A B2B Buyer’s Guide to Eyelets Boots: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for eyelets boots

In today’s competitive landscape, sourcing high-quality eyelets boots poses a significant challenge for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With a myriad of options available—from rugged steel-toe combat boots to stylish punk designs—making informed purchasing decisions becomes crucial for businesses aiming to meet their customers’ needs while optimizing costs. This guide serves as a comprehensive resource, covering everything from the various types of eyelets boots and their specific applications to essential supplier vetting practices and cost considerations.

Understanding the nuances of the eyelets boots market is vital for buyers looking to establish long-term supplier relationships and ensure product quality. With insights into the latest trends, material specifications, and regional preferences, this guide empowers you to navigate the complexities of the global market effectively. Whether you are in Brazil seeking durable footwear for urban adventurers or in Nigeria looking for stylish options that resonate with local fashion, you will find actionable insights tailored to your unique business context. By leveraging the information presented here, B2B buyers can streamline their sourcing processes, enhance their product offerings, and ultimately drive customer satisfaction.

Understanding eyelets boots Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Combat Boots | Steel toe protection, rugged design, typically 10 eyelets | Military, security, outdoor work | Pros: High durability, versatile use; Cons: Heavier, may require breaking in. |

| Punk Boots | Unique styles (flames, graffiti), often made with vibrant materials | Fashion retail, music festivals | Pros: Eye-catching designs, appeals to niche markets; Cons: Limited practicality for everyday use. |

| Work Boots | Enhanced comfort features, slip-resistant soles, reinforced stitching | Construction, manufacturing, heavy-duty labor | Pros: Safety features, long-lasting; Cons: Can be bulky, may not suit all environments. |

| Fashion Boots | Trendy designs, often made from leather or synthetic materials | Retail fashion, urban lifestyle | Pros: Stylish, lightweight; Cons: May lack durability for heavy use. |

| Hiking Boots | Waterproof materials, rugged soles, ankle support | Outdoor recreation, adventure tourism | Pros: Excellent grip, designed for terrain; Cons: Heavier than casual boots, specialized use. |

What Are the Key Characteristics of Combat Boots?

Combat boots are known for their robust construction and protective features, particularly the inclusion of steel toe caps. Designed for rugged environments, they often feature 10 eyelets for enhanced ankle support and stability. These boots are ideal for military, security, and outdoor work applications. When considering a B2B purchase, buyers should focus on the durability of materials and comfort for extended wear, as these factors significantly influence user satisfaction and safety.

How Do Punk Boots Stand Out in the Market?

Punk boots are characterized by their bold designs, including motifs like flames or graffiti. These boots cater to a niche market, appealing to fashion-forward consumers at music festivals and trendy retail outlets. While they offer unique aesthetic value, B2B buyers must consider the practicality of these designs. The primary purchasing consideration should be the balance between style and comfort, as these boots may not be suitable for everyday wear in more conventional settings.

What Are the Features of Work Boots for Heavy-Duty Applications?

Work boots are engineered for safety and comfort, often featuring slip-resistant soles and reinforced stitching. They are essential for industries such as construction and manufacturing, where foot protection is paramount. Buyers should prioritize boots that meet safety standards while also offering comfort for long hours on the job. The trade-off can be bulkiness, which may deter some users, so it’s vital to assess the specific work environment and user needs when purchasing.

Why Are Fashion Boots Important for Retail Buyers?

Fashion boots are designed to be trendy and stylish, often made from leather or synthetic materials. They are popular among urban lifestyle consumers and can significantly enhance a retailer’s offering. While these boots are lightweight and appealing, they may not provide the durability required for heavy-duty use. Retail buyers should focus on seasonal trends and consumer preferences, ensuring they stock a variety of styles to cater to different tastes while maintaining quality.

How Do Hiking Boots Meet the Demands of Outdoor Activities?

Hiking boots are specifically designed for outdoor adventures, featuring waterproof materials and rugged soles for superior traction. They are essential for businesses in outdoor recreation and adventure tourism, where safety and performance are critical. When sourcing hiking boots, B2B buyers should consider the fit, weight, and support offered by the boots, as these factors can greatly affect the user experience on challenging terrains. While they may be heavier than casual footwear, their specialized features justify the investment for outdoor enthusiasts.

Key Industrial Applications of eyelets boots

| Industry/Sector | Specific Application of Eyelets Boots | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Heavy Industry | Safety footwear for construction workers | Provides essential foot protection and compliance with safety regulations | Look for steel-toe options, durable materials, and slip-resistant soles |

| Event Management & Entertainment | Footwear for staff at outdoor events | Ensures comfort and durability during long hours of standing and walking | Consider styles that are easy to clean and available in various colors for branding |

| Military & Security | Tactical boots for personnel | Offers protection and support in demanding environments | Prioritize lightweight materials and waterproof options for diverse terrains |

| Fashion Retail | Trendy footwear for retail display | Attracts customers with unique designs and styles | Source from manufacturers that offer customization and quick turnaround times |

| Agriculture & Farming | Protective boots for farm workers | Safeguards against hazards in agricultural settings | Ensure boots are waterproof and easy to clean for practical use in muddy conditions |

How Are Eyelets Boots Utilized in the Construction and Heavy Industry?

In the construction and heavy industry, eyelets boots serve as essential safety footwear for workers. These boots are designed with steel-toe protection to prevent injuries from falling objects, while their rugged construction ensures durability on job sites. For international buyers, especially in developing markets like Nigeria and Brazil, compliance with local safety regulations is critical. Sourcing durable materials that withstand harsh conditions while providing comfort can enhance worker productivity and reduce workplace accidents.

What Role Do Eyelets Boots Play in Event Management and Entertainment?

In the event management and entertainment sectors, eyelets boots are favored for staff working at outdoor events, concerts, and festivals. These boots offer the necessary comfort and durability required for long hours spent on their feet, navigating various terrains. International buyers should consider sourcing styles that are not only robust but also easy to clean, as they may encounter mud and spills during events. Customizable colors can also help align staff footwear with branding initiatives, enhancing the overall event experience.

