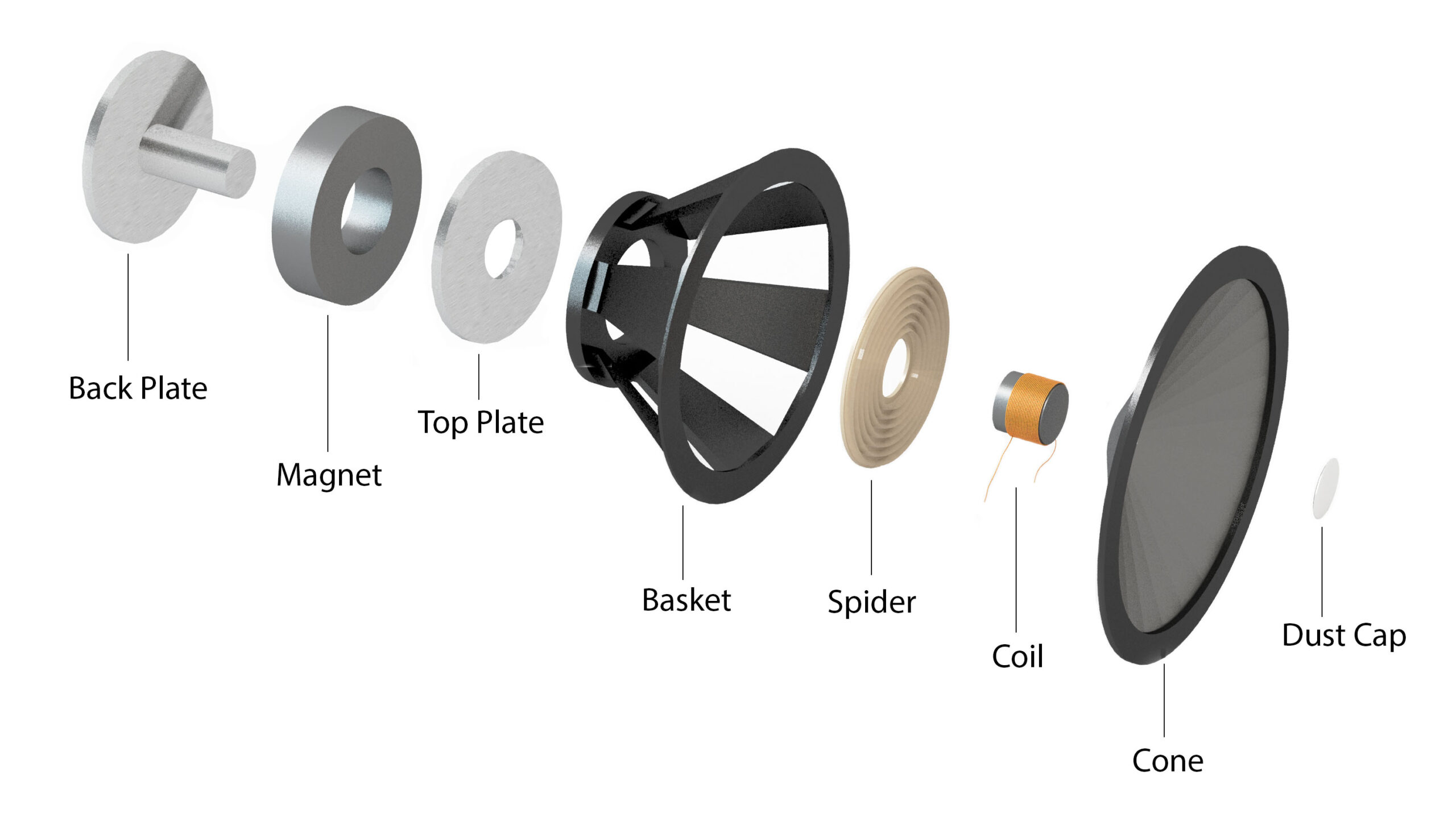

Understanding loudspeaker voice coil Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Voice Coils | Commonly made with copper wire, various sizes | General audio applications, consumer electronics | Pros: Widely available, cost-effective; Cons: Limited power handling in some models |

| Dual Voice Coils | Two coils per speaker, allows for flexibility | Subwoofers, high-performance audio systems | Pros: Enhanced power handling, versatile; Cons: More complex wiring and installation |

| Flat Wire Voice Coils | Utilizes flat wire for improved thermal performance | High-end audio systems, professional sound reinforcement | Pros: Better heat dissipation, high efficiency; Cons: Higher production costs |

| Edge-Wound Voice Coils | Wire is wound at the edge of the bobbin, providing better linearity | High-fidelity audio systems, studio monitors | Pros: Superior sound quality, reduced distortion; Cons: More expensive, requires precision manufacturing |

| Aluminum Voice Coils | Lightweight and offers good thermal properties | Lightweight speaker designs, portable audio equipment | Pros: Lightweight, good thermal performance; Cons: Can be less durable than copper coils |

What Are Standard Voice Coils and Their Applications?

Standard voice coils are the most prevalent type, typically constructed from copper wire and available in various sizes. These coils are ideal for general audio applications, including consumer electronics like home audio systems and portable speakers. For B2B buyers, their widespread availability and cost-effectiveness make them a go-to choice. However, it’s essential to consider that some models may have limitations in power handling, which could affect performance in high-demand scenarios.

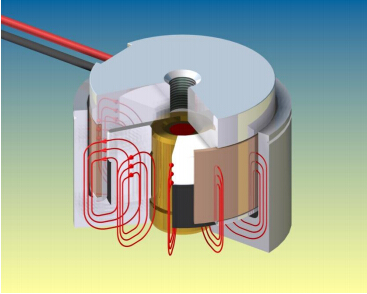

Illustrative image related to loudspeaker voice coil

How Do Dual Voice Coils Enhance Performance?

Dual voice coils consist of two coils per speaker, providing enhanced flexibility in wiring configurations. This type is especially popular in subwoofers and high-performance audio systems, allowing for increased power handling and improved sound quality. For B2B buyers, dual voice coils can be advantageous for applications requiring higher output levels. However, they may introduce complexity in installation and wiring, which should be factored into purchasing decisions.

What Are the Benefits of Flat Wire Voice Coils?

