Slime Containers: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for slime containers

In an increasingly competitive landscape, sourcing the right slime containers can pose a significant challenge for international B2B buyers. As the demand for vibrant, durable, and aesthetically pleasing packaging grows—particularly in markets across Africa, South America, the Middle East, and Europe—businesses must navigate a complex array of options to ensure their products stand out. This guide serves as a comprehensive resource, covering essential topics such as the diverse types of slime containers available, their specific applications, effective supplier vetting strategies, and cost considerations.

Understanding the intricacies of slime container procurement is vital for achieving operational efficiency and product integrity. Whether you are a small craft business in Brazil or a large-scale distributor in Nigeria, this guide will equip you with the insights needed to make informed purchasing decisions. It emphasizes the importance of selecting containers that not only preserve the quality of your slime products but also enhance your brand’s appeal.

By exploring the nuances of materials, design, and functionality, this guide empowers you to choose the best solutions tailored to your market needs. With actionable insights and expert recommendations, you will be well-prepared to navigate the global market for slime containers, ensuring your business remains competitive and your products remain appealing.

Understanding slime containers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Jars | Lightweight, various sizes, high durability | Retail packaging, storage for slime | Pros: Cost-effective, versatile; Cons: Less eco-friendly compared to glass. |

| Glass Jars | Premium feel, excellent visibility, airtight seals | High-end retail, display purposes | Pros: Aesthetic appeal, better for long-term storage; Cons: Heavier, more fragile. |

| Airtight Containers | Specialized sealing mechanisms to prevent air exposure | Long-term storage, shipping solutions | Pros: Keeps slime fresh longer; Cons: Higher cost, bulkier. |

| Sample Packs | Smaller, portable jars for trial sizes | Promotional items, market testing | Pros: Lower investment for buyers; Cons: Limited quantity. |

| Customizable Containers | Options for branding, size, and material | Personalized packaging solutions | Pros: Enhances brand recognition; Cons: Longer lead times for production. |

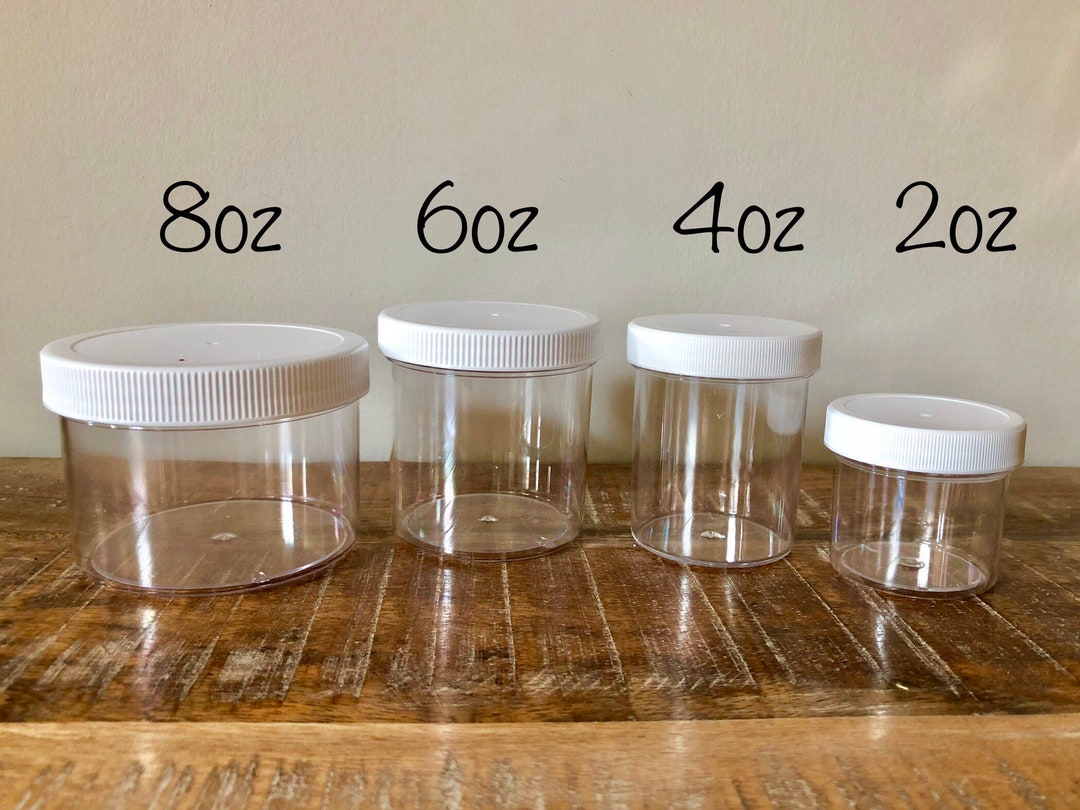

What Are the Key Characteristics of Plastic Jars for Slime Storage?

Plastic jars are a staple in the slime industry due to their lightweight nature and varying size options, making them ideal for both retail and storage purposes. These containers are crafted from durable materials, ensuring they withstand the rigors of transit and handling. B2B buyers should consider the cost-effectiveness of plastic jars, as they are generally more affordable than glass options. However, they may not be as environmentally friendly, which could be a concern for businesses focused on sustainability.

How Do Glass Jars Enhance the Presentation of Slime Products?

Glass jars are often preferred for high-end slime products due to their premium appearance and excellent visibility. They feature airtight seals that help maintain the freshness of the slime, making them suitable for long-term storage and display in retail environments. B2B buyers should note that while glass jars offer aesthetic advantages, they are heavier and more fragile, which could lead to higher shipping costs and potential breakage during transport.

Why Are Airtight Containers Essential for Slime Preservation?

