Bubble Hash Machine Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for bubble hash machine

In the evolving landscape of cannabis extraction, sourcing an efficient bubble hash machine presents a crucial challenge for international B2B buyers. As businesses seek to capitalize on the burgeoning demand for high-quality cannabis concentrates, understanding the nuances of these machines becomes essential. This guide serves as a comprehensive resource, detailing various types of bubble hash machines, their applications, and critical factors to consider when vetting suppliers. From assessing production capacity to evaluating cost-effectiveness, we provide actionable insights tailored for buyers in Africa, South America, the Middle East, and Europe, including regions like Nigeria and Vietnam.

Navigating the global market for bubble hash machines requires a strategic approach, particularly in identifying reliable manufacturers and understanding the regulatory environment unique to each region. This guide empowers buyers to make informed purchasing decisions by highlighting best practices for supplier evaluation, essential features to look for, and the importance of quality control in the extraction process. With this knowledge, businesses can ensure they invest in equipment that not only meets their operational needs but also adheres to local standards. By leveraging the information in this guide, B2B buyers can enhance their production capabilities and stay competitive in the fast-growing cannabis market.

Understanding bubble hash machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Small-Scale Bubble Hash Machines | Compact design, typically 5-10 gallons, manual or semi-automated | Small dispensaries, home producers | Pros: Affordable, easy to use. Cons: Limited capacity, less efficiency for large batches. |

| Commercial Bubble Hash Machines | Larger capacity (20+ gallons), fully automated | Large-scale cannabis producers, extraction labs | Pros: High efficiency, consistent quality. Cons: Higher initial investment, requires more space. |

| Hybrid Bubble Hash Machines | Combination of manual and automated features, adjustable settings | Versatile producers, both small and large operations | Pros: Flexibility in operation, suitable for various batch sizes. Cons: More complex to operate. |

| Portable Bubble Hash Machines | Lightweight, compact, designed for mobility | Mobile extraction services, events, and pop-ups | Pros: Easy to transport, ideal for on-the-go production. Cons: Smaller capacity, may lack advanced features. |

| High-Tech Bubble Hash Machines | Integrated technology for monitoring and control | Research facilities, high-end production facilities | Pros: Precision control, data tracking capabilities. Cons: Requires technical knowledge, expensive. |

What Are the Characteristics of Small-Scale Bubble Hash Machines?

Small-scale bubble hash machines are ideal for individuals or small dispensaries looking to produce bubble hash without a significant investment. These machines typically range from 5 to 10 gallons in capacity and can be manual or semi-automated. They are well-suited for small batch production, allowing users to experiment with different strains and techniques. When considering a purchase, buyers should assess the machine’s ease of use and maintenance requirements, as well as the availability of customer support.

How Do Commercial Bubble Hash Machines Operate?

Commercial bubble hash machines are designed for large-scale production, capable of processing 20 gallons or more of plant material per batch. These fully automated machines ensure consistent agitation and temperature control, resulting in high-quality hash efficiently. They are primarily used by large cannabis producers and extraction labs that require high output. Buyers should consider the machine’s capacity, efficiency, and the technical support provided, as well as the initial investment required for a commercial setup.

What Benefits Do Hybrid Bubble Hash Machines Offer?

Hybrid bubble hash machines combine both manual and automated features, providing versatility for producers of varying scales. They allow operators to adjust settings based on the specific needs of each batch, making them suitable for both small and larger operations. This flexibility can enhance production quality and efficiency. When purchasing, buyers should evaluate how the machine balances automation with user control, ensuring it fits their operational workflow.

Why Choose Portable Bubble Hash Machines?

Portable bubble hash machines are designed for mobility, making them ideal for mobile extraction services, events, or pop-up operations. These compact units are lightweight and easy to transport, allowing producers to create bubble hash on-site. However, they typically have smaller capacities and may lack some advanced features found in larger models. Buyers should weigh the convenience of portability against the limitations in capacity and functionality when considering a purchase.

What Are the Advantages of High-Tech Bubble Hash Machines?

High-tech bubble hash machines incorporate advanced technology for monitoring and control, making them suitable for research facilities and high-end production environments. These machines often feature data tracking capabilities and precise control systems that enhance the extraction process. While they provide superior quality and efficiency, buyers should be prepared for a steeper learning curve and higher costs. It’s essential to assess the technical knowledge required for operation and the potential return on investment.

Key Industrial Applications of bubble hash machine

| Industry/Sector | Specific Application of bubble hash machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Cannabis Cultivation | Production of high-quality bubble hash | Enhances product value and market competitiveness | Ensure machine capacity aligns with production scale; consider local regulations on cannabis processing. |

| Food and Beverage | Incorporation of bubble hash in edibles | Expands product offerings with premium cannabis-infused items | Look for machines that maintain food safety standards; assess ease of cleaning and maintenance. |

| Pharmaceutical | Research and development of cannabinoid-based therapies | Facilitates extraction of pure cannabinoids for clinical applications | Source machines that comply with pharmaceutical regulations; prioritize equipment durability and reliability. |

| Retail and Distribution | Retail of bubble hash products | Attracts a niche market of consumers seeking quality concentrates | Consider machines that produce consistent quality; evaluate support and warranty options for equipment. |

| Cosmetic Industry | Development of cannabis-infused skincare products | Leverages the therapeutic benefits of cannabinoids in cosmetics | Ensure machines are capable of producing high-purity extracts; assess compatibility with cosmetic formulations. |

How is a bubble hash machine used in cannabis cultivation, and what problems does it solve?

