The Definitive Guide to Ball Shaft: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for ball shaft

In today’s global market, sourcing the right ball shaft can be a daunting challenge for B2B buyers, particularly those operating across diverse regions like Africa, South America, the Middle East, and Europe. With a variety of designs, specifications, and applications available, making an informed decision is crucial. This comprehensive guide aims to demystify the complexities surrounding ball shafts, providing insights into the different types, such as high-torque models and linear ball bearings, along with their applications in industries ranging from robotics to manufacturing.

Buyers will benefit from detailed information on supplier vetting processes, ensuring that they partner with reliable manufacturers capable of meeting quality and performance standards. Additionally, we delve into cost considerations, helping businesses understand pricing structures and negotiate effectively. By addressing key factors such as design features, material specifications, and maintenance requirements, this guide empowers international B2B buyers to make well-informed purchasing decisions.

Whether you are in Nigeria seeking innovative solutions for industrial automation or in Germany looking for precision components for advanced machinery, this resource is tailored to enhance your sourcing strategy. Equip yourself with the knowledge to navigate the global market for ball shafts confidently and effectively.

Understanding ball shaft Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High Torque Ball Spline | Features three crests with six rows of balls; high rigidity; no angular backlash | Industrial robots, automatic loaders, transfer machines | Pros: High precision, compact design. Cons: Higher initial cost. |

| Hollow Spline Shaft | Lightweight design; allows for piping and wiring; reduced weight | Applications requiring weight savings, such as aerospace | Pros: Space-efficient, versatile. Cons: May have lower load capacity. |

| Precision Solid Spline Shaft | Cold-drawn construction; precision ground raceway | High-precision machinery, automotive applications | Pros: High durability, excellent load handling. Cons: Requires precise installation. |

| Self-Aligning Linear Ball Bearing | Designed to accommodate misalignment; available in various sizes | Robotics, conveyor systems, and automated machinery | Pros: Flexibility in installation. Cons: May require more maintenance. |

| Compact Linear Ball Bearing | Space-saving design; suitable for tight spaces | Compact machinery, medical devices, and small-scale automation | Pros: Ideal for limited space. Cons: Limited load capacity compared to larger options. |

What Are the Key Features of High Torque Ball Splines?

High torque ball splines are engineered for applications requiring high precision and load-bearing capacity. Their design incorporates three crests, each with two rows of balls, allowing for even torque distribution and minimal angular backlash. This makes them ideal for industrial robots and automatic loaders, where reliability and accuracy are paramount. When purchasing, consider the initial investment against long-term performance benefits, as these components can be cost-effective over time due to reduced maintenance needs.

How Does a Hollow Spline Shaft Improve Efficiency?

The hollow spline shaft is designed for applications that prioritize weight reduction without compromising functionality. Its hollow construction allows for the integration of piping and wiring, making it suitable for aerospace and automotive applications where space and weight are critical. When evaluating options, buyers should assess the specific load requirements, as the hollow design may result in a lower load capacity compared to solid shafts. This type is particularly advantageous for projects requiring innovative design solutions.

What Advantages Do Precision Solid Spline Shafts Offer?

Precision solid spline shafts are constructed through cold-drawing processes, resulting in high durability and precision. They are commonly used in high-precision machinery and automotive applications where reliability is essential. Buyers should consider the installation precision required, as these shafts demand strict adherence to tolerance specifications. The investment in precision solid spline shafts often pays off through enhanced performance and extended service life.

Why Choose Self-Aligning Linear Ball Bearings?

Self-aligning linear ball bearings are designed to accommodate misalignment, making them a versatile choice for various applications, including robotics and conveyor systems. Their ability to adjust to slight misalignments ensures smoother operations and reduces wear on machinery. However, buyers should be aware that these bearings may require more frequent maintenance compared to fixed options. Evaluating the specific operational environment will help determine if this flexibility is beneficial for your application.

What Are the Benefits of Compact Linear Ball Bearings?

Compact linear ball bearings are ideal for applications with limited space, such as in medical devices and small-scale automation. Their design allows for efficient use of space while maintaining a reasonable load capacity. Buyers should weigh the advantages of space-saving designs against the potential limitations in load-bearing capabilities. These bearings are particularly useful in environments where every millimeter counts, providing a balance between functionality and compactness.

Key Industrial Applications of ball shaft

| Industry/Sector | Specific Application of ball shaft | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Robotics | Linear motion systems in robotic arms | Enhanced precision and reliability | Need for high rigidity and low backlash; consider local suppliers for quick delivery. |

| Manufacturing | Automated assembly lines | Increased efficiency and reduced downtime | Ensure compatibility with existing systems; evaluate load capacity and speed requirements. |

| Automotive | Powertrain components | Improved performance and durability | Focus on material quality and corrosion resistance; consider local regulations and standards. |

| Aerospace | Actuation systems in aircraft | High reliability under extreme conditions | Look for certifications and testing standards; prioritize suppliers with aerospace experience. |

| Packaging | Conveyance systems in packaging machinery | Enhanced throughput and reduced wear | Assess the need for custom dimensions; prioritize suppliers with a robust support network. |

How is ‘ball shaft’ utilized in robotics, and what are the sourcing considerations?

In the robotics sector, ball shafts are integral to linear motion systems used in robotic arms, allowing for precise movements essential for tasks such as assembly and welding. These systems benefit from the high rigidity and low backlash offered by ball shafts, ensuring accuracy in operations. For international buyers, especially from regions like Africa and Europe, sourcing considerations include selecting suppliers that can provide high-quality components with minimal lead times, as well as those who understand the specific requirements of robotics applications.

What role do ball shafts play in manufacturing automation?

In manufacturing, ball shafts are often found in automated assembly lines where they facilitate smooth and efficient linear motion. Their design allows for high-speed operations while maintaining positional accuracy, which is crucial for reducing downtime and improving overall productivity. Buyers should consider sourcing from manufacturers who can offer customizable options to fit specific machine requirements and ensure compatibility with existing systems to avoid costly retrofits.

