Top 4 Weld Brush Suppliers (And How to Choose)

Introduction: Navigating the Global Market for weld brush

In the rapidly evolving landscape of industrial fabrication, sourcing the right weld brush can be a daunting task for B2B buyers, particularly when navigating the complexities of global supply chains. The need for efficient and effective weld cleaning solutions is paramount, especially for businesses in regions like Africa, South America, the Middle East, and Europe. This guide aims to demystify the world of weld brushes, offering insights into various types, applications, and innovative technologies that enhance the weld cleaning process.

Within these pages, you will find comprehensive information on the latest advancements in weld cleaning technology, including the benefits of electrolytic cleaning systems versus traditional methods. We will also cover critical factors for supplier vetting, enabling you to assess quality, reliability, and cost-effectiveness. Additionally, we will delve into pricing structures, helping you understand the financial implications of your purchasing decisions.

By equipping international B2B buyers with actionable insights and practical guidance, this guide empowers you to make informed decisions that enhance operational efficiency and product quality. Whether you’re in Nigeria, Saudi Arabia, or elsewhere, understanding the nuances of weld brush sourcing will position your business for success in a competitive marketplace.

Understanding weld brush Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Wire Brush | Durable stainless steel bristles, various sizes | Metal fabrication, automotive, aerospace | Pros: Effective for cleaning welds; Cons: Can wear out quickly if used improperly. |

| Carbon Steel Wire Brush | Strong carbon steel bristles, cost-effective | Heavy-duty industrial applications | Pros: Affordable; Cons: Less effective on stainless steel; risk of rust. |

| Electrolytic Weld Cleaner | Advanced cleaning technology, combines cleaning & passivation | Food processing, pharmaceutical, marine | Pros: Fast, safe, reduces hazardous waste; Cons: Higher initial investment. |

| Speed Brush Attachments | Quick-attach feature, compatible with various machines | High-volume manufacturing, assembly lines | Pros: Increases efficiency; Cons: May require specific equipment. |

| Applicator Pump Brushes | Designed for fluid delivery, threaded style | Precision cleaning in tight spaces | Pros: Ideal for intricate jobs; Cons: Limited to specific applications. |

What Are the Key Characteristics of Stainless Steel Wire Brushes?

Stainless steel wire brushes are designed with durable bristles that effectively remove oxidation and contaminants from weld seams. They are particularly suitable for stainless steel applications, making them a staple in industries such as metal fabrication, automotive, and aerospace. When purchasing, consider the brush size and bristle density, as these can significantly impact cleaning efficiency and surface finish.

How Do Carbon Steel Wire Brushes Differ from Other Types?

Carbon steel wire brushes are known for their strength and cost-effectiveness, making them a popular choice for heavy-duty industrial applications. However, they are less effective on stainless steel and are prone to rust if not maintained properly. Buyers should evaluate the type of materials they will be working with and balance cost against performance to determine suitability.

Why Choose Electrolytic Weld Cleaners for Industrial Applications?

Electrolytic weld cleaners leverage advanced technology to clean and passivate metal surfaces simultaneously, providing a safer alternative to traditional pickling methods. These machines are particularly beneficial in industries like food processing, pharmaceuticals, and marine applications, where cleanliness is paramount. While the initial investment may be higher, the long-term savings in labor and hazardous waste disposal make them an attractive option.

What Advantages Do Speed Brush Attachments Offer?

Speed brush attachments are designed for quick and easy integration with existing cleaning machines, enhancing productivity in high-volume manufacturing settings. They allow for rapid changes between different cleaning tasks, which is crucial for assembly lines. However, buyers must ensure compatibility with their existing equipment to maximize efficiency.

How Are Applicator Pump Brushes Used in Precision Cleaning?

Applicator pump brushes are specifically designed for fluid delivery, making them ideal for cleaning intricate welds in tight spaces. Their threaded style ensures a secure fit and ease of use. When considering this type of brush, businesses should assess the specific cleaning needs and the types of fluids being used to ensure optimal performance.

Key Industrial Applications of weld brush

| Industry/Sector | Specific Application of Weld Brush | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Cleaning and passivating stainless steel welds | Enhances corrosion resistance and aesthetic quality | Compatibility with various stainless steel grades |

| Construction | Surface preparation for structural steel welding | Ensures strong, durable welds for safety compliance | Availability of brushes suitable for heavy-duty use |

| Food and Beverage | Maintaining hygiene standards in stainless steel | Prevents contamination, ensuring product safety | Compliance with industry-specific sanitation standards |

| Oil and Gas | Cleaning welds on pipelines and equipment | Reduces maintenance costs and downtime | Resistance to harsh chemicals and environmental factors |

| Automotive | Finishing welds on chassis and exhaust systems | Improves product longevity and performance | Availability of specialized brushes for high-heat applications |

How is Weld Brush Used in Manufacturing?

In the manufacturing sector, weld brushes are essential for cleaning and passivating stainless steel welds. This process not only removes discoloration and oxidation but also enhances the corrosion resistance of the welded joints. By ensuring a clean weld surface, manufacturers can improve the aesthetic quality of their products, which is particularly important for industries focusing on high-end finishes. Buyers must consider the compatibility of the brushes with various stainless steel grades to ensure optimal results.

What Role Does Weld Brush Play in Construction?

In construction, weld brushes are used for surface preparation of structural steel before welding. A clean surface is crucial for achieving strong, durable welds that meet safety compliance standards. The use of weld brushes minimizes the risk of weld defects, which can lead to structural failures. Buyers should look for brushes that are durable enough to handle heavy-duty applications, as construction environments often involve rigorous use and exposure to various contaminants.

