Unlocking Value: A Strategic Analysis of the Swing Check Valve Pvc Market

Introduction: Navigating the Global Market for swing check valve pvc

In the rapidly evolving landscape of industrial applications, sourcing reliable swing check valves made of PVC can be a complex challenge for international B2B buyers. These valves are critical in preventing backflow, which can lead to costly damages and operational inefficiencies. Understanding the various types, applications, and specifications of PVC swing check valves is essential for making informed purchasing decisions. This guide is designed to navigate you through the intricacies of the global market for swing check valves, covering an array of topics from different valve types, such as standard and industrial variants, to their applications in diverse industries.

We delve into the essential aspects of supplier vetting, ensuring you partner with reputable manufacturers and distributors that meet international quality standards. Additionally, we provide insights into pricing structures, helping you to budget effectively while maximizing value. Whether you are operating in Africa, South America, the Middle East, or Europe—regions that present unique market dynamics and regulatory considerations—this guide empowers you with the knowledge to make confident decisions. By leveraging this comprehensive resource, you will enhance your procurement strategies, minimize risks, and ultimately ensure the integrity of your operations across various applications.

Understanding swing check valve pvc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PVC Swing Check Valve | Simple design, available in various sizes, automatic function | Water supply, irrigation systems | Pros: Easy installation, cost-effective. Cons: May create turbulence in flow. |

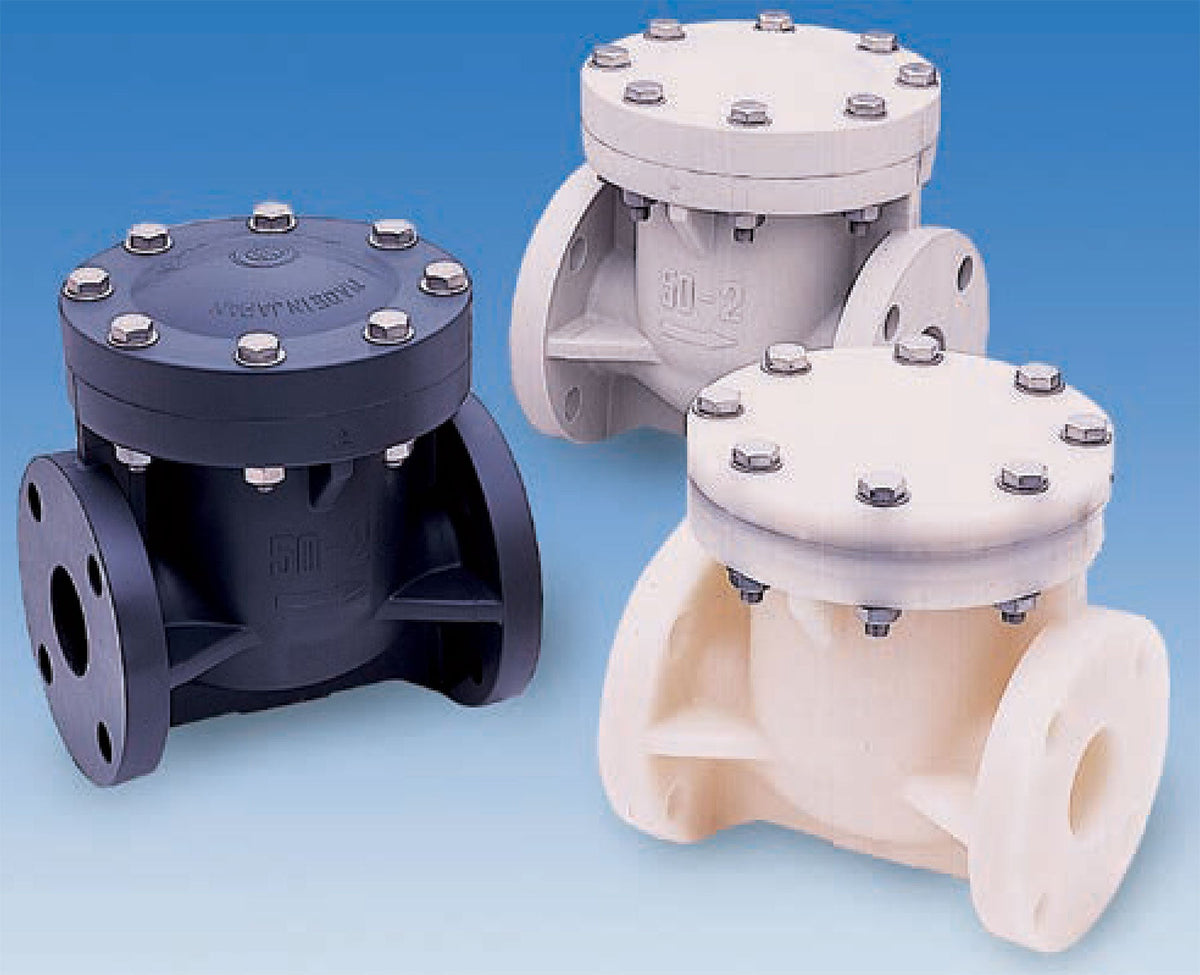

| Industrial PVC Swing Check Valve | Robust construction, higher pressure tolerance, larger sizes | Chemical processing, industrial applications | Pros: Durable, suitable for harsh conditions. Cons: Higher initial investment. |

| Clear PVC True Union Swing Check Valve | Visibility of flow, true union design for easy maintenance | Aquaculture, water treatment facilities | Pros: Allows for flow monitoring, easy to clean. Cons: May be more expensive than standard models. |

| Backwater Valve | Designed to prevent backflow in sewer systems | Wastewater management, municipal applications | Pros: Protects against flooding, reliable. Cons: Limited to specific applications. |

| Clear PVC Swing Check Valve | Transparent material for monitoring flow | Laboratory settings, aquariums | Pros: Visual flow confirmation, lightweight. Cons: Less durable than opaque options. |

What Are the Characteristics of Standard PVC Swing Check Valves?

