How to Source Mini Catalytic Converter Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for mini catalytic converter

Navigating the complexities of sourcing mini catalytic converters can be a daunting task for international B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe, including pivotal regions like Germany and Saudi Arabia. The challenge lies not only in identifying high-quality suppliers but also in understanding the various types, applications, and regulatory considerations associated with these essential components. Mini catalytic converters serve a crucial role in enhancing vehicle performance while complying with emission standards, making them indispensable for businesses aiming to maintain competitiveness and sustainability.

This comprehensive guide is designed to empower B2B buyers with actionable insights into the global market for mini catalytic converters. We delve into various types of mini catalytic converters, their specific applications in different automotive contexts, and the critical factors to consider when vetting suppliers. Additionally, we provide a detailed analysis of cost structures, ensuring that buyers can make informed purchasing decisions that align with their operational needs and budget constraints.

By leveraging the knowledge contained within this guide, international buyers will not only enhance their procurement strategies but also mitigate risks associated with compliance and product quality. Whether you are a distributor, manufacturer, or automotive service provider, understanding the nuances of the mini catalytic converter market will enable you to make strategic decisions that drive your business forward.

Understanding mini catalytic converter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mini Cat O2 Sensor CEL Fix | Incorporates a mini catalytic converter; universal fit | Automotive aftermarket, racing applications | Pros: Cost-effective solution for error codes; easy installation. Cons: Not street legal; may void vehicle warranty. |

| Straight Mini Catalytic Converter | Direct bolt-on design; eliminates specific error codes (e.g., P0420) | Performance tuning, vehicle inspections | Pros: Quick fix for emissions issues; high compatibility. Cons: Limited to specific vehicle types; potential for counterfeits. |

| 90-Degree Mini Catalytic Converter | Angled design for specific installation needs; high-grade materials | Custom exhaust systems, off-road vehicles | Pros: Tailored fit for complex setups; durable construction. Cons: Higher cost; may require professional installation. |

| 45-Degree Mini Catalytic Converter | Intermediate angle for unique configurations; versatile application | Specialty vehicles, racing mods | Pros: Flexibility in installation; reduces installation strain. Cons: Availability may vary; requires precise measurements. |

| High-Flow Mini Catalytic Converter | Designed for increased exhaust flow; enhances performance | Performance racing, high-performance vehicles | Pros: Significant power gains; optimized for speed. Cons: May not comply with emissions regulations; expensive. |

What Are the Key Characteristics of the Mini Cat O2 Sensor CEL Fix?

The Mini Cat O2 Sensor CEL Fix is designed primarily for vehicles experiencing check engine light (CEL) issues linked to catalytic converter efficiency. Its universal fit makes it suitable for a wide range of vehicles, particularly in the automotive aftermarket and racing sectors. This product is appealing to B2B buyers seeking cost-effective solutions for error codes such as P0420 and P0430. However, it is crucial to note that this product is intended solely for off-road use, as installation on street-legal vehicles may violate emissions regulations and lead to warranty issues.

How Does the Straight Mini Catalytic Converter Work?

The Straight Mini Catalytic Converter serves as a direct replacement or addition to existing systems, specifically targeting error codes related to catalytic efficiency. Its straightforward installation process makes it popular among automotive professionals and enthusiasts who require quick fixes for emissions-related problems. While it offers broad compatibility, buyers should be cautious of counterfeit products that may compromise vehicle performance. Ensuring the authenticity of the product is vital for maintaining the integrity of the installation.

What Applications Benefit from a 90-Degree Mini Catalytic Converter?

The 90-Degree Mini Catalytic Converter is tailored for installations where space constraints or specific exhaust routing are considerations. Its high-grade materials ensure durability, making it a preferred choice for custom exhaust systems and off-road vehicles. B2B buyers should evaluate their installation needs carefully, as this product may come at a higher price point. Professional installation may be required, adding to the overall cost but ensuring optimal performance and longevity.

Why Choose a 45-Degree Mini Catalytic Converter?

The 45-Degree Mini Catalytic Converter provides flexibility in installation, making it suitable for vehicles with unique exhaust configurations. Its design helps reduce strain during installation, which can be a significant advantage for automotive technicians. B2B buyers should consider precise measurements when selecting this type, as availability can vary based on demand and vehicle specifications. Its versatility allows it to fit various applications, from specialty vehicles to racing modifications.

What Are the Advantages of a High-Flow Mini Catalytic Converter?

High-Flow Mini Catalytic Converters are engineered for performance, allowing for increased exhaust flow and significant power gains. They are primarily utilized in racing and high-performance vehicles where maximizing speed is essential. B2B buyers must be aware that while these converters can enhance vehicle performance, they may not comply with emissions regulations, making them unsuitable for street-legal vehicles. The higher cost associated with these products reflects their specialized nature and the performance benefits they deliver.

Key Industrial Applications of mini catalytic converter

| Industry/Sector | Specific Application of mini catalytic converter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Emission Control in Performance Vehicles | Reduces harmful emissions while maintaining engine efficiency | Compliance with local regulations, compatibility with various models |

| Heavy Machinery | Exhaust Treatment for Construction Equipment | Enhances engine performance and reduces environmental impact | Durability under harsh conditions, ease of installation |

| Marine | Pollution Control in Small Vessels | Minimizes emissions, ensuring regulatory compliance | Resistance to corrosion, size constraints for compact designs |

| Generator Manufacturing | Emission Reduction in Portable Generators | Improves fuel efficiency and meets environmental standards | Customization options, reliability in varying climates |

| Motorcycle Manufacturing | Performance Enhancement in Motorcycles | Increases power output while complying with emission norms | Lightweight materials, universal fit for various models |

How is the Mini Catalytic Converter Used in the Automotive Sector?

In the automotive industry, mini catalytic converters are primarily used in performance vehicles to manage exhaust emissions effectively. They are designed to fit in compact spaces and are crucial for eliminating check engine lights related to catalytic efficiency errors, such as P0420 and P0430. For international buyers, especially in regions like Europe and the Middle East, compliance with stringent emission regulations is essential. Buyers should ensure that the mini catalytic converters meet local environmental standards and are compatible with various vehicle models to avoid installation issues.

What Role Does the Mini Catalytic Converter Play in Heavy Machinery?

Heavy machinery, particularly in construction, utilizes mini catalytic converters to treat exhaust gases, enhancing engine performance while reducing harmful emissions. These converters are essential for machinery operating in urban environments where emission regulations are strict. For B2B buyers in South America and Africa, sourcing durable and heat-resistant converters is critical, given the often harsh operational conditions. Buyers should prioritize suppliers that provide robust products with proven performance in challenging environments.

How is the Mini Catalytic Converter Beneficial for Marine Applications?

