The Definitive Guide to Scientific Bench: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for scientific bench

In the quest for optimizing laboratory environments, sourcing the right scientific bench can pose significant challenges, particularly for international B2B buyers navigating diverse markets. From ensuring durability and safety to accommodating specific scientific tasks, the complexity of selection can be daunting. This guide delves into the multifaceted world of scientific benches, covering various types, applications, and essential features that cater to diverse laboratory needs.

As you explore this comprehensive resource, you’ll gain insights into the different materials and designs available, such as corrosion-resistant and vibration-dampening options, which are crucial for maintaining the integrity of sensitive experiments. Additionally, the guide addresses supplier vetting processes, enabling buyers to identify reliable partners in Africa, South America, the Middle East, and Europe, including markets like Vietnam and Saudi Arabia.

Understanding the cost implications and value propositions associated with different scientific benches will empower you to make informed purchasing decisions. By leveraging this guide, you can navigate the global market with confidence, ensuring that your laboratory is equipped with high-quality, functional benches tailored to meet your unique operational demands. Ultimately, this resource aims to streamline your procurement process, enhancing your laboratory’s efficiency and productivity.

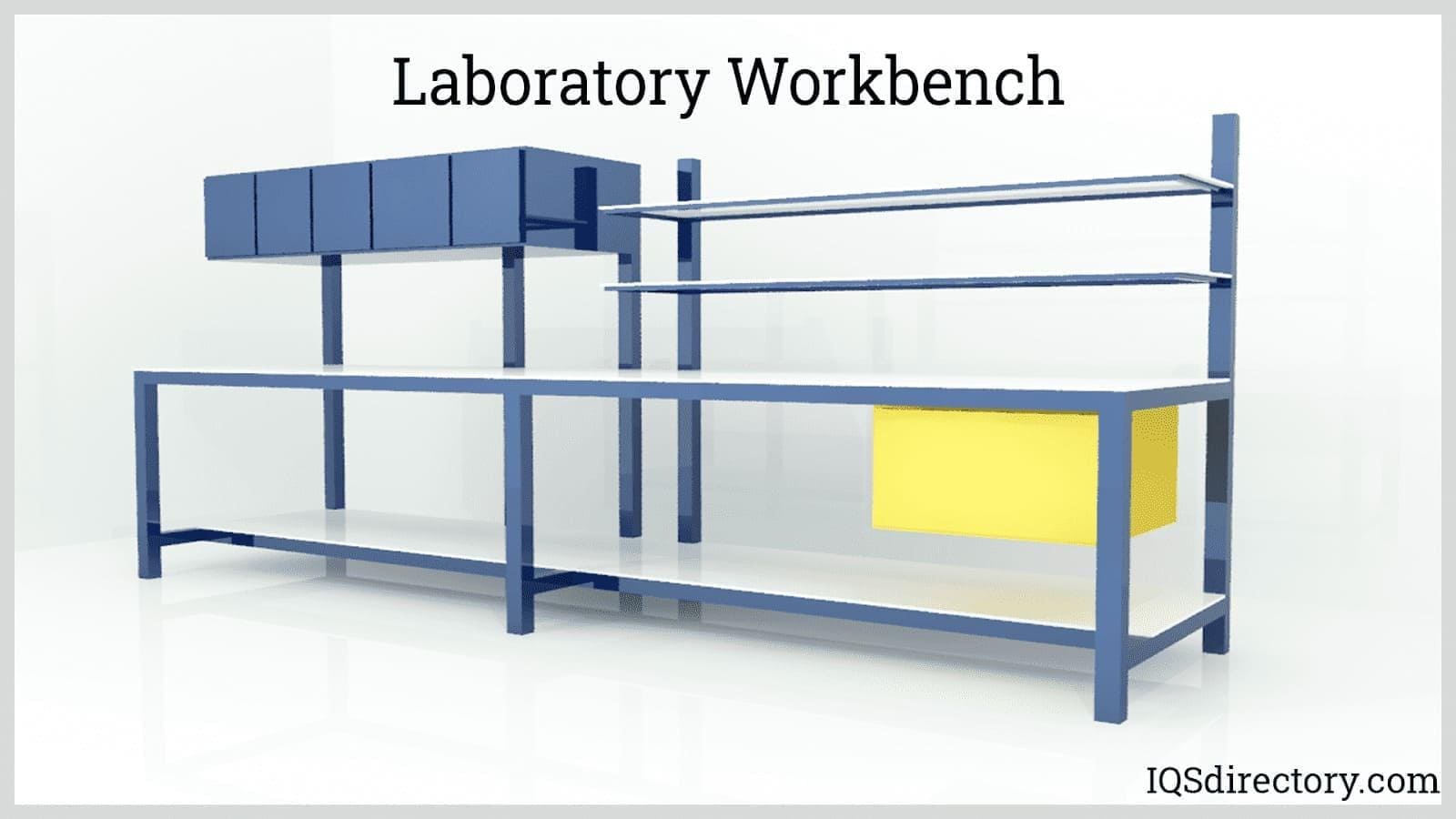

Understanding scientific bench Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Height Workbench | Non-adjustable height; sturdy construction; often heavy-duty. | General laboratory tasks; assembly. | Pros: Durable and stable. Cons: Limited ergonomic flexibility. |

| Adjustable Height Workbench | Height can be modified; accommodates various tasks and users. | Research labs; educational institutions. | Pros: Ergonomic; versatile. Cons: Typically higher cost. |

| Mobile Workbench | Equipped with casters; easily relocatable; flexible configurations. | Fieldwork; temporary setups. | Pros: Space-saving; adaptable. Cons: May sacrifice stability. |

| ESD (Electrostatic Discharge) Workbench | Designed to prevent static electricity buildup; often grounded. | Electronics labs; cleanrooms. | Pros: Protects sensitive equipment. Cons: Limited to specific applications. |

| Chemical Resistant Workbench | Made with materials that resist corrosion; often has a phenolic top. | Chemical analysis; pharmaceutical labs. | Pros: Long-lasting; safe for hazardous materials. Cons: Heavier and more expensive. |

What are the Characteristics of Fixed Height Workbenches?

