A Deep Dive into Molino Para Moler Maiz Solution

Introduction: Navigating the Global Market for molino para moler maiz

In the competitive landscape of the global grain processing industry, sourcing the right molino para moler maiz can pose significant challenges for B2B buyers. As the demand for high-quality maize flour and masa rises across diverse markets—from bustling urban centers in South America to artisanal kitchens in Europe—understanding the nuances of milling equipment becomes essential. This comprehensive guide is designed to equip international buyers with actionable insights into the types of molinos available, their various applications, and the critical factors to consider when vetting suppliers.

From electric models ideal for small-scale operations to industrial-grade equipment capable of handling large volumes, the market offers a wide range of options tailored to different needs. Additionally, the guide delves into cost considerations, maintenance requirements, and the importance of sourcing from reputable manufacturers to ensure product reliability and quality. By addressing these key areas, this guide empowers buyers from Africa, the Middle East, and Europe, including countries like Saudi Arabia and Vietnam, to make informed purchasing decisions.

Navigating the complexities of the molino para moler maiz market can be daunting, but with the right knowledge and resources, B2B buyers can streamline their procurement processes, enhance their product offerings, and ultimately drive their business success.

Understanding molino para moler maiz Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Molinos | Powered by electricity, often with adjustable settings for grind size | Food processing, small-scale milling | Pros: Efficient, easy to use, consistent results. Cons: May require reliable power source. |

| Manual Hand Crank Molinos | Operated by hand, portable, and simple design | Small farms, artisan food production | Pros: No electricity needed, low cost. Cons: Labor-intensive, slower production rate. |

| Industrial Scale Molinos | High-capacity machines designed for large-scale production | Commercial milling, food manufacturing | Pros: High output, durable materials. Cons: High initial investment, requires maintenance. |

| Specialty Grain Molinos | Designed for specific grains like nixtamal or specialty corn types | Ethnic food markets, gourmet restaurants | Pros: Tailored grinding for specific needs, high quality. Cons: Limited versatility for other grains. |

| Portable Tabletop Molinos | Compact, lightweight, suitable for small spaces | Home kitchens, small businesses | Pros: Space-saving, easy to transport. Cons: Limited capacity, may not handle large volumes. |

What are the Key Features of Electric Molinos for Maíz Milling?

Electric molinos are designed for efficiency and ease of use, making them ideal for food processing and small-scale milling. They offer adjustable settings for grind size, allowing users to customize the fineness of the maize flour. B2B buyers should consider the availability of power sources, as these machines require consistent electricity to operate effectively. Their reliability and consistent output make them a popular choice for businesses looking to streamline their operations.

How Do Manual Hand Crank Molinos Benefit Small-Scale Producers?

Manual hand crank molinos are portable and straightforward, making them suitable for small farms and artisan food production. These molinos do not rely on electricity, making them an economical choice for remote areas. However, they require more labor and time, which may not be feasible for larger operations. Buyers should assess their production needs and the trade-off between labor intensity and cost savings.

What Advantages Do Industrial Scale Molinos Offer for Commercial Milling?

Industrial scale molinos are engineered for high-capacity production, making them perfect for commercial milling and food manufacturing. These machines are built with durable materials to withstand heavy use and provide high output. While they are a significant investment upfront, their efficiency can lead to cost savings over time. Buyers should evaluate their production volume to determine if the investment aligns with their business goals.

Why Choose Specialty Grain Molinos for Specific Needs?

Specialty grain molinos are tailored for specific grains, such as nixtamal or unique corn varieties. They are particularly beneficial for ethnic food markets and gourmet restaurants that prioritize high-quality, authentic ingredients. While these molinos excel in producing specific types of flour, their limited versatility may not justify the investment for businesses that require more general milling capabilities. Buyers should consider their target market and product offerings when selecting this type of molino.

How Do Portable Tabletop Molinos Fit into Small Business Operations?

Portable tabletop molinos are compact and lightweight, making them ideal for home kitchens and small businesses with limited space. Their design allows for easy transportation and storage, which is a significant advantage for businesses that attend markets or events. However, their limited capacity may not meet the demands of larger operations. B2B buyers should assess their production requirements and space constraints before investing in this type of molino.

Key Industrial Applications of molino para moler maiz

| Industry/Sector | Specific Application of molino para moler maiz | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Grinding corn for tortillas and masa-based products | Ensures high-quality, fresh ingredients for authentic cuisine | Assess machine capacity, motor power, and material durability for local use |

| Agriculture | Production of animal feed from corn and other grains | Enhances feed quality, promoting better livestock growth | Consider energy efficiency, maintenance support, and local sourcing options |

| Restaurant & Catering | Preparing fresh masa for on-site cooking | Improves menu authenticity, attracting more customers | Evaluate size, weight, and ease of cleaning for kitchen integration |

| Export & Import | Milling corn for international shipping to various markets | Supports trade with high-quality, processed agricultural products | Understand compliance with export regulations and local market demands |

| Artisan Food Production | Small-scale milling for specialty products like cornmeal or polenta | Offers unique product differentiation in the marketplace | Focus on machine versatility and after-sales service for artisanal needs |

How Is ‘molino para moler maiz’ Used in Food Processing?