In the marine sector, mini catalytic converters are employed in small vessels to control emissions and ensure compliance with maritime regulations. They help reduce pollutants released into the water and air, which is increasingly vital as environmental regulations tighten globally. Buyers from regions with significant marine activities, such as the Middle East, should consider the corrosion resistance of the materials used in these converters. Selecting a product designed for marine environments will ensure longevity and reliability.

Why Use Mini Catalytic Converters in Generator Manufacturing?

Portable generators benefit significantly from mini catalytic converters, which help reduce emissions and improve fuel efficiency. This is particularly important for businesses that operate in environmentally sensitive areas or regions with strict emission laws. Buyers need to focus on sourcing converters that can be easily integrated into various generator designs and that perform reliably under different climatic conditions. Customization options may also be a key consideration to meet specific performance requirements.

How Do Mini Catalytic Converters Enhance Motorcycle Performance?

In the motorcycle manufacturing industry, mini catalytic converters are increasingly used to enhance performance while ensuring compliance with emission standards. They allow for improved power output without sacrificing environmental responsibility. For international buyers, especially in Europe where emission regulations are stringent, it is crucial to source lightweight and universally compatible converters that can fit a variety of motorcycle models. This ensures that manufacturers can maintain performance while adhering to legal requirements.

3 Common User Pain Points for ‘mini catalytic converter’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for Emission Controls

The Problem: B2B buyers of mini catalytic converters often grapple with understanding and adhering to the complex regulatory frameworks surrounding emissions controls. This is particularly relevant in regions like Europe and the Middle East, where stringent environmental regulations can lead to significant penalties for non-compliance. Buyers may struggle to determine whether the products they are sourcing meet local legislation, especially when importing components from different countries.

The Solution: To navigate these regulatory challenges, it is crucial to thoroughly research the specific emissions regulations applicable to your region and industry. Start by consulting with local environmental authorities or regulatory bodies to obtain the most current information. When sourcing mini catalytic converters, prioritize suppliers who provide clear documentation about compliance with relevant standards, such as the EU’s Euro 6 emissions regulations or the Clean Air Act in the U.S. Additionally, consider investing in products that come with a certification of compliance. This not only ensures that you are adhering to local laws but also positions your company as a responsible business partner committed to environmental sustainability. Engaging with suppliers who can offer comprehensive support regarding compliance can also mitigate risks associated with regulatory violations.

Scenario 2: Dealing with Quality Assurance Issues in Supply Chains

The Problem: Quality inconsistencies in mini catalytic converters can lead to serious performance issues, including frequent check engine lights and poor vehicle performance. For B2B buyers, the implications of sourcing subpar products can result in costly repairs, increased downtime, and damaged customer relationships. This is particularly concerning for businesses that operate fleets or provide aftermarket automotive solutions, where reliability is paramount.

The Solution: Establishing strong relationships with reputable suppliers is essential for mitigating quality assurance issues. Conduct thorough due diligence by researching potential suppliers’ manufacturing processes, quality control measures, and customer feedback. Request samples and conduct performance tests to ensure the mini catalytic converters meet your specific requirements before committing to larger orders. Additionally, consider implementing a robust inspection protocol upon receipt of products to catch any discrepancies early in the process. This proactive approach not only safeguards your operations but also reinforces trust with your customers, as you can confidently offer high-quality solutions.

Scenario 3: Addressing Installation and Technical Challenges

The Problem: B2B buyers often encounter installation challenges when integrating mini catalytic converters into existing systems. This is especially true for businesses in regions with varying vehicle standards and configurations. Incorrect installation can lead to performance issues, including inefficient emissions control and potential legal liabilities due to non-compliance with environmental regulations.

The Solution: To streamline installation processes, invest in training for your technical staff or partner with suppliers who provide installation support. Comprehensive training programs can enhance your team’s understanding of the nuances involved in fitting mini catalytic converters to different vehicle models. Additionally, seek out suppliers who offer detailed installation guides or technical support hotlines. When purchasing, consider requesting products that feature user-friendly designs, such as direct bolt-on solutions that require minimal modifications. By prioritizing training and support, you can significantly reduce installation errors, ensuring that your products operate effectively and comply with regulatory standards.

Strategic Material Selection Guide for mini catalytic converter

What Are the Key Materials Used in Mini Catalytic Converters?

When selecting materials for mini catalytic converters, it is crucial to consider their properties, advantages, and limitations. The choice of material can significantly impact performance, durability, and compliance with international standards. Here, we analyze four common materials used in mini catalytic converters.

How Does Stainless Steel Perform in Mini Catalytic Converters?

Key Properties: Stainless steel is known for its excellent corrosion resistance and high-temperature stability. It can withstand temperatures exceeding 1,000°C, making it suitable for high-performance applications.

Pros & Cons: The durability of stainless steel ensures a long lifespan, reducing the need for frequent replacements. However, it is more expensive than other materials, which can affect the overall cost of the catalytic converter. The manufacturing process can also be complex due to the need for precise welding techniques.

Impact on Application: Stainless steel is compatible with various exhaust gases, making it versatile for different vehicle types. Its resistance to oxidation and scaling ensures efficient catalytic reactions.