Fixed height workbenches are designed for stability and durability, making them ideal for general laboratory tasks and assembly lines. They are often constructed from heavy-duty materials, ensuring they can withstand significant wear and tear. However, their non-adjustable height can limit ergonomic adaptability, making them less suitable for environments where multiple users of varying heights operate.

How Do Adjustable Height Workbenches Enhance Ergonomics?

Adjustable height workbenches offer flexibility by allowing users to modify the height according to their specific needs. This feature is particularly beneficial in research labs and educational settings where different users interact with the bench. While these workbenches promote better ergonomics and comfort, they typically come at a higher price point, which is a crucial consideration for budget-conscious B2B buyers.

Why Choose Mobile Workbenches for Dynamic Work Environments?

Mobile workbenches are equipped with casters, allowing for easy relocation within a workspace. This flexibility is particularly advantageous in fieldwork or temporary setups, where space may be limited. However, buyers should be aware that while mobile benches provide convenience, they may sacrifice some stability compared to fixed options, which could impact performance in high-precision tasks.

What Makes ESD Workbenches Essential in Electronics Labs?

ESD workbenches are specifically designed to mitigate the risks associated with electrostatic discharge, which can damage sensitive electronic components. These benches are often grounded and made from materials that dissipate static electricity. While they are crucial for electronics labs and cleanrooms, their specialized nature may limit their use in other types of laboratories, making it essential for buyers to evaluate their specific needs.

How Do Chemical Resistant Workbenches Ensure Safety in Laboratories?

Chemical resistant workbenches are constructed from materials that withstand corrosive substances, often featuring a phenolic top. These benches are vital in settings such as chemical analysis and pharmaceutical labs, where safety is paramount. Although they provide long-lasting durability and protection for hazardous materials, their heavier construction and higher costs can be a consideration for businesses operating under tighter budgets.

Key Industrial Applications of scientific bench

| Industry/Sector | Specific Application of Scientific Bench | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Laboratory testing and diagnostics | Enhanced accuracy in test results and patient safety | Compliance with health regulations and material safety standards |

| Pharmaceuticals | Drug formulation and quality control | Improved efficiency in drug development processes | Customizable designs for specific workflows and chemical resistance |

| Education | Research and experimentation in educational labs | Fosters innovation and practical learning | Durability and adaptability for various educational settings |

| Environmental Testing | Soil and water sample analysis | Reliable data collection for environmental assessments | Corrosion-resistant materials and easy maintenance |

| Food and Beverage | Quality assurance testing | Ensures product safety and compliance with regulations | Specific configurations for food safety standards and easy cleaning |

How is a Scientific Bench Used in Healthcare Laboratories?

In healthcare settings, scientific benches are essential for laboratory testing and diagnostics. They provide a stable and safe environment for conducting various tests, including blood analysis and pathogen detection. The benches are often designed with features that facilitate easy cleaning and compliance with health regulations. For international buyers, especially from regions with stringent health standards, sourcing benches that meet specific material safety and durability requirements is crucial to ensure patient safety and accurate results.

What Role Does a Scientific Bench Play in Pharmaceuticals?

In the pharmaceutical industry, scientific benches are vital for drug formulation and quality control processes. These benches support activities such as mixing compounds, conducting stability tests, and ensuring adherence to regulatory standards. Buyers in this sector should consider benches that offer customizable designs to fit specific workflows and are made from chemical-resistant materials. This customization helps streamline production and enhances operational efficiency, which is critical for meeting market demands.

How Do Educational Institutions Benefit from Scientific Benches?

Educational institutions utilize scientific benches for research and experimentation in laboratory courses. These benches are designed to foster innovation and practical learning experiences for students. They must be durable and adaptable to accommodate various experiments and educational needs. For international buyers in emerging markets, selecting benches that can withstand heavy usage while maintaining safety and functionality is essential for enhancing the educational experience.

Why are Scientific Benches Important for Environmental Testing?

Scientific benches are key in environmental testing labs where soil and water samples are analyzed. These benches facilitate reliable data collection, essential for environmental assessments and compliance with environmental regulations. Buyers should prioritize benches made from corrosion-resistant materials to ensure longevity and ease of maintenance. For international buyers, especially in developing regions, ensuring that the benches can handle various environmental conditions is critical for effective testing.

How Do Food and Beverage Industries Utilize Scientific Benches?

In the food and beverage sector, scientific benches are used for quality assurance testing to ensure product safety and compliance with health regulations. They provide a controlled environment for testing food samples, which is crucial for maintaining quality standards. Buyers should look for benches that meet specific configurations required by food safety standards and are easy to clean to prevent contamination. This focus on safety and compliance is particularly important for international buyers in regions with strict food safety regulations.

3 Common User Pain Points for ‘scientific bench’ & Their Solutions

Scenario 1: Adapting to Diverse Laboratory Environments

The Problem: B2B buyers often face challenges in selecting the right scientific bench that meets the unique requirements of diverse laboratory environments. Laboratories across sectors—such as pharmaceuticals, biotechnology, and education—demand different specifications. A buyer may struggle with benches that are either too rigid or lack adaptability, leading to inefficient workflows or safety hazards. For instance, in a pharmaceutical lab, the need for corrosion-resistant surfaces is paramount, while in an educational setting, mobility and flexibility for various activities are essential.

The Solution: To navigate this complexity, buyers should conduct a thorough needs assessment before sourcing scientific benches. Consider the specific applications and environment in which the bench will be used. For laboratories handling corrosive substances, opt for benches with phenolic resin or stainless steel surfaces to ensure durability and safety. Additionally, seek benches with adjustable heights or mobile units that can easily be reconfigured for different tasks. Suppliers that offer customization options or modular designs can help ensure that the benches fit seamlessly into the existing layout, enhancing both functionality and safety.