In the food processing industry, the molino para moler maiz is essential for grinding corn into masa, which is crucial for producing tortillas, tamales, and other traditional dishes. The use of freshly milled corn ensures superior flavor and texture, which are vital for maintaining authenticity in culinary offerings. Businesses in this sector must consider the milling capacity and the power of the motor to meet production demands, as well as the quality of materials used in the machine to ensure durability in high-volume settings.

What Role Does ‘molino para moler maiz’ Play in Agriculture?

In agriculture, the molino para moler maiz is frequently utilized to produce animal feed from corn and other grains. This application is significant as it improves the quality of feed, directly impacting livestock growth and productivity. Buyers in this sector should focus on energy efficiency and ease of maintenance to ensure that their operations remain cost-effective and sustainable, particularly in regions where agricultural practices are critical for economic stability.

How Does ‘molino para moler maiz’ Benefit Restaurants and Catering Businesses?

Restaurants and catering services leverage the molino para moler maiz to prepare fresh masa on-site, enhancing the authenticity of their menu offerings. This practice not only attracts customers seeking genuine culinary experiences but also allows establishments to control ingredient quality. Key considerations for buyers include the size and weight of the machine, as well as its ease of cleaning and integration into existing kitchen workflows, especially in smaller or high-traffic environments.

How Is ‘molino para moler maiz’ Used in Export and Import?

In the export and import sector, the molino para moler maiz is utilized for milling corn to meet international market standards. This application is crucial for ensuring that the processed agricultural products are of high quality and comply with the regulations of the destination markets. Businesses engaged in this trade must understand the specific compliance requirements and market demands of the regions they are serving, ensuring that their milling equipment can adapt to various standards.

What Is the Importance of ‘molino para moler maiz’ in Artisan Food Production?

Artisan food producers use the molino para moler maiz to create specialty products such as cornmeal or polenta, which can differentiate their offerings in a competitive marketplace. The ability to mill small batches of high-quality ingredients allows these producers to cater to niche markets that value authenticity and craftsmanship. Buyers in this sector should prioritize machine versatility and the availability of after-sales service, ensuring they can maintain operations smoothly while meeting consumer expectations for unique, quality products.

3 Common User Pain Points for ‘molino para moler maiz’ & Their Solutions

Scenario 1: Insufficient Grinding Capacity for High Demand

The Problem: A food production company sourcing a ‘molino para moler maiz’ finds that the grinding capacity of their current equipment is insufficient to meet the increasing demand for corn-based products. With production rates stagnating at 20 kg/hour, they struggle to fulfill orders on time, risking client relationships and potential revenue loss. Additionally, the machines often overheat, leading to frequent downtimes and maintenance costs.

The Solution: To address this challenge, the company should consider upgrading to a high-capacity electric molino designed for industrial use. When sourcing a new molino, they should look for models that offer a production capacity of at least 50 kg/hour, which can ensure they keep up with demand. Additionally, investing in a molino with a robust cooling system will minimize overheating issues. It’s crucial to evaluate suppliers that provide detailed specifications, including motor horsepower and grinding stone quality. Engaging with manufacturers that offer after-sales support can also assist in optimizing the machine’s performance and ensuring timely maintenance, thus enhancing overall productivity.

Scenario 2: Inconsistent Quality of Ground Corn

The Problem: A bakery in South America that specializes in traditional corn products is facing quality control issues with the maize flour produced by their molino. The inconsistency in grind size leads to varying textures in their baked goods, causing customer complaints and affecting brand reputation. The bakery is caught in a cycle of trial and error, trying to adjust settings on their molino without a clear understanding of how to achieve the desired results.

The Solution: To resolve quality inconsistencies, the bakery should invest in a molino that allows for precise adjustments in grind size. Features such as variable speed controls and interchangeable grinding stones can help achieve the desired texture. It is advisable to conduct a series of tests with different maize varieties to identify the optimal settings for each type. Additionally, documenting the grinding process and results will provide valuable data to refine their approach. Collaborating with suppliers who offer training on equipment usage can also empower the bakery’s staff to maximize the molino’s capabilities, ensuring uniform quality in their corn-based products.

Scenario 3: Limited Space for Equipment Installation

The Problem: A small-scale producer in Europe is eager to enter the corn milling market but is constrained by limited kitchen space. They are overwhelmed by the prospect of integrating a bulky molino into their existing setup, which could disrupt workflow and reduce efficiency. The fear of investing in a machine that may not fit their spatial constraints is holding them back from expanding their product line.

