Is Your Diy Urethane Bushings Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for diy urethane bushings

The demand for DIY urethane bushings has surged as businesses seek cost-effective solutions to enhance their automotive performance and longevity. However, sourcing high-quality materials and understanding the nuances of manufacturing can pose significant challenges for international B2B buyers. This comprehensive guide addresses these issues by exploring the various types of urethane bushings, their applications across different industries, and best practices for supplier vetting.

Buyers will gain insights into the intricacies of production, including mold-making techniques and material specifications, which are essential for ensuring compliance with industry standards. We also delve into cost considerations, helping you navigate pricing structures and identify potential cost-saving strategies without compromising quality. By providing a thorough understanding of the global market landscape for DIY urethane bushings, this guide empowers businesses from Africa, South America, the Middle East, and Europe—such as Germany and Nigeria—to make informed purchasing decisions.

Armed with actionable insights and expert recommendations, B2B buyers can confidently engage with suppliers, optimize their procurement processes, and ultimately enhance their operational efficiency. Whether you are a small workshop or a large-scale manufacturer, this guide is designed to facilitate your journey in the dynamic world of DIY urethane bushings.

Understanding diy urethane bushings Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Molded Urethane Bushings | Custom-shaped, typically softer than Delrin | Automotive suspension, machinery | Pros: Cost-effective for bulk orders. Cons: Longer lead times for custom molds. |

| Delrin Urethane Bushings | Harder, more durable, precision machined | High-performance automotive parts | Pros: Excellent wear resistance. Cons: Higher cost and requires machining expertise. |

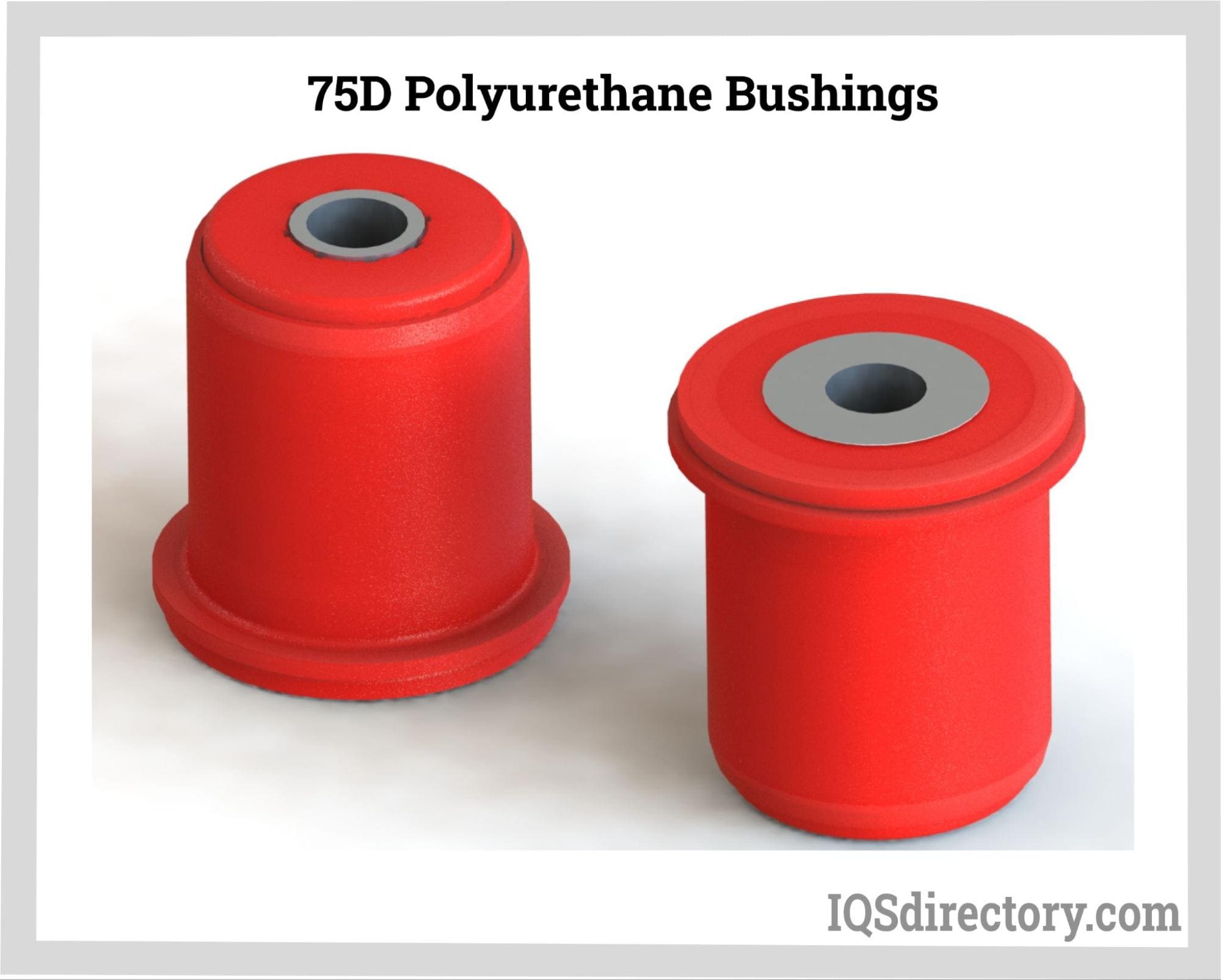

| Shore Hardness Varieties | Available in various hardness levels (Shore A/D) | Varying automotive applications | Pros: Tailored stiffness for specific applications. Cons: Requires careful selection based on application. |

| Reusable Mold Bushings | Designed for multiple uses, easy to demold | Prototyping and small production | Pros: Cost-effective for multiple copies. Cons: Limited durability compared to single-use molds. |

| Hybrid Urethane Bushings | Combination of urethane and other materials | Specialized automotive components | Pros: Enhanced performance characteristics. Cons: Potentially more complex supply chain. |

What Are Molded Urethane Bushings and Their Uses?