Airtight containers are designed with specialized sealing mechanisms that prevent air exposure, which is crucial for maintaining the quality of slime over time. These containers are ideal for businesses looking to store slime for extended periods or ship it without compromising its integrity. While they offer significant advantages in terms of freshness, buyers should be aware that these containers often come at a higher price point and may take up more space in storage.

What Benefits Do Sample Packs Provide for Market Testing?

Sample packs consist of smaller, portable jars that allow businesses to offer trial sizes of their slime products. These packs serve as effective promotional items and are useful for market testing before committing to larger production runs. B2B buyers appreciate the lower investment associated with sample packs, though they should consider the limitation in quantity, which may not meet the demands of larger consumer bases.

How Can Customizable Containers Boost Brand Recognition?

Customizable containers provide businesses with the opportunity to enhance their brand visibility through personalized packaging solutions. Buyers can choose from various sizes and materials to create a unique presentation that aligns with their brand identity. While these containers can significantly boost brand recognition, B2B buyers should factor in the longer lead times for production, which may affect inventory management and delivery schedules.

Key Industrial Applications of slime containers

| Industry/Sector | Specific Application of Slime Containers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Toy Manufacturing | Packaging of DIY slime kits for children | Enhances product appeal and retention; promotes creativity | Need for clear, durable jars that can withstand rough handling |

| Craft Supplies Retail | Storage for slime and craft materials | Improves organization; increases upsell opportunities | Variety of sizes and airtight seals are essential |

| Educational Institutions | Use in science projects and educational workshops | Supports hands-on learning; engages students | Containers must be safe and easy to use for children |

| Cosmetics and Skincare | Packaging for DIY beauty products like lip scrubs | Appeals to eco-conscious consumers; aligns with trends | Non-toxic materials and aesthetic design are crucial |

| Food and Beverage | Storage for edible slime products or novelty snacks | Unique product offering; attracts diverse customer base | Compliance with food safety regulations is mandatory |

How Are Slime Containers Utilized in Toy Manufacturing?

In the toy manufacturing sector, slime containers are essential for packaging DIY slime kits aimed at children. These containers not only enhance the visual appeal of the product but also ensure that the slime remains fresh and intact. The ability to display vibrant colors through clear jars attracts young consumers, making the product more marketable. For international buyers, especially from regions like Africa and South America, sourcing durable containers that can withstand shipping challenges is paramount to maintaining product integrity.

What Role Do Slime Containers Play in Craft Supplies Retail?

Craft supplies retailers utilize slime containers for storing various materials, including slime, beads, and glitter. This organization improves the shopping experience and encourages customers to purchase additional crafting supplies. Retailers should consider containers with airtight seals to maintain product quality and prevent spillage. For buyers from Europe and the Middle East, offering a variety of sizes can cater to diverse customer needs, enhancing the overall value proposition.

How Are Slime Containers Beneficial in Educational Institutions?

Educational institutions leverage slime containers for hands-on science projects and workshops, engaging students in creative learning. These containers allow for safe storage and easy access to slime, making them ideal for classroom environments. Buyers in this sector must prioritize safety features, ensuring that containers are non-toxic and user-friendly for children. Sourcing partners should provide reliable shipping options to accommodate bulk orders for educational supplies, especially in developing regions.

