A B2B Buyer’s Guide to Soundproofing Contractors: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for soundproofing contractors

In today’s increasingly noisy world, sourcing effective soundproofing contractors can be a daunting challenge for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, the quest for high-quality soundproofing solutions is paramount for enhancing privacy, comfort, and productivity within your spaces. This comprehensive guide serves as your essential resource, navigating the complex landscape of soundproofing contractors by exploring various types of soundproofing solutions, their applications across different industries, and key considerations for supplier vetting.

From acoustic panels that enhance sound quality in entertainment venues to specialized materials that mitigate noise in multi-family residential projects, understanding the diverse offerings is crucial. Additionally, we delve into cost considerations, providing insights into budgeting for your soundproofing needs without compromising on quality. This guide empowers B2B buyers to make informed purchasing decisions by equipping them with the knowledge to evaluate potential contractors effectively, ensuring they select partners who can deliver tailored solutions that meet specific requirements. By demystifying the process and offering actionable insights, we aim to facilitate successful collaborations that transform noisy environments into serene spaces, enhancing overall well-being and operational efficiency.

Understanding soundproofing contractors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commercial Soundproofing | Specializes in large-scale projects; often includes compliance review | Offices, hotels, schools, and hospitals | Pros: Expertise in regulations; efficient for large spaces. Cons: Higher costs; longer timelines. |

| Residential Soundproofing | Focused on individual homes; tailored solutions for specific needs | Apartments, single-family homes, and condos | Pros: Customized solutions; often more affordable. Cons: Limited scalability for larger projects. |

| Acoustical Consulting Firms | Provide assessments and design recommendations; expertise in acoustics | Legal disputes, property management, and design projects | Pros: In-depth analysis; tailored recommendations. Cons: May charge for consultations; longer process. |

| DIY Soundproofing Solutions | Offer products for self-installation; often cost-effective | Small businesses, home offices, and personal projects | Pros: Lower costs; flexibility in implementation. Cons: Requires DIY skills; potential for suboptimal results. |

| Specialized Acoustic Contractors | Focus on unique spaces (e.g., studios, theaters); advanced techniques | Music venues, recording studios, and performance spaces | Pros: High expertise in acoustics; tailored solutions. Cons: Niche market; potentially higher costs. |

What Are the Key Characteristics of Commercial Soundproofing Contractors?

Commercial soundproofing contractors are adept at managing large-scale projects, often necessitating compliance with local building codes and regulations. They typically work on offices, hotels, schools, and hospitals, making them suitable for organizations that require noise control across extensive spaces. When considering a contractor, B2B buyers should assess their experience with similar projects, timelines, and cost structures, as these can vary significantly.

How Do Residential Soundproofing Contractors Differ?

Residential soundproofing contractors focus on individual homes and apartments, delivering tailored solutions for specific noise issues. They are particularly beneficial for homeowners looking to enhance privacy and comfort. B2B buyers, such as property developers or real estate agents, should evaluate these contractors based on their ability to customize solutions, affordability, and past project success to ensure optimal results.

What Services Do Acoustical Consulting Firms Offer?

Acoustical consulting firms specialize in providing assessments and design recommendations for soundproofing solutions. They are often engaged in legal disputes or by property managers needing expert advice on sound issues. Buyers should consider the firm’s expertise in acoustics, the comprehensiveness of their analysis, and their ability to deliver actionable recommendations. This approach can lead to effective sound control solutions tailored to specific project needs.

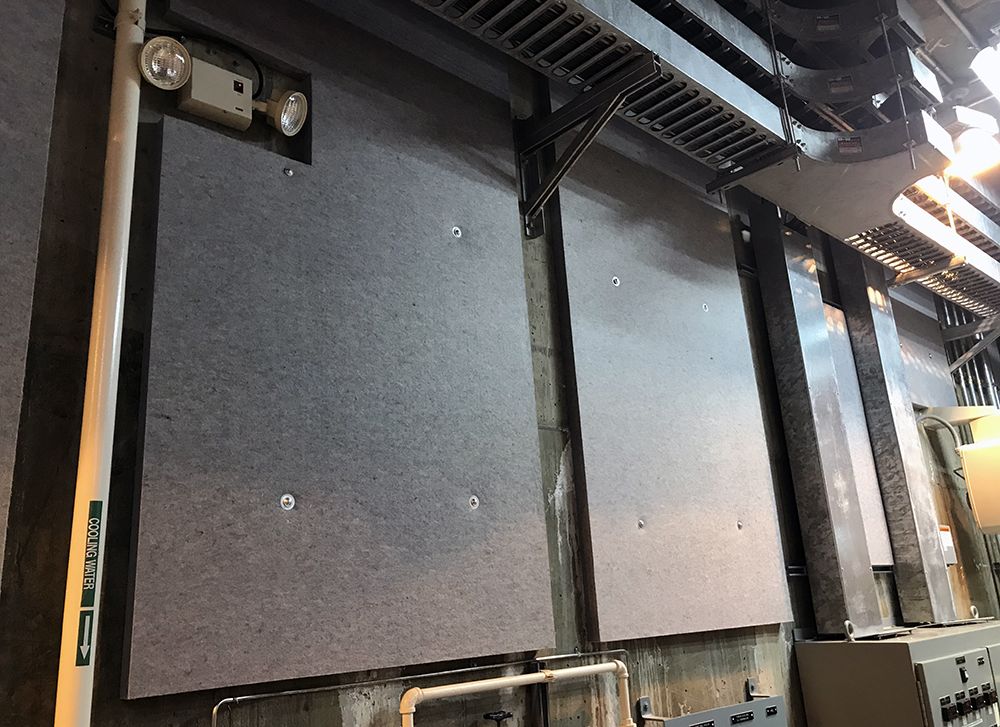

Illustrative image related to soundproofing contractors

What Are the Advantages of DIY Soundproofing Solutions?

DIY soundproofing solutions cater to those looking for cost-effective measures to reduce noise in small spaces like home offices or personal projects. These solutions typically include products that can be self-installed, appealing to budget-conscious buyers. However, potential customers should possess some DIY skills and be aware that improper installation can lead to less effective results. Evaluating product reviews and installation guides can aid in making informed purchasing decisions.