In the cannabis cultivation sector, bubble hash machines are employed to efficiently produce high-quality bubble hash from harvested plant material. These machines automate the ice water extraction process, which traditionally required manual labor and could lead to inconsistent results. By using a bubble hash machine, cultivators can ensure a uniform extraction, significantly improving the quality of the final product. Buyers in regions like Africa and South America should consider the machine’s capacity and local regulations regarding cannabis production to ensure compliance and optimal use.

What role does a bubble hash machine play in the food and beverage industry?

In the food and beverage industry, bubble hash machines are utilized to produce cannabis-infused edibles. This application allows manufacturers to create premium products that cater to the growing market for cannabis edibles. The machines solve issues related to the manual extraction process, which can be time-consuming and less hygienic. When sourcing equipment, businesses should prioritize machines that adhere to food safety standards and are easy to clean, especially in regions with stringent health regulations.

How can pharmaceutical companies benefit from using bubble hash machines?

Pharmaceutical companies leverage bubble hash machines for the extraction of pure cannabinoids, which are crucial for developing cannabinoid-based therapies. These machines streamline the extraction process, ensuring high purity and consistency, which are essential for clinical applications. Buyers in the pharmaceutical sector must consider machines that comply with industry regulations and prioritize durability and reliability to support ongoing research and development efforts.

In what ways can retailers and distributors utilize bubble hash machines?

Retailers and distributors use bubble hash machines to produce and sell high-quality bubble hash products. This not only attracts a niche market but also enhances brand reputation through the provision of premium offerings. The machines provide a solution to the challenges of maintaining consistent quality in hash production. When sourcing equipment, businesses should evaluate the machine’s ability to produce uniform results and consider warranty options and customer support to safeguard their investment.

How does the cosmetic industry integrate bubble hash machines in product development?

The cosmetic industry integrates bubble hash machines to create cannabis-infused skincare products, leveraging the therapeutic benefits of cannabinoids. These machines ensure the extraction of high-purity bubble hash, which is essential for formulating effective cosmetic products. Buyers in this sector should ensure that the machines can produce extracts that meet cosmetic formulation requirements and assess their compatibility with various ingredients to maintain product integrity.

3 Common User Pain Points for ‘bubble hash machine’ & Their Solutions

Scenario 1: Challenges with Consistency in Bubble Hash Production

The Problem: Many B2B buyers, particularly those operating at a commercial scale, face difficulties in achieving consistency when producing bubble hash. Variability in agitation speed, temperature control, and the quality of raw materials can lead to inconsistent product outcomes. This inconsistency not only affects product quality but can also harm brand reputation and customer satisfaction, as consumers expect a reliable product.

The Solution: To address this challenge, buyers should invest in high-quality bubble hash machines equipped with advanced features such as variable speed settings, integrated timers, and temperature control systems. When sourcing a machine, it’s essential to prioritize models that offer precise agitation control and consistent water temperature, as these factors significantly influence the extraction process. Additionally, training staff on optimal operational practices can enhance consistency. Implementing a standardized process for material preparation and machine operation will further minimize variability and ensure uniform product quality across batches.

Scenario 2: High Operational Costs and Resource Waste

The Problem: Another common pain point for B2B buyers is the high operational costs associated with bubble hash production. This includes expenses for water, energy, and labor, which can accumulate quickly, especially for larger operations. Furthermore, inefficient use of resources can lead to significant waste, affecting overall profitability.

The Solution: Buyers can mitigate these costs by selecting bubble hash machines that feature water recycling systems and energy-efficient designs. For instance, investing in a machine like The Nest, which allows for multiple washes using the same water, can drastically reduce water consumption and costs. Additionally, incorporating a comprehensive operational strategy that includes scheduled maintenance and staff training on efficient use can optimize resource utilization. This not only minimizes waste but also ensures that the production process remains cost-effective and sustainable in the long run.