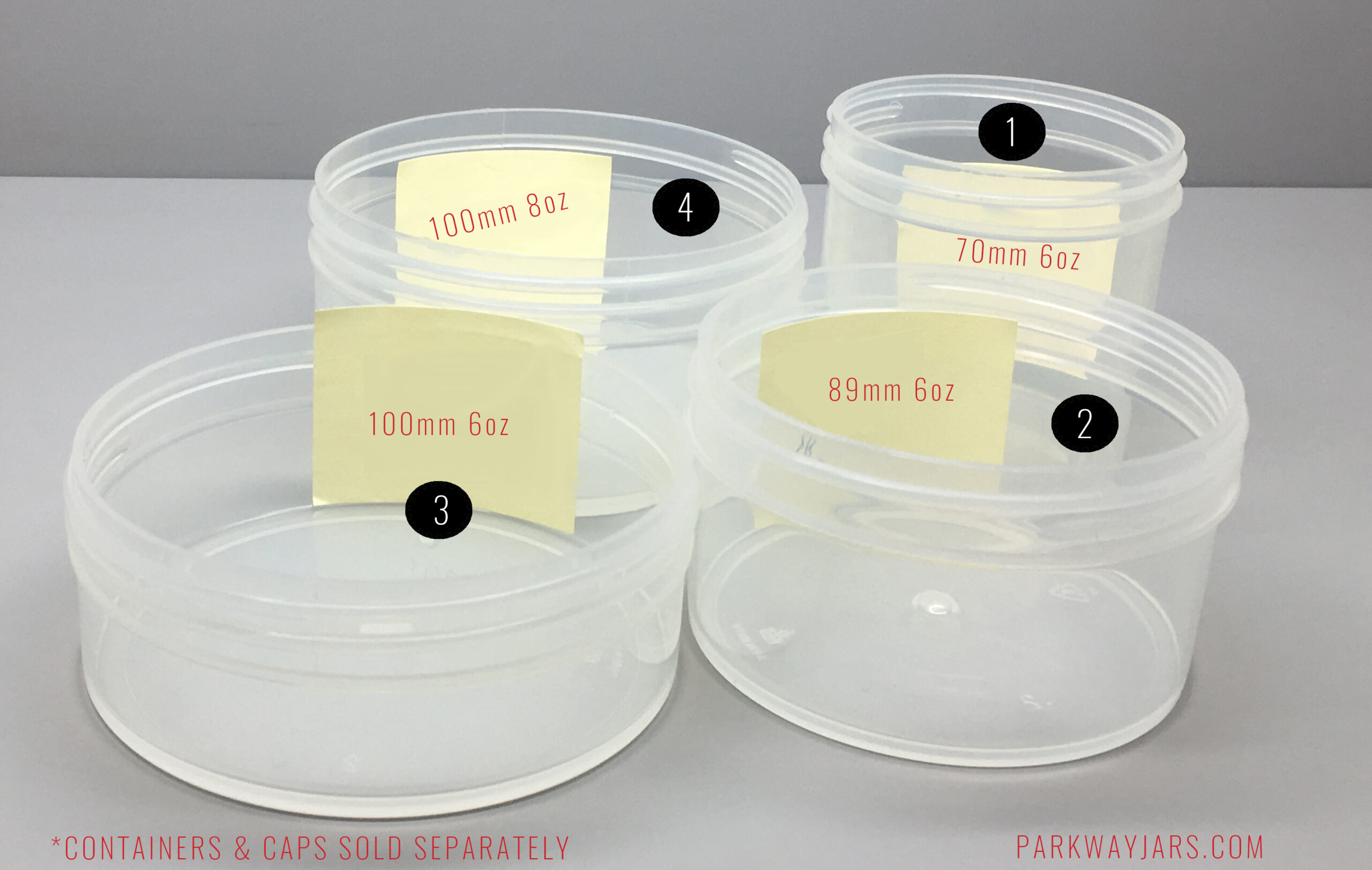

Illustrative image related to slime containers

In What Ways Do Cosmetics and Skincare Brands Use Slime Containers?

In the cosmetics and skincare industry, slime containers are increasingly popular for packaging DIY beauty products such as lip scrubs and face masks. These containers appeal to eco-conscious consumers who favor sustainable and customizable options. Buyers in this sector should focus on sourcing non-toxic, aesthetically pleasing containers that align with current trends. Ensuring that packaging complies with safety regulations is critical for international buyers, particularly in markets with stringent cosmetic guidelines.

How Are Slime Containers Employed in the Food and Beverage Sector?

Slime containers find a unique application in the food and beverage industry, particularly for novelty edible slime products. These containers help businesses offer creative and fun food items that attract a wide customer base. It is essential for suppliers to ensure that the materials used are compliant with food safety regulations, particularly for international markets like Africa and Brazil, where food safety standards can vary significantly. Providing clear labeling options can also enhance product visibility and consumer trust.

3 Common User Pain Points for ‘slime containers’ & Their Solutions

Scenario 1: The Fragility of Slime Containers During Shipping

The Problem: B2B buyers often face significant challenges related to the fragility of slime containers during shipping. Many suppliers use low-quality materials that can crack or break in transit, leading to damaged products and increased costs. This not only results in financial losses due to returns and replacements but also affects customer satisfaction and brand reputation. Buyers are left scrambling to find reliable containers that can withstand the rigors of shipping without compromising the integrity of the slime inside.

The Solution: To mitigate shipping-related issues, buyers should prioritize sourcing slime containers made from high-quality materials like polypropylene (PP) or PET. These materials are known for their durability and resistance to impacts. When selecting a supplier, it is crucial to inquire about their shipping practices and whether they conduct thorough quality checks before dispatching products. Additionally, buyers can request samples to evaluate the sturdiness of the containers firsthand. Packaging the jars with protective materials, such as bubble wrap or foam inserts, can further ensure they arrive intact. Investing in robust containers ultimately saves costs in the long run and boosts customer confidence in your products.

Scenario 2: Difficulty in Maintaining Slime Freshness

The Problem: Another common issue faced by B2B buyers is the difficulty in maintaining the freshness of slime products. Many containers do not provide an airtight seal, leading to issues like drying out or altering the slime’s texture over time. This not only reduces the quality of the product but can also result in unsatisfied customers who may seek refunds or replacements. Buyers need containers that ensure long-term preservation of slime while also being user-friendly for end consumers.

The Solution: To address this issue, buyers should focus on sourcing slime containers with airtight lids designed specifically for preserving moisture. Look for options that feature a silicone gasket or a screw-on design that minimizes air exposure. Additionally, consider the size of the container; smaller jars can be useful for limited batches to reduce air exposure when opened. When making purchasing decisions, ask suppliers about their lid technology and how it contributes to product longevity. Implementing these solutions will help maintain the quality of the slime, leading to higher customer satisfaction and repeat business.

Scenario 3: Inadequate Size Options for Diverse Product Lines

The Problem: Many B2B buyers encounter challenges with the limited size options of slime containers, which can hinder their ability to market different product lines effectively. For instance, a buyer may find that their current supplier only offers a few standard sizes, making it difficult to cater to diverse customer preferences or create appealing bundles. This can lead to wasted inventory and lost sales opportunities, as customers may be unable to find the size that suits their needs.

The Solution: To overcome size limitations, buyers should seek suppliers that offer a wide range of container sizes, from small sample jars to larger bulk options. Customization capabilities can also be a significant advantage; consider suppliers that allow for bespoke sizes or designs tailored to specific product lines. Additionally, implementing a flexible inventory management system can help in quickly adapting to market demands and trends. Engage with suppliers who understand the importance of variety and can provide insights into which sizes are trending in the slime market. By diversifying container sizes, buyers can better meet customer needs and maximize their sales potential.

Illustrative image related to slime containers

Strategic Material Selection Guide for slime containers

When selecting materials for slime containers, it’s crucial for B2B buyers to understand the properties, advantages, and limitations of various materials. This knowledge directly influences product performance, cost-effectiveness, and compliance with international standards. Here, we analyze four common materials used in slime containers: Polypropylene (PP), Polyethylene Terephthalate (PET), Glass, and High-Density Polyethylene (HDPE).