Why Choose Specialized Acoustic Contractors for Unique Spaces?

Specialized acoustic contractors focus on unique environments such as music venues, recording studios, and theaters. Their expertise in advanced soundproofing techniques ensures optimal acoustic performance tailored to the specific requirements of these spaces. B2B buyers in the entertainment or creative industries should prioritize contractors with a proven track record in similar projects, as this can significantly impact the quality of sound and overall experience in the venue.

Key Industrial Applications of soundproofing contractors

| Industry/Sector | Specific Application of soundproofing contractors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Acoustic insulation in multi-family residential buildings | Enhances tenant satisfaction and property value | Compliance with local building codes, selection of eco-friendly materials |

| Hospitality | Soundproofing hotel rooms and conference areas | Improves guest experience and boosts occupancy rates | Expertise in managing diverse room types and soundproofing solutions |

| Healthcare | Noise control in hospitals and clinics | Promotes patient comfort and confidentiality | Understanding of healthcare regulations and specialized acoustical needs |

| Education | Soundproofing classrooms and auditoriums | Enhances learning environments and reduces distractions | Tailored solutions for varying room sizes and layouts |

| Entertainment | Acoustic treatment in music studios and theaters | Optimizes sound quality for performances and recordings | Knowledge of industry standards for sound quality and acoustics |

How Can Soundproofing Contractors Benefit the Construction Industry?

In the construction sector, soundproofing contractors play a vital role in enhancing acoustic insulation for multi-family residential buildings. With the growing demand for urban living spaces, noise complaints can significantly impact tenant satisfaction and retention. By employing soundproofing solutions, contractors can ensure that walls, floors, and ceilings are treated effectively, thereby enhancing the overall living experience. Buyers must consider local building codes and opt for eco-friendly materials to align with sustainability goals in various regions, including Europe and the Middle East.

What Advantages Does Soundproofing Provide to the Hospitality Sector?

For the hospitality industry, soundproofing contractors are essential in creating peaceful environments within hotels and conference centers. By effectively soundproofing guest rooms and communal areas, businesses can significantly improve guest experiences, leading to higher occupancy rates and positive reviews. International buyers should seek contractors with a proven track record in managing the unique challenges posed by diverse room types, ensuring that solutions are both effective and aesthetically pleasing.

How Do Soundproofing Solutions Enhance Healthcare Facilities?

In healthcare settings, soundproofing contractors are crucial for managing noise levels in hospitals and clinics. Effective sound control contributes to patient comfort and confidentiality, which are paramount in these environments. Buyers in the healthcare sector should prioritize contractors who understand the specific regulations and acoustical needs of medical facilities, ensuring compliance with healthcare standards while promoting a calming atmosphere for patients and staff.

Why Is Soundproofing Important in Educational Institutions?

Educational institutions benefit greatly from soundproofing solutions in classrooms and auditoriums. By minimizing external noise and reverberation, soundproofing enhances the learning environment, allowing students to focus better and engage more effectively. Buyers from the education sector must consider tailored solutions that accommodate various room sizes and layouts, ensuring that the soundproofing measures meet specific educational needs and enhance overall learning outcomes.

How Can Soundproofing Contractors Improve the Entertainment Industry?

In the entertainment sector, soundproofing contractors provide essential acoustic treatments for music studios and theaters. By optimizing sound quality, these contractors help ensure that performances and recordings meet industry standards. Buyers in this sector should look for contractors with extensive knowledge of acoustics and sound quality, as well as experience in delivering customized solutions that cater to the unique demands of various performance spaces.

3 Common User Pain Points for ‘soundproofing contractors’ & Their Solutions

Scenario 1: Overcoming Miscommunication in Soundproofing Projects

The Problem: One of the most significant challenges B2B buyers face when working with soundproofing contractors is miscommunication regarding project specifications. This issue often arises from unclear expectations about the required soundproofing levels, materials, and installation techniques. For instance, property developers may have different interpretations of sound transmission class (STC) ratings or impact insulation class (IIC) requirements. This can lead to inadequate soundproofing solutions, resulting in dissatisfied clients, increased costs, and project delays.

The Solution: To mitigate miscommunication, B2B buyers should prioritize establishing clear lines of communication with soundproofing contractors from the outset. This involves drafting a detailed project brief that outlines specific requirements, desired outcomes, and compliance with local regulations. Buyers should also request a comprehensive consultation where contractors can provide expert insights based on their experience with similar projects. Additionally, leveraging visual aids, such as diagrams and sound testing reports, can help ensure all parties have a mutual understanding of the project scope. Regular check-ins throughout the project can further facilitate open dialogue, allowing for adjustments as needed.

Illustrative image related to soundproofing contractors

Scenario 2: Navigating Compliance and Building Regulations

The Problem: Compliance with local building codes and regulations is a common headache for B2B buyers in the soundproofing sector. Each region has its own set of laws regarding sound insulation standards, which can vary significantly across countries in Africa, South America, the Middle East, and Europe. For instance, developers in Germany must adhere to stringent noise protection regulations, while those in Saudi Arabia may face different requirements. Failing to comply can result in costly fines and project rework.

The Solution: To navigate the complex landscape of compliance, B2B buyers should engage soundproofing contractors who have a deep understanding of local building codes and regulations. Buyers can initiate this process by conducting thorough research on the specific requirements for their project location. When selecting contractors, prioritize those who offer compliance review services and can provide documented evidence of their expertise in local standards. Additionally, requesting a compliance checklist as part of the project planning phase can ensure that all necessary regulations are considered and adhered to throughout the project lifecycle.

Scenario 3: Achieving Cost-Effective Soundproofing Solutions

The Problem: Many B2B buyers struggle with balancing budget constraints while seeking effective soundproofing solutions. The misconception that high-quality soundproofing must be prohibitively expensive can lead to subpar installations that do not meet the desired acoustic performance. This is particularly pressing for buyers in emerging markets, where cost sensitivity is heightened, and there’s a need to demonstrate value for investment.

