Ga Murdock Inc Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for ga murdock inc

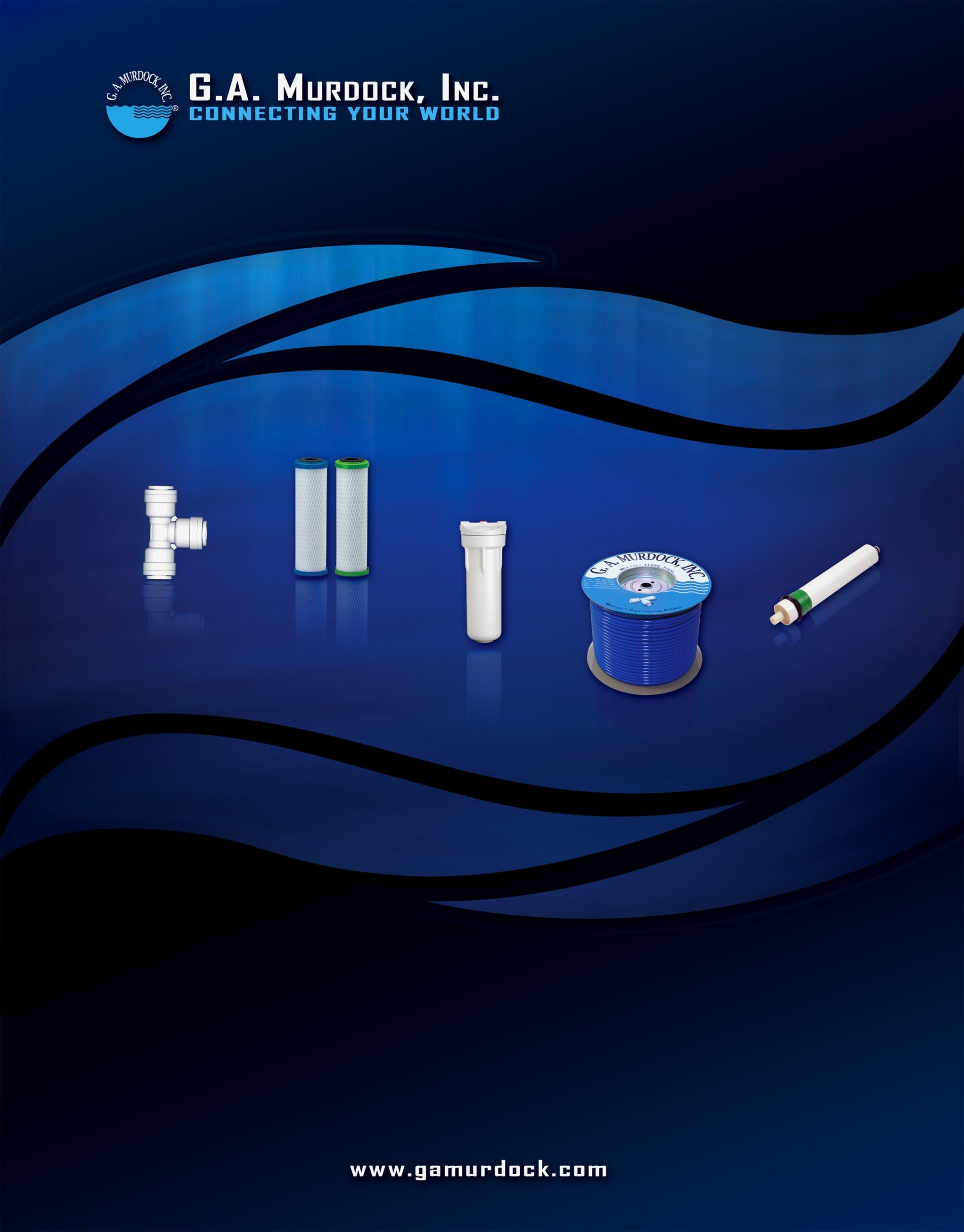

Navigating the complexities of sourcing reliable water conditioning supplies can be a daunting challenge for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. G.A. Murdock Inc. stands as a beacon of quality and innovation in this sector, offering a comprehensive range of plumbing parts, fittings, and valves essential for various applications within the water treatment industry. This guide serves as an invaluable resource for businesses looking to streamline their purchasing processes, ensuring they make informed decisions that align with their operational needs.

Within these pages, you will find an in-depth exploration of G.A. Murdock’s product offerings, including detailed specifications and applications tailored to different market demands. Furthermore, we will provide insights into effective supplier vetting practices to ensure that you are partnering with a reputable company that adheres to stringent quality control standards. Cost analysis will also be a key focus, enabling you to identify competitive pricing strategies that can enhance your bottom line while maintaining the quality you expect.

By leveraging the knowledge contained in this guide, B2B buyers will be empowered to make strategic purchasing decisions that not only meet their immediate needs but also foster long-term relationships with suppliers like G.A. Murdock. With a commitment to excellence and a robust product lineup, G.A. Murdock is positioned to support your business in achieving its water treatment goals efficiently and effectively.