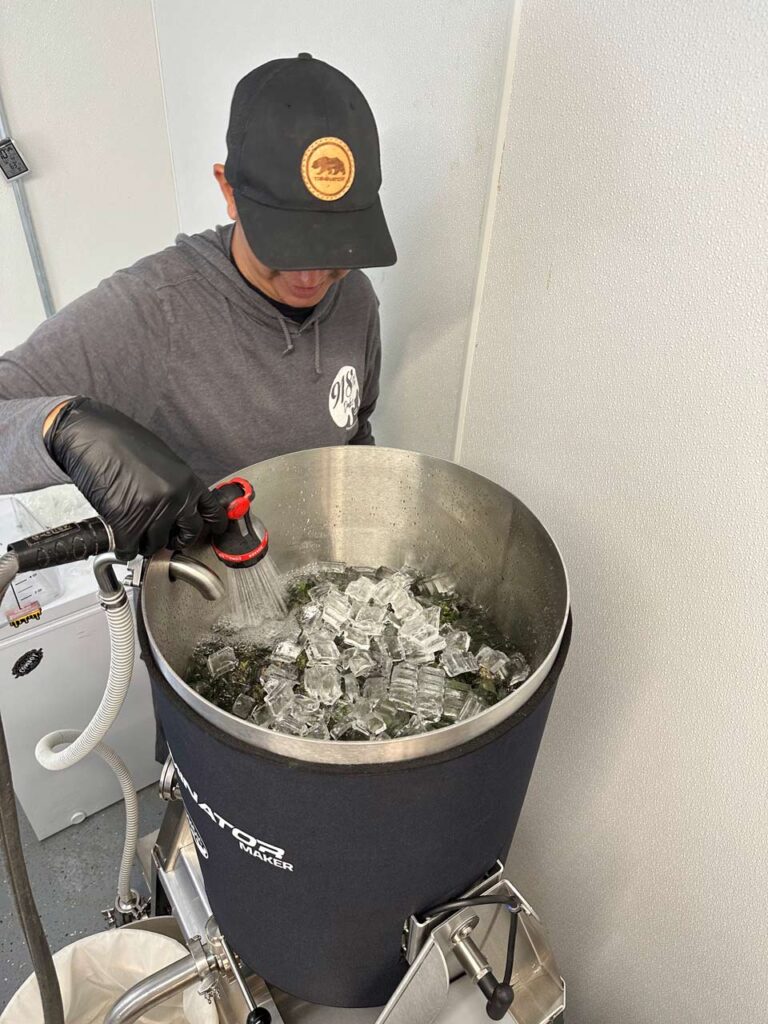

Illustrative image related to bubble hash machine

Scenario 3: Difficulty in Scaling Production

The Problem: As businesses grow, many B2B buyers encounter difficulties in scaling their bubble hash production to meet increasing demand. Limited capacity of existing equipment can hinder expansion efforts, leading to missed opportunities and reduced market competitiveness. Buyers may find themselves in a position where they need to invest in additional machinery but are unsure of the right specifications to accommodate future growth.

The Solution: To effectively scale production, buyers should choose bubble hash machines that are designed for modular scalability. Selecting a model with a larger capacity, such as a 20-gallon machine, provides the flexibility needed to increase production without requiring a complete overhaul of the existing system. Additionally, buyers should consider machines that offer upgrade options or compatibility with supplementary equipment, such as recirculation tanks, to enhance efficiency. Engaging with suppliers who understand the nuances of the cannabis market can also provide valuable insights into future trends and help buyers make informed decisions about their scaling strategies.

Strategic Material Selection Guide for bubble hash machine

What Materials Are Commonly Used in Bubble Hash Machines?

When selecting materials for bubble hash machines, it’s essential to consider their properties and how they impact the machine’s performance and the quality of the final product. Here, we analyze four common materials used in the construction of these machines: stainless steel, food-grade plastics, aluminum, and glass. Each material has distinct advantages and disadvantages that can influence the decision-making process for international B2B buyers.

How Does Stainless Steel Perform in Bubble Hash Machines?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. This material can handle the cold temperatures required during the bubble hash extraction process without compromising structural integrity.

Pros & Cons: The durability of stainless steel makes it a preferred choice for commercial applications, as it can withstand heavy usage and is easy to clean. However, the initial cost is relatively high compared to other materials, which can be a consideration for budget-conscious buyers.

Impact on Application: Stainless steel’s non-reactive nature ensures that there are no contaminants introduced into the bubble hash, preserving the quality of the final product.

Considerations for International Buyers: Compliance with food safety standards, such as those set by the FDA or EU regulations, is crucial. Buyers from regions like Africa and South America should verify that the stainless steel used meets local health regulations.

What Role Does Food-Grade Plastic Play?

Key Properties: Food-grade plastics are lightweight and resistant to moisture and chemicals, making them suitable for the wet environment of bubble hash production.

Pros & Cons: These plastics are generally more affordable and easier to manufacture than metals, which can lower the overall cost of the machine. However, they may not offer the same level of durability and can be prone to wear and tear over time.

Impact on Application: While suitable for small-scale operations, food-grade plastics may not withstand the rigors of high-volume production, potentially affecting the consistency of the bubble hash.

Considerations for International Buyers: Buyers should ensure that the plastics used are compliant with local food safety regulations. In regions like the Middle East and Europe, adherence to standards such as ASTM or DIN is essential.

How Does Aluminum Compare?

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can withstand low temperatures, making it a viable option for bubble hash machines.

Pros & Cons: Its lower cost compared to stainless steel makes it an attractive option for budget-conscious buyers. However, aluminum may not be as durable under heavy use, leading to potential issues with longevity.

Impact on Application: Aluminum can effectively handle the extraction process, but its potential for scratching can lead to contamination if not properly maintained.

Considerations for International Buyers: Buyers should check for compliance with relevant international standards, as well as the machine’s ability to maintain quality during the extraction process.

What Advantages Does Glass Offer?

Key Properties: Glass is non-reactive and offers excellent visibility, allowing operators to monitor the extraction process easily.

Pros & Cons: While glass is ideal for ensuring purity, it is fragile and can be prone to breakage, which can lead to increased maintenance costs. Additionally, glass components can significantly increase the overall weight of the machine.

Impact on Application: Glass components can enhance the aesthetic appeal and functionality of the machine, but they may not be suitable for high-volume operations due to their fragility.

Considerations for International Buyers: Ensuring that glass components meet safety standards is crucial, especially in regions where operational safety regulations are stringent.

Illustrative image related to bubble hash machine

Summary Table of Material Selection for Bubble Hash Machines

| Material | Typical Use Case for bubble hash machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Commercial-scale machines | Excellent durability and corrosion resistance | High initial cost | High |

| Food-Grade Plastic | Small-scale or home use | Affordable and lightweight | Less durable, prone to wear | Low |

| Aluminum | Mid-scale operations | Cost-effective and lightweight | Less durable compared to stainless steel | Medium |

| Glass | Monitoring and aesthetic components | Non-reactive and allows visibility | Fragile and prone to breakage | Medium |

This strategic material selection guide provides valuable insights for B2B buyers, helping them make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for bubble hash machine

What Are the Main Stages in the Manufacturing Process of Bubble Hash Machines?