What Are the Key Properties of Polypropylene (PP) for Slime Containers?

Polypropylene is a thermoplastic polymer known for its durability and resistance to various chemicals. It can withstand temperatures up to 100°C (212°F) without deforming, making it suitable for storing slime that may be sensitive to heat. Additionally, PP is resistant to moisture and provides a good barrier against gases, which helps maintain the freshness of slime products.

Pros and Cons of Polypropylene (PP)

The advantages of PP include its lightweight nature, low cost, and excellent impact resistance. However, it can be more challenging to recycle compared to other plastics, which may be a concern for environmentally conscious buyers. In terms of manufacturing complexity, PP is relatively easy to mold, making it a popular choice for high-volume production.

Impact on Application

PP is compatible with various slime media, including those that contain borax or other additives. Its chemical resistance ensures that it won’t react with the slime, preserving the product’s integrity.

Considerations for International Buyers

B2B buyers from regions like Africa, South America, and the Middle East should ensure that their suppliers comply with international standards such as ASTM D638 for tensile properties. Additionally, understanding local regulations regarding plastic use and recycling can help mitigate compliance risks.

How Does Polyethylene Terephthalate (PET) Perform in Slime Container Applications?

PET is another widely used plastic known for its excellent clarity and strength. It can handle temperatures up to 60°C (140°F) and is often chosen for its aesthetic appeal, allowing consumers to see the vibrant colors of the slime inside.

Pros and Cons of Polyethylene Terephthalate (PET)

The main advantage of PET is its recyclability, which aligns with sustainability goals. However, it is generally more expensive than PP and may not offer the same level of impact resistance. The manufacturing process for PET can be more complex, often requiring specialized equipment.

Impact on Application

PET is compatible with a range of slime formulations but may not be ideal for those containing high levels of moisture, as it can be less effective at preventing moisture ingress compared to PP.

Illustrative image related to slime containers

Considerations for International Buyers

Buyers should be aware of recycling capabilities in their regions, especially in Europe, where PET recycling is well-established. Compliance with DIN EN ISO 1183 for density can also be crucial for ensuring quality.

Why Choose Glass for Slime Containers?

Glass containers offer a premium feel and excellent barrier properties, making them ideal for high-end slime products. They can withstand high temperatures and are non-reactive, ensuring that the slime remains uncontaminated.

Pros and Cons of Glass

The primary advantage of glass is its durability and recyclability. However, it is heavier than plastic and can break easily during transport, which may lead to increased shipping costs and potential product loss. Manufacturing glass containers is also more complex and costly compared to plastics.

Impact on Application

Glass is suitable for all types of slime, especially those that require long-term storage. Its inert nature means that it won’t leach any chemicals into the slime.

Considerations for International Buyers

B2B buyers must consider the fragility of glass during shipping, particularly in regions with less reliable logistics. Compliance with safety standards, such as ASTM C162 for glass containers, is also essential.

What Are the Benefits of High-Density Polyethylene (HDPE) for Slime Containers?

HDPE is known for its high strength-to-density ratio and resistance to impact and chemicals. It can withstand temperatures up to 120°C (248°F), making it versatile for various applications.

Pros and Cons of HDPE

The advantages of HDPE include its durability and cost-effectiveness. However, it is less transparent than PP or PET, which may not appeal to all consumers. The manufacturing process is straightforward, allowing for efficient production.

Impact on Application

HDPE is suitable for slime formulations that require a robust container but may not be ideal for products that benefit from visibility.

Considerations for International Buyers

Buyers should ensure that HDPE containers comply with international standards like ASTM D3350 for polyethylene pipe. Understanding local regulations on plastic use is also critical, especially in regions with stringent environmental laws.

Summary Table of Material Selection for Slime Containers

| Material | Typical Use Case for Slime Containers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | General-purpose slime storage | Lightweight and impact-resistant | Less recyclable | Low |

| Polyethylene Terephthalate (PET) | High-visibility slime products | Excellent clarity and recyclability | Higher cost and manufacturing complexity | Med |

| Glass | Premium slime packaging | Non-reactive and recyclable | Heavy and fragile | High |

| High-Density Polyethylene (HDPE) | Durable slime storage | Cost-effective and strong | Less visibility | Low |

By understanding the properties and implications of these materials, B2B buyers can make informed decisions that align with their product goals and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for slime containers

What Are the Key Stages in the Manufacturing Process of Slime Containers?

The manufacturing process for slime containers involves several critical stages that ensure high-quality production. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting the appropriate plastic materials, typically Polypropylene (PP) or Styrene. These materials are chosen for their durability and safety for storing slime. Raw materials are often sourced from certified suppliers to ensure compliance with international standards. The materials undergo rigorous testing to confirm their chemical properties and suitability for food-grade applications, if necessary.

-

Forming: Once the materials are prepared, they are fed into a molding machine. Common techniques include injection molding and blow molding. In injection molding, molten plastic is injected into a mold to create the desired shape of the slime container. Blow molding, on the other hand, involves inflating a heated plastic tube within a mold to form hollow containers. Both methods allow for precise control over the dimensions and wall thickness of the containers, which is vital for ensuring durability during shipping and storage.

-

Assembly: After forming, the containers are often combined with their respective lids. This step is crucial as the effectiveness of the lid can significantly impact the freshness and usability of the slime inside. Automated assembly lines are commonly used to enhance efficiency and ensure consistent quality.

-

Finishing: The final stage involves quality checks and surface treatments, such as labeling or applying shrink sleeves for branding. Containers may also undergo additional processes like UV treatment to enhance clarity and resistance to yellowing over time.

