Everything You Need to Know About Acid Etched Bronze Sourcing in 2025

Introduction: Navigating the Global Market for acid etched bronze

Navigating the intricacies of sourcing acid etched bronze can be a significant challenge for B2B buyers in today’s competitive global market. With diverse applications ranging from architectural design to decorative elements, the demand for high-quality acid etched bronze is on the rise across regions, including Africa, South America, the Middle East, and Europe. This guide is designed to provide comprehensive insights into the various types of acid etched bronze products available, their specific applications, and the key factors to consider when selecting a supplier.

In this resource, international buyers will explore essential topics such as the different finishes and thicknesses of acid etched bronze, the process of vetting suppliers for quality assurance, and strategies to optimize cost without compromising on quality. Additionally, we will delve into the market trends and innovations that are shaping the future of acid etched bronze, ensuring that your purchasing decisions are informed and strategic.

By leveraging the knowledge contained within this guide, B2B buyers can confidently navigate the complexities of sourcing acid etched bronze, ensuring that they secure the right products for their projects while enhancing their competitive edge in the global marketplace.

Understanding acid etched bronze Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bronze Acid-Etched Glass | Dark, rich substrate; available in multiple finishes | Interior partitions, doors, wall panels | Pros: Aesthetic appeal, easy maintenance. Cons: Minimum order requirements. |

| Pearl™ Bronze Satin Etched Glass | Smooth, translucent finish; high light transmission | Commercial and residential applications | Pros: Privacy with light diffusion. Cons: Limited thickness options. |

| Two-Sided Etched Bronze Glass | Etching on both sides for enhanced visual effects | Furniture inserts, shower enclosures | Pros: Versatile design options. Cons: Higher fabrication costs. |

| Decorative Etched Bronze Patterns | Custom patterns for unique designs | Architectural features, art installations | Pros: Customization potential. Cons: Longer lead times. |

| Low Iron Bronze Satin Etched Glass | Enhanced clarity and reduced green tint | High-end residential and commercial projects | Pros: Superior optical quality. Cons: Higher price point. |

What are the Characteristics of Bronze Acid-Etched Glass?

Bronze Acid-Etched Glass is characterized by its dark, rich substrate that offers a sophisticated aesthetic. Available in various finishes, including satin, velour, and opaque, it is suitable for both interior and exterior applications. This type of glass is easy to clean and maintain, making it an ideal choice for high-traffic areas. Buyers should consider the minimum order requirements when purchasing, as this may affect project budgets and timelines.

How Does Pearl™ Bronze Satin Etched Glass Stand Out?

Pearl™ Bronze Satin Etched Glass features a smooth, pearl-like finish that provides privacy while allowing a high level of visible light transmission. This product is particularly beneficial for applications where light diffusion is necessary, such as in office partitions and decorative doors. B2B buyers should note its versatility in design applications, though the limited thickness options may restrict certain architectural uses.

Why Choose Two-Sided Etched Bronze Glass?

Two-Sided Etched Bronze Glass offers etching on both sides, enhancing visual effects and depth. This feature is particularly advantageous for applications like furniture inserts and shower enclosures, where both sides are visible. While this type allows for creative design solutions, buyers should be aware of potentially higher fabrication costs associated with two-sided etching.

What Are the Benefits of Decorative Etched Bronze Patterns?

Decorative Etched Bronze Patterns provide custom designs that enhance architectural features and art installations. These patterns can introduce unique textures and dimensions, making them an appealing choice for high-end projects. However, buyers should consider the longer lead times associated with custom orders, which may impact project schedules.

How Does Low Iron Bronze Satin Etched Glass Compare?

Low Iron Bronze Satin Etched Glass is designed to provide enhanced clarity and a reduced green tint, making it ideal for high-end residential and commercial applications. Its superior optical quality contributes to a more refined aesthetic, although the higher price point may be a consideration for budget-conscious buyers. This type is particularly suited for projects that demand both elegance and functionality.

Key Industrial Applications of acid etched bronze

| Industry/Sector | Specific Application of acid etched bronze | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Architectural Design | Interior partitions and doors | Enhances aesthetic appeal while providing privacy | Ensure availability of custom sizes and finishes |

| Furniture Manufacturing | Decorative glass inserts for cabinetry | Adds sophistication and durability to furniture pieces | Consider lead times for custom fabrication and delivery |

| Hospitality | Shower enclosures and restroom partitions | Combines elegance with functionality in high-traffic areas | Verify scratch resistance and ease of maintenance |

| Retail Displays | Display cases and signage | Attracts customers with a high-end look | Look for suppliers who offer tailored solutions |

| Construction | Wall cladding and exterior facades | Provides weather resistance and enhances building longevity | Check for certifications related to durability and safety |

How is Acid Etched Bronze Used in Architectural Design?

In architectural design, acid etched bronze is commonly utilized for interior partitions and doors. Its unique finish not only enhances the aesthetic appeal of spaces but also provides necessary privacy without sacrificing light. For international buyers, especially from regions like Africa and the Middle East, it’s essential to consider the availability of custom sizes and finishes that align with local architectural styles. The durability and scratch-resistant nature of the material are critical in high-use environments.

What Role Does Acid Etched Bronze Play in Furniture Manufacturing?

In the furniture manufacturing sector, acid etched bronze serves as a decorative glass insert for cabinetry, tables, and other furniture pieces. This application adds a touch of sophistication while ensuring longevity and ease of maintenance. Buyers should prioritize suppliers who can provide custom fabrication options to meet specific design requirements. Additionally, understanding local market preferences for finishes and textures is vital for successful sourcing in diverse regions such as South America and Europe.

How is Acid Etched Bronze Beneficial for Hospitality Settings?

In hospitality, acid etched bronze is ideal for shower enclosures and restroom partitions, where both elegance and functionality are paramount. This material provides a luxurious appearance while being resistant to wear and easy to clean, making it suitable for high-traffic areas. B2B buyers in this sector should verify the scratch resistance and maintenance requirements to ensure that the product meets the demands of busy environments. Compliance with local building codes and standards is also a significant consideration.