Standard PVC swing check valves are among the most commonly used types in various applications, particularly in water supply and irrigation systems. Their straightforward design allows for easy installation and operation, making them a go-to choice for businesses looking to prevent backflow. However, buyers should be aware that while they are cost-effective, the design can induce turbulence in the fluid, potentially leading to pressure drops in certain systems.

How Do Industrial PVC Swing Check Valves Differ?

Industrial PVC swing check valves are engineered for more demanding environments, featuring a robust construction that can withstand higher pressures and larger flow rates. These valves are ideal for chemical processing and other industrial applications where durability is paramount. While their strength and reliability justify a higher initial investment, buyers should consider the long-term benefits of reduced maintenance and replacement costs in harsh conditions.

Why Choose Clear PVC True Union Swing Check Valves?

Clear PVC true union swing check valves are designed for applications where visibility of the flow is essential, such as in aquaculture or water treatment facilities. The true union feature allows for easy disassembly, making maintenance straightforward. While they offer the advantage of flow monitoring and are easy to clean, businesses must weigh the higher costs against the benefits of visibility and ease of maintenance.

What Are the Benefits of Using Backwater Valves?

Backwater valves are specifically designed to prevent backflow in sewer systems, making them critical for wastewater management and municipal applications. Their reliable operation helps protect against flooding, providing peace of mind for businesses in areas prone to heavy rain or flooding. However, their specialized nature means they may not be suitable for all applications, and buyers should ensure they meet specific requirements.

When Should You Consider Clear PVC Swing Check Valves?

Clear PVC swing check valves are particularly useful in laboratory settings and aquariums, where monitoring the flow of liquids is crucial. Their transparent material allows users to visually confirm flow, which is beneficial for quality control. However, buyers should note that these valves may be less durable than their opaque counterparts, which could impact longevity in demanding environments.

Key Industrial Applications of swing check valve pvc

| Industry/Sector | Specific Application of swing check valve pvc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Preventing backflow in filtration systems | Ensures clean water supply, protecting infrastructure and resources | Sourcing durable, corrosion-resistant materials; compliance with local regulations |

| Agriculture | Irrigation systems to control water flow | Reduces water wastage and optimizes irrigation efficiency | Compatibility with existing systems; availability of various sizes |

| Chemical Processing | Managing flow in chemical transfer systems | Protects sensitive equipment from backflow and contamination | Resistance to specific chemicals; quality assurance certifications |

| HVAC Systems | Preventing backflow in heating and cooling systems | Maintains system efficiency and prevents damage to components | Temperature and pressure ratings; ease of installation and maintenance |

| Mining and Minerals | Controlling flow in slurry pipelines | Prevents backflow that can damage pumps and pipelines | Ability to handle abrasive materials; customization options for sizes |

How Are Swing Check Valves Used in Water Treatment Applications?

In water treatment facilities, PVC swing check valves are critical for preventing backflow in filtration systems. They ensure that clean water remains uncontaminated by blocking any reverse flow that could compromise the supply. For international buyers, especially from Africa and South America where water scarcity is a pressing issue, sourcing valves that comply with local water quality standards and are made from durable, corrosion-resistant materials is essential. This guarantees long-term reliability and minimizes maintenance costs.

What Role Do Swing Check Valves Play in Agriculture?

In agricultural settings, swing check valves are employed in irrigation systems to control water flow effectively. By preventing backflow, these valves help optimize water usage and reduce wastage, which is especially crucial in regions facing water shortages. Buyers from the Middle East, where water conservation is vital, should consider the compatibility of these valves with existing irrigation systems and their availability in various sizes to meet specific agricultural needs.

How Are Swing Check Valves Essential in Chemical Processing?

In chemical processing industries, PVC swing check valves are integral for managing the flow of various chemicals. They protect sensitive equipment from backflow, which can lead to contamination and costly damages. When sourcing for this application, international buyers must prioritize valves that are resistant to specific chemicals and have quality assurance certifications. This ensures that the valves can withstand harsh conditions while maintaining operational integrity.

Illustrative image related to swing check valve pvc

Why Are Swing Check Valves Important in HVAC Systems?

In HVAC systems, swing check valves prevent backflow, ensuring efficient operation of heating and cooling processes. They help maintain system efficiency and protect components from potential damage caused by reverse flow. For buyers in Europe, particularly in regions with stringent energy efficiency regulations, selecting valves with appropriate temperature and pressure ratings is crucial. Additionally, ease of installation and maintenance can significantly impact operational costs.

How Do Swing Check Valves Benefit the Mining Industry?

In the mining and minerals sector, swing check valves are used to control flow in slurry pipelines, preventing backflow that can damage pumps and other equipment. This application is vital for maintaining operational efficiency and reducing downtime. Buyers from regions with extensive mining operations should focus on sourcing valves that can handle abrasive materials and offer customization options to fit various pipeline sizes, ensuring they meet specific operational demands.

3 Common User Pain Points for ‘swing check valve pvc’ & Their Solutions

Scenario 1: Navigating Installation Challenges with Swing Check Valves

The Problem: B2B buyers often face significant challenges during the installation of PVC swing check valves, particularly in complex systems. Misalignment during installation can lead to backflow issues, causing potential flooding or damage to sensitive equipment downstream. Buyers may also struggle with the varying sizes and types of valves, making it difficult to ensure compatibility with existing piping systems. This not only results in costly delays but can also lead to safety hazards if the valves do not function correctly.