Understanding ga murdock inc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mur-Lok® Ball Valves | High reliability, made from premium materials, various sizes | Water treatment, plumbing, industrial uses | Pros: Durable, low maintenance; Cons: Higher initial cost. |

| Push-Fit Connectors | Easy installation, no tools required, versatile fittings | Residential and commercial plumbing | Pros: Quick installation, flexible; Cons: Limited pressure ratings. |

| Faucet Supply Adapters | Designed for connecting faucets to supply lines, multiple sizes | Residential kitchens, bathrooms | Pros: Cost-effective, easy to replace; Cons: May require additional fittings. |

| Air Gap Fittings | Prevents backflow, available in various configurations | Water purification systems | Pros: Ensures safety, reliable; Cons: Installation can be complex. |

| Inline Ball Valves | Compact design, suitable for tight spaces, manual operation | Water filtration systems, irrigation | Pros: Space-saving, precise control; Cons: Manual operation can be inconvenient. |

What are Mur-Lok® Ball Valves and Why Are They Important for B2B Buyers?

Mur-Lok® Ball Valves are recognized for their reliability and durability, making them essential in various applications, including water treatment and industrial settings. Constructed from high-quality materials, these valves ensure optimal performance and longevity. B2B buyers should consider their initial investment against long-term savings from reduced maintenance and replacement costs. Choosing the right size and compatibility with existing systems is crucial for seamless integration.

How Do Push-Fit Connectors Enhance Installation Efficiency?

Push-Fit Connectors stand out for their user-friendly design, requiring no tools for installation. This feature significantly reduces labor time, making them ideal for both residential and commercial plumbing projects. However, buyers should assess the pressure ratings to ensure they meet specific operational requirements. The flexibility in application allows for a variety of uses, but understanding the limitations regarding pressure and flow is essential.

Why Choose Faucet Supply Adapters for Plumbing Needs?

Faucet Supply Adapters are vital components for connecting faucets to water supply lines, available in multiple sizes to fit different systems. They are cost-effective and easy to replace, making them a popular choice among B2B buyers in the plumbing sector. However, buyers should be aware that additional fittings may be necessary depending on the specific installation requirements. Evaluating the compatibility with existing plumbing systems can prevent future issues.

What Role Do Air Gap Fittings Play in Water Safety?

Air Gap Fittings are crucial for preventing backflow in water purification systems, ensuring safety and compliance with health regulations. They come in various configurations to suit different installation needs. While they provide a reliable solution, their installation can be complex, requiring skilled labor. B2B buyers must weigh the importance of safety against installation costs and potential disruptions during setup.

How Do Inline Ball Valves Benefit Water Filtration Systems?

Inline Ball Valves are designed for compact spaces and offer precise control over water flow, making them ideal for water filtration systems and irrigation applications. Their manual operation allows for easy adjustments, but buyers should consider the inconvenience this may pose in larger systems requiring frequent adjustments. Evaluating the specific needs of the application will help determine if these valves are the right fit for operational efficiency.

Key Industrial Applications of ga murdock inc

| Industry/Sector | Specific Application of ga murdock inc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Point of Use (POU) and Point of Entry (POE) Systems | Enhances water quality and safety, ensuring compliance with regulations | Quality certifications, local regulations, and environmental standards |

| Plumbing and HVAC | Valves and fittings for plumbing installations | Reliable operation reduces maintenance costs and downtime | Material compatibility, pressure ratings, and installation requirements |

| Agriculture and Irrigation | Irrigation system components | Optimizes water usage, improving crop yield and sustainability | Availability of bulk orders, durability under varying climates |

| Aquaculture | Water quality control in fish farming | Ensures optimal conditions for aquatic life, boosting productivity | Resistance to corrosion and biofouling, along with local support services |

| Construction and Infrastructure | Plumbing parts for large-scale projects | Streamlined installation processes and reduced project timelines | Sourcing from local suppliers for timely delivery and support |

How Does G.A. Murdock, Inc. Support Water Treatment Needs?

G.A. Murdock, Inc. provides essential components for Point of Use (POU) and Point of Entry (POE) systems in the water treatment industry. These products, such as valves and fittings, are crucial for maintaining water quality and ensuring compliance with health regulations. For international buyers, especially in regions like Africa and South America, sourcing reliable equipment is vital to meet local standards and improve public health. The durability and performance of Murdock’s products help mitigate issues like contamination and system failures, offering significant value to businesses focused on water safety.

What Role Do G.A. Murdock Products Play in Plumbing and HVAC?

In the plumbing and HVAC sectors, G.A. Murdock’s extensive range of valves and fittings enhances the reliability of installations. Their products are designed for high performance, which minimizes maintenance requirements and operational downtime. For buyers in Europe and the Middle East, where stringent building codes are in place, ensuring the compatibility of materials and adherence to local regulations is essential. Murdock’s offerings provide peace of mind, ensuring installations are efficient and compliant, which can lead to cost savings over the lifespan of the infrastructure.

How Can G.A. Murdock Enhance Agricultural Practices?

In agriculture, G.A. Murdock’s irrigation system components play a crucial role in optimizing water usage. By ensuring efficient distribution and management of water resources, these products can significantly improve crop yields and sustainability. For buyers in regions like Brazil, where agriculture is a key economic driver, the ability to source durable and reliable irrigation components can lead to enhanced productivity. Additionally, Murdock’s focus on quality helps farmers overcome challenges related to water scarcity and environmental regulations.

What Benefits Do G.A. Murdock Products Provide in Aquaculture?

In aquaculture, maintaining water quality is critical for the health and productivity of fish stocks. G.A. Murdock’s products are tailored to meet the rigorous demands of aquaculture, ensuring optimal conditions for aquatic life. Their resistance to corrosion and biofouling is particularly beneficial in harsh environments. Buyers in the Middle East and Africa, where aquaculture is rapidly growing, can leverage Murdock’s expertise to enhance their operations. Sourcing high-quality components is essential to prevent losses and improve the overall sustainability of fish farming.