How Can Retail Displays Utilize Acid Etched Bronze?

Retail displays benefit from acid etched bronze through the creation of eye-catching display cases and signage. The material’s rich tones and smooth finish can attract customers, enhancing the overall shopping experience. For businesses in regions like Europe and the Middle East, sourcing from suppliers who offer tailored solutions can be advantageous. Buyers should also consider the design flexibility and lead times for custom orders to align with marketing strategies.

Why is Acid Etched Bronze Important in Construction?

In the construction industry, acid etched bronze is frequently used for wall cladding and exterior facades. Its weather-resistant properties and ability to withstand environmental stressors make it an excellent choice for enhancing building longevity. Buyers should check for certifications related to durability and safety to ensure compliance with local regulations. Additionally, understanding the specific needs of projects in different regions, such as Vietnam or Saudi Arabia, can help in making informed sourcing decisions.

3 Common User Pain Points for ‘acid etched bronze’ & Their Solutions

Scenario 1: Ensuring Consistent Quality in Acid Etched Bronze Products

The Problem: For B2B buyers, sourcing acid etched bronze can often lead to inconsistencies in product quality. Variability in the etching process can result in differences in finish texture, depth, and color that do not meet project specifications. This is particularly challenging when the product is intended for high-profile projects such as commercial buildings or luxury interiors, where aesthetic consistency is paramount. Discrepancies can lead to increased costs due to rework or product returns, ultimately affecting project timelines and client satisfaction.

The Solution: To mitigate quality inconsistencies, buyers should prioritize sourcing from reputable suppliers with a proven track record in acid etching processes. It’s essential to request samples of the etched bronze to evaluate the finish and ensure it aligns with your project requirements. Establish clear communication regarding your specifications, such as etching depth and finish type. Additionally, consider suppliers who offer customization options and have stringent quality control measures in place. Engaging in regular quality audits and establishing a partnership with your supplier can lead to better long-term results and consistency across orders.

Scenario 2: Navigating Minimum Order Requirements and Fabrication Options

The Problem: Many manufacturers of acid etched bronze impose minimum order quantities, which can be a significant barrier for smaller projects or businesses. This can lead to excess inventory and wasted resources if the product is not utilized. Furthermore, understanding the various fabrication options available—such as thickness, size, and dual-sided etching—can complicate the procurement process, especially when buyers are not familiar with the technical aspects of acid etched bronze.

The Solution: Buyers should engage directly with suppliers to negotiate minimum order quantities that align with their specific needs. Inquire about flexibility in orders and whether smaller batches can be produced without significant price hikes. When discussing fabrication options, request comprehensive product catalogs that detail the available sizes and thicknesses, along with their applications. It may also be beneficial to work with a supplier that offers a full-service approach, including design consultation, to better understand how to leverage acid etched bronze in various applications. This proactive approach can help streamline the ordering process and reduce waste.

Scenario 3: Addressing Maintenance and Longevity Concerns of Acid Etched Bronze

The Problem: Buyers often worry about the long-term durability and maintenance of acid etched bronze products. Concerns about surface degradation, fading, and the ease of cleaning can impact purchasing decisions, particularly in regions with harsh environmental conditions. If buyers feel that maintenance will be too burdensome or that the product will not withstand the test of time, they may opt for alternative materials, ultimately affecting their project’s design and functionality.

The Solution: To alleviate these concerns, buyers should look for suppliers that provide warranties and detailed care instructions for acid etched bronze products. A ten-year limited warranty against surface degradation, for example, can instill confidence in the product’s longevity. Furthermore, understanding the cleaning process—such as using non-abrasive cleaners and soft cloths—can help maintain the aesthetic appeal of the bronze without damaging the etched surface. Buyers should also consider the environmental conditions of the installation site and discuss with suppliers how specific finishes may perform in those settings. By selecting high-quality products and adhering to recommended maintenance practices, buyers can ensure that their acid etched bronze features remain beautiful and functional for years to come.

Strategic Material Selection Guide for acid etched bronze

What Are the Key Properties of Common Materials for Acid Etched Bronze?

When selecting materials for acid etched bronze, it is essential to consider their properties, advantages, disadvantages, and how they align with specific application needs. Here, we analyze four common materials used in conjunction with acid etched bronze: standard bronze, low-iron glass, tempered glass, and laminated glass.

How Does Standard Bronze Perform in Acid Etching Applications?

Key Properties: Standard bronze is known for its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for various applications.

Pros & Cons: The primary advantage of standard bronze is its aesthetic appeal, which provides a rich, warm tone that enhances the visual quality of acid-etched products. However, it can be more expensive than other metals, and the etching process may require careful handling to prevent unwanted surface degradation.

Impact on Application: Standard bronze is compatible with various media, including water and air, but it may not be suitable for aggressive chemical environments.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is crucial. Buyers from regions like Africa and the Middle East should ensure that their suppliers can provide documentation regarding corrosion resistance and mechanical properties.

What Are the Advantages of Low-Iron Glass in Acid Etched Bronze?

Key Properties: Low-iron glass has a higher clarity and lower green tint compared to standard glass, making it ideal for applications where light transmission is critical.

Pros & Cons: Its primary advantage lies in its transparency and aesthetic quality, which enhances the visual appeal of acid-etched surfaces. However, low-iron glass can be more expensive and may require specialized handling during fabrication.

Impact on Application: Low-iron glass is highly compatible with various environmental conditions and is particularly effective in applications requiring high light transmission, such as interior partitions and decorative features.

Considerations for International Buyers: Buyers should be aware of the specific glass standards in their region, such as JIS in Japan or EN in Europe, to ensure compliance and quality.

Why Choose Tempered Glass for Acid Etched Bronze Applications?