The Solution: To achieve cost-effective soundproofing, B2B buyers should focus on collaborating with contractors who can provide tailored solutions based on their specific needs and budget. During the initial consultation, buyers should discuss their budget openly and ask for multiple options that vary in price and effectiveness. Contractors can leverage innovative materials and installation techniques that deliver high performance without breaking the bank. Additionally, buyers should consider the long-term benefits of investing in quality soundproofing, such as reduced noise complaints and improved tenant satisfaction, which can lead to higher occupancy rates and ultimately, greater profitability. Seeking out case studies or testimonials from contractors who have successfully delivered cost-effective solutions can also provide valuable insights and reassurance.

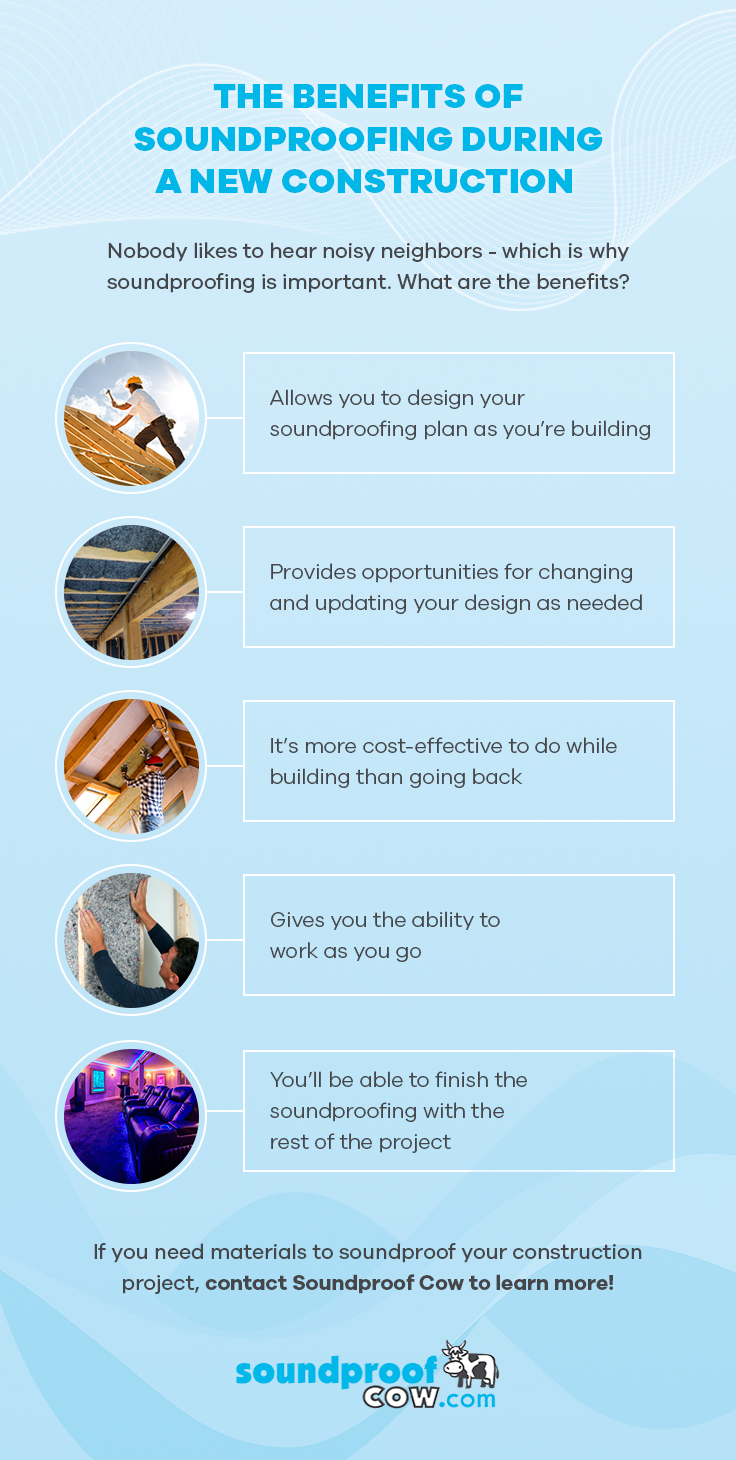

Strategic Material Selection Guide for soundproofing contractors

What Are the Key Materials for Soundproofing Contractors?

When selecting materials for soundproofing applications, contractors must consider a variety of factors, including performance properties, cost-effectiveness, and compliance with local regulations. Below, we analyze four common soundproofing materials, focusing on their key properties, advantages and disadvantages, and specific considerations for international buyers.

Illustrative image related to soundproofing contractors

How Do Acoustic Foam Panels Perform in Soundproofing?

Key Properties: Acoustic foam panels are designed to absorb sound waves and reduce echo in a space. They typically have a temperature rating that can withstand standard indoor environments and are lightweight, making them easy to install.

Pros & Cons: The primary advantage of acoustic foam is its ability to significantly improve sound quality by reducing reverberation. However, they are not effective at blocking sound transmission between rooms, which limits their application in environments requiring complete sound isolation. Their durability is moderate, as they can degrade over time if exposed to moisture.

Impact on Application: Acoustic foam is best suited for studios, offices, and entertainment venues where sound quality is paramount. They are generally compatible with various surfaces, including walls and ceilings.

International Considerations: Buyers in regions like Europe and the Middle East should ensure that the foam complies with fire safety standards, such as EN 13501. In contrast, buyers in South America may prioritize cost over compliance, given the varying local regulations.

Illustrative image related to soundproofing contractors

What Role Does Mass Loaded Vinyl (MLV) Play in Soundproofing?

Key Properties: Mass Loaded Vinyl is a dense material that effectively blocks sound transmission. It has a high mass-to-thickness ratio, making it suitable for various applications, including walls, ceilings, and floors.

Pros & Cons: MLV is highly effective at soundproofing due to its density, providing excellent sound isolation. However, its installation can be labor-intensive, and it may require additional framing or support, increasing overall project complexity. The cost of MLV is relatively high compared to other materials.