Why is Weld Brush Important in the Food and Beverage Industry?

The food and beverage industry mandates strict hygiene standards, making the use of weld brushes for cleaning stainless steel welds critical. These brushes help remove contaminants that could compromise food safety, ensuring that all surfaces are clean and passivated. This process protects against corrosion and bacterial growth, which is vital in maintaining product safety. Buyers in this sector should prioritize brushes that comply with industry-specific sanitation standards to meet regulatory requirements.

How Does Weld Brush Benefit the Oil and Gas Sector?

In the oil and gas industry, weld brushes are crucial for cleaning welds on pipelines and equipment. These brushes help to remove oxidation and other contaminants that can lead to corrosion, thereby reducing maintenance costs and extending the lifespan of the equipment. Given the harsh environments and chemical exposure typical in this sector, buyers should consider weld brushes that are resistant to harsh chemicals and environmental factors to ensure reliability and performance.

What Advantages Does Weld Brush Provide in the Automotive Industry?

In the automotive sector, weld brushes are used to finish welds on chassis and exhaust systems. A clean, polished weld not only improves the aesthetic appeal of the vehicle but also contributes to its longevity and performance. By using weld brushes, manufacturers can ensure that their products meet quality standards while reducing the likelihood of future repairs. Buyers should seek specialized brushes designed for high-heat applications to cater to the unique requirements of automotive welding processes.

3 Common User Pain Points for ‘weld brush’ & Their Solutions

Scenario 1: Struggling with Ineffective Weld Cleaning Techniques

The Problem: Many B2B buyers, particularly in industries involving stainless steel fabrication, face challenges with traditional weld cleaning methods that are labor-intensive and time-consuming. These methods, such as manual brushing or using pickling pastes, not only prolong production time but can also result in inconsistent finishes. Companies often grapple with the risk of damaging the stainless steel surface, leading to costly rework and potential delays in delivery timelines. This can be particularly problematic for businesses striving to maintain high-quality standards and meet customer expectations.

The Solution: To overcome this issue, B2B buyers should consider investing in advanced electrolytic weld cleaning machines, such as those offered by brands like TIG Brush or Weldbrush. These machines are designed to clean and passivate welds in a single step, drastically reducing the time and effort required for weld finishing. When sourcing these machines, it’s crucial to evaluate their performance specifications, such as the duty cycle, power settings, and ease of use. Opt for machines that allow for adjustable power settings to cater to various types of welds and materials. Additionally, training personnel on the optimal use of these machines will further enhance efficiency and consistency in weld cleaning processes.

Scenario 2: Difficulty in Sourcing Durable and Effective Weld Brushes

The Problem: A common pain point for B2B buyers is the challenge of sourcing high-quality weld brushes that withstand the rigors of frequent use. Many companies find that lower-quality brushes wear out quickly, leading to increased costs over time and potential interruptions in production. This issue can be compounded in regions where access to premium welding supplies is limited, causing businesses to settle for subpar products that do not perform adequately, resulting in unsatisfactory weld finishes.

The Solution: To ensure the procurement of durable and effective weld brushes, buyers should establish relationships with reputable suppliers who specialize in high-performance welding consumables. It’s beneficial to compare different brands and product lines, focusing on materials such as stainless steel or carbon fiber for brushes that offer superior durability. When evaluating options, look for brushes that feature reinforced bristles and ergonomic handles to enhance user comfort and effectiveness. Additionally, consider bulk purchasing agreements with suppliers to secure lower pricing and ensure a steady supply of quality brushes, ultimately streamlining operations and reducing downtime.

Scenario 3: Managing Safety Concerns Related to Weld Cleaning

The Problem: B2B buyers are increasingly concerned about the safety implications of traditional weld cleaning methods, particularly those involving hazardous chemicals like pickling pastes. The use of these substances not only poses health risks to workers but also creates environmental concerns that companies must navigate. This situation can lead to compliance issues, potential fines, and a tarnished reputation among environmentally conscious clients.

The Solution: Transitioning to safer alternatives, such as electrolytic weld cleaning systems, can significantly alleviate these safety concerns. These systems eliminate the need for harmful chemicals and reduce the risk of workplace accidents associated with chemical exposure. When implementing this change, it’s essential to conduct thorough research on various systems available in the market, assessing their safety features and environmental impact. Additionally, providing comprehensive training for employees on the new cleaning processes will enhance workplace safety and ensure that staff are well-informed about the benefits of using non-toxic cleaning methods. Promoting these safety improvements can also enhance the company’s reputation, appealing to clients who prioritize sustainability in their sourcing decisions.

Strategic Material Selection Guide for weld brush

What Are the Common Materials Used in Weld Brushes and Their Key Properties?

When selecting a weld brush, understanding the materials that comprise the brush is crucial for ensuring optimal performance and longevity. Below, we analyze four common materials used in weld brushes, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel brushes are known for their excellent corrosion resistance, high-temperature tolerance, and durability. They can withstand harsh cleaning environments and are less prone to rusting, making them ideal for stainless steel weld cleaning.