Key Properties: Tempered glass is heat-treated to increase its strength and thermal resistance, making it ideal for high-stress environments.

Pros & Cons: The significant advantage of tempered glass is its safety; it shatters into small, blunt pieces rather than sharp shards. However, it can be more expensive to produce and may require more complex fabrication processes.

Impact on Application: Tempered glass is suitable for applications such as shower enclosures and glass doors, where safety and durability are paramount.

Considerations for International Buyers: It is essential to verify that tempered glass meets local safety standards, such as those outlined by the International Organization for Standardization (ISO).

What Benefits Does Laminated Glass Offer for Acid Etched Bronze?

Key Properties: Laminated glass consists of two or more layers of glass bonded with an interlayer, providing enhanced safety and sound insulation.

Pros & Cons: The key advantage of laminated glass is its ability to hold together when shattered, making it a safer option for various applications. However, it can be heavier and more expensive than standard glass options.

Impact on Application: Laminated glass is ideal for applications requiring additional safety measures, such as in commercial buildings or areas prone to impact.

Considerations for International Buyers: Buyers should ensure that laminated glass complies with relevant safety standards in their region, particularly in high-traffic areas.

Summary Table of Material Selection for Acid Etched Bronze

| Material | Typical Use Case for Acid Etched Bronze | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard Bronze | Decorative architectural elements | Aesthetic appeal and durability | Higher cost and handling complexity | High |

| Low-Iron Glass | Interior partitions and decorative features | High clarity and light transmission | More expensive and specialized handling | Medium |

| Tempered Glass | Shower enclosures and glass doors | Safety and thermal resistance | Higher production cost and complexity | High |

| Laminated Glass | Commercial buildings and impact areas | Enhanced safety and sound insulation | Heavier and more expensive | Medium |

This guide provides a strategic overview for B2B buyers considering acid etched bronze applications. By understanding the properties and implications of each material, buyers can make informed decisions that align with their specific needs and compliance requirements.