How Does G.A. Murdock Support Construction and Infrastructure Projects?

G.A. Murdock’s plumbing parts are integral to large-scale construction and infrastructure projects. By providing reliable and efficient components, they help streamline installation processes, ultimately reducing project timelines. For international buyers, especially in developing markets, the ability to source bulk orders can facilitate smoother project execution. Additionally, local support services and timely delivery are crucial considerations for ensuring project success, making Murdock a preferred partner in the construction industry.

3 Common User Pain Points for ‘ga murdock inc’ & Their Solutions

Scenario 1: Navigating Complex Sourcing Requirements for Water Treatment Components

The Problem: B2B buyers in regions such as Africa and South America often face significant challenges in sourcing high-quality water treatment components. Many suppliers provide products that do not meet local regulations or specific industry standards, leading to compliance issues and potential operational disruptions. This can be particularly frustrating for businesses that require reliable and durable components, such as valves and fittings, to ensure the integrity of their water systems. Buyers may feel overwhelmed by the variety of options and the need for rigorous product specifications, which can complicate the purchasing process.

The Solution: To effectively source from G.A. Murdock Inc., buyers should begin by thoroughly understanding their local regulations and requirements for water treatment components. This means collaborating with local authorities or industry experts to clarify the necessary certifications and standards. Once these requirements are established, buyers can utilize G.A. Murdock’s extensive catalog of products, ensuring they select items that are compliant with their specific needs.

Additionally, engaging directly with G.A. Murdock’s customer service team can provide insights into the best-fit products for particular applications, as they can recommend items that have been successfully used in similar scenarios. Buyers should also consider ordering samples or smaller quantities to evaluate the quality and compatibility of the products before committing to larger orders. By taking these proactive steps, businesses can streamline their sourcing process and ensure they receive components that enhance their operational efficiency.

Scenario 2: Managing Bulk Orders and Inventory Levels

The Problem: Companies dealing with large-scale water treatment projects often struggle with managing bulk orders and maintaining optimal inventory levels. Fluctuations in demand can lead to overstocking or stockouts, which negatively impact cash flow and project timelines. This issue is exacerbated for international buyers who may face longer lead times and logistical challenges when ordering from abroad.

The Solution: To mitigate these inventory management challenges, B2B buyers should implement a just-in-time (JIT) inventory strategy in conjunction with G.A. Murdock’s bulk purchasing options. By analyzing past consumption patterns and forecasting future demand, buyers can better align their orders with actual needs, reducing excess inventory and associated costs.

Moreover, establishing a relationship with G.A. Murdock’s sales representatives can facilitate better communication regarding lead times and availability. This partnership allows buyers to negotiate favorable terms, such as volume discounts or priority shipping options for urgent orders. Additionally, utilizing inventory management software can help track stock levels in real-time and automate reorder processes, ensuring that businesses maintain optimal inventory without sacrificing responsiveness to project demands.

Scenario 3: Overcoming Technical Challenges with Product Compatibility

The Problem: Many B2B buyers encounter compatibility issues when integrating new components into existing systems. For example, the water treatment industry often requires specialized fittings and connectors that must work seamlessly with various types of plumbing and water systems. When components from different manufacturers are incompatible, it can lead to costly delays and operational inefficiencies.

The Solution: To avoid compatibility pitfalls, buyers should prioritize purchasing from G.A. Murdock, known for its high-quality, standardized products. Before placing an order, buyers should conduct a thorough review of their current systems and identify the specific types of fittings and connectors required. Consulting G.A. Murdock’s product specifications and technical data sheets will help ensure that the selected components meet the necessary criteria for compatibility.

Furthermore, buyers can leverage G.A. Murdock’s technical support services to address any questions about product compatibility before making a purchase. Engaging in pre-purchase consultations can clarify how to integrate new components into existing systems effectively. By taking these steps, buyers can minimize the risk of technical challenges and ensure that their installations run smoothly, ultimately enhancing operational efficiency and reducing downtime.

Strategic Material Selection Guide for ga murdock inc

What Are the Key Properties of Common Materials Used in G.A. Murdock Inc. Products?

G.A. Murdock Inc. specializes in high-quality fluid valves and fittings, utilizing various materials to ensure optimal performance. Understanding the properties, advantages, and limitations of these materials is crucial for international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe.

1. Polypropylene

Key Properties: Polypropylene is a thermoplastic polymer known for its excellent chemical resistance and low density. It can withstand temperatures up to 100°C (212°F) and has a good pressure rating, making it suitable for various applications.

Pros & Cons: The primary advantages of polypropylene include its lightweight nature and resistance to a wide range of chemicals. However, it has lower impact resistance compared to other materials and can degrade under UV light, which may limit its use in outdoor applications.

Impact on Application: Polypropylene is ideal for applications involving water treatment and filtration systems, where chemical compatibility is critical. Its non-toxic nature makes it suitable for potable water applications.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding materials used in water systems. For instance, standards such as ASTM F876 for plastic piping should be considered, especially in regions like Brazil and Nigeria, where regulatory compliance is crucial.

2. PVC (Polyvinyl Chloride)

Key Properties: PVC is a widely used thermoplastic with good tensile strength and rigidity. It can handle temperatures up to 60°C (140°F) and is resistant to corrosion and chemicals.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it a popular choice for plumbing and water systems. However, it has limitations in high-temperature applications and can become brittle over time when exposed to UV light.