The manufacturing process of bubble hash machines involves several key stages that ensure the final product meets both performance and quality standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is material preparation, which involves sourcing high-quality raw materials. For bubble hash machines, this typically includes stainless steel or food-grade plastics that are durable and resistant to corrosion. Manufacturers often partner with reputable suppliers to ensure that the materials meet international quality standards.

Before fabrication, materials undergo a thorough inspection to identify any defects. This initial quality control (IQC) step is crucial, as it helps eliminate subpar materials from the production line, ensuring only the best components are used in the final assembly.

How Are Bubble Hash Machines Formed?

Once materials are prepared, the next step is forming, which involves shaping the components of the bubble hash machine. This process typically employs techniques such as laser cutting, CNC machining, and welding.

Illustrative image related to bubble hash machine

Laser cutting provides precision when creating parts like the drum and housing, while CNC machining is utilized for complex components that require intricate designs. Welding is then employed to assemble various parts, ensuring a robust structure that can withstand the demands of commercial use.

Advanced forming techniques also allow manufacturers to create features such as integrated drainage systems and insulation to maintain optimal temperature during operation.

What Does the Assembly Process Involve?

The assembly stage is where all the prepared and formed components come together. Skilled technicians follow detailed assembly instructions to ensure each machine is built to specification. This stage often includes the installation of electronic components, such as timers and agitators, which are critical for the machine’s functionality.

Illustrative image related to bubble hash machine

During assembly, operators conduct interim quality checks to ensure that all parts fit correctly and function as intended. This in-process quality control (IPQC) step helps identify and rectify issues before the machine moves to the finishing stage.

What Quality Assurance Practices Are Essential for Bubble Hash Machines?

Quality assurance is a vital component of the manufacturing process for bubble hash machines, as it ensures that each unit meets the required standards for safety and performance.

Which International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 are crucial for manufacturers of bubble hash machines. ISO 9001 outlines requirements for a quality management system, emphasizing customer satisfaction and continuous improvement. Compliance with this standard demonstrates a manufacturer’s commitment to quality and reliability.

Additionally, industry-specific certifications like CE marking indicate that the product meets European safety, health, and environmental protection standards. For manufacturers targeting the pharmaceutical market, adherence to API (Active Pharmaceutical Ingredient) standards may be necessary, particularly for machines used in the extraction of cannabis for medicinal purposes.

What Are Common Quality Control Checkpoints?

Quality control for bubble hash machines typically involves several checkpoints throughout the manufacturing process:

Illustrative image related to bubble hash machine

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival at the manufacturing facility.

-

In-Process Quality Control (IPQC): Conducted during the assembly stage, this checkpoint ensures that each component is assembled correctly and functions as intended.

-

Final Quality Control (FQC): Before shipping, the completed machine undergoes a thorough inspection, which includes performance testing to ensure it operates according to specifications.

Common testing methods employed during these checkpoints include functional testing, pressure testing, and safety inspections. These tests help identify any defects that could compromise the machine’s performance.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of potential suppliers is essential to ensure they receive reliable equipment.

What Steps Can Buyers Take to Verify QC?

-

Request Documentation: Buyers should ask for quality assurance documentation, including certificates of compliance with international standards (ISO, CE, etc.) and internal QC protocols.

-

Supplier Audits: Conducting on-site audits can provide insights into the manufacturer’s QC practices. During the audit, buyers can assess the production processes, equipment used, and adherence to safety standards.

-

Third-party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and final product quality. These inspections can help verify that the machines meet specified standards before shipment.

-

Reviews and References: Checking reviews and references from previous clients can also provide valuable insights into the supplier’s reliability and the quality of their products.

What Nuances Should International Buyers Consider Regarding QC?

International buyers need to consider several nuances when it comes to quality control. Variations in regulatory requirements between countries can affect the standards that manufacturers must meet. For example, a machine that meets CE standards in Europe may not necessarily comply with local regulations in African or South American markets.

Buyers should also be aware of the potential for language barriers and cultural differences in business practices. Establishing clear communication regarding quality expectations and standards is crucial for successful transactions.

Conclusion

Understanding the manufacturing processes and quality assurance practices associated with bubble hash machines is essential for B2B buyers looking to invest in this equipment. By familiarizing themselves with the stages of production, relevant international standards, and effective verification methods, buyers can make informed decisions that align with their operational needs and quality expectations. As the market for cannabis concentrates continues to grow, ensuring the reliability and performance of bubble hash machines will be vital for maintaining competitive advantage in the industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bubble hash machine’

Introduction

This sourcing guide aims to equip B2B buyers with a clear, actionable checklist for procuring bubble hash machines. Understanding the nuances of these specialized devices is essential for ensuring optimal quality and efficiency in cannabis concentrate production. Follow these steps to make informed purchasing decisions that align with your operational needs and business goals.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, outline the specific technical requirements for your bubble hash machine. Consider factors such as capacity, automation features, and material construction.

– Capacity: Determine the volume of cannabis you intend to process per batch, as machines range from small personal units to large commercial systems.

– Automation Features: Look for machines with programmable settings for agitation and temperature control to enhance consistency and reduce manual labor.

Illustrative image related to bubble hash machine

Step 2: Research Supplier Reputation

Identifying reputable suppliers is crucial for ensuring reliability and quality. Conduct thorough research on potential vendors by checking customer reviews, industry certifications, and their history in the market.

– Reviews and Testimonials: Seek feedback from existing users to gauge satisfaction levels and the machine’s performance in real-world scenarios.

– Industry Certifications: Verify if suppliers hold relevant certifications that comply with international standards, particularly those applicable in your region.