Scenario 2: Ensuring Compliance with Regulatory Standards

The Problem: Compliance with local and international regulatory standards is a significant concern for B2B buyers in scientific industries. Buyers may find it challenging to ensure that the scientific benches they purchase meet all necessary safety and quality standards. Non-compliance can lead to costly fines, operational disruptions, and damage to reputation. For example, in laboratories that work with hazardous materials, benches must meet strict guidelines for safety and material integrity, which can vary by region.

The Solution: To address compliance issues, buyers should engage with suppliers who have a strong understanding of local regulations and industry standards. This can be achieved by requesting documentation and certifications that demonstrate compliance with relevant safety standards, such as ISO or ASTM certifications. Buyers should also consider investing in benches that have been tested for specific applications, ensuring they can withstand the rigors of laboratory work. Regular training for staff on compliance requirements and proper usage of the benches can further mitigate risks and enhance overall safety in the laboratory environment.

Scenario 3: Managing Budget Constraints Without Compromising Quality

The Problem: Budget constraints are a common pain point for many B2B buyers when sourcing scientific benches. Buyers often feel pressured to choose lower-cost options to stay within budget, which can compromise quality and longevity. This dilemma can lead to increased replacement costs and operational inefficiencies down the line. For instance, a cheaper bench may not withstand the rigors of daily use, resulting in frequent repairs or replacements, which ultimately leads to higher long-term costs.

The Solution: To effectively manage budget constraints while maintaining quality, buyers should adopt a value-based purchasing approach. This involves looking beyond the initial price tag and considering the total cost of ownership (TCO). Evaluate the expected lifespan of the bench, warranty options, and the availability of replacement parts. Opting for high-quality materials and reputable brands may require a larger upfront investment but can lead to significant savings over time. Additionally, buyers can explore financing options or bulk purchase discounts that may allow them to acquire high-quality benches within their budget constraints. Regular maintenance and proper usage can also extend the lifespan of laboratory furniture, ensuring it remains a wise investment for years to come.

Illustrative image related to scientific bench

Strategic Material Selection Guide for scientific bench

What Are the Key Properties of Common Materials Used in Scientific Benches?

When selecting materials for scientific benches, it is crucial to consider their properties in relation to the intended applications. Here, we analyze four common materials: Stainless Steel, Phenolic Resin, Laminate, and Wood. Each material has unique characteristics that can significantly impact performance and suitability for various laboratory environments.

How Does Stainless Steel Perform in Laboratory Settings?

Stainless steel is renowned for its exceptional durability and resistance to corrosion, making it a popular choice for scientific benches. It can withstand high temperatures and pressure, which is essential in laboratories that conduct experiments involving heat or chemical reactions. The primary advantage of stainless steel is its longevity and ease of cleaning, which is crucial for maintaining sterile environments.

However, stainless steel can be more expensive than other materials, and its manufacturing process is complex, which can lead to higher costs for buyers. Additionally, while it is highly resistant to most chemicals, certain aggressive acids can cause pitting or corrosion over time. International buyers should ensure compliance with standards such as ASTM A240 for stainless steel grades, especially in regions like Europe and the Middle East, where specific regulations may apply.

Illustrative image related to scientific bench

What Are the Benefits of Using Phenolic Resin for Scientific Benches?

Phenolic resin is another widely used material, particularly valued for its chemical resistance and durability. It is impervious to many solvents, acids, and bases, making it suitable for laboratories that handle hazardous materials. The ability to withstand high temperatures without degrading adds to its appeal.

On the downside, phenolic resin may not be as structurally robust as stainless steel and can be prone to chipping or cracking under extreme conditions. Its cost is generally moderate, making it a viable option for budget-conscious buyers. For international B2B transactions, it is essential to check compliance with local safety standards, such as ISO 9001, to ensure quality assurance.

Why Choose Laminate for Laboratory Benches?

Laminate surfaces are often chosen for their aesthetic appeal and cost-effectiveness. They come in various colors and finishes, allowing for customization to match laboratory themes. Laminate is resistant to stains and easy to clean, which is beneficial in maintaining hygiene.

However, laminate surfaces can be less durable than metal options and may not withstand high temperatures or heavy impacts. Their lifespan can be significantly shorter in environments where harsh chemicals are used. For B2B buyers, particularly in regions like South America and Africa, understanding local preferences for durability versus aesthetics can guide material selection.

What Role Does Wood Play in Scientific Bench Design?

Wood, particularly hardwoods like maple and oak, is sometimes used in laboratory settings for its natural look and feel. It is relatively easy to work with and can be less expensive than metal options. Wood surfaces can provide a warm aesthetic, which may be desirable in educational or less intensive laboratory environments.

The major limitation of wood is its susceptibility to moisture and chemicals, which can lead to warping or degradation over time. Moreover, it requires regular maintenance to ensure longevity. Buyers in regions with high humidity or exposure to chemicals should consider these factors carefully. Compliance with relevant standards, such as those from the American National Standards Institute (ANSI), can also influence purchasing decisions.

Summary Table of Material Selection for Scientific Benches

| Material | Typical Use Case for scientific bench | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical and heat-resistant labs | Exceptional durability and corrosion resistance | Higher cost and complex manufacturing process | High |

| Phenolic Resin | Laboratories handling hazardous materials | Excellent chemical resistance | Prone to chipping and moderate durability | Medium |

| Laminate | General lab use and educational settings | Cost-effective and customizable | Less durable and sensitive to heat | Low |

| Wood | Educational labs and low-intensity environments | Aesthetic appeal and easy to work with | Susceptible to moisture and chemical damage | Medium |

This guide provides a strategic overview of material selection for scientific benches, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for scientific bench

What Are the Key Stages in the Manufacturing Process of Scientific Benches?

The manufacturing process of scientific benches involves several critical stages that ensure the final product meets the specific needs of laboratory environments. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage is crucial as it determines the overall quality and durability of the scientific bench. Common materials used include steel, stainless steel, wood, and phenolic resin. Suppliers must ensure that raw materials are sourced from reputable vendors, adhering to stringent quality standards. This phase often involves cutting, shaping, and treating materials to enhance their properties, such as corrosion resistance or vibration dampening.