How Are Eyelets Boots Essential for Military and Security Applications?

Eyelets boots are vital in military and security applications, providing tactical footwear for personnel in the field. These boots are engineered to offer support, protection, and comfort during extended periods of use in challenging environments. For international buyers, especially those sourcing for military contracts, it’s important to prioritize lightweight materials, waterproof features, and heat resistance. The right footwear can significantly impact operational effectiveness and soldier safety in diverse climates and terrains.

Why Are Eyelets Boots Important for Fashion Retail?

In the fashion retail sector, eyelets boots serve as trendy footwear that can captivate customers. Retailers can leverage unique designs and bold colors to attract attention and enhance store displays. For B2B buyers in Europe and South America, sourcing from manufacturers who offer customization and quick turnaround times is crucial for staying ahead of fashion trends. This agility in sourcing allows retailers to keep their inventory fresh and appealing, ultimately driving sales and customer engagement.

How Do Eyelets Boots Benefit Workers in Agriculture and Farming?

In agriculture and farming, eyelets boots provide protective footwear that safeguards workers from various hazards, including chemicals, sharp tools, and muddy conditions. These boots must be waterproof and easy to clean to ensure practicality in the field. For international buyers in regions like Africa and South America, sourcing durable, high-quality materials that can withstand the rigors of agricultural work is essential. This not only enhances worker safety but also contributes to overall productivity in farming operations.

3 Common User Pain Points for ‘eyelets boots’ & Their Solutions

Scenario 1: Sourcing Durable Eyelets Boots for Harsh Environments

The Problem: B2B buyers in industries such as construction or outdoor recreation often struggle to find eyelets boots that can withstand extreme conditions. Buyers may face challenges with products that wear out quickly, fail to provide adequate protection, or do not offer the necessary comfort for long hours on the job. This can lead to employee dissatisfaction, increased costs due to frequent replacements, and potential safety hazards on the worksite.

The Solution: To address these concerns, it is essential for buyers to prioritize sourcing eyelets boots made from high-quality materials, such as full-grain leather and reinforced stitching. When selecting a supplier, buyers should request detailed specifications on the boots’ durability features, including steel-toe reinforcement and rubber, screw-on soles that provide both traction and longevity. Conducting thorough research and requesting samples can also help ensure that the boots meet the required performance standards. Additionally, establishing long-term partnerships with manufacturers known for their durable products can lead to better pricing and reliability in supply, which is vital for maintaining workforce safety and productivity.

Scenario 2: Ensuring Proper Fit and Comfort for Employees

The Problem: Many B2B buyers encounter difficulties ensuring that the eyelets boots they order fit their employees properly. Ill-fitting boots can lead to discomfort, foot pain, and reduced productivity, ultimately affecting employee morale and performance. Additionally, the challenge of managing various sizes and styles complicates inventory management, particularly when catering to a diverse workforce.

The Solution: A practical approach to solving this issue involves implementing a size assessment program before placing bulk orders. Buyers can provide employees with fitting guides or host fitting sessions to determine the correct sizes. Offering a range of sizes and widths will accommodate different foot shapes, ensuring a better fit. Furthermore, selecting boots with adjustable features such as speed laces or hooks allows for a more customized fit. Buyers should also consider establishing a return or exchange policy with suppliers to accommodate any sizing issues that may arise after the purchase. This proactive strategy not only enhances employee satisfaction but also optimizes inventory management.

Scenario 3: Managing Diverse Style Preferences in Eyelets Boots

The Problem: In the fashion-conscious segments of the B2B market, such as retail or entertainment, buyers face the challenge of catering to diverse style preferences while ensuring that the eyelets boots they procure meet quality and durability standards. Balancing aesthetics with functionality can be complex, particularly when dealing with a clientele that expects both performance and style.

The Solution: To effectively manage this challenge, buyers should engage in market research to understand current trends and preferences in eyelets boot styles. Collaborating with suppliers who offer a variety of designs—such as punk, gothic, or classic styles—can help meet the diverse demands of their customer base. Buyers should also consider creating a curated collection that features a range of designs while maintaining consistent quality standards. Regular communication with suppliers about upcoming styles and innovations can further enhance the selection. Additionally, incorporating customer feedback into the selection process will help refine the offerings and ensure that the boots remain appealing and functional, driving sales and customer satisfaction.

Strategic Material Selection Guide for eyelets boots

What Are the Key Materials Used in Eyelets Boots?

When selecting materials for eyelets boots, B2B buyers must consider various factors, including performance properties, cost, and regional compliance standards. Here, we analyze four common materials—leather, synthetic fabrics, rubber, and metal—highlighting their properties, advantages, disadvantages, and specific considerations for international markets.

How Does Leather Perform in Eyelets Boots?

Leather, particularly full-grain cowhide, is a traditional choice for eyelets boots due to its durability and aesthetic appeal. It offers excellent temperature regulation and breathability, making it suitable for various climates. Leather is also resistant to abrasion and can withstand significant wear and tear, which is essential for boots used in rugged environments.

Pros: Leather’s natural flexibility and comfort increase over time, enhancing user experience. It also provides a classic look that appeals to various consumer segments, including fashion-conscious buyers.

Cons: The primary drawbacks include higher costs and the need for regular maintenance to prevent cracking and drying. Additionally, leather may not be the best choice in extremely wet conditions unless treated for water resistance.

Impact on Application: Leather is compatible with a range of environments but may require additional treatments for moisture-prone areas, which is crucial for buyers in regions like Africa and South America.

What Are the Benefits of Synthetic Fabrics for Eyelets Boots?

Synthetic fabrics, such as nylon and polyester, are increasingly popular in the production of eyelets boots due to their lightweight nature and resistance to moisture. These materials often come with enhanced breathability and quick-drying properties, making them ideal for humid climates.

Pros: Synthetic materials are generally more affordable than leather and offer a variety of colors and styles. They are also easier to clean and maintain, appealing to buyers looking for low-maintenance options.

