Freight Pallets: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for freight pallets

In today’s competitive landscape, effectively sourcing freight pallets can significantly impact your logistics strategy and bottom line. As international B2B buyers navigate the complexities of global shipping, understanding the nuances of pallet options is critical. This guide delves into the diverse types of freight pallets available—ranging from wood and plastic to corrugated fiberboard—each with its unique strengths and applications. Additionally, we will cover essential aspects such as the importance of pallet strength, durability, and cost considerations, which play a pivotal role in ensuring your cargo arrives safely and efficiently.

With an eye on the specific needs of buyers from regions like Africa, South America, the Middle East, and Europe—including countries such as Nigeria and Vietnam—this comprehensive resource empowers you to make informed purchasing decisions. We will explore how to vet suppliers effectively, ensuring that you partner with reliable manufacturers who meet international quality standards. By providing actionable insights and expert recommendations, this guide aims to enhance your freight operations and optimize your supply chain management. Join us as we navigate the global market for freight pallets, equipping you with the knowledge to streamline your shipping processes and drive business success.

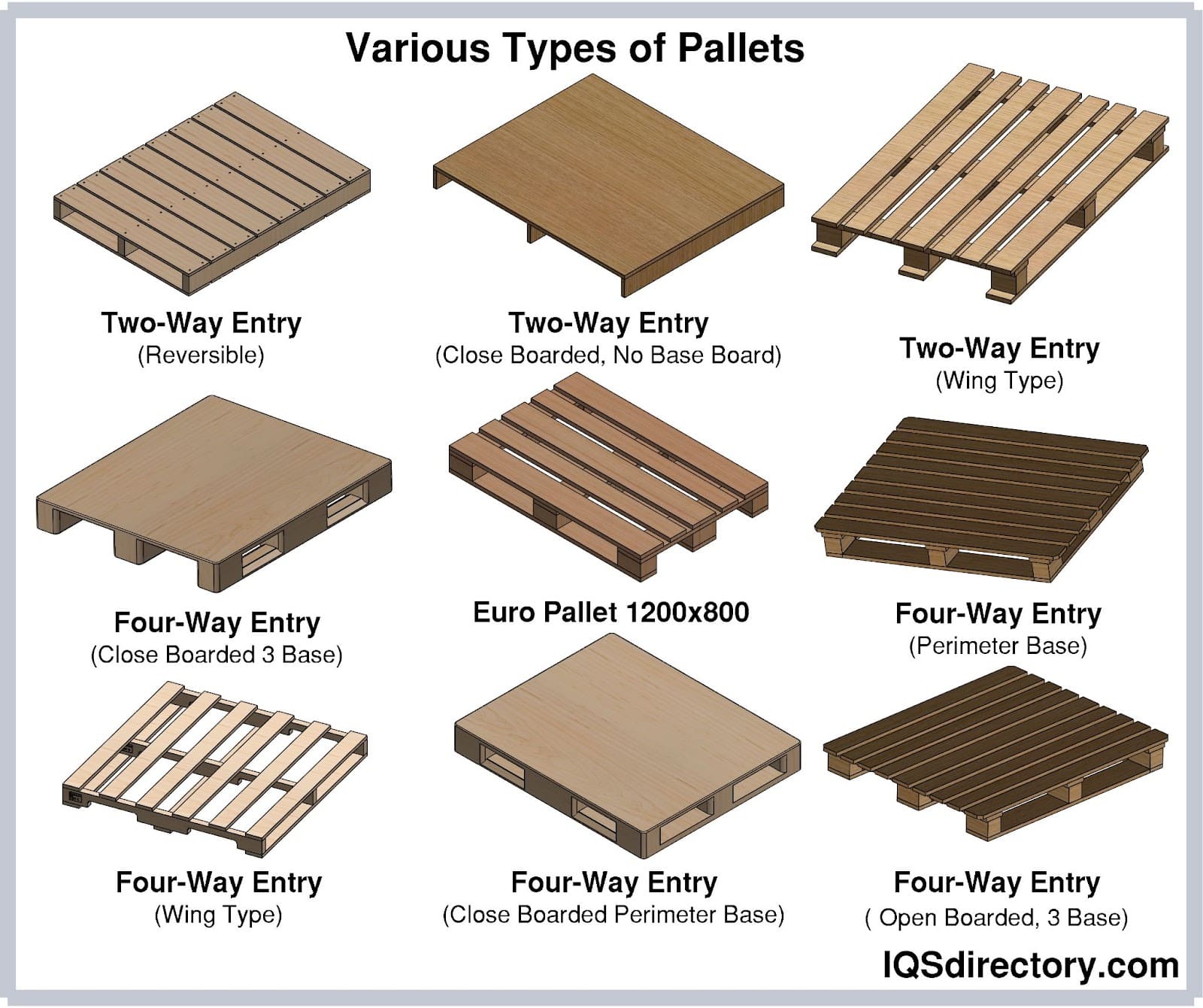

Understanding freight pallets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Wood Pallet | Typically 40″ x 48″, four-way entry, sturdy construction | General freight shipping, heavy loads | Pros: Cost-effective, strong, widely available. Cons: Susceptible to moisture and pests. |

| Plastic Pallet | More expensive, reusable, solid deck options available | Food and pharmaceutical industries | Pros: Durable, hygienic, resistant to moisture. Cons: Higher initial cost, potential slippage. |

| Corrugated Fiberboard | Lightweight, often not reusable, moisture-sensitive | Light, non-perishable goods | Pros: Cost-effective, lightweight. Cons: Easily damaged, not suitable for heavy loads. |

| Pressed Block Pallet | Made from compressed wood, lighter than traditional pallets | Export markets, light loads | Pros: Lightweight, often more affordable. Cons: Less durable, lower load capacity. |