Flat wire voice coils are designed to improve thermal performance, making them suitable for high-end audio systems and professional sound reinforcement applications. They are known for better heat dissipation and efficiency, which can enhance overall sound quality. B2B buyers should consider the higher production costs associated with flat wire coils, but the investment may be justified for projects requiring superior audio fidelity.

Why Choose Edge-Wound Voice Coils for High-Fidelity Systems?

Edge-wound voice coils feature wire that is wound at the edge of the bobbin, leading to improved linearity and sound quality. They are commonly used in high-fidelity audio systems and studio monitors where sound precision is critical. While edge-wound coils can provide significant advantages in terms of reduced distortion and superior sound quality, B2B buyers should also be aware of the higher costs and the need for precision manufacturing.

What Makes Aluminum Voice Coils a Lightweight Option?

Aluminum voice coils are favored for their lightweight characteristics and good thermal properties, making them ideal for portable audio equipment and lightweight speaker designs. They offer a balance between performance and weight, which can be crucial for specific applications. However, buyers should weigh the benefits against potential durability issues compared to traditional copper coils, especially in demanding environments.

Key Industrial Applications of loudspeaker voice coil

| Industry/Sector | Specific Application of loudspeaker voice coil | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Professional Audio Equipment | High-performance loudspeakers for concerts and events | Enhanced sound quality and reliability in live settings | Durability, power handling, and compatibility with existing systems |

| Automotive Industry | Custom sound systems in vehicles | Improved audio experience leading to customer satisfaction | Size constraints, thermal management, and resistance to vibrations |

| Consumer Electronics | Home theater systems and soundbars | High fidelity sound reproduction for immersive experience | Cost-effectiveness, compact design, and ease of integration |

| Telecommunications | Speaker systems for conference calls and communication devices | Clear audio transmission and reception | Size, weight, and compatibility with wireless technologies |

| Industrial Machinery | Sound alert systems and alarms in manufacturing environments | Safety improvements through audible alerts | Environmental resistance and compliance with safety regulations |

How is the loudspeaker voice coil used in professional audio equipment?

In the professional audio sector, loudspeaker voice coils are integral to high-performance loudspeakers utilized in concerts and large events. They convert electrical signals into sound, ensuring high fidelity and clarity even at elevated volumes. Buyers in this industry must consider durability and power handling capabilities, as equipment is frequently subjected to rigorous use. Additionally, compatibility with existing sound systems is crucial, particularly for international buyers who may face varying standards across regions.

What role does the loudspeaker voice coil play in the automotive industry?

In the automotive sector, loudspeaker voice coils are customized for integration into sound systems within vehicles, enhancing the audio experience for passengers. These coils must meet specific size constraints due to limited space in car interiors, while also managing heat and vibrations effectively. For B2B buyers in regions like Africa and South America, sourcing high-quality voice coils that ensure optimal performance under diverse environmental conditions can significantly impact customer satisfaction and brand loyalty.

How does the loudspeaker voice coil enhance consumer electronics?

In consumer electronics, voice coils are pivotal in home theater systems and soundbars, where they contribute to high-quality sound reproduction. The demand for compact and cost-effective solutions drives the need for advanced voice coil designs that maintain audio fidelity. Buyers should prioritize sourcing options that offer a balance between performance and price, particularly in competitive markets in Europe and the Middle East, where consumer expectations are high.

Why are loudspeaker voice coils important for telecommunications?

In telecommunications, voice coils are used in speaker systems for conference calls and communication devices, providing clear audio transmission. The importance of size and weight cannot be overstated, as these factors influence the portability and usability of devices. B2B buyers must also consider compatibility with wireless technologies, ensuring seamless integration into modern communication systems, especially in rapidly evolving markets.

What applications exist for loudspeaker voice coils in industrial machinery?

In industrial environments, loudspeaker voice coils are employed in sound alert systems and alarms, crucial for maintaining safety standards. These coils must be resistant to environmental factors such as dust, moisture, and temperature fluctuations. International buyers, particularly those from regions with varying regulatory requirements, should focus on sourcing voice coils that comply with safety regulations and can withstand harsh conditions, thereby ensuring reliable operation in critical situations.

3 Common User Pain Points for ‘loudspeaker voice coil’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Voice Coil for Specific Applications

The Problem: B2B buyers often face challenges when trying to find the right loudspeaker voice coil that meets the unique specifications of their projects. Given the vast array of options—varying in size, impedance, and material—buyers may struggle to determine which coil will provide optimal performance for their specific use case, such as automotive audio systems, professional sound reinforcement, or consumer electronics. This can lead to costly delays and dissatisfaction with the final product if the wrong components are selected.

The Solution: To overcome this challenge, buyers should begin by clearly defining the requirements of their application, including power handling, frequency response, and mechanical dimensions. Collaborating with manufacturers or distributors who offer detailed specifications and comparison tools can streamline the selection process. For instance, utilizing tools like impedance calculators and compatibility charts available from reputable suppliers can help buyers quickly narrow down their options. Additionally, consider requesting samples or prototypes to evaluate how different voice coils perform under actual operating conditions before making a bulk purchase.

Scenario 2: Quality Control Issues with Imported Voice Coils

The Problem: Many international buyers, particularly from regions like Africa and South America, experience quality control issues when sourcing loudspeaker voice coils from overseas manufacturers. Variability in production standards and materials can result in inconsistencies in performance, such as overheating, distortion, or even failure during operation. Such issues not only affect product reliability but can also tarnish the reputation of businesses that rely on these components.

The Solution: To mitigate quality control issues, it’s essential to establish strong relationships with suppliers that adhere to recognized quality standards, such as ISO certifications. Conducting thorough due diligence by visiting manufacturing facilities or requesting third-party quality assurance reports can provide insights into production practices. Additionally, buyers should implement a robust testing protocol upon receiving shipments, including stress tests and performance evaluations, to ensure that the coils meet their specifications before integration into final products. Establishing clear communication with suppliers about quality expectations and potential penalties for non-compliance can further ensure consistent product quality.

Scenario 3: Understanding and Managing Thermal Limitations of Voice Coils

The Problem: Another common challenge faced by B2B buyers is understanding the thermal limitations of loudspeaker voice coils. Many users underestimate how heat affects performance, leading to issues like voice coil burnout or distortion during high-demand scenarios. This lack of understanding can result in product failures, increased warranty claims, and dissatisfied customers, especially in high-power audio applications.