Cons: However, synthetic fabrics may lack the durability and aesthetic appeal of leather. They can also be less comfortable over extended wear periods, particularly if not designed with proper cushioning.

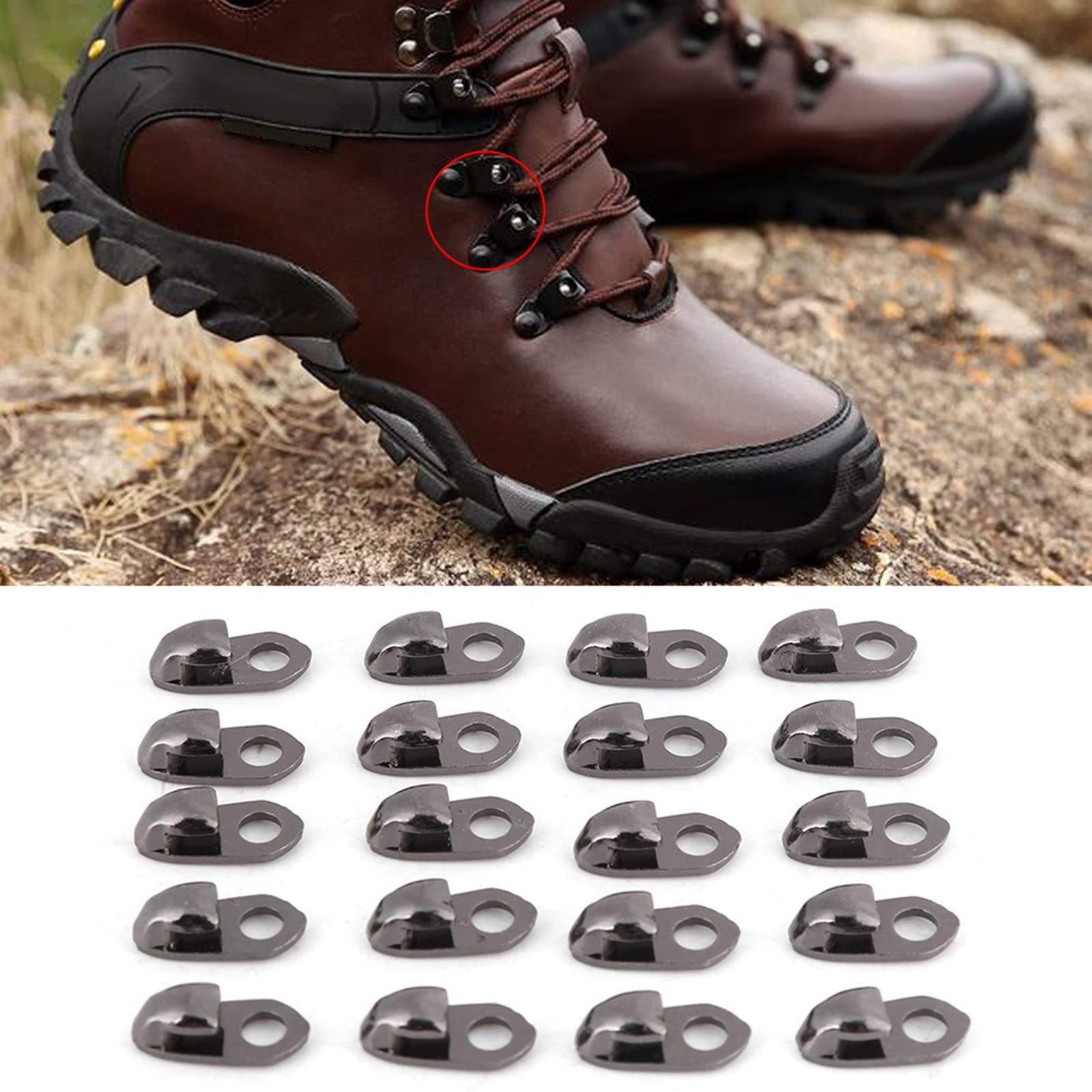

Illustrative image related to eyelets boots

Impact on Application: For international buyers, synthetic materials can meet compliance standards for various markets, but they may not resonate as well with consumers preferring traditional materials.

Why Choose Rubber for Eyelets Boots?

Rubber is commonly used for soles and waterproofing in eyelets boots, providing excellent grip and durability. It is inherently resistant to water, making it ideal for wet conditions.

Pros: Rubber soles offer superior traction and shock absorption, enhancing comfort and safety. They are also relatively inexpensive and can be produced quickly.

Illustrative image related to eyelets boots

Cons: The main limitation is that rubber can degrade over time when exposed to UV light or extreme temperatures, which may affect the longevity of the boots.

Impact on Application: Buyers in regions with high humidity or wet conditions, such as the Middle East, will find rubber soles particularly beneficial. However, they should ensure that the rubber meets local standards for durability and performance.