Step 3: Evaluate Potential Suppliers

Before committing, it’s essential to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Case Studies: Ask for examples of successful implementations and the outcomes achieved by other clients.

– References: Contact previous customers to discuss their experiences, particularly regarding after-sales support and machine reliability.

Step 4: Assess Machine Features and Functionality

When comparing bubble hash machines, pay close attention to their features and functionalities that can impact your production efficiency.

– Built-in Timers and Drain Valves: These features can simplify the extraction process and improve workflow.

– Variable Speed Settings: Adjustable agitation speeds can help optimize the quality of the hash produced, allowing for customization based on the specific cannabis strain used.

Step 5: Consider Maintenance and Support

Factor in the maintenance requirements and the level of support offered by the supplier post-purchase.

– Maintenance Needs: Understand the cleaning and upkeep processes necessary to maintain the machine’s efficiency and lifespan.

– Customer Support: Evaluate the availability of technical support and warranty options. A robust support system can save time and costs in the long run.

Step 6: Request Samples and Demonstrations

Before finalizing your purchase, request product samples or demonstrations to better understand the machine’s capabilities.

– Live Demonstrations: If possible, arrange for a hands-on demonstration to see the machine in action and assess its performance firsthand.

– Sample Outputs: Request samples of bubble hash produced by the machine to evaluate quality and consistency.

Step 7: Negotiate Terms and Finalize Purchase

Once you have selected a supplier, negotiate the terms of sale, including pricing, delivery, and payment options.

– Pricing Flexibility: Discuss volume discounts or package deals if purchasing multiple units or additional equipment.

– Delivery Timeline: Confirm lead times and shipping arrangements to ensure the timely arrival of your equipment.

By following this structured checklist, you can confidently navigate the procurement process for bubble hash machines, ensuring that you choose the right equipment to meet your business needs.

Comprehensive Cost and Pricing Analysis for bubble hash machine Sourcing

What are the Key Cost Components in Bubble Hash Machine Manufacturing?

When analyzing the cost structure for bubble hash machines, several components contribute to the overall pricing. The primary cost elements include:

-

Materials: The choice of materials significantly impacts costs. High-quality stainless steel is often used for durability and ease of cleaning, but it comes at a premium. Plastic components may reduce costs but can affect the machine’s longevity and performance.

-

Labor: Labor costs vary by region and can be a significant factor in manufacturing. Skilled labor is often necessary for assembly and quality control, especially for more complex machines with advanced features.

-

Manufacturing Overhead: This includes costs associated with the production facility, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help in minimizing overhead costs.

-

Tooling: Initial setup costs for tooling and molds can be substantial, particularly for custom or specialized machines. These costs are usually amortized over production runs, impacting pricing.

-

Quality Control (QC): Implementing a robust QC process ensures product reliability and compliance with industry standards, which can increase costs but is essential for maintaining brand reputation.

-

Logistics: Shipping and handling costs, including customs duties and taxes, can add significantly to the final price. These costs are especially relevant for international buyers who may face additional fees.

-

Margin: Suppliers typically apply a markup to cover risks and generate profit. This margin varies depending on market demand, competition, and the supplier’s business strategy.

What Influences Pricing for Bubble Hash Machines?

Several factors can influence the pricing of bubble hash machines:

-

Volume/MOQ: Purchasing in larger volumes often leads to lower per-unit costs. Suppliers may offer discounts for bulk orders, making it beneficial for businesses anticipating high demand.

-

Specifications and Customization: Custom features or specifications, such as capacity or additional functionalities, can increase costs. Standard models typically have lower prices due to economies of scale.

-

Material Quality and Certifications: Machines made from premium materials or those that comply with specific certifications (e.g., food-grade standards) often come at a higher price. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their track record, while newer suppliers might offer competitive pricing to gain market entry.

-

Incoterms: Understanding shipping terms and responsibilities can affect the total landed cost. Different Incoterms dictate who pays for shipping, insurance, and tariffs, influencing the final price.

How Can Buyers Negotiate for Better Prices on Bubble Hash Machines?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant savings:

-

Research and Preparation: Understand the market prices and be prepared with data on competitors’ offerings. This knowledge can empower buyers during negotiations.

-

Flexibility on Specifications: Being open to standard models rather than custom solutions can lead to cost reductions. Suppliers are often more willing to negotiate on standard offerings.

-

Long-Term Relationships: Building a rapport with suppliers can result in better pricing and terms. Suppliers may offer loyalty discounts or priority service to repeat customers.

-

Total Cost of Ownership (TCO): Evaluate the TCO, including maintenance, operational costs, and longevity. A higher upfront investment may yield lower overall costs in the long run.

-

Cultural Sensitivity: Understanding cultural nuances in negotiation styles can enhance communication and foster better relationships with suppliers from different regions.

What are the Pricing Nuances for International Buyers?

International buyers should be aware of several pricing nuances:

-

Currency Fluctuations: Exchange rates can significantly impact costs. Locking in prices or negotiating contracts in a stable currency can mitigate risks.

-

Import Duties and Taxes: Be aware of applicable tariffs and taxes that may apply when importing machinery. These can add considerable costs beyond the initial purchase price.

-

Shipping Costs: International shipping can vary widely based on location and shipping method. It’s crucial to factor in these costs when budgeting for a purchase.

-

Regulatory Compliance: Ensure that the machines meet local regulations, which can affect both pricing and the ability to use the equipment legally.