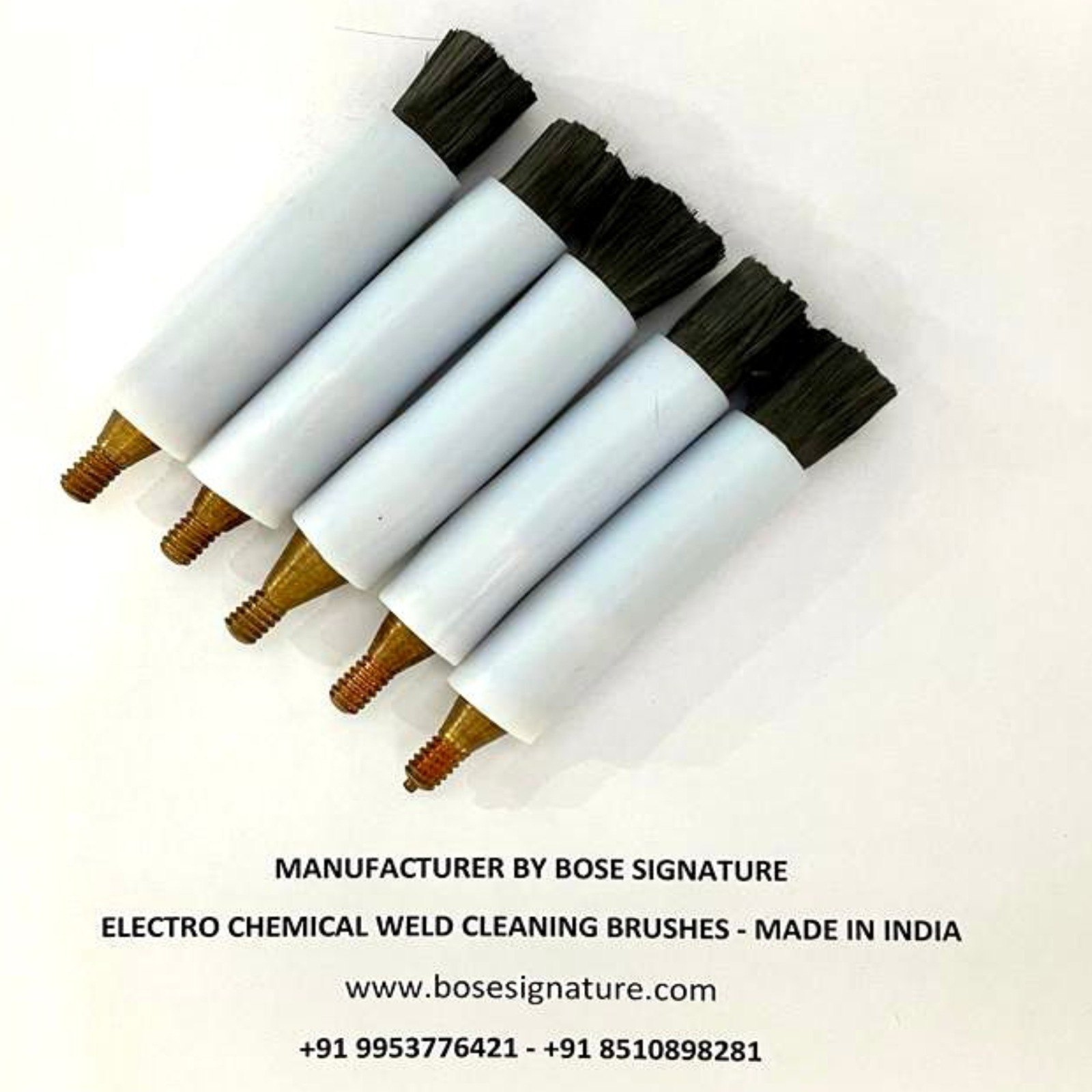

Illustrative image related to weld brush

Pros & Cons:

The durability of stainless steel brushes allows for extended use without significant wear. However, they can be more expensive than other materials, which may deter budget-conscious buyers. Manufacturing complexity is relatively low, but the cost of raw stainless steel can fluctuate.

Impact on Application:

Stainless steel brushes are particularly effective for cleaning stainless steel welds, as they do not introduce contaminants that could lead to corrosion. They are compatible with various cleaning media, including electrolytic solutions.

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East should ensure compliance with relevant standards such as ASTM and DIN for stainless steel quality. Additionally, buyers should consider local sourcing to mitigate costs related to import tariffs.

2. Carbon Steel

Key Properties:

Carbon steel brushes are known for their strength and ability to withstand high pressures. They are effective for heavy-duty applications but are more susceptible to rust and corrosion compared to stainless steel.

Illustrative image related to weld brush

Pros & Cons:

These brushes are typically less expensive than stainless steel, making them an attractive option for budget-conscious buyers. However, their susceptibility to corrosion can limit their lifespan, especially in humid environments.

Impact on Application:

Carbon steel brushes are suitable for cleaning ferrous materials but may introduce rust if not properly maintained. They work well with abrasive cleaning agents but are less effective on non-ferrous metals.

Considerations for International Buyers:

Buyers from humid regions such as Nigeria and parts of South America should be wary of carbon steel brushes’ corrosion issues. Compliance with local standards for steel quality is essential to ensure product reliability.

3. Brass

Key Properties:

Brass brushes offer good corrosion resistance and are softer than stainless and carbon steel, making them less abrasive. They are effective for delicate applications where surface scratching must be minimized.

Pros & Cons:

The softness of brass brushes makes them ideal for cleaning sensitive surfaces without damaging the underlying material. However, they wear out faster than steel brushes and may not be suitable for heavy-duty cleaning tasks.

Impact on Application:

Brass brushes are particularly effective for cleaning aluminum and other soft metals, as they do not leave behind metal particles that can cause corrosion. They are compatible with various cleaning solutions.

Considerations for International Buyers:

Buyers in regions with strict environmental regulations should consider brass brushes, as they produce less waste compared to harsher materials. Compliance with local standards for non-ferrous materials is also crucial.