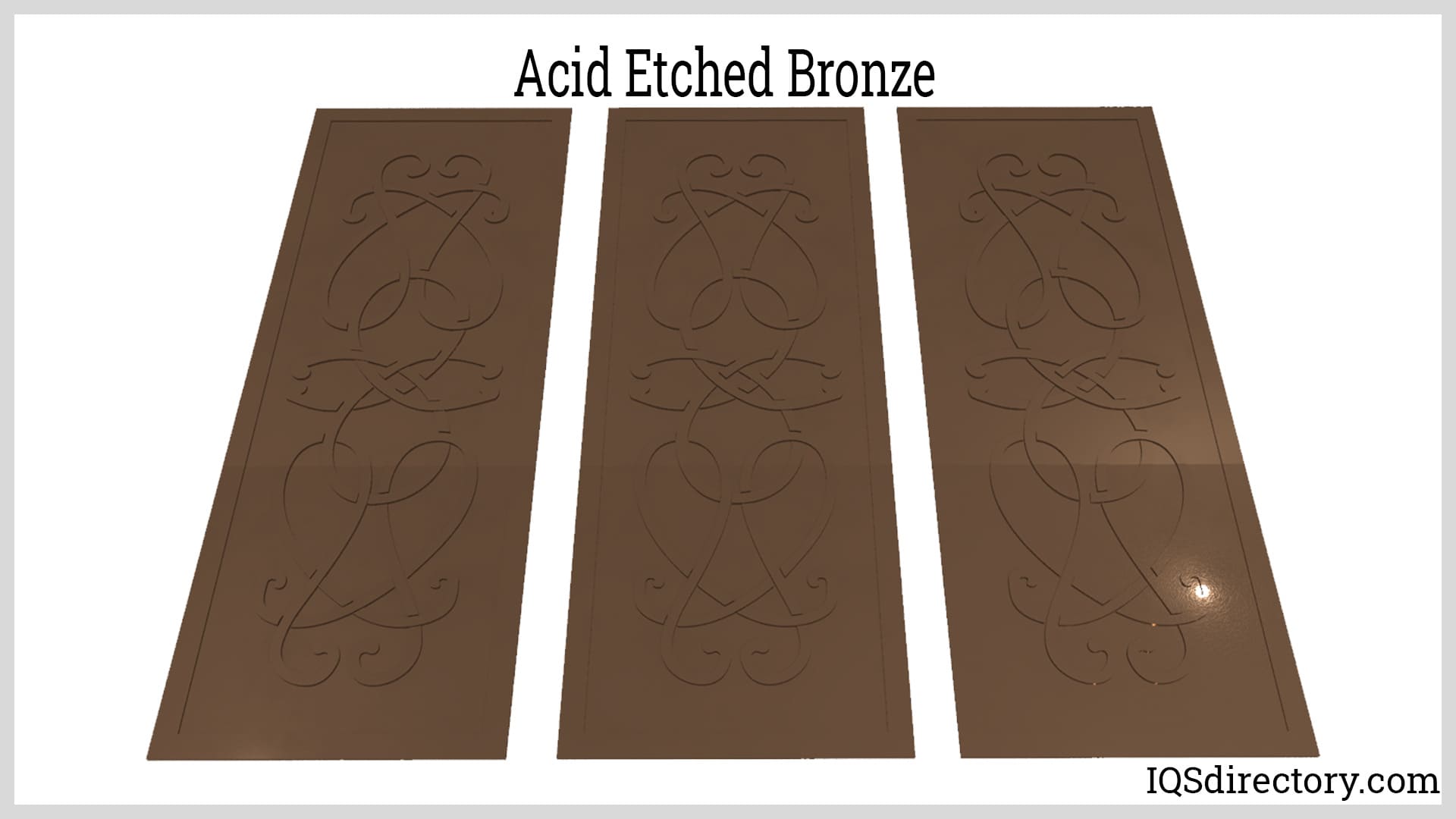

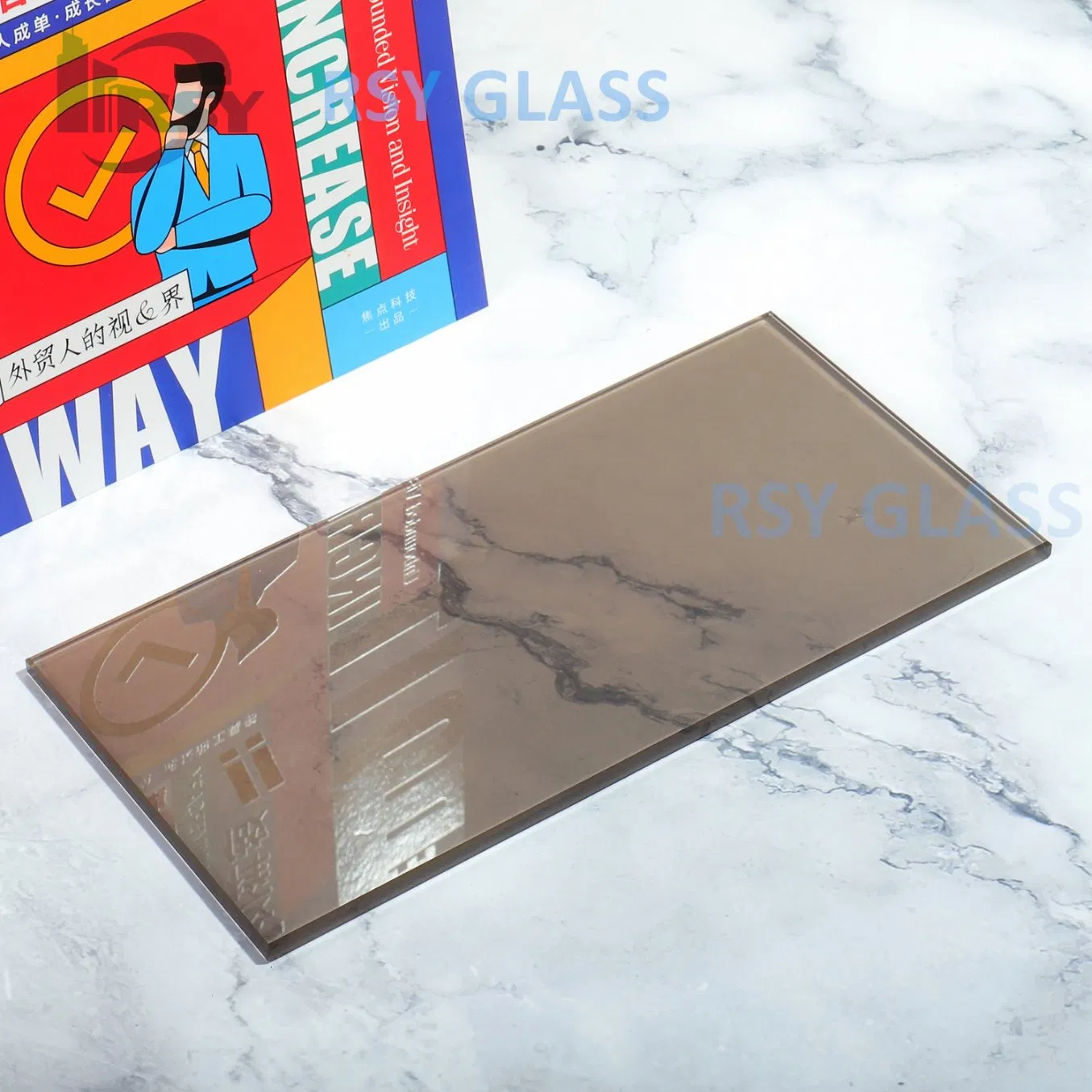

Illustrative image related to acid etched bronze

In-depth Look: Manufacturing Processes and Quality Assurance for acid etched bronze

What are the Key Stages in the Manufacturing Process of Acid Etched Bronze?

The manufacturing process of acid etched bronze involves several critical stages that ensure the final product meets both aesthetic and functional requirements. Understanding these stages can help B2B buyers gauge the quality and reliability of their suppliers.

Material Preparation: What Comes First in Acid Etched Bronze Production?

The first step in manufacturing acid etched bronze is material preparation. This involves sourcing high-quality bronze glass substrates, which can be tinted or clear, depending on the desired finish. Suppliers often utilize a controlled acid-etching process to create a uniform surface that enhances both light diffusion and aesthetic appeal. The bronze substrate is thoroughly cleaned to remove any contaminants, ensuring that the etching process adheres effectively to the surface.

Forming: How is Acid Etched Bronze Shaped?

Once the materials are prepared, the next stage is forming. The bronze glass is cut to specified dimensions and thicknesses—commonly ranging from 3mm to 12mm—using precision cutting tools. This step may also involve laminating or tempering the glass, depending on the intended application, such as interior partitions or exterior cladding. Forming is crucial as it dictates the final dimensions and shapes that will be available for further processing.

Assembly: What Techniques are Used for Joining Components?

After forming, the acid etched bronze components may require assembly. This could involve the integration of additional elements such as frames or fixtures. Techniques such as adhesive bonding or mechanical fastening are commonly employed to ensure a secure connection. It is essential that assembly methods are compatible with the aesthetic and structural properties of the etched bronze.

Finishing: How is the Final Product Prepared for Market?

The finishing stage is where the acid etched bronze truly comes to life. This includes applying the desired etched patterns, whether decorative or functional. Techniques like satin, velour, or opaque finishes are applied to enhance the product’s visual appeal while also providing a level of privacy and light diffusion. Finally, the product undergoes cleaning and polishing to ensure it is free of any residues and ready for shipping.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a critical component in the manufacturing process of acid etched bronze. Buyers should be aware of various international and industry-specific standards that ensure product integrity and performance.

Which International Standards are Most Relevant?