The Solution: Buyers should educate themselves and their teams on the thermal characteristics of the voice coils they are considering. This involves understanding parameters such as power handling (watts), thermal resistance, and the cooling mechanisms available in their designs. To manage thermal limitations effectively, consider selecting voice coils designed with advanced materials that enhance heat dissipation, such as aluminum or edge-wound copper wire. Implementing proper enclosure designs that promote airflow and using thermal management systems can further protect the voice coils during operation. Regular monitoring of performance metrics during testing phases can also help identify potential thermal issues before they lead to failures, ensuring long-term reliability and satisfaction in the field.

By addressing these common pain points with actionable solutions, B2B buyers can enhance their sourcing strategies and ensure the successful integration of loudspeaker voice coils into their products.

Strategic Material Selection Guide for loudspeaker voice coil

What Are the Key Materials Used for Loudspeaker Voice Coils?

Selecting the right materials for loudspeaker voice coils is crucial for optimizing performance and ensuring reliability. The choice of materials impacts the voice coil’s efficiency, durability, and overall sound quality. Below, we analyze four common materials used in the manufacturing of loudspeaker voice coils, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to loudspeaker voice coil

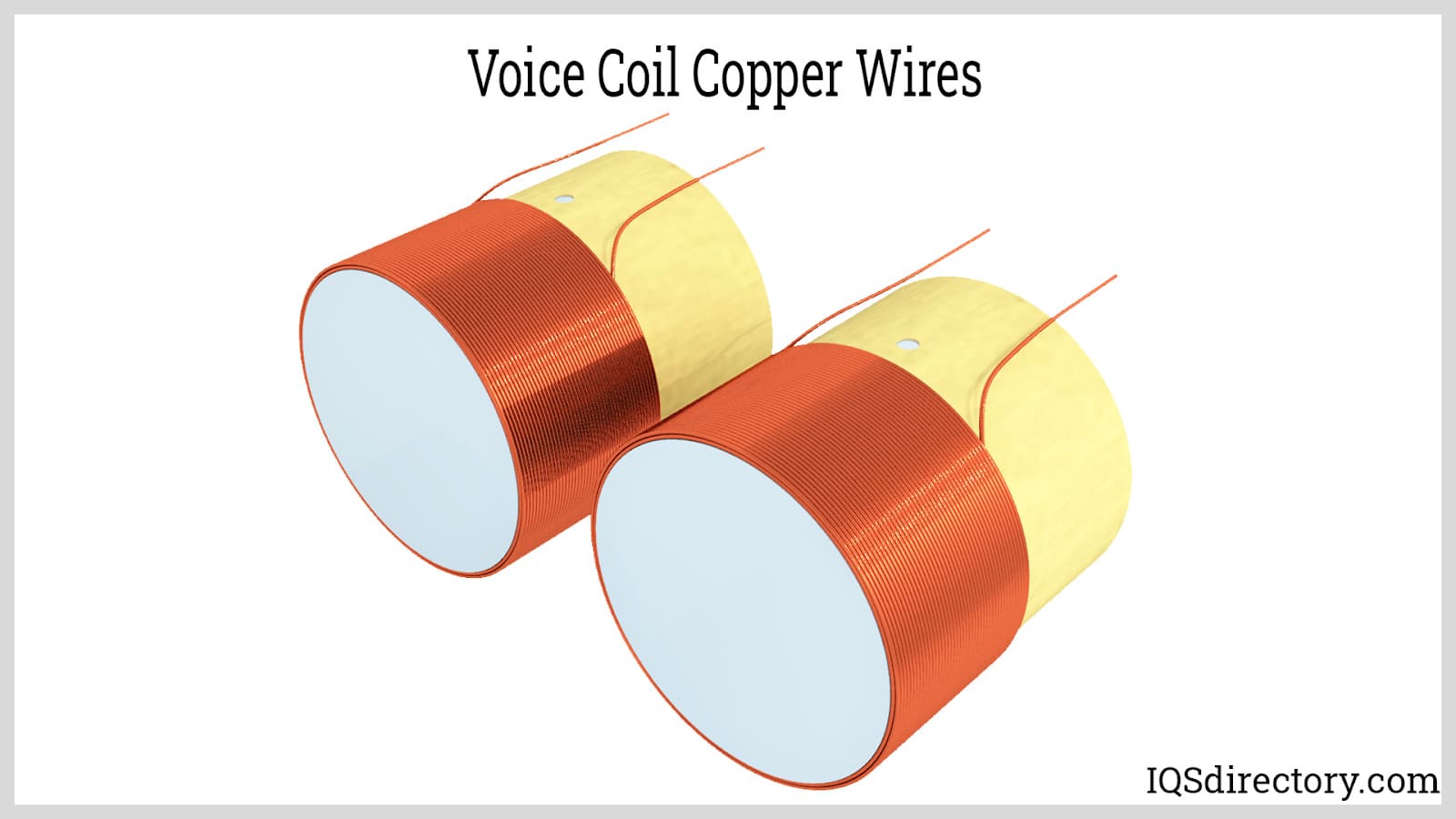

Copper Wire: The Standard for Voice Coils

Key Properties: Copper is known for its excellent electrical conductivity, which is essential for audio performance. It can withstand high temperatures, making it suitable for high-power applications.

Pros & Cons: The primary advantage of copper is its superior conductivity, leading to better sound quality. However, it is prone to oxidation, which can affect performance over time. Additionally, the cost of copper can fluctuate significantly due to market demands.

Impact on Application: Copper’s compatibility with various audio systems makes it a go-to choice for many manufacturers. However, buyers should consider the oxidation issue, especially in humid environments, which may be prevalent in regions like Africa and South America.

Considerations for International Buyers: Compliance with international standards such as ASTM B187 for copper wire is essential. Buyers should also be aware of local regulations regarding material sourcing and environmental impact.

Aluminum Wire: A Lightweight Alternative

Key Properties: Aluminum wire is lighter than copper and offers decent conductivity. It has a lower melting point, which can be a disadvantage in high-temperature applications.