How Is Quality Assurance Integrated into the Manufacturing of Slime Containers?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final products meet stringent international standards. For slime container manufacturers, adhering to standards such as ISO 9001 is essential.

-

International Standards: ISO 9001 is a globally recognized quality management standard that emphasizes consistent quality and customer satisfaction. Manufacturers often pursue this certification to demonstrate their commitment to quality processes and continuous improvement.

-

Industry-Specific Certifications: Depending on the intended market, additional certifications may be required. For instance, CE marking is crucial for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards. In regions like Africa and South America, suppliers may also need to adhere to local regulations, which can vary significantly.

-

Quality Control Checkpoints: Manufacturers typically implement a multi-tiered quality control (QC) system, which includes:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor production processes and identify any deviations from quality standards.

- Final Quality Control (FQC): After production, each batch of slime containers undergoes rigorous testing, which may include dimensional checks, leak tests, and impact resistance assessments.

What Common Testing Methods Are Used to Ensure Slime Container Quality?

Several testing methods are employed to verify the quality and safety of slime containers, ensuring they meet customer and regulatory expectations.

-

Dimensional Testing: This ensures that containers are produced to the exact specifications. Measurements are taken to confirm that the size, shape, and capacity of the containers align with design parameters.

-

Leak Testing: Since freshness is vital for slime products, containers are subjected to leak tests. This may involve filling the containers with water and subjecting them to pressure to check for any leaks.

-

Impact Resistance Testing: This assesses the durability of the containers during handling and shipping. Containers are dropped from various heights to simulate real-world conditions and ensure they can withstand impacts without breaking.

-

Chemical Resistance Testing: For safety, containers must be tested for their ability to resist interactions with the slime’s ingredients. This is particularly important for custom formulations that may include various additives.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial.

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. Buyers should inquire about the frequency of these audits and the areas of focus.

-

Quality Reports: Requesting access to quality control reports can help buyers assess the supplier’s performance over time. These reports typically include results from various tests and any corrective actions taken to address issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services often conduct inspections at various stages of production, offering additional reassurance regarding product quality.

-

Certification Verification: Buyers should verify the authenticity of any certifications claimed by suppliers. This can often be done through the certifying bodies or by requesting documentation that supports the claims made by the supplier.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers should be aware of specific nuances in quality control when sourcing slime containers from different regions.

Illustrative image related to slime containers

-

Regulatory Compliance: Different countries have varying regulations regarding plastic containers. For example, European buyers must ensure compliance with REACH regulations, which govern the use of chemicals in products. Understanding these regulations is essential to avoid potential fines or product recalls.

-

Cultural Considerations: Quality expectations can vary significantly across cultures. B2B buyers should communicate their quality requirements clearly and be open to understanding local manufacturing practices that may influence these standards.

-

Logistics and Transportation: Quality assurance does not end with production. Buyers must also consider how the containers are packaged and shipped. Ensuring that containers are packed securely to prevent damage during transit is crucial, especially when shipping internationally.

-

After-Sales Support: Finally, establishing a relationship with suppliers that includes after-sales support can help in managing any quality issues that may arise post-delivery. A responsive supplier can make a significant difference in maintaining product quality and customer satisfaction.

In conclusion, understanding the manufacturing processes and quality assurance practices for slime containers is vital for B2B buyers. By focusing on the stages of production, quality control measures, and verification processes, buyers can make informed decisions that align with their business needs and market expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘slime containers’

Introduction

This sourcing guide is designed to assist B2B buyers in effectively procuring slime containers, ensuring that the chosen products meet both quality and functionality standards. Whether you are sourcing for a manufacturing business, a retail operation, or a craft supply company, following this checklist will help you make informed decisions that align with your specific needs.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline the specifications for your slime containers. Consider factors such as material type (e.g., polypropylene or PET), size options (ranging from small 2 oz jars to larger 32 oz containers), and design features (like airtight lids). Defining these parameters early on will streamline the sourcing process and help you communicate your needs effectively to potential suppliers.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify suppliers with a solid reputation in the industry. Look for companies that specialize in plastic containers and have experience supplying slime jars. Utilize online platforms, industry directories, and trade shows to compile a list of potential suppliers.

- Check Reviews: Read customer testimonials and reviews to gauge satisfaction levels and product quality.

- Request Samples: Don’t hesitate to ask for product samples to evaluate the containers’ durability and functionality firsthand.

Step 3: Evaluate Supplier Certifications

Before making a purchase, verify that the suppliers hold relevant certifications. Certifications such as ISO 9001 for quality management systems or compliance with food safety standards can indicate a supplier’s commitment to quality.

Illustrative image related to slime containers

- Ask for Documentation: Request copies of certifications and compliance documents to ensure that the products meet international standards.

- Look for Sustainability Practices: Inquire about the supplier’s environmental policies, especially if sustainability is a priority for your business.

Step 4: Assess Product Quality and Durability

Quality is paramount when it comes to slime containers, as they need to withstand shipping and handling without cracking or leaking. Evaluate the materials used in the containers and ensure they are robust enough to protect the slime during transit.

- Material Testing: Consider suppliers that conduct rigorous testing on their products to guarantee strength and safety.

- User Feedback: Gather insights from other businesses regarding their experiences with the supplier’s products, focusing on durability and usability.

Step 5: Understand Pricing and Payment Terms

Engage suppliers in discussions about pricing structures and payment terms. A clear understanding of costs, including bulk pricing and potential discounts, is crucial for budgeting.

- Compare Quotes: Request quotes from multiple suppliers to assess competitive pricing.

- Negotiate Terms: Don’t hesitate to negotiate payment terms that align with your cash flow needs, such as net 30 or net 60 options.