Impact on Application: MLV is particularly effective in multi-family housing and commercial buildings where sound transmission between units is a concern. Its compatibility with various substrates enhances its versatility.

Illustrative image related to soundproofing contractors

International Considerations: In regions like Germany, MLV must meet specific sound insulation ratings (e.g., DIN 4109), while buyers in Africa may face challenges in sourcing high-quality MLV due to limited local availability.

How Effective Are Resilient Channels in Soundproofing Systems?

Key Properties: Resilient channels are metal strips that decouple drywall from framing, reducing sound transmission. They are designed to withstand standard building pressures and have a high tensile strength.

Pros & Cons: The primary advantage of resilient channels is their ability to enhance sound isolation without adding significant weight or bulk to the structure. However, they require precise installation to be effective, and improper installation can lead to suboptimal performance. The cost is moderate, making them a cost-effective solution for many projects.

Impact on Application: Resilient channels are ideal for use in wall and ceiling assemblies in both residential and commercial settings, particularly where sound isolation is critical.

International Considerations: Compliance with local building codes is crucial, especially in regions like Saudi Arabia, where regulations may dictate specific installation methods to achieve desired STC ratings.

What Are the Benefits of Using Green Glue in Soundproofing?

Key Properties: Green Glue is a viscoelastic compound used between two layers of drywall to dampen sound vibrations. It performs well under a range of temperatures and is resistant to moisture.

Pros & Cons: The key advantage of Green Glue is its ease of application and effectiveness in reducing sound transmission. However, it requires two layers of drywall for optimal performance, which can increase material costs. Its long-term durability is generally good, but it may not be suitable for extreme environmental conditions.

Illustrative image related to soundproofing contractors

Impact on Application: Green Glue is particularly effective in residential applications, such as home theaters and bedrooms, where sound isolation is desired.

International Considerations: Buyers in Europe should ensure that Green Glue complies with relevant acoustic performance standards, while those in Africa may need to consider logistics and availability when sourcing this product.

Summary of Material Selection for Soundproofing Contractors

| Material | Typical Use Case for soundproofing contractors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acoustic Foam Panels | Studios, offices, entertainment venues | Excellent sound absorption | Limited sound blocking capability | Medium |

| Mass Loaded Vinyl (MLV) | Multi-family housing, commercial buildings | High effectiveness in sound isolation | Labor-intensive installation | High |

| Resilient Channels | Wall and ceiling assemblies | Enhances sound isolation without added weight | Requires precise installation | Medium |

| Green Glue | Residential applications (e.g., home theaters) | Easy application and effective sound dampening | Requires two layers of drywall for best results | Medium |

This guide aims to equip soundproofing contractors with the necessary insights to make informed material selections that meet both performance and compliance requirements in various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for soundproofing contractors

What Are the Main Stages in the Manufacturing Process for Soundproofing Materials?

The manufacturing process for soundproofing materials is crucial to delivering effective and reliable solutions to contractors. It typically involves several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This stage involves sourcing raw materials known for their sound-dampening properties, such as mass-loaded vinyl, acoustic foam, or specialized soundproofing boards. Manufacturers often assess the quality of these materials through rigorous testing to ensure they meet industry standards. This could involve measuring density, thickness, and elasticity, which are critical factors in soundproofing performance.

-

Forming: During the forming stage, raw materials are shaped into the desired product. This may include cutting, molding, or extruding materials into sheets, tiles, or other forms. For instance, acoustic panels may be formed using a molding process that ensures uniform thickness and density, which are essential for consistent soundproofing capabilities.

-

Assembly: In this phase, various components are brought together to create the final product. This could involve layering different materials to enhance soundproofing effectiveness or adding features such as adhesive backing for easy installation. Automation may play a role here, but skilled labor is also vital to ensure precision and quality in assembly.

-

Finishing: The finishing stage includes applying protective coatings, branding, or other aesthetic elements that ensure the product not only performs well but also meets the visual expectations of clients. This step may also involve quality checks to confirm that the finished products are free from defects.

Which Key Techniques Are Employed in Soundproofing Manufacturing?

Manufacturers utilize various techniques to enhance the soundproofing effectiveness of their products. Some notable methods include:

Illustrative image related to soundproofing contractors

-

Layering: Combining multiple materials with different properties can significantly improve sound absorption and insulation. For example, using a combination of dense and porous materials can help target various sound frequencies.

-

Damping: This involves using viscoelastic materials that convert sound energy into heat, reducing sound transmission. Techniques like applying damping compounds between layers can enhance the overall soundproofing performance.

-

Decoupling: This technique involves separating two surfaces to reduce sound transmission, particularly in wall assemblies. Products like sound isolation clips and resilient channels are commonly used to achieve this effect.

-

Sound Absorption: Incorporating materials designed to absorb sound waves, such as acoustic foams and fiberglass, is essential for reducing echo and improving overall acoustics in a space.

What Quality Control Measures Are Relevant for Soundproofing Contractors?

Quality control (QC) is integral to ensuring that soundproofing materials meet both performance and safety standards. Here are some critical QC measures:

-

International Standards: Compliance with international standards such as ISO 9001 ensures that manufacturers maintain a consistent quality management system. This standard focuses on customer satisfaction and continuous improvement.

-

Industry-Specific Standards: Certifications like CE marking in Europe or API specifications in specific markets can indicate compliance with local regulations and safety standards. These certifications assure B2B buyers of the product’s reliability and safety.

-

QC Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Regular checks during the manufacturing process help identify defects early, allowing for timely corrections.

– Final Quality Control (FQC): A comprehensive inspection of the finished products ensures they meet all specifications before shipping.

What Common Testing Methods Are Used in Soundproofing QC?

Testing methods are vital for verifying the performance of soundproofing materials. Common techniques include:

-

Sound Transmission Class (STC) Testing: This measures how well a material can reduce sound transmission. Higher STC ratings indicate better soundproofing capabilities.

-

Impact Insulation Class (IIC) Testing: This assesses the impact noise reduction provided by a material, particularly important for floors in multi-family dwellings.