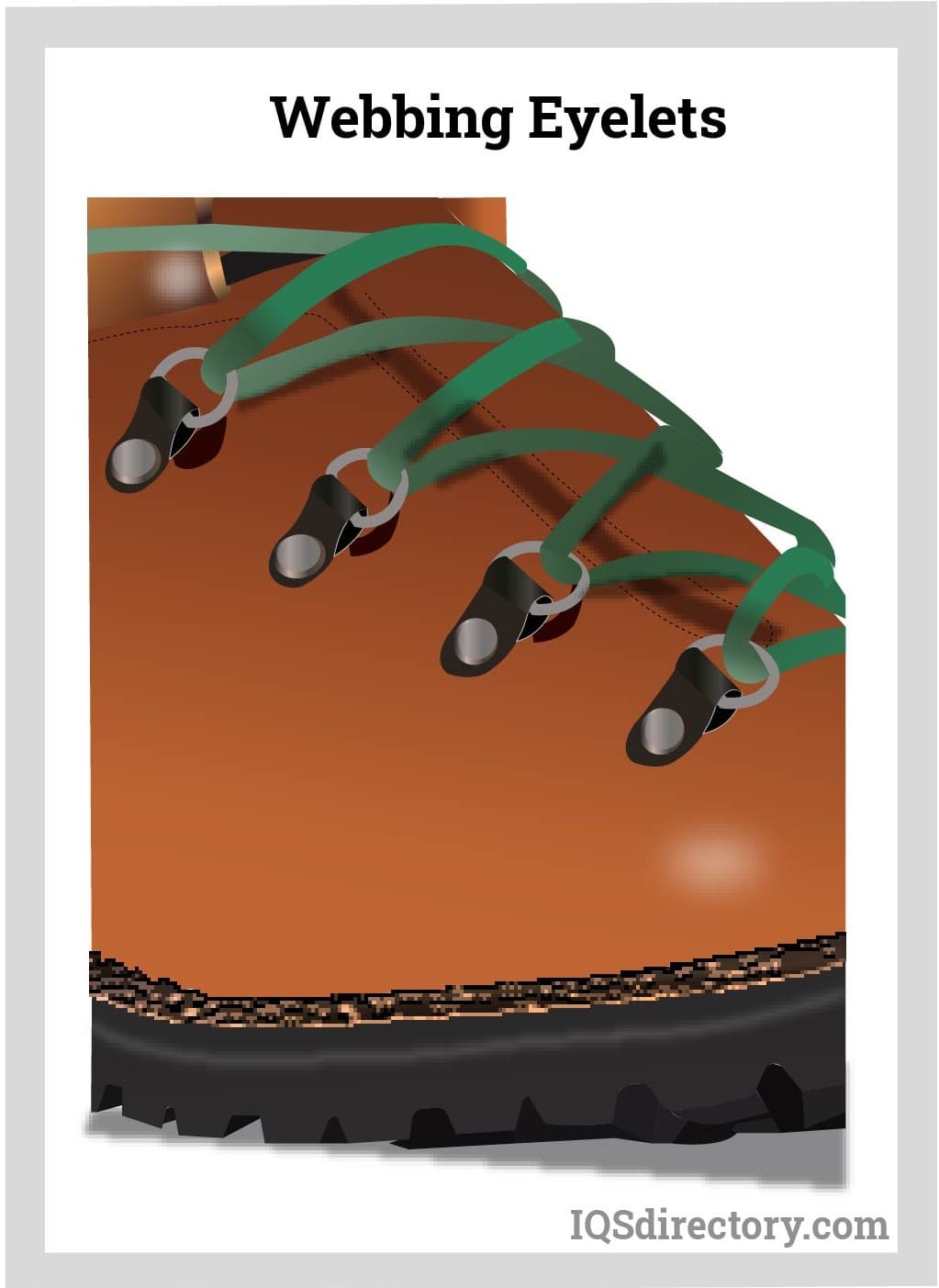

What Role Does Metal Play in Eyelets Boots?

Metal components, such as eyelets and hooks, are crucial for the functionality and durability of eyelets boots. Typically made from steel or brass, these materials provide strength and resistance to wear.

Pros: Metal eyelets enhance the overall durability of the boots and allow for secure lacing, which is essential for maintaining fit and comfort.

Illustrative image related to eyelets boots

Cons: The primary drawback is the potential for corrosion, especially in humid environments. Buyers must ensure that the metal components are treated or coated to resist rust.

Impact on Application: Compliance with international standards for metal components is vital, particularly for buyers in Europe, where regulations may be stricter regarding materials used in footwear.

Summary Table of Material Selection for Eyelets Boots

| Material | Typical Use Case for eyelets boots | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Fashion and rugged outdoor boots | Durability and aesthetic appeal | Higher cost and maintenance | High |

| Synthetic Fabric | Lightweight and casual boots | Affordability and easy maintenance | Less durable and comfort issues | Medium |

| Rubber | Waterproof and traction-focused boots | Excellent grip and shock absorption | Degrades under UV exposure | Low |

| Metal | Structural components (eyelets/hooks) | Enhanced durability and fit | Corrosion potential | Medium |

This strategic material selection guide provides B2B buyers with critical insights into the various materials used in eyelets boots, helping them make informed decisions based on performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for eyelets boots

What are the Key Stages in the Manufacturing Process of Eyelets Boots?

The manufacturing of eyelets boots typically involves several critical stages, each essential to ensuring the final product meets both aesthetic and functional standards. The main stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Eyelets Boots?

The manufacturing process begins with the careful selection and preparation of materials. High-quality full-grain leather is often the primary material due to its durability and aesthetic appeal. Suppliers must ensure that the leather is sourced from reputable tanneries that adhere to sustainable practices.

Once the leather is acquired, it undergoes treatments to enhance its properties. This can include processes such as conditioning and dyeing, which not only improve the leather’s durability but also its visual appeal. Other materials, such as rubber for soles and metal for eyelets, are also sourced, ensuring they meet specific quality standards.

What Techniques are Used in the Forming Process of Eyelets Boots?

The forming stage involves cutting the prepared materials into specific patterns. Advanced cutting techniques, such as die-cutting or laser cutting, are often employed to ensure precision and minimize waste. Each component of the boot, including the upper, lining, and tongue, is cut according to predefined specifications.

Following cutting, the leather pieces undergo a shaping process, which can include molding and stitching. This stage is critical for creating the boot’s silhouette and fit. Techniques like triple stitching are frequently used to enhance durability, especially in high-stress areas like the eyelets and seams.

How are Eyelets Boots Assembled?

Assembly is a multi-step process that combines various components to create the final product. The upper part of the boot is first stitched together, incorporating features like eyelets for lacing. At this stage, quality checks are vital to ensure that stitching is consistent and meets design specifications.

The soles are then attached, often using methods such as cementing or Goodyear welt construction, which provides additional durability and waterproofing. The installation of additional features, such as steel toe caps or cushioned insoles, occurs during assembly. This is also the phase where any embellishments or custom designs are added to meet buyer specifications.