4. Nylon

Key Properties:

Nylon brushes are synthetic and provide excellent flexibility and resistance to chemicals. They are non-abrasive, making them suitable for a variety of applications without risking surface damage.

Pros & Cons:

Nylon brushes are lightweight and resistant to many chemicals, which enhances their versatility. However, they may not be as durable as metal brushes and can degrade under high temperatures.

Impact on Application:

These brushes are ideal for cleaning delicate surfaces and can be used with various cleaning agents without risking damage. They are particularly effective in environments where metal brushes may introduce contaminants.

Considerations for International Buyers:

Nylon brushes are a good option for buyers in regions with varying environmental conditions, as they perform well in both wet and dry environments. Ensuring compliance with local manufacturing standards is essential for product quality.

Summary Table of Weld Brush Materials

| Material | Typical Use Case for weld brush | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Cleaning stainless steel welds | Excellent corrosion resistance | Higher cost compared to others | High |

| Carbon Steel | Heavy-duty cleaning of ferrous metals | Cost-effective | Susceptible to rust | Medium |

| Brass | Cleaning delicate surfaces | Non-abrasive, minimizes damage | Wears out faster than steel | Medium |

| Nylon | Versatile cleaning for various surfaces | Lightweight, chemical resistant | Less durable under high temperatures | Low |

This analysis provides a comprehensive overview of the materials used in weld brushes, helping B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for weld brush

The manufacturing processes and quality assurance protocols for weld brushes are critical components that ensure the products meet the high standards expected by B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. Understanding these processes can help buyers make informed decisions when selecting suppliers.

What Are the Main Stages of Weld Brush Manufacturing?

Material Preparation: What Materials Are Used in Weld Brush Production?

The manufacturing of weld brushes typically begins with the careful selection of materials. Commonly used materials include stainless steel and carbon steel for the bristles, which provide durability and effective cleaning capabilities. The handle may be made from various materials, including plastic or metal, depending on the desired strength and ergonomics. Material preparation also involves sourcing high-quality raw materials that comply with international standards to ensure longevity and performance.

How Is the Forming Process Executed for Weld Brushes?

The forming stage involves shaping the bristles and handles into their final forms. For the bristles, techniques such as wire drawing, cutting, and bundling are employed. Advanced manufacturing methods like automated CNC machinery may be utilized to ensure precision in the bristle length and density. Handles are often molded or extruded, with specific attention to ergonomics to facilitate ease of use during welding operations.

What Assembly Techniques Are Commonly Used in Weld Brush Production?

Assembly of weld brushes involves integrating the bristles with the handle. This can be achieved through various methods, such as crimping, adhesive bonding, or using mechanical fasteners. Quality control checkpoints are crucial at this stage to ensure that the bristles are securely attached and that the overall assembly meets the required specifications.

What Finishing Processes Are Applied to Weld Brushes?

Finishing processes enhance the performance and aesthetic appeal of weld brushes. This may include surface treatments such as galvanization or powder coating to improve corrosion resistance. Additionally, brushes may undergo quality checks for uniformity, ensuring that each product meets established standards for both appearance and functionality.

What Quality Assurance Standards Are Relevant for Weld Brushes?

Which International Standards Should B2B Buyers Look For?

B2B buyers should seek suppliers that comply with recognized international quality management standards, such as ISO 9001. This certification indicates that the manufacturer has implemented a quality management system that meets customer and regulatory requirements. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for applications in the oil and gas sector are important indicators of quality.

What Are the Key Quality Control Checkpoints in Weld Brush Manufacturing?

Quality control in weld brush manufacturing is typically organized into several checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specifications before production begins.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards. This can include checking the dimensions of bristles and ensuring proper assembly.

-

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is performed to verify that the weld brushes meet all established quality standards and specifications.

What Common Testing Methods Are Employed for Weld Brushes?

How Are Weld Brushes Tested for Performance and Durability?

Several testing methods are utilized to ensure the performance and durability of weld brushes. Common tests include:

-

Tensile Strength Testing: This evaluates the strength of the bristles and handles, ensuring they can withstand the rigors of use.

-

Corrosion Resistance Testing: Since weld brushes are often used in environments where corrosion is a concern, manufacturers may conduct tests to assess how well the materials resist rust and degradation.

-

Functional Testing: This involves using the brushes in real-world scenarios to ensure they effectively clean welds without damaging the underlying surface.

How Can B2B Buyers Verify Supplier Quality Control?

What Steps Can Buyers Take to Ensure Supplier Compliance with Quality Standards?

To verify a supplier’s quality control processes, B2B buyers can take the following steps:

-

Conduct Supplier Audits: Regular audits of potential suppliers can help assess their adherence to quality standards. This includes reviewing their manufacturing processes, quality control measures, and certifications.

-

Request Quality Reports: Buyers should ask for detailed quality assurance reports that outline the supplier’s testing methods, results, and compliance with relevant standards.

-

Engage Third-Party Inspection Services: Utilizing independent third-party inspectors can provide an unbiased evaluation of the supplier’s quality control processes and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

How Do Regional Standards Affect Quality Assurance in Weld Brush Manufacturing?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, must be aware of regional standards and regulations that can affect quality assurance. For instance, European buyers may prioritize CE certification, while buyers in the Middle East might focus on local compliance standards. Understanding these nuances is crucial for ensuring that the supplied products meet local market requirements and customer expectations.

What Should Buyers Know About Warranty and Return Policies?