ISO 9001 is one of the most recognized quality management standards globally. It outlines requirements for a quality management system and emphasizes continuous improvement, which is vital for manufacturers of acid etched bronze. Suppliers who are ISO 9001 certified demonstrate their commitment to maintaining high-quality processes and products.

Other relevant standards may include CE marking, which indicates compliance with European safety standards, and API standards for specific applications in the oil and gas industry. B2B buyers should inquire about these certifications to ensure their suppliers adhere to necessary regulations.

What are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is essential in ensuring the final product meets both industry standards and customer expectations. Key checkpoints in the manufacturing process include:

Incoming Quality Control (IQC)

Before production begins, materials undergo IQC to verify their quality. This involves inspecting incoming bronze glass substrates for defects, thickness consistency, and compliance with specifications. Reliable suppliers will maintain detailed records of these inspections.

In-Process Quality Control (IPQC)

During manufacturing, IPQC checks are conducted at various stages to monitor the etching process, ensure precise dimensions, and verify the quality of finishes. This real-time quality assessment allows for immediate corrections, reducing waste and improving efficiency.

Final Quality Control (FQC)

Once the product is completed, FQC involves a comprehensive review of the finished acid etched bronze. This includes visual inspections for aesthetic quality, tests for durability and performance, and adherence to specified dimensions. It is crucial that FQC processes are thorough, as this is the final opportunity to catch any defects before the product reaches the customer.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For B2B buyers, verifying a supplier’s quality assurance practices is essential for ensuring product reliability. Here are several strategies:

Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards. Buyers should request audit reports and consider third-party assessments to gain an unbiased view of a supplier’s capabilities.

Request Quality Control Documentation

Buyers should ask for documentation that outlines the supplier’s quality control processes, including IQC, IPQC, and FQC records. This transparency helps in understanding how the supplier maintains product quality throughout the manufacturing process.

Engage in Third-Party Inspections

Utilizing third-party inspection services can further validate a supplier’s claims regarding quality assurance. These inspections can assess compliance with international standards and provide an additional layer of confidence in the supplier’s capabilities.

What are the Specific Quality Control Nuances for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances related to quality control. This includes understanding local regulations and standards that may differ from international norms. Buyers should also consider logistical aspects, such as shipping regulations and customs checks, which can impact product quality upon arrival.

Furthermore, cultural differences in communication and business practices may affect how quality assurance issues are addressed. Establishing clear lines of communication and understanding the local market dynamics can lead to more successful partnerships.

Illustrative image related to acid etched bronze

Conclusion: Ensuring Quality in Acid Etched Bronze Manufacturing

In summary, the manufacturing process of acid etched bronze involves meticulous stages from material preparation to finishing, each supported by robust quality assurance practices. For B2B buyers, understanding these processes and implementing thorough verification methods can significantly enhance the likelihood of sourcing high-quality products that meet their specifications and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘acid etched bronze’

To successfully procure acid-etched bronze, a systematic approach is essential. This guide provides a step-by-step checklist designed for B2B buyers, particularly those operating in diverse international markets, to navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your acid-etched bronze products. This includes the desired thickness, dimensions, and finish types, such as satin or opaque. Knowing these specifications upfront helps to streamline communication with suppliers and ensures that the products meet your project’s needs.

- Thickness Options: Common thicknesses range from 3mm to 12mm.

- Dimension Considerations: Standard dimensions, such as 96” x 130”, should be noted, but custom sizes may also be available.

Step 2: Identify Suitable Suppliers

Research potential suppliers who specialize in acid-etched bronze products. Look for manufacturers with a solid reputation and proven track records in your target regions, such as Africa, South America, the Middle East, and Europe.

- Online Research: Utilize B2B marketplaces and industry directories to compile a list of potential suppliers.

- Local Recommendations: Seek recommendations from industry peers or local trade associations.

Step 3: Verify Supplier Certifications

Before proceeding with any supplier, it’s crucial to confirm their certifications and compliance with international standards. This step ensures that the products meet quality and safety regulations, reducing the risk of subpar materials.

- Quality Assurance: Check for ISO certifications or similar quality management standards.

- Sustainability Credentials: Look for Environmental Product Declarations (EPD) that indicate eco-friendly practices.

Step 4: Request Product Samples

Once you have shortlisted potential suppliers, request samples of the acid-etched bronze to evaluate their quality and finish. This is a vital step to ensure that the product meets your expectations in terms of aesthetics and functionality.

- Assess Finish Quality: Look for consistency in etching and color depth.

- Test Durability: Evaluate the scratch resistance and ease of cleaning.

Step 5: Compare Pricing and Minimum Order Quantities

Gather detailed quotes from your selected suppliers and compare pricing structures. Pay attention to minimum order quantities, as these can vary significantly between suppliers and impact your overall budget.

- Bulk Discounts: Inquire about volume pricing if you plan to order large quantities.

- Shipping Costs: Factor in logistics and shipping fees, especially for international orders.

Step 6: Evaluate Supplier Communication and Support

Effective communication is key to a successful partnership. Assess how responsive and helpful potential suppliers are during your initial interactions. This can indicate their level of customer service and support once you become a client.

Illustrative image related to acid etched bronze

- Response Time: Note how quickly suppliers respond to inquiries and how thoroughly they address your questions.

- Post-Purchase Support: Confirm what kind of after-sales support and warranty options they offer.

Step 7: Finalize Agreements and Place Orders

After selecting the most suitable supplier, review and finalize the purchase agreement. Ensure all terms, including delivery timelines and payment conditions, are clearly documented to avoid misunderstandings.

- Contract Clarity: Include specifics regarding product specifications, delivery schedules, and warranty terms.

- Payment Terms: Discuss flexible payment options, particularly for large orders.

By following this checklist, B2B buyers can navigate the complexities of sourcing acid-etched bronze effectively, ensuring that they secure high-quality products that meet their project needs.