Step 6: Confirm Shipping and Logistics Capabilities

Ensure that the supplier can meet your logistics requirements, including shipping timelines and methods. Discuss shipping costs and options to avoid unexpected expenses.

- Shipping Reliability: Ask about the supplier’s track record for on-time deliveries and how they handle potential shipping issues.

- Global Shipping Expertise: If you are sourcing internationally, confirm the supplier’s experience in exporting to your region, considering customs and import regulations.

Step 7: Establish a Communication Protocol

Set up a clear communication plan with your chosen supplier to facilitate ongoing dialogue. This includes regular updates on order status, product availability, and any potential changes in specifications.

Illustrative image related to slime containers

- Designate Contacts: Identify key contacts on both sides for efficient communication.

- Utilize Technology: Consider using project management or communication tools to streamline interactions and maintain transparency throughout the sourcing process.

By following this checklist, B2B buyers can ensure a thorough and effective sourcing process for slime containers, leading to successful procurement and long-term supplier relationships.

Comprehensive Cost and Pricing Analysis for slime containers Sourcing

What Are the Key Cost Components in Sourcing Slime Containers?

When sourcing slime containers, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of plastic, such as Polypropylene (PP) or Styrene, significantly affects cost. Higher-quality materials ensure durability and transparency, but they also come at a premium. Buyers should evaluate the trade-offs between cost and quality to meet their product requirements.

-

Labor: Labor costs vary based on geographical location and the complexity of the manufacturing process. Automated production lines can reduce labor costs but may require higher initial capital investment.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize overhead, impacting the final product price.

-

Tooling: For custom container designs, tooling costs can be substantial. Investing in high-quality molds can lead to better product quality and longer lifespan, which could justify the initial expense.

-

Quality Control: Effective QC processes ensure that containers meet industry standards and customer expectations. While this adds to costs, it can prevent returns and enhance customer satisfaction.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping method, and import duties can significantly influence total costs.

-

Margin: Suppliers typically mark up prices to cover operational costs and generate profit. Understanding a supplier’s margin expectations can aid in negotiation.

How Do Pricing Influencers Impact the Cost of Slime Containers?

Several factors can influence the final pricing of slime containers. These include volume and minimum order quantities (MOQs), specifications or customization, material quality and certifications, supplier reliability, and Incoterms.

-

Volume/MOQ: Bulk orders often lead to lower per-unit prices due to economies of scale. Buyers should assess their inventory needs to negotiate favorable terms.

-

Specs/Customization: Custom designs or specialized features (like child-resistant lids) can add to costs. Buyers should weigh the benefits of customization against its impact on pricing.

-

Materials and Quality: Higher-grade materials may yield better durability and shelf appeal but will increase costs. Certifications such as FDA approval can also add to the price.

-

Supplier Factors: The supplier’s reputation, reliability, and location can affect pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) determine responsibilities for shipping costs and risks, impacting the total landed cost for buyers.

What Are Effective Buyer Tips for Negotiating Slime Container Prices?

To maximize cost-efficiency and achieve favorable pricing, B2B buyers should consider the following strategies:

-

Negotiate Terms: Engage in discussions about payment terms, delivery schedules, and MOQs. Flexibility on either side can lead to a win-win situation.

-

Evaluate Total Cost of Ownership: Beyond the initial purchase price, consider the total cost of ownership, including shipping, storage, and potential waste. A lower upfront cost may lead to higher long-term expenses.

-

Understand Pricing Nuances for International Buyers: International buyers must be aware of currency fluctuations, import duties, and regional market conditions that may impact pricing.

-

Explore Multiple Suppliers: Obtaining quotes from multiple suppliers can provide leverage in negotiations and help identify the best value for money.

Disclaimer

Prices for slime containers can vary significantly based on the factors outlined above. The information provided is indicative and should be verified with suppliers for accurate pricing tailored to specific needs.

Illustrative image related to slime containers

Alternatives Analysis: Comparing slime containers With Other Solutions

Introduction to Alternative Solutions for Slime Storage

In the competitive landscape of slime production and distribution, selecting the right storage solution is crucial for maintaining product quality and ensuring customer satisfaction. While specialized slime containers are a popular choice, there are alternative methods and technologies that can also serve the purpose. This section compares slime containers with two viable alternatives: silicone molds and vacuum-sealed bags. Understanding the strengths and weaknesses of each option can empower B2B buyers to make informed decisions based on their specific operational needs.

Comparison Table

| Comparison Aspect | Slime Containers | Silicone Molds | Vacuum-Sealed Bags |

|---|---|---|---|

| Performance | Excellent for visibility and freshness | Good for shaping, but limited storage | Great for preserving freshness |

| Cost | Moderate cost per unit | Higher initial investment | Low cost per unit |

| Ease of Implementation | Simple to use and available in various sizes | Requires molding process | Requires vacuum sealing equipment |

| Maintenance | Minimal, easy to clean | Requires careful cleaning | Low, but bags may need replacing |

| Best Use Case | Retail display and long-term storage | Crafting unique shapes and designs | Short-term storage and transport |

Detailed Breakdown of Alternatives

Silicone Molds

Silicone molds offer a unique approach to slime storage by allowing producers to create specific shapes and designs. These molds are flexible, making it easy to remove the slime without damaging its structure. However, while they excel in crafting appealing shapes, they are less effective for long-term storage and visibility. Additionally, the initial investment in molds can be higher than that of traditional slime containers, making them a less budget-friendly option for businesses focused on volume production.

Vacuum-Sealed Bags

Vacuum-sealed bags present an economical alternative for storing slime, especially for short-term needs. By removing air, these bags help preserve the slime’s freshness and prevent it from drying out or becoming sticky. They are particularly useful for transporting products, as they reduce the risk of spills and damage during shipping. However, vacuum-sealed bags lack the visibility that containers provide, making it difficult for consumers to see the product before purchase. Moreover, the need for vacuum sealing equipment adds complexity to the implementation process.