Buyers should inquire about warranty and return policies as part of their quality assurance verification process. A comprehensive warranty indicates a manufacturer’s confidence in their product quality. Additionally, understanding the return policy can provide insights into the supplier’s commitment to customer satisfaction and product reliability.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for weld brushes empowers B2B buyers to make informed decisions. By prioritizing suppliers that adhere to international standards and demonstrate robust quality control measures, buyers can ensure they receive high-quality products that meet their specific needs.

Illustrative image related to weld brush

Practical Sourcing Guide: A Step-by-Step Checklist for ‘weld brush’

When sourcing weld brushes for your business, ensuring you make informed decisions is crucial for maintaining quality and efficiency in your welding processes. This guide provides a practical checklist to help you navigate the procurement of weld brushes effectively, enabling you to select the best products for your specific needs.

1. Identify Your Specific Application Needs

Before starting your procurement process, clearly define the applications for which you will use the weld brushes. Different welding processes and materials require specific brush types, such as stainless steel, carbon steel, or specialty brushes for unique finishes. Understanding your requirements will help narrow down suitable options.

- Types of Weld Brushes: Consider whether you need hand brushes, power brushes, or specialized cleaning machines.

- Material Compatibility: Ensure the brush material is compatible with the metals you are working with to avoid contamination.

2. Determine Quality Standards

Quality is paramount when selecting weld brushes, as inferior products can lead to poor weld finishes and increased rework costs. Research industry standards relevant to your region or sector.

- ISO Certifications: Look for suppliers with ISO certifications, indicating adherence to international quality standards.

- Material Specifications: Check the material specifications and durability ratings of the brushes to ensure they meet your operational demands.

3. Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and product quality. This step is essential to avoid disruptions in your supply chain.

- Request Documentation: Ask for company profiles, product catalogs, and case studies.

- References and Reviews: Seek references from other businesses in your industry and check online reviews to assess supplier reputation.

4. Compare Pricing and Value

While price is an important factor, it should not be the sole consideration. Compare the total value offered by different suppliers, including product quality, service, and warranty options.

- Bulk Purchase Discounts: Inquire about volume discounts if you plan to order large quantities.

- Long-Term Cost Analysis: Consider the long-term costs associated with lower-quality products, such as increased maintenance and replacement frequency.

5. Assess Availability and Lead Times

Understanding the availability of products and lead times is crucial for maintaining your production schedule. Delays in sourcing can impact your operations significantly.

- Stock Levels: Confirm the supplier’s stock levels and ability to fulfill large orders promptly.

- Shipping Options: Evaluate shipping options and costs, especially if you are sourcing from international suppliers.

6. Verify After-Sales Support and Warranty

Reliable after-sales support can significantly affect your overall satisfaction with the product. Ensure the supplier provides adequate support and warranty options.

- Customer Support: Check if the supplier offers technical support for product usage and troubleshooting.

- Warranty Terms: Review warranty policies to understand the coverage for defects or failures.

7. Finalize the Purchase and Establish a Relationship

Once you have selected a supplier, finalize the purchase while ensuring all terms are clear. Building a strong relationship with your supplier can lead to better service and future collaboration.

Illustrative image related to weld brush

- Contractual Agreements: Ensure all agreements are documented to avoid misunderstandings.

- Regular Communication: Maintain open lines of communication for future orders and feedback on product performance.

By following this checklist, you can make informed decisions when sourcing weld brushes, ensuring that you select the right products to meet your business needs effectively.

Comprehensive Cost and Pricing Analysis for weld brush Sourcing

What Are the Key Cost Components in Weld Brush Sourcing?

When sourcing weld brushes, understanding the cost structure is essential for effective budgeting and pricing negotiations. The primary cost components include:

-

Materials: The type of materials used significantly affects the cost. Stainless steel and carbon steel are common options, with stainless steel often commanding a higher price due to its durability and resistance to corrosion.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing and assembly processes. Regions with higher labor costs, such as parts of Europe, may see increased pricing compared to those with lower labor rates in regions like Africa and South America.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Companies with optimized operations may be able to offer more competitive prices by effectively managing these overhead costs.

-

Tooling: The initial investment in tooling can be significant, especially for custom or specialized weld brushes. Suppliers may pass these costs onto buyers, so it’s vital to consider tooling costs when evaluating quotes.

-

Quality Control (QC): Rigorous QC processes ensure that products meet specified standards. While this adds to the overall cost, it enhances product reliability and can reduce long-term costs associated with defects.

-

Logistics: Shipping and handling costs can vary widely depending on distance, shipping methods, and the chosen Incoterms. Buyers should factor in logistics when assessing total costs.

-

Margin: Suppliers typically add a margin to cover their expenses and profit. Understanding the market average can help buyers negotiate better prices.

How Do Price Influencers Affect Weld Brush Costs?

Several factors influence the pricing of weld brushes, making it essential for buyers to consider them during sourcing:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should aim to consolidate orders to benefit from bulk pricing.

-

Specifications and Customization: Custom specifications can lead to increased costs. While tailored products may meet specific needs, buyers should weigh the benefits against potential price hikes.

-

Quality and Certifications: Brushes that meet international quality standards or possess certifications (like ISO) may be more expensive. However, investing in quality can lead to better performance and longevity.

-

Supplier Factors: The reputation and reliability of a supplier can impact pricing. Established suppliers with a track record of quality may charge more, but they often provide peace of mind.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) significantly affects logistics costs and risk. Understanding these terms is crucial for evaluating total costs.

What Buyer Tips Can Help Optimize Weld Brush Sourcing?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, several strategies can enhance sourcing effectiveness:

Illustrative image related to weld brush

-

Negotiation: Engage suppliers in discussions about pricing, especially when placing large orders. Leverage your position as a buyer to negotiate better terms.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors such as durability, maintenance, and potential downtime costs.