Molded urethane bushings are made by pouring liquid urethane into a custom mold, allowing for specific shapes and sizes suited to various applications. They are particularly popular in automotive suspension systems and machinery due to their ability to absorb vibrations and reduce noise. B2B buyers should consider the cost-effectiveness of bulk orders, although lead times can be longer due to the custom mold creation process.

How Do Delrin Urethane Bushings Differ?

Delrin urethane bushings are characterized by their high hardness and durability, making them ideal for high-performance automotive parts. They are precision machined from a thermoplastic material known for its low friction and excellent wear resistance. B2B buyers looking for long-lasting solutions should weigh the benefits of Delrin bushings against their higher cost and the need for specialized machining expertise.

Why Choose Shore Hardness Varieties?

Urethane bushings are available in various hardness levels, measured on the Shore scale. This variety allows businesses to select bushings tailored to specific applications, whether they require softer bushings for comfort or harder options for performance. Buyers must carefully assess the application requirements to ensure the selected hardness level meets their operational needs.

What Are Reusable Mold Bushings?

Reusable mold bushings are designed for multiple uses, making them ideal for prototyping and small production runs. Their construction allows for easy demolding, which can significantly reduce costs for businesses that require several copies of a part. However, their durability may be limited compared to single-use molds, which is a crucial consideration for B2B buyers focused on longevity.

What Are the Benefits of Hybrid Urethane Bushings?

Hybrid urethane bushings combine urethane with other materials to enhance performance characteristics, such as load-bearing capacity and vibration dampening. These bushings are often used in specialized automotive components where traditional materials may fall short. B2B buyers should consider the complexity of the supply chain and potential costs associated with sourcing hybrid materials, but the performance benefits can justify the investment.

Key Industrial Applications of diy urethane bushings

| Industry/Sector | Specific Application of diy urethane bushings | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom suspension components for racing vehicles | Enhanced performance and compliance with racing regulations | Material hardness, mold compatibility, and precision machining |

| Industrial Machinery | Vibration dampening in heavy machinery | Reduced wear and tear, extended machinery lifespan | Load-bearing capacity, environmental resistance, and durability |

| Construction Equipment | Bushings for excavators and loaders | Improved operational efficiency and reduced downtime | Custom fit, weather resistance, and compatibility with existing systems |

| Aerospace | Components in lightweight aircraft designs | Weight reduction and enhanced performance | Compliance with safety standards, material specifications, and testing |

| Marine Applications | Engine mounts and steering components in boats | Improved stability and handling in challenging conditions | Corrosion resistance, compatibility with marine environments |

How Are diy Urethane Bushings Used in the Automotive Sector?

In the automotive industry, DIY urethane bushings are essential for creating custom suspension components, particularly for racing vehicles where performance and regulatory compliance are crucial. These bushings replace traditional rubber bushings, offering increased stiffness and better handling characteristics. For international buyers, especially in regions like Germany and South Africa, sourcing high-quality urethane materials that meet specific hardness requirements is vital to ensure compliance with racing regulations and enhance vehicle performance.

What Role Do Urethane Bushings Play in Industrial Machinery?

In industrial machinery, DIY urethane bushings serve as effective vibration dampeners that mitigate wear and tear on equipment. By replacing conventional rubber bushings with urethane alternatives, businesses can significantly extend the lifespan of their machinery while improving operational efficiency. For buyers in South America and the Middle East, it is essential to consider the load-bearing capacity and environmental resistance of the urethane used, as these factors directly impact the performance and durability of the machinery in challenging operational environments.

How Are Urethane Bushings Beneficial for Construction Equipment?

Construction equipment, such as excavators and loaders, often utilizes DIY urethane bushings to enhance performance and reliability. These bushings improve the operational efficiency of heavy machinery by reducing downtime due to maintenance and repairs. Buyers in Africa and Europe should focus on sourcing bushings that offer a custom fit and weather resistance, as these characteristics are critical for equipment that operates in harsh outdoor conditions, ensuring longevity and reduced operational costs.

Why Are Urethane Bushings Important in Aerospace Applications?

In the aerospace sector, DIY urethane bushings are used in lightweight aircraft designs to reduce weight while maintaining structural integrity. These bushings are crucial for enhancing overall aircraft performance and fuel efficiency. B2B buyers in this industry must prioritize compliance with stringent safety standards and material specifications, ensuring that the urethane meets the rigorous testing required for aerospace applications to guarantee safety and reliability during flight operations.

How Do Urethane Bushings Enhance Marine Applications?

In marine applications, DIY urethane bushings are utilized in engine mounts and steering components to improve stability and handling in challenging maritime conditions. These bushings are designed to withstand corrosion and harsh marine environments, making them essential for boat performance. International buyers in regions with significant marine activities should consider the compatibility of urethane materials with marine environments, focusing on sourcing options that offer long-lasting performance and reliability in saltwater conditions.

3 Common User Pain Points for ‘diy urethane bushings’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Urethane Materials

The Problem: B2B buyers often struggle to find high-quality urethane materials suitable for DIY bushing projects. Many suppliers may offer urethane, but the specifications regarding hardness, chemical resistance, and durability can be vague or inconsistent. This lack of clarity can lead to poor performance of the bushings, resulting in increased wear and tear on vehicles and equipment, ultimately impacting operational efficiency and safety.