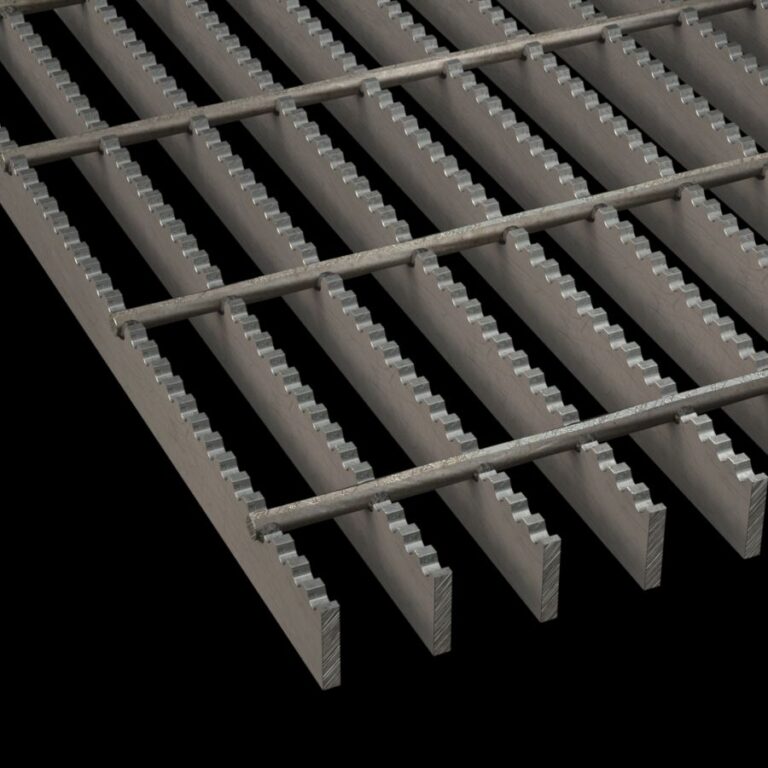

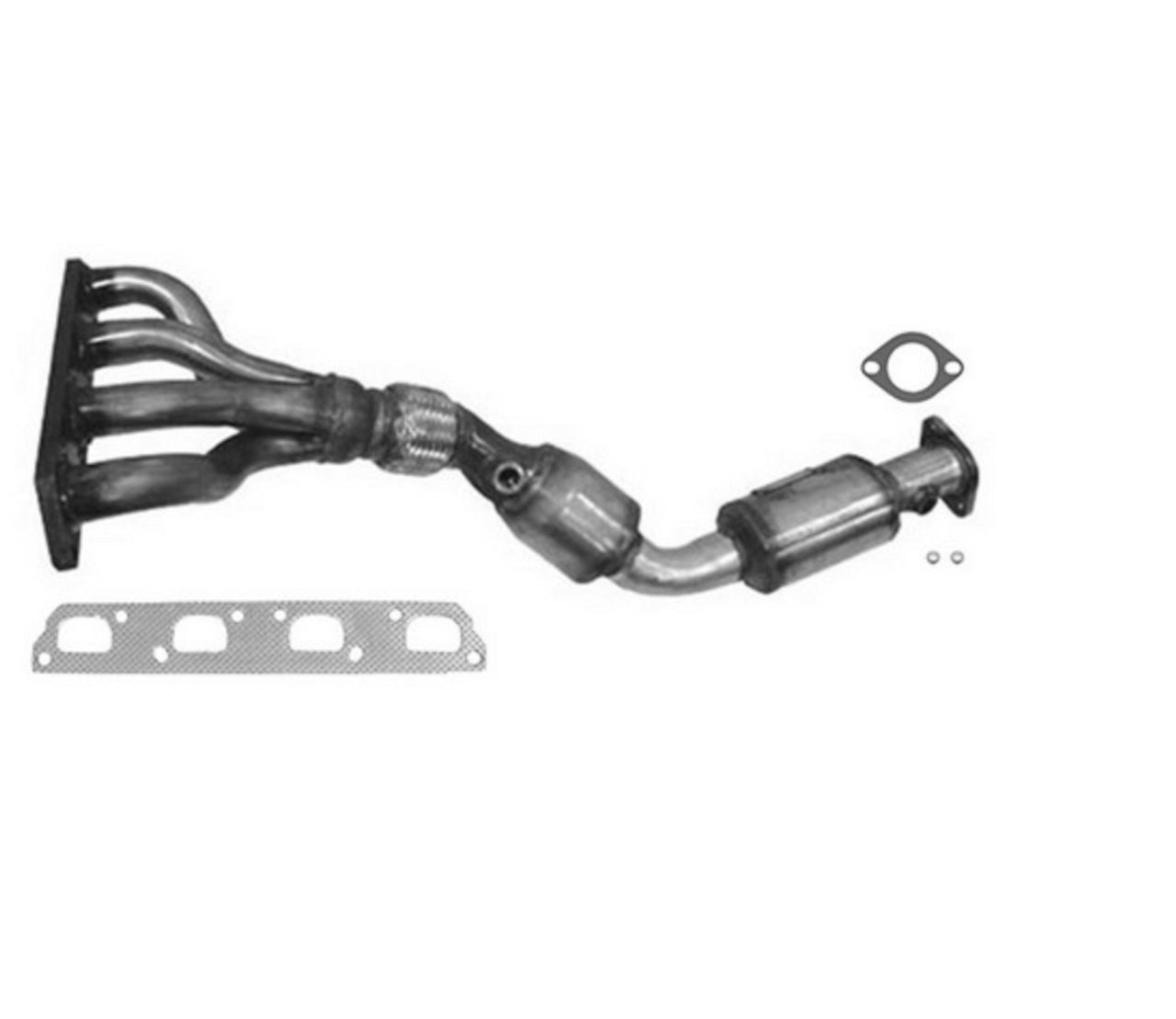

Illustrative image related to mini catalytic converter

Considerations for International Buyers: Buyers from regions like Germany and Saudi Arabia must ensure compliance with local emission standards, such as Euro 6 or Saudi Arabia’s environmental regulations. Stainless steel components should meet relevant standards like DIN for quality assurance.

What Role Does Aluminum Play in Mini Catalytic Converters?

Key Properties: Aluminum is lightweight and offers good thermal conductivity. While it has lower corrosion resistance than stainless steel, it can still perform adequately in less harsh environments.

Pros & Cons: The primary advantage of aluminum is its cost-effectiveness and ease of manufacturing. However, its lower melting point (around 660°C) limits its use in high-performance applications. Additionally, aluminum may require protective coatings to enhance its corrosion resistance.

Impact on Application: Aluminum is suitable for applications where weight reduction is critical, such as in performance vehicles. However, it may not be ideal for heavy-duty applications due to its lower durability.

Considerations for International Buyers: Buyers in Africa and South America may find aluminum to be a more affordable option. However, they should verify that the aluminum used meets local standards for automotive components to ensure reliability.

Illustrative image related to mini catalytic converter

Why Is Ceramic a Preferred Material for Mini Catalytic Converters?

Key Properties: Ceramics are known for their high-temperature resistance and excellent catalytic properties. They can withstand extreme conditions, making them ideal for catalytic applications.

Pros & Cons: The main advantage of ceramics is their ability to promote catalytic reactions effectively, leading to reduced emissions. However, ceramics are brittle and can be prone to cracking under mechanical stress, which limits their application in high-vibration environments.

Impact on Application: Ceramic substrates are often used in applications requiring high efficiency, such as in electric vehicles. Their compatibility with a wide range of exhaust gases enhances their effectiveness.

Illustrative image related to mini catalytic converter

Considerations for International Buyers: In Europe, where stringent emission regulations are in place, ceramic materials are widely accepted. Buyers should ensure that the ceramics used comply with Euro 6 standards for emissions.

How Does Carbon Steel Compare for Mini Catalytic Converters?

Key Properties: Carbon steel is known for its strength and affordability. It has moderate corrosion resistance, making it suitable for less demanding applications.

Pros & Cons: The cost-effectiveness of carbon steel makes it an attractive option for budget-conscious buyers. However, its susceptibility to rust and lower temperature tolerance (around 400°C) can limit its lifespan and performance in harsh conditions.

Impact on Application: Carbon steel is suitable for applications where cost is a primary concern, but it may not be ideal for high-performance or long-term use due to its limitations.