-

Understand Pricing Nuances: Be aware that pricing can vary significantly across regions due to local market conditions, tariffs, and shipping costs. Research competitors and market trends to inform negotiations.

-

Consider Local Suppliers: Where possible, sourcing from local suppliers can reduce shipping costs and lead times, making it a cost-effective option for many businesses.

Disclaimer on Indicative Prices

Prices for weld brushes can vary widely based on specifications, suppliers, and market conditions. The figures provided in this analysis are indicative and should be used as a guideline rather than a definitive cost. Always request detailed quotations from multiple suppliers to ensure a comprehensive understanding of current pricing dynamics in the market.

Alternatives Analysis: Comparing weld brush With Other Solutions

Exploring Alternatives to Weld Brushes for Effective Weld Cleaning

In the realm of weld cleaning, various solutions exist beyond the traditional weld brush. Understanding these alternatives enables businesses to make informed decisions that align with their operational needs and budget constraints. Below is a comparative analysis of the weld brush against two prominent alternatives: electrolytic weld cleaning systems and pickling paste.

| Comparison Aspect | Weld Brush | Electrolytic Weld Cleaner | Pickling Paste |

|---|---|---|---|

| Performance | Effective for surface rust and minor discoloration. | Quickly removes discoloration and passes stainless steel in one step. | Effective but slower; requires multiple applications. |

| Cost | Generally low to moderate initial investment. | Higher initial cost, but potential long-term savings on labor and materials. | Low initial cost, but ongoing costs for application and disposal. |

| Ease of Implementation | Simple to use; minimal training required. | Requires some training; more complex equipment setup. | Labor-intensive; requires careful handling of chemicals. |

| Maintenance | Low maintenance; regular cleaning required. | Moderate maintenance; requires periodic servicing of the equipment. | High maintenance; requires careful disposal of hazardous materials. |

| Best Use Case | Ideal for small-scale jobs or quick touch-ups. | Best for large projects requiring high efficiency and safety. | Suitable for projects where cost is a primary concern, despite safety risks. |

What are the Pros and Cons of Electrolytic Weld Cleaning Systems?

Electrolytic weld cleaning systems utilize a combination of electric currents and cleaning fluids to effectively remove discoloration and passivate stainless steel surfaces. Pros include faster cleaning times, reduced labor costs, and a safer process compared to traditional methods. These systems can handle large volumes efficiently, making them suitable for industrial applications. However, the cons include a higher initial investment and the need for staff training to operate the equipment effectively.

Illustrative image related to weld brush

How Does Pickling Paste Compare to Weld Brushes?

Pickling paste is a chemical solution used to clean and passivate welds, particularly stainless steel. While it is generally less expensive than other methods, it poses significant safety risks due to its corrosive nature. Pros include its effectiveness for thorough cleaning and passivation. However, cons include the labor-intensive application process, the need for protective gear, and potential environmental disposal issues. This method is often viewed as outdated due to its hazardous nature and the advancements in cleaner technologies.

Conclusion: How Should B2B Buyers Choose the Right Weld Cleaning Solution?

Selecting the right weld cleaning solution hinges on multiple factors, including performance needs, budget, and safety considerations. For businesses focused on efficiency and safety, electrolytic weld cleaners may provide the best long-term value despite their higher upfront costs. Conversely, for smaller projects or those with budget constraints, weld brushes or pickling paste may suffice. Ultimately, B2B buyers should assess their specific requirements and operational context to determine the most appropriate weld cleaning method that aligns with their quality standards and safety protocols.

Essential Technical Properties and Trade Terminology for weld brush

What Are the Key Technical Properties of a Weld Brush?

When selecting a weld brush, understanding its technical specifications is crucial for ensuring optimal performance and longevity. Here are some essential properties to consider:

Illustrative image related to weld brush

1. Material Grade

Weld brushes are commonly made from materials such as stainless steel, carbon steel, or brass. Stainless steel brushes are particularly popular due to their corrosion resistance and durability, making them ideal for cleaning stainless steel welds. Understanding the material grade helps buyers assess the brush’s suitability for specific applications and environments, especially in industries where hygiene and corrosion resistance are paramount.

2. Wire Diameter

The diameter of the wires in a weld brush significantly impacts its cleaning efficiency and the surface finish it provides. Thicker wires can remove more material and are suited for heavy-duty applications, while finer wires offer a gentler touch for delicate surfaces. Selecting the right wire diameter is essential to avoid damaging the base material while achieving effective cleaning.

3. Brush Size and Shape

Weld brushes come in various sizes and shapes, including handheld, rotary, and power-assisted configurations. The choice of size and shape should align with the specific welding tasks and the accessibility of the welds being cleaned. For example, smaller brushes are better for tight spaces, while larger brushes can cover more area quickly. Understanding the application context is vital for selecting the appropriate brush.

4. Duty Cycle

The duty cycle refers to the amount of time a weld brush can be used continuously before needing a rest period. A 100% duty cycle indicates that the brush can operate continuously without overheating. This specification is critical for businesses that require consistent and uninterrupted cleaning operations, as it affects productivity and operational efficiency.

5. Compatibility with Cleaning Solutions

Many weld brushes are designed to work in conjunction with specific cleaning solutions or chemicals, such as electrolytic fluids. Compatibility ensures that the brush can effectively clean and passivate welds without damaging the material. Buyers must consider the chemicals they plan to use and select brushes that are chemically resistant and designed for such applications.