Conclusion: Choosing the Right Solution for Slime Storage

When selecting a storage solution for slime, B2B buyers must consider various factors, including performance, cost, ease of implementation, and maintenance requirements. Slime containers offer the best overall performance for visibility and freshness, making them ideal for retail settings. Conversely, silicone molds are better suited for creative applications, while vacuum-sealed bags are cost-effective for short-term storage and transport. Ultimately, the choice depends on the specific operational needs and strategic goals of the business, whether that’s maximizing shelf appeal, reducing costs, or enhancing transport efficiency. By weighing these alternatives carefully, buyers can optimize their slime storage strategy to achieve greater customer satisfaction and operational success.

Essential Technical Properties and Trade Terminology for slime containers

What Are the Key Technical Properties of Slime Containers?

When sourcing slime containers, understanding their technical specifications is crucial for ensuring product integrity and customer satisfaction. Here are some essential properties to consider:

1. Material Grade

The most common materials for slime containers are Polypropylene (PP) and Polystyrene (PS). PP is known for its durability, chemical resistance, and flexibility, making it ideal for holding slime without cracking. PS offers excellent clarity, allowing the vibrant colors of slime to be visible, which is essential for retail displays. Choosing the right material can affect the longevity and visual appeal of the product.

2. Tolerance

Tolerance refers to the allowable variation in dimensions during manufacturing. For slime containers, tolerances are crucial for ensuring that lids fit securely and prevent leaks. High-quality manufacturers maintain strict tolerances to ensure that every container is uniform in size, which is particularly important for bulk orders. This consistency minimizes production issues and enhances the overall user experience.

3. Seal Type

The effectiveness of the seal on a slime container determines its ability to keep the contents fresh and prevent spills. Airtight seals are preferred, as they protect the slime from drying out and maintain its texture. Understanding the different types of seals (e.g., screw-on, snap-on) can help buyers select containers that best meet their product needs.

4. Size Options

Slime containers come in various sizes, typically ranging from small sample jars (2 oz) to larger retail containers (32 oz). The choice of size impacts shipping costs, shelf space, and customer convenience. Offering a range of sizes allows businesses to cater to different market segments, from individual consumers to bulk buyers.

Illustrative image related to slime containers

5. UV Resistance

For products that may be displayed in sunlight, UV resistance is an important property. Containers that are UV resistant help prevent discoloration and degradation of the slime inside. This feature can be a selling point for retailers who want to ensure that their products maintain their vibrant appearance over time.

6. Customization Options

Many suppliers offer customization options, such as colors, labeling, and packaging. This can include in-mold labeling or custom printing, which enhances brand visibility. Buyers should consider how these options can differentiate their products in a competitive market.

What Are Common Trade Terms Related to Slime Containers?

Familiarity with industry jargon can streamline the purchasing process and facilitate better negotiations. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are sold under another company’s brand name. In the context of slime containers, buyers may engage with OEMs to produce custom designs or branded containers, ensuring their product stands out in the market.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is vital for buyers, especially smaller businesses that may not need large quantities. Suppliers often set MOQs based on production efficiency, so negotiating this can lead to cost savings.

3. RFQ (Request for Quotation)

An RFQ is a formal document that a buyer sends to suppliers to request pricing information on specific products or services. This document typically outlines the required specifications, quantities, and delivery timelines. Using RFQs can help buyers obtain competitive pricing and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Understanding these terms is crucial for B2B transactions involving slime containers, as they clarify who is responsible for shipping costs, insurance, and customs duties. Familiarity with Incoterms can help avoid misunderstandings and protect both parties in a transaction.

5. Lead Time

Lead time refers to the period between placing an order and receiving the products. For businesses that depend on timely inventory replenishment, understanding lead times is essential. This allows for better planning and ensures that stock levels meet customer demand without delays.

By considering these technical properties and familiarizing themselves with industry terminology, B2B buyers can make informed decisions that enhance their operations and product offerings in the competitive slime market.

Navigating Market Dynamics and Sourcing Trends in the slime containers Sector

What Are the Key Market Dynamics and Trends Affecting Slime Container Sourcing?

The global slime container market is experiencing a notable shift driven by various factors, including the rising popularity of DIY crafts and the increased demand for visually appealing packaging. As slime-related products gain traction across different demographics, particularly among children and young adults, the need for durable and aesthetically pleasing containers has surged. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are capitalizing on this trend, seeking suppliers who can provide high-quality, versatile containers that cater to local preferences and market conditions.

Emerging technologies are also influencing sourcing trends in the slime container sector. The adoption of advanced materials, such as biodegradable plastics, and innovations in container design, such as tamper-evident lids, are making products more appealing. Furthermore, the shift towards e-commerce has necessitated packaging solutions that ensure safe transit while maintaining visual integrity. Suppliers that offer comprehensive logistics solutions, including bulk shipping options and inventory management tools, are becoming increasingly valuable to B2B buyers looking to streamline operations.

How Are Sustainability and Ethical Sourcing Influencing Slime Container Purchases?

Sustainability is a paramount concern for today’s B2B buyers, particularly in markets that are increasingly eco-conscious. The environmental impact of plastic waste has led to a demand for slime containers made from recycled or biodegradable materials. Suppliers that offer eco-friendly packaging solutions not only attract environmentally aware customers but also position themselves as leaders in responsible manufacturing practices.