The Solution: To overcome this challenge, B2B buyers should establish relationships with reputable suppliers who provide detailed product specifications, including Shore hardness ratings and chemical compatibility. It’s advisable to request samples to evaluate the material’s performance before making a bulk purchase. Additionally, buyers can consult industry forums or trade groups for recommendations on reliable suppliers and best practices in sourcing urethane materials. By leveraging these resources, buyers can ensure they are investing in high-quality materials that meet their specific needs, thereby enhancing the longevity and effectiveness of their DIY bushings.

Scenario 2: Challenges in Molding and Machining Urethane Bushings

The Problem: Another common pain point is the complexity involved in molding and machining urethane bushings. Many B2B buyers may lack the necessary equipment or expertise to create precise molds or perform accurate machining, leading to subpar bushings that do not fit properly or perform effectively. This can result in increased labor costs and delays in production, frustrating buyers who need timely solutions.

The Solution: To address these challenges, it is crucial to invest in user-friendly molding kits that come with comprehensive instructions and tips for successful execution. Buyers should consider collaborating with local machine shops that have experience in working with urethane to assist with the machining process, particularly for complex designs. Additionally, attending workshops or online tutorials focused on DIY urethane projects can significantly enhance their skills and confidence in handling these materials. By equipping themselves with the right knowledge and partnerships, buyers can streamline the production process and achieve better results with their bushings.

Illustrative image related to diy urethane bushings

Scenario 3: Ensuring Compliance with Industry Standards

The Problem: B2B buyers often face difficulties in ensuring that their DIY urethane bushings comply with industry regulations and standards. Non-compliance can lead to legal repercussions, product recalls, and damage to a company’s reputation. This is particularly pressing in sectors such as automotive and aerospace, where safety and performance are paramount.

The Solution: To navigate compliance issues, buyers should familiarize themselves with the relevant industry standards for bushings, such as those set by the Society of Automotive Engineers (SAE) or other regulatory bodies. Consulting with compliance experts or legal advisors can provide valuable insights into the specific requirements that must be met. Additionally, buyers can implement a quality assurance program that includes regular testing of their bushings for compliance with durability and performance standards. By proactively addressing compliance, buyers can mitigate risks and reinforce their commitment to quality and safety in their products.

Strategic Material Selection Guide for diy urethane bushings

What Are the Key Materials for DIY Urethane Bushings?

When selecting materials for DIY urethane bushings, it’s essential to consider various options that can meet specific performance requirements. Below, we analyze four common materials: urethane, Delrin, nylon, and rubber, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Urethane Perform as a Material for Bushings?

Urethane is a popular choice for bushings due to its excellent elasticity and durability. It can withstand a wide range of temperatures, typically from -30°C to 80°C, and offers good resistance to abrasion and chemicals. Urethane bushings are particularly effective in automotive applications, providing improved handling and reduced noise.

Pros: Urethane is highly durable and can be formulated to various hardness levels, making it versatile for different applications. It also offers excellent vibration dampening properties.

Cons: Urethane can be more expensive than other materials, and its manufacturing process may require specialized equipment for molding, which can complicate production.

Impact on Application: Urethane is compatible with various automotive fluids, making it suitable for use in environments where exposure to oils and lubricants is common.

Illustrative image related to diy urethane bushings

Considerations for International Buyers: Urethane bushings must comply with international standards such as ASTM and DIN. Buyers should ensure that their suppliers can provide certifications that meet regional requirements, especially in Europe and the Middle East.

Why Consider Delrin for DIY Urethane Bushings?

Delrin, a type of polyoxymethylene (POM), is known for its high strength and rigidity. It performs well in applications requiring precision and low friction, making it suitable for bushings that need to withstand high loads and stresses.

Pros: Delrin offers excellent dimensional stability and is resistant to wear and chemicals, making it a long-lasting option for bushings.

Illustrative image related to diy urethane bushings

Cons: While it is durable, Delrin is less flexible than urethane, which may lead to a harsher ride in automotive applications. Additionally, machining Delrin requires specialized tools and knowledge.

Impact on Application: Delrin is suitable for applications where precision is critical, but it may not perform as well in environments with significant vibration or shock.

Considerations for International Buyers: Delrin is widely accepted in various industries, but buyers should verify compliance with local standards, particularly in regions with strict manufacturing regulations like Germany.

How Does Nylon Compare for Bushings?

Nylon is another viable material for bushings, known for its toughness and resistance to wear. It performs well in environments where moisture is present, making it suitable for applications in humid climates.

Illustrative image related to diy urethane bushings

Pros: Nylon is relatively inexpensive and easy to machine, making it accessible for DIY projects. It also has good self-lubricating properties, reducing the need for additional lubrication.

Cons: Nylon can absorb moisture, which may lead to dimensional changes over time. It is also less resistant to UV radiation compared to urethane and Delrin.

Impact on Application: Nylon bushings are suitable for applications where moisture exposure is a concern, but they may not be ideal for high-temperature environments.

Illustrative image related to diy urethane bushings

Considerations for International Buyers: Buyers in humid regions, such as parts of Africa and South America, should consider nylon for its moisture resistance but ensure that the material meets local standards.

Is Rubber a Suitable Option for DIY Bushings?

Rubber is the traditional material for bushings, offering excellent vibration dampening and flexibility. It is often used in automotive applications for its ability to absorb shocks.

Pros: Rubber is cost-effective and provides a comfortable ride due to its flexibility and cushioning properties.

Cons: Rubber can degrade over time due to exposure to oils, UV light, and temperature fluctuations, leading to a shorter lifespan compared to synthetic materials.

Impact on Application: While rubber is suitable for many applications, its susceptibility to degradation limits its use in high-performance settings.

Considerations for International Buyers: Buyers should be aware of the varying quality of rubber materials available globally. Compliance with standards like ASTM is crucial to ensure product reliability.