Illustrative image related to mini catalytic converter

Considerations for International Buyers: Buyers in regions with less stringent emission regulations may opt for carbon steel. However, they should be aware of the potential for corrosion and plan for more frequent replacements.

Summary Table of Material Selection for Mini Catalytic Converters

| Material | Typical Use Case for mini catalytic converter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-performance vehicles | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Aluminum | Lightweight applications | Cost-effective, easy to manufacture | Lower durability, requires coatings | Medium |

| Ceramic | High-efficiency catalytic applications | Promotes effective catalytic reactions | Brittle, prone to cracking | Medium |

| Carbon Steel | Budget-friendly applications | Affordable | Susceptible to rust, lower temp tolerance | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties and implications of various materials used in mini catalytic converters, helping them make informed decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for mini catalytic converter

What Are the Main Stages in the Manufacturing Process of Mini Catalytic Converters?

The manufacturing process of mini catalytic converters is a meticulous operation that encompasses several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring that the final product meets the stringent performance and durability requirements expected by B2B buyers.

Material Preparation

The first step involves selecting high-quality materials that can withstand extreme temperatures and corrosive environments. Typically, manufacturers use T-304 premium stainless steel for its superior resistance to rust and heat, which is vital for catalytic converters. This stage may also involve sourcing precious metals such as platinum, palladium, and rhodium, which are critical for the catalytic reaction that reduces harmful emissions.

Forming

Once the materials are prepared, they undergo various forming techniques. This can include processes like stamping, bending, and welding to create the substrate and housing of the mini catalytic converter. Advanced techniques such as laser cutting and CNC machining are often employed to achieve precise dimensions and complex shapes. Precision is essential, as even minor deviations can affect the efficiency of the catalytic converter.

Assembly

The assembly stage involves integrating the substrate with the housing. Manufacturers typically use high-temperature resistant adhesives or welding techniques to ensure a robust bond. This is also when any additional components, such as O2 sensor adapters or heat shields, are incorporated. The assembly must be done in a controlled environment to prevent contamination, which could compromise the converter’s performance.

Finishing

The final stage involves surface treatments and quality checks. Coatings may be applied to enhance corrosion resistance, and the product is often polished to improve aesthetics. This stage also includes thorough cleaning to remove any residues from the manufacturing process.

What Quality Control (QC) Standards Are Relevant for Mini Catalytic Converters?

Quality assurance is a critical aspect of mini catalytic converter manufacturing, ensuring that products meet international and industry-specific standards. For B2B buyers, understanding these standards is essential for making informed purchasing decisions.

International Standards

ISO 9001 is the most recognized quality management standard globally. It outlines a framework for consistent quality and continuous improvement. Manufacturers seeking this certification must demonstrate their ability to meet customer and regulatory requirements, which adds a layer of assurance for buyers.

Industry-Specific Standards

In addition to ISO 9001, there are several industry-specific certifications relevant to catalytic converters, including CE marking for products sold in the European market and API standards for automotive parts. Compliance with these standards ensures that the mini catalytic converters not only meet performance expectations but also adhere to safety regulations.