Ethical sourcing plays a critical role in establishing a trustworthy supply chain. Buyers are now prioritizing suppliers who adhere to fair labor practices and can demonstrate transparency in their sourcing methods. Certifications such as the Forest Stewardship Council (FSC) for sustainable materials or ISO 14001 for environmental management are becoming essential benchmarks for B2B buyers. By investing in containers that meet these criteria, companies can enhance their brand reputation while contributing to a more sustainable future.

How Has the Slime Container Market Evolved Over Time?

The evolution of slime containers can be traced back to the rise of the slime trend itself, which gained significant momentum in the early 2010s. Initially, simple plastic jars were used to store homemade slime, but as the market expanded, so did the diversity of container options. Manufacturers began to innovate with designs that not only enhanced functionality but also improved the visual appeal of products. This evolution has led to a variety of sizes, shapes, and materials tailored to meet the needs of both consumers and businesses.

In recent years, the integration of technology in manufacturing processes has allowed for more efficient production methods, resulting in cost-effective solutions for B2B buyers. As the market continues to grow, the focus on sustainability and ethical sourcing will likely shape the future trajectory of slime container development, ensuring that the industry remains aligned with global standards and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of slime containers

-

How do I ensure the slime containers I order are of high quality?

To ensure you receive high-quality slime containers, consider sourcing from reputable suppliers with a proven track record. Request samples before placing a bulk order to assess material strength, lid effectiveness, and overall durability. Look for containers made from robust materials like polypropylene (PP) or PET, which are known for their sturdiness. Additionally, check for customer reviews and ratings to gauge satisfaction levels and any potential issues with the products. -

What is the best size for slime containers based on usage?

The best size for slime containers largely depends on your target market and the volume of slime you intend to sell. For retail, smaller jars (2-8 oz) are ideal for individual sales or samples, while larger containers (16 oz or more) can be suitable for bulk purchases or DIY kits. Offering a variety of sizes can cater to different customer preferences and maximize your market reach, allowing for both impulse buys and larger orders. -

What customization options are available for slime containers?

Many suppliers offer customization options for slime containers, including color, size, and labeling. You can request specific colors that align with your brand or add custom designs to enhance visual appeal. Some manufacturers provide in-mold labeling or shrink sleeves for branding purposes. Discuss your requirements with potential suppliers to understand their capabilities and minimum order quantities for customized products. -

What are the typical minimum order quantities (MOQs) for slime containers?

Minimum order quantities for slime containers can vary significantly among suppliers. Generally, MOQs range from 500 to 5,000 units, depending on the product type and customization options. It’s essential to communicate your needs with potential suppliers to negotiate terms that fit your business model. If you’re a smaller business, some suppliers may offer flexible options or allow for mixed orders to meet MOQ requirements. -

How do I vet potential suppliers for slime containers?

To effectively vet suppliers, start by researching their reputation in the industry. Look for reviews, testimonials, and any certifications that indicate compliance with quality standards. Request references from other businesses they’ve worked with and inquire about their production capabilities, lead times, and customer service responsiveness. Additionally, consider visiting their facility if possible or requesting a video tour to assess their operations firsthand. -

What payment terms should I expect when ordering slime containers internationally?

Payment terms can vary based on the supplier and the nature of the transaction. Common arrangements include a deposit upon order confirmation, with the balance due before shipping. Some suppliers may offer net payment terms after delivery. It’s advisable to clarify payment methods (such as wire transfer, credit card, or PayPal) and any associated fees. Establishing clear terms upfront helps avoid misunderstandings and ensures a smoother transaction process. -

What logistics considerations should I keep in mind for shipping slime containers?

When shipping slime containers internationally, consider factors such as shipping costs, delivery times, and customs regulations. Choose a logistics provider experienced in handling your type of goods and ensure they offer tracking capabilities. Be aware of import duties and taxes that may apply in your destination country. To minimize shipping costs, consider consolidating orders or using bulk shipping methods when feasible. -

How can I maintain quality assurance (QA) for my slime containers?

To maintain quality assurance for your slime containers, implement a multi-step QA process. Start with inspecting incoming shipments for defects or inconsistencies. Establish criteria for evaluating container integrity, such as checking for cracks or improper seals. Regularly communicate with your supplier about quality expectations and consider periodic audits of their manufacturing processes. This proactive approach helps ensure that your products consistently meet your quality standards.

Top 2 Slime Containers Manufacturers & Suppliers List

1. Parkway – Slime Jars

Domain: parkwayjars.com

Registered: 1996 (29 years)

Introduction: Slime Jars by Parkway are high-quality, clarified and styrene containers designed for slime projects. Key features include:

– Crystal clear quality for showcasing vibrant colors.

– Durable and stylish construction from high-quality materials.

– Available in various sizes, including mini jars and larger options.

– Wide mouth design for easy access and packaging.

– Keeps slime fresh, preventing…

2. Target – Slime Storage Solutions

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Slime Storage Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for slime containers

In the ever-evolving market for slime containers, strategic sourcing emerges as a vital component for success. By carefully selecting suppliers that prioritize quality, durability, and functionality, businesses can ensure their products remain fresh and visually appealing, ultimately enhancing customer satisfaction. The demand for reliable slime storage solutions is growing, particularly in regions such as Africa, South America, the Middle East, and Europe. This presents a significant opportunity for B2B buyers to partner with manufacturers who understand the unique needs of the slime industry.

Illustrative image related to slime containers

Investing in high-quality containers not only protects your product during transit but also elevates your brand’s reputation. As you navigate supplier options, consider features such as material strength, airtight seals, and a variety of sizes to meet diverse market demands.

Looking ahead, the slime container market is set for expansion, driven by increasing consumer interest in DIY crafts and creative play. Now is the time for international buyers to establish strong partnerships with trusted suppliers, ensuring a steady supply of innovative and durable containers. Embrace this opportunity to enhance your product offerings and meet the growing needs of your clientele.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.