Summary Table of Material Selection for DIY Urethane Bushings

| Material | Typical Use Case for DIY Urethane Bushings | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Urethane | Automotive suspension bushings | Excellent durability and elasticity | Higher manufacturing complexity | Medium |

| Delrin | Precision bushings in high-load applications | High strength and rigidity | Less flexible, harsher ride | High |

| Nylon | Bushings in humid environments | Cost-effective and easy to machine | Moisture absorption can lead to dimensional changes | Low |

| Rubber | General-purpose automotive bushings | Good vibration dampening | Degrades over time, shorter lifespan | Low |

This guide provides a comprehensive overview of material options for DIY urethane bushings, equipping international B2B buyers with the insights needed to make informed decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for diy urethane bushings

What Are the Main Stages of Manufacturing DIY Urethane Bushings?

The manufacturing process for DIY urethane bushings consists of several critical stages, including material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the final product meets the desired specifications for performance and durability.

How Is Material Prepared for Urethane Bushings?

The first step in manufacturing urethane bushings involves selecting the appropriate materials. Urethane, known for its elasticity and resilience, is available in various hardness levels measured on the Shore scale. The choice of urethane grade will depend on the specific application and performance requirements of the bushings.

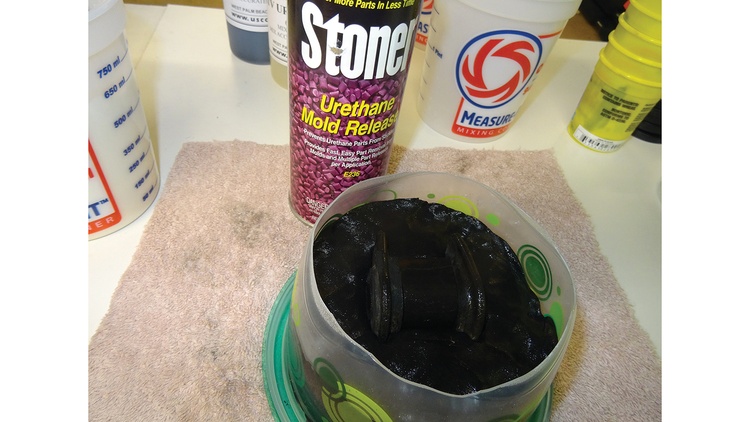

Once the material is selected, it must be properly prepared. This includes measuring and mixing the two components of urethane (resin and hardener) in precise ratios to ensure optimal curing and performance. It’s essential to use clean, contamination-free containers to avoid any adverse reactions that could compromise the quality of the bushings.

What Techniques Are Used in the Forming Process?

The forming process primarily involves molding, as most bushing-grade urethane is not machined but rather poured into molds. The creation of molds can be done through various methods, including:

-

Silicone Molding: This technique involves creating a mold from a silicone rubber that captures intricate details of the original part. This method is popular due to its flexibility and ease of use.

-

Plaster Molding: As discussed in the DIY process, plaster can be used for creating molds, especially for low-volume production. However, it may not be suitable for high-volume manufacturing due to its brittleness.

-

Injection Molding: For larger production runs, injection molding can be an efficient method. It requires specialized machinery that injects the liquid urethane into a pre-made mold, allowing for faster production cycles.

What Is Involved in the Assembly Stage?

After the urethane has cured, the assembly stage may involve the integration of additional components, such as metal sleeves or inserts. These components are crucial for ensuring that the bushings fit properly within the vehicle’s suspension system. Proper alignment and fitting are vital to maintain the integrity of the suspension and prevent premature wear.

It is also during this stage that any necessary modifications, such as drilling holes for mounting, are performed. Ensuring that these modifications are carried out with precision is essential for the overall performance of the bushings.

How Are Urethane Bushings Finished?

Finishing involves the removal of any excess material, known as flash, that may have formed during the molding process. This can be done through trimming or sanding to achieve the desired surface finish. A smooth finish is critical not only for aesthetic reasons but also to prevent any interference during installation.

Finally, a quality assurance check is performed to ensure that the bushings meet the specified dimensions and hardness. This step is crucial before the products are packaged and shipped to customers.

What International Standards Guide Quality Assurance for Urethane Bushings?

Quality assurance is a cornerstone of manufacturing, particularly for B2B buyers who require consistent performance and reliability. Adhering to international standards, such as ISO 9001, ensures that manufacturers implement effective quality management systems. This certification demonstrates a commitment to quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications may also apply, such as CE marking for products sold in the European market or API specifications for automotive components. These certifications help B2B buyers ensure that the products comply with regulatory requirements and industry norms.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are essential throughout the manufacturing process to detect and rectify any issues early on. The typical QC checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the required specifications. Any materials that do not comply should be rejected or returned.

-

In-Process Quality Control (IPQC): During production, continuous monitoring is necessary to ensure that the manufacturing process remains within specified parameters. This may include checks on temperature, mixing ratios, and curing times.

-

Final Quality Control (FQC): Before packaging and shipping, a final inspection is conducted. This includes verifying dimensions, hardness, and overall appearance of the bushings. Non-conforming products must be identified and addressed before they reach customers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify a supplier’s quality control practices:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes and quality assurance measures firsthand. This can reveal the extent to which the supplier adheres to international standards and internal QC protocols.

-

Quality Reports: Requesting quality reports and certifications can provide insights into the supplier’s compliance with relevant standards. These documents often include details on past performance, inspection results, and any corrective actions taken.

-

Third-Party Inspections: Engaging independent third-party inspectors can offer an unbiased assessment of the supplier’s quality control processes. These inspections can be particularly useful for international buyers who may face challenges visiting suppliers in person.

What Are the Nuances of Quality Control for International Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Each region may have specific regulatory requirements, cultural practices, and market expectations that influence the quality of products.