Illustrative image related to loudspeaker voice coil

Pros & Cons: The lightweight nature of aluminum makes it easier to handle and install. However, its lower conductivity compared to copper can result in reduced sound quality. Additionally, aluminum is more susceptible to corrosion, which can limit its lifespan.

Impact on Application: Aluminum is often used in portable speakers where weight is a critical factor. However, its limitations in high-performance audio applications make it less suitable for professional-grade speakers.

Considerations for International Buyers: Buyers should ensure that aluminum wire meets international standards such as ASTM B231. They should also consider the environmental impact of aluminum production, especially in regions with strict regulations.

Illustrative image related to loudspeaker voice coil

Flat Wire: Enhancing Efficiency

Key Properties: Flat wire is designed to maximize surface area, which improves heat dissipation and reduces distortion. It is often made from copper or aluminum.

Pros & Cons: The main advantage of flat wire is its ability to handle higher power levels without overheating. However, manufacturing flat wire can be more complex and costly compared to round wire.

Impact on Application: This type of wire is particularly beneficial in high-performance audio applications where sound fidelity is paramount. However, its higher cost may deter budget-conscious buyers.

Considerations for International Buyers: Buyers should look for compliance with specific manufacturing standards, such as JIS C 3102 for flat wire. Understanding the local market’s willingness to invest in high-quality components is also vital.

CCA Wire (Copper-Clad Aluminum): A Cost-Effective Solution

Key Properties: CCA wire combines the conductivity of copper with the lightweight properties of aluminum. It features a thin layer of copper over an aluminum core.

Illustrative image related to loudspeaker voice coil

Pros & Cons: The cost-effectiveness of CCA wire makes it an attractive option for budget-conscious manufacturers. However, its conductivity is still inferior to pure copper, which can impact audio quality.

Impact on Application: CCA wire is often used in consumer-grade speakers where cost is a significant factor. However, it may not be suitable for high-end audio applications due to its lower performance.

Considerations for International Buyers: Buyers should ensure CCA wire meets relevant standards, such as DIN EN 60228. They should also consider the trade-offs between cost and audio performance when sourcing materials.

Summary Table of Material Selection for Loudspeaker Voice Coils

| Material | Typical Use Case for loudspeaker voice coil | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper Wire | Professional audio systems | Excellent conductivity | Prone to oxidation | High |

| Aluminum Wire | Portable speakers | Lightweight | Lower conductivity, prone to corrosion | Medium |

| Flat Wire | High-performance audio applications | Better heat dissipation | Higher manufacturing complexity | High |

| CCA Wire | Budget consumer speakers | Cost-effective | Inferior conductivity | Low |

This guide provides a comprehensive overview of the materials commonly used in loudspeaker voice coils, enabling B2B buyers to make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for loudspeaker voice coil

What Are the Main Stages of Manufacturing Loudspeaker Voice Coils?

The manufacturing of loudspeaker voice coils involves several critical stages, each of which plays a vital role in ensuring the final product meets performance and quality standards. Understanding these stages can help B2B buyers make informed decisions when sourcing from manufacturers.

-

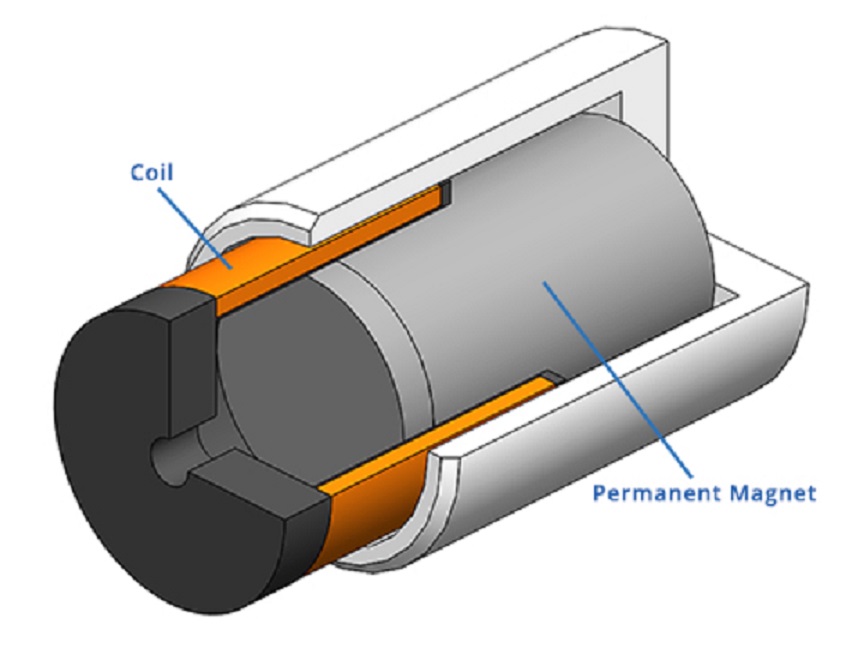

Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Commonly used materials include copper or aluminum wire for the coil, which must be insulated to prevent short circuits. The choice of bobbin material—often made from materials like polyimide or paper—also affects the coil’s durability and performance. This stage may also involve pre-treating materials to enhance their properties, such as applying coatings for better heat resistance. -

Coil Forming

In this stage, the wire is precisely wound around the bobbin to form the voice coil. Techniques such as flat winding or edge-wound configurations can be employed, depending on the design requirements. Advanced machines are used to ensure consistent tension and winding precision, which are crucial for optimal performance. This process may include the application of adhesives to secure the wire in place, particularly in high-performance applications. -

Assembly

Once the coil is formed, it is assembled with other components, such as the diaphragm and magnet system. This assembly is often done in a clean environment to prevent contaminants from affecting the final product. The alignment of components is critical; improper alignment can lead to distortion in sound quality. Automated assembly lines are commonly employed to enhance efficiency and consistency. -

Finishing

The finishing stage involves testing and applying any necessary coatings or treatments to the assembled voice coils. This may include insulation treatments to enhance electrical properties or coatings to improve durability against environmental factors. Quality checks are integral during this phase, ensuring that each unit meets specified performance criteria before packaging.

What Quality Control Measures Are Essential in Voice Coil Manufacturing?