The Solution: To mitigate installation challenges, it’s crucial to thoroughly assess the specifications of the existing system before purchasing PVC swing check valves. Buyers should opt for valves that match the diameter and pressure ratings of their pipelines. Additionally, investing in clear PVC swing check valves can provide visual confirmation of proper flow direction during installation, enhancing reliability. Detailed installation guides or manufacturer-provided videos can offer step-by-step assistance, ensuring proper alignment and secure fittings. Collaborating with experienced technicians during installation can further minimize errors and ensure compliance with industry standards.

Scenario 2: Addressing Material Compatibility Concerns

The Problem: Many international B2B buyers face difficulties in ensuring that their chosen PVC swing check valves are compatible with the fluids in their systems. This is particularly critical in regions where water quality varies widely or where systems transport corrosive chemicals. Using the wrong material can lead to premature valve failure, resulting in costly downtime and repairs. Buyers may also be uncertain about the long-term performance of PVC in harsh environments, leading to hesitation in their purchasing decisions.

Illustrative image related to swing check valve pvc

The Solution: To address material compatibility concerns, buyers should conduct a thorough analysis of the fluids that will flow through the swing check valves. Opting for PVC swing check valves with EPDM seals can enhance chemical resistance and ensure longevity in corrosive environments. Additionally, consulting with manufacturers for detailed chemical compatibility charts will help in selecting the appropriate valve material. For systems dealing with particularly aggressive fluids, considering alternative materials such as CPVC or PVDF might be beneficial. Regular maintenance checks should also be scheduled to monitor valve performance and integrity, allowing for proactive replacements before failure occurs.

Scenario 3: Managing Flow Turbulence and Pressure Drops

The Problem: Another common pain point for B2B buyers is managing flow turbulence and pressure drops associated with PVC swing check valves. The design of these valves can create turbulence in the fluid flow, which may not only affect system efficiency but can also lead to increased energy costs and reduced performance in pumping systems. Buyers often struggle to balance the need for effective backflow prevention with the desire for optimal flow rates.

The Solution: To effectively manage flow turbulence, buyers should evaluate the specific flow characteristics of their systems. Selecting swing check valves with a streamlined design can significantly reduce turbulence and minimize pressure drops. Additionally, incorporating larger diameter valves can facilitate smoother flow and lessen the impact of pressure loss. Buyers should also consider the installation of a bypass line in systems where pressure fluctuations are critical, allowing for better control over flow dynamics. Consulting with fluid dynamics experts can provide tailored solutions to ensure that the system operates efficiently while still preventing backflow effectively. Regular system evaluations and flow assessments will help in making informed decisions about valve replacements or upgrades, ultimately enhancing operational efficiency.

Strategic Material Selection Guide for swing check valve pvc

When selecting materials for PVC swing check valves, it is crucial to consider the specific properties, advantages, and limitations of each material. This analysis focuses on four common materials used in the manufacturing of swing check valves: PVC, CPVC, PP (Polypropylene), and PVDF (Polyvinylidene Fluoride). Each material offers unique characteristics that can impact performance, durability, and suitability for various applications.

Illustrative image related to swing check valve pvc

What are the Key Properties of PVC for Swing Check Valves?

PVC (Polyvinyl Chloride) is the most widely used material for swing check valves due to its excellent balance of performance and cost. It has a temperature rating of up to 140°F (60°C) and can withstand moderate pressure, making it suitable for many water and wastewater applications. PVC is also resistant to corrosion from a variety of chemicals, which is essential in industrial settings.

Pros and Cons of PVC: The primary advantage of PVC is its affordability and ease of installation. It is lightweight and can be easily joined using solvent cement. However, its temperature limitations may restrict its use in high-temperature applications, and it can become brittle over time when exposed to UV light.

How Does CPVC Compare for Swing Check Valves?

CPVC (Chlorinated Polyvinyl Chloride) is similar to PVC but has a higher temperature rating, typically up to 200°F (93°C). This makes it a better option for hot water applications and environments with higher thermal demands. CPVC also exhibits good chemical resistance, particularly against acids and bases.

Pros and Cons of CPVC: The key advantage of CPVC is its ability to handle higher temperatures without compromising structural integrity. However, CPVC is generally more expensive than PVC and may require specialized fittings and adhesives, increasing manufacturing complexity.

Illustrative image related to swing check valve pvc

What are the Benefits of Using Polypropylene (PP) for Swing Check Valves?

Polypropylene is a thermoplastic polymer known for its high chemical resistance and low density. It can handle temperatures up to 200°F (93°C) and is particularly effective in applications involving aggressive chemicals, such as acids and bases.

Pros and Cons of PP: The main advantage of polypropylene is its superior chemical resistance, making it ideal for harsh environments. However, it may not be suitable for high-pressure applications, and its cost is generally higher than PVC and CPVC. Additionally, the manufacturing process can be more complex due to its unique properties.

Why Choose PVDF for Swing Check Valves?

PVDF (Polyvinylidene Fluoride) is a high-performance plastic known for its exceptional chemical resistance and ability to withstand extreme temperatures (up to 300°F or 149°C). It is often used in high-purity applications, such as pharmaceuticals and food processing.

Pros and Cons of PVDF: The key advantage of PVDF is its durability and resistance to aggressive chemicals, making it suitable for specialized applications. However, it is the most expensive option among the materials discussed and may require specialized manufacturing processes, which can increase lead times and costs.