Illustrative image related to eyelets boots

What Finishing Techniques are Applied to Eyelets Boots?

The finishing stage involves several processes designed to enhance the boot’s overall appearance and functionality. This can include polishing, which gives the leather a refined look, and applying protective coatings to improve water resistance and longevity.

Final inspections are conducted to check for any defects in craftsmanship, alignment, and overall aesthetics. Boots that pass inspection are then cleaned and packaged for shipment.

How is Quality Assurance Implemented in Eyelets Boot Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for eyelets boots, ensuring that products meet both international standards and customer expectations.

What International Standards Apply to Eyelets Boots?

For eyelets boots, compliance with international standards such as ISO 9001 is crucial. This standard outlines a framework for quality management systems, emphasizing customer satisfaction and continuous improvement. Additionally, industry-specific certifications like CE marking for European markets or ANSI standards for safety footwear may also apply, depending on the intended use of the boots.

What are the Key Quality Control Checkpoints in Eyelets Boot Production?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure adherence to standards. These checkpoints typically include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival, ensuring they meet predefined specifications before they enter production.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes and detect any deviations from quality standards. This includes checking stitching accuracy, material alignment, and the integrity of components.

-

Final Quality Control (FQC): Once the boots are assembled, a comprehensive final inspection is performed. This checks for aesthetic flaws, functional performance, and compliance with safety standards.

What Testing Methods are Commonly Used for Eyelets Boots?

Various testing methods are employed to assess the quality and performance of eyelets boots. These include:

-

Durability Testing: Boots are subjected to wear and tear simulations to evaluate their longevity under various conditions.

-

Water Resistance Testing: Boots may undergo tests to assess their ability to repel water, which is essential for outdoor or work environments.

-

Safety Testing: For boots featuring steel toes or other protective elements, impact resistance and compression tests are conducted to ensure they meet safety regulations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to ensure quality assurance in their sourcing of eyelets boots should take proactive steps to verify supplier QC processes.

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed reports from suppliers that outline their QA processes, including any certifications held and the results of recent audits. Additionally, engaging in supplier audits can provide firsthand insight into the manufacturing environment and QC practices.

How Can Third-Party Inspections Enhance Buyer Confidence?

Utilizing third-party inspection services can further enhance confidence in supplier quality. These independent entities can conduct thorough inspections at various stages of production, providing unbiased assessments of compliance with international standards.

What are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

What Challenges Do International Buyers Face in Quality Assurance?

Cultural differences, varying standards, and logistical challenges can complicate the sourcing process. Buyers should familiarize themselves with local regulations and industry standards specific to their region, ensuring that the products they source not only meet their needs but also comply with any legal requirements.

How Can Buyers Leverage Technology for Quality Assurance?

Technology, such as supply chain management software and digital quality assurance tools, can streamline the QC process. Buyers can track shipments, monitor supplier compliance, and manage documentation digitally, enhancing transparency and accountability throughout the sourcing process.

In conclusion, understanding the manufacturing processes and quality assurance measures for eyelets boots is crucial for B2B buyers looking to make informed sourcing decisions. By focusing on these aspects, buyers can enhance their procurement strategies and ensure they receive high-quality products that meet their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘eyelets boots’

This guide provides a comprehensive checklist for B2B buyers looking to source eyelet boots effectively. Whether you are catering to the fashion industry, supplying workwear, or addressing the punk and alternative markets, following these steps will ensure a successful procurement process.

Illustrative image related to eyelets boots

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the eyelet boots you intend to source. This includes material (e.g., leather, vegan options), design (e.g., steel-toe, combat style), color variants, and sizes. Defining these criteria not only helps streamline your search but also ensures that the products meet your customers’ needs and expectations.

- Material Considerations: Assess the durability, comfort, and aesthetics of different materials.

- Design Features: Consider additional features like waterproofing or insulation, depending on the intended use.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a solid reputation in the eyelet boots market. Look for manufacturers that specialize in your required specifications and have a proven track record.

- Verify Credentials: Check for certifications, quality control processes, and industry affiliations.

- Read Reviews: Look for feedback from other buyers to gauge reliability and product quality.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; ask for specific examples of previous work that aligns with your requirements.

- Production Capacity: Ensure the supplier can meet your order quantities and deadlines.

- Customization Options: Confirm if they can accommodate custom designs or branding.

Step 4: Request Samples

Always request samples of the eyelet boots before placing a bulk order. This allows you to assess the quality, fit, and design firsthand, minimizing the risk of dissatisfaction upon delivery.

Illustrative image related to eyelets boots

- Quality Assessment: Inspect the stitching, material finish, and overall craftsmanship.

- Comfort Testing: Try the boots for comfort and fit, as this is crucial for end-user satisfaction.

Step 5: Negotiate Terms and Pricing

Once you’ve shortlisted potential suppliers, initiate negotiations on pricing, payment terms, and delivery schedules. Clear communication during this phase is essential to avoid misunderstandings later.

- Understand Pricing Structures: Inquire about bulk discounts and shipping costs.

- Clarify Payment Terms: Ensure you understand payment schedules and methods accepted.

Step 6: Establish Clear Contracts

Draft contracts that outline all agreed terms, including specifications, prices, and delivery timelines. A well-defined contract protects both parties and sets clear expectations.

- Include Quality Assurance Clauses: Specify quality standards and remedies for non-compliance.

- Detail Delivery Terms: Clarify responsibilities regarding shipping and handling.

Step 7: Plan for Post-Purchase Follow-Up

After securing your order, establish a follow-up plan to ensure timely delivery and quality compliance. Stay in touch with the supplier to address any potential issues proactively.

- Track Deliveries: Implement a system to monitor shipping status and delivery times.

- Feedback Loop: After receiving the boots, provide feedback to the supplier, fostering a long-term relationship.

By following this practical sourcing guide, B2B buyers can confidently navigate the procurement of eyelet boots, ensuring they meet their business needs while maintaining quality and supplier relationships.