-

Forming: In this stage, the prepared materials are shaped into the desired components of the bench. Techniques like bending, welding, and machining are employed to create parts like legs, tabletops, and frames. Precision is vital here, as any defects can affect the structural integrity and functionality of the bench. Advanced technologies such as CNC (Computer Numerical Control) machining may be utilized for high accuracy.

-

Assembly: Once the individual components are formed, they are assembled into the final product. This process often involves welding, bolting, or using adhesives to ensure a strong and stable structure. Quality control measures should be in place during assembly to check for alignment, stability, and overall craftsmanship.

-

Finishing: The final stage focuses on applying protective and aesthetic finishes to the bench. This may include powder coating, painting, or applying laminate surfaces. The finishing not only enhances the appearance but also adds to the durability and resistance to chemicals and wear.

How Is Quality Assurance Integrated into the Manufacturing of Scientific Benches?

Quality assurance is a fundamental aspect of the manufacturing process, particularly for scientific benches, which must meet high standards of safety and reliability.

-

International Standards Compliance: Manufacturers of scientific benches often adhere to international quality management standards such as ISO 9001. Compliance with ISO standards ensures that the manufacturing processes are consistently monitored and improved, leading to higher product quality. Additionally, industry-specific certifications like CE marking (for safety in Europe) or API (American Petroleum Institute) standards may also apply depending on the intended use of the bench.

-

Quality Control Checkpoints: Effective quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to catch any defects early in the process. This includes monitoring dimensions, weld quality, and surface finishes.

– Final Quality Control (FQC): Before shipping, a thorough inspection is performed on the finished product to ensure it meets all specifications and quality standards. -

Testing Methods: Various testing methods are employed to assess the performance and durability of scientific benches. Common tests include load-bearing tests, stability assessments, and chemical resistance evaluations. These tests help verify that the benches can withstand the rigors of laboratory use.

What Can B2B Buyers Do to Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential.

-

Conducting Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should look for documented procedures, records of quality checks, and adherence to international standards.

-

Requesting Quality Reports: Suppliers should be able to provide comprehensive quality reports that detail their manufacturing processes, quality checkpoints, and outcomes of quality tests. These reports should be readily available and transparent to ensure trust.

-

Utilizing Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes. These inspectors can verify compliance with relevant standards and provide detailed reports on their findings.

What Nuances Should International B2B Buyers Consider Regarding Quality Control Certifications?

When dealing with international suppliers, especially from diverse regions, buyers must be aware of specific nuances related to quality control certifications.

-

Understanding Regional Standards: Different regions may have unique standards and certifications. For example, while CE marking is crucial in Europe, other regions may have their own requirements. Buyers should familiarize themselves with these standards to ensure compliance and safety.

-

Navigating Language Barriers: Documentation and certification details may not always be in the buyer’s preferred language. It’s advisable to engage translators or local representatives who can assist in understanding quality reports and certifications.

-

Evaluating Supplier Reputation: A supplier’s reputation can significantly impact the perceived quality of their products. Buyers should research suppliers’ histories, customer reviews, and case studies to gauge their reliability and quality assurance practices.

Conclusion

Understanding the manufacturing processes and quality assurance practices for scientific benches is vital for B2B buyers looking to procure reliable and durable laboratory furniture. By familiarizing themselves with the stages of manufacturing, quality control checkpoints, and the nuances of international standards, buyers can make informed decisions that align with their operational needs and compliance requirements. Engaging in thorough due diligence will ultimately lead to successful partnerships and high-quality laboratory environments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘scientific bench’

This guide is designed to assist B2B buyers in the strategic procurement of scientific benches. As laboratories and research facilities increasingly demand specialized furniture to meet their operational needs, understanding the essential steps in sourcing these products is crucial. This checklist will ensure you make informed purchasing decisions that align with your laboratory’s requirements.