| Molded Pulp Pallet | Made from recycled paper, biodegradable | Eco-friendly shipping solutions | Pros: Environmentally friendly, lightweight. Cons: Limited strength, not suitable for heavy items. |

What Are the Key Features of Standard Wood Pallets?

Standard wood pallets are the most common type used in freight shipping, typically measuring 40″ x 48″. They are designed for four-way entry, allowing easy access from any side, which is crucial for efficient handling in warehouses and shipping docks. These pallets can support heavy loads and are constructed to withstand the rigors of transport. However, they can be susceptible to moisture and pest damage, making them less ideal for certain environments.

How Do Plastic Pallets Compare to Wood Pallets?

Plastic pallets are a more durable alternative, often used in industries requiring high hygiene standards, such as food and pharmaceuticals. They are generally heavier and more expensive than wood pallets but offer the advantage of being reusable and resistant to moisture and chemicals. The solid deck design protects products from damage during loading and unloading. However, their slippery surface can make securing loads challenging, requiring additional precautions.

Why Are Corrugated Fiberboard Pallets Considered Less Reliable?

Corrugated fiberboard pallets are lightweight and cost-effective, making them suitable for shipping light, non-perishable goods. However, they are not recommended for heavy loads due to their susceptibility to moisture damage and lack of reusability. These pallets are typically used in short-distance shipping or for products that will be quickly consumed or used, where durability is not a primary concern.

What Advantages Do Pressed Block Pallets Offer?

Pressed block pallets are made from compressed wood and are often lighter and more affordable than traditional wood pallets. They are suitable for export markets and light loads, providing a good balance between cost and functionality. However, they lack the durability and load capacity of standard wood pallets, making them less suitable for heavier freight applications.

How Do Molded Pulp Pallets Support Eco-Friendly Shipping?

Molded pulp pallets are made from recycled paper, making them an eco-friendly option for businesses focused on sustainability. They are lightweight and biodegradable, which can appeal to environmentally conscious buyers. However, their limited strength and durability mean they are not suitable for heavy items, and their use is often restricted to lighter, less critical shipments.