Buyers should also be aware of potential language barriers and differences in quality perceptions. Establishing clear communication channels and expectations upfront can help mitigate misunderstandings and ensure that the final products meet the desired standards.

Additionally, factors such as shipping times, customs regulations, and local market conditions can affect the overall quality assurance process. By considering these elements, international buyers can make more informed decisions and establish successful partnerships with suppliers in the urethane bushing manufacturing sector.

In conclusion, understanding the manufacturing processes and quality assurance protocols for DIY urethane bushings is critical for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, alongside adhering to international quality standards, buyers can ensure they source high-quality products that meet their performance needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diy urethane bushings’

To assist B2B buyers in procuring DIY urethane bushings, this guide provides a structured checklist designed to streamline the sourcing process. By following these steps, businesses can ensure they are making informed decisions when selecting materials and suppliers for their bushing needs.

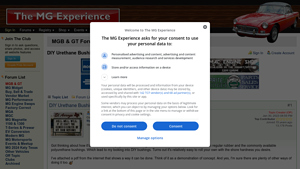

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your project is crucial before sourcing materials. Define the dimensions, hardness (measured on the Shore scale), and intended application of the urethane bushings. This clarity will guide your selection of materials and ensure compatibility with existing components.

Illustrative image related to diy urethane bushings

- Considerations:

- Hardness levels suitable for your application (e.g., softer for comfort, harder for performance).

- Dimensions that align with existing parts to avoid compatibility issues.

Step 2: Research Material Options

Urethane comes in various grades, each suited for different applications. Research the properties of the urethane you plan to use, such as temperature resistance, chemical stability, and durability.

- Details to examine:

- Supplier specifications for mechanical properties.

- Reviews or case studies demonstrating performance in similar applications.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and quality. Assess their experience in producing urethane bushings and request detailed company profiles, references, and client testimonials.

- Key actions:

- Ask for samples to verify quality.

- Check for certifications that validate their manufacturing processes (e.g., ISO standards).

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of suppliers, request quotes that include not only pricing but also lead times, shipping costs, and any minimum order quantities. Comparing these factors will help you find the best value.

- What to compare:

- Pricing per unit versus total costs including shipping.

- Payment terms and conditions offered by suppliers.

Step 5: Assess Production Capabilities

Understanding a supplier’s production capabilities is essential to ensure they can meet your demands. Inquire about their manufacturing processes, equipment, and capacity to handle orders of varying sizes.

- Consider:

- Whether they can accommodate custom orders or modifications.

- Lead times for both initial orders and reorders.

Step 6: Verify Compliance and Quality Assurance

Ensure that the materials you are sourcing comply with local regulations and industry standards. This is particularly important in regions with stringent quality controls.

- Verification methods:

- Request documentation that demonstrates compliance with relevant regulations.

- Review their quality assurance processes to guarantee consistent product quality.

Step 7: Finalize Agreements and Terms

Before placing your order, ensure all agreements are documented. Confirm delivery schedules, payment terms, and return policies to mitigate any potential disputes.

- Key agreements to include:

- Clear timelines for production and delivery.

- Defined terms for product returns or exchanges in case of defects.

By following this checklist, B2B buyers can navigate the complexities of sourcing DIY urethane bushings effectively, ensuring they obtain high-quality materials that meet their specific needs.

Comprehensive Cost and Pricing Analysis for diy urethane bushings Sourcing

When sourcing DIY urethane bushings, understanding the comprehensive cost structure and pricing factors is crucial for international B2B buyers. This analysis will help you navigate the complexities of pricing and ensure that you make informed purchasing decisions.

What Are the Key Cost Components in DIY Urethane Bushings?

The cost structure for DIY urethane bushings is made up of several key components:

-

Materials: The primary material for urethane bushings is polyurethane, which can vary in price based on quality and hardness. A basic two-part urethane kit might range from $15 to $30 for 16 ounces, sufficient for a few bushings. Other materials, such as Delrin, can also contribute to costs if used in conjunction with urethane.

-

Labor: If you are outsourcing the manufacturing process, labor costs can significantly impact the overall price. Skilled labor is required for machining and molding, and this varies by region. In countries like Germany, labor costs may be higher than in Nigeria or South America.

-

Manufacturing Overhead: This includes costs related to equipment, facility maintenance, and utilities. Overhead is typically calculated as a percentage of direct costs and can range from 10% to 30% depending on the efficiency of the manufacturing process.

-

Tooling: The initial setup for molds and machinery can be a significant upfront investment. Depending on the complexity of the designs, tooling costs can range from a few hundred to several thousand dollars.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the bushings meet necessary specifications. This may add 5% to 10% to the overall cost, depending on the level of testing and certification required.

-

Logistics: Shipping and handling costs can vary widely based on distance and shipping methods. International shipping can be particularly expensive due to tariffs and customs duties, which should be factored into the total cost.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. This margin can vary based on competition, market demand, and the uniqueness of the product.

What Influences the Pricing of DIY Urethane Bushings?

Several factors can influence pricing for urethane bushings:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes can lead to discounts, while smaller orders may incur higher per-unit costs due to fixed setup expenses. Establishing a good relationship with suppliers can often yield better pricing for larger quantities.

-

Specifications and Customization: Custom designs or specific hardness levels can affect pricing. Be clear about your specifications to avoid unexpected costs.

-

Material Quality and Certifications: Urethane hardness is measured on the Shore scale. Premium materials with certifications (like ISO or ASTM) can be priced higher due to their reliability and performance.

-

Supplier Factors: Supplier reputation, reliability, and historical performance can influence pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) can help you gauge potential additional costs related to shipping, insurance, and delivery responsibilities.

What Tips Can Help Buyers Negotiate Better Prices?

-

Negotiate Effectively: Be prepared to discuss your needs and expectations clearly. Use market research to support your negotiation, especially if you can demonstrate competitive pricing from other suppliers.