Impact on Application: PVC is suitable for a variety of plumbing fittings and valves, particularly in residential and commercial water systems. Its ability to resist corrosion makes it ideal for harsh environments.

Considerations for International Buyers: Compliance with standards such as ASTM D1784 is essential when selecting PVC products. Buyers should also consider the availability of PVC in their local markets, as some regions may have restrictions on its use.

3. Brass

Key Properties: Brass is an alloy of copper and zinc, known for its excellent corrosion resistance and mechanical properties. It can withstand high temperatures and pressures, making it suitable for various applications.

Pros & Cons: The durability and aesthetic appeal of brass are significant advantages, particularly in fittings and valves. However, brass can be more expensive than plastic alternatives and may require additional maintenance to prevent tarnishing.

Impact on Application: Brass is commonly used in high-pressure applications and is suitable for both hot and cold water systems. Its compatibility with a wide range of media makes it a versatile choice for various industries.

Illustrative image related to ga murdock inc

Considerations for International Buyers: Buyers should be aware of the regulations regarding lead content in brass, especially in Europe and North America, where strict standards exist. Compliance with standards like EN 12164 is crucial for ensuring product safety.

4. Stainless Steel

Key Properties: Stainless steel is known for its exceptional strength and corrosion resistance. It can handle high temperatures and pressures, making it suitable for demanding applications.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to corrosion, which extends the lifespan of products. However, it is more expensive than other materials and may require specialized manufacturing processes.

Impact on Application: Stainless steel is ideal for applications in harsh environments, such as industrial water treatment systems. Its ability to withstand extreme conditions makes it a preferred choice for critical applications.

Considerations for International Buyers: Buyers should ensure that stainless steel products comply with international standards such as ASTM A312 for pipe and tube fittings. Understanding local regulations regarding stainless steel grades is also essential for ensuring compatibility.

Summary Table of Material Selection for G.A. Murdock Inc.

| Material | Typical Use Case for G.A. Murdock Inc. | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Water treatment systems | Excellent chemical resistance | Lower impact resistance | Low |

| PVC | Plumbing fittings | Cost-effective and easy to manufacture | Limited high-temp use | Low |

| Brass | High-pressure valves | Durable and corrosion-resistant | Higher cost than plastics | Med |

| Stainless Steel | Industrial water systems | Exceptional strength | More expensive | High |

This strategic material selection guide provides a comprehensive overview of the materials used in G.A. Murdock Inc. products, enabling international B2B buyers to make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for ga murdock inc

What Are the Key Stages of Manufacturing at G.A. Murdock Inc.?

G.A. Murdock Inc. employs a comprehensive manufacturing process to ensure the production of high-quality fluid valves, fittings, and accessories for the water treatment industry. The manufacturing process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How Does Material Preparation Ensure Quality?

Material preparation is the foundational step in G.A. Murdock’s manufacturing process. The company sources only the finest raw materials, which are essential for producing durable and reliable products. Incoming materials undergo rigorous inspection and testing to verify compliance with industry standards. This includes checking for material composition, strength, and durability, ensuring that only the best materials enter the production line.

What Techniques Are Used in the Forming Process?

The forming stage involves various techniques tailored to the specific requirements of the components being produced. G.A. Murdock utilizes advanced machinery and technologies such as CNC machining and injection molding. These methods allow for precision shaping and cutting of materials, minimizing waste and optimizing efficiency. The company’s commitment to using state-of-the-art equipment ensures that all products meet stringent dimensional tolerances, which is critical for their functionality in fluid applications.

How Is Assembly Conducted to Maintain Quality?

Once components are formed, they move to the assembly stage, where skilled technicians assemble the products with a keen eye for detail. G.A. Murdock emphasizes the importance of trained personnel who understand the intricacies of each product line. This stage also includes the installation of various components, such as seals and valves, which require precise fitting to prevent leaks and ensure reliable operation.

What Finishing Techniques Are Applied for Enhanced Durability?

The final stage in the manufacturing process is finishing, where products undergo surface treatments to enhance durability and resistance to corrosion. G.A. Murdock employs techniques such as powder coating and anodizing, which provide protective layers that extend the life of the products. This attention to detail not only enhances the aesthetic appeal but also ensures that the products can withstand the rigors of their intended applications.

How Does G.A. Murdock Ensure Quality Assurance Throughout the Manufacturing Process?

Quality assurance (QA) is integral to G.A. Murdock’s operations, with a structured approach to maintaining high standards at every manufacturing stage. The company adheres to international standards such as ISO 9001, which outlines the criteria for a quality management system.

What International Standards and Certifications Are Followed?

G.A. Murdock is committed to meeting various international quality standards, including CE marking for compliance with European health, safety, and environmental protection standards, and API standards relevant to the petroleum and natural gas industries. These certifications signify that the company’s products are manufactured to meet rigorous performance and safety criteria, providing B2B buyers with confidence in their purchases.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that products meet specifications. G.A. Murdock employs several key checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials before they enter production, ensuring they meet predefined standards.

-

In-Process Quality Control (IPQC): During manufacturing, samples are taken at various intervals to monitor production quality and identify any deviations from standards immediately.

-

Final Quality Control (FQC): Before products are shipped, they undergo final inspections and testing to verify their functionality and safety. This may include pressure testing, leak testing, and functional testing of valves and fittings.