The Solution: The producer should explore compact and portable molino options specifically designed for limited spaces. Models like the Molinito, which feature a compact design without sacrificing performance, can be ideal for such scenarios. It is essential to measure available space and compare it with the dimensions of potential machines before making a purchase. Additionally, seeking out suppliers that offer modular or stackable systems can provide flexibility for future expansions. Engaging with other small businesses that have successfully integrated similar equipment can also yield practical insights and solutions, alleviating concerns about operational disruptions.

Strategic Material Selection Guide for molino para moler maiz

What Are the Common Materials Used in ‘molino para moler maiz’?

When selecting a molino para moler maiz, the choice of materials significantly impacts performance, durability, and suitability for specific applications. Here, we analyze four common materials used in these machines: stainless steel, cast iron, aluminum, and high-carbon steel. Each material presents unique properties, advantages, and disadvantages that international B2B buyers should consider.

How Does Stainless Steel Benefit ‘molino para moler maiz’?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. This makes it suitable for environments where moisture is prevalent, such as in food processing.

Pros & Cons: The primary advantages of stainless steel include its durability and ease of cleaning, which is critical in food applications. However, it is more expensive than other materials and can be challenging to machine, increasing manufacturing complexity.

Impact on Application: Stainless steel is particularly compatible with food-grade applications, ensuring that the end product remains uncontaminated. Its resilience to rust and staining makes it ideal for long-term use in humid conditions.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East often require compliance with food safety standards such as FDA or EU regulations. Ensuring that the stainless steel used meets these standards is crucial for market acceptance.

Why Choose Cast Iron for ‘molino para moler maiz’?

Key Properties: Cast iron is known for its excellent wear resistance and ability to absorb vibrations, which can enhance the grinding process’s efficiency.

Pros & Cons: While cast iron is robust and provides a traditional aesthetic, it is prone to rust if not properly maintained. Additionally, it is heavier than other materials, which can complicate shipping and installation.

Impact on Application: Cast iron is suitable for grinding dry grains and can handle high volumes, making it a popular choice for commercial applications. However, it may not be ideal for wet or moist materials due to its susceptibility to corrosion.

Considerations for International Buyers: Buyers from regions with high humidity, such as parts of Africa and South America, should consider the maintenance requirements of cast iron to prevent rust. Compliance with local material standards is also essential.

How Does Aluminum Compare in ‘molino para moler maiz’?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, making it suitable for various applications.

Pros & Cons: The lightweight nature of aluminum makes it easy to transport and install. However, it is less durable than stainless steel or cast iron and may not withstand high-impact applications as effectively.

Impact on Application: Aluminum is ideal for smaller, portable models of molinos, especially for home use. It is not recommended for heavy-duty commercial applications where durability is paramount.

Considerations for International Buyers: Buyers in regions like Saudi Arabia and Vietnam may appreciate aluminum’s lightweight nature for easier handling and transport. However, they should be aware of its limitations in terms of durability and consider local preferences for materials.

What Role Does High-Carbon Steel Play in ‘molino para moler maiz’?

Key Properties: High-carbon steel is known for its hardness and ability to maintain a sharp edge, making it ideal for grinding applications.

Pros & Cons: The primary advantage of high-carbon steel is its exceptional cutting ability, which can enhance the efficiency of the grinding process. However, it is more susceptible to rust and requires regular maintenance to prevent corrosion.

Impact on Application: This material is particularly effective for grinding tough grains and can produce a fine flour. However, its maintenance needs can be a drawback in humid environments.

Considerations for International Buyers: Buyers should be aware of the need for proper care and maintenance of high-carbon steel components, especially in humid climates. Compliance with local standards for food safety and material quality is also critical.

Summary Table of Material Selection

| Material | Typical Use Case for molino para moler maiz | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, commercial use | Corrosion resistance, easy to clean | Higher cost, complex manufacturing | High |

| Cast Iron | Heavy-duty grinding, commercial applications | Excellent wear resistance | Prone to rust, heavy | Medium |

| Aluminum | Portable, home use | Lightweight, corrosion-resistant | Less durable, not suitable for heavy use | Low |

| High-Carbon Steel | Grinding tough grains | Exceptional cutting ability | Requires maintenance, prone to rust | Medium |

This strategic material selection guide provides actionable insights for international B2B buyers to make informed decisions when sourcing molinos para moler maiz, ensuring compatibility with their specific needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for molino para moler maiz

In the competitive landscape of B2B transactions for milling equipment, understanding the manufacturing processes and quality assurance measures for a molino para moler maiz is crucial. This guide aims to provide international buyers, particularly those from Africa, South America, the Middle East, and Europe, with actionable insights into the intricacies of production and quality control in this sector.

What Are the Main Stages in the Manufacturing Process of Molino Para Moler Maiz?

The manufacturing process for a molino para moler maiz typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring that the final product meets the specific requirements of end-users.

-

Material Preparation: The first step involves selecting high-quality raw materials, such as stainless steel for the body and high-durability alloys for grinding components. Suppliers often source these materials based on industry standards to ensure durability and performance. Advanced techniques like laser cutting may be employed to achieve precise dimensions.