-

Absorption Coefficient Testing: This evaluates how effectively a material absorbs sound at different frequencies, which is crucial for optimizing acoustic performance.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers:

-

Conduct Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes, quality standards, and adherence to regulations.

-

Request Documentation: Buyers should ask for quality assurance documentation, including test reports, certification documents, and quality management system details.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can help validate the quality of the products being supplied, ensuring they meet the required standards before purchase.

What Are the QC and Certification Nuances for International Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

-

Regional Standards: Different regions may have varying regulations regarding soundproofing materials. Understanding these can help buyers ensure compliance and avoid potential legal issues.

-

Import Regulations: Buyers must be aware of import requirements in their respective countries, which may include specific testing or certification for soundproofing products.

-

Cultural Considerations: In some regions, cultural preferences for aesthetics and design may influence soundproofing choices. Suppliers should be able to accommodate these preferences while maintaining quality standards.

Conclusion

Understanding the manufacturing processes and quality assurance measures in the soundproofing industry is essential for B2B buyers. By focusing on the key stages of production, employing effective techniques, and adhering to rigorous quality control standards, soundproofing contractors can deliver reliable solutions. Buyers should leverage this knowledge to select suppliers that align with their quality expectations and regional requirements, ensuring successful project outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘soundproofing contractors’

The following guide offers a structured approach to sourcing soundproofing contractors, ensuring that international B2B buyers make informed decisions. Whether you are in Africa, South America, the Middle East, or Europe, these steps will help streamline your procurement process.

Step 1: Define Your Technical Specifications

Before reaching out to contractors, it’s essential to clearly define your project requirements. Consider the type of noise issues you are facing—whether it’s airborne noise, impact noise, or vibration—and the specific areas that need treatment, such as walls, ceilings, or floors. Having a well-documented specification helps contractors provide accurate proposals and ensures that solutions are tailored to your unique needs.

Step 2: Research Potential Contractors

Conduct thorough research to identify soundproofing contractors with relevant experience. Look for companies that specialize in your industry and have a track record of successful projects similar to yours. Utilize platforms like LinkedIn, industry forums, and trade associations to gather a list of potential candidates, paying attention to their client reviews and project portfolios.

Step 3: Evaluate Contractor Credentials

Verify the credentials and certifications of each contractor on your shortlist. Ensure they have the necessary licenses to operate in your region and check for certifications related to acoustics and soundproofing, such as STC (Sound Transmission Class) and IIC (Impact Insulation Class) ratings. This step is crucial to ascertain their expertise and compliance with local regulations.

Step 4: Request Detailed Proposals

Once you have narrowed down your options, request detailed proposals from your top candidates. A comprehensive proposal should include a breakdown of costs, timelines, and the specific materials and methods they plan to use. Look for transparency in their pricing and be cautious of bids that seem unusually low, as they may indicate subpar materials or rushed work.

Step 5: Conduct Interviews and Site Visits

Arrange interviews with the contractors to discuss their proposals and clarify any questions you may have. This personal interaction allows you to gauge their professionalism and communication style. If possible, visit previous project sites to assess the quality of their work firsthand and talk to past clients about their experiences.

Illustrative image related to soundproofing contractors

Step 6: Review Warranties and Support Services

Before making a final decision, ensure you understand the warranties and post-installation support offered by the contractors. A reliable contractor should provide warranties on both materials and workmanship, as well as ongoing support for any potential issues that may arise after the project is completed. This assurance can save you significant costs and headaches in the long run.

Step 7: Make Your Selection

After evaluating all factors—technical specifications, contractor credentials, proposals, interviews, and warranties—choose the contractor that best meets your needs. Ensure that all agreements are documented in a formal contract that outlines the scope of work, payment terms, and project timelines. This final step is critical to protecting your investment and ensuring a smooth project execution.

Following this checklist will help you navigate the complexities of sourcing soundproofing contractors effectively, leading to a successful outcome for your noise control project.

Comprehensive Cost and Pricing Analysis for soundproofing contractors Sourcing

What Are the Key Cost Components in Sourcing Soundproofing Contractors?

When sourcing soundproofing contractors, several cost components play a crucial role in the overall pricing structure. The primary elements include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

-

Materials: The type of soundproofing materials used (e.g., acoustic panels, soundproof drywall, insulation) significantly impacts costs. High-quality, certified products often come at a premium but can provide better long-term performance and compliance with industry standards.

-

Labor: Labor costs vary by region and the complexity of the installation. Skilled labor is essential for effective soundproofing, as improper installation can lead to subpar results and increased costs over time.

-

Manufacturing Overhead and Tooling: These are the indirect costs associated with production, including facility expenses and equipment maintenance. Efficient manufacturing processes can help minimize these costs, ultimately affecting the final pricing.

-

Quality Control (QC): Ensuring that products meet specific soundproofing standards requires rigorous quality control, which adds to the overall cost. Buyers should seek contractors that prioritize QC to avoid future issues.

-

Logistics: Shipping and handling costs can vary widely, especially for international buyers. Understanding the logistics involved in sourcing materials and the contractor’s location is vital for an accurate cost estimate.

-

Margin: The profit margin for soundproofing contractors can vary based on market competition and service offerings. It’s essential to assess whether the quoted margin reflects the value provided.

How Do Price Influencers Affect Soundproofing Contractor Quotes?

Several factors can influence the pricing of soundproofing services and products, including volume or minimum order quantity (MOQ), specifications and customization, material quality, supplier relationships, and Incoterms.

-

Volume/MOQ: Higher volumes often lead to lower per-unit costs, making it advantageous for larger projects. Contractors may offer discounts for bulk orders, which can significantly reduce overall expenses.

-

Specifications and Customization: Unique project requirements or custom solutions may increase costs due to specialized materials or additional labor. Buyers should clearly communicate their needs to avoid unexpected costs.

-

Materials and Quality/Certifications: The quality of materials directly affects performance and cost. Certified products that meet specific sound ratings (IIC, STC) may have higher upfront costs but can provide savings over time through durability and effectiveness.