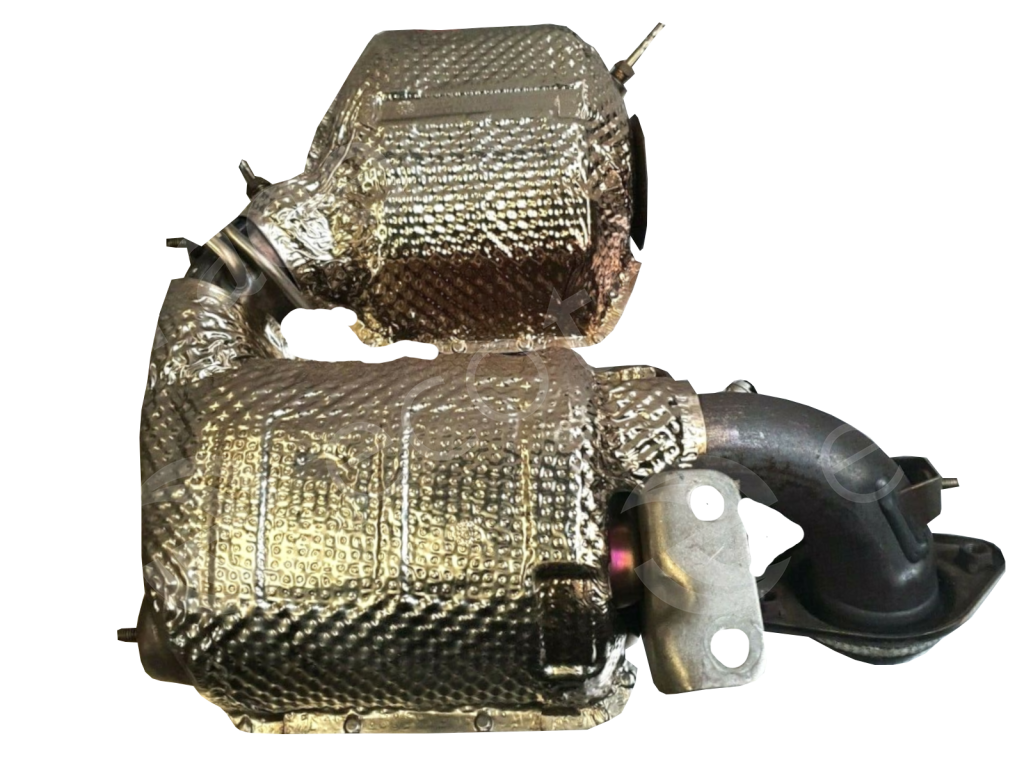

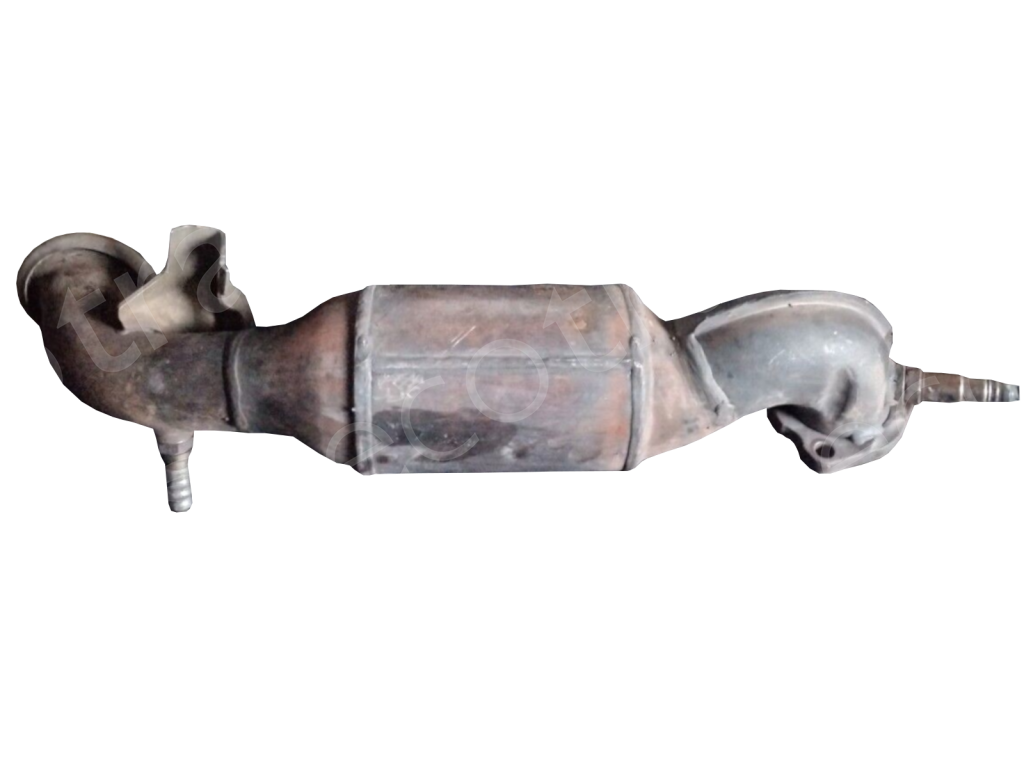

Illustrative image related to mini catalytic converter

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated throughout the manufacturing process to catch any defects early and ensure that each product meets the necessary standards. Common QC checkpoints include:

Incoming Quality Control (IQC)

This initial checkpoint involves inspecting raw materials upon arrival. Quality inspectors verify that materials meet specified standards and are free from defects. This stage is crucial as it sets the foundation for the entire manufacturing process.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC ensures that each stage adheres to quality standards. Inspectors monitor key parameters such as dimensions, material properties, and assembly integrity. This proactive approach helps identify and rectify issues before they escalate.

Final Quality Control (FQC)

Before shipping, final inspections are conducted to ensure that each mini catalytic converter meets the required specifications. This may include functional testing, visual inspections, and performance evaluations to confirm that the product will operate effectively under real-world conditions.

Illustrative image related to mini catalytic converter

What Testing Methods Are Commonly Used for Mini Catalytic Converters?

Various testing methods are employed to evaluate the performance and durability of mini catalytic converters. Understanding these methods can provide B2B buyers with insights into the reliability of the products they intend to purchase.

Performance Testing

This involves simulating real-world operating conditions to assess the catalytic converter’s efficiency in reducing emissions. Manufacturers may use dynamometer testing to evaluate how the converter performs under different loads and speeds.

Durability Testing

Durability tests expose the catalytic converters to extreme temperatures and corrosive environments to ensure longevity. This may include thermal cycling tests, where the product is subjected to rapid temperature changes to assess its structural integrity.

Compliance Testing

For products intended for specific markets, compliance testing ensures that the mini catalytic converters meet local emissions regulations. This is particularly important for buyers in regions with stringent environmental laws.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should be proactive in verifying the quality control processes of potential suppliers to mitigate risks associated with product quality. Here are several strategies:

Illustrative image related to mini catalytic converter

Supplier Audits

Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes, quality control measures, and compliance with relevant standards. This firsthand observation can provide valuable insights into the supplier’s capabilities.

Quality Reports

Requesting detailed quality reports from suppliers can help buyers understand the QC processes in place. These reports should include information on test results, inspection findings, and any corrective actions taken.

Third-Party Inspections

Engaging third-party inspection agencies can provide an objective assessment of the supplier’s quality control processes. These agencies can conduct independent audits and testing to ensure compliance with international standards.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must be aware of specific nuances related to QC and certification. These can include:

Regional Regulations

Different regions may have varying regulations concerning emissions and safety standards. Buyers should ensure that the mini catalytic converters they purchase comply with local laws to avoid legal issues.

Documentation and Certification

Buyers should verify that suppliers provide the necessary documentation and certifications. This includes compliance certificates, test reports, and evidence of adherence to ISO and other relevant standards.

Counterfeit Risks

With the rise of counterfeit products, buyers should be vigilant when sourcing mini catalytic converters. Ensuring that products are purchased through authorized channels and verifying certifications can help mitigate the risk of acquiring substandard goods.

Illustrative image related to mini catalytic converter

In summary, understanding the manufacturing processes and quality assurance protocols for mini catalytic converters is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they source reliable and compliant products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mini catalytic converter’

In today’s competitive automotive market, sourcing mini catalytic converters effectively can significantly enhance your product offerings and ensure compliance with emissions standards. This guide provides a practical checklist for B2B buyers to navigate the procurement process efficiently, ensuring that you find a reliable supplier that meets your technical and regulatory requirements.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications of the mini catalytic converters you need. Consider factors such as size, material (e.g., stainless steel vs. carbon steel), and compatibility with various vehicle models. This clarity will help you communicate your requirements effectively and filter out unsuitable options.

Step 2: Research Regulatory Compliance

Understanding the regulatory environment in your target markets is crucial. Mini catalytic converters must comply with local emissions regulations, which vary by region. Ensure that your suppliers can provide documentation proving that their products meet the necessary standards, such as ISO certifications or compliance with the Clean Air Act in the U.S.

Step 3: Evaluate Potential Suppliers

Conduct thorough due diligence on potential suppliers. Request company profiles, customer references, and case studies relevant to your industry. Look for suppliers with a proven track record in delivering quality products, especially those who have experience in your geographic region, as they will be more familiar with local regulations and market dynamics.

Step 4: Assess Product Quality and Durability

Quality is paramount when sourcing mini catalytic converters. Inquire about the materials used and the manufacturing processes employed. Look for products made from high-quality stainless steel, as these are more resistant to corrosion and can withstand higher temperatures. Request samples, if possible, to evaluate the product’s durability and performance firsthand.

Step 5: Verify Certifications and Warranty Options

Make sure that the suppliers you are considering have the necessary certifications for their products. This could include environmental compliance certifications or industry-specific quality standards. Additionally, inquire about warranty options, as a solid warranty can serve as a safeguard against product defects and performance issues.

Step 6: Analyze Pricing and Payment Terms

While price shouldn’t be the only consideration, it is a significant factor. Obtain detailed quotes from multiple suppliers and compare them not just on price but also on the total value offered, including shipping costs and delivery times. Additionally, clarify payment terms and conditions, as favorable terms can improve your cash flow management.