-

Forming: This stage includes the shaping of components through processes like stamping and forging. For instance, the grinding plates are often forged to enhance their strength and resilience. The use of CNC (Computer Numerical Control) machines is prevalent to ensure accuracy and repeatability in component production.

-

Assembly: Once the individual parts are formed, they are assembled. This step requires skilled labor to ensure that all components fit together correctly, which is vital for the machine’s operational efficiency. Automated assembly lines may be utilized to streamline this process, reducing labor costs and time.

-

Finishing: The final stage involves surface treatments, such as polishing and coating, to enhance aesthetics and protect against corrosion. Some manufacturers also apply anti-wear coatings to grinding surfaces to extend the lifespan of the equipment.

How Is Quality Assurance Implemented in Molino Manufacturing?

Quality assurance (QA) is integral to the manufacturing of molinos, ensuring that the final products meet both international standards and customer expectations. Various QA practices are employed throughout the production process.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001 standards, which outline requirements for a quality management system. Compliance with these standards is crucial for B2B buyers, as it assures them of consistent quality and reliability in products.

-

Industry-Specific Certifications: Depending on the market, additional certifications such as CE marking for European markets or API standards for specific applications may be necessary. These certifications indicate that the products comply with relevant safety and performance requirements.

-

Quality Control Checkpoints: Manufacturers implement several checkpoints throughout the production process:

– Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Monitoring the manufacturing process to detect any deviations from quality standards early on.

– Final Quality Control (FQC): Conducting thorough inspections and tests on the finished products before they are shipped. This may include performance testing and durability assessments. -

Testing Methods: Common testing methods include tensile strength tests, hardness tests, and operational performance tests to ensure that the molino operates efficiently and safely under expected conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is critical. Here are several strategies to ensure that suppliers maintain high standards:

-

Supplier Audits: Conducting audits of potential suppliers allows buyers to assess their manufacturing processes, quality assurance practices, and adherence to international standards. These audits can be performed on-site or through remote assessments, depending on logistical considerations.

-

Requesting Quality Reports: Buyers should request detailed quality control reports from suppliers, including test results, inspection records, and compliance certifications. This documentation serves as evidence of the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These services can conduct random checks and tests, ensuring that the products meet the required specifications.

-

Understanding Certification Nuances: Buyers should familiarize themselves with the specific certifications relevant to their markets. For instance, while CE marking may be essential for European buyers, other certifications may hold more significance in regions like Africa or the Middle East. Understanding these nuances can help buyers make informed decisions.

What Are the Common Challenges in Quality Assurance for International Buyers?

B2B buyers face several challenges when it comes to quality assurance in the molino manufacturing industry. These include:

-

Regulatory Variability: Different regions have varying regulations and standards, making it essential for buyers to understand the specific requirements applicable to their markets.

-

Communication Barriers: Language differences and cultural nuances can hinder effective communication between buyers and suppliers, potentially leading to misunderstandings regarding quality expectations.

-

Logistical Issues: International shipping can introduce complexities, such as delays and damages, which may affect product quality upon arrival. Buyers should consider insurance and reliable logistics partners to mitigate these risks.

-

Supplier Reliability: Ensuring that suppliers consistently meet quality standards can be challenging, particularly when dealing with new or unverified suppliers. Establishing long-term relationships and regular evaluations can help mitigate this risk.

Conclusion

Understanding the manufacturing processes and quality assurance measures for molinos para moler maiz is essential for international B2B buyers. By familiarizing themselves with these aspects, buyers can make informed decisions, ensuring that they procure equipment that meets their operational needs while adhering to the highest quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘molino para moler maiz’

When sourcing a molino para moler maiz, it is essential to approach the process methodically to ensure you select a machine that meets your operational needs and quality standards. This checklist will guide you through the critical steps to make an informed procurement decision.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications your molino must meet. Consider factors such as:

– Capacity: Determine the volume of maize you need to process (e.g., pounds per hour).

– Power Requirements: Assess the voltage and horsepower needed to ensure compatibility with your local electricity supply.

– Material: Look for durable materials, such as stainless steel, which ensure longevity and sanitation.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers to gauge their reputation and reliability. Check for:

– Online Reviews: Read customer feedback and testimonials to understand the performance and reliability of their machines.

– Market Presence: A well-established supplier is often more reliable, especially in international markets.

– Certifications: Ensure suppliers have relevant industry certifications, which can indicate compliance with safety and quality standards.

Step 3: Evaluate Supplier Credentials

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request:

– Company Profiles: This should include information about their manufacturing processes and quality control measures.

– Case Studies: Look for examples of similar businesses that have successfully used their products.

– References: Ask for references from buyers in similar industries or regions to gain insights into their experiences.

Step 4: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations. Ensure the quotations include:

– Pricing Breakdown: Understand what factors contribute to the total cost, including shipping and any additional fees.

– Warranty Information: Check what warranties are offered on the machines, as this can protect your investment.

– Lead Times: Clarify delivery timelines to ensure they align with your operational schedule.