Key Industrial Applications of freight pallets

| Industry/Sector | Specific Application of freight pallets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Transporting bulk food items and beverages | Ensures safe and compliant transport, reducing spoilage | Compliance with food safety standards; durability against moisture and temperature changes |

| Pharmaceuticals | Shipping medical supplies and equipment | Maintains product integrity and prevents contamination | Material certifications; anti-static properties for sensitive items |

| Retail and E-commerce | Distribution of packaged goods to retail outlets | Optimizes space and facilitates quick loading/unloading | Standardized sizes for compatibility; cost-effectiveness for high-volume shipments |

| Automotive | Shipping parts and assemblies to manufacturing plants | Enhances logistics efficiency and reduces damage risk | Strength and stiffness for heavy loads; reliable returnable pallet systems |

| Construction and Building | Transporting building materials and supplies | Supports heavy loads and minimizes damage during transit | Custom sizing; resistance to harsh environmental conditions |

How Are Freight Pallets Used in the Food and Beverage Industry?

In the food and beverage sector, freight pallets are essential for transporting bulk items such as grains, beverages, and processed foods. They provide a stable base that helps maintain the integrity of products during transit, ensuring compliance with health regulations. Buyers in this sector must prioritize pallets that meet food safety standards, are resistant to moisture, and can withstand temperature fluctuations to prevent spoilage.

What Role Do Freight Pallets Play in Pharmaceuticals?

Freight pallets are critical in the pharmaceutical industry for the safe transport of medical supplies and equipment. They help maintain product integrity and prevent contamination, which is vital for regulatory compliance. When sourcing pallets for pharmaceuticals, businesses should consider materials that have appropriate certifications and properties, such as anti-static features, to protect sensitive items from damage.

Illustrative image related to freight pallets

How Do Retail and E-commerce Benefit from Freight Pallets?

In retail and e-commerce, freight pallets facilitate the efficient distribution of packaged goods to various outlets. They optimize space during transport and streamline the loading and unloading process, which is particularly beneficial for high-volume shipments. International buyers should seek standardized pallet sizes to ensure compatibility with existing logistics systems and consider cost-effective options that do not compromise quality.

Why Are Freight Pallets Important in the Automotive Industry?

The automotive sector relies on freight pallets for shipping parts and assemblies to manufacturing plants. These pallets enhance logistics efficiency and minimize the risk of damage during transit, which is crucial for maintaining production schedules. Buyers should focus on the strength and stiffness of pallets to support heavy loads, as well as the availability of returnable pallet systems to optimize costs.

How Are Freight Pallets Used in Construction and Building?

In the construction industry, freight pallets are used to transport building materials and supplies, which can be quite heavy and bulky. They provide the necessary support to minimize damage during transit, ensuring that materials arrive at job sites in good condition. Key considerations for sourcing pallets in this sector include custom sizing to accommodate various materials and durability to withstand harsh environmental conditions.

3 Common User Pain Points for ‘freight pallets’ & Their Solutions

Scenario 1: Inadequate Load Support and Damage Risk

The Problem: Many B2B buyers encounter issues with pallets that fail to support the weight of their goods during transit. This can lead to damaged products, financial losses, and dissatisfied customers. For instance, a company shipping heavy machinery parts may find that their pallets buckle or break, causing delays and potential liability claims. Such scenarios not only compromise the integrity of the shipment but also result in increased costs associated with replacements and returns.

The Solution: To mitigate these risks, buyers must prioritize the selection of pallets based on the specific weight and dimensions of their products. This involves assessing the load capacity of different pallet types. Buyers should opt for standard wood pallets that are rated for heavy loads and are designed with sufficient stiffness and durability to withstand the rigors of shipping. It’s crucial to perform a thorough inspection of pallets before use, ensuring they are free of cracks, splinters, or other damage. Additionally, implementing proper stacking techniques—such as the column stacking method—can enhance load stability and reduce the chances of damage during transit.

Illustrative image related to freight pallets

Scenario 2: Inefficient Pallet Handling and Transportation

The Problem: Inefficient handling of pallets during loading and unloading can lead to delays in shipping and increased labor costs. Buyers often face challenges when their pallets do not conform to standard handling equipment, resulting in longer loading times and potential damage to both the pallets and products. For example, a logistics company may struggle with pallets that are too heavy or incompatible with their forklifts, causing inefficiencies in their supply chain.

The Solution: To address this challenge, buyers should ensure that their pallets meet industry standards for compatibility with handling equipment. This includes opting for pallets that have four-way entry capabilities, allowing for easy access from all sides. Furthermore, investing in lighter plastic pallets can enhance handling efficiency while still providing the necessary strength. Training staff on best practices for loading and unloading pallets can also minimize damage and improve operational efficiency. Regularly reviewing and optimizing pallet specifications based on evolving operational needs will further streamline handling processes.