How do ball shafts enhance automotive powertrain components?

In the automotive industry, ball shafts are used in various powertrain components, contributing to improved performance and durability. They enable smooth rotation and efficient torque transfer, essential for vehicle functionality. Buyers in this sector need to prioritize sourcing from suppliers who can provide materials that withstand high temperatures and corrosive environments, particularly in regions with diverse climates, such as South America and the Middle East.

Why are ball shafts critical in aerospace actuation systems?

Ball shafts serve a critical function in actuation systems within the aerospace industry, where they must operate reliably under extreme conditions. Their precise motion control is vital for safety and performance in aircraft systems. International buyers must ensure that their suppliers meet stringent aerospace certification standards and have a proven track record in delivering high-performance components that can withstand rigorous testing and operational demands.

How do ball shafts improve efficiency in packaging machinery?

In the packaging sector, ball shafts are utilized in conveyance systems that streamline the movement of products through various stages of packaging. Their ability to reduce friction and wear enhances throughput while minimizing maintenance needs. Buyers should focus on sourcing from manufacturers that can provide tailored solutions, including custom dimensions and materials, to meet specific operational requirements, ensuring that the components are reliable and efficient in high-volume environments.

3 Common User Pain Points for ‘ball shaft’ & Their Solutions

Scenario 1: High Torque Demand in Heavy Machinery Operations

The Problem: In industries such as manufacturing and construction, machinery often requires components that can handle high torque loads. B2B buyers may face challenges when their existing ball shafts cannot accommodate these loads, leading to premature wear and operational failures. This not only disrupts production but also increases maintenance costs and downtime, which can significantly impact overall profitability. Buyers need a solution that ensures reliable performance under high torque conditions while maintaining precision and longevity.

The Solution: To address high torque demands, buyers should consider sourcing high torque type ball splines. These splines feature a unique design with multiple rows of balls arranged to evenly distribute the load, enhancing torque capacity and stability. When selecting a ball shaft, it’s crucial to specify the correct diameter and type based on the intended application. Collaborating with manufacturers who provide detailed specifications and load capacity charts can help in identifying the right solution. Regular maintenance, including lubrication and alignment checks, will further extend the lifespan of these components, ensuring they meet the rigorous demands of heavy machinery operations.

Scenario 2: The Challenge of Angular Backlash in Precision Applications

The Problem: Precision machining applications often require components that can maintain accurate positioning without any angular backlash. B2B buyers in sectors like robotics or aerospace may find that traditional ball shafts exhibit backlash due to the design of their spline nuts. This can lead to inaccuracies in automated systems, resulting in defective products and costly rework. Buyers are under pressure to find a reliable solution that minimizes backlash and enhances the precision of their machinery.

The Solution: High torque ball splines specifically designed to eliminate angular backlash are an excellent choice for precision applications. These splines utilize a single spline nut that provides a preload, which effectively reduces the gap that typically causes backlash. When sourcing these components, buyers should look for suppliers that offer models with documented preload specifications and performance data. Implementing these high-precision ball splines in machinery will significantly improve accuracy. Additionally, regular calibration and maintenance can help sustain the performance, ensuring that positioning remains precise over time.

Scenario 3: Difficulty in Selecting the Right Ball Shaft for Diverse Applications

The Problem: B2B buyers often encounter the challenge of selecting the appropriate ball shaft for diverse applications across various industries. With a wide range of options available, including solid and hollow shafts, different sizes, and load capacities, buyers may struggle to identify the best fit for their specific needs. Misalignment in selection can lead to inefficient operations, increased costs, and even equipment failure, which can be detrimental to business operations.

The Solution: To simplify the selection process, buyers should begin by conducting a thorough needs assessment that considers the specific operational requirements, such as load capacity, environmental conditions, and application type. Engaging with suppliers who offer comprehensive product catalogs, including CAD files and technical support, can facilitate informed decision-making. It’s advisable to request samples or prototypes before making large orders to test compatibility and performance in real-world conditions. Furthermore, leveraging supplier expertise can provide insights into the latest innovations in ball shaft technology that may better serve emerging needs in the industry. By taking a structured approach to sourcing, buyers can ensure they select the most suitable ball shafts for their operations, ultimately enhancing efficiency and reducing costs.

Strategic Material Selection Guide for ball shaft

What Are the Key Properties of Common Materials Used for Ball Shafts?

When selecting materials for ball shafts, it is crucial to consider their properties, performance under various conditions, and suitability for specific applications. Here, we analyze four common materials: carbon steel, stainless steel, aluminum, and plastic composites.

How Does Carbon Steel Perform as a Material for Ball Shafts?

Key Properties: Carbon steel is known for its high tensile strength and hardness, making it suitable for high-load applications. It typically has a temperature rating up to 300°C and can withstand moderate pressures.

Pros & Cons: The primary advantages of carbon steel include its durability and cost-effectiveness, as it is generally less expensive than other materials. However, it is prone to corrosion, which can limit its use in harsh environments unless properly coated or treated.