Comprehensive Cost and Pricing Analysis for acid etched bronze Sourcing

What Are the Key Cost Components for Sourcing Acid Etched Bronze?

When sourcing acid etched bronze, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The raw materials for acid etched bronze include the bronze substrate and the chemicals used for the etching process. Prices for bronze can vary based on market conditions, but it typically represents a significant portion of the total cost. Additionally, specialized etching chemicals may contribute to overall material costs.

-

Labor: Labor costs encompass the wages of skilled workers involved in the etching process, including machine operators and quality inspectors. Skilled labor is essential for ensuring precision in the etching process, which can affect the final product’s quality and durability.

-

Manufacturing Overhead: This includes costs associated with the operation of manufacturing facilities, such as utilities, rent, and equipment maintenance. These fixed costs can be distributed across production volume, making them a critical factor in pricing.

-

Tooling: The initial investment in tooling for acid etching can be substantial, particularly for custom designs. Tooling costs may be amortized over larger production runs, making it essential to consider order volumes when negotiating prices.

-

Quality Control: Ensuring product quality through rigorous QC processes adds to the overall cost. This includes testing for surface integrity, finish consistency, and compliance with any relevant certifications, which may be particularly important for international buyers seeking quality assurance.

-

Logistics: Shipping and handling costs can vary widely, especially for international transactions. Factors such as distance, shipping method, and customs duties need to be accounted for in the total cost.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can fluctuate based on competition, market demand, and the supplier’s positioning within the market.

What Influences the Pricing of Acid Etched Bronze?

Several factors influence the pricing structure for acid etched bronze products:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower unit prices due to economies of scale. Suppliers may set MOQs that buyers must meet to receive bulk pricing, making it essential to plan orders effectively.

-

Specifications and Customization: Custom designs or specifications can lead to increased costs. Standard products usually have lower prices, while unique or intricate designs may incur additional tooling and labor expenses.

-

Material Quality and Certifications: The quality of the bronze used and any certifications required for specific applications (e.g., safety or environmental standards) can impact pricing. Products that meet higher standards typically command a premium.

-

Supplier Factors: The reputation and reliability of suppliers play a role in pricing. Established suppliers may charge more due to their track record, while newer entrants may offer competitive pricing to gain market share.

-

Incoterms: The shipping terms agreed upon in the contract can significantly affect the final price. Different Incoterms (e.g., FOB, CIF) dictate who bears shipping costs and risks, impacting overall pricing and cost management.

How Can Buyers Negotiate for Better Pricing on Acid Etched Bronze?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, effective negotiation strategies can yield significant savings:

-

Understand Total Cost of Ownership: Beyond the initial purchase price, consider the total cost of ownership, including maintenance, logistics, and potential rework costs due to quality issues. This broader perspective can inform more strategic purchasing decisions.

-

Leverage Volume Discounts: If possible, consolidate orders to meet or exceed MOQs for better pricing. Establishing long-term relationships with suppliers can also lead to favorable pricing agreements.

-

Research Market Conditions: Stay informed about market trends and material costs to negotiate more effectively. Understanding the market landscape can empower buyers to request competitive pricing based on current conditions.

-

Explore Multiple Suppliers: Engaging with multiple suppliers can foster competition and lead to better pricing options. Requesting quotes from various sources can provide leverage during negotiations.

-

Customization Considerations: If customization is necessary, negotiate on aspects that may allow for cost savings, such as simplified designs or alternative materials that meet performance requirements without the premium pricing.

Disclaimer on Pricing

Pricing for acid etched bronze can fluctuate due to various factors, including market demand, raw material costs, and supplier conditions. Therefore, it is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing and secure the best deal.

Alternatives Analysis: Comparing acid etched bronze With Other Solutions

Exploring Alternative Solutions to Acid Etched Bronze

In the realm of architectural and design materials, acid etched bronze offers unique aesthetic and functional benefits. However, several alternatives exist that can achieve similar results with varying characteristics. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and specific application requirements.

Comparison Table

| Comparison Aspect | Acid Etched Bronze | Pearl™ Bronze Satin Etched Glass | Low-Iron Satin Etched Glass |

|---|---|---|---|

| Performance | Scratch-resistant, depth in design | High light transmission, privacy | Excellent clarity, light diffusion |

| Cost | Generally higher due to material | Moderate, depends on customization | Competitive for high-end applications |

| Ease of Implementation | Requires specialized etching process | Available in standard sizes, easy to fabricate | Custom fabrication options available |

| Maintenance | Easy to clean, limited degradation | Fingerprint resistant, easy to maintain | Easy to clean, resistant to wear |

| Best Use Case | High-end architectural projects | Interior partitions, doors | Decorative applications, furniture |

Detailed Breakdown of Alternatives

What is Pearl™ Bronze Satin Etched Glass and Why Consider It?

Pearl™ Bronze Satin Etched Glass is a sophisticated alternative that combines aesthetic appeal with functionality. Its controlled acid-etching process ensures a uniform, smooth surface that provides privacy while allowing for significant light transmission. This glass option is ideal for applications such as interior partitions and doors where both elegance and utility are paramount. The main advantages include its durability and resistance to fingerprints, making it low-maintenance. However, the cost may be a consideration for projects with tighter budgets.

Illustrative image related to acid etched bronze

How Does Low-Iron Satin Etched Glass Compare?

Low-Iron Satin Etched Glass is another compelling alternative that offers exceptional clarity and a high degree of light diffusion. The reduced iron content enhances the transparency of the glass, making it suitable for high-end applications that demand visual clarity. This option is particularly favored in environments where natural light is a priority, such as in retail or hospitality settings. While it may be slightly more expensive than traditional glass, its premium quality justifies the investment for many B2B buyers. Maintenance is also straightforward, as it resists wear and is easy to clean.

Conclusion: Which Solution is Right for Your Needs?