Comprehensive Cost and Pricing Analysis for eyelets boots Sourcing

What Are the Key Cost Components for Sourcing Eyelets Boots?

When sourcing eyelets boots, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Full-grain leather is typically more expensive but offers superior durability and aesthetics. Vegan alternatives may reduce costs but can influence market appeal.

-

Labor: Labor costs vary by region and are influenced by local wage standards. In countries with higher labor costs, manufacturers may charge more, impacting the final price.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, equipment maintenance, and factory lease. Efficient production processes can lower overhead, thus reducing overall costs.

-

Tooling: The initial investment in molds and tools for boot production can be substantial. Custom designs or unique specifications often require additional tooling costs, which should be factored into the pricing.

-

Quality Control (QC): Implementing stringent QC measures ensures that products meet buyer specifications and regulatory standards. This process, while adding to the cost, can save money in the long term by reducing returns and increasing customer satisfaction.

-

Logistics: Shipping costs are influenced by distance, shipping method, and volume. International shipments may incur customs duties and tariffs, which should be considered when calculating the total cost.

-

Margin: Suppliers typically apply a markup to cover their costs and profit margins. Understanding the average margins in the industry can help buyers gauge fair pricing.

How Do Volume and Customization Affect Pricing for Eyelets Boots?

Pricing is heavily influenced by order volume and customization requests. Suppliers often offer discounts for bulk purchases, which can significantly reduce the cost per unit. For international buyers, negotiating minimum order quantities (MOQs) is crucial; larger orders may allow for better pricing and terms.

Customization options—such as specific colors, materials, or designs—can also impact pricing. While tailored products may command higher prices, they can enhance brand identity and marketability. Buyers should assess whether the added value justifies the increased expense.

What External Factors Influence Eyelets Boots Pricing?

Several external factors can affect the pricing of eyelets boots:

-

Material Prices: Fluctuations in raw material costs, driven by market demand or supply chain disruptions, can lead to price adjustments. Staying informed about these trends can help buyers negotiate better terms.

-

Quality Certifications: Boots that meet specific safety or quality certifications may come at a premium. Buyers in industries requiring compliance should prioritize certified products, as they can mitigate risks and ensure safety.

-

Supplier Reliability: Established suppliers with a track record of quality and timely delivery may charge higher prices. However, the reliability they offer can lead to lower total costs in terms of reduced returns and better customer satisfaction.

-

Incoterms: Understanding shipping terms is critical for international transactions. Incoterms define the responsibilities of buyers and sellers, influencing overall costs. Buyers should clarify these terms to avoid unexpected expenses.

What Buyer Tips Can Optimize Cost-Efficiency in Eyelets Boots Sourcing?

To maximize cost-efficiency when sourcing eyelets boots, consider the following strategies:

-

Negotiate Terms: Always engage in negotiations. Suppliers may have flexibility in pricing, especially for larger orders or long-term contracts.

-

Evaluate Total Cost of Ownership: Look beyond the initial purchase price. Consider factors such as durability, maintenance costs, and potential returns when assessing the total cost of ownership.

-

Leverage Local Suppliers: For buyers in regions like Africa or South America, sourcing from local manufacturers can reduce shipping costs and lead times. This strategy can also support local economies.

-

Research Market Trends: Stay informed about market trends, including popular styles and materials. This knowledge can empower buyers during negotiations and help identify potential cost-saving opportunities.

-

Build Long-Term Relationships: Establishing strong relationships with suppliers can lead to better pricing, priority service, and exclusive offers. Consistent business often rewards buyers with favorable terms.

Disclaimer on Indicative Prices

Prices for eyelets boots can vary widely based on the aforementioned factors. Buyers should seek multiple quotes and conduct thorough market research to ensure they are receiving competitive pricing aligned with their specific needs.

Illustrative image related to eyelets boots

Alternatives Analysis: Comparing eyelets boots With Other Solutions

When evaluating footwear solutions for various industrial and casual applications, it is crucial to consider alternatives to traditional eyelet boots. Eyelet boots, known for their durability and style, may not always be the best fit for every scenario. Below, we will compare eyelet boots against alternative footwear options that may serve similar purposes, particularly for B2B buyers operating in diverse markets across Africa, South America, the Middle East, and Europe.

| Comparison Aspect | Eyelets Boots | Safety Shoes | Tactical Boots |

|---|---|---|---|

| Performance | High durability; good grip | Excellent protection; slip-resistant | Enhanced mobility; rugged design |

| Cost | Moderate (€124-€139) | Moderate to high (€80-€200) | High (€150-€300) |

| Ease of Implementation | Simple design; easy to wear | Requires training for specific safety standards | Requires familiarity with tactical gear |

| Maintenance | Low; easy to clean | Moderate; needs regular checks | Moderate; cleaning and care necessary |

| Best Use Case | Casual wear, light-duty work | Industrial environments; construction | Military, police, outdoor activities |

What Are the Advantages and Disadvantages of Safety Shoes Compared to Eyelets Boots?

Safety shoes are designed specifically for environments where foot protection is paramount. They often include features like reinforced toes, slip-resistant soles, and puncture-resistant materials.

Pros:

– Superior protection against workplace hazards.

– Compliance with safety regulations in industrial settings.

– Enhanced comfort options for long wear.

Cons:

– Can be more expensive than standard eyelet boots.

– May lack the aesthetic appeal that some users seek.

– Heavier and bulkier, which can limit mobility.

How Do Tactical Boots Compare to Eyelets Boots in Terms of Performance?

Tactical boots are built for performance in demanding conditions, offering features such as waterproofing, breathability, and specialized traction. They are favored by military and law enforcement personnel.

Illustrative image related to eyelets boots

Pros:

– Designed for high-performance scenarios, providing agility and support.

– Often equipped with additional features like insulation and waterproofing.

– Rugged construction suitable for extreme environments.

Cons:

– Higher price point may not be justifiable for all buyers.

– Bulkier design may not be suitable for all users.