Disclaimer

The prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. Always seek updated quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing bubble hash machine With Other Solutions

Introduction to Alternatives in Hash Extraction Solutions

As the demand for high-quality cannabis concentrates continues to rise, businesses are exploring various methods to produce bubble hash. While bubble hash machines offer a streamlined and efficient solution, it’s essential to consider alternative extraction methods and equipment that may suit specific operational needs or budget constraints. This analysis will compare bubble hash machines with two viable alternatives: traditional hand-washing techniques and solvent-based extraction methods.

Comparison Table

| Comparison Aspect | Bubble Hash Machine | Traditional Hand-Washing Technique | Solvent-Based Extraction Method |

|---|---|---|---|

| Performance | High consistency and efficiency | Variable results, labor-intensive | High yield, but potential impurities |

| Cost | $200 – $75,000+ depending on capacity | Low cost (manual labor only) | High initial investment, plus solvents |

| Ease of Implementation | User-friendly, minimal training needed | Requires experience and skill | Complex setup and safety measures |

| Maintenance | Low, easy to clean and maintain | High, requires thorough cleaning | Moderate, requires careful handling |

| Best Use Case | Commercial production and large batches | Small-scale or artisanal production | High-volume production with quality control |

Detailed Breakdown of Alternatives

Traditional Hand-Washing Technique

The traditional hand-washing method involves manually agitating cannabis plant material in ice water to separate trichomes. This method is often favored by artisanal producers for its simplicity and low cost. However, it demands significant labor and expertise to achieve consistent quality. The lack of automation means results can vary significantly from batch to batch, which may not meet the quality standards required for commercial sales. For small-scale operations or those focused on craft production, this method can be effective, albeit labor-intensive.

Illustrative image related to bubble hash machine

Solvent-Based Extraction Method

Solvent-based extraction employs chemicals like ethanol or butane to dissolve cannabinoids and terpenes from cannabis. This method can yield high concentrations of active compounds, making it attractive for large-scale producers. However, it comes with higher costs associated with equipment and safety measures due to the flammable nature of solvents. Additionally, there is a risk of impurities if not managed correctly. Solvent extraction is ideal for businesses that prioritize high yield and potency, but it may not appeal to those seeking a solventless, natural product.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate extraction method for cannabis concentrates, B2B buyers should evaluate their production goals, budget, and desired product quality. Bubble hash machines provide an efficient, consistent, and user-friendly option for commercial producers, while traditional hand-washing may be more suited for artisanal, small-scale operations. On the other hand, solvent-based extraction offers high yields but requires careful safety and quality control measures. By weighing these factors, buyers can make an informed decision that aligns with their operational needs and market demands.

Essential Technical Properties and Trade Terminology for bubble hash machine

What Are the Essential Technical Properties of a Bubble Hash Machine?

Understanding the critical specifications of bubble hash machines is vital for B2B buyers seeking to invest in high-quality extraction equipment. Here are some key technical properties:

1. Material Grade

Bubble hash machines are typically constructed from stainless steel or food-grade plastic. Stainless steel is favored for its durability, resistance to corrosion, and ease of cleaning, which is essential for maintaining hygiene in cannabis processing. A higher material grade ensures longevity and reliability, making it a critical factor for companies focused on long-term investments.

Illustrative image related to bubble hash machine

2. Capacity

The capacity of a bubble hash machine refers to the amount of plant material it can process in a single run, usually measured in gallons. Machines can range from small 5-gallon units suitable for home use to large 30-gallon commercial machines. Selecting the appropriate capacity is vital for businesses to meet production demands and optimize operational efficiency.

3. Agitation Mechanism

The agitation mechanism is a key feature that determines how effectively the trichomes are separated from the plant material. Machines may employ various agitation methods, such as mechanical stirring or gentle tumbling. A reliable agitation system enhances extraction efficiency and product consistency, crucial for maintaining quality in commercial operations.

4. Temperature Control

Maintaining the correct temperature during extraction is crucial for preserving the quality of the trichomes. Advanced bubble hash machines often come equipped with temperature control systems that ensure optimal conditions throughout the extraction process. This feature is particularly important for companies aiming to produce high-grade bubble hash consistently.

5. Ease of Cleaning

B2B buyers should consider the design of the bubble hash machine, specifically its ease of cleaning. Machines with removable parts and smooth surfaces facilitate quicker and more effective cleaning processes, reducing downtime between batches. A hygienic environment is essential for compliance with safety standards and ensuring product quality.

6. Power Consumption

Understanding the energy efficiency of bubble hash machines can significantly impact operational costs. Machines with lower power consumption ratings can lead to reduced electricity bills, making them more economically viable for businesses. Evaluating energy efficiency is especially important for large-scale operations where energy costs can accumulate.

What Are Common Trade Terms Used in the Bubble Hash Machine Industry?

Navigating the bubble hash machine market requires familiarity with industry jargon. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the bubble hash machine industry, buyers may engage with OEMs for custom parts or specific machine configurations, ensuring they meet their operational needs.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of products a supplier is willing to sell. For bubble hash machines, understanding the MOQ is essential for B2B buyers to plan their budget and inventory effectively. It may also affect the ability to scale production based on market demand.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. In the context of bubble hash machines, submitting an RFQ can help buyers compare prices and features, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. For bubble hash machine transactions, understanding Incoterms is crucial for clarifying shipping costs, delivery timelines, and liability, ensuring smooth cross-border transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the bubble hash machine sector, shorter lead times can be a competitive advantage, allowing businesses to respond quickly to market demands and maintain production schedules.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when investing in bubble hash machines, ultimately enhancing their operational efficiency and product quality.

Illustrative image related to bubble hash machine

Navigating Market Dynamics and Sourcing Trends in the bubble hash machine Sector

What Are the Current Market Dynamics and Key Trends in the Bubble Hash Machine Sector?