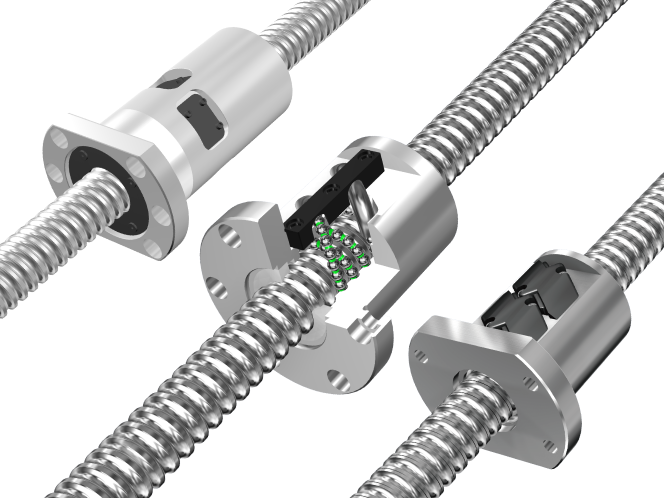

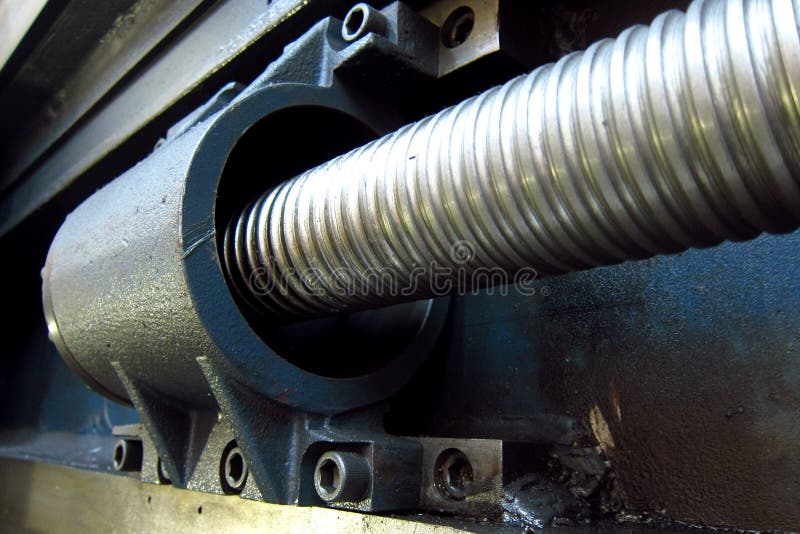

Illustrative image related to ball shaft

Impact on Application: Carbon steel ball shafts are ideal for applications requiring high strength, such as in heavy machinery and automotive components. However, their susceptibility to rust makes them less suitable for applications involving moisture or corrosive substances.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of the need for protective coatings or treatments to enhance corrosion resistance. Compliance with standards such as ASTM A36 is also essential for ensuring quality and performance.

What Advantages Does Stainless Steel Offer for Ball Shafts?

Key Properties: Stainless steel provides excellent corrosion resistance and can operate effectively in temperatures ranging from -200°C to 800°C. It is also known for its high strength-to-weight ratio.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to rust, making it suitable for a wide range of environments. However, it is typically more expensive than carbon steel and may require more complex manufacturing processes.

Impact on Application: Stainless steel ball shafts are often used in food processing, pharmaceuticals, and marine applications due to their hygienic properties and resistance to corrosion. This makes them a preferred choice in industries where cleanliness is paramount.

Illustrative image related to ball shaft

Considerations for International Buyers: Buyers in Europe, particularly Germany, should ensure compliance with DIN standards for stainless steel grades, such as 1.4401 (AISI 316). Understanding local regulations regarding material certifications is also critical.

How Does Aluminum Compare as a Material for Ball Shafts?

Key Properties: Aluminum is lightweight and has good corrosion resistance, with a temperature rating up to 150°C. It is also non-magnetic and has excellent thermal conductivity.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which can lead to reduced energy consumption in applications requiring motion. However, it has lower tensile strength compared to steel, making it less suitable for high-load applications.

Impact on Application: Aluminum ball shafts are commonly used in robotics and lightweight machinery where weight savings are crucial. However, they may not be ideal for heavy-duty applications.

Considerations for International Buyers: Buyers should be aware of the need for anodizing or other surface treatments to enhance corrosion resistance. Compliance with international standards such as ISO 9001 for quality management is also important.

What Role Do Plastic Composites Play in Ball Shaft Applications?

Key Properties: Plastic composites offer excellent chemical resistance and can operate effectively in a wide range of temperatures, typically between -40°C and 100°C. They are lightweight and can be engineered for specific applications.

Pros & Cons: The advantages of plastic composites include their resistance to corrosion and low friction properties, which can enhance performance. However, they may not withstand high loads or temperatures as effectively as metals.

Impact on Application: Plastic composite ball shafts are suitable for applications in chemical processing and environments where metal fatigue could be a concern. Their lightweight nature also makes them beneficial in reducing overall system weight.

Considerations for International Buyers: Buyers should consider the specific chemical compatibility of the composite material with the media it will encounter. Compliance with relevant standards, such as ASTM D638 for plastic materials, is essential for ensuring quality.

Summary Table of Material Selection for Ball Shafts

| Material | Typical Use Case for ball shaft | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Heavy machinery, automotive components | High strength and cost-effective | Prone to corrosion | Low |

| Stainless Steel | Food processing, pharmaceuticals, marine | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Robotics, lightweight machinery | Lightweight and good corrosion resistance | Lower tensile strength | Medium |

| Plastic Composites | Chemical processing, low-load applications | Corrosion resistance and low friction | Limited load and temperature capacity | Medium |

This detailed analysis provides international B2B buyers with actionable insights into material selection for ball shafts, ensuring they make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for ball shaft

What Are the Main Stages in the Manufacturing Process of Ball Shafts?