– Less versatility for casual or fashion-oriented use compared to eyelet boots.

How Can B2B Buyers Choose the Right Footwear Solution?

Choosing the right footwear solution hinges on understanding the specific needs of the environment and the user. Eyelet boots offer a stylish and durable option for casual settings and light-duty work, making them suitable for urban adventurers and alternative fashion enthusiasts. In contrast, safety shoes are indispensable in industrial settings where compliance and protection are critical. Tactical boots are ideal for high-stakes environments requiring agility and specialized features.

Buyers should assess the operational context, budget constraints, and the specific requirements of their workforce. By weighing the pros and cons of each option, businesses can make informed decisions that enhance both safety and employee satisfaction in their respective environments.

Essential Technical Properties and Trade Terminology for eyelets boots

What Are the Key Technical Properties of Eyelets Boots?

When considering eyelets boots for B2B procurement, understanding the essential technical properties is crucial for making informed decisions. Here are some critical specifications that should be taken into account:

1. Material Grade

Eyelets boots are primarily constructed from various types of leather, including full-grain and top-grain options. Full-grain leather is the highest quality, retaining the natural grain and providing durability, breathability, and resistance to wear. For B2B buyers, selecting the right material grade can influence the product’s longevity and performance, directly impacting customer satisfaction and brand reputation.

2. Steel-Toe Reinforcement

Many eyelets boots come equipped with a steel-toe cap, offering enhanced protection against impacts and compression. This feature is particularly important for industries where workers are exposed to heavy machinery or hazardous environments. B2B buyers should prioritize suppliers who provide detailed information on the safety ratings of the steel-toe caps, as this can affect compliance with workplace safety regulations.

3. Sole Construction

The sole of eyelets boots can vary significantly in design and materials, including rubber, EVA, and PU options. Rubber soles offer excellent traction and durability, while EVA provides lightweight cushioning. Understanding the sole construction is essential for B2B buyers, as it determines the boot’s suitability for specific environments, whether urban, rugged, or industrial.

4. Shaft Height

Shaft height is a critical dimension in eyelets boots, usually ranging from ankle height to mid-calf. A taller shaft offers more support and protection, making it ideal for outdoor or heavy-duty applications. B2B buyers must consider the intended use of the boots when evaluating shaft height, ensuring they meet the specific needs of their customer base.

5. Comfort Features

Comfort is a significant factor influencing purchase decisions. Features such as cushioned insoles, moisture-wicking linings, and shock-absorbing midsoles can enhance the wearer’s experience. B2B buyers should look for suppliers who provide detailed information on comfort features, as these can lead to higher employee satisfaction and lower return rates.

6. Size Range

The availability of a comprehensive size range is essential for meeting diverse customer needs. Eyelets boots typically come in various sizes, accommodating different foot shapes and preferences. B2B buyers should ensure that suppliers offer a wide selection of sizes to cater to their target demographics, which can enhance market reach and sales potential.

What Common Trade Terms Should B2B Buyers Understand When Sourcing Eyelets Boots?

Navigating the B2B landscape for eyelets boots requires familiarity with specific industry jargon. Here are several common terms that are vital for effective communication and procurement:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. Understanding OEM relationships can help buyers identify reliable suppliers and negotiate better pricing structures.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers to understand, as it impacts inventory management and cash flow. Knowing the MOQ can help businesses plan their purchases effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process allows buyers to compare offers and negotiate better deals. A well-prepared RFQ can streamline the procurement process and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can prevent misunderstandings and ensure smooth logistics, particularly for B2B transactions across borders.

5. Lead Time

Lead time refers to the time it takes from placing an order until it is delivered. Understanding lead times is essential for B2B buyers to manage inventory and meet customer demands effectively. Suppliers should provide clear information on lead times to facilitate better planning.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and longevity of a product. B2B buyers should always inquire about warranty details to ensure they are protected against defects and can maintain customer satisfaction.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing eyelets boots, ensuring they meet the needs of their clients and enhance their market positioning.

Illustrative image related to eyelets boots

Navigating Market Dynamics and Sourcing Trends in the eyelets boots Sector

What Are the Key Trends Driving the Eyelets Boots Market?

The eyelets boots market is witnessing a dynamic shift influenced by various global drivers, particularly among international B2B buyers from regions such as Africa, South America, the Middle East, and Europe. One of the primary drivers is the rising demand for multifunctional footwear that combines style with durability. As urbanization accelerates in developing regions, consumers are increasingly seeking boots that can withstand diverse environments, from city streets to rugged terrains.

Emerging trends in B2B technology, such as e-commerce platforms and digital supply chain solutions, are revolutionizing sourcing practices. Buyers are now able to access a wider range of products directly from manufacturers, facilitating faster decision-making and reducing lead times. Moreover, data analytics is playing a crucial role in understanding consumer preferences, enabling manufacturers to tailor their offerings to specific market demands, such as color variations, materials, and design styles.

Sustainability is also becoming a key consideration for B2B buyers. Brands are increasingly focusing on eco-friendly materials and ethical manufacturing processes. This trend is particularly strong among younger consumers, who are likely to influence purchasing decisions in emerging markets like Brazil and Nigeria. Companies that prioritize sustainability in their sourcing strategies will not only meet market demands but also enhance their brand reputation globally.

Illustrative image related to eyelets boots

How Is Sustainability Reshaping Sourcing Practices in the Eyelets Boots Sector?

The environmental impact of the footwear industry has prompted a significant shift toward sustainable practices in the eyelets boots sector. B2B buyers are increasingly aware of the ecological footprint associated with manufacturing processes and are looking for suppliers who prioritize ethical sourcing. This includes the use of eco-friendly materials, such as recycled leathers and organic cotton, which reduce waste and promote sustainability.

Ethical supply chains are essential for building trust with consumers and business partners alike. Companies that can demonstrate compliance with international labor standards and environmental regulations are likely to gain a competitive edge. Certifications such as Fair Trade, Global Organic Textile Standard (GOTS), and Leather Working Group (LWG) are becoming increasingly relevant, as they provide assurance of sustainable practices and responsible sourcing.