Step 5: Assess After-Sales Support

Strong after-sales support can be a game-changer in ensuring machine longevity and efficiency. Look for:

– Technical Support: Verify if they provide technical assistance and how easily accessible it is.

– Spare Parts Availability: Ensure that spare parts are readily available to minimize downtime in case of repairs.

– Training Services: Check if they offer training on machine operation and maintenance, which can enhance your team’s efficiency.

Step 6: Conduct a Site Visit (If Possible)

If feasible, visit the supplier’s facility to observe their operations firsthand. This allows you to:

– Inspect Equipment: Evaluate the quality of machinery and manufacturing processes.

– Meet the Team: Establish rapport with the supplier and discuss any concerns directly.

– Understand Logistics: Gain insights into their shipping processes and timelines.

Step 7: Finalize the Purchase Agreement

Once you’ve selected a supplier, finalize the purchase agreement. Ensure that it includes:

– Terms of Payment: Agree on payment methods and schedules.

– Delivery and Installation: Confirm who is responsible for delivery and whether installation services are included.

– Return Policy: Understand the return policy in case the product does not meet your expectations.

By following this checklist, you can confidently source a molino para moler maiz that aligns with your operational needs and business goals, ensuring a successful procurement process.

Comprehensive Cost and Pricing Analysis for molino para moler maiz Sourcing

What Are the Key Cost Components for Sourcing a Molino Para Moler Maiz?

When sourcing a molino para moler maiz, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. High-quality stainless steel, for example, is more expensive than lower-grade metals but offers durability and performance benefits. The composition of components like the grinding stones and motor also plays a role.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Countries with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality. It’s essential to evaluate the skill level of the workforce involved in production.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturers often have lower overhead costs, which can lead to more competitive pricing for buyers.

-

Tooling: The initial investment in tooling and equipment required to produce the molino can significantly affect pricing. Custom designs or specialized machinery can increase the tooling costs, which may be reflected in the final product price.

-

Quality Control (QC): Rigorous quality assurance processes ensure that the product meets the required standards. While this may increase upfront costs, it can save buyers from future expenses related to product failures or recalls.

-

Logistics: Shipping and handling costs can vary widely based on the destination, shipping method, and volume. Understanding these factors is critical for international buyers who may face additional import duties and tariffs.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on the supplier’s positioning in the market and their perceived value of the product.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence the pricing of molinos para moler maiz:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Negotiating for bulk purchases can be advantageous, especially for businesses that require multiple units.

-

Specifications and Customization: Custom features or specifications can raise the price. Buyers should assess whether these enhancements justify the additional costs.

-

Materials and Quality Certifications: Products made from premium materials or those certified for quality assurance (such as ISO or CE certifications) may command higher prices but can offer better performance and longevity.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their track record of quality and service, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The terms of delivery agreed upon between the buyer and supplier (such as FOB or CIF) can influence the overall costs. Buyers should be clear on who bears the costs and risks at each stage of the shipping process.

What Buyer Tips Can Help in Negotiating Costs?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Terms: Always negotiate pricing and terms. Suppliers may have flexibility, especially for bulk orders or repeat business. Building a strong relationship can also yield better pricing over time.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational costs, and potential downtime when evaluating the overall investment in a molino.

-

Understand Pricing Nuances: Be aware of regional pricing differences and how local economic conditions can impact costs. For instance, currency fluctuations can affect international purchases.

-

Evaluate Logistics Costs: Factor in shipping and customs duties when comparing prices from different suppliers. Sometimes, a lower initial price can lead to higher overall costs due to poor logistics planning.

Disclaimer on Indicative Prices

Prices for molinos para moler maiz can vary significantly based on the factors mentioned above. The prices referenced in various sources may serve as a starting point, but buyers should conduct thorough market research and supplier evaluations to obtain accurate quotes tailored to their specific needs.

Alternatives Analysis: Comparing molino para moler maiz With Other Solutions

Exploring Alternatives to Molino Para Moler Maiz

In the quest for efficient grain processing, businesses often seek alternatives to traditional mills like the molino para moler maiz. Understanding the comparative advantages and limitations of different solutions can aid in making informed purchasing decisions. Below, we explore two viable alternatives to the molino: stone mills and industrial hammer mills.

| Comparison Aspect | Molino Para Moler Maiz | Stone Mill | Industrial Hammer Mill |

|---|---|---|---|

| Performance | 45-50 lbs/hr | 30-40 lbs/hr | 500-1,000 lbs/hr |

| Cost | $3,995 – $9,279 | $1,500 – $3,000 | $10,000 – $50,000 |

| Ease of Implementation | Moderate (requires setup) | Easy (minimal installation) | Complex (needs professional setup) |

| Maintenance | Low (occasional cleaning) | Moderate (stone wear) | High (frequent parts replacement) |

| Best Use Case | Small to medium-scale production of masa and flour | Artisanal and specialty grain milling | Large-scale grain processing for industrial applications |

What Are the Pros and Cons of Stone Mills?