Scenario 3: Environmental Concerns and Compliance Issues

The Problem: With increasing global emphasis on sustainability, many B2B buyers face pressure to select environmentally friendly shipping options. Traditional wood pallets may present compliance challenges in certain regions, especially where regulations around deforestation and pest control are strict. Buyers may find themselves at a crossroads, needing to balance cost, compliance, and environmental responsibility while selecting the right pallets for international shipments.

The Solution: To navigate these complexities, buyers should consider sourcing pallets that are certified by recognized environmental standards, such as the Forest Stewardship Council (FSC). This not only ensures compliance with international regulations but also enhances the company’s sustainability credentials. Additionally, exploring reusable plastic pallets can be a sustainable alternative, as they are often made from recycled materials and can withstand multiple shipping cycles without degrading. Engaging with suppliers who prioritize sustainable practices can help companies align their pallet choices with broader corporate responsibility goals, ultimately enhancing their brand reputation in the global marketplace.

Illustrative image related to freight pallets

Strategic Material Selection Guide for freight pallets

When selecting materials for freight pallets, international B2B buyers must consider various factors that impact performance, durability, and compliance with regional standards. Here, we analyze four common materials used in freight pallets: wood, plastic, metal, and corrugated fiberboard. Each material has distinct properties, advantages, and limitations that can significantly affect shipping operations.

What Are the Key Properties of Wood Pallets?

Wood pallets, typically made from hardwood or softwood, are known for their strength and structural integrity. They can support heavy loads and withstand various environmental conditions. Key properties include a high load-bearing capacity, natural resistance to certain environmental factors, and ease of repair.

Pros: Wood pallets are relatively inexpensive and widely available, making them a cost-effective option for many businesses. They are also reusable and recyclable, appealing to companies focused on sustainability.

Illustrative image related to freight pallets

Cons: However, wood pallets can be susceptible to moisture, pests, and decay if not properly treated. They may also not be suitable for certain industries that require stringent hygiene standards, such as food and pharmaceuticals.

How Do Plastic Pallets Compare in Performance?

Plastic pallets are increasingly popular due to their durability and resistance to moisture, chemicals, and pests. They are often designed with a solid deck, providing additional protection against damage during handling.

Pros: The primary advantage of plastic pallets is their longevity; they can be reused many times without significant wear. They are also easier to clean and sanitize, making them suitable for industries with strict hygiene requirements.

Illustrative image related to freight pallets

Cons: The main drawback is their higher initial cost compared to wood pallets. Additionally, plastic pallets can be heavier, which may affect shipping costs and logistics.

What Are the Benefits of Metal Pallets?

Metal pallets, usually made from aluminum or steel, offer exceptional strength and durability. They are capable of handling extreme loads and are resistant to corrosion and environmental damage.

Pros: The key advantage of metal pallets is their longevity and ability to withstand harsh conditions, making them ideal for heavy-duty applications. They also offer excellent security against theft and damage.

Illustrative image related to freight pallets

Cons: On the downside, metal pallets are significantly more expensive than wood or plastic options. They can also be heavier, which may increase shipping costs and complicate handling.

Are Corrugated Fiberboard Pallets a Viable Option?

Corrugated fiberboard pallets are lightweight and made from recycled materials, making them an eco-friendly choice. They are primarily used for lightweight products and in situations where cost savings are paramount.

Pros: The advantages include low cost and ease of disposal, as they are recyclable. They are also lightweight, which can reduce shipping costs.

Cons: However, corrugated fiberboard pallets are not as durable as other materials. They are easily damaged, especially by moisture, and are typically not reusable, limiting their application in long-term shipping strategies.