Choosing the right solution between acid etched bronze and its alternatives largely depends on the specific requirements of your project. For high-end architectural applications, acid etched bronze may provide the desired aesthetic depth and durability. Conversely, if light transmission and privacy are critical, options like Pearl™ Bronze Satin Etched Glass or Low-Iron Satin Etched Glass may serve better. B2B buyers should weigh factors such as cost, ease of implementation, and maintenance requirements to select the most suitable glass solution for their unique applications.

Essential Technical Properties and Trade Terminology for acid etched bronze

What Are the Key Technical Properties of Acid Etched Bronze?

When considering acid etched bronze for your projects, understanding its technical properties is essential for making informed purchasing decisions. Here are some critical specifications:

-

Material Grade

Acid etched bronze typically consists of copper alloys that contain tin, aluminum, or nickel. The grade of bronze affects its durability and aesthetic appeal. For B2B buyers, selecting the right material grade ensures that the finished product meets the specific strength and corrosion resistance requirements of their applications. -

Thickness

The thickness of acid etched bronze ranges from 3mm to 12mm (1/8” to 1/2”). This specification is crucial for determining the material’s strength and suitability for various applications, such as architectural features or decorative elements. Thicker materials provide enhanced durability, making them ideal for high-traffic areas. -

Surface Finish

Acid etching creates a unique texture that enhances the aesthetic qualities of bronze. Common finishes include satin, velour, and opaque. The choice of finish can impact light diffusion, privacy, and overall design. Buyers should specify their preferred finish to achieve the desired visual effect in their projects. -

Dimensions

Standard dimensions for acid etched bronze sheets are typically around 96” x 130”. Custom sizes may be available but often come with minimum order requirements. Understanding dimensional specifications helps buyers plan their projects accurately and avoid material waste. -

Scratch Resistance

Acid etched bronze is generally scratch-resistant, which is a vital property for materials used in high-visibility or high-usage environments. This characteristic not only maintains the aesthetic quality over time but also reduces maintenance costs, making it appealing for B2B buyers focused on long-term value. -

Warranty

Many suppliers offer warranties on acid etched bronze products, often up to 10 years against surface degradation. This assurance is critical for B2B buyers, as it reflects the manufacturer’s confidence in the product’s longevity and can influence purchasing decisions.

What Are Common Trade Terms Related to Acid Etched Bronze?

Understanding industry-specific terminology can facilitate smoother transactions and better communication with suppliers. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, working with OEMs can ensure high-quality components tailored to specific project needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. Knowing the MOQ is crucial for budget planning and inventory management. Buyers should clarify MOQs to avoid unexpected costs or delays in their projects. -

RFQ (Request for Quotation)

An RFQ is a formal process through which buyers request pricing information from suppliers. This term is essential for B2B transactions, as it helps buyers compare offers and negotiate better terms. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers to understand shipping responsibilities, risk transfer, and cost allocations. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. For B2B buyers, understanding lead times helps in project planning and inventory management. Buyers should inquire about lead times to ensure timely completion of their projects. -

Custom Fabrication

This term describes the process of creating tailored products according to specific client requirements. For buyers seeking unique solutions, understanding custom fabrication options is essential to ensure that the final product meets their exact specifications.

By familiarizing yourself with these technical properties and trade terms, you can navigate the procurement process for acid etched bronze more effectively, ensuring that your projects meet both aesthetic and functional requirements.

Navigating Market Dynamics and Sourcing Trends in the acid etched bronze Sector

What Are the Current Market Dynamics and Key Trends in the Acid Etched Bronze Sector?

The acid etched bronze market is witnessing significant growth driven by the increasing demand for aesthetically pleasing architectural solutions and high-performance materials. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are prioritizing innovative design options that merge functionality with visual appeal. Key trends include the rise of customizable solutions, where buyers can specify finishes and dimensions to meet unique project requirements. Furthermore, the use of advanced acid-etching techniques enables manufacturers to produce intricate designs that enhance the product’s aesthetic value.

Emerging technologies are also shaping sourcing trends. For instance, the integration of digital fabrication methods allows for precise customization and faster turnaround times, appealing to a global market that values efficiency. Additionally, the growing e-commerce platforms enable buyers from diverse regions to access a wider array of suppliers and products, fostering competition and driving prices down.

Sourcing strategies are increasingly focused on long-term partnerships with suppliers who can guarantee consistent quality and reliability. This is particularly pertinent for international buyers who may face logistical challenges in different regions. Establishing strong relationships with manufacturers that understand local regulations and market nuances can provide a competitive edge in securing favorable terms and timely deliveries.

Illustrative image related to acid etched bronze

How Is Sustainability and Ethical Sourcing Influencing the Acid Etched Bronze Market?

Sustainability has become a pivotal concern in the acid etched bronze sector, influencing both production practices and buyer preferences. As global awareness of environmental issues rises, buyers are increasingly seeking suppliers that prioritize eco-friendly practices. The environmental impact of acid etching, particularly regarding chemical waste management and energy consumption, is under scrutiny. Suppliers who adopt sustainable manufacturing processes and use non-toxic etching solutions are gaining favor among conscientious buyers.

Ethical sourcing is equally critical, as businesses aim to ensure that their supply chains are transparent and responsible. Buyers are looking for suppliers who can provide certifications that demonstrate adherence to environmental standards, such as EPD (Environmental Product Declaration) and other green certifications. These credentials not only reflect a commitment to sustainability but also enhance the credibility of the products in competitive markets.

Moreover, the demand for recycled materials is on the rise, prompting suppliers to explore the use of recycled bronze in their products. This not only reduces the environmental footprint but also appeals to buyers who are committed to sustainable construction practices. By prioritizing sustainability and ethical sourcing, businesses can not only meet regulatory requirements but also resonate with the values of their customers, thereby enhancing brand loyalty.

What Is the Historical Context of Acid Etched Bronze in B2B Markets?

The practice of acid etching dates back centuries, initially utilized in printmaking and jewelry design. Over time, this technique evolved and found applications in various industries, including architecture and interior design. The introduction of bronze as a substrate for acid etching marked a significant advancement, combining the durability of metal with the aesthetic versatility of glass.