The global market for bubble hash machines is experiencing robust growth driven by increasing demand for high-quality cannabis concentrates. As the cannabis industry expands in regions such as Africa, South America, the Middle East, and Europe, B2B buyers are increasingly seeking reliable and efficient extraction methods. Key trends include automation and the rise of sophisticated extraction technology, which enhance production efficiency and product consistency. Buyers are particularly interested in machines that can process larger volumes, with innovative features such as built-in timers and variable speed settings that allow for greater control over the extraction process.

Emerging markets are also witnessing a shift toward sustainability, with B2B buyers prioritizing eco-friendly solutions. Machines designed for energy efficiency, waste reduction, and recycling capabilities are gaining traction. The ongoing legalization of cannabis in various countries is fostering a competitive landscape, leading suppliers to innovate continually. Additionally, as consumers become more discerning about product quality, B2B buyers are turning to machines that ensure superior extraction results, thus enhancing the final product’s marketability.

In regions like Nigeria and Vietnam, where cannabis cultivation is on the rise, the demand for bubble hash machines is expected to escalate. Local buyers are keen to invest in equipment that not only meets international quality standards but also supports their unique operational needs. By aligning with these market dynamics, B2B buyers can strategically position themselves within the burgeoning cannabis industry.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the Bubble Hash Machine Sector?

Sustainability is becoming a critical consideration for B2B buyers in the bubble hash machine sector. The environmental impact of manufacturing processes, energy consumption, and waste management are key factors influencing purchasing decisions. Machines that utilize energy-efficient technologies and minimize water usage are increasingly desirable as they align with global sustainability goals. Furthermore, buyers are looking for suppliers who can demonstrate a commitment to reducing their carbon footprint through sustainable practices.

Ethical sourcing also plays a vital role in the decision-making process. Buyers are more likely to partner with manufacturers that maintain transparent supply chains and adhere to fair labor practices. This trend is particularly pronounced in emerging markets where consumers are increasingly aware of the ethical implications of their purchases. Certifications such as ISO 14001 for environmental management and other green certifications can significantly enhance a supplier’s credibility and appeal.

Illustrative image related to bubble hash machine

Investing in bubble hash machines that incorporate sustainable materials and processes not only meets regulatory requirements but also resonates with environmentally conscious consumers. As the industry evolves, B2B buyers who prioritize sustainability and ethical sourcing will likely gain a competitive advantage and foster long-term partnerships.

What is the Brief Evolution and History of Bubble Hash Machines?

The evolution of bubble hash machines can be traced back to traditional hash-making methods, which utilized simple mechanical processes to extract trichomes from cannabis. Initially, these processes were labor-intensive, requiring manual agitation and filtration. However, advancements in technology led to the development of automated machines that streamline extraction, significantly enhancing efficiency and consistency.

As the demand for cannabis concentrates grew, so did the complexity of extraction methods. The introduction of bubble hash machines marked a significant turning point, allowing for the production of high-quality, solventless concentrates. Over the years, manufacturers have continued to innovate, incorporating features such as temperature control, automated agitation, and advanced filtration systems to meet the evolving needs of the cannabis market.

Today, bubble hash machines are essential tools for both commercial producers and small-scale operators, reflecting the industry’s shift towards higher quality and greater accessibility. This evolution not only demonstrates the technological advancements in extraction methods but also highlights the growing importance of quality and sustainability in the cannabis industry.

Frequently Asked Questions (FAQs) for B2B Buyers of bubble hash machine

-

How do I choose the right bubble hash machine for my business needs?

Selecting the right bubble hash machine involves assessing your production capacity requirements, operational scale, and budget. Consider the machine’s volume capacity—ranging from small units for personal use to larger commercial models. Evaluate features like agitation speed, ease of cleaning, and material durability, such as stainless steel. Additionally, ensure the machine includes warranty support and user-friendly operation to streamline the extraction process. -

What are the most important features to look for in a bubble hash machine?

Key features to consider include the machine’s agitation mechanism, which should provide consistent and controlled mixing of ice, water, and cannabis. Look for models with built-in timers and drain valves for efficiency. Variable speed settings offer greater control over extraction, while a durable construction ensures longevity. Consider machines that are easy to disassemble for cleaning, as hygiene is critical in cannabis processing. -

What are the typical payment terms for purchasing a bubble hash machine?

Payment terms can vary significantly by supplier, but common practices in B2B transactions include a deposit of 30-50% upfront, with the balance due upon shipment or delivery. Some suppliers may offer financing options or payment plans, especially for larger equipment purchases. It’s essential to clarify terms before finalizing your order to avoid any misunderstandings later. Always request a pro forma invoice detailing the payment structure. -

What is the minimum order quantity (MOQ) for bubble hash machines?

Minimum order quantities can differ among suppliers, with some offering machines as single units while others may require bulk orders for wholesale pricing. It’s beneficial to inquire directly with manufacturers about their MOQ policies, as many are willing to negotiate terms for international buyers. Additionally, consider the logistics of shipping and customs when determining the quantity that best suits your operational needs. -

How do I ensure the quality of bubble hash machines from international suppliers?

To ensure quality, conduct thorough research on potential suppliers. Look for manufacturers with established reputations, positive customer reviews, and industry certifications. Request product samples or references from previous clients, and consider visiting the manufacturing facility if feasible. Engaging with a third-party quality assurance service can also help verify that the equipment meets your standards before shipment. -

What logistics considerations should I be aware of when importing bubble hash machines?