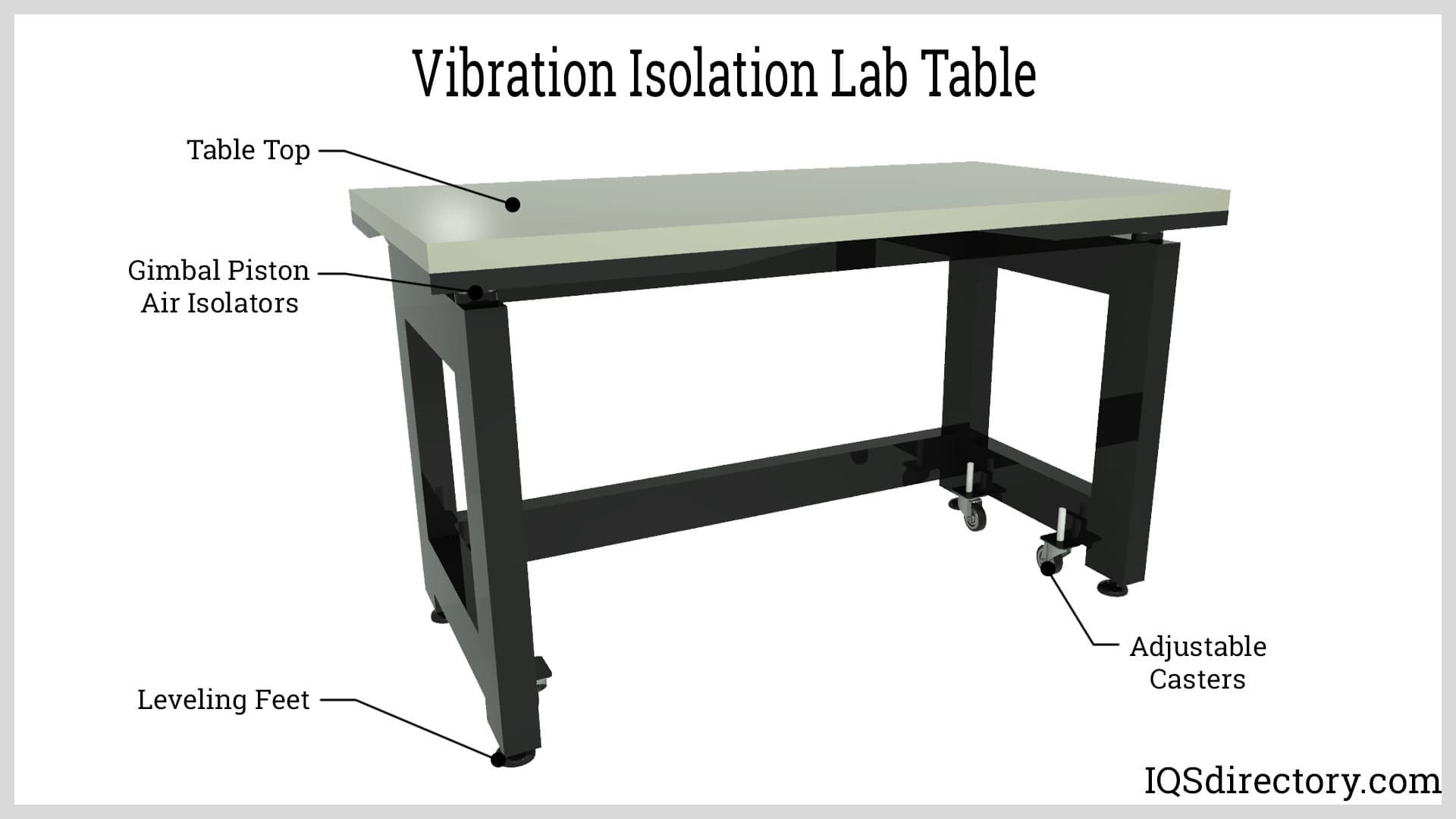

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Consider factors such as load-bearing capacity, materials (e.g., stainless steel, phenolic resin), and dimensions that suit your workspace. Additionally, account for features like corrosion resistance and vibration isolation, which are critical for maintaining a safe and efficient laboratory environment.

Step 2: Identify Your Budget Constraints

Understanding your budget is vital to narrow down your options effectively. Determine the total cost of ownership, which includes not only the purchase price but also installation, maintenance, and potential upgrades. Look for suppliers who offer flexible pricing or financing options that can accommodate your financial situation.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Focus on suppliers with a proven track record in delivering high-quality laboratory furniture and those who understand the specific regulatory requirements of your region.

- Check for certifications: Ensure that the supplier complies with relevant industry standards, such as ISO certifications or local safety regulations.

- Assess customer service: A responsive supplier can greatly enhance your procurement experience, offering support when needed.

Step 4: Request Samples or Demonstrations

Whenever possible, request samples or arrange for demonstrations of the benches you are considering. This step allows you to assess the build quality and ergonomics firsthand. Pay attention to aspects such as the finish, stability, and ease of assembly, as these factors can significantly affect user experience in a laboratory setting.

Step 5: Consider Customization Options

Every laboratory has unique needs, and customization may be necessary to optimize functionality. Inquire about the possibility of tailoring bench designs, sizes, or features to better fit your workflow. Customization can enhance productivity and ensure that the bench integrates seamlessly into your existing setup.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate the terms of the purchase. Discuss warranties, return policies, and delivery timelines to ensure that they align with your expectations. A favorable agreement can safeguard your investment and provide peace of mind in case of unforeseen issues.

Step 7: Plan for Installation and Maintenance

Finally, consider how the benches will be installed and maintained. Some suppliers may offer installation services, which can save time and ensure proper setup. Additionally, inquire about maintenance requirements and whether the supplier provides ongoing support, as this can impact the longevity and performance of your benches.

By following these steps, you can ensure that your procurement process for scientific benches is thorough and aligned with your laboratory’s operational needs.

Comprehensive Cost and Pricing Analysis for scientific bench Sourcing

What Are the Key Cost Components in Scientific Bench Manufacturing?

When sourcing scientific benches, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly affects the overall cost. Common materials include various types of wood (like oak and maple), metal (stainless steel, aluminum), and specialized surfaces (phenolic resin). Higher-quality materials tend to have a longer lifespan and better resistance to chemicals and wear, which can justify a higher price.

-

Labor: Labor costs can vary widely depending on the region and the complexity of the bench design. Skilled labor is essential for the assembly and finishing processes, particularly for customized benches that require precision.

-

Manufacturing Overhead: This includes costs associated with facilities, equipment, utilities, and administrative expenses. Efficient manufacturing processes can help in reducing these overheads, ultimately impacting the price.

-

Tooling: The initial investment in tooling for production can be substantial. Custom designs often require specific tooling, which can increase costs, particularly for low-volume orders.

-

Quality Control (QC): Ensuring that benches meet safety and performance standards requires a dedicated QC process. This adds to the overall cost but is essential for maintaining product integrity, especially in laboratory settings.

-

Logistics: Shipping costs can vary based on the weight and size of the benches, as well as the destination. International shipping can involve additional fees such as customs duties and tariffs, which should be factored into the total cost.

-

Margin: Finally, suppliers will add a profit margin to cover their costs and ensure profitability. This margin can vary based on market competition and the supplier’s positioning.

How Do Price Influencers Affect the Cost of Scientific Benches?

Several factors influence the pricing of scientific benches, which B2B buyers should consider when negotiating:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it advantageous for organizations planning to outfit multiple labs.

-

Specifications and Customization: Custom features such as adjustable heights, specific finishes, or additional storage options can significantly increase the price. Clearly defining requirements before sourcing can help manage costs.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., ESD protection, chemical resistance) may command premium prices. Buyers should assess whether these features align with their operational needs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more for their experience and service quality, while newer entrants might offer lower prices to attract business.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international buyers. These terms define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, affecting the total landed cost of the benches.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Scientific Benches?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, strategic sourcing can lead to significant cost savings:

-

Negotiate Effectively: Leverage your order volume and long-term potential to negotiate better pricing and terms. Establishing a partnership with suppliers can also yield discounts over time.