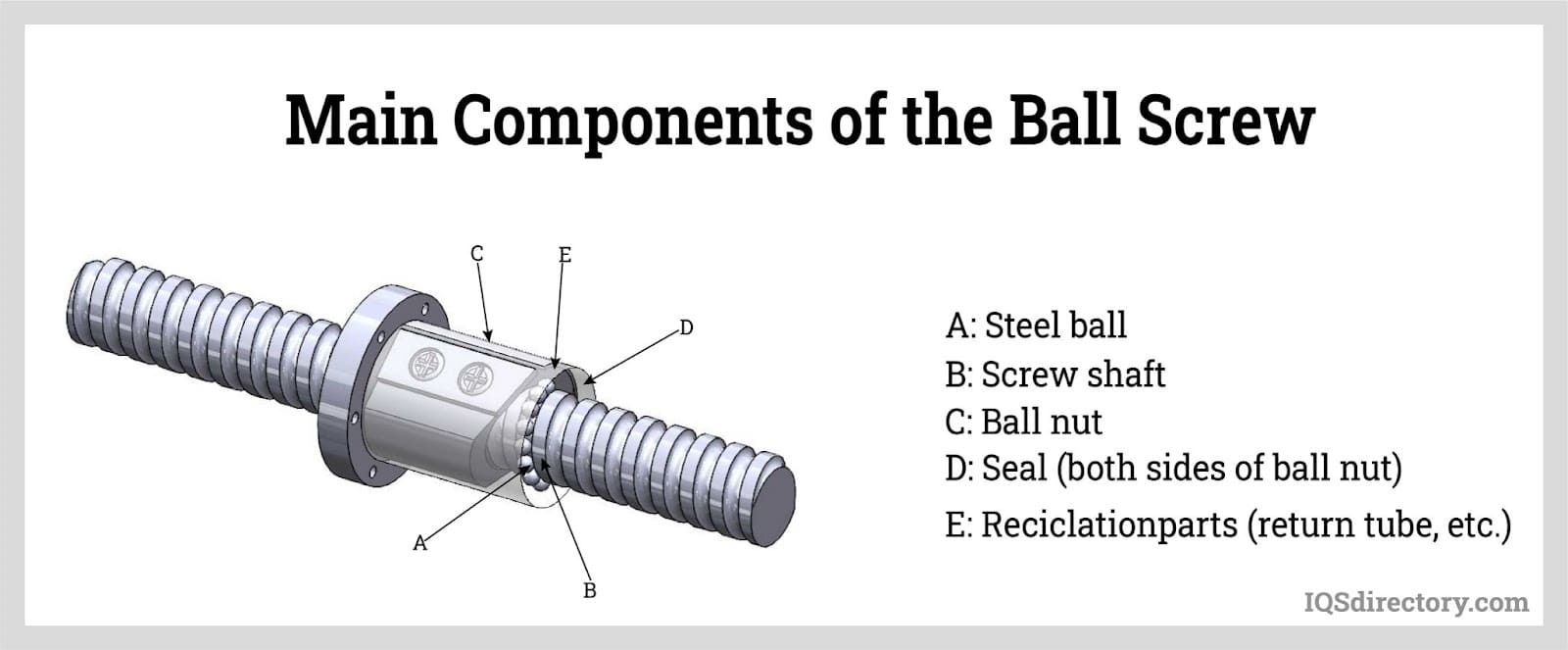

The manufacturing of ball shafts involves several critical stages that ensure precision, durability, and performance. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to ball shaft

Material Preparation: What Materials Are Commonly Used for Ball Shafts?

Ball shafts are typically manufactured from high-strength materials such as carbon steel, stainless steel, or alloy steel. The selection of material is crucial as it directly affects the shaft’s performance under load and its resistance to wear and corrosion.

During material preparation, raw materials undergo processes like cold drawing or hot rolling to achieve the desired mechanical properties and dimensions. This step often includes inspection for material integrity through non-destructive testing methods such as ultrasonic or magnetic particle inspection.

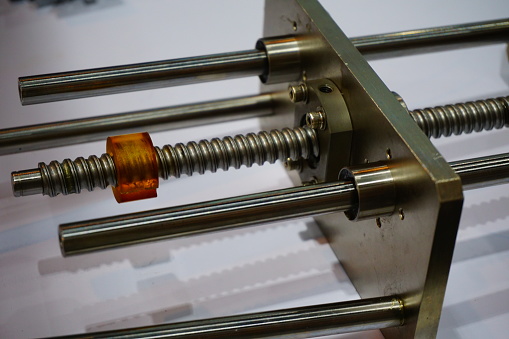

How Are Ball Shafts Formed to Achieve Precision?

The forming process primarily involves machining operations such as turning, milling, and grinding. These processes are essential to create the longitudinal grooves that allow for the smooth movement of the balls within the spline.

Illustrative image related to ball shaft

Precision grinding is particularly important as it ensures that the raceways are accurately shaped and dimensioned, which is vital for minimizing friction and maximizing the load-bearing capacity. Computer Numerical Control (CNC) machines are commonly employed to enhance precision and repeatability in these operations.

What Assembly Techniques Are Used in Ball Shaft Manufacturing?

After the forming stage, the assembly of the ball shaft involves integrating the spline nut and steel balls. The assembly process is highly precise; the balls are placed in their designated tracks within the nut and then lubricated for optimal performance.

This assembly is often performed in a controlled environment to prevent contamination from dust or debris, which could compromise the quality of the final product. The use of ball retainers is also crucial as it prevents the balls from falling out during installation or operation.

How Is the Finishing Process Conducted for Ball Shafts?

The finishing stage includes surface treatments such as hardening, coating, and polishing to improve wear resistance and reduce friction. Techniques like heat treatment are employed to enhance the mechanical properties of the shaft, making it more durable under stress.

Additionally, surface coatings, such as chrome plating or nitriding, can be applied to improve corrosion resistance. The finishing process also involves meticulous inspection to ensure that surface roughness and dimensional tolerances meet the required specifications.

What Are the Quality Control Standards for Ball Shafts?

Quality assurance is crucial in the manufacturing of ball shafts, ensuring that the products meet international standards and customer specifications.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are fundamental for quality management systems in manufacturing. Compliance with ISO 9001 indicates that the manufacturer has a robust quality management system in place, ensuring consistency and reliability in production.

Industry-specific certifications like CE marking for products sold in Europe, or API standards for oil and gas applications, are also critical. These certifications ensure that the products comply with safety and performance regulations specific to their applications.

What Are the Key Quality Control Checkpoints in Ball Shaft Manufacturing?

Quality control during the manufacturing process includes several checkpoints:

-

Incoming Quality Control (IQC): This phase involves the inspection of raw materials before production begins. It ensures that materials meet specified standards and are free from defects.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular inspections are conducted to monitor critical parameters such as dimensions, surface finish, and assembly integrity. This helps identify issues early in the process, reducing waste and rework.

-

Final Quality Control (FQC): After the assembly and finishing processes, a comprehensive inspection is performed. This may include dimensional checks, functional tests, and performance evaluations to ensure the product meets all specifications.