Considerations for International B2B Buyers

When sourcing swing check valves for international markets, buyers should consider compliance with local standards such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). Different regions may have specific regulations regarding material safety and environmental impact. Additionally, understanding the local market preferences and availability of materials can significantly influence procurement decisions.

| Material | Typical Use Case for swing check valve pvc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Water and wastewater systems | Cost-effective and easy to install | Limited temperature resistance | Low |

| CPVC | Hot water applications | Higher temperature tolerance | More expensive and complex installation | Medium |

| PP | Chemical processing | Excellent chemical resistance | Not suitable for high-pressure applications | Medium |

| PVDF | High-purity industries | Superior durability and chemical resistance | Highest cost and complex manufacturing | High |

This strategic material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions when sourcing swing check valves, ensuring compatibility with specific applications and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for swing check valve pvc

What Are the Key Stages in the Manufacturing Process of PVC Swing Check Valves?

The manufacturing of PVC swing check valves involves several critical stages that ensure both performance and reliability. The process typically includes material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing PVC swing check valves is the careful selection and preparation of materials. High-quality polyvinyl chloride (PVC) is often chosen for its excellent corrosion resistance and durability. Raw PVC is sourced and tested to ensure it meets the necessary specifications for pressure and temperature tolerances. This stage may also involve blending the PVC with additives to enhance properties such as flexibility and UV resistance.

Forming Techniques

Once the materials are prepared, the next phase is forming the valve components. This process often employs advanced injection molding techniques, which allow for precise shaping of complex geometries required for the valve body and internal components. Molding machines are calibrated to maintain consistent temperature and pressure, ensuring high-quality parts with minimal defects.

Illustrative image related to swing check valve pvc

In some cases, extrusion may be utilized for specific valve components. This method involves forcing the PVC through a die to create uniform shapes, which are then cut to length. The choice of forming technique can significantly affect the valve’s performance characteristics, including flow rates and backpressure resistance.

Assembly of Components

After the individual components are formed, they are assembled into the final product. This stage involves integrating the valve body, flap, hinge, and sealing elements. The assembly must be executed with precision to ensure proper alignment and function of the valve. Automated assembly lines are commonly used to enhance efficiency, reduce human error, and maintain consistency across production runs.

Finishing Processes

The final stage of manufacturing involves finishing processes that may include trimming excess material, surface treatment, and quality checks. Components are often subjected to rigorous cleaning to remove any contaminants that could affect performance. In some cases, additional coatings may be applied to enhance chemical resistance or aesthetic appeal.

How Is Quality Assurance Implemented in PVC Swing Check Valve Manufacturing?

Quality assurance (QA) is a crucial aspect of manufacturing PVC swing check valves, ensuring that products meet international standards and customer expectations.

What International Standards Apply to Quality Control in Valve Manufacturing?

Manufacturers of PVC swing check valves typically adhere to several international quality standards. The ISO 9001 standard for quality management systems is widely recognized and ensures that companies follow consistent processes that enhance customer satisfaction. Compliance with the CE marking indicates that the products meet European safety and health requirements, making them more marketable in Europe and other regions.

Illustrative image related to swing check valve pvc

Additionally, industry-specific certifications such as those from the American Petroleum Institute (API) may apply, especially for valves used in oil and gas applications. These standards provide a framework for manufacturers to demonstrate their commitment to quality and safety.

What Are the Key Quality Control Checkpoints in Valve Production?

Quality control checkpoints play a vital role in the manufacturing process, ensuring that each valve meets the required specifications. The main checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon delivery. Tests are performed to confirm that materials meet the specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, various tests are conducted at different stages to detect any deviations from quality standards. This includes monitoring temperature and pressure during molding and assembly processes.

-

Final Quality Control (FQC): After assembly, each valve undergoes a comprehensive inspection that may include functional testing, pressure testing, and dimensional checks to ensure compliance with specifications.

What Testing Methods Are Commonly Used for PVC Swing Check Valves?

To verify the integrity and performance of swing check valves, several testing methods are employed, including:

-

Hydrostatic Testing: This method involves filling the valve with water and subjecting it to high pressure to check for leaks and structural integrity.

-

Functional Testing: This ensures that the valve opens and closes correctly under the expected flow conditions, mimicking real-world operational scenarios.

-

Material Testing: Tests such as tensile strength and impact resistance are conducted to assess the durability of the PVC material used in the valve’s construction.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability and compliance with standards.

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request and review supplier audits, which provide insights into the manufacturing process, quality control measures, and compliance with relevant standards. Regular audits conducted by third-party organizations can enhance confidence in the supplier’s practices.

Additionally, buyers should seek detailed quality reports that outline testing results, certifications, and any corrective actions taken in response to quality issues. This transparency can help buyers assess the reliability of the supplier’s products.

How Do Quality Control Nuances Affect International Trade?

Navigating quality control nuances is crucial for international B2B transactions. Buyers should be aware of the specific regulations and standards that apply in their respective countries and ensure that suppliers are compliant. This is particularly important in regions with stringent safety and quality requirements, such as Germany and Saudi Arabia.

Understanding the local market’s expectations can also help buyers avoid costly delays and non-compliance penalties. Engaging in direct communication with suppliers about quality control practices can foster stronger partnerships and ensure that both parties are aligned on quality expectations.

Conclusion

The manufacturing processes and quality assurance measures for PVC swing check valves are complex yet essential for ensuring product reliability and performance. By understanding these processes and actively engaging with suppliers on quality control practices, B2B buyers can make informed decisions that enhance their operational efficiency and reduce risks associated with valve failures.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘swing check valve pvc’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in procuring PVC swing check valves effectively. By following this step-by-step checklist, you can ensure that your selection process is thorough, aligning with your technical requirements, budget constraints, and supplier capabilities.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the swing check valves you need. Consider factors such as diameter size, pressure ratings, and material specifications (e.g., PVC grade).