Summary Table of Material Selection for Freight Pallets

| Material | Typical Use Case for freight pallets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | General freight shipping, heavy loads | Cost-effective and widely available | Susceptible to moisture and pests | Low |

| Plastic | Food, pharmaceuticals, and hygienic needs | Durable, reusable, and easy to clean | Higher initial cost | High |

| Metal | Heavy-duty applications, industrial use | Exceptional strength and durability | Expensive and heavier | High |

| Corrugated Fiberboard | Lightweight products, short-term use | Low cost and recyclable | Easily damaged and not reusable | Low |

In conclusion, the selection of pallet materials is crucial for optimizing shipping efficiency and ensuring product safety. B2B buyers should evaluate the specific requirements of their products, shipping conditions, and regional compliance standards to make informed decisions that align with their operational goals.

Illustrative image related to freight pallets

In-depth Look: Manufacturing Processes and Quality Assurance for freight pallets

What Are the Key Stages in the Manufacturing Process of Freight Pallets?

The manufacturing process for freight pallets involves several critical stages that ensure the final product meets the necessary strength, durability, and functionality standards. Here’s a breakdown of these stages:

1. Material Preparation: What Materials Are Used for Freight Pallet Manufacturing?

The first step in manufacturing freight pallets is material preparation. The most commonly used materials include wood, plastic, and metal. For wooden pallets, the lumber is typically sourced from softwood species such as pine or fir, which offer a good balance between weight and strength.

For plastic pallets, high-density polyethylene (HDPE) is often chosen due to its resistance to moisture and chemicals, making it suitable for diverse shipping environments. In metal pallets, steel or aluminum may be used for heavy-duty applications.

Once the materials are sourced, they undergo treatment processes, such as heat treatment or chemical treatment, to enhance their durability and resistance to pests and moisture.

Illustrative image related to freight pallets

2. Forming: How Are Freight Pallets Shaped and Assembled?

After preparing the raw materials, the next stage involves forming the pallets. For wooden pallets, this includes cutting the lumber into required dimensions and shaping the components, such as deck boards and stringers. Automated cutting machines and CNC routers are often employed to ensure precision and efficiency.

For plastic pallets, the manufacturing process may involve injection molding or blow molding, where molten plastic is shaped into the desired pallet form. Metal pallets may require welding or bending techniques to achieve the correct shape.

3. Assembly: What Techniques Are Used for Assembling Freight Pallets?

The assembly of freight pallets involves joining the formed components together. For wooden pallets, nails or staples are commonly used to secure the deck boards to the stringers. Some manufacturers may also use glue or dowels for added strength.

In the case of plastic and metal pallets, the assembly process may involve interlocking mechanisms or fasteners designed for quick assembly and disassembly. This modular approach is particularly advantageous for reusable pallets, allowing for easy maintenance and repair.

4. Finishing: What Final Touches Are Applied to Ensure Quality?

The finishing stage includes surface treatments that enhance the pallet’s resistance to wear and environmental factors. For wooden pallets, this may involve sanding, staining, or applying a protective coating. Plastic pallets may undergo a process to ensure uniform surface texture, which can help in securing loads.

Illustrative image related to freight pallets

In addition, the pallets are often stamped or labeled to indicate compliance with international standards and to provide essential information for logistics and tracking.

How Is Quality Assurance Implemented in Freight Pallet Manufacturing?

Quality assurance (QA) is a vital component of the freight pallet manufacturing process. It ensures that the pallets meet both international standards and specific customer requirements. Here are the key aspects of QA in pallet manufacturing:

What International Standards Apply to Freight Pallet Manufacturing?

Several international standards govern the quality and safety of freight pallets. The most significant among these is ISO 9001, which outlines the criteria for a quality management system. Compliance with this standard indicates that a manufacturer follows a systematic approach to managing quality.

In addition to ISO 9001, pallets may also need to adhere to industry-specific standards such as the European CE marking, which signifies conformity with health, safety, and environmental protection standards, and the American Pallet Association (APA) guidelines. Understanding these standards is crucial for B2B buyers to ensure their suppliers are compliant.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure that defects are identified and addressed promptly. These checkpoints typically include:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon delivery to ensure they meet predefined specifications.

-

In-Process Quality Control (IPQC): During the manufacturing stages, continuous checks are performed to monitor production processes and identify any deviations from standards.

-

Final Quality Control (FQC): Once the pallets are fully assembled, a final inspection is conducted to evaluate the overall quality, including dimensional accuracy, structural integrity, and surface finish.