-

Supplier Factors: Building strong relationships with reliable suppliers can lead to better pricing and terms. Consider the contractor’s sourcing practices and how they impact the overall cost structure.

-

Incoterms: Understanding shipping terms is crucial for international transactions. Incoterms dictate the responsibilities of buyers and sellers, impacting costs related to shipping, insurance, and customs duties.

What Are Effective Buyer Tips for Negotiating Soundproofing Costs?

To maximize value when sourcing soundproofing contractors, consider these actionable tips:

-

Negotiate: Don’t hesitate to negotiate pricing and terms. Contractors often have flexibility, especially for larger projects or repeat business.

-

Focus on Cost-Efficiency: Assess the total cost of ownership (TCO) rather than just the initial price. Investing in higher-quality materials and skilled labor may reduce long-term expenses associated with repairs or replacements.

-

Understand Pricing Nuances for International Buyers: International buyers should factor in additional costs such as tariffs, shipping fees, and currency fluctuations. Engage local experts or consultants familiar with the region’s market dynamics to navigate these complexities.

-

Request Multiple Quotes: Obtaining quotes from several contractors can provide a better understanding of the market rate and help identify competitive pricing.

-

Evaluate Value Beyond Price: Consider the contractor’s experience, customer service, and the quality of materials when assessing quotes. A lower price may not always equate to better value if it compromises quality or service.

Disclaimer on Indicative Prices

Prices for soundproofing services and materials can vary significantly based on geographical location, project specifics, and market conditions. This analysis provides a framework for understanding cost components and pricing influences, but buyers are encouraged to conduct thorough research and obtain tailored quotes for their unique needs.

Alternatives Analysis: Comparing soundproofing contractors With Other Solutions

In today’s competitive landscape, businesses often face the challenge of noise pollution, which can significantly impact productivity and comfort. When considering solutions for soundproofing, it’s essential to evaluate various methods and their effectiveness. Soundproofing contractors are a popular choice, but alternatives exist that may suit different needs and budgets. Below, we compare soundproofing contractors with two viable alternatives: acoustic panels and soundproofing materials.

| Comparison Aspect | Soundproofing Contractors | Acoustic Panels | Soundproofing Materials |

|---|---|---|---|

| Performance | High, tailored solutions with professional installation | Moderate, effective for echoes and reverberations | Variable, depends on quality and application |

| Cost | Higher initial investment, but may save costs in the long run | Moderate, affordable options available | Can be low to high, depending on materials chosen |

| Ease of Implementation | Requires professional installation; longer timeline | DIY-friendly; quicker setup | Varies; some materials require expertise for installation |

| Maintenance | Minimal, once installed properly | Low; occasional cleaning may be needed | Depends on the type; some may require replacements |

| Best Use Case | Large-scale projects needing customized solutions | Small to medium spaces needing echo reduction | General soundproofing needs across varied environments |

What Are the Advantages and Disadvantages of Acoustic Panels as an Alternative to Soundproofing Contractors?

Acoustic panels are a popular alternative for reducing noise, particularly in smaller spaces. They are designed to absorb sound waves, reducing echoes and improving sound quality. One of the main advantages is their affordability and ease of installation, as many panels can be mounted by the end-user. However, they may not provide comprehensive soundproofing, particularly against low-frequency sounds or external noise. Their effectiveness is also highly dependent on the placement and density of the panels. Thus, while they are suitable for improving acoustics in environments like offices or studios, they might not be ideal for larger commercial applications requiring extensive soundproofing.

How Do Soundproofing Materials Compare to Contractors in Terms of Effectiveness and Cost?

Soundproofing materials, such as mass-loaded vinyl or insulation batts, offer a versatile option for noise reduction. They can be used in various applications, from residential to commercial settings. The cost can vary widely, depending on the material chosen, ranging from budget-friendly options to high-end products. These materials can often be installed by contractors or skilled DIYers, making them accessible for various budgets. However, the effectiveness largely depends on proper installation and the specific materials used. Unlike professional contractors who provide tailored solutions, using soundproofing materials may require additional research and expertise to achieve the desired results.

How Can B2B Buyers Select the Right Soundproofing Solution for Their Needs?

When deciding between soundproofing contractors and alternative solutions, B2B buyers should assess their specific requirements, including the scale of the project, budget constraints, and the level of noise reduction needed. For large-scale operations or unique sound challenges, engaging a soundproofing contractor may provide the most effective and tailored solution. Conversely, for smaller projects or those with limited budgets, exploring acoustic panels or soundproofing materials can yield satisfactory results without the need for professional installation. Ultimately, understanding the nuances of each option will enable buyers to make an informed decision that best fits their operational needs.

Essential Technical Properties and Trade Terminology for soundproofing contractors

Understanding the essential technical properties and trade terminology in soundproofing is crucial for contractors and B2B buyers alike. This knowledge ensures effective communication, precise project execution, and compliance with industry standards, ultimately leading to successful soundproofing solutions.

What Are the Key Technical Properties for Soundproofing Materials?

-

Sound Transmission Class (STC)

STC is a rating that measures how well a building material attenuates airborne sound. Higher STC values indicate better sound insulation, making it critical for contractors to specify materials that meet the desired STC rating for their projects. For example, an STC rating of 50 or higher is often recommended for residential walls between units to ensure adequate privacy. -

Impact Insulation Class (IIC)

IIC measures a material’s ability to reduce impact noise, such as footsteps or dropped objects, between floors. This property is particularly important in multi-story buildings where noise transfer can disrupt the living or working environment. Selecting materials with a high IIC rating can enhance comfort and satisfaction for occupants. -

Material Density

Density refers to the mass per unit volume of soundproofing materials. Denser materials typically provide better soundproofing capabilities, as they are less likely to vibrate and transmit sound waves. For instance, materials like mass-loaded vinyl (MLV) are popular due to their high density and effectiveness in blocking sound. -

Sound Absorption Coefficient

This coefficient indicates how much sound a material can absorb rather than reflect. A higher absorption coefficient means the material is more effective at reducing echoes and reverberations within a space. It’s important for contractors to consider this property when designing spaces like auditoriums or conference rooms, where sound quality is paramount. -

Thermal Resistance (R-Value)

Although primarily a measure of thermal insulation, R-value also plays a role in soundproofing. Materials with higher R-values can contribute to sound attenuation by providing additional mass and structural integrity. Understanding R-value is crucial when selecting materials that will perform dual functions in a building.