In B2B contexts, acid etched bronze has gained prominence as architects and designers seek unique materials that can provide both structural integrity and visual appeal. The evolution of acid etching technology has allowed for more complex designs and finishes, making it a sought-after choice for commercial and residential projects alike. As the market continues to grow, understanding the historical context can provide valuable insights into current trends and future developments in the acid etched bronze sector.

Frequently Asked Questions (FAQs) for B2B Buyers of acid etched bronze

-

How do I choose the right acid etched bronze supplier?

When selecting a supplier for acid etched bronze, consider their industry experience, product quality, and customer reviews. Verify their certifications, such as ISO or EPD, to ensure they meet international standards. Request samples to assess the finish and durability of their products. Additionally, engage with their customer service to gauge responsiveness and support, which is crucial for ongoing business relations, especially in international trade. -

What are the typical applications for acid etched bronze?

Acid etched bronze is versatile and commonly used in both interior and exterior applications. It is ideal for architectural elements like partitions, doors, and wall panels, where aesthetics and privacy are essential. Additionally, it can enhance furniture design and is often used in high-end residential and commercial projects due to its elegant finish and ability to diffuse light while maintaining privacy. -

What customization options are available for acid etched bronze?

Many suppliers offer customization options, including different thicknesses, sizes, and finishes. You can choose from various etched patterns or even request specific designs to align with your project requirements. Ensure to communicate your needs clearly and inquire about the minimum order quantities (MOQs) for custom products, as these can vary significantly between suppliers. -

What are the minimum order quantities (MOQs) for acid etched bronze products?

MOQs for acid etched bronze can vary by supplier and product type. Typically, suppliers may require a minimum order of several sheets or specific quantities for custom designs. It’s important to clarify this during your initial discussions and factor it into your project planning, especially if you are working within a budget or timeline constraints. -

How do I ensure quality assurance when sourcing acid etched bronze?

To ensure quality, request documentation such as product specifications, testing results, and warranty information. Establish clear quality standards upfront, including surface finishes and durability expectations. Regular communication with your supplier during production can help address any concerns early. Consider visiting the manufacturing facility or asking for third-party inspection services, especially for large orders. -

What payment terms should I expect when buying acid etched bronze internationally?

Payment terms can vary widely based on the supplier and the nature of the transaction. Common terms include advance payment, letter of credit, or payment on delivery. It’s vital to discuss and agree on payment methods that provide both parties with security. Be aware of any additional costs related to currency exchange or international banking fees, which could impact your total expenditure. -

What logistical considerations should I keep in mind when importing acid etched bronze?

Logistics involve several factors, including shipping methods, customs clearance, and delivery timelines. Ensure that your supplier has experience with international shipping and can provide necessary documentation for customs. Discuss shipping costs upfront and consider using a freight forwarder to manage logistics efficiently. Factor in potential delays and ensure that your order aligns with your project schedule. -

How can I effectively communicate my design requirements for acid etched bronze?

Effective communication begins with a clear and detailed design brief. Provide visual references, sketches, or CAD drawings to convey your vision accurately. Specify dimensions, finishes, and any unique requirements. Regular updates and feedback during the design process can help align expectations. Utilize professional terminology and be open to suggestions from your supplier, as their expertise can enhance your design outcomes.

Top 3 Acid Etched Bronze Manufacturers & Suppliers List

1. Walker Glass – Bronze Acid-etched Glass

Domain: walkerglass.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “Bronze Acid-etched Glass”, “Manufacturer”: “Walker Glass”, “Thicknesses”: “3mm to 12mm (1/8’’ to 1/2’’)”, “Dimensions”: “Standard 96’’ x 130’’”, “Substrates”: “Bronze”, “Etching Finishes”: [“Satin”, “Velour”, “Opaque”], “Common Finish”: “Satin”, “Surface”: “Etching on both sides available”, “Applications”: [“Interior”, “Exterior”], “Warranty”: “10 year limited warranty on surface…

2. Fotofab – Bronze Etching Services

Domain: fotofab.com

Registered: 1996 (29 years)

Introduction: Bronze Etching Chemical Services: Acid etched bronze services for robust, metal-on-metal contact parts. Bronze is a ductile alloy primarily composed of Copper and Tin, with potential additions of Aluminum, Manganese, Nickel, Zinc, Arsenic, Phosphorous, and Silicon. Benefits include precise and accurate etching for complex designs, consistency across parts, efficiency with minimal material waste, a…

3. Bendheim – SatinTech™ Etched Architectural Glass

Domain: bendheim.com

Registered: 1997 (28 years)

Introduction: SatinTech™ Etched Architectural Glass in “Bronze Beige” Color; Light-brown-colored etched glass; Pristine, satin-smooth, acid-etched surface; Diffuses light, reduces glare, and minimizes reflections; Maintenance-friendly: resists fingerprints and staining.

Strategic Sourcing Conclusion and Outlook for acid etched bronze

In the evolving landscape of architectural and design materials, acid etched bronze stands out for its unique combination of aesthetic appeal and functional versatility. By strategically sourcing high-quality acid etched bronze, international B2B buyers can enhance their projects with products that offer both elegance and durability. The acid etching process not only provides a sophisticated finish but also ensures ease of maintenance, making it a preferred choice for various applications, from interior partitions to exterior facades.

For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the specific requirements and preferences of local markets is essential. Sourcing from reputable manufacturers ensures compliance with quality standards and enhances the longevity of the product, ultimately leading to greater customer satisfaction.

Looking ahead, the demand for acid etched bronze is poised to grow as architectural trends shift towards more sustainable and visually striking materials. We encourage international buyers to explore partnerships with leading suppliers who can provide tailored solutions that meet both aesthetic and functional needs. Embrace the potential of acid etched bronze to elevate your projects and stay ahead in the competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.