Quality assurance is a pivotal aspect of manufacturing loudspeaker voice coils, ensuring that each product adheres to international standards and meets customer expectations. Here are key quality control measures that B2B buyers should consider:

-

International Standards Compliance

Manufacturers should comply with international quality standards such as ISO 9001, which outlines requirements for a quality management system (QMS). Certification to these standards indicates that the manufacturer has implemented processes for continuous improvement and customer satisfaction. Industry-specific certifications, such as CE marking for products sold in Europe, should also be verified. -

Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint ensures that all raw materials meet specified quality standards before production begins.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the production process and identify defects early.

– Final Quality Control (FQC): The final products undergo rigorous testing to ensure they meet design specifications and performance requirements before shipment. -

Testing Methods

Common testing methods for voice coils include:

– Electrical Testing: Measuring impedance, resistance, and inductance to ensure electrical properties align with specifications.

– Mechanical Testing: Assessing the physical integrity of the coil, including tests for tensile strength and thermal stability.

– Acoustic Testing: Evaluating sound quality and performance through frequency response and distortion analysis.

How Can B2B Buyers Verify Supplier Quality Control Processes?

When sourcing loudspeaker voice coils, it is crucial for B2B buyers to verify the quality control processes of potential suppliers. Here are actionable steps to ensure supplier reliability:

-

Supplier Audits

Conducting on-site audits can provide insight into a manufacturer’s quality control processes and adherence to standards. This allows buyers to assess the facilities, equipment, and overall operational practices directly. -

Requesting Quality Reports

Suppliers should be able to provide detailed quality reports, including compliance certificates and testing results. These documents can serve as evidence of the supplier’s commitment to quality and regulatory compliance. -

Third-Party Inspections

Engaging independent third-party inspection services can offer an unbiased evaluation of the manufacturer’s quality control measures. This is particularly beneficial for buyers who may not have the resources to perform thorough audits themselves.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For B2B buyers operating in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential:

-

Regional Compliance Requirements

Different markets may have unique compliance requirements. For example, products sold in the European market must comply with CE regulations, while buyers in the Middle East may require certification from local regulatory bodies. Understanding these requirements can help avoid costly compliance issues. -

Cultural Considerations

Building strong relationships with suppliers is often crucial in international markets. Understanding local business practices and cultural nuances can facilitate smoother negotiations and more effective communication regarding quality expectations. -

Logistics and Supply Chain Management

Quality control does not stop at manufacturing; it extends to logistics and supply chain management. Buyers should ensure that their suppliers have robust processes for maintaining quality during transportation and storage, as environmental factors can impact product integrity.

In conclusion, understanding the manufacturing processes and quality assurance measures for loudspeaker voice coils is essential for B2B buyers looking to make informed purchasing decisions. By focusing on material preparation, assembly techniques, and robust quality control practices, buyers can ensure they are sourcing high-quality components that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘loudspeaker voice coil’

This guide aims to provide B2B buyers with a clear and actionable checklist for sourcing loudspeaker voice coils. Understanding the specific requirements and evaluating potential suppliers is crucial to ensuring product quality and reliability.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the voice coils you need. This includes dimensions, impedance ratings, wire types, and winding configurations. Being precise in your requirements helps prevent costly errors and ensures compatibility with your existing speaker systems.

- Key specifications to consider:

- Diameter of the voice coil

- Impedance (4, 8, or 16 ohms)

- Type of winding (flat wire, round wire)

Step 2: Research Supplier Capabilities

Investigate the manufacturing capabilities of potential suppliers. Look for companies that specialize in voice coils, as they will likely have more expertise and better quality control processes. Understanding their production techniques, such as winding methods and materials used, can provide insights into the durability and performance of their products.

- Questions to ask:

- What materials do you use for winding?

- Can you provide information on your production process?

Step 3: Evaluate Supplier Certifications

Confirm that suppliers possess relevant industry certifications, which can indicate their commitment to quality and safety standards. Certifications like ISO 9001 can be a good benchmark for assessing supplier reliability. This step is crucial to ensure that the products meet international standards, particularly if you’re sourcing from regions with varying manufacturing regulations.

- Certifications to look for:

- ISO 9001 (Quality Management)

- RoHS Compliance (Restriction of Hazardous Substances)

Step 4: Request Samples for Testing

Before making a bulk purchase, always request samples of the voice coils. Testing samples allows you to evaluate the sound quality and performance under real-world conditions. This step can prevent future issues related to product quality and compatibility.

- Testing criteria to consider:

- Frequency response

- Thermal performance

- Durability under stress

Step 5: Analyze Pricing and Payment Terms

Carefully analyze the pricing structure and payment terms provided by suppliers. Compare costs among different suppliers while considering the quality of materials and craftsmanship. Additionally, favorable payment terms can improve your cash flow management, making it easier to maintain operational budgets.

- Considerations include:

- Bulk order discounts

- Payment methods (e.g., credit terms, upfront payments)

Step 6: Assess Logistics and Delivery Times

Understand the logistics involved in the supply chain, including lead times and shipping options. Reliable delivery timelines are essential for maintaining production schedules and meeting customer demands. Discuss potential delays and how they will be communicated.

- Logistics factors to evaluate:

- Shipping methods and costs

- Estimated delivery times

Step 7: Establish a Relationship for Future Collaboration

Build a strong relationship with your chosen supplier to facilitate future orders and negotiations. A good relationship can lead to better pricing, priority service, and access to new products. Open communication channels will help both parties address any issues that may arise quickly.

- Ways to strengthen relationships:

- Regular check-ins and feedback

- Participation in supplier training or workshops

By following this checklist, B2B buyers can make informed decisions when sourcing loudspeaker voice coils, ensuring quality and reliability in their audio products.

Comprehensive Cost and Pricing Analysis for loudspeaker voice coil Sourcing

What are the Key Cost Components in Loudspeaker Voice Coil Manufacturing?

When sourcing loudspeaker voice coils, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Illustrative image related to loudspeaker voice coil

-

Materials: The choice of materials significantly impacts the cost. Common materials include copper wire for winding, bobbin materials (like polyimide or aluminum), and adhesives. High-quality materials can enhance performance but also increase costs.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs may offer more competitive pricing, but this can also affect the quality of workmanship.

-

Manufacturing Overhead: This encompasses costs related to facilities, equipment, and utilities. Efficient manufacturing processes can reduce overhead and thus lower prices for buyers.