How Can B2B Buyers Verify the Quality Assurance Practices of G.A. Murdock?

B2B buyers can take several proactive steps to verify the quality assurance practices of G.A. Murdock and ensure they meet their specific needs.

Illustrative image related to ga murdock inc

What Auditing Processes Can Buyers Implement?

Buyers should consider conducting audits of G.A. Murdock’s facilities. This can include reviewing their quality management system, production processes, and compliance with international standards. Regular audits help buyers understand the supplier’s commitment to quality and identify areas for improvement.

How Can Buyers Access Quality Control Reports?

Buyers should request access to quality control reports that detail the results of IQC, IPQC, and FQC processes. These reports provide insight into the consistency and reliability of the products, allowing buyers to make informed decisions based on empirical data.

What Role Do Third-Party Inspections Play?

Engaging third-party inspectors can offer an additional layer of assurance. These independent entities can perform thorough examinations of the manufacturing processes and product quality, providing unbiased evaluations that enhance buyer confidence.

What Nuances Should International B2B Buyers Consider Regarding QC?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, there are specific nuances to consider regarding quality control.

How Do Different Regions Approach Quality Standards?

Understanding the regional differences in quality standards is crucial. For instance, European buyers may prioritize CE compliance, while buyers in the Middle East might focus on local certifications that align with regional regulations. It is essential for buyers to communicate their specific quality requirements clearly to G.A. Murdock.

What Challenges May Arise in Quality Assurance for International Orders?

Challenges such as varying regulatory requirements and logistical issues can impact quality assurance for international orders. Buyers should ensure that G.A. Murdock is well-versed in the compliance requirements of their respective countries and can provide the necessary documentation and certifications.

In conclusion, G.A. Murdock Inc. combines meticulous manufacturing processes with rigorous quality assurance practices to deliver high-quality products tailored for the water treatment industry. B2B buyers can leverage the insights provided here to assess the company’s capabilities and ensure they receive reliable, compliant products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ga murdock inc’

To assist international B2B buyers in effectively sourcing products from G.A. Murdock Inc., this guide provides a comprehensive checklist. This step-by-step approach ensures that you make informed decisions, ultimately leading to successful procurement of water conditioning supplies and accessories.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is the foundation of successful sourcing. Clearly outline the types of products you need, such as valves, fittings, and connectors, including their sizes and materials. This clarity helps streamline communication with suppliers and ensures that you receive the correct products tailored to your operational needs.

Step 2: Research G.A. Murdock Inc. Product Range

Familiarize yourself with the comprehensive product offerings of G.A. Murdock Inc. Explore their catalog to identify specific items that meet your specifications. Pay attention to product features, specifications, and any unique selling points that differentiate their offerings in the market.

- Focus on Quality: Ensure that the products meet the industry standards and regulations applicable in your region.

- Consider Compatibility: Check if the products are compatible with your existing systems and components.

Step 3: Evaluate Potential Suppliers

Before finalizing a supplier, conduct a thorough evaluation. Request detailed company profiles, product samples, and references from businesses in similar industries. This step is crucial to ascertain the reliability and reputation of G.A. Murdock Inc. as a supplier.

- Check Reviews and Testimonials: Look for feedback from other B2B buyers to gauge satisfaction levels.

- Assess Customer Support: Inquire about their support services for post-purchase assistance.

Step 4: Verify Supplier Certifications and Compliance

Ensure that G.A. Murdock Inc. holds relevant certifications and adheres to quality standards. Certifications such as ISO or other industry-specific accreditations can indicate a commitment to quality and compliance with international regulations.

- Request Documentation: Ask for copies of certifications and compliance documents.

- Understand Warranty Policies: Review warranty terms and conditions to safeguard your investment.

Step 5: Negotiate Pricing and Terms

Engage in discussions to negotiate pricing, payment terms, and delivery schedules. Establishing favorable terms can significantly affect your overall procurement costs and cash flow.

- Consider Bulk Discounts: Inquire about pricing structures for large orders to maximize savings.

- Clarify Shipping Costs: Understand all shipping and handling fees to avoid unexpected expenses.

Step 6: Place Your Order and Confirm Details

Once all terms are agreed upon, place your order while ensuring that all details are correct. Double-check quantities, specifications, and delivery timelines to prevent any misunderstandings.

- Document Everything: Keep records of all communications and agreements for future reference.

- Set Up Tracking: Establish a system to track your order from confirmation to delivery.

Step 7: Conduct Quality Checks Upon Receipt

Upon receiving your order, conduct thorough quality checks to ensure that all items meet your specifications and quality standards. This step is vital to address any discrepancies immediately.

- Inspect Products: Verify that the items are undamaged and function as intended.

- Provide Feedback: Share your experiences with G.A. Murdock Inc. to help improve their offerings and services.

By following this structured approach, B2B buyers can effectively source products from G.A. Murdock Inc., ensuring a smooth procurement process and fostering long-term business relationships.

Comprehensive Cost and Pricing Analysis for ga murdock inc Sourcing

In analyzing the cost structure and pricing strategy for G.A. Murdock Inc., a key player in the wholesale water conditioning supplies industry, it is essential to break down the various cost components and price influencers that affect international B2B buyers.

What Are the Key Cost Components in G.A. Murdock’s Pricing?

Materials: G.A. Murdock utilizes high-quality materials for its products, which significantly impacts production costs. The choice of durable materials ensures reliability but may increase the overall price. For international buyers, understanding the material specifications can help gauge the value of the product.