-

Consider Total Cost of Ownership (TCO): Look beyond the purchase price. Evaluate the long-term costs associated with maintenance, durability, and operational efficiency. A higher upfront cost may result in lower TCO if the bench lasts longer or requires less maintenance.

-

Understand Pricing Nuances: Familiarize yourself with the pricing landscape in your region. Factors like currency fluctuations, local economic conditions, and demand variability can influence costs.

-

Plan for Lead Times: Factor in lead times when placing orders, especially if customization is required. Delays can lead to increased operational costs if labs are unable to function without the necessary equipment.

-

Research Supplier Options: Explore multiple suppliers to compare costs and offerings. Consider both local and international suppliers to find the best balance of price and quality.

In conclusion, a thorough understanding of the cost components, price influencers, and strategic buying tips can empower B2B buyers to make informed decisions when sourcing scientific benches. Always seek to establish a collaborative relationship with suppliers to enhance value and drive down costs.

Alternatives Analysis: Comparing scientific bench With Other Solutions

Introduction to Alternative Solutions for Scientific Bench

When considering laboratory infrastructure, the choice of workspace can significantly influence operational efficiency and research outcomes. While the scientific bench is a popular choice for various laboratory tasks, buyers should also explore alternative solutions that may offer unique advantages. This analysis compares the scientific bench against two viable alternatives: modular laboratory workstations and mobile lab tables, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Scientific Bench | Modular Laboratory Workstations | Mobile Lab Tables |

|---|---|---|---|

| Performance | High load-bearing capacity; stable | Versatile configurations; customizable | Flexible and portable; good for dynamic tasks |

| Cost | Moderate to high investment | Varies; can be cost-effective for multiple setups | Generally lower cost; economical for temporary setups |

| Ease of Implementation | Requires professional installation | Moderate; can be self-assembled | Easy to set up; minimal installation required |

| Maintenance | Low; durable materials | Low; easy to clean and maintain | Moderate; depends on material and usage |

| Best Use Case | Fixed lab settings with heavy equipment | Laboratories needing flexibility and space optimization | Fieldwork or temporary lab setups requiring mobility |

Detailed Breakdown of Alternatives

Modular Laboratory Workstations

Modular laboratory workstations offer a flexible approach to laboratory design. These workstations can be easily reconfigured to accommodate different tasks or groups, making them ideal for dynamic environments. The primary advantage is their versatility; users can adjust the layout based on current projects or expand the workspace as needed. However, the initial investment can vary widely depending on the configuration and accessories chosen, making it essential to assess long-term needs before purchasing. Maintenance is generally low, as many components are designed for easy cleaning and durability.

Mobile Lab Tables

Mobile lab tables are designed for flexibility and mobility, allowing researchers to easily move their workspace as needed. This is particularly beneficial in environments where experiments or tasks shift frequently, such as in educational settings or collaborative research. The cost of mobile lab tables tends to be lower than that of traditional scientific benches, making them an attractive option for organizations with budget constraints. However, they may not support as heavy a load as fixed benches, and their stability can be a concern when performing rigorous tasks. Maintenance varies based on the materials used, but many modern mobile tables are designed for easy upkeep.

Conclusion: Choosing the Right Laboratory Solution

In selecting the right laboratory solution, B2B buyers must consider their specific operational needs, budget constraints, and the nature of their work. A scientific bench may be the best choice for laboratories requiring a stable and heavy-duty workspace, while modular workstations are ideal for those needing adaptability in a changing research environment. For temporary setups or mobile applications, mobile lab tables provide a cost-effective and flexible option. By carefully evaluating these alternatives, buyers can make informed decisions that enhance their laboratory efficiency and effectiveness.

Essential Technical Properties and Trade Terminology for scientific bench

What Are the Key Technical Properties of Scientific Benches?

When selecting a scientific bench for laboratory or industrial applications, understanding its technical specifications is crucial for ensuring optimal performance and durability. Here are some essential properties to consider:

-

Material Grade: The material used in constructing a scientific bench significantly affects its durability and resistance to chemicals. Common materials include stainless steel, phenolic resin, and laminate. For instance, stainless steel offers corrosion resistance and is easy to clean, making it ideal for environments that handle hazardous substances. Selecting the appropriate material ensures longevity and reduces maintenance costs.

-

Load Bearing Capacity: This specification indicates how much weight the bench can safely support. It is typically measured in pounds or kilograms. For example, a bench with a load capacity of 2000 lb (approximately 907 kg) is suitable for heavy equipment or multiple users. Understanding this property helps prevent structural failures and ensures safety in the workspace.

-

Height Adjustability: Many scientific benches come with adjustable heights to accommodate various tasks and user preferences. This feature promotes ergonomic practices, which can improve worker comfort and productivity. Adjustable benches can also cater to different user heights, making them versatile for shared lab environments.

-

Vibration Resistance: Some scientific benches are designed to minimize vibrations, which is essential for sensitive equipment like balances and microscopes. Vibration isolation features can include specialized casters or heavy-duty construction that absorbs shock. Selecting a bench with these properties can enhance measurement accuracy and equipment longevity.

-

Corrosion Resistance: This property is critical for benches used in laboratories where chemical exposure is common. Materials such as epoxy-coated steel or phenolic resin provide excellent resistance to corrosive agents. This specification is vital for maintaining the integrity of the bench and ensuring a safe working environment.

What Are Common Trade Terms Related to Scientific Benches?

Understanding industry-specific terminology can facilitate smoother transactions and better decision-making. Here are some common terms to be familiar with:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of scientific benches, an OEM may supply components that are integrated into a larger laboratory setup. Knowing OEMs helps buyers identify reliable suppliers.

-

MOQ (Minimum Order Quantity): MOQ is the smallest number of units a supplier is willing to sell. For B2B buyers, understanding MOQ is essential for budgeting and inventory planning. A lower MOQ may allow businesses to test products without significant upfront investment.