-

Tooling: Custom tooling can be a significant upfront cost for specialized voice coils. However, it is amortized over larger production runs, making it more cost-effective for high-volume orders.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to the overall cost. Suppliers with certifications (like ISO) may charge more but provide assurance of quality.

-

Logistics: Transportation costs can vary widely depending on the shipping method and distance. Incoterms also play a crucial role in determining who bears the costs and risks during transit.

-

Margin: Suppliers typically apply a margin on their costs, which can vary based on market conditions and competition.

What Influences Pricing for Loudspeaker Voice Coils?

Several factors can influence the pricing of loudspeaker voice coils:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate the price per unit. Larger orders typically benefit from economies of scale, leading to lower unit costs.

-

Specifications and Customization: Customized voice coils tailored to specific requirements can significantly increase costs. Buyers should balance their need for customization with budget constraints.

-

Material Quality and Certifications: Higher quality materials or certified products will generally command higher prices. Buyers should consider whether the additional investment aligns with their performance needs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding shipping terms is crucial. For instance, FOB (Free on Board) pricing may require buyers to cover shipping costs, impacting the total cost of ownership.

What Tips Can Help Buyers Negotiate Better Prices?

To effectively navigate the sourcing process and secure competitive pricing, consider the following strategies:

-

Negotiate Terms: Engage in negotiations around pricing, payment terms, and delivery schedules. Suppliers may be willing to offer discounts for larger orders or prompt payments.

-

Focus on Cost-Efficiency: Assess the total cost of ownership rather than just the unit price. Factors such as durability and performance can lead to long-term savings.

-

Explore Multiple Suppliers: Conduct market research to identify several suppliers. This not only provides leverage in negotiations but also helps in comparing quality and pricing.

-

Understand Regional Pricing Nuances: Pricing can vary significantly across regions. For international buyers from Africa, South America, the Middle East, and Europe, being aware of local market conditions and currency fluctuations can inform better purchasing decisions.

-

Stay Informed About Industry Trends: Keeping abreast of trends in material costs and manufacturing technologies can provide insights into potential price changes and help in strategic planning.

Conclusion

In summary, sourcing loudspeaker voice coils involves navigating a complex landscape of costs and pricing influencers. By understanding the cost components and employing strategic negotiation tactics, B2B buyers can optimize their procurement processes and achieve favorable outcomes. It’s essential to remain vigilant about market dynamics and supplier capabilities, ensuring that decisions align with long-term business goals.

Alternatives Analysis: Comparing loudspeaker voice coil With Other Solutions

Exploring Alternative Solutions to Loudspeaker Voice Coils

When considering loudspeaker technologies, it’s important to evaluate not only the traditional voice coil but also alternative solutions that may better meet specific project requirements. The right choice depends on various factors such as performance needs, budget constraints, and application contexts. Below, we compare the loudspeaker voice coil with two viable alternatives: Electrostatic Speakers and Planar Magnetic Drivers.

| Comparison Aspect | Loudspeaker Voice Coil | Electrostatic Speakers | Planar Magnetic Drivers |

|---|---|---|---|

| Performance | High efficiency and dynamic range | Exceptional clarity and low distortion | Good transient response and clarity |

| Cost | Moderate, varies by type | High due to specialized materials | Moderate to high, depending on design |

| Ease of Implementation | Standardized, widely available | Complex setup, requires high voltage | Moderate, requires specific housing |

| Maintenance | Low, simple repairs possible | Higher, sensitive to humidity and dust | Moderate, but generally durable |

| Best Use Case | General audio applications | Audiophile-grade listening | High-fidelity audio in controlled environments |

In-Depth Analysis of Alternatives

Electrostatic Speakers

Electrostatic speakers use a thin diaphragm suspended between two conductive panels. When a voltage is applied, the diaphragm moves, producing sound. These speakers are renowned for their exceptional audio clarity and low distortion levels, making them a favorite among audiophiles. However, their high cost and complexity in setup can be significant drawbacks. Moreover, they require a dedicated power supply and are sensitive to environmental factors like humidity and dust, which can impact longevity and performance.

Illustrative image related to loudspeaker voice coil

Planar Magnetic Drivers

Planar magnetic drivers utilize a flat diaphragm with a voice coil that is positioned in a magnetic field. This design allows for a very efficient conversion of electrical energy into sound. They are known for their good transient response and clarity, making them suitable for high-fidelity audio applications. While the cost is generally moderate to high, depending on the sophistication of the design, they are more robust than electrostatic speakers. Installation is less complex than electrostatics, but they still require specific housing to optimize performance.

Making the Right Choice for Your Needs

When deciding between a loudspeaker voice coil and its alternatives, consider the specific requirements of your application. If your focus is on general audio performance with ease of implementation and lower maintenance, the traditional voice coil remains a strong choice. For audiophile applications where sound quality is paramount, electrostatic speakers may be worth the investment, albeit with higher costs and maintenance needs. Planar magnetic drivers offer a balanced solution, providing excellent sound quality with reasonable durability and complexity.

Ultimately, understanding the strengths and weaknesses of each option will help B2B buyers make informed decisions that align with their operational goals and budget constraints. Whether prioritizing performance, cost, or ease of use, assessing these factors will lead to a more effective audio solution tailored to specific needs.

Essential Technical Properties and Trade Terminology for loudspeaker voice coil

What Are the Key Technical Properties of Loudspeaker Voice Coils?

When sourcing loudspeaker voice coils, understanding their technical properties is essential for ensuring product quality and compatibility. Here are several critical specifications to consider:

-

Material Grade: Voice coils are typically made from copper or aluminum wire. Copper offers better conductivity, leading to improved efficiency and sound quality, while aluminum is lighter and often more cost-effective. Selecting the appropriate material impacts performance and durability, influencing both the sound output and longevity of the loudspeaker.

-

Impedance: Measured in ohms (Ω), impedance is a crucial factor in matching voice coils to amplifiers. Common values include 4Ω, 8Ω, and 16Ω. Understanding impedance helps prevent equipment damage and ensures optimal power transfer, which is vital for achieving the desired audio performance.

-

Winding Configuration: This refers to how the wire is arranged around the bobbin and affects the coil’s thermal and electrical performance. Common configurations include round wire and flat wire. Each configuration has distinct benefits, such as heat dissipation and efficiency, which can influence the overall sound quality and reliability of the loudspeaker.