Step 7: Plan for After-Sales Support and Service

Finally, assess the level of after-sales support the supplier offers. This includes customer service availability, technical support, and the ease of returning or replacing defective products. Strong after-sales service can enhance your purchasing experience and ensure ongoing support for your customers.

By following this checklist, B2B buyers can streamline the sourcing process for mini catalytic converters, ensuring they partner with reliable suppliers who meet their specific needs and compliance requirements.

Comprehensive Cost and Pricing Analysis for mini catalytic converter Sourcing

Understanding the cost structure and pricing dynamics of mini catalytic converters is crucial for international B2B buyers. This section delves into the cost components, price influencers, and practical buyer tips, particularly for those operating in Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia.

What are the Key Cost Components in Mini Catalytic Converter Production?

The cost structure of mini catalytic converters typically comprises several components:

-

Materials: The primary materials include high-quality stainless steel for durability and resistance to corrosion, along with precious metals like platinum, palladium, and rhodium used as catalysts. The choice of materials significantly impacts both cost and performance.

-

Labor: Labor costs vary by region. Skilled labor is often required for precision manufacturing and assembly, especially in regions with advanced manufacturing capabilities.

-

Manufacturing Overhead: This encompasses utilities, factory maintenance, and equipment depreciation. Overhead costs can differ based on the manufacturing location and efficiency of operations.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. Tooling expenses are amortized over the production run, making them a critical consideration for pricing.

-

Quality Control (QC): Rigorous QC processes are essential to ensure compliance with emission standards and customer expectations. This adds to the overall cost but is necessary to avoid costly returns or reputation damage.

-

Logistics: Shipping costs can fluctuate based on the mode of transport, destination, and weight of the products. Buyers should consider these costs in their total sourcing expenses.

-

Margin: Supplier margins can vary significantly based on their market positioning and competitive strategy. Understanding the typical margins in your target market can aid in negotiations.

How Do Pricing Influencers Affect Mini Catalytic Converter Costs?

Several factors influence the pricing of mini catalytic converters:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs. Negotiating favorable MOQs can enhance cost efficiency, particularly for businesses with steady demand.

-

Specifications and Customization: Custom specifications can lead to higher costs due to unique tooling and material requirements. However, tailored products may offer better performance and compliance with specific regulations.

-

Quality and Certifications: Products meeting stringent quality standards (e.g., ISO certifications) may command higher prices. Buyers should assess whether these certifications align with their operational needs.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge a premium for their credibility and service levels.

-

Incoterms: Understanding Incoterms is vital for determining who bears shipping costs, insurance, and risk during transportation. This can significantly affect the overall cost structure.

What Practical Tips Can Buyers Use to Negotiate Better Prices?

Buyers should adopt several strategies to optimize sourcing costs:

-

Engage in Negotiation: Building a strong relationship with suppliers can lead to better pricing and terms. Be transparent about your volume and long-term needs to negotiate effectively.

-

Focus on Total Cost of Ownership (TCO): Rather than just the purchase price, consider the TCO, which includes maintenance, operational efficiency, and potential downtime costs. This holistic view can inform better purchasing decisions.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations and import duties can affect the final cost. Conduct thorough market research to anticipate these variables, especially in regions with volatile economies.

-

Evaluate Local Suppliers: In regions like Africa and South America, local suppliers may offer competitive pricing and reduced shipping costs. However, ensure they meet quality and compliance standards.

Conclusion

Navigating the cost and pricing landscape of mini catalytic converters requires a thorough understanding of the cost components, pricing influencers, and effective negotiation strategies. By considering these factors, international B2B buyers can enhance their sourcing efficiency and make informed purchasing decisions. Keep in mind that the prices discussed herein are indicative and can vary based on specific requirements and market conditions.

Alternatives Analysis: Comparing mini catalytic converter With Other Solutions

When evaluating solutions for managing vehicle emissions and addressing check engine light issues, it is essential to explore various alternatives to the mini catalytic converter. Each option presents unique advantages and challenges, influencing the decision-making process for B2B buyers across diverse regions such as Africa, South America, the Middle East, and Europe.

| Comparison Aspect | Mini Catalytic Converter | O2 Sensor Spacer | High-Flow Catalytic Converter |

|---|---|---|---|

| Performance | Efficiently resolves CEL codes, particularly P0420 and P0430, in various vehicles. | Temporarily alleviates CEL issues by adjusting sensor readings but does not address underlying problems. | Enhances exhaust flow and performance, reducing emissions while maintaining compliance with regulations. |

| Cost | Generally priced between $25 – $50. | More affordable, typically $20 – $30. | Higher initial investment, ranging from $150 – $300, depending on vehicle compatibility. |

| Ease of Implementation | Simple installation with minimal modifications required. | Very easy installation; often a direct bolt-on solution. | Installation can be complex, sometimes requiring professional assistance for optimal performance. |

| Maintenance | Low maintenance with durable stainless steel construction. | Requires no maintenance but may lead to further issues if not monitored. | May need periodic checks and potential replacements depending on vehicle usage. |

| Best Use Case | Ideal for regular vehicles needing a quick CEL fix without extensive modifications. | Suitable for temporary fixes in vehicles with mild CEL issues. | Best for performance vehicles or those requiring significant emissions control improvements. |

What Are the Pros and Cons of Using an O2 Sensor Spacer as an Alternative?

The O2 sensor spacer is a cost-effective solution that can help eliminate CEL issues by modifying the sensor’s readings. Its installation is straightforward, making it accessible for many vehicle owners. However, this solution is more of a temporary fix rather than a permanent resolution. It does not rectify the underlying issues with the catalytic converter or the exhaust system, which may lead to more significant problems down the line if not addressed.

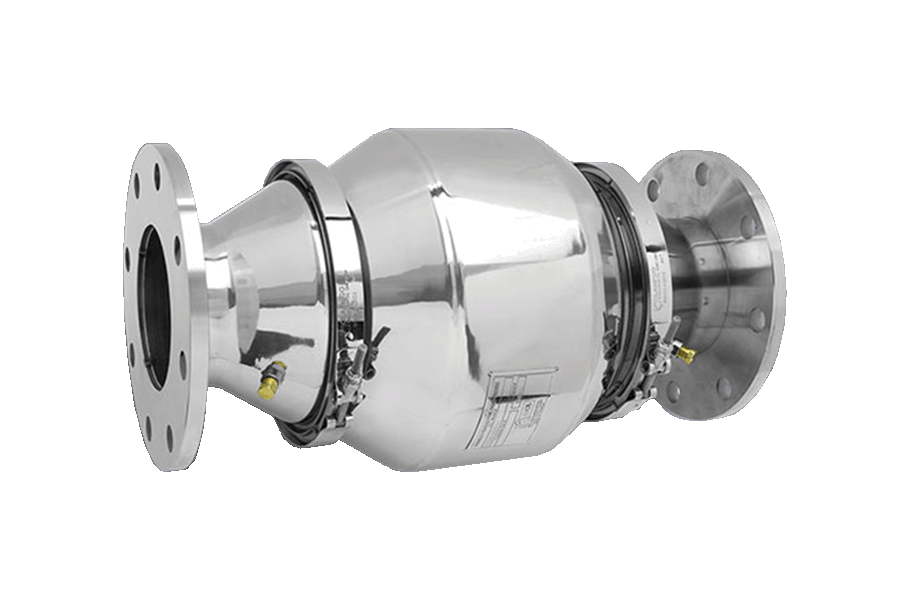

Illustrative image related to mini catalytic converter

How Does a High-Flow Catalytic Converter Compare?