What Testing Methods Are Commonly Used for Ball Shafts?

Various testing methods are employed to assess the quality and performance of ball shafts:

-

Dimensional Testing: Calipers and micrometers are used to verify that the shaft dimensions conform to specifications.

-

Load Testing: Ball shafts are subjected to load tests to evaluate their performance under operational conditions. This testing can simulate real-world applications to ensure reliability.

-

Fatigue Testing: This test assesses the durability of the shaft under cyclic loading, helping to predict its lifespan and reliability in service.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or dye penetrant testing are utilized to detect internal or surface defects without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential.

Illustrative image related to ball shaft

What Methods Can Buyers Use to Ensure Supplier Compliance?

-

Supplier Audits: Conducting audits of the supplier’s manufacturing facilities can provide insights into their quality management practices. This includes reviewing their certifications, quality control processes, and manufacturing capabilities.

-

Quality Reports: Requesting quality assurance documentation, including inspection reports and certificates of compliance, can help buyers assess the reliability of the supplier’s products.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control processes and product quality. These inspections can be particularly beneficial for buyers who are unable to visit the manufacturing site.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate specific challenges related to quality control, including language barriers, differing standards, and varying levels of regulatory compliance.

To mitigate these challenges, it is advisable for buyers to:

-

Establish Clear Communication: Ensure that specifications and quality expectations are clearly communicated and understood by both parties.

-

Be Aware of Local Standards: Familiarize yourself with local and international standards relevant to your industry to ensure compliance.

-

Build Relationships with Suppliers: Developing a strong relationship with suppliers can facilitate better communication and collaboration, leading to improved quality outcomes.

In conclusion, understanding the manufacturing processes and quality assurance measures for ball shafts is vital for B2B buyers. By being informed about these aspects, buyers can make more strategic decisions, ensuring they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ball shaft’

In this practical guide, we aim to equip B2B buyers with a comprehensive checklist for sourcing ball shafts. Understanding the nuances of ball shaft procurement is crucial for ensuring optimal performance in applications ranging from robotics to manufacturing equipment. This guide will help streamline your sourcing process, reduce risks, and enhance the quality of your supply chain.

Step 1: Define Your Technical Specifications

Clearly outline your technical requirements before initiating the sourcing process. Consider factors such as load capacity, shaft diameter, type of spline (solid, hollow, or specialized), and any specific material needs (e.g., stainless steel for corrosion resistance). Precise specifications will help you communicate effectively with suppliers and ensure you receive products that meet your operational demands.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers in the market. Look for companies with a strong reputation in the industry, particularly those that specialize in high-quality ball shafts. Utilize online directories, trade shows, and industry publications to compile a list of credible suppliers. Evaluating multiple options will give you leverage in negotiations and help you identify the best fit for your needs.

Illustrative image related to ball shaft

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that your chosen suppliers hold relevant industry certifications. Certifications such as ISO 9001 indicate a commitment to quality management, while others might pertain specifically to manufacturing processes or material standards. Ensuring your suppliers are certified can provide peace of mind regarding product quality and consistency.

Step 4: Request Samples for Testing

Once you narrow down your supplier options, request samples of the ball shafts for testing. This step is vital to assess the quality and performance of the shafts in your specific application. Evaluate factors such as precision, durability, and ease of installation to ensure the products will meet your operational requirements.

Step 5: Review Pricing and Payment Terms

Analyze pricing structures and payment terms from various suppliers. Ensure you understand what is included in the quoted price, such as delivery charges, taxes, and any additional fees for custom specifications. Competitive pricing should not compromise quality; thus, consider the total cost of ownership, including maintenance and potential downtime.

Step 6: Assess Lead Times and Delivery Options

Inquire about lead times and delivery options from your shortlisted suppliers. Timely delivery is critical to maintaining your production schedule, so confirm that the supplier can meet your required timelines. Additionally, assess their logistics capabilities, particularly if you are sourcing from international suppliers.

Step 7: Establish a Clear Communication Channel

Effective communication is essential throughout the sourcing process. Establish a direct line of communication with your supplier’s representative to address any questions or concerns promptly. Ensure that you have a clear understanding of the ordering process, product updates, and support services to facilitate a smooth transaction.

Following this checklist will help ensure that your sourcing process for ball shafts is efficient, cost-effective, and aligned with your operational requirements. By taking the time to define your needs and thoroughly vet suppliers, you can secure high-quality components that enhance your business’s performance.

Comprehensive Cost and Pricing Analysis for ball shaft Sourcing

What Are the Key Cost Components for Sourcing Ball Shafts?

When sourcing ball shafts, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. Common materials include stainless steel, carbon steel, and specialized alloys. Higher-grade materials that offer enhanced durability or corrosion resistance will incur higher costs.

-

Labor: Labor costs are influenced by the complexity of manufacturing processes. For instance, precision machining and assembly require skilled labor, which can increase the overall cost.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient production processes can help minimize these costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs are amortized over production runs, so larger orders can benefit from lower per-unit tooling costs.

-

Quality Control (QC): Ensuring high quality often requires rigorous QC processes. The costs associated with testing and certification can vary, impacting the final price of the product.

-

Logistics: Shipping and handling costs are crucial, particularly for international buyers. Factors such as distance, shipping method, and packaging can influence overall logistics costs.

-

Margin: Suppliers will add a profit margin to the total cost of production. This margin can vary widely based on market conditions, competition, and supplier strategy.

What Factors Influence the Pricing of Ball Shafts?

Several factors can influence the pricing of ball shafts, particularly in a B2B context:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically secure better pricing due to economies of scale. Understanding the supplier’s MOQ is essential for negotiating favorable terms.

-

Specifications and Customization: Custom designs or specific dimensions often lead to increased costs. Standard products are typically more cost-effective than custom solutions.

-

Quality and Certifications: Products that meet international quality standards or have specific certifications (like ISO) can command higher prices. Buyers must assess the value of these certifications in relation to their own quality requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their perceived reliability and product quality.