-

Focus on Cost-Efficiency: Consider the total cost of ownership (TCO) rather than just the initial purchase price. Cheaper bushings may lead to higher replacement costs due to lower durability.

-

Understand Pricing Nuances in International Markets: Be aware of currency fluctuations, local economic conditions, and import/export regulations that may affect pricing in different regions, particularly in Africa, South America, and the Middle East.

-

Seek Long-Term Partnerships: Building a strong relationship with suppliers can lead to better pricing, priority access to materials, and improved service.

Disclaimer on Indicative Prices

Prices for DIY urethane bushings can vary widely based on numerous factors. The figures provided are indicative and should be verified with suppliers for accurate quotes tailored to your specific needs and circumstances. Always conduct due diligence before finalizing any agreements.

Illustrative image related to diy urethane bushings

Alternatives Analysis: Comparing diy urethane bushings With Other Solutions

Introduction: Exploring Alternatives to DIY Urethane Bushings

In the automotive industry, particularly for performance vehicles, the choice of bushings can significantly influence handling, ride quality, and overall vehicle performance. While DIY urethane bushings present a cost-effective and customizable solution, there are several alternative options that businesses should consider. Understanding the strengths and weaknesses of these alternatives can help B2B buyers make informed purchasing decisions that align with their specific operational needs.

Comparison Table

| Comparison Aspect | DIY Urethane Bushings | Pre-Made Urethane Bushings | Metal Bushings |

|---|---|---|---|

| Performance | Custom hardness; good vibration dampening; can be optimized for specific applications. | Consistent quality; designed for specific vehicle applications; often performance-oriented. | High durability; excellent load-bearing capabilities; less flexibility. |

| Cost | Low material costs; potential for high labor costs if not machined in-house. | Moderate cost; prices vary by brand and specifications. | Generally higher upfront costs; long-term durability can justify investment. |

| Ease of Implementation | Requires skills in machining/molding; time-consuming. | Easy to install; plug-and-play design for most applications. | Installation can be complex; may require specialized tools or skills. |

| Maintenance | Can wear out if improperly mixed; requires periodic inspection. | Low maintenance; durable and designed to last. | Minimal maintenance; however, can corrode or wear over time. |

| Best Use Case | Ideal for custom builds or when specific performance tuning is required. | Best for standard replacements or performance upgrades without custom needs. | Suitable for heavy-duty applications where maximum strength is required. |

Detailed Breakdown of Alternatives

Pre-Made Urethane Bushings

Pre-made urethane bushings are designed and manufactured to meet specific vehicle performance standards. They offer consistent quality and reliability, making them a popular choice for businesses looking for quick replacements or upgrades. The ease of installation is a significant advantage, as these bushings typically fit directly into existing setups without the need for additional modifications. However, they may not offer the same level of customization as DIY solutions, which can be a drawback for specialized applications.

Metal Bushings

Metal bushings, often made from steel or aluminum, provide exceptional durability and load-bearing capacity. They are ideal for heavy-duty applications where strength is paramount, such as in racing or off-road vehicles. While they can offer superior performance in terms of handling and longevity, metal bushings may result in a harsher ride due to their rigidity. Additionally, their installation can be complex, often requiring specialized tools and expertise, which can lead to higher labor costs.

Conclusion: How to Choose the Right Bushing Solution for Your Needs

When selecting the right bushing solution, B2B buyers should consider their specific operational requirements, including performance expectations, budget constraints, and ease of implementation. DIY urethane bushings can be an excellent choice for custom applications where specific tuning is necessary, while pre-made urethane options provide reliability and ease of use for standard applications. Metal bushings, while more expensive and potentially less comfortable, are indispensable for heavy-duty situations requiring maximum strength. Ultimately, the best choice will depend on the unique needs and capabilities of the buyer’s operations.

Illustrative image related to diy urethane bushings

Essential Technical Properties and Trade Terminology for diy urethane bushings

What Are the Key Technical Properties of DIY Urethane Bushings?

When considering the production and application of DIY urethane bushings, several critical technical properties must be understood. These properties not only affect performance but also impact manufacturing processes and cost considerations.

1. Material Grade

Urethane bushings are typically made from thermoplastic polyurethanes (TPU) or thermoset urethanes. The material grade is crucial as it determines the bushing’s hardness, flexibility, and durability. Urethane hardness is measured on the Shore scale, with common grades for bushings ranging from Shore A 70 to Shore D 80. Selecting the appropriate material grade is vital for ensuring that the bushings perform optimally under specific load conditions, making it a key factor in B2B purchasing decisions.

2. Tolerances

Tolerance refers to the allowable deviation from a specified dimension. In the context of urethane bushings, tight tolerances are essential to ensure proper fitment and functionality within the suspension system. Variations in tolerance can lead to premature wear or failure of components, affecting the overall performance of the vehicle. Buyers must consider the required tolerances for their specific applications to avoid costly rework or replacement.

3. Load Capacity

The load capacity of urethane bushings is a measure of the maximum weight or force they can withstand without failing. This property is especially important in automotive applications where bushings are subjected to dynamic loads during operation. Understanding the load capacity helps businesses assess whether the bushings will meet the demands of their specific applications, thereby influencing purchasing decisions.

4. Chemical Resistance

Urethane bushings must resist various chemicals, including oils, fuels, and road salts, to ensure longevity and reliability. Chemical resistance is a critical property for bushings used in environments with exposure to harsh substances. Buyers need to consider the operating environment when selecting bushings to avoid degradation that could lead to failure.

5. Temperature Resistance

Temperature resistance indicates the range of temperatures the urethane can withstand without losing its mechanical properties. Urethane bushings often operate in environments with varying temperatures, making this property essential for ensuring that they maintain performance in extreme conditions. Buyers should evaluate the temperature requirements of their applications to select the right urethane material.