Labor: Labor costs are a substantial component of the total cost structure. G.A. Murdock’s products are manufactured in the U.S., where labor costs can be higher than in other regions. This factor can lead to higher pricing, especially for bulk orders.

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. G.A. Murdock’s commitment to quality control and stringent manufacturing standards can elevate these overhead costs, which are typically reflected in the pricing.

Tooling: The initial investment in tooling and molds for production can be significant. For custom orders or unique specifications, these costs may be amortized over larger production runs, impacting the unit price.

Quality Control: G.A. Murdock emphasizes quality assurance, which involves rigorous testing and inspection processes. While this ensures a high-quality product, it also adds to the overall cost structure.

Logistics: Shipping and handling costs can vary widely based on destination, volume, and chosen Incoterms. These logistics costs are critical for international buyers who must consider additional fees like tariffs and duties.

Margin: Finally, the profit margin that G.A. Murdock incorporates into its pricing will depend on competitive positioning and market demand. Understanding their margin can provide insight into pricing flexibility during negotiations.

What Influences Pricing for International B2B Buyers?

Volume and Minimum Order Quantity (MOQ): Pricing often varies significantly based on order volume. Buyers should inquire about MOQ, as larger orders typically result in lower per-unit costs. This is particularly relevant for businesses in Africa and South America, where economies of scale can be beneficial.

Specifications and Customization: Custom orders can lead to higher costs due to additional tooling and production processes. Buyers should assess whether the customization aligns with their needs and budget.

Materials and Quality Certifications: The materials used and any quality certifications (e.g., ISO standards) can influence pricing. Buyers should ensure that the specifications meet their operational requirements, especially in regulated markets.

Supplier Factors: The reputation and reliability of the supplier can affect pricing. G.A. Murdock’s established presence in the industry may command a premium, but this often translates to better service and support.

Incoterms: Understanding the implications of Incoterms is crucial for international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly influence total landed costs.

What Are Effective Buyer Tips for Negotiating Prices?

Leverage Volume Discounts: Engage in discussions about bulk purchasing to secure better pricing. Presenting a commitment to larger orders can provide leverage during negotiations.

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase prices, consider maintenance, potential downtime, and replacement costs associated with the products. A slightly higher upfront cost may yield savings in the long run through enhanced durability and reliability.

Negotiate Terms: Ensure clarity on payment terms, delivery schedules, and warranties. Flexible payment options or extended warranties can enhance the value of your purchase.

Research Market Prices: Conduct comparative analyses with other suppliers to understand competitive pricing. This knowledge can empower buyers during negotiations.

In conclusion, understanding the comprehensive cost structure and pricing dynamics of G.A. Murdock Inc. is essential for international B2B buyers. By considering the outlined cost components, price influencers, and effective negotiation tips, businesses can make informed purchasing decisions that align with their operational needs and budgets.

Alternatives Analysis: Comparing ga murdock inc With Other Solutions

Understanding Alternatives in Water Treatment Solutions

When considering water treatment solutions, it’s crucial for B2B buyers to evaluate multiple options to identify the best fit for their specific operational needs. G.A. Murdock Inc. is well-known for its high-quality fluid valves and fittings, but alternatives exist that may offer different advantages in performance, cost, and implementation. This analysis compares G.A. Murdock with two viable alternatives, providing insights to help international buyers make informed decisions.

| Comparison Aspect | G.A. Murdock Inc | AquaTech Solutions | PureFlow Technologies |

|---|---|---|---|

| Performance | High reliability and durability | Moderate reliability, suitable for light use | High performance, advanced filtration technology |

| Cost | Mid-range pricing | Lower cost | Higher cost, premium quality |

| Ease of Implementation | Straightforward installation | Easy to install, user-friendly | Requires technical expertise |

| Maintenance | Low maintenance needs | Moderate maintenance | Regular maintenance required |

| Best Use Case | Industrial and commercial settings | Residential and light commercial | Industrial applications requiring advanced filtration |

What are the Advantages and Disadvantages of AquaTech Solutions?

AquaTech Solutions provides a more budget-friendly alternative for buyers focusing on light use applications. Its products are designed for ease of installation, making them accessible for businesses without extensive technical expertise. However, their moderate reliability means they may not perform well under high-demand conditions, making them less suitable for heavy industrial applications. Buyers looking for cost-effective, simpler solutions may find AquaTech appealing, but they should be cautious if their operations require robust performance.

How Does PureFlow Technologies Compare?

PureFlow Technologies stands out with its advanced filtration technology, ideal for industrial applications that demand high performance. Its products are engineered to deliver superior water quality, making them suitable for sectors like pharmaceuticals and food processing. However, the premium price point and the requirement for technical expertise for installation and maintenance can be barriers for some businesses. Companies with stringent quality standards and the budget to support them may find PureFlow to be a worthwhile investment, despite the higher initial costs.

How to Choose the Right Water Treatment Solution for Your Business?

Selecting the right water treatment solution involves assessing your specific operational needs, budget constraints, and maintenance capabilities. G.A. Murdock Inc. is a reliable choice for businesses requiring durable and high-performance components. In contrast, AquaTech Solutions may be better suited for smaller operations needing cost-effective solutions. Lastly, for industries demanding advanced filtration, PureFlow Technologies offers unmatched performance despite the higher investment. By carefully analyzing these factors, B2B buyers can make informed decisions that align with their operational goals and financial strategies.