-

Voice Coil Diameter: The diameter affects the power handling capabilities and the speaker’s overall sound output. Larger coils can handle more power, which is beneficial for high-output applications. Buyers should consider the application to determine the appropriate size for their needs.

-

Bobbin Material: The bobbin, which houses the voice coil wire, can be made from various materials, including plastic or aluminum. The choice of bobbin material impacts the voice coil’s weight, thermal properties, and overall durability. Selecting the right bobbin material can enhance the performance and reliability of the loudspeaker.

-

Thermal Rating: This specification indicates the maximum temperature the voice coil can withstand without degradation. A higher thermal rating allows the voice coil to operate effectively under more demanding conditions, making it critical for applications requiring high power or extended use.

What Are Common Trade Terms Used in the Loudspeaker Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the loudspeaker market. Here are several key terms:

Illustrative image related to loudspeaker voice coil

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers assess product quality and compatibility for their needs.

-

MOQ (Minimum Order Quantity): This is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps buyers plan their inventory and budgeting, ensuring they meet supplier requirements while aligning with their purchasing strategy.

-

RFQ (Request for Quotation): An RFQ is a document that potential buyers send to suppliers to request pricing and terms for specific products. This process helps buyers compare costs and services from different suppliers, facilitating informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping arrangements. Understanding Incoterms is crucial for managing logistics and ensuring compliance with international shipping standards.

-

Lead Time: This term refers to the amount of time it takes for an order to be processed and delivered. Knowing the lead time is essential for project planning and inventory management, as it impacts production schedules and customer satisfaction.

-

Customs Clearance: This is the process of passing goods through customs so they can enter or leave a country. Understanding customs clearance is vital for international buyers, as it affects delivery times and costs associated with importing goods.

By grasping these technical specifications and trade terms, B2B buyers can make more informed decisions when sourcing loudspeaker voice coils, ensuring they select products that meet their operational needs and quality standards.

Navigating Market Dynamics and Sourcing Trends in the loudspeaker voice coil Sector

What Are the Current Market Dynamics and Key Trends in the Loudspeaker Voice Coil Sector?

The loudspeaker voice coil market is experiencing significant growth driven by several global factors. The increasing demand for high-quality audio in consumer electronics, coupled with the rise of smart devices, is propelling the market forward. Additionally, the professional audio sector, including live sound systems and studio equipment, continues to expand, creating further opportunities for suppliers. Buyers in regions like Africa, South America, the Middle East, and Europe are increasingly looking for high-performance components, reflecting a growing consumer base that values sound quality.

Emerging technologies, such as advancements in voice coil manufacturing techniques and materials, are also influencing sourcing trends. For instance, the adoption of flat wire technology and advanced bobbin materials improves efficiency and sound fidelity, making these components more attractive to B2B buyers. Moreover, the shift towards e-commerce platforms for sourcing components is reshaping the procurement process, allowing international buyers to access a wider range of products and suppliers quickly.

Another noteworthy trend is the consolidation of suppliers in Asia, which has resulted in competitive pricing and improved supply chain logistics. This is particularly beneficial for B2B buyers in developing regions, such as Nigeria and Vietnam, where cost-effectiveness is a critical consideration. Overall, understanding these dynamics can help international buyers make informed sourcing decisions that align with their operational needs and market demands.

How Can Sustainability and Ethical Sourcing Impact the Loudspeaker Voice Coil Supply Chain?

Sustainability is becoming a pivotal concern in the loudspeaker voice coil sector, particularly as global awareness of environmental issues rises. Buyers are increasingly prioritizing suppliers who adopt sustainable practices and materials. This shift is not only driven by regulatory pressures but also by consumer demand for eco-friendly products. For B2B buyers, sourcing from manufacturers that utilize recyclable materials or adhere to sustainable production methods can enhance brand reputation and customer loyalty.

Ethical sourcing is equally important. Ensuring that supply chains are free from exploitation and adhere to fair labor practices can significantly impact a company’s brand image. Buyers should seek out suppliers with certifications such as ISO 14001 (Environmental Management) and Fair Trade to validate their commitment to ethical practices. These certifications often indicate a supplier’s dedication to minimizing environmental impact and promoting fair labor conditions, which can be crucial for buyers looking to differentiate themselves in competitive markets.

Moreover, the use of ‘green’ materials, such as biodegradable plastics for voice coil components, is gaining traction. This not only reduces the environmental footprint but also aligns with the growing consumer expectation for corporate responsibility. By focusing on sustainability and ethical sourcing, B2B buyers in regions like Europe and the Middle East can enhance their competitive advantage and meet the demands of increasingly eco-conscious customers.

How Has the Loudspeaker Voice Coil Sector Evolved Over Time?

The loudspeaker voice coil sector has undergone significant evolution since its inception, shaped by technological advancements and changing market demands. Initially, voice coils were simple copper wire windings, but innovations in materials and techniques have transformed them into complex components that enhance audio performance. The introduction of flat wire technology allowed for greater efficiency and improved thermal management, leading to higher power handling capabilities.

From the 2010s onward, the manufacturing landscape shifted dramatically as many production facilities relocated to Asia and Mexico, primarily due to lower labor costs and increased production efficiency. This globalization has made high-quality voice coils more accessible to international buyers, while also introducing challenges related to supply chain management and quality assurance.

As the demand for high-fidelity audio continues to rise, particularly in professional audio and consumer electronics, the voice coil sector is likely to see further innovations. Staying abreast of these developments is crucial for B2B buyers looking to leverage the latest technologies and maintain a competitive edge in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of loudspeaker voice coil

-

How do I determine the right voice coil specifications for my loudspeakers?

To select the appropriate voice coil specifications, consider the speaker’s intended application, power handling, and impedance requirements. Key factors include the voice coil diameter, wire gauge, and winding configuration, which affect sound quality and performance. Collaborate with suppliers who can provide detailed technical data and recommendations based on your specific needs. Additionally, reviewing existing designs and consulting with engineers can help ensure optimal compatibility with your loudspeaker system. -

What is the best type of voice coil for high-performance loudspeakers?