What Common Testing Methods Are Used to Ensure Pallet Quality?

To verify that pallets meet quality standards, manufacturers employ various testing methods. These may include:

-

Load Testing: Assessing the load-bearing capacity of pallets to ensure they can withstand the intended weight during storage and transportation.

-

Impact Testing: Evaluating the pallet’s ability to absorb shocks and resist damage during handling.

-

Environmental Testing: Exposing pallets to different environmental conditions, such as humidity and temperature fluctuations, to assess their durability.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality assurance processes of suppliers is critical. Here are actionable steps to ensure supplier compliance:

What Steps Can Buyers Take to Conduct Supplier Audits?

Buyers can conduct on-site audits of their suppliers to evaluate their manufacturing processes and quality control systems. During these audits, buyers should look for:

Illustrative image related to freight pallets

-

Compliance with International Standards: Check for certifications such as ISO 9001 and CE, which indicate adherence to global quality norms.

-

Documentation and Records: Request access to quality control reports, inspection records, and test results to assess the reliability of the supplier’s QA practices.

How Can Buyers Utilize Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance processes. These inspections can be scheduled at various points in the manufacturing process, offering insights into compliance with quality standards.

What Are the Specific Quality Control Nuances for International Buyers?

Buyers from different regions may face unique challenges related to quality control, such as varying regulations and standards. It is essential for buyers to:

-

Stay Informed: Keep abreast of regional regulations that may affect pallet specifications and compliance requirements.

-

Build Strong Relationships: Foster communication with suppliers to address quality concerns proactively and ensure alignment on expectations.

In conclusion, understanding the manufacturing processes and quality assurance protocols in freight pallet production is crucial for B2B buyers. By focusing on material selection, manufacturing techniques, and rigorous quality control measures, buyers can ensure they receive high-quality pallets that meet their shipping and logistical needs.

Illustrative image related to freight pallets

Practical Sourcing Guide: A Step-by-Step Checklist for ‘freight pallets’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in efficiently procuring freight pallets. By following this step-by-step checklist, you can ensure that your selection process is thorough, aligning with your shipping requirements and operational needs.

Step 1: Define Your Technical Specifications

Before you start sourcing pallets, clearly outline the specifications needed for your shipment. Consider factors such as load weight, dimensions, and the type of goods you are transporting. This will help you narrow down your options and ensure that the pallets you choose can adequately support your products without compromising safety.

- Weight Capacity: Determine the maximum weight your pallets must support during transport.

- Dimensions: Specify the size of the pallets that fit your storage and shipping needs.

Step 2: Choose the Right Material

Selecting the appropriate pallet material is critical for your shipping strategy. Common options include wood, plastic, and metal, each offering unique benefits and limitations. Your choice should reflect both your budget and the environmental conditions your pallets will encounter.

Illustrative image related to freight pallets

- Wood Pallets: Generally cost-effective and strong, suitable for most shipments.

- Plastic Pallets: More durable and resistant to moisture, ideal for sensitive goods but typically more expensive.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, perform a thorough evaluation to ensure reliability and quality. Request detailed company profiles, case studies, and references from other businesses in your industry. This step is vital to avoid future complications in your supply chain.

- Certifications: Verify if the supplier has industry certifications, which can indicate adherence to quality standards.

- Experience: Look for suppliers with a proven track record in your specific market or region.

Step 4: Assess Quality Control Measures

Understanding a supplier’s quality control processes is essential for maintaining product integrity during shipping. Inquire about their inspection methods and any guarantees they offer regarding pallet durability and performance.

- Inspection Protocols: Ask about how they assess pallet quality before shipment.

- Return Policies: Know the supplier’s policy on defective or damaged pallets to safeguard your investment.

Step 5: Consider Logistics and Delivery Times

Evaluate the logistics involved in your procurement process, including lead times and delivery methods. Timeliness is crucial in maintaining your supply chain efficiency, so ensure that the supplier can meet your deadlines.

Illustrative image related to freight pallets

- Shipping Options: Understand how the supplier ships pallets and any associated costs.