6. Adjustable Power Settings

Some advanced weld cleaning machines offer adjustable power settings, allowing users to tailor the cleaning intensity based on the specific needs of the job. This feature is particularly beneficial in a B2B context, as it enhances versatility and accommodates a wide range of materials and weld types.

What Common Trade Terms Should B2B Buyers Know When Purchasing Weld Brushes?

Understanding industry terminology is essential for effective communication and decision-making in the B2B landscape. Here are some common terms related to weld brushes:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another company. In the context of weld brushes, buyers often seek OEM products for reliability and quality assurance, ensuring that the brushes meet specific manufacturing standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers as it affects inventory management and cost efficiency. Understanding the MOQ can help businesses plan their purchases according to budget and storage capacity.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. B2B buyers should be familiar with this term to facilitate negotiations and ensure they receive competitive pricing for weld brushes and related equipment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding shipping, delivery, and insurance. Familiarity with Incoterms is crucial for international buyers to avoid misunderstandings about costs and responsibilities during the procurement process.

5. SKU (Stock Keeping Unit)

SKU is a unique identifier for each distinct product and service that can be purchased. Understanding SKUs helps buyers accurately track inventory levels and streamline ordering processes.

6. Lead Time

Lead time refers to the time taken from placing an order to its delivery. For B2B buyers, knowing the lead time is essential for project planning and ensuring timely availability of weld brushes, which can impact production schedules.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product quality in their welding processes.

Illustrative image related to weld brush

Navigating Market Dynamics and Sourcing Trends in the weld brush Sector

What Are the Current Market Dynamics and Key Trends in the Weld Brush Sector?

The global weld brush market is witnessing significant growth, driven by the increasing demand for high-quality welding solutions across various industries, including construction, automotive, and manufacturing. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to enhance their manufacturing capabilities, they are increasingly looking for advanced weld cleaning technologies. Key trends include the rising adoption of electrolytic cleaning systems, which offer faster, safer, and more efficient methods of weld cleaning compared to traditional techniques. These systems not only streamline the cleaning process but also improve the quality of weld finishes, thereby enhancing product aesthetics and durability.

Emerging technologies such as automated weld cleaning machines are also gaining traction. These innovations allow for precision cleaning and reduce the labor intensity associated with manual methods. Additionally, the integration of IoT (Internet of Things) in weld cleaning equipment is becoming more prevalent, enabling real-time monitoring and maintenance, which is particularly beneficial for B2B buyers focused on minimizing downtime and optimizing operational efficiency.

Market dynamics are further influenced by regulatory changes aimed at improving workplace safety and environmental standards. As countries tighten regulations on hazardous materials, B2B buyers are increasingly prioritizing suppliers that offer compliant and innovative solutions. This shift presents an opportunity for international buyers to align with manufacturers that can provide cutting-edge, compliant products.

How Are Sustainability and Ethical Sourcing Impacting the Weld Brush Market?

Sustainability has emerged as a crucial consideration for B2B buyers in the weld brush sector. The environmental impact of traditional cleaning methods, particularly those involving hazardous chemicals, has prompted a shift towards safer, eco-friendly alternatives. The adoption of electrolytic cleaning systems, which eliminate the need for toxic pickling pastes, exemplifies this trend. These systems not only reduce chemical waste but also enhance worker safety, aligning with the growing demand for sustainable practices in manufacturing.

Moreover, ethical sourcing is becoming increasingly important. Buyers are now more inclined to partner with suppliers who prioritize transparency and sustainability in their supply chains. The presence of ‘green’ certifications, such as ISO 14001 for environmental management, can serve as a critical factor in supplier selection. B2B buyers are encouraged to evaluate their suppliers based on their environmental practices, ensuring that the materials used in weld brushes are sourced responsibly and sustainably.

Investing in suppliers that adhere to ethical standards not only mitigates risks associated with environmental regulations but also enhances brand reputation. As the global market evolves, B2B buyers who prioritize sustainability and ethical sourcing will likely gain a competitive advantage, appealing to a more environmentally conscious customer base.

What Is the Historical Context of the Weld Brush Sector?

The evolution of the weld brush sector can be traced back to the early days of welding technology. Initially, manual cleaning methods dominated, with wire brushes and chemical solutions being the primary tools for weld finishing. Over time, as industries began to recognize the importance of weld aesthetics and integrity, the demand for more efficient cleaning solutions surged.

The introduction of automated and electrolytic cleaning systems marked a significant turning point in the industry. These advancements not only improved cleaning efficiency but also addressed safety and environmental concerns associated with traditional methods. Today, the weld brush market is characterized by ongoing innovation, with manufacturers continuously developing products that meet the demands of a rapidly changing global landscape.

In summary, the weld brush sector is undergoing transformative changes, driven by technological advancements and a growing emphasis on sustainability. B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their operational goals and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of weld brush

-

How do I solve issues with weld discoloration on stainless steel?

Discoloration on stainless steel welds can be effectively addressed by using specialized weld cleaning brushes designed for this purpose. These brushes, often made with stainless steel or brass bristles, can remove oxidation and restore the metal’s appearance. For optimal results, consider using an electrolytic cleaning system, which not only cleans but also passivates the surface in one step, ensuring a long-lasting finish. Regular maintenance with quality brushes can prevent discoloration from becoming a recurring issue. -

What is the best type of weld brush for stainless steel cleaning?

The best type of weld brush for stainless steel cleaning typically features stainless steel bristles due to their durability and effectiveness in removing oxidation without damaging the metal surface. Brushes with a combination of different bristle sizes can provide a more thorough clean, reaching into crevices and seams. Additionally, using brushes compatible with electrolytic cleaning systems can enhance the cleaning process and improve the overall finish of the weld. -

What should I consider when sourcing weld brushes internationally?