-

Incoterms: The terms of shipping and delivery (Incoterms) play a crucial role in the total cost. Buyers should be aware of who is responsible for shipping costs, duties, and insurance to avoid unexpected expenses.

What Negotiation Strategies Can Help Ensure Cost-Efficiency?

When negotiating prices for ball shafts, consider these tips to enhance cost-efficiency:

-

Leverage Volume Discounts: Clearly communicate your expected order volume to negotiate better pricing. Suppliers are often willing to lower prices for larger commitments.

-

Compare Multiple Suppliers: Obtain quotes from several suppliers to understand the market range. This not only provides leverage in negotiations but also helps in identifying the best value.

-

Discuss Long-Term Partnerships: Propose a long-term relationship with suppliers, which can lead to better pricing, priority service, and improved payment terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial price but also the long-term costs associated with maintenance, replacement, and potential downtime. A slightly higher upfront cost may result in lower TCO.

-

Understand Pricing Nuances for International Markets: Be aware of currency fluctuations, tariffs, and local market conditions that may affect pricing when sourcing from different regions, such as Africa, South America, the Middle East, or Europe.

What Should International Buyers Keep in Mind When Sourcing Ball Shafts?

International buyers, particularly from regions like Nigeria or Germany, should consider the following:

-

Cultural Differences: Understand negotiation styles and business practices in the supplier’s country to build rapport and facilitate smoother transactions.

-

Regulatory Compliance: Ensure that the products meet local regulations and standards to avoid delays and additional costs.

-

Shipping and Customs: Familiarize yourself with the logistics of international shipping, including potential delays and customs duties, to avoid unexpected expenses.

Disclaimer on Indicative Prices

The pricing for ball shafts can vary widely based on the aforementioned factors. Buyers should treat any indicative prices as a starting point for negotiation and further analysis, rather than fixed quotes.

Alternatives Analysis: Comparing ball shaft With Other Solutions

Understanding Alternatives to Ball Shafts in Motion Systems

When evaluating options for linear motion systems, it’s essential to consider various technologies that can meet your operational needs. While ball shafts are widely recognized for their precision and efficiency, alternatives such as linear bearings and roller guides may also provide suitable solutions depending on the specific application and industry context.

| Comparison Aspect | Ball Shaft | Linear Bearings | Roller Guides |

|---|---|---|---|

| Performance | High precision and low friction; suitable for high-speed applications. | Good load-bearing capacity but may experience wear over time. | Excellent for heavy loads; lower friction than traditional systems. |

| Cost | Generally higher initial investment due to precision engineering. | More affordable upfront, but may incur higher replacement costs. | Moderate cost, balancing initial investment and longevity. |

| Ease of Implementation | Requires precise installation and alignment. | Easier to install with flexible mounting options. | Straightforward installation, often with less precise alignment needed. |

| Maintenance | Low maintenance, but lubrication is essential for optimal performance. | Requires regular checks for wear; lubrication is also necessary. | Low maintenance, but may require periodic inspections. |

| Best Use Case | Ideal for applications requiring high precision and speed, such as robotics. | Suitable for general-purpose applications with moderate load requirements. | Best for heavy-duty applications in manufacturing and material handling. |

What Are Linear Bearings and What Are Their Advantages?

Linear bearings utilize balls or rollers to facilitate smooth movement along a shaft. They are commonly used in applications where moderate precision is acceptable. One of the main advantages of linear bearings is their cost-effectiveness, making them an attractive choice for budget-conscious projects. However, they may require more frequent maintenance and replacement due to wear and tear, especially in high-load situations.

Illustrative image related to ball shaft

How Do Roller Guides Compare to Ball Shafts?

Roller guides offer an alternative that excels in handling heavy loads with lower friction compared to traditional sliding systems. These systems are designed to accommodate a broader range of load conditions and can be advantageous in environments where durability is a priority. The straightforward installation process and reduced need for precise alignment can facilitate quicker setup times. However, they may not achieve the same level of precision as ball shafts, making them less ideal for applications where exact positioning is critical.

Conclusion: How Should B2B Buyers Choose Between Ball Shafts and Their Alternatives?

Selecting the appropriate linear motion system depends on various factors, including precision requirements, load capacities, budget constraints, and maintenance capabilities. B2B buyers should evaluate their specific operational needs, considering how each alternative aligns with their goals. For high-speed, high-precision applications, ball shafts may be the best option. In contrast, linear bearings or roller guides could be more suitable for general-purpose or heavy-duty applications. Conducting a thorough analysis of these options will empower buyers to make informed decisions that enhance operational efficiency and product reliability.

Essential Technical Properties and Trade Terminology for ball shaft

What Are the Key Technical Properties of a Ball Shaft?

Understanding the critical specifications of a ball shaft is essential for B2B buyers to ensure optimal performance and compatibility with their machinery. Here are several key properties to consider:

-

Material Grade

The material grade of a ball shaft typically refers to the steel used in its construction, which can affect strength, corrosion resistance, and overall durability. Common materials include carbon steel, stainless steel, and alloy steel. Selecting the right material is crucial for applications exposed to harsh environments or heavy loads, as it impacts the longevity and maintenance requirements of the component. -

Tolerance

Tolerance defines the permissible limits of variation in dimensions of the ball shaft. It is often specified in terms of H7, J6, etc., which indicate the fit between the shaft and the housing. Proper tolerance is essential to ensure smooth operation, minimize wear, and prevent mechanical failures. Inaccurate tolerances can lead to increased friction and reduced efficiency, which can be costly in terms of downtime and repairs. -

Load Capacity

Load capacity is a measure of the maximum load a ball shaft can support during operation. This includes both radial and axial loads. Understanding the load capacity is vital for selecting the right shaft for specific applications, especially in industries like manufacturing and automation where high loads are common. Exceeding the load capacity can lead to premature failure, impacting productivity. -

Ball Configuration

The arrangement and number of balls within the spline shaft can significantly influence performance characteristics such as torque transmission and rotational stability. For instance, configurations like the high-torque type with multiple rows of balls enhance load distribution and reduce backlash. Buyers must consider these configurations to ensure they meet their operational requirements. -

Operating Speed

Operating speed refers to the maximum speed at which the ball shaft can rotate without compromising performance or safety. This is especially important in applications involving high-speed machinery. Selecting a ball shaft with an appropriate operating speed can enhance efficiency and prevent wear due to excessive centrifugal forces. -

Grease Retention

The design of the ball shaft can affect grease retention, which is critical for reducing friction and wear. Features that enhance grease retention lead to longer intervals between maintenance and improved operational longevity. Understanding the grease retention characteristics can help buyers optimize maintenance schedules and reduce operational costs.