What Are Common Trade Terms Used in the Soundproofing Industry?

-

OEM (Original Equipment Manufacturer)

In the soundproofing industry, OEM refers to companies that produce parts or materials that are used in the final product but are not branded. Knowing OEM suppliers can help contractors find reliable and cost-effective materials. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for contractors when budgeting and planning purchases, ensuring they meet suppliers’ requirements without overcommitting to excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document that contractors issue to suppliers to obtain pricing and terms for specific products or services. This process is essential for comparing costs and ensuring that the selected materials align with budgetary constraints. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade that define the responsibilities of buyers and sellers. Familiarity with Incoterms helps contractors understand shipping responsibilities, risks, and costs, which is especially important when sourcing materials from international suppliers. -

Acoustic Panels

Acoustic panels are specialized materials designed to absorb sound and reduce echo in a space. Understanding the various types and applications of acoustic panels allows contractors to provide tailored solutions for different environments, enhancing overall sound quality.

By grasping these technical properties and trade terms, soundproofing contractors can make informed decisions that optimize project outcomes, improve client satisfaction, and maintain competitive advantage in the marketplace.

Navigating Market Dynamics and Sourcing Trends in the soundproofing contractors Sector

What Are the Current Market Dynamics in the Soundproofing Contractors Sector?

The soundproofing contractors market is experiencing significant growth driven by several global factors. Increased urbanization, a rising focus on noise pollution, and heightened awareness of acoustic comfort in both residential and commercial spaces are reshaping the landscape. In regions such as Africa, South America, the Middle East, and Europe, buyers are increasingly investing in soundproofing solutions to enhance living conditions and improve productivity in work environments. For instance, in countries like Saudi Arabia and Germany, government initiatives promoting sustainable construction practices are propelling demand for soundproofing technologies.

Emerging B2B technology trends are also influencing sourcing strategies. Digital platforms for project management and acoustic analysis are gaining traction, allowing soundproofing contractors to offer customized solutions more efficiently. The integration of building information modeling (BIM) is enabling contractors to visualize soundproofing needs in real-time, fostering collaboration between architects, builders, and clients. Furthermore, the rise of e-commerce is streamlining the procurement process, allowing international buyers to source products from multiple suppliers globally, increasing competition and driving innovation in soundproofing materials.

How Is Sustainability Shaping Sourcing Trends for Soundproofing Contractors?

Sustainability is becoming a cornerstone of sourcing strategies for soundproofing contractors. The environmental impact of construction activities is under scrutiny, prompting businesses to seek eco-friendly materials and practices. This shift is critical for international buyers, particularly in regions where environmental regulations are becoming more stringent.

Ethical sourcing is gaining importance as businesses recognize the need for transparency in their supply chains. Buyers are increasingly looking for suppliers who can demonstrate compliance with environmental standards and certifications, such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 for environmental management. These certifications not only enhance a company’s reputation but also ensure that the materials used in soundproofing solutions are sourced responsibly.

The market is witnessing a rise in demand for ‘green’ soundproofing materials, such as recycled acoustic panels and low-VOC (volatile organic compounds) sealants. These materials not only contribute to a healthier indoor environment but also align with corporate social responsibility goals that many businesses are adopting. For soundproofing contractors, integrating sustainable practices into their offerings can differentiate them in a competitive marketplace, appealing to conscious buyers who prioritize environmental stewardship.

What Is the Historical Context Behind the Soundproofing Contractors Market?

The soundproofing industry has evolved significantly since its inception, driven by advances in acoustical science and technology. Initially, soundproofing solutions were primarily focused on basic insulation techniques and materials, often yielding subpar results. However, with the development of specialized products and systems—such as the Silentium System for comprehensive acoustic isolation—contractors are now able to address complex sound challenges more effectively.

The increasing demand for acoustic comfort in both residential and commercial spaces has further propelled this evolution. The rise of multi-family housing and open-office layouts has led to a greater need for effective soundproofing solutions, marking a shift from reactive to proactive approaches in design and construction. Today, soundproofing contractors leverage a deep understanding of acoustics, innovative materials, and advanced installation techniques to deliver tailored solutions that meet the diverse needs of international B2B buyers. This historical context underscores the importance of continuous innovation and adaptation in a rapidly changing market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of soundproofing contractors

-

How do I solve noise issues in a commercial space?

To address noise issues in a commercial space, start by identifying the primary sources of sound transmission, which can include walls, ceilings, floors, and even windows. Engage a qualified soundproofing contractor who can conduct an acoustic assessment to determine the most effective solutions tailored to your specific environment. Solutions may involve installing sound-absorbing materials, sound isolation systems, or acoustic panels. Collaborating with a contractor experienced in commercial soundproofing ensures that you achieve a balance between functionality and aesthetics while complying with local regulations. -

What is the best soundproofing material for reducing impact noise?

The best soundproofing materials for reducing impact noise typically include products designed to absorb shock and vibrations. High-density materials like mass-loaded vinyl, resilient channels, and acoustic underlays are effective for floors, while soundproof drywall and insulation can be utilized for walls and ceilings. Each material has its unique properties and benefits, so it’s crucial to consult with a soundproofing contractor who can recommend the best combination for your specific needs, taking into account factors such as budget, installation complexity, and building regulations. -

How can I ensure compliance with local sound regulations?

To ensure compliance with local sound regulations, first familiarize yourself with the applicable noise ordinances and building codes in your area. Engage a soundproofing contractor who specializes in compliance and can conduct necessary sound testing. They should provide recommendations on materials and construction techniques that meet or exceed local sound transmission class (STC) ratings. Regular communication with local authorities and adherence to guidelines will help mitigate potential legal issues related to noise complaints. -

What factors should I consider when vetting soundproofing contractors?