High-performance loudspeakers often benefit from voice coils made of lightweight materials, such as aluminum or flat wire designs, which enhance efficiency and thermal management. Dual voice coils can also provide better power handling and improved sound quality. When sourcing, prioritize reputable manufacturers known for high-quality materials and precise winding techniques to ensure consistent performance and durability in demanding applications. -

What minimum order quantities (MOQs) should I expect when sourcing voice coils?

MOQs for voice coils can vary significantly based on the supplier and the complexity of the product. Generally, expect MOQs to range from 50 to 500 units. Some manufacturers may offer lower MOQs for standard products, while custom designs might require larger orders. When negotiating, consider your production needs and discuss flexibility with suppliers to accommodate future scaling. -

How can I vet potential suppliers for loudspeaker voice coils?

Vetting suppliers involves assessing their industry reputation, production capabilities, and quality assurance processes. Request product samples and certifications to evaluate material quality and manufacturing standards. Additionally, check references from other clients, especially those in your region, to gauge reliability and service levels. Engaging in direct communication about your requirements can also reveal their responsiveness and willingness to collaborate. -

What payment terms are typically offered by suppliers of voice coils?

Payment terms can vary widely, but common practices include net 30 or net 60 days after delivery. Some suppliers may require a deposit upfront, particularly for custom orders. It’s advisable to negotiate terms that align with your cash flow needs while ensuring the supplier feels secure in the transaction. Always review the contract for any additional fees or conditions that may apply. -

What quality assurance measures should I expect from voice coil suppliers?

Reputable suppliers should implement strict quality assurance protocols, including material inspections, dimensional checks, and performance testing. Look for suppliers that adhere to international quality standards such as ISO 9001. Request documentation on their testing procedures and certifications to ensure that the voice coils meet your specific performance criteria and reliability expectations. -

How does international shipping affect the procurement of voice coils?

International shipping can introduce complexities such as customs duties, tariffs, and shipping times that vary by region. It’s crucial to understand the logistics involved, including the supplier’s ability to manage shipping and handle necessary documentation. Work with suppliers who have experience in international trade and can provide transparent shipping options, ensuring that your voice coils arrive on time and within budget. -

Can I customize voice coils to fit specific design requirements?

Yes, many suppliers offer customization options for voice coils, including variations in diameter, impedance, wire materials, and winding configurations. When considering customization, provide detailed specifications and performance goals to your supplier. Collaborating early in the design process can ensure the final product meets your needs while also allowing for adjustments based on prototype testing and feedback.

Top 6 Loudspeaker Voice Coil Manufacturers & Suppliers List

1. Miscospeakers – Voice Coil Technology

Domain: blog.miscospeakers.com

Registered: 1998 (27 years)

Introduction: The voice coil in a loudspeaker is a thin strand of wire, typically made of copper, wrapped around a tube or former. When electricity passes through the coil, it becomes an electromagnet, interacting with a permanent magnet to produce sound. The voice coil converts electrical energy into mechanical energy, pushing the cone to create sound. It only uses about 3-5% of the energy input for sound prod…

2. Reconings – Voice Coils

Domain: reconingspeakers.com

Registered: 2010 (15 years)

Introduction: [{‘name’: ‘1.000″ Voice Coil VC3000-4’, ‘specifications’: ‘1.000″ ID, .812″ FH, .312″ WW, 4 Ohm, 2 Layer’, ‘price’: ‘$18.00’}, {‘name’: ‘1.000″ Voice Coil VC3000-8’, ‘specifications’: ‘1.000″ ID, .812″ FH, .312″ WW, 8 Ohm, 2 Layer’, ‘price’: ‘$18.00’}, {‘name’: ‘1.005″ Voice Coil VC3310-16’, ‘specifications’: ‘1.005 ID, 1.0″ FH, .312″ WW, 16 Ohm, 2 Layer’, ‘price’: ‘$17.00’}, {‘name’: ‘1.270″ Voic…

3. Madisound – Voice Coil Replacements

Domain: madisoundspeakerstore.com

Registered: 2011 (14 years)

Introduction: Voice Coil Replacements: Audax Voice Coils, Morel Voice Coils, ScanSpeak Voice Coils, Seas Voice Coils, Vifa Voice Coils, Fostex Voice Coils, RAAL Replacement Ribbons.

4. IQS Directory – Voice Coils

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Voice coils are coils of wire, typically made of copper, aluminum, or copper-clad aluminum, wrapped around a bobbin or former. They are attached to the apex of a speaker cone and interact with a magnetic field to produce sound. Key details include: 1. **Types of Voice Coils**: Moving coil design and moving magnet design. 2. **Materials**: Copper and aluminum are commonly used for winding; aluminum…

5. Stanford Magnets – Voice Coil Motor Solutions

Domain: stanfordmagnets.com

Registered: 1998 (27 years)

Introduction: Voice Coil Motor Characteristics: Reliability, Simplicity, Flexible Configuration, Fast Operation, Controllability, Low Hysteresis, Flexible Production. Speaker Voice Coil Components: Shaft material options include stainless steel and titanium. Magnet assembly designed for good volumetric efficiency and useful linear stroke. High energy density magnets used. Custom designs available for better lin…

6. Springfield Speaker Repair – Quality Speaker Restoration

Domain: springfieldspeakerrepair.com

Registered: 2010 (15 years)

Introduction: This company, Springfield Speaker Repair – Quality Speaker Restoration, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for loudspeaker voice coil

In today’s competitive audio market, strategic sourcing of loudspeaker voice coils presents significant opportunities for international B2B buyers. By focusing on quality and performance, companies can differentiate their offerings, ensuring superior sound reproduction that meets diverse customer needs. Understanding the nuances of voice coil specifications—such as wire materials, winding techniques, and bobbin sizes—enables buyers to make informed decisions that enhance product reliability and longevity.

Emphasizing strategic sourcing not only optimizes supply chain efficiency but also fosters strong partnerships with manufacturers, particularly those in regions like Asia and Europe where advanced production capabilities reside. This approach can lead to cost-effective solutions while maintaining high standards of quality.

As we look to the future, the demand for innovative loudspeaker solutions will only grow, especially in emerging markets across Africa and South America. Buyers are encouraged to leverage these insights and prioritize collaboration with trusted suppliers who can deliver the specialized voice coils required for cutting-edge audio applications. By doing so, businesses will be well-positioned to capture market share and drive sustainable growth in a dynamic industry landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.