High-flow catalytic converters are designed for performance enhancement while still complying with emissions regulations. They allow for greater exhaust flow, which can improve engine performance significantly. However, they come with a higher price point and may require professional installation. Additionally, while they improve efficiency, they may not be suitable for all vehicle types, particularly those with strict emissions regulations.

Conclusion: How Can B2B Buyers Choose the Right Emission Solution?

When selecting an emission control solution, B2B buyers must consider the specific needs of their fleet or vehicles. The mini catalytic converter offers a balanced approach for those seeking a reliable and straightforward solution to CEL issues. In contrast, the O2 sensor spacer can be a quick fix for less severe problems, while the high-flow catalytic converter is ideal for performance-oriented applications. Ultimately, the decision should factor in performance requirements, budget constraints, and compliance with local regulations to ensure the best fit for their operational needs.

Essential Technical Properties and Trade Terminology for mini catalytic converter

What Are the Key Technical Properties of Mini Catalytic Converters?

Understanding the technical specifications of mini catalytic converters is crucial for B2B buyers, particularly those involved in automotive parts procurement. Here are some essential properties to consider:

-

Material Grade: Most mini catalytic converters are made from T-304 stainless steel due to its excellent corrosion resistance and durability. This material ensures longevity, which is essential for reducing replacement costs and minimizing downtime for vehicles. High-quality materials also contribute to better performance and compliance with emission standards.

-

Size and Dimensions: The size of the mini catalytic converter, often specified in millimeters, is critical for compatibility with various vehicle models. Proper sizing ensures optimal performance and efficiency, as an improperly sized converter can lead to issues such as reduced exhaust flow or increased backpressure, ultimately affecting vehicle performance.

-

Thread Specifications: Many mini catalytic converters utilize universal thread sizes, such as M18 x 1.5. This specification is vital for ensuring compatibility across different vehicle types and simplifies installation. B2B buyers should prioritize products with standardized threading to facilitate easier integration into existing systems.

-

Temperature Resistance: The ability to withstand high temperatures is essential for mini catalytic converters, especially in performance vehicles. High-temperature resistance protects the catalytic materials from degradation, ensuring consistent functionality. This property is particularly important for buyers in regions with extreme weather conditions.

-

Error Code Compatibility: Mini catalytic converters often serve to eliminate specific error codes (e.g., P0420, P0430) related to catalytic efficiency. Understanding which codes a product addresses can help buyers select the right solution for their needs, ultimately improving customer satisfaction and vehicle reliability.

What Are Common Trade Terms Related to Mini Catalytic Converters?

Familiarity with industry jargon can significantly enhance B2B negotiations and procurement processes. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts that are used in the original manufacturing of vehicles. Buyers often seek OEM parts for their guaranteed compatibility and reliability. Understanding OEM specifications is vital for ensuring that the mini catalytic converters meet the original performance standards.

-

MOQ (Minimum Order Quantity): MOQ denotes the smallest quantity of product that a supplier is willing to sell. This term is crucial for B2B buyers as it helps manage inventory levels and cash flow. Knowing the MOQ can also influence purchasing decisions, especially for smaller businesses.

-

RFQ (Request for Quotation): An RFQ is a formal document requesting a supplier to provide pricing and terms for specific products. For buyers, issuing an RFQ can lead to better pricing and terms, ensuring competitive procurement of mini catalytic converters.

-

Incoterms (International Commercial Terms): Incoterms define the responsibilities of buyers and sellers in international trade, particularly concerning shipping and delivery. Familiarity with these terms is essential for B2B buyers engaged in cross-border transactions, as they dictate who bears the costs and risks at various stages of the shipping process.

-

Lead Time: This term refers to the time it takes from placing an order to the delivery of the product. Understanding lead times is crucial for inventory management and planning, ensuring that businesses can meet customer demand without delay.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when purchasing mini catalytic converters, ultimately leading to more efficient operations and enhanced customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the mini catalytic converter Sector

What Are the Key Market Dynamics and Trends in the Mini Catalytic Converter Sector?

The mini catalytic converter market is experiencing robust growth, driven by increasing environmental regulations and the demand for improved vehicle performance. Globally, the push for reduced emissions is prompting manufacturers to innovate and enhance the efficiency of catalytic converters. Emerging technologies, such as advanced sensor integration and the use of high-quality materials like stainless steel, are becoming pivotal in product development. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is essential for making informed sourcing decisions.

Key trends include the rising adoption of mini catalytic converters in the aftermarket sector, especially for performance vehicles and off-road applications. This shift is largely attributed to consumers seeking cost-effective solutions for emissions compliance without compromising vehicle performance. Moreover, the market is witnessing a surge in digital solutions for sourcing, including online platforms that facilitate direct connections between buyers and manufacturers. These platforms offer a streamlined purchasing process, reducing lead times and enabling buyers to compare products effectively.

Additionally, sustainability is becoming a focal point for B2B buyers. The increasing prevalence of eco-conscious consumers is pushing suppliers to prioritize environmentally friendly practices in their production processes. As such, buyers must stay attuned to these trends to ensure they align with their own sustainability goals while sourcing mini catalytic converters.

How Does Sustainability and Ethical Sourcing Influence the Mini Catalytic Converter Market?

Sustainability and ethical sourcing are paramount in the mini catalytic converter sector, given the environmental implications of catalytic converter manufacturing and disposal. The production of these components can generate significant waste and emissions; therefore, companies are increasingly adopting sustainable practices to mitigate their environmental impact. For B2B buyers, sourcing from manufacturers who prioritize sustainability not only enhances their corporate social responsibility (CSR) profile but also aligns with global environmental standards.

Moreover, certifications such as ISO 14001 for environmental management and compliance with local regulations can serve as crucial indicators of a supplier’s commitment to ethical practices. Buyers are encouraged to seek partnerships with suppliers who utilize green materials, such as recyclable metals and eco-friendly coatings, which can improve the overall lifecycle impact of their products.