Stone mills provide a traditional approach to grain milling, often preferred for their ability to produce high-quality flour with retained nutrients. They are generally easier to operate and require minimal setup, making them suitable for small-scale operations or artisanal producers. However, they typically have a lower throughput compared to industrial mills, making them less ideal for large-scale production. Additionally, the stones may wear down over time, necessitating occasional replacement, which can increase operational costs.

How Do Industrial Hammer Mills Compare?

Industrial hammer mills are designed for high-capacity grain processing, boasting the ability to produce large quantities of flour quickly. These mills can handle a wide range of grain types and are particularly effective for operations requiring consistent particle size. However, their complexity in setup and maintenance can be a drawback for smaller businesses. The upfront investment is significant, making them more suitable for enterprises with high-volume milling needs. Frequent parts replacement and maintenance can also lead to increased operational costs.

Conclusion: Which Milling Solution Should B2B Buyers Choose?

When selecting the right milling solution, B2B buyers must consider their specific operational needs and constraints. For small to medium-sized businesses focused on quality and artisanal production, the molino para moler maiz or stone mills may be the best fit. Conversely, large-scale operations requiring high throughput and efficiency might find industrial hammer mills more suitable. Conducting a thorough analysis of production capacity, budget, and maintenance capabilities will ultimately guide buyers toward the most effective milling solution for their needs.

Essential Technical Properties and Trade Terminology for molino para moler maiz

What Are the Key Technical Properties of a Molino Para Moler Maiz?

Understanding the essential technical properties of a molino para moler maiz is crucial for B2B buyers, particularly those looking to invest in high-quality milling equipment. Here are several critical specifications to consider:

-

Material Grade

The construction material significantly impacts the durability and performance of the molino. Common materials include stainless steel (e.g., 304 grade) and cast iron. Stainless steel is preferred for its resistance to corrosion and ease of cleaning, making it ideal for food processing applications. In contrast, cast iron offers robustness and longevity but may require more maintenance. Buyers should evaluate their operational environment and choose materials that align with their hygiene and durability requirements. -

Motor Power

The motor power, typically measured in horsepower (HP), determines the machine’s capacity to handle different types of grains. For example, a 1 HP motor can produce between 45-50 lbs/hr of ground maize, making it suitable for small to medium-scale operations. Understanding the motor specifications helps buyers assess whether the molino can meet their production needs without overheating or underperforming. -

Production Capacity

This specification refers to the amount of grain a molino can process within a given timeframe, often expressed in pounds per hour (lbs/hr). A higher production capacity is essential for businesses aiming to meet large-scale demand efficiently. Buyers should consider their operational scale and choose a molino that can deliver the required output without compromising on quality. -

Dimensions and Weight

The physical dimensions and weight of the molino affect its placement and mobility within the workspace. A compact design, like that of the Molinito, is advantageous for limited kitchen spaces, while larger models may be better suited for industrial settings. Buyers should assess their operational layout to ensure the molino fits seamlessly into their production line. -

Voltage Compatibility

Different regions have varying electrical standards, typically measured in volts (e.g., 110-127V or 220V). Ensuring that the molino is compatible with local voltage requirements is critical to avoid operational disruptions. Buyers should confirm the voltage specifications to ensure compatibility with their existing electrical infrastructure. -

Grinding Mechanism

The grinding mechanism, which can include stone or metal grinding discs, plays a vital role in the quality of the final product. Stone grinding is known for producing finer flour and maintaining the grain’s natural flavors, while metal discs may offer faster processing times. Buyers should consider the intended use of the ground maize to select the appropriate grinding mechanism.

What Common Trade Terms Should B2B Buyers Know When Purchasing a Molino?

Familiarizing oneself with industry-specific terminology can help streamline the procurement process. Here are some key terms relevant to the purchase of a molino para moler maiz:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers ensure they are purchasing high-quality, reliable equipment that meets industry standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to plan their budgets and inventory effectively, especially when sourcing from international suppliers. -

RFQ (Request for Quotation)

An RFQ is a formal document that a buyer sends to suppliers to request pricing and terms for specific products. This process is crucial for comparing offers and negotiating the best deals, ensuring transparency and competitiveness in pricing. -

Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and rights in the procurement process. -

Lead Time

Lead time refers to the time taken from placing an order until it is delivered. Understanding lead times is vital for planning production schedules and managing supply chain expectations, especially for international shipments. -

Warranty and After-Sales Service

Warranty terms specify the duration and conditions under which a product is guaranteed against defects. Additionally, after-sales service includes support provided post-purchase, such as maintenance and repairs. Knowing these details can influence a buyer’s decision, ensuring long-term satisfaction and operational efficiency.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing a molino para moler maiz, ensuring that they select the best equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the molino para moler maiz Sector

What Are the Key Market Dynamics and Trends in the Molino Para Moler Maiz Sector?