-

RFQ (Request for Quotation): An RFQ is a document that potential buyers send to suppliers to request pricing and terms for specific products or services. Crafting a detailed RFQ can lead to more accurate quotes and better negotiation outcomes, particularly when purchasing multiple scientific benches.

-

Incoterms (International Commercial Terms): These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers understand shipping costs, risks, and delivery responsibilities.

-

Lead Time: This term refers to the time it takes from placing an order to receiving the product. Knowing the lead time is crucial for project planning and ensuring that laboratory setups are completed on schedule. Long lead times may impact operational efficiency, so buyers should factor this into their procurement strategies.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting scientific benches, ultimately leading to enhanced productivity and safety in their operations.

Illustrative image related to scientific bench

Navigating Market Dynamics and Sourcing Trends in the scientific bench Sector

What are the Key Trends Influencing the Scientific Bench Market?

The global scientific bench market is witnessing significant evolution driven by technological advancements, regulatory changes, and shifting buyer preferences. Key trends include the increasing demand for customized laboratory furniture that meets specific operational needs, which is particularly relevant for international buyers in Africa, South America, the Middle East, and Europe. Buyers are gravitating towards modular and flexible designs that can adapt to diverse laboratory environments, facilitating a more efficient workflow.

Additionally, the integration of smart technology in laboratory setups is reshaping sourcing strategies. Innovations such as IoT-enabled benches that monitor environmental conditions and equipment usage are becoming popular. This trend is particularly pertinent in regions like Saudi Arabia and Vietnam, where investments in modernizing laboratories are on the rise. Moreover, the focus on ergonomics and user-friendly designs is becoming a priority, as organizations recognize the importance of worker safety and productivity.

International B2B buyers are also navigating complexities related to supply chain management, including increased freight costs and delays. To mitigate these challenges, buyers are increasingly leveraging digital platforms for sourcing, allowing for greater transparency and improved supplier relationships. This shift not only enhances procurement efficiency but also enables buyers to make informed decisions based on real-time data.

Illustrative image related to scientific bench

How is Sustainability and Ethical Sourcing Impacting the Scientific Bench Sector?

Sustainability and ethical sourcing have become paramount considerations for B2B buyers in the scientific bench market. The environmental impact of laboratory furniture, including the materials used and the manufacturing processes, is under scrutiny. Buyers are increasingly prioritizing products that minimize ecological footprints, such as those made from recycled materials or those that utilize sustainable production methods.

Certifications such as LEED (Leadership in Energy and Environmental Design) and GREENGUARD, which indicate low emissions of volatile organic compounds (VOCs), are gaining traction among buyers. These certifications not only enhance product credibility but also align with the global push for greener laboratory practices. B2B buyers are also looking for suppliers who maintain ethical supply chains, ensuring fair labor practices and transparency throughout the production process.

The demand for eco-friendly materials, such as phenolic resin tops and powder-coated steel, reflects a broader commitment to sustainability. By choosing scientifically engineered materials that meet stringent safety and environmental standards, buyers can contribute to a healthier planet while also meeting regulatory requirements in their respective regions.

How Has the Scientific Bench Market Evolved Over Time?

The evolution of the scientific bench market can be traced back to the early days of laboratory setups, where functionality was prioritized over aesthetics. Initially, laboratory benches were rudimentary, made from basic materials that lacked durability and adaptability. As scientific research advanced, so did the need for specialized workspaces that catered to diverse applications, leading to the development of more robust and versatile designs.

In the late 20th century, the introduction of modular workstations allowed for greater flexibility, enabling laboratories to customize their setups based on specific research needs. This shift not only improved operational efficiency but also paved the way for the integration of technology into laboratory furniture. Today, the scientific bench market continues to evolve, driven by technological innovations and a growing emphasis on sustainability and ethical sourcing, reflecting the changing demands of a more sophisticated global buyer landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of scientific bench

-

How do I choose the right scientific bench for my laboratory needs?

Selecting the appropriate scientific bench involves assessing your specific laboratory requirements, including the types of experiments and equipment you’ll use. Consider the material of the bench; for instance, stainless steel is ideal for corrosion resistance, while phenolic resin tops provide durability against chemicals. Evaluate the size and layout of your lab to ensure the bench fits comfortably and allows for efficient workflow. Additionally, think about whether you need features such as adjustable height or mobility, which can enhance flexibility in your workspace. -

What is the best material for a scientific bench in a laboratory setting?

The best material for a scientific bench largely depends on your laboratory’s specific applications. Stainless steel is highly recommended for its durability and resistance to chemicals and corrosion, making it ideal for environments where spills are common. For chemical resistance without the weight of metal, phenolic resin tops are an excellent choice. Wood benches, while aesthetically pleasing, may not hold up in high-chemical environments but can be suitable for certain educational labs or dry environments. -

What customization options are typically available for scientific benches?

Many suppliers offer customization options for scientific benches, including size, material, and additional features such as drawers, shelving, and integrated electrical outlets. You can also select finishes that match your laboratory’s aesthetic or specific functional requirements. When considering customization, discuss your needs with the supplier to explore potential modifications that enhance functionality, such as adjustable height mechanisms or mobile bases for versatile lab configurations. -

What are the typical minimum order quantities (MOQ) for scientific benches?

Minimum order quantities can vary significantly depending on the supplier and the specific bench model. Some manufacturers may have an MOQ as low as one unit for standard products, while others might require larger orders for customized or specialized benches. When sourcing, inquire about the MOQ upfront to avoid unexpected costs and to determine if bulk purchasing is necessary for your budget and operational needs. -

What payment terms should I expect when purchasing scientific benches internationally?

Payment terms for international purchases can vary widely between suppliers. Common terms include advance payment, letter of credit, or payment upon delivery. It’s essential to clarify these terms before finalizing your order. Consider negotiating favorable terms that suit your cash flow, and always ensure that payment methods are secure and reliable to protect against potential fraud or disputes. -

How can I verify the quality assurance processes of a scientific bench supplier?