Essential Technical Properties and Trade Terminology for ga murdock inc

What Are the Essential Technical Properties of G.A. Murdock Inc. Products?

G.A. Murdock Inc. specializes in high-quality water conditioning supplies, including fittings, valves, and accessories. Understanding the technical properties of these products is crucial for B2B buyers looking to ensure reliability and compliance in their operations.

1. Material Grade

G.A. Murdock products are primarily made from high-grade polypropylene and PVC, known for their durability and resistance to corrosion. In B2B transactions, specifying material grade is vital as it directly affects product longevity and performance in various environments, particularly in water treatment applications.

2. Tolerance Levels

Tolerance refers to the allowable deviation in dimensions for manufactured components. For instance, fittings may have specific tolerance levels to ensure a proper fit with piping systems. This is essential for maintaining system integrity and preventing leaks, which can lead to costly damages and downtime.

3. Pressure Ratings

Pressure ratings indicate the maximum pressure that a valve or fitting can withstand during operation. G.A. Murdock products often feature pressure ratings that comply with industry standards, making them suitable for various applications. Understanding these ratings helps buyers select appropriate components for their specific pressure requirements, ensuring safety and operational efficiency.

4. Flow Rate

Flow rate measures the volume of fluid that can pass through a valve or fitting over a specified time, typically expressed in gallons per minute (GPM). For B2B buyers, knowing the flow rate is crucial when designing systems to meet specific water supply needs, ensuring that the system can handle expected demand without compromising performance.

5. Operating Temperature

Operating temperature defines the range within which a product can function effectively. G.A. Murdock products are designed to perform under varying temperature conditions, which is important for applications in different climates. Buyers must consider this property to avoid product failure in extreme temperatures.

What Are Common Trade Terms Used in B2B Transactions with G.A. Murdock Inc.?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B settings. Here are some common terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of G.A. Murdock, understanding OEM relationships can help buyers identify the source of quality and reliability in the components they purchase.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ for G.A. Murdock products is crucial for budget planning and inventory management, especially when sourcing large volumes.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When engaging with G.A. Murdock, submitting an RFQ can facilitate better pricing negotiations and ensure that all required specifications are addressed.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers as they dictate shipping costs, risk transfer, and delivery responsibilities.

5. POU and POE (Point of Use and Point of Entry)

POU and POE refer to systems that treat water at the point where it is consumed (e.g., faucets) and at the point where it enters a facility (e.g., main water lines), respectively. Understanding these terms is vital for buyers seeking to implement effective water treatment solutions that align with their operational needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right products for their specific applications and optimize their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the ga murdock inc Sector

What Are the Key Market Dynamics and Trends Affecting G.A. Murdock Inc.?

The global market for water treatment components, including fittings and valves, is experiencing significant growth, driven by increasing concerns over water quality and the need for efficient water management systems. International B2B buyers, particularly in emerging markets such as Nigeria and Brazil, are increasingly prioritizing high-quality water conditioning supplies to meet rising domestic and industrial demand. The integration of technology in sourcing processes is also becoming prominent; for instance, the adoption of digital platforms for procurement is streamlining supply chains and enhancing transparency.

Emerging trends indicate a shift towards automation and IoT-enabled devices within the water treatment sector. These innovations not only optimize operational efficiencies but also provide real-time monitoring capabilities, which are crucial for maintaining water quality standards. As regulatory frameworks tighten globally, particularly in regions like Europe and the Middle East, businesses must stay abreast of compliance requirements, leading to increased demand for reliable suppliers like G.A. Murdock Inc. who adhere to stringent quality control measures.

Furthermore, the ongoing focus on sustainability is reshaping sourcing strategies. Buyers are increasingly looking for suppliers who can demonstrate their commitment to environmentally friendly practices and products. This trend is particularly relevant for international buyers from regions that are actively working to improve their sustainability profiles.

How Is Sustainability Influencing B2B Sourcing Decisions in the G.A. Murdock Inc. Sector?

Sustainability is no longer just a buzzword; it has become a critical factor in B2B sourcing decisions. The environmental impact of water treatment products, including the materials used in manufacturing and the lifecycle of these products, is under scrutiny. International buyers are now prioritizing suppliers who offer sustainable solutions, such as those utilizing eco-friendly materials and practices.

G.A. Murdock Inc. is well-positioned to meet these demands, as the company is committed to producing high-quality products that minimize environmental impact. The use of durable materials and efficient manufacturing processes not only reduces waste but also enhances product longevity, aligning with the growing preference for ‘green’ certifications among buyers.

Moreover, ethical sourcing practices are becoming increasingly important. Buyers are demanding transparency in the supply chain to ensure that products are sourced responsibly. G.A. Murdock’s adherence to ethical standards in its operations and sourcing is a significant advantage in attracting conscientious B2B buyers across various global markets.

What Is the Historical Context of G.A. Murdock Inc. That Influences Its Current B2B Standing?

Founded in 1987, G.A. Murdock Inc. has established itself as a reliable provider of water treatment components, including valves and fittings. The company’s long-standing commitment to quality and innovation has allowed it to maintain a strong presence in the market. By continually adapting to industry trends and technological advancements, G.A. Murdock has positioned itself as a leader in the water treatment sector.

Over the years, the company has developed a robust product line that caters to diverse customer needs, enhancing its appeal to international B2B buyers. G.A. Murdock’s emphasis on manufacturing in the U.S. ensures rigorous quality control, providing buyers with confidence in the reliability of their products. This historical foundation of quality and innovation remains a cornerstone of G.A. Murdock’s strategy as it navigates the evolving market dynamics and sourcing trends.