When vetting soundproofing contractors, consider their experience in the industry, client testimonials, and portfolio of completed projects. Evaluate their expertise in specific soundproofing solutions relevant to your needs, such as commercial versus residential applications. It’s also essential to check for proper certifications and insurance coverage. Request a detailed proposal outlining project scope, timelines, and pricing, and ensure they offer post-installation support and warranties for their work. -

What is the minimum order quantity (MOQ) for soundproofing materials?

Minimum order quantities (MOQ) for soundproofing materials can vary significantly depending on the supplier and the type of materials required. For large-scale commercial projects, suppliers may offer bulk pricing, which typically lowers the per-unit cost. However, for smaller projects, some suppliers may allow for smaller orders. It’s advisable to discuss your specific project requirements with multiple suppliers to compare MOQs and pricing, ensuring you find the best option that fits your budget and project size. -

What payment terms should I expect from soundproofing contractors?

Payment terms for soundproofing contractors can vary widely based on project size, scope, and the contractor’s policies. Typically, you may be asked to pay a deposit upfront (commonly 10-30% of the total project cost) with the remainder due upon completion. Some contractors may offer phased payment options based on project milestones. Always clarify payment terms in writing before starting the project, and ensure you understand any additional costs related to materials, labor, or potential changes in scope. -

How do I manage logistics for international soundproofing projects?

Managing logistics for international soundproofing projects involves careful planning and coordination. Start by identifying reliable suppliers and contractors with experience in international shipping and customs regulations. Consider using a freight forwarder to navigate shipping logistics, including documentation and potential tariffs. Establish clear timelines for delivery and installation, and ensure that all materials comply with local standards. Effective communication with all parties involved will help mitigate delays and ensure a smooth project execution. -

What quality assurance measures should be in place for soundproofing projects?

Quality assurance measures for soundproofing projects should include detailed project specifications, regular site inspections, and adherence to industry standards. Contractors should provide documentation of all materials used, including test reports for soundproofing effectiveness. Establishing clear communication channels allows for ongoing feedback and adjustments throughout the project. Post-installation evaluations, including sound testing, should be conducted to ensure the achieved results meet the expected performance criteria, providing peace of mind and satisfaction with the completed work.

Top 6 Soundproofing Contractors Manufacturers & Suppliers List

1. Performance Acoustics – Soundproofing Solutions

Domain: performance-acoustics.com

Registered: 2013 (12 years)

Introduction: Performance Acoustics LLC offers a variety of soundproofing products and services including: wall and ceiling insulation, door and window sealing, acoustic curtains and drapes, soundproofed rooms, and noise control for businesses. They also provide acoustical consulting services such as soundproofing analysis, noise control planning, and acoustical testing and measurement. The company emphasizes c…

2. Soundproofing Company – Green Glue 5 Gallon Pail

Domain: soundproofingcompany.com

Registered: 2007 (18 years)

Introduction: Green Glue 5 Gallon Pail, Speedload Dispenser, Serena Underlay, IB-1 Sound Isolation Clip, IB-3 Decoupling Bracket, Acoustical Putty Pads.

3. Quiet Batt – Soundproofing Insulation

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Quiet Batt 30 soundproofing insulation, size: 16in on center spacing (42sqft)

4. Insulation Specialists – QuietZone® Acoustic System

Domain: insulationsc.com

Registered: 2011 (14 years)

Introduction: Insulation Specialists offers the QuietZone ® Acoustic System for soundproofing. Key products include Owens Corning’s QuietZone ® Acoustic Batts, which absorb sound vibrations within wall cavities and are easy to install. Additionally, the QuietZone ® Acoustic Floor Mat is designed to isolate sound, placed between the subfloor and a plywood or gypsum concrete overlayment to form an isolation layer…

5. Soundproof Cow – Acoustic Panels & Soundproofing Solutions

Domain: soundproofcow.com

Registered: 2008 (17 years)

Introduction: Soundproof Cow offers a variety of soundproofing and acoustic solutions including:

1. Acoustic Panels: Art Acoustic Panels, Fabric Wrapped Acoustic Panels, Perforated Wood Art Panels, Ceiling Acoustic Panels, Wall-Mounted Acoustic Panels, Free-Standing Acoustic Panels.

2. Soundproofing Materials: Quiet Batt® Soundproofing Insulation, Soundproofing Barriers, Sound Isolation Systems, Dampening & De…

6. Snap-Wall – Customized Sound Control Solutions

Domain: snap-wall.com

Registered: 1998 (27 years)

Introduction: Snap-Wall provides customized sound control solutions for various spaces including commercial, healthcare, hospitality, industrial, institutional, and worship environments. Their products are designed to enhance acoustics while matching aesthetic requirements. They serve a range of sectors such as offices, fitness centers, restaurants, hotels, schools, and religious institutions. Snap-Wall has bee…

Strategic Sourcing Conclusion and Outlook for soundproofing contractors

In the ever-evolving landscape of soundproofing, strategic sourcing is essential for international B2B buyers looking to optimize their investments in acoustic solutions. By carefully selecting soundproofing contractors who not only understand the complexities of acoustical science but also demonstrate a proven track record of successful implementations, businesses can significantly enhance their environments—be it residential, commercial, or industrial.

Illustrative image related to soundproofing contractors

Key takeaways include the importance of thorough consultations, tailored solutions, and compliance with local regulations to ensure that your soundproofing investments yield tangible benefits. Furthermore, engaging contractors who provide transparent pricing, detailed product information, and a variety of options can help streamline the decision-making process and align with your budgetary constraints.

As you navigate the diverse soundproofing market, consider the unique challenges and opportunities within your region, whether in Africa, South America, the Middle East, or Europe. The demand for effective sound management solutions is on the rise, making this an opportune moment to partner with industry experts. Leverage this potential by reaching out to soundproofing contractors who can transform your spaces into harmonious environments conducive to productivity and comfort. Your next step in strategic sourcing could redefine your acoustic experience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to soundproofing contractors

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.