– Why it matters: This step ensures that the valves will fit seamlessly into your existing systems and perform under the necessary conditions.

– What to look for: Review the specifications of your current systems and consult engineering standards relevant to your industry.

Step 2: Assess Application Needs

Evaluate the specific applications where the PVC swing check valves will be used. Determine if they will be handling water, chemicals, or other fluids.

– Why it matters: Different applications may require unique valve features, such as corrosion resistance or specific sealing materials (like EPDM).

– What to look for: Identify any industry regulations or standards that may impact the type of valve you need, especially in sectors like water treatment or chemical processing.

Step 3: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Look for manufacturers with a strong reputation in the industry and experience with PVC swing check valves.

– Why it matters: Partnering with reliable suppliers can minimize risks associated with quality and delivery.

– What to look for: Check customer reviews, industry certifications, and case studies that demonstrate the supplier’s experience and reliability.

Step 4: Request Samples and Documentation

Before making a bulk purchase, request samples of the swing check valves. Also, ask for technical datasheets and installation manuals.

– Why it matters: Samples allow you to evaluate the quality and suitability of the valves for your application. Documentation provides essential insights into installation and maintenance.

– What to look for: Ensure the samples meet your specifications and review installation guidelines to assess compatibility with your existing systems.

Step 5: Evaluate Pricing and Terms

Gather quotes from multiple suppliers and compare pricing structures. Look for any additional costs, such as shipping or customs duties, especially when sourcing internationally.

– Why it matters: A thorough cost analysis helps you stay within budget while ensuring you receive the best value for your investment.

– What to look for: Evaluate not just the price but also the terms of payment, delivery timelines, and warranty conditions.

Step 6: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers have the necessary certifications and comply with international standards relevant to PVC products.

– Why it matters: Compliance with quality and safety standards protects your investment and ensures reliability in your applications.

– What to look for: Request documentation proving compliance with standards such as ISO, ASTM, or other relevant industry certifications.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, negotiate the terms of the purchase agreement. Ensure all aspects, including delivery schedules, payment terms, and return policies, are clearly outlined.

– Why it matters: A well-defined agreement protects both parties and sets clear expectations.

– What to look for: Pay attention to clauses regarding warranty, support, and liability, ensuring they align with your business needs.

By following this checklist, you can navigate the procurement process for PVC swing check valves with confidence, ensuring that you select the right products and suppliers for your business needs.

Comprehensive Cost and Pricing Analysis for swing check valve pvc Sourcing

What Are the Key Cost Components in Sourcing PVC Swing Check Valves?

When sourcing PVC swing check valves, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The primary material for these valves is PVC, which is known for its durability and resistance to corrosion. Prices for raw PVC can fluctuate based on global oil prices and demand. Special materials or coatings may increase costs, especially for valves designed for corrosive environments.

-

Labor and Manufacturing Overhead: Labor costs vary significantly depending on the region of production. Countries with lower labor costs may offer competitive pricing, but this must be weighed against potential quality issues. Manufacturing overhead includes the costs of facilities, utilities, and administrative expenses, which can also vary widely.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. For standard sizes, tooling expenses can be amortized over larger production runs, reducing the per-unit cost.

-

Quality Control: Ensuring the valves meet industry standards and certifications (such as ISO or ANSI) adds to the cost but is essential for reliability, especially in critical applications.

-

Logistics: Shipping costs can vary based on the distance from the manufacturer to the buyer, mode of transport, and any tariffs or duties applicable in the buyer’s country.

-

Margin: Suppliers typically add a margin to cover their costs and profits. This margin can vary based on the supplier’s market position, brand reputation, and service levels offered.

How Do Price Influencers Affect the Cost of PVC Swing Check Valves?

Several factors influence the final price of PVC swing check valves:

-

Volume/MOQ: Bulk purchasing often leads to reduced per-unit costs. Suppliers may offer discounts for larger orders, making it essential for buyers to assess their long-term needs to take advantage of economies of scale.

-

Specifications and Customization: Custom sizes or specifications will typically incur additional costs. Standard models are generally more cost-effective due to established production processes.

-

Materials and Quality Certifications: Higher quality materials or those with specific certifications will increase costs. Buyers should consider the long-term implications of investing in higher-quality valves to minimize maintenance and replacement costs.

-

Supplier Factors: Supplier reliability, reputation, and customer service can affect pricing. Establishing a good relationship with suppliers can lead to better pricing and terms.

-

Incoterms: Understanding the terms of trade (Incoterms) is crucial. They dictate the responsibilities of buyers and sellers in shipping costs and risks, impacting the total landed cost.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing PVC Swing Check Valves?

To maximize value when sourcing PVC swing check valves, consider the following tips:

-

Negotiate Pricing: Engage suppliers in discussions about pricing, especially if you have a long-term purchasing plan. Many suppliers are willing to negotiate terms for established buyers.

-

Evaluate Total Cost of Ownership (TCO): Assess not just the initial purchase price but also installation, maintenance, and potential downtime costs. Cheaper valves may result in higher TCO if they fail prematurely.

-

Be Aware of Pricing Nuances for International Buyers: Different regions may have varying standards and expectations regarding quality and pricing. For instance, buyers in Europe may prioritize certifications more than those in Africa or South America.

-

Conduct Market Research: Before finalizing your supplier, compare prices and terms across different manufacturers. This can help identify fair pricing and potentially uncover better deals.