- Lead Times: Confirm expected delivery schedules and any potential delays that may arise.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, it’s time to negotiate pricing and payment terms. Aim for a balance between cost and quality, considering the potential for bulk discounts if you plan to order large quantities.

- Bulk Discounts: Inquire about pricing structures for larger orders.

- Payment Terms: Clarify payment schedules to manage cash flow effectively.

Step 7: Finalize Your Order and Confirm Details

Before placing your order, double-check all specifications, quantities, and pricing. Clear communication with the supplier will help prevent misunderstandings and ensure that your pallets meet your expectations upon delivery.

- Confirmation of Specs: Reiterate your requirements to avoid discrepancies.

- Written Agreement: Ensure all terms are documented in a formal agreement for reference.

By following this checklist, you can streamline your procurement process for freight pallets, ensuring that you make informed decisions that align with your business needs.

Comprehensive Cost and Pricing Analysis for freight pallets Sourcing

Understanding the cost structure and pricing dynamics for sourcing freight pallets is crucial for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This analysis will help you navigate the complexities of pallet procurement, ensuring you make informed purchasing decisions.

What Are the Key Cost Components in Freight Pallet Sourcing?

-

Materials: The primary cost driver in pallet manufacturing is the raw materials used. Wood, plastic, and metal pallets each have distinct price points. Wood pallets are generally more affordable, while plastic and metal options provide additional durability but at a higher cost. The choice of materials will directly influence the overall pricing.

-

Labor: Labor costs vary significantly based on geographical location and the complexity of the manufacturing process. For instance, regions with higher labor costs may see increased pallet prices. Understanding the labor market in your supplier’s location can help anticipate costs.

-

Manufacturing Overhead: This includes expenses related to factory operation, such as utilities, maintenance, and indirect labor. High overhead costs can affect the pricing of pallets, especially if the supplier is located in an area with elevated operational costs.

-

Tooling: Custom pallets often require specialized tooling, which can add to the upfront costs. If you need unique designs or sizes, factor in these tooling expenses when negotiating prices.

-

Quality Control (QC): Ensuring that pallets meet industry standards and your specific requirements necessitates rigorous quality control processes. Suppliers with robust QC measures might charge a premium, but this can save costs associated with damaged goods during transit.

-

Logistics: Freight and transportation costs are significant, particularly for international shipments. Factors such as distance, shipping method, and local logistics capabilities can vary widely, impacting your total cost.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding the typical margins in the industry can help you identify competitive pricing.

How Do Price Influencers Affect Freight Pallet Costs?

-

Volume/MOQ: Purchasing in bulk often leads to lower per-unit costs. Suppliers may offer tiered pricing based on Minimum Order Quantities (MOQ), incentivizing larger orders.

-

Specifications and Customization: Custom pallets that meet specific requirements (e.g., size, weight capacity) tend to be more expensive than standard options. Clearly defining your specifications can help avoid unexpected costs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ISPM 15 for wood pallets) can increase costs but may reduce risk and liability during shipping.

-

Supplier Factors: Supplier reputation, reliability, and location can influence pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for determining who is responsible for shipping costs and risks. Choosing the right Incoterm can impact your total landed cost.

What Are the Best Practices for Negotiating Freight Pallet Prices?

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, durability, and potential replacement costs. A lower-priced pallet may not be the most economical choice long-term if it has a shorter lifespan.

-

Leverage Volume Discounts: If your business has consistent pallet needs, negotiate for better pricing based on projected purchase volumes.

-

Explore Multiple Suppliers: Don’t settle for the first quote. Comparing offers from various suppliers can provide leverage in negotiations and help identify the best value.

-

Be Aware of Pricing Nuances for International Buyers: Different regions may have unique pricing structures due to local demand, supply chain challenges, and shipping costs. Understanding these nuances can help you negotiate better deals.

Conclusion

When sourcing freight pallets, a thorough understanding of the cost components and price influencers will empower you to make strategic purchasing decisions. By focusing on negotiation tactics and total cost considerations, you can optimize your pallet procurement for cost efficiency and reliability, ultimately enhancing your supply chain performance. Always remember that prices can fluctuate based on market conditions, so it’s prudent to stay informed and adaptable.