When vetting suppliers, request documentation of their quality assurance (QA) processes, including certifications like ISO 9001. Ask about their testing procedures for materials and finished products to ensure they meet industry standards. Additionally, seek references from previous customers or read reviews to gauge their reputation. A reliable supplier should be transparent about their QA practices and willing to provide samples for your inspection. -

What logistics considerations should I keep in mind when importing scientific benches?

Logistics is a critical aspect of importing scientific benches. Consider shipping methods, lead times, and costs associated with transportation, including duties and tariffs that may apply in your region. Verify the supplier’s ability to handle export documentation and customs clearance to prevent delays. Additionally, assess the reliability of their shipping partners to ensure your products arrive safely and on time. -

Are there any specific regulations I need to be aware of when sourcing scientific benches?

Yes, various regulations may apply when sourcing scientific benches, depending on your country and the specific applications of the benches. Research local safety standards and certifications required for laboratory furniture. Additionally, be aware of any import regulations that might affect the materials used in the benches, such as chemical safety guidelines. Consulting with a legal or compliance expert can help you navigate these requirements effectively.

Top 8 Scientific Bench Manufacturers & Suppliers List

1. Fisher Scientific – Laboratory Benches and Tables

Domain: fishersci.com

Registered: 1995 (30 years)

Introduction: Laboratory benches and tables designed for safe laboratory tasks and handling of reagents and samples. Features include corrosion-resistant and vibration-resistant finishes, with options for mobile units. Available colors: Almond, Amber Stain, Auburn Stain, Black, Gray, Gray Maple, Green, Harvest Stain, Honey Stain, Light Gray, Maple, Mocha Stain, Natural Maple, Natural Stain, Oak, Oak Black, Silv…

2. Loc Scientific – Laboratory Workstations

Domain: locscientific.com

Registered: 1998 (27 years)

Introduction: Laboratory Benches & Workstations include: “ERGO-LINE” Workbench, “Millennium II” Workbench, “HD” Modular Workbench, “BASICS” Modular Workbench, “DIMENSION NEXT” Expandable Workbench, “HDL” Workbench, “ELECTRIC WIRE HARNESS” Workbench. These products are designed for durability, adaptability, and performance, catering to specialized industries with features such as advanced electrical integration,…

3. Thomas Scientific – Lab Workbenches & Work Tables

Domain: thomassci.com

Registered: 1995 (30 years)

Introduction: Lab Workbenches & Work Tables are essential components in laboratory settings, designed for versatility and durability. They provide a stable surface for experiments, handling lab equipment, and data analysis. Key features include robust construction with materials like stainless steel or chemically resistant laminates, adjustable heights, integrated shelving, and customizable drawer configuration…

4. ICIScientific – Envision Laboratory Bench System

Domain: iciscientific.com

Registered: 2013 (12 years)

Introduction: This company, ICIScientific – Envision Laboratory Bench System, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Kewaunee – Laboratory Solutions

Domain: kewaunee.com

Registered: 1995 (30 years)

Introduction: Kewaunee offers a wide range of laboratory solutions including: 1. Casework: Steel and wood casework with various cabinet styles, color palettes, construction details, and hardware choices. 2. Educational Furniture: Customizable options with different color palettes and hardware choices. 3. Fume Hoods: Laboratory fume hoods including Supreme Air Venturi, Supreme Air Hoods, and TruView Hood with co…

6. Genie Scientific – Lab Benches

Domain: geniescientific.com

Registered: 2001 (24 years)

Introduction: Lab benches are categorized into wet and dry types, with options for specialized purposes such as cleanrooms, sink lab benches, island lab benches, side benches, and reagent racks. They can be classified by function (e.g., chemical lab benches, biological lab benches) and structure (suspended, floor-mounted, mobile). Key types include: 1. Dry Lab Bench: For computational research, equipped with co…

7. Peak Scientific – MS Bench SCI 1

Domain: peakscientific.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “MS Bench SCI 1”, “part_number”: “3302382”, “status”: “Available”, “description”: “Developed exclusively for SCIEX, the MS Bench SCI range provides a modular workstation with provision for either integrated gas generation or a noise abating enclosure for roughing pumps. Designed specifically for use with the current and latest mass spectrometers at SCIEX.”, “variants”: [{“name”: “…

8. Discovery Scientific Solutions – Laboratory Bench Systems

Domain: discoveryscientificsolutions.com

Registered: 2015 (10 years)

Introduction: Discovery Scientific Solutions offers a variety of laboratory bench systems designed for workflow efficiency and reliability. The product lines include: 1. A.T. Villa Basic Laboratory Bench Systems – Ideal for start-up and traditional educational laboratory needs. 2. A.T. Villa Bravo Laboratory Bench Systems – The industry’s first adaptable benching system with true plug-and-play services for rout…

Strategic Sourcing Conclusion and Outlook for scientific bench

How Can Strategic Sourcing Enhance Your Scientific Bench Procurement?

In the ever-evolving landscape of laboratory equipment, strategic sourcing remains a cornerstone for international B2B buyers aiming to optimize their scientific bench procurement. By focusing on quality, durability, and functionality, companies can ensure their laboratory environments not only meet regulatory standards but also enhance operational efficiency. Key takeaways include the importance of selecting benches that are corrosion and vibration resistant, as well as customizable options that cater to specific laboratory needs.

Moreover, leveraging global supplier networks can provide access to innovative materials and designs, fostering a competitive edge. Buyers should prioritize suppliers who offer sustainable solutions, reflecting a commitment to environmental responsibility while meeting the rigorous demands of scientific work.

As we look ahead, the integration of advanced technology and smart design in laboratory benches will drive further improvements in productivity and safety. International buyers, particularly from Africa, South America, the Middle East, and Europe, are encouraged to engage in strategic partnerships with reputable suppliers. This proactive approach will not only enhance your laboratory’s capabilities but also position your business for success in a global market that increasingly values innovation and sustainability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.