Disclaimer on Indicative Prices

Prices for PVC swing check valves can fluctuate based on market conditions and supplier pricing strategies. The examples provided in this analysis are indicative and should be verified with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing swing check valve pvc With Other Solutions

When considering the implementation of a check valve in fluid systems, it’s essential to explore various alternatives to ensure optimal performance, cost-effectiveness, and suitability for specific applications. PVC swing check valves are popular for their efficiency in preventing backflow, but other solutions may offer advantages depending on the context. This analysis will compare PVC swing check valves with two viable alternatives: ball check valves and diaphragm check valves.

| Comparison Aspect | Swing Check Valve PVC | Ball Check Valve | Diaphragm Check Valve |

|---|---|---|---|

| Performance | Effective for moderate flow; can create turbulence | Excellent for low-pressure applications; minimal turbulence | Good for precise flow control; sensitive to pressure changes |

| Cost | Generally affordable, ranging from $20 to $400+ | Typically lower cost, starting around $23 | Higher initial investment, often $100+ |

| Ease of Implementation | Simple installation with socket or threaded options | Easy to install, typically lighter | Installation can be more complex due to diaphragm requirements |

| Maintenance | Low maintenance; periodic checks recommended | Low maintenance; generally durable | Moderate maintenance; diaphragm replacement may be needed |

| Best Use Case | Suitable for water and moderate corrosive fluids | Ideal for low-pressure systems with clean fluids | Best for applications requiring precise flow control and pressure management |

What Are the Benefits and Drawbacks of Ball Check Valves?

Ball check valves are designed to allow flow in one direction while preventing backflow. They operate using a ball that seals the flow path when backflow occurs. One of the primary advantages of ball check valves is their simplicity and effectiveness in low-pressure applications. They tend to be less expensive than swing check valves, making them a cost-effective choice for many systems. However, they may not perform as well in high-pressure scenarios and can be susceptible to wear if particles are present in the fluid.

How Do Diaphragm Check Valves Compare?

Diaphragm check valves utilize a flexible diaphragm to control fluid flow, providing precise regulation. They are particularly beneficial in applications where pressure changes are frequent, as they can adapt quickly to varying conditions. While diaphragm check valves offer excellent control, they usually come with a higher price tag and may require more maintenance due to the diaphragm’s wear over time. This makes them suitable for specialized applications, such as in the pharmaceutical or food processing industries, where precision is crucial.

Conclusion: How to Choose the Right Valve for Your Needs?

Selecting the right check valve involves assessing various factors, including the specific application, fluid characteristics, and budget constraints. For general applications where backflow prevention is critical, PVC swing check valves provide a reliable and cost-effective solution. However, if your system operates under low pressure and requires a simpler, less expensive option, ball check valves may be the best fit. Conversely, for applications demanding precise flow control and the ability to handle pressure fluctuations, diaphragm check valves would be more appropriate. Ultimately, understanding the unique requirements of your system will guide you in choosing the most suitable valve solution.

Essential Technical Properties and Trade Terminology for swing check valve pvc

What Are the Key Technical Properties of PVC Swing Check Valves?

When evaluating PVC swing check valves for industrial applications, several technical properties are critical for ensuring optimal performance and reliability. Here are the essential specifications to consider:

-

Material Grade

PVC swing check valves are primarily made from high-quality polyvinyl chloride (PVC), which is known for its durability and resistance to corrosion. This material is essential for applications involving water, chemicals, and other fluids, providing a robust solution that can withstand harsh environmental conditions. Selecting the right material grade ensures longevity and reduces maintenance costs. -

Pressure Rating

The pressure rating indicates the maximum pressure the valve can handle without failure. For PVC swing check valves, this typically ranges from 150 to 300 psi. Understanding the pressure requirements of your specific application is crucial, as exceeding the pressure rating can lead to valve failure, risking system integrity and safety. -

Size and Connection Type

PVC swing check valves are available in various sizes, typically ranging from ½ inch to 8 inches in diameter. The connection type—socket or threaded—also plays a vital role in installation flexibility. Choosing the correct size and connection type ensures compatibility with existing piping systems, facilitating easier installation and preventing leaks. -

Seal Material

The seals within PVC swing check valves are often made from EPDM (Ethylene Propylene Diene Monomer) rubber, which provides excellent resistance to heat, ozone, and weathering. The choice of seal material is crucial for maintaining a leak-proof operation, particularly in applications involving corrosive fluids or extreme temperatures. -

Flow Coefficient (Cv)

The flow coefficient measures the valve’s capacity to allow fluid to flow through it. A higher Cv value indicates less resistance to flow, making the valve more efficient in allowing fluid movement. Understanding the Cv helps buyers assess how the valve will perform in their specific system, impacting overall efficiency and energy consumption. -

Actuation Method

PVC swing check valves typically operate automatically without the need for external power. The design features a disc or flap that opens with forward flow and closes with backflow. Understanding the actuation method is essential for ensuring that the valve will function as intended in your specific application, contributing to system reliability.

What Are Common Trade Terms Used in PVC Swing Check Valve Transactions?

Navigating the procurement landscape for PVC swing check valves requires familiarity with specific trade terminology. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that are sold under another company’s brand. In the context of PVC swing check valves, understanding whether a supplier is an OEM can help buyers assess the quality and reliability of the products being offered. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a buyer must purchase in a single order. Knowing the MOQ is critical for B2B buyers, especially when managing budgets and inventory levels. Suppliers may set MOQs to ensure profitability, and understanding these requirements can aid in negotiation. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For buyers of PVC swing check valves, issuing an RFQ allows for better price comparisons and helps ensure that they receive competitive offers from multiple suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers, as they outline who is responsible for shipping, insurance, and tariffs, impacting overall costs and delivery timelines. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the products. This is an essential consideration for B2B buyers to ensure that their projects remain on schedule. Understanding lead times can help in planning inventory and managing customer expectations. -

Certification Standards

Certification standards, such as ISO or ASTM, indicate that a product meets specific quality and safety benchmarks. For buyers, ensuring that PVC swing check valves have the appropriate certifications is vital for compliance with industry regulations and for assuring product reliability.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing PVC swing check valves, optimizing their procurement processes and ensuring the success of their projects.