Incorporating ‘green’ certifications into product offerings not only appeals to environmentally conscious buyers but also helps businesses align with regulatory requirements. As countries in Africa, South America, and the Middle East implement stricter environmental laws, the demand for sustainably sourced eyelets boots is expected to rise. Thus, investing in sustainable practices is not just a trend but a strategic necessity for B2B buyers looking to thrive in the global market.

What Is the Historical Context of Eyelets Boots in the B2B Market?

The evolution of eyelets boots can be traced back to their original purpose as functional footwear for military and labor use. Traditionally designed for durability and protection, these boots have undergone significant transformations to meet modern aesthetic and functional demands. The introduction of eyelets allowed for enhanced ankle support and adjustability, making them popular among various consumer segments, including outdoor enthusiasts and fashion-forward individuals.

Over the years, eyelets boots have transcended their utilitarian origins to become a staple in alternative fashion, particularly within punk, gothic, and metal subcultures. This cultural significance has fueled demand and led manufacturers to diversify their offerings in terms of design, materials, and functionalities. As the global market continues to evolve, understanding this historical context is crucial for B2B buyers seeking to navigate current trends and make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of eyelets boots

-

How do I ensure the quality of eyelets boots before purchasing?

To ensure the quality of eyelets boots, request samples from suppliers to assess materials, craftsmanship, and comfort. Evaluate the use of full-grain leather, stitching techniques, and sole construction. Additionally, inquire about quality assurance processes, including certifications and testing standards. Establishing a clear communication line with the supplier regarding your quality expectations can also help mitigate risks associated with bulk purchases. -

What is the best material for eyelets boots in varying climates?

The best material for eyelets boots depends on the climate of the target market. For humid regions, breathable materials like leather or synthetic fabrics with moisture-wicking properties are ideal. In contrast, for colder climates, insulated leather boots with waterproof features are preferable. Always consider the end-user’s environment when selecting materials to ensure durability and comfort. -

What customization options are available for eyelets boots?

Many manufacturers offer customization options, including color, size, sole type, and additional features like steel toes or unique designs. When sourcing, clarify your customization needs upfront and ensure the supplier can accommodate them. This may involve minimum order quantities (MOQs) or additional costs, so it’s essential to discuss these details during negotiations. -

What are the typical minimum order quantities (MOQs) for eyelets boots?

MOQs for eyelets boots can vary significantly by supplier and product type. Generally, they range from 50 to 500 pairs per order. Larger orders may qualify for discounts, while smaller orders might incur higher per-unit costs. Always confirm MOQs with your supplier early in the negotiation process to align with your purchasing strategy. -

What payment terms should I expect when sourcing eyelets boots?

Payment terms can vary based on the supplier’s policies and your negotiation. Common arrangements include a 30% deposit upon order confirmation and the balance upon shipping. Some suppliers may offer flexible terms such as letters of credit or payment upon delivery, especially for established relationships. Always ensure that payment methods are secure and reliable to protect your investment. -

How can I vet suppliers for eyelets boots effectively?

Vetting suppliers involves several steps, including checking their industry reputation, reviewing customer testimonials, and verifying certifications. Request references from previous clients and assess their production capabilities through factory visits or audits. It is also beneficial to conduct online research regarding their business history and any potential complaints or issues. -

What logistics considerations should I keep in mind when importing eyelets boots?

When importing eyelets boots, consider shipping methods, lead times, and customs regulations specific to your country. Assess the total landed cost, including shipping, duties, and taxes, to avoid unexpected expenses. Partnering with a reliable logistics provider can facilitate smoother customs clearance and ensure timely delivery to your destination. -

How do I handle disputes with suppliers in the eyelets boots industry?

Dispute resolution should begin with clear communication. Address issues promptly and professionally, providing documented evidence of the problem. If direct negotiation fails, refer to the terms outlined in your contract, which may include mediation or arbitration. Establishing a clear return and exchange policy in advance can also help mitigate disputes before they escalate.

Top 1 Eyelets Boots Manufacturers & Suppliers List

1. Weaver Leather Supply – Boot Hooks and Speed Lace Hooks

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Boot Hooks and Speed Lace Hooks – Weaver Leather Supply offers a variety of boot hooks and speed lace hooks essential for repair work. Key details include:

– Available sizes: 1/4″, 3/8″, 1/2″, 5/8″, 3/4″

– Materials: Steel, Solid Brass

– Color options: Antique Brass, Brass, Gunmetal, Nickel, Shiny Black

– Prices range from $0.23 to $0.70 depending on the style and size.

– Products include boot lac…

Strategic Sourcing Conclusion and Outlook for eyelets boots

What Are the Key Takeaways for Sourcing Eyelets Boots?

In the competitive landscape of eyelets boots, strategic sourcing emerges as a pivotal factor for success. Buyers must prioritize quality and durability, opting for boots crafted from premium materials like full-grain leather, which offer both comfort and resilience. The diversity in styles—from classic combat boots to unique punk aesthetics—allows businesses to cater to various market segments, including fashion-forward consumers and light-duty workers. Establishing strong relationships with reliable suppliers ensures timely access to stock, enabling businesses to meet customer demands efficiently.

How Can B2B Buyers Leverage Market Trends?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should leverage emerging trends such as the increasing demand for vegan and eco-friendly options. By offering a range of styles and materials, businesses can attract a broader audience and enhance their market position. Additionally, staying informed about global shipping logistics and import regulations can streamline operations and reduce lead times.

What Steps Should Buyers Take Moving Forward?

As the market for eyelets boots continues to evolve, now is the time for B2B buyers to act. Embrace strategic sourcing by exploring diverse suppliers and innovative designs that resonate with your target audience. Invest in building a robust supply chain that can adapt to changing consumer preferences. By doing so, you will not only meet market demands but also position your business for sustainable growth in the dynamic world of footwear.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.