Logistics is a crucial aspect of importing machinery. Be mindful of shipping methods, customs regulations, and potential tariffs that may apply. Select a freight forwarder experienced in handling cannabis-related equipment to facilitate smooth transport. Ensure that the supplier provides the necessary documentation for customs clearance. Plan for potential delays and have a contingency strategy in place to minimize disruption to your operations. -

Can bubble hash machines be customized for specific production needs?

Many manufacturers offer customization options to cater to specific business requirements. You can request modifications in terms of capacity, features, and design based on your production volume and operational preferences. Discuss your needs with the supplier during the initial consultation, and ensure that any customizations are documented in the purchase agreement to avoid misunderstandings. -

What is the expected lifespan of a bubble hash machine, and how can I maintain it?

The lifespan of a bubble hash machine typically ranges from 5 to 15 years, depending on usage, maintenance, and quality of construction. Regular maintenance, including thorough cleaning after each use, helps prevent buildup and ensures optimal performance. Follow the manufacturer’s maintenance guidelines and schedule periodic professional inspections to extend the machine’s lifespan. Proper care not only enhances efficiency but also protects your investment over time.

Top 7 Bubble Hash Machine Manufacturers & Suppliers List

1. Lowtemp – Turnkey Solventless Lab Bundle

Domain: lowtemp-plates.com

Registered: 2015 (10 years)

Introduction: {“products”:[{“name”:”Lowtemp Turnkey Solventless Lab Bundle”,”price”:”$75,814.98″},{“name”:”Mini Lab Starter Bundle”,”price”:”$15,495.00″},{“name”:”The Osprey™ – 75 Gallon Commercial Washing Machine”,”price”:”$28,495.00″},{“name”:”Mini Osprey™ – 30 Gallon Home Washing Machine”,”regular_price”:”$6,995.00″,”sale_price”:”$5,995.00″},{“name”:”Mini Nest Water Recycle Kit”,”price”:”$2,795.00″},{“name”:…

2. Trimleaf – Bubble Hash Machine

Domain: trimleaf.com

Registered: 2016 (9 years)

Introduction: Bubble Hash Machine – Ice Water Extraction

Key Features:

– Streamlines the process of creating high-quality bubble hash

– Reliable method to extract potent trichomes from cannabis plant material

– Automates the extraction process for consistency and efficiency

– Maintains ideal temperature for trichome separation

– Simplifies extraction, accessible for novice and experienced users

Product Option…

3. Bubble Magic – 5 Gallon Washer

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Bubble Magic 5 gallon washer works good for personal use. Stock up on ice and freeze your material first. Make sure you have bubble bags. Some users prefer using buckets and manual sieving with bubble bags. A homemade rocker that holds 4 5-gallon buckets is also mentioned as a convenient option.

4. Bubble Magic – 20 Gallon Hash Maker

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Bubble Magic 20 Gallon Washing Machine Extraction Bubble Hash Maker”, “Condition”: “New”, “Price”: “$385.00”, “Shipping Cost”: “$50.00”, “Location”: “Veradale, Washington, United States”, “Estimated Delivery”: “between Sat, Sep 20 and Fri, Sep 26”, “Returns”: “Seller does not accept returns”, “Brand”: “Bubble Magic”, “Type”: “extraction”, “Custom Bundle”: “No”, “Style”: “Traditio…

5. Bubble Magic – 20 Gallon Upgrade

Domain: overgrow.com

Registered: 2014 (11 years)

Introduction: This company, Bubble Magic – 20 Gallon Upgrade, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. The Original Resinator – Ice Water Bubble Hash Machine

Domain: theoriginalresinator.com

Registered: 2014 (11 years)

Introduction: Ice Water Bubble Hash Machine by The Original Resinator

– Purpose: Separates trichome heads from cannabis plant material using cold water and agitation for ice water extraction.

– Models: Resinator OG Base Model ($3,999) and Resinator XL Base Model ($4,999).

– Features: Patented multi-use units, mixing process in tumbling chamber, different micron size screens, built-in drain, suspended drum for t…

7. Monster Gardens – Bubble Magic 20 Gallon Extraction Machine

Domain: monstergardens.com

Registered: 2009 (16 years)

Introduction: {“product_name”: “Bubble Magic 20 Gallon Extraction Machine”, “price”: “$287.50”, “availability”: “Backordered”, “shipping_lead_time”: “2 – 5 Days”, “description”: “More efficient and affordable than anything else on the market, the Bubble Magic 20 Gallon Extraction Machine (for essential oils, not clothing) utilizes the most advanced technology in the extraction industry! Easy to use, durable, an…

Strategic Sourcing Conclusion and Outlook for bubble hash machine

In navigating the evolving landscape of cannabis extraction, strategic sourcing of bubble hash machines is paramount for international B2B buyers. By investing in high-quality equipment, companies can enhance their production capabilities, ensuring consistency and efficiency in creating premium bubble hash. The automation provided by these machines not only reduces labor costs but also improves product quality, making it a wise choice for businesses aiming to scale operations.

Illustrative image related to bubble hash machine

As buyers from Africa, South America, the Middle East, and Europe evaluate their sourcing options, it is essential to consider factors such as machine capacity, material durability, and manufacturer support. Understanding these elements can lead to informed purchasing decisions that align with business goals and regulatory requirements.

Looking ahead, the demand for solventless cannabis products is poised to grow, driven by consumer preference for purity and quality. Now is the time for businesses to position themselves strategically in the market. Engage with reputable suppliers, explore diverse product offerings, and invest in technology that will enhance your production efficiency. By doing so, you will not only meet the rising demand but also establish a strong foothold in the competitive cannabis industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to bubble hash machine

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.