What Are Common Trade Terms Related to Ball Shafts?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of ball shafts, knowing OEM specifications ensures that components fit seamlessly into existing machinery, which is crucial for maintaining operational efficiency. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to plan inventory levels and budgeting. It can also impact pricing, as larger orders often lead to lower per-unit costs. -

RFQ (Request for Quotation)

An RFQ is a formal request from a buyer to suppliers asking for price quotes for specific products or services. Submitting an RFQ for ball shafts can help buyers compare options and negotiate better pricing, ensuring they receive the best value for their investment. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping and delivery process. Familiarity with Incoterms helps buyers understand their obligations concerning costs, risks, and logistics associated with transporting ball shafts from suppliers. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is crucial for supply chain management, especially when planning production schedules or inventory restocking. -

Quality Assurance (QA)

QA is a systematic process to ensure that products meet specified quality standards. For ball shafts, having robust QA processes in place is critical for ensuring reliability and performance, reducing the risk of product failure in demanding applications.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and operational efficiency.

Illustrative image related to ball shaft

Navigating Market Dynamics and Sourcing Trends in the ball shaft Sector

What Are the Current Market Dynamics and Key Trends in the Ball Shaft Sector?

The global ball shaft market is driven by the increasing demand for precision engineering components across various industries, including automation, robotics, and manufacturing. Notably, regions like Africa, South America, the Middle East, and Europe are witnessing a surge in manufacturing activities, spurred by economic growth and industrialization. For instance, Nigeria’s burgeoning manufacturing sector is creating a robust market for ball shafts, while Germany remains a leader in high-precision engineering, emphasizing the need for high-quality ball spline solutions.

Emerging B2B technology trends such as Industry 4.0 and IoT are reshaping sourcing strategies. Buyers are increasingly looking for suppliers who can provide not only high-quality products but also advanced technologies that enhance operational efficiency. This includes components that integrate seamlessly with automated systems, offering features like high torque capacity and minimal backlash, which are critical for precision applications.

Furthermore, the trend towards customization is growing, with manufacturers offering tailored solutions to meet specific operational requirements. This trend is particularly relevant for international buyers who need to address unique challenges in their respective markets. As companies strive for competitive advantages, understanding these dynamics is essential for making informed sourcing decisions.

How Is Sustainability and Ethical Sourcing Affecting the Ball Shaft Market?

Sustainability has become a pivotal factor in the B2B procurement landscape, especially in the ball shaft sector. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes using eco-friendly materials and processes that minimize waste and reduce carbon footprints.

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains are free from exploitative practices. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a supplier’s commitment to sustainability. Additionally, the use of recyclable materials in the production of ball shafts is gaining traction, aligning with global efforts to promote a circular economy.

By prioritizing sustainability and ethical sourcing, international B2B buyers can not only meet regulatory requirements but also enhance their brand reputation and appeal to environmentally conscious consumers. This shift not only contributes to a healthier planet but also positions companies as leaders in responsible sourcing practices.

What Is the Historical Context of the Ball Shaft Industry?

The evolution of the ball shaft industry can be traced back to the early 20th century when advancements in engineering and manufacturing technologies began to influence the design of mechanical components. Initially, ball shafts were primarily used in heavy machinery and industrial applications. Over time, innovations such as precision machining and materials science led to the development of high-performance ball spline systems.

As industries grew more automated and the demand for precision components increased, the ball shaft market expanded significantly. Today, these components are integral to a wide range of applications, from robotics to aerospace, demonstrating their versatility and importance in modern manufacturing. This historical perspective underscores the continuous innovation within the sector, providing a solid foundation for current trends and future developments in the ball shaft market.

Frequently Asked Questions (FAQs) for B2B Buyers of ball shaft

-

How do I choose the right ball shaft for my application?

Selecting the appropriate ball shaft involves evaluating factors such as load capacity, speed requirements, and environmental conditions. Consider the specific application needs—whether it’s for robotics, automated machinery, or other heavy-duty systems. Also, assess the required shaft diameter and length, and whether you need a solid or hollow design. Consulting with suppliers about your operational parameters can lead to tailored recommendations that enhance performance and longevity. -

What is the best type of ball shaft for high-torque applications?

For high-torque applications, a high torque type ball spline is recommended. This design features multiple rows of balls that distribute torque evenly, providing excellent rigidity and positioning accuracy. The unique structure minimizes angular backlash, making it ideal for heavy-duty operations in industrial settings. Suppliers can offer models with various diameter options to suit your specific requirements. -

How can I customize a ball shaft to fit my machinery?

Customization options for ball shafts often include alterations in diameter, length, and material. Some manufacturers also provide specialized designs, such as hollow shafts for weight reduction or integrated features for specific applications. It’s essential to communicate your precise needs to suppliers, including load requirements and environmental factors, to ensure the final product meets your operational standards. -

What are the typical minimum order quantities (MOQs) for ball shafts?

Minimum order quantities for ball shafts can vary significantly among suppliers, typically ranging from a few pieces to several hundred. Smaller manufacturers may accommodate lower MOQs, while larger suppliers often have higher thresholds due to production costs. When sourcing internationally, it’s advisable to negotiate MOQs based on your specific requirements and potential for future orders. -

What payment terms should I expect when sourcing ball shafts internationally?