What Are Common Trade Terms Related to DIY Urethane Bushings?

Familiarity with industry-specific terminology is crucial for effective communication and decision-making in the B2B sector. Here are some common terms relevant to DIY urethane bushings.

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts that are sold to another company for incorporation into a larger product. In the context of urethane bushings, understanding OEM specifications can help businesses align their products with industry standards, ensuring compatibility and performance.

2. MOQ (Minimum Order Quantity)

MOQ represents the minimum number of units a supplier is willing to sell. This term is critical for B2B transactions as it affects inventory management and purchasing strategies. Buyers need to be aware of MOQ requirements to optimize their supply chain and avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. In the context of urethane bushings, issuing an RFQ allows businesses to compare offers from multiple suppliers, ensuring they secure the best pricing and terms for their needs.

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers engaged in global sourcing of urethane bushings, as they clarify shipping costs, risk, and delivery responsibilities.

Illustrative image related to diy urethane bushings

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This term is significant in the B2B context as it affects project timelines and inventory planning. Buyers should consider lead times when placing orders for urethane bushings to ensure timely availability for production or assembly.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing DIY urethane bushings, ultimately enhancing their operational efficiency and product performance.

Navigating Market Dynamics and Sourcing Trends in the diy urethane bushings Sector

What Are the Current Market Dynamics and Key Trends in the DIY Urethane Bushings Sector?

The global DIY urethane bushings market is witnessing a surge driven by increased consumer interest in automotive customization and performance enhancements. This trend is particularly pronounced among international B2B buyers from regions like Africa, South America, the Middle East, and Europe, where local automotive markets are evolving. The DIY culture, combined with a growing awareness of the benefits of urethane bushings—such as improved durability and performance—has led to a shift towards more accessible manufacturing techniques.

Emerging technologies such as 3D printing and advanced molding processes are making it easier for businesses to produce custom bushings at scale. These technologies allow for rapid prototyping and cost-effective small-batch production, which is particularly beneficial for B2B buyers looking to offer tailored solutions to niche markets. Additionally, the rise of online platforms for sourcing materials and supplies is enabling buyers to connect with manufacturers directly, streamlining the procurement process.

Illustrative image related to diy urethane bushings

Furthermore, regulatory dynamics are influencing sourcing trends. Buyers must consider compliance with local automotive regulations, which may vary significantly across regions. For instance, in Europe, stringent environmental regulations may drive demand for eco-friendly materials, while in emerging markets, cost-effectiveness and performance are often prioritized. Understanding these dynamics is essential for B2B buyers aiming to capitalize on the burgeoning DIY urethane bushings market.

How Is Sustainability and Ethical Sourcing Influencing the DIY Urethane Bushings Sector?

The push towards sustainability is reshaping the DIY urethane bushings landscape. B2B buyers are increasingly prioritizing environmentally-friendly practices, recognizing that consumers are more conscious of the ecological impact of their purchases. The use of sustainable materials in the production of urethane bushings can not only reduce environmental footprints but also enhance brand reputation and customer loyalty.

Ethical sourcing is becoming a vital consideration, particularly in regions where supply chains may be less transparent. Buyers are encouraged to seek out suppliers that adhere to responsible sourcing practices, ensuring that materials are obtained in ways that do not exploit labor or harm communities. Certifications such as ISO 14001 (Environmental Management) or the use of recycled materials can serve as indicators of a supplier’s commitment to sustainability.

In addition, the market is witnessing a rise in the availability of bio-based urethane materials, which offer a sustainable alternative to traditional petroleum-based products. This trend aligns with global efforts to reduce dependency on fossil fuels and promote circular economy principles. B2B buyers who invest in sustainable options not only contribute to environmental conservation but also position themselves as leaders in an increasingly eco-conscious market.

What Is the Evolution of the DIY Urethane Bushings Market?

The evolution of the DIY urethane bushings market can be traced back to the early days of automotive customization when performance enthusiasts began seeking alternatives to factory-installed rubber bushings. Initially, urethane bushings were primarily utilized in motorsports due to their superior performance characteristics. However, as the DIY automotive community expanded, so did the accessibility of materials and knowledge regarding urethane bushings.

Over the years, advancements in material science have improved the quality and performance of urethane bushings, making them a popular choice for both amateur and professional automotive projects. The advent of user-friendly manufacturing techniques, such as molding and 3D printing, has democratized the production of custom bushings, enabling a wider range of consumers to engage in DIY projects.

Today, the market is characterized by a diverse array of suppliers and products, catering to various performance needs and budgets. As interest in automotive customization continues to grow globally, the DIY urethane bushings sector is poised for further innovation and expansion, driven by both technological advancements and shifting consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of diy urethane bushings

-

How do I select the right supplier for DIY urethane bushings?

When sourcing DIY urethane bushings, it’s crucial to vet suppliers thoroughly. Look for manufacturers with a proven track record in producing high-quality bushings, preferably with certifications such as ISO 9001. Request samples to assess quality and durability. Additionally, check their production capabilities and experience with the specific requirements of your market, whether it’s for automotive, industrial, or custom applications. Establishing clear communication channels and understanding their lead times and customer service can also help in making an informed decision. -

What factors should I consider for customizing urethane bushings?

Customization of urethane bushings can depend on several factors, including hardness, size, and design specifications. Discuss your specific application needs with the supplier, such as load-bearing requirements, environmental resistance, and compatibility with existing components. Additionally, consider the production methods available, as some may offer more flexibility for customization than others. Ensure you understand the implications of customization on pricing and lead times, as bespoke solutions may require more extensive tooling and production adjustments. -

What are the typical minimum order quantities (MOQs) for DIY urethane bushings?