The importance of ethical supply chains cannot be overstated. Ensuring that suppliers adhere to responsible sourcing practices—such as fair labor conditions and minimal environmental impact—can significantly enhance a company’s reputation in the market. As consumers increasingly demand transparency, B2B buyers must ensure that their supply chains reflect these values to maintain competitiveness and foster customer loyalty.

Illustrative image related to mini catalytic converter

What Has Been the Evolution of the Mini Catalytic Converter Market?

The mini catalytic converter market has evolved significantly over the past few decades, driven by technological advancements and regulatory changes. Initially, catalytic converters were bulky and primarily designed for standard vehicles. However, as emission regulations tightened globally, the need for more compact and efficient designs led to the development of mini catalytic converters, particularly for high-performance and off-road vehicles.

In the early 2000s, advancements in materials science and manufacturing processes allowed for the miniaturization of catalytic converters without compromising their effectiveness. This evolution was particularly important for performance enthusiasts who sought to improve their vehicle’s power output while adhering to emissions standards. Today, mini catalytic converters are not only recognized for their performance benefits but also for their role in achieving compliance with increasingly stringent environmental regulations.

As the market continues to grow, it is essential for B2B buyers to remain informed about these developments, ensuring they source products that meet both performance and regulatory standards. Understanding the historical context of the mini catalytic converter market can provide valuable insights into current trends and future opportunities.

Illustrative image related to mini catalytic converter

Frequently Asked Questions (FAQs) for B2B Buyers of mini catalytic converter

-

How do I solve check engine light issues related to catalytic converters?

To address check engine light (CEL) issues, particularly codes like P0420 and P0430, consider installing a mini catalytic converter or O2 sensor spacer. These products can effectively eliminate CEL warnings by improving the efficiency of the exhaust system. When sourcing, ensure the product is compatible with your vehicle’s make and model. Always verify that the supplier provides proper documentation and compliance information to avoid legal issues, especially in regions with stringent emissions regulations. -

What is the best mini catalytic converter for my vehicle?

The best mini catalytic converter depends on your specific vehicle requirements, including engine size and performance needs. For high-performance applications, opt for models designed for boosted engines or those with specific flow rates. Review product specifications from multiple suppliers to compare features such as material quality, durability, and installation ease. Additionally, consider customer reviews and ratings to gauge performance and reliability in similar vehicle types. -

How can I ensure the quality of mini catalytic converters from suppliers?

To ensure quality, start by vetting suppliers through reviews and industry reputation. Request product samples or certifications that demonstrate compliance with international standards. Evaluate the materials used, such as stainless steel, which is preferred for its durability and resistance to corrosion. Additionally, inquire about the supplier’s quality assurance processes and warranty policies to safeguard your investment. -

What are the typical minimum order quantities (MOQs) for mini catalytic converters?

MOQs can vary significantly by supplier, often ranging from 50 to several hundred units. It’s advisable to discuss your specific needs with potential suppliers and negotiate terms that align with your purchasing strategy. If you’re entering a new market or testing product demand, some suppliers may offer flexibility on MOQs or allow for trial orders to build a business relationship. -

What payment terms should I expect when sourcing mini catalytic converters internationally?

Payment terms typically include options like bank transfers, letters of credit, or payment upon delivery, depending on the supplier’s policies and your relationship with them. Common practices include a deposit upfront (30-50%) with the balance due before shipment. Always clarify terms in advance and ensure that they are documented in your purchase agreement to avoid misunderstandings. -

How can I facilitate logistics for importing mini catalytic converters?

Effective logistics management involves selecting a reliable freight forwarder familiar with international shipping regulations. Confirm that your supplier can provide necessary documentation, such as customs invoices and certificates of origin, to streamline the import process. Consider shipping methods based on urgency and cost, and ensure you account for potential tariffs or duties in your overall budget. -

What customization options are available for mini catalytic converters?

Many suppliers offer customization options, such as specific sizes, configurations, or materials tailored to your vehicle or application needs. Discuss your requirements with suppliers and request their capabilities regarding custom designs. Customization may also extend to branding or packaging, allowing you to differentiate your product in the market. -

What should I know about compliance and legal considerations for mini catalytic converters?

Compliance with local emissions regulations is crucial when sourcing mini catalytic converters. Ensure the products meet the standards of the countries where you plan to sell. Research specific regulations in your target markets, as they may have varying restrictions on aftermarket parts. Engage with suppliers who provide documentation to demonstrate compliance, and consider consulting with legal experts to navigate complex regulations effectively.

Top 3 Mini Catalytic Converter Manufacturers & Suppliers List

1. Mini Catalizador® – CEL Fix O2 Sensor Spacer

Domain: minicatalizador.com

Registered: 2023 (2 years)

Introduction: Mini Catalizador® Official | CEL Fix O2 Sensor Spacer for P0420 P0430 | Rated ‘GREAT’ on Google (4.8/5.0) | Free Shipping from CA, USA | Up to 40% OFF | Buy More, Save Bigger!

2. MINI – Direct Fit Catalytic Converters

Domain: converterwarehouse.com

Registered: 2003 (22 years)

Introduction: MINI Catalytic Converters include models such as MINI COOPER, MINI COOPER COUNTRYMAN, MINI COOPER PACEMAN, and MINI COOPER S. They offer Direct Fit Catalytic Converters that are fast and bolt-on for installation, requiring no cutting or welding. The converters are factory new, not remanufactured, and are available at competitive prices. The company also stocks complete exhaust systems, including m…

3. MagnaFlow – High-Quality Catalytic Converters

Domain: magnaflow.com

Registered: 1996 (29 years)

Introduction: This company, MagnaFlow – High-Quality Catalytic Converters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for mini catalytic converter

In navigating the evolving landscape of the mini catalytic converter market, strategic sourcing emerges as an essential practice for international B2B buyers. Understanding the nuances of product specifications, compliance with local emissions regulations, and the importance of quality assurance can significantly impact purchasing decisions. By prioritizing suppliers who offer verified products, such as those made from high-quality materials, buyers can mitigate risks associated with counterfeit items and ensure long-term operational efficiency.

Moreover, the mini catalytic converter serves not only as a critical component for performance enhancement but also as a solution to compliance challenges faced by vehicle operators. With the increasing demand for eco-friendly solutions across regions, including Africa, South America, the Middle East, and Europe, there exists a unique opportunity for businesses to capitalize on this trend by sourcing reliable, high-performance products.

As you consider your procurement strategies, remain vigilant about market trends and technological advancements in catalytic converter technology. Engage with reputable suppliers and explore innovative solutions that align with your operational needs. Together, let’s drive forward in embracing sustainable automotive practices that promise to elevate your business in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.