Payment terms can differ based on the supplier and the region. Common terms include advance payment, letter of credit, or payment upon delivery. It’s crucial to clarify these terms before finalizing an order, as they can impact cash flow and supply chain operations. Additionally, consider payment security measures, especially when dealing with international transactions, to mitigate risks. -

How do I ensure quality assurance when sourcing ball shafts?

To ensure quality assurance, request certifications such as ISO compliance from potential suppliers. Conducting a factory audit or requesting samples can also help assess manufacturing standards. Engaging in a clear dialogue about quality control processes, testing methods, and material specifications will provide insights into the supplier’s commitment to quality, which is vital for long-term operational success. -

What logistics considerations should I take into account for international shipments of ball shafts?

Logistics for international shipments involve evaluating shipping methods, costs, and delivery timelines. It’s important to work with suppliers who have experience in your target regions, as they can navigate customs regulations effectively. Additionally, consider the total landed cost, including freight, duties, and insurance, to get an accurate picture of the expenses involved in importing ball shafts. -

What should I look for when vetting suppliers of ball shafts?

When vetting suppliers, assess their industry experience, client testimonials, and product quality standards. It’s beneficial to check for certifications and compliance with international standards. Additionally, evaluate their customer service responsiveness and willingness to accommodate your specific needs. Building a relationship with a reliable supplier can lead to better pricing, consistency, and support throughout your sourcing journey.

Top 6 Ball Shaft Manufacturers & Suppliers List

1. THK – Ball Spline Bearings

Domain: thk.com

Registered: 1995 (30 years)

Introduction: Ball Spline is a spline bearing with a rolling guide that transmits torque while performing linear motion. It has a greater permissible load than linear bushings due to balls rolling in a groove on the shaft. Types include: High Torque Caged Ball Spline, High Torque Type Ball Spline, Medium Torque Type Ball Spline, Rotary Ball Spline with Gear, and Rotary Ball Spline with Support Bearing. Features…

2. McMaster – Ball-End Driver Shafts

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Ball-End Driver Shafts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Rollco – STANDARD SBE Linear Ball Bearing

Domain: rollco.eu

Introduction: Rollco linear ball bearings are available in closed, open, compact or self-aligning versions with corresponding hardened shafts in many sizes. Options include stainless steel ball bushings. Key products include:

– STANDARD SBE: Self-aligning closed type linear ball bearing, Ø 16-50 mm.

– STANDARD LME: Closed type linear ball bearing, Ø 5-60 mm.

– STANDARD LMES: Closed type stainless linear ball…

4. NB Corporation – Ball Spline Solutions

Domain: nbcorporation.com

Registered: 1997 (28 years)

Introduction: The NB BALL SPLINE is a linear motion mechanism utilizing recirculating ball elements, suitable for various applications including robotics and transport equipment. The NB ROTARY BALL SPLINE supports both rotational and linear motion, ideal for SCARA robots, assembly equipment vertical shafts, and tool changers/loaders. The NB BALL SCREW SPLINE integrates ball screw and ball spline functionalities…

5. VEX – High Strength Shaft Ball Bearing (11-Pack)

Domain: vexrobotics.com

Registered: 2004 (21 years)

Introduction: {“product_name”: “High Strength Shaft Ball Bearing (11-Pack)”, “price”: “$42.99”, “SKU”: “276-8402”, “description”: “These ball bearings are compatible with VEX High Strength Shafts. Unlike traditional Bearing Flats, Ball Bearings achieve a lower rotational friction through the use of rolling balls that are built into the Bearing. Great for high speed mechanisms, such as shooters and intakes!”, “c…

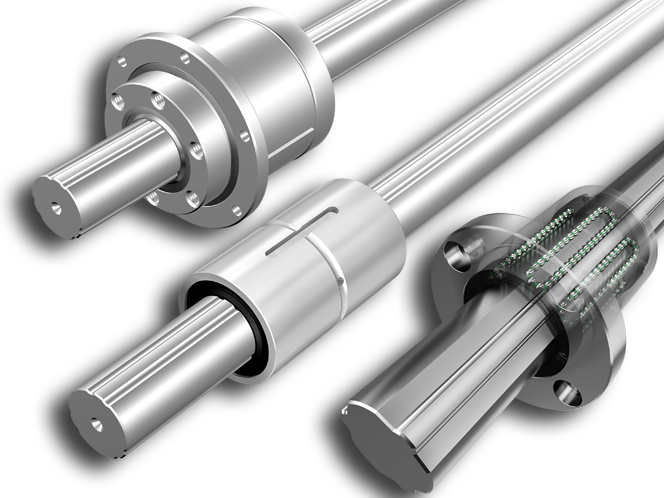

6. MISUMI – Ball Screws

Domain: us.misumi-ec.com

Registered: 2007 (18 years)

Introduction: Ball Screws are mechanical devices used to convert rotary motion into linear motion with high efficiency. They consist of a screw and a ball nut containing several ball bearings, which reduce friction and increase precision. Commonly used in applications requiring accurate positioning, such as CNC machines and robotics, they are essential components in various industrial settings. Key features inc…

Strategic Sourcing Conclusion and Outlook for ball shaft

In today’s competitive landscape, the strategic sourcing of ball shafts is pivotal for enhancing operational efficiency and ensuring product reliability. As outlined in this guide, key factors such as precision engineering, load capacity, and design versatility must inform your sourcing decisions. Engaging with reputable suppliers who offer high-quality products, such as high torque ball splines and linear bearings, can significantly reduce maintenance costs and enhance productivity across various applications.

Illustrative image related to ball shaft

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should prioritize partnerships with manufacturers that demonstrate a commitment to innovation and quality assurance. This approach not only mitigates risks associated with sourcing but also supports the development of robust supply chains capable of meeting evolving market demands.

Looking ahead, the demand for advanced ball shaft technologies is expected to rise, driven by industrial automation and the need for enhanced performance. By aligning your sourcing strategy with emerging trends and technological advancements, you can position your business for long-term success. Now is the time to take action—evaluate your current suppliers, explore new options, and invest in high-quality ball shafts that will propel your operations forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.