Minimum order quantities for urethane bushings can vary significantly between suppliers. Typically, MOQs can range from a few dozen to several hundred pieces, depending on the complexity of the design and the supplier’s production capacity. When negotiating MOQs, consider your project needs and future demand to avoid excess inventory. Some suppliers may offer lower MOQs for standard sizes, while custom designs often necessitate larger orders. Always confirm the MOQ upfront to align with your budgeting and supply chain strategy. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely among international suppliers, often influenced by the country of origin and industry norms. Common arrangements include payment in advance, partial payment before production, and the balance upon delivery. Letter of Credit (LC) is another secure method often used in international trade, providing protection for both parties. It’s essential to discuss and agree on payment terms upfront, including currency exchange considerations and any applicable tariffs or duties, to ensure a smooth transaction process. -

How do I ensure quality assurance for urethane bushings?

To ensure quality assurance, request detailed documentation from your supplier regarding their manufacturing processes and quality control measures. Establish key performance indicators (KPIs) relevant to your application, such as tensile strength and resilience. It’s beneficial to conduct regular inspections or audits, especially for bulk orders. Some suppliers may offer third-party testing services to validate the performance characteristics of the bushings. Additionally, consider establishing a return policy for defective items to safeguard your investment. -

What logistics considerations should I keep in mind when importing bushings?

When importing urethane bushings, logistics considerations include shipping methods, lead times, and customs clearance processes. Evaluate the most cost-effective shipping options, balancing speed and expense. Understand the import regulations of your country, including duties and taxes that may apply. It’s advisable to work with a freight forwarder experienced in your specific industry to navigate complex logistics and ensure timely delivery. Clear communication with your supplier regarding packaging and labeling can also help mitigate delays at customs. -

How can I address potential supply chain disruptions?

To address potential supply chain disruptions, diversify your supplier base across different regions to reduce dependency on a single source. Maintain a safety stock of critical components to buffer against unexpected delays. Establish strong relationships with your suppliers to facilitate open communication about potential issues. Additionally, keep an eye on global trends that could impact logistics, such as geopolitical events or natural disasters, and have contingency plans in place to adapt to changing circumstances. -

What are the benefits of using urethane bushings over rubber alternatives?

Urethane bushings offer several advantages over traditional rubber options, including increased durability, enhanced performance, and better resistance to environmental factors such as oil and temperature fluctuations. Urethane’s superior hardness can lead to improved handling and responsiveness in automotive applications. Additionally, they tend to have a longer lifespan, which can reduce replacement frequency and maintenance costs. For businesses looking to enhance the performance of their vehicles or machinery, investing in urethane bushings can provide significant long-term benefits.

Top 4 Diy Urethane Bushings Manufacturers & Suppliers List

1. Delrin – Thermoplastic for Bushings

Domain: grassrootsmotorsports.com

Registered: 1999 (26 years)

Introduction: Delrin (polyoxymethylene) – thermoplastic sold by DuPont; available under different names like Celcon, Ramtal, and Kepital; 4-foot stick purchased for less than $50; used for making bushings. Urethane – bushing-grade urethane is typically molded; a 16-ounce kit costs under $20; two-part mixture that takes about 10 minutes to start thickening and 24 hours to cure; hardness measured on the Shore sca…

2. Driftworks – EasyFlo 60 Liquid Plastic Resin

Domain: driftworks.com

Registered: 2002 (23 years)

Introduction: EasyFlo 60 Liquid Plastic Polyurethane Casting RESIN, 1kg, super low viscosity, 1:1 by volume, 2 min. working time, 15-30 min. demould, cured product is white or can be filled with dry fillers, ideal for decorative objects, prototype or production parts, tools, models, duplicate masters.

3. VW Vortex – DIY Poly Bushings

Domain: vwvortex.com

Registered: 1997 (28 years)

Introduction: DIY poly bushings made from windshield glue, which is identified as polyurethane. Concerns include the thickness of the glue for proper application. Users have discussed using Sika track drive windshield glue and have shared experiences with other polyurethane products. Some have attempted to use black adhesion primer to improve bonding with OEM rubber, but results have varied. The hardness of the…

4. MGExp – Custom DIY Urethane Bushings

Domain: mgexp.com

Registered: 2011 (14 years)

Introduction: DIY urethane bushings for MGB & GT vehicles; customizable shore hardness between regular rubber and standard polyurethane; ability to fine-tune to unique requirements; materials can include acid cure polyurethane sealants; requires molds, which can be made using a lathe; molds need non-stick coating; polyurethane rubber available in different hardness levels (60 to 90 Shore Hardness); may require …

Strategic Sourcing Conclusion and Outlook for diy urethane bushings

As the market for DIY urethane bushings continues to expand, strategic sourcing emerges as a critical component for businesses aiming to capitalize on this trend. By identifying reliable suppliers and leveraging local resources, companies can reduce costs, enhance product quality, and ensure compliance with international standards. The hands-on approach to creating urethane bushings not only fosters innovation but also enables businesses to meet specific customer needs, particularly in competitive markets across Africa, South America, the Middle East, and Europe.

Investing in the necessary tools and materials, such as high-quality urethane compounds and efficient molding techniques, can significantly improve production efficiency. Furthermore, establishing partnerships with local machining services can streamline the manufacturing process, allowing for quicker turnaround times and responsiveness to market demands.

Illustrative image related to diy urethane bushings

Looking ahead, the DIY urethane bushing sector presents significant opportunities for international B2B buyers. By embracing strategic sourcing and staying ahead of technological advancements, businesses can position themselves as leaders in this burgeoning market. Now is the time to explore new partnerships and invest in the tools and expertise needed to thrive in the evolving landscape of automotive parts manufacturing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.