The global market for molino para moler maiz is witnessing significant growth driven by increasing consumer demand for fresh, high-quality maize products. This trend is particularly prominent in regions such as Africa, South America, the Middle East, and Europe, where traditional maize-based dishes are staples. Innovations in milling technology are emerging, with electric and portable models gaining traction among small-scale producers and home chefs alike. Features such as stainless steel components for durability, energy efficiency, and ease of use are becoming critical factors for buyers.

Furthermore, the rise of e-commerce platforms has transformed sourcing dynamics, allowing international buyers to access a broader range of products and suppliers. Buyers can easily compare specifications, prices, and reviews, leading to informed purchasing decisions. Additionally, the integration of IoT (Internet of Things) technologies in milling equipment is on the horizon, promising improved efficiency and automation in production processes.

How Is Sustainability and Ethical Sourcing Shaping the Molino Para Moler Maiz Sector?

Sustainability is becoming a pivotal concern for B2B buyers in the molino para moler maiz sector. The environmental impact of manufacturing processes and the sourcing of raw materials are under scrutiny. Ethical supply chains are essential, as buyers increasingly prefer suppliers that demonstrate commitment to sustainable practices. This includes using renewable energy in production, minimizing waste, and ensuring fair labor practices.

Moreover, certification programs for environmentally friendly materials are gaining popularity. Suppliers who can offer green certifications or utilize recyclable materials in their products are likely to have a competitive edge in the marketplace. For instance, manufacturers who produce mills from recycled steel or use eco-friendly packaging can attract environmentally conscious buyers. This shift toward sustainability not only enhances brand reputation but also aligns with the global push for more responsible consumption patterns.

What Is the Evolution of the Molino Para Moler Maiz Industry and Its Relevance Today?

Historically, the molino para moler maiz has roots in traditional agrarian societies where manual stone mills were used for grinding maize. As technology evolved, so did the mills, leading to the development of electric models that significantly increased efficiency and production capacity. The introduction of stainless steel and advanced motor systems has further enhanced the functionality and longevity of these machines.

Today, the market is characterized by a blend of traditional craftsmanship and modern technology, catering to both artisanal producers and industrial-scale operations. The evolution of this sector reflects broader changes in consumer preferences, with an increasing emphasis on quality and sustainability. Understanding this historical context helps B2B buyers appreciate the value of investing in advanced milling solutions that can meet contemporary demands while honoring traditional practices.

In conclusion, international buyers looking to source molino para moler maiz should consider the interplay of market dynamics, sustainability, and historical evolution to make informed purchasing decisions that align with their operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of molino para moler maiz

-

How do I choose the right molino para moler maiz for my business needs?

Selecting the ideal molino para moler maiz involves assessing your specific production requirements, such as the volume of corn to be processed and the desired fineness of the flour. Consider factors like the machine’s motor power, capacity (measured in lbs/hr), and whether it can handle both wet and dry milling. Additionally, evaluate durability, ease of cleaning, and maintenance needs. For international buyers, also check if the equipment meets local electrical standards and if the supplier provides adequate support and warranty. -

What is the best molino para moler maiz for small-scale operations?

For small-scale operations, consider a compact, electric molino like the Molinito, which is designed for both home and professional use. It features stainless steel construction, a 1 HP motor, and a production capacity of 45-50 lbs/hr. This type of machine is versatile, capable of milling not just corn but also grains and spices. Ensure it fits your workspace and meets your output requirements while being energy-efficient. -

What are the common payment terms for purchasing molinos internationally?

Payment terms can vary significantly by supplier and region. Common options include full payment in advance, 30% deposit with the balance due prior to shipping, or letters of credit. It’s crucial to negotiate terms that ensure security for both parties. Always confirm the payment methods accepted by the supplier, such as bank transfers, PayPal, or escrow services, to facilitate a smooth transaction. -

How can I verify the reliability of a molino supplier?

To ensure a supplier is reliable, conduct thorough research that includes checking their business credentials, customer reviews, and references from previous clients. Request detailed product specifications and certifications, particularly for international compliance. Engaging with them directly through inquiries can also provide insight into their responsiveness and customer service. Consider visiting their facility if possible or using third-party verification services. -

What is the minimum order quantity (MOQ) for molinos para moler maiz?

The MOQ for molinos can vary widely depending on the manufacturer and the specific model. Some suppliers may allow single-unit purchases, especially for smaller machines, while others might set a higher MOQ for bulk orders to ensure cost-effectiveness. Always clarify this with the supplier before proceeding, as it can affect your budgeting and inventory planning. -

How do I handle logistics for importing molinos para moler maiz?

Logistics involves several key steps, including selecting a reliable freight forwarder experienced in handling agricultural machinery. You’ll need to consider shipping methods (air vs. sea), customs clearance, and import duties specific to your country. Ensure the supplier provides the necessary documentation, such as invoices and packing lists, to facilitate the import process. Planning for potential delays in shipping is also advisable, especially for large or heavy equipment. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers of molinos should offer quality assurance measures, including product testing before shipment, adherence to international standards (like ISO certification), and warranties on their equipment. Request information on their manufacturing processes and materials used. It’s also beneficial to inquire about after-sales support and maintenance services to ensure long-term operational efficiency. -

Can I customize my molino para moler maiz for specific requirements?