Frequently Asked Questions (FAQs) for B2B Buyers of ga murdock inc

-

How do I solve supply chain disruptions when sourcing from G.A. Murdock, Inc.?

To mitigate supply chain disruptions, establish clear communication with G.A. Murdock’s sales and logistics teams. Ensure you understand their production schedules and lead times. Utilize tracking tools provided by the company to monitor your orders in real time. Additionally, consider diversifying your sourcing strategy by establishing relationships with multiple suppliers to reduce reliance on a single source. -

What is the best way to ensure product quality when purchasing from G.A. Murdock, Inc.?

To ensure product quality, request detailed specifications and certifications for the products you are interested in. G.A. Murdock, Inc. prides itself on stringent quality control standards, so asking for samples can help assess quality firsthand. Establish a quality assurance process that includes regular inspections and feedback loops to address any issues immediately, ensuring that products meet your specific requirements. -

How can I customize products from G.A. Murdock, Inc. to meet my business needs?

G.A. Murdock, Inc. offers customization options for various products, including fittings and valves. To initiate the customization process, contact their sales team directly with your specific requirements. Be prepared to provide details about your application, desired materials, and any regulatory standards you need to meet. This will help the team provide tailored solutions that fit your operational needs. -

What is the minimum order quantity (MOQ) for G.A. Murdock, Inc. products?

The minimum order quantity (MOQ) may vary based on the specific product category and customization options. Generally, G.A. Murdock, Inc. accommodates various purchasing needs, from small orders to bulk purchases. For precise MOQ information, it’s advisable to contact their sales department or check their product catalogs directly, ensuring you receive the most accurate and relevant details. -

What payment terms does G.A. Murdock, Inc. offer for international buyers?

G.A. Murdock, Inc. typically offers flexible payment terms for international buyers, including options for wire transfers, letters of credit, and payment upon delivery. It’s essential to discuss payment terms upfront during negotiations to ensure clarity and mutual agreement. Additionally, inquire about any applicable taxes, duties, or fees associated with international transactions to budget accordingly. -

How does G.A. Murdock, Inc. handle shipping and logistics for international orders?

G.A. Murdock, Inc. partners with reliable logistics providers to manage shipping and delivery for international orders. They offer various shipping options to accommodate different timelines and budgets. It’s crucial to communicate your shipping requirements and destination clearly to ensure the best service. Additionally, confirm whether they handle customs clearance or if you need to arrange that independently. -

What should I consider when vetting suppliers like G.A. Murdock, Inc. for my business?

When vetting suppliers, consider their industry reputation, years of experience, and customer reviews. Investigate their manufacturing capabilities, quality assurance processes, and compliance with international standards. Request references from other B2B clients, particularly those in your region, to gain insights into their reliability and service quality. A thorough vetting process helps ensure a successful and long-term partnership. -

How can I stay updated on product offerings and innovations from G.A. Murdock, Inc.?

To stay informed about new products and innovations, subscribe to G.A. Murdock, Inc.’s newsletter and follow their social media channels. Attend trade shows and industry events where they may showcase their latest offerings. Engaging with their sales representatives can also provide insights into upcoming products and technologies, ensuring your business remains competitive in the market.

Top 5 Ga Murdock Inc Manufacturers & Suppliers List

1. Gamurdock – Professional Water Treatment Solutions

Domain: gamurdock.com

Registered: 1997 (28 years)

Introduction: This company, Gamurdock – Professional Water Treatment Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. GA Murdock – Water Purification Supplies

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, GA Murdock – Water Purification Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. LinkedIn – Dedicated API

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: To scrape Linkedin use our dedicated Linkedin API.

4. G.A. Murdock – Plumbing Parts

Domain: freshwatersystems.com

Registered: 1998 (27 years)

Introduction: This company, G.A. Murdock – Plumbing Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. GA Murdock, Inc. – Fluid Valves & Fittings

Domain: bulkreefsupply.com

Registered: 2007 (18 years)

Introduction: This company, GA Murdock, Inc. – Fluid Valves & Fittings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for ga murdock inc

What Are the Key Takeaways for International Buyers Considering G.A. Murdock Inc.?

G.A. Murdock Inc. stands out in the water treatment industry by offering a diverse range of high-quality fluid valves, fittings, and accessories. Their commitment to using premium materials and strict quality control ensures that products meet the rigorous demands of various applications. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, sourcing from G.A. Murdock provides not only reliability but also value through competitive pricing and bulk purchasing options.

How Can Strategic Sourcing Enhance Your Supply Chain?

Strategic sourcing with G.A. Murdock allows businesses to optimize their supply chain while securing high-performance products tailored to specific needs. By partnering with a reputable supplier, buyers can leverage G.A. Murdock’s extensive expertise and innovative solutions to enhance operational efficiency and reduce costs. This collaboration can foster long-term relationships, ensuring consistent quality and service.

What’s Next for B2B Buyers in the Global Market?

As the global market evolves, G.A. Murdock Inc. is poised to expand its offerings to meet emerging needs. International buyers are encouraged to take proactive steps in engaging with G.A. Murdock to explore customized solutions that align with their specific requirements. Embrace the opportunity to enhance your supply chain and drive growth by connecting with G.A. Murdock today. Your future in reliable water treatment solutions starts here.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.