When sourcing weld brushes internationally, consider factors such as the supplier’s reputation, product quality, and compliance with international standards. Evaluate their ability to provide certifications, such as ISO, which can ensure product reliability. Additionally, assess shipping logistics, including lead times and costs, to avoid delays. Engaging with suppliers that offer samples can also help you evaluate the quality before committing to a larger order. -

What are the minimum order quantities (MOQ) for weld brushes?

Minimum order quantities (MOQ) for weld brushes can vary significantly depending on the supplier and the specific product line. Many manufacturers may set MOQs ranging from 100 to 1,000 units, especially for specialized or customized brushes. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, particularly if you are exploring bulk purchasing or establishing a long-term partnership. -

What payment terms are common for international transactions in weld brush procurement?

Common payment terms for international transactions often include options such as Letters of Credit (LC), wire transfers, or payment in advance. Depending on the supplier’s policies, you might negotiate partial payments upfront with the balance due upon delivery. Ensure to clarify payment terms in your contract to protect both parties, and consider using escrow services for larger transactions to minimize risk. -

How can I ensure quality assurance (QA) for weld brushes I import?

To ensure quality assurance (QA) for imported weld brushes, request detailed product specifications and certifications from suppliers. Conducting pre-shipment inspections can be beneficial, where a third-party service checks the product quality against your standards before shipment. Establishing a clear return policy and warranty terms in your agreement will also provide recourse should the products not meet your expectations. -

What logistics considerations should I keep in mind when importing weld brushes?

Key logistics considerations when importing weld brushes include understanding shipping methods (air freight vs. sea freight), customs regulations, and potential tariffs or duties that may apply. Partnering with a reliable freight forwarder can simplify the process and ensure compliance with local import regulations. Additionally, consider the lead times associated with different shipping options to align with your production schedules. -

How can I customize weld brushes to meet specific project requirements?

Many manufacturers offer customization options for weld brushes, allowing you to specify bristle type, size, and handle design. Discuss your project requirements with potential suppliers and inquire about their capabilities to produce custom brushes. Providing samples or detailed specifications can facilitate the customization process. Ensure to confirm the MOQ and lead times associated with custom orders to effectively plan your procurement strategy.

Top 4 Weld Brush Manufacturers & Suppliers List

1. Capital Weld Cleaners – Durable Weld Cleaning Brushes

Domain: capitalweldcleaners.com

Registered: 2008 (17 years)

Introduction: Durable Weld Cleaning Brushes available in multiple variants. Options include: 1X50 and 2X80 Weld Cleaning Brushes, 1X30 and 2X40 compatible ($54.34 – $1,629.97), Applicator Pump Gun and Fluid Delivery Gun Brushes – Threaded Style ($64.13 – $1,925.00), CW110 and CW200 High Amperage Brushes ($67.10 – $1,834.25), Speed Brush attachment – Standard ($125.00), Speed Brush Weld Cleaning Brushes ($48.75 …

2. Lincoln – Wire Brushes and Chipping Hammer Combo

Domain: harrisweldingsupplies.com

Registered: 2000 (25 years)

Introduction: [{‘name’: ‘Lincoln 4 x 16 Row Carbon Steel Wire Brush’, ‘model’: ‘K3185-1’, ‘price’: ‘$6.00’, ‘original_price’: ‘$10.00’}, {‘name’: ‘Lincoln 3 x 19 Row Stainless Steel Wire Brush’, ‘model’: ‘K3181-1’, ‘price’: ‘$7.00’, ‘original_price’: ‘$13.00’}, {‘name’: ‘Lincoln Chipping Hammer & Wire Brush Combo’, ‘model’: ‘K4021-1’, ‘price’: ‘$20.00’, ‘original_price’: ‘$26.00’}, {‘name’: ‘Lincoln 3 x 7 Row S…

3. TIG Brush – Pre-Weld Aluminum Cleaning Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: TIG brush for aluminum pre-weld cleaning; inquiry about a pre-weld prep solution for aluminum; interest in a brush-type electrolytic remover for mill scale; discussion on cleaning methods including acetone and scotch brite; mention of dedicated stainless brush for oxide removal prior to welding.

4. Weld Fabulous – TIG Brush Weld Cleaning System

Domain: weldfabulous.com

Registered: 2003 (22 years)

Introduction: This company, Weld Fabulous – TIG Brush Weld Cleaning System, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for weld brush

In the competitive landscape of welding supplies, strategic sourcing of weld brushes offers significant advantages to international buyers. By prioritizing quality, efficiency, and innovation, businesses can enhance their welding processes while ensuring compliance with safety and environmental standards. The evolution of weld cleaning technology, particularly with the rise of electrolytic cleaning systems, underscores the need for buyers to partner with reputable suppliers that provide reliable and effective solutions.

Investing in high-quality weld brushes not only improves the aesthetic and functional aspects of welded products but also contributes to long-term cost savings through reduced labor and material waste. As markets in Africa, South America, the Middle East, and Europe continue to grow, the demand for efficient and safe welding solutions will expand, making it crucial for businesses to stay ahead of industry trends.

To capitalize on these opportunities, international B2B buyers are encouraged to explore partnerships with trusted distributors and manufacturers. By doing so, they can ensure access to the latest technologies and best practices in weld cleaning. Embrace this moment to elevate your welding operations and achieve a competitive edge in your market. Your next step could redefine quality in your production line.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.