Navigating Market Dynamics and Sourcing Trends in the swing check valve pvc Sector

What Are the Current Market Dynamics and Key Trends in the Swing Check Valve PVC Sector?

The swing check valve PVC market is witnessing robust growth driven by increasing demand for efficient fluid control solutions across various industries, including water treatment, chemical processing, and construction. Internationally, B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly prioritizing durable and corrosion-resistant materials like PVC for their systems. The global push for automation and smart technology integration is also influencing sourcing trends, with manufacturers developing valves that can be integrated into IoT frameworks for real-time monitoring and maintenance alerts.

Emerging trends include the adoption of true union swing check valves, which offer ease of maintenance and replacement due to their design. Additionally, suppliers are expanding their product ranges to include a variety of sizes and configurations, catering to the specific needs of diverse applications. Cost-efficiency remains a key consideration for buyers; thus, sourcing decisions are increasingly influenced by the total cost of ownership, including installation and long-term maintenance. As the market evolves, buyers are encouraged to explore suppliers that offer customization options, ensuring that the valves meet their specific operational requirements.

How Is Sustainability and Ethical Sourcing Influencing the Swing Check Valve PVC Market?

Sustainability is becoming an essential criterion for B2B buyers in the swing check valve PVC sector, reflecting a broader commitment to environmental stewardship. The production of PVC materials typically involves significant energy consumption and emissions, prompting manufacturers to adopt more sustainable practices. Buyers are increasingly interested in suppliers who prioritize ethical sourcing and offer “green” certifications for their products. Certifications such as ISO 14001 (Environmental Management) and compliance with REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations are becoming important indicators of a supplier’s commitment to sustainability.

Furthermore, the trend toward using recycled PVC in manufacturing swing check valves is gaining traction. This not only reduces the environmental impact but also aligns with the circular economy principles that many companies are now adopting. Buyers should actively seek suppliers who can demonstrate their sustainability initiatives, including lifecycle assessments of their products, which can significantly enhance brand reputation and appeal to environmentally conscious consumers.

What Is the Brief Evolution and History of Swing Check Valves in the PVC Sector?

Swing check valves have evolved significantly since their inception, transitioning from traditional metal components to more advanced PVC materials. Initially developed to prevent backflow in piping systems, the design has been refined to enhance efficiency and durability. The introduction of PVC as a primary material for these valves in the late 20th century revolutionized the market, offering advantages such as lightweight construction, corrosion resistance, and lower installation costs.

As industries began to recognize the benefits of PVC, the demand for swing check valves surged, leading to innovations in design and manufacturing processes. Today, manufacturers are focused on optimizing valve performance through advanced engineering, ensuring that these components meet the increasing pressures and complexities of modern fluid systems. This evolution reflects a broader trend in the industry toward more reliable, efficient, and sustainable fluid control solutions, positioning swing check valves as essential components across various sectors.

Frequently Asked Questions (FAQs) for B2B Buyers of swing check valve pvc

-

1. How do I solve issues with backflow in my piping system?

To address backflow issues effectively, consider installing PVC swing check valves. These valves automatically prevent reverse flow, thus safeguarding sensitive equipment and systems from potential damage. Ensure that you select the correct size and type (socket or threaded) based on your system requirements. Additionally, regular maintenance checks can help identify any wear or malfunction in the valves, ensuring optimal performance. -

2. What is the best PVC swing check valve for high-pressure applications?

For high-pressure applications, opt for industrial-grade PVC swing check valves designed to withstand elevated pressure levels. Look for valves that specify pressure ratings appropriate for your system, typically indicated in psi. Valves with EPDM seals are also recommended for enhanced durability and resistance to harsh chemicals, making them suitable for a variety of industrial uses. -

3. How can I ensure the quality of PVC swing check valves from international suppliers?

To guarantee the quality of PVC swing check valves, conduct thorough supplier vetting. Request certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, consider asking for product samples and customer references. Engaging with suppliers who offer warranties or guarantees can also provide peace of mind regarding the product’s reliability. -

4. What customization options are available for PVC swing check valves?

Many manufacturers offer customization options for PVC swing check valves, including specific sizes, connection types, and materials. You can request modifications such as unique flange dimensions or specialized seals to meet your operational requirements. Discuss your needs with potential suppliers, as they may also offer tailored solutions to better fit your application. -

5. What is the minimum order quantity (MOQ) for PVC swing check valves?

Minimum order quantities for PVC swing check valves vary by supplier, typically ranging from 10 to 100 units. It’s essential to inquire about MOQs upfront to understand your purchasing commitments. Some suppliers may offer lower MOQs for specific products or during promotional periods, so exploring multiple options can help you find favorable terms. -

6. What payment terms should I expect when sourcing PVC swing check valves internationally?

Payment terms can vary significantly among suppliers. Common terms include advance payment, net 30, or letter of credit arrangements. It’s advisable to negotiate terms that align with your cash flow needs while ensuring that the supplier’s terms are secure. Always confirm payment methods accepted, as options may include wire transfers, credit cards, or PayPal. -

7. How can I manage logistics when importing PVC swing check valves?

Managing logistics for importing PVC swing check valves involves coordinating with freight forwarders who can handle customs clearance and shipping. Ensure you have a clear understanding of import regulations in your country, including tariffs and duties. Establishing a reliable shipping schedule and monitoring transit times will help you manage your supply chain effectively. -

8. What quality assurance measures should I look for when sourcing from international suppliers?

When sourcing PVC swing check valves, look for suppliers who implement strict quality assurance measures. This may include in-process inspections, final testing, and adherence to international standards. Requesting detailed product specifications and quality control documentation can help ensure that the valves meet your operational needs and industry regulations.