Many suppliers offer customization options for molinos to meet specific business needs, such as modifications for different grain types or adjustments in motor size and capacity. When discussing customization, communicate your requirements clearly and ask about lead times and additional costs involved. This ensures that the machine will perform optimally for your intended applications, whether for commercial milling or artisanal production.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Molino Para Moler Maiz Manufacturers & Suppliers List

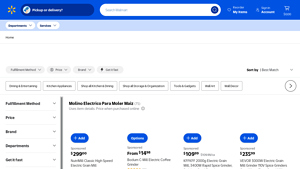

1. Walmart – Molino Electrico Para Moler Maiz

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – Molino Electrico Para Moler Maiz, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Masienda – Molinito Molino de Maíz

Domain: masienda.com

Registered: 2013 (12 years)

Introduction: Molinito Molino de Maíz | Molino Eléctrico de Sobremesa para Moler Maíz

– Materiales de superficie: Acero inoxidable 304

– Motor: 1 HP, 110-127 Voltios

– Piedras: 5″ (Dos juegos incluidos, 8lbs. por par)

– Capacidad de producción: 45-50 lbs/hr

– Peso del Molinito: 92 lbs

– Peso de envío: 143 lbs (se envía en un palé)

– Dimensiones de la unidad Molinito: 26.5″ (l) x 14.5″ (w) x 18″ (h)

– Descuento…

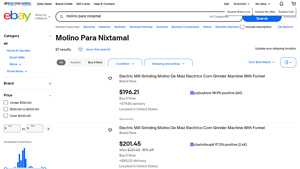

3. Electric Corn Grinder – Molino Para Nixtamal

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Molino Para Nixtamal listings include various electric corn grinder machines with prices ranging from $61.99 to $369.99. Most products are brand new and offer free delivery within the United States. Some listings include features like funnels for easy grain processing and have received positive ratings. Specific models mentioned include ‘Electric Mill Grinding Molino De Maiz Electrico’ and ‘Mexica…

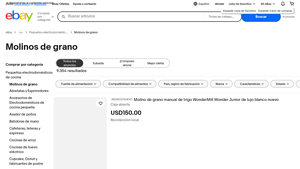

4. Back to Basics – 555 Hand Grain Mill

Domain: ar.ebay.com

Registered: 1995 (30 years)

Introduction: Molinos de grano disponibles en eBay incluyen: 1. Back to Basics 555 Hand Grain Mill – Silver, Precio: USD39.99 (Nuevos), USD29.88 (Usados) 2. WonderMill Wonder Junior Deluxe Manual Wheat Flour Hand Grain Mill, Precio: USD269.95 (Nuevos) 3. Victorio VKP1012 Grain Mill – Black, Precio: USD107.92 (Nuevos), USD90.00 (Usados) 4. KitchenAid KGM All Metal Grain Mill Attachment – Silver, Precio: USD152.9…

5. Swissmex – Molinos Agrícolas Turbo

Domain: swissmex.com

Registered: 2001 (24 years)

Introduction: Molinos Para Granos y Forraje:

– 610115 Molino Agrícola de Levante Turbo Industrial

– 610120 Molino Agrícola TURBO de Levante con Patas

– 610130 Molino Agrícola TURBO de Levante sin Patas

– 610400 Molino Agrícola Turbo de Tirón para Rastrojo

6. Hogar Universal – Molino para Maíz

Domain: hogaruniversal.com

Registered: 2014 (11 years)

Introduction: Molino para moler maíz, ideal para preparar tortillas y arepas frescas. Promueve la tradición y el sabor auténtico en la cocina. Envíos gratis desde $279.900. Crédito 100% en línea.

Strategic Sourcing Conclusion and Outlook for molino para moler maiz

In conclusion, the strategic sourcing of molinos para moler maiz presents a significant opportunity for international B2B buyers to enhance their operational efficiency and product offerings. As we’ve explored, these machines are not only integral to food production but also reflect a growing trend towards sustainability and quality in the sourcing of raw materials. Buyers from regions like Africa, South America, the Middle East, and Europe should prioritize suppliers that offer robust, efficient, and versatile milling solutions, such as those featuring stainless steel construction and high-capacity output.

Additionally, understanding the diverse specifications and capabilities of various models—ranging from compact, electric grinders for smaller operations to larger industrial mills—can inform purchasing decisions that align with specific business needs. As the demand for high-quality maize products continues to rise, investing in the right molino is vital for maintaining competitiveness and meeting customer expectations.

Looking ahead, we encourage B2B buyers to actively engage with suppliers, explore new technologies, and consider the evolving market dynamics. By adopting a strategic sourcing approach, businesses can secure not only the best equipment but also foster long-term partnerships that drive growth and innovation in the milling industry.