Top 6 Swing Check Valve Pvc Manufacturers & Suppliers List

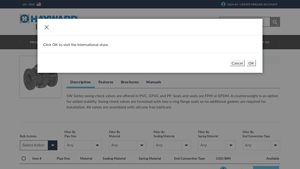

1. PVC Fittings Online – PVC Swing Check Valves

Domain: pvcfittingsonline.com

Registered: 2011 (14 years)

Introduction: This company, PVC Fittings Online – PVC Swing Check Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Asahi – Check Valves

Domain: alscoplastics.com

Registered: 2006 (19 years)

Introduction: Check Valves: 27 products available. Brands include Asahi (7), Banjo (6), Cepex (3), Champion (1), Clear PVC Pipe (1), Georg Fischer (1), Hayward (2), NDS (1), Plast-O-Matic (2), Spears (3). Materials: PVC (14), CPVC (5), PP (11), PVDF (3), Ductile Iron (1). Valve Types: Check (26). Sizes and Connections: 1/2 in. to 8 in. sizes, connections include Butt, DIN Soc, Flanged, IPS Soc, Soc & Thr, Socke…

3. Hayward – SW Series Swing Check Valves

Domain: haywardflowcontrol.com

Registered: 2004 (21 years)

Introduction: {‘description’: ‘SW Series swing check valves are offered in PVC, CPVC and PP. Seals and seats are FPM or EPDM. A counterweight is an option for added stability. Swing check valves are furnished with two o-ring flange seals so no additional gaskets are required for installation. All valves are assembled with silicone free lubricant.’, ‘features’: [‘Available in PVC, CPVC and GFPP’, ‘High Temperatu…

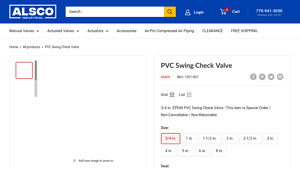

4. Asahi – PVC Swing Check Valve

Domain: asahivalves.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “PVC Swing Check Valve”, “SKU”: “1201-007”, “Sizes Available”: [“3/4 in.”, “1 in.”, “1-1/2 in.”, “2 in.”, “2-1/2 in.”, “3 in.”, “4 in.”, “5 in.”, “6 in.”, “8 in.”], “Seals Available”: [“EPDM”, “FKM”], “Price Range”: {“3/4 in. / EPDM”: “$557.00”, “1 in. / EPDM”: “$644.00”, “1-1/2 in. / EPDM”: “$802.00”, “2 in. / EPDM”: “$992.00”, “2-1/2 in. / EPDM”: “$1,385.00”, “3 in. / EPDM”: “$1…

5. Drainage Connect – 1-1/4 Clear PVC Swing Check Valve

Domain: drainageconnect.com

Registered: 2016 (9 years)

Introduction: {‘product_name’: ‘1-1/4″ Clear PVC Swing Check Valve’, ‘price’: ‘$39.25’, ‘sku’: ‘1520C12’, ‘valve_size’: ‘1-1/4″‘, ‘pressure_rating’: ‘125 PSI’, ‘static_pressure’: ’72°F’, ‘material’: ‘PVC Type I’, ‘connections’: ‘IPS SLIP to IPS SLIP’, ‘certifications’: ‘NSF-ANSI 61 and NSF/ANSI/CAN 372’, ‘color’: ‘Clear’, ‘brand’: ‘NDS’, ‘applications’: ‘Irrigation systems, water treatment plants, industrial pr…

6. Clear PVC – Swing Check Valve

Domain: clearpvcpipe.com

Registered: 1998 (27 years)

Introduction: {“name”: “Swing Check Valve”, “material”: “Clear PVC”, “sizes_available”: [“1/2 in.”, “3/4 in.”, “1 in.”, “1-1/4 in.”, “1-1/2 in.”, “2 in.”, “2-1/2 in.”, “3 in.”, “4 in.”, “6 in.”], “threaded”: true, “price”: {“1/2 in.”: “$41.40”, “3/4 in.”: “$42.21”, “1 in.”: “$43.02”, “1-1/4 in.”: “$45.18”, “1-1/2 in.”: “$49.12”, “2 in.”: “$70.69”, “2-1/2 in.”: “$117.84”, “3 in.”: “$130.92”, “4 in.”: “$176.25”, …

Strategic Sourcing Conclusion and Outlook for swing check valve pvc

As international markets continue to evolve, the strategic sourcing of PVC swing check valves presents significant opportunities for B2B buyers in Africa, South America, the Middle East, and Europe. These valves, known for their durability and corrosion resistance, are essential in a variety of applications, from water management systems to industrial processes. By investing in high-quality PVC swing check valves, businesses can mitigate the risk of backflow, ensuring the integrity of their operations and protecting valuable equipment.

The key to successful sourcing lies in understanding the specific needs of your application, including size, pressure ratings, and material compatibility. Collaborating with reliable suppliers who can provide tailored solutions and comprehensive support is crucial. This proactive approach not only enhances operational efficiency but also drives long-term cost savings.

Looking ahead, the demand for PVC swing check valves is expected to rise, driven by ongoing infrastructure developments and increased industrial activities. We encourage B2B buyers to engage with manufacturers and distributors that prioritize innovation and quality. By doing so, you can secure a competitive edge in your market and contribute to sustainable growth in your operations. Take the next step in optimizing your supply chain today!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.