Alternatives Analysis: Comparing freight pallets With Other Solutions

Exploring Alternative Solutions to Freight Pallets

When it comes to shipping and logistics, choosing the right solution can significantly impact efficiency and cost-effectiveness. While freight pallets are a popular choice for transporting goods, various alternatives exist that may better suit specific needs. Below, we compare freight pallets against two viable alternatives: freight boxes and shipping crates.

| Comparison Aspect | Freight Pallets | Freight Boxes | Shipping Crates |

|---|---|---|---|

| Performance | High load capacity; suitable for large items | Good for smaller, lighter shipments | Excellent protection for fragile items |

| Cost | Generally low cost, especially for wood pallets | Moderate cost, varies by size and material | Higher cost due to construction materials |

| Ease of Implementation | Requires forklift or pallet jack | Easy to handle manually or with equipment | Requires assembly and may need special handling |

| Maintenance | Minimal maintenance; can be reused if intact | Usually disposable; less durable | Higher maintenance due to potential wear |

| Best Use Case | Bulk shipments; standard-sized goods | Small packages; quick delivery | Fragile items; high-value shipments |

What Are the Advantages and Disadvantages of Freight Boxes?

Freight boxes, often made from cardboard or plastic, provide a lightweight and flexible shipping solution. They are particularly suitable for smaller, lighter items and can be easily handled by workers without heavy machinery. However, their performance may be limited when it comes to stacking heavy items, and they often do not offer the same level of durability as pallets. While they can be a cost-effective choice for smaller shipments, they may not provide the necessary protection for fragile goods during transit.

Illustrative image related to freight pallets

Why Consider Shipping Crates for Fragile Items?

Shipping crates are an excellent alternative for businesses that need to transport fragile or high-value items. These robust containers offer superior protection against damage and environmental factors, making them ideal for delicate products. However, they can be more expensive than pallets and require more effort in terms of assembly and maintenance. Moreover, their bulkiness can complicate storage and handling, making them less practical for bulk shipments compared to pallets.

How Can B2B Buyers Choose the Right Shipping Solution?

Selecting the right shipping solution depends on various factors, including the nature of the products being shipped, budget considerations, and logistical capabilities. For bulk shipments of standard-sized goods, freight pallets remain a strong choice due to their cost-effectiveness and ease of movement. Conversely, if you’re handling smaller items or need to ensure the utmost protection for fragile goods, freight boxes or shipping crates may offer better alternatives. Ultimately, understanding the specific needs of your business and weighing the advantages and disadvantages of each option will guide you in making an informed decision that enhances your shipping strategy.

Essential Technical Properties and Trade Terminology for freight pallets

When selecting freight pallets for your shipping needs, understanding their technical properties and industry terminology is crucial. This knowledge not only aids in making informed purchasing decisions but also ensures compliance with international shipping standards.

What Are the Key Technical Properties of Freight Pallets?

1. Material Grade

The material used in pallets can significantly impact their durability and load capacity. Common materials include wood, plastic, and metal. Each material has its strengths; for example, wood pallets are typically strong and cost-effective, while plastic pallets offer moisture resistance and reusability. Selecting the appropriate material grade is essential for ensuring that the pallets can withstand the weight and conditions of your shipment.

Illustrative image related to freight pallets

2. Load Capacity

This specification indicates the maximum weight a pallet can support safely. Load capacity is vital for preventing damage during transport. Overloading a pallet can lead to structural failure, resulting in product loss and increased shipping costs. Understanding the load capacity allows businesses to choose pallets that align with their shipping requirements.

3. Stiffness

Stiffness refers to a pallet’s ability to resist bending or deformation under load. A stiff pallet ensures that the products stacked on it remain stable and secure throughout transit. Inadequate stiffness can lead to shifting or damage, particularly during handling. Choosing a pallet with the right stiffness is essential for maintaining product integrity.

4. Durability

Durability encompasses the pallet’s resistance to wear, moisture, and environmental conditions. A durable pallet can endure the rigors of shipping and storage, minimizing the risk of damage to both the pallet and its contents. This is especially important for international shipping, where pallets may be exposed to varying climates and handling practices.

5. Standard Dimensions

Common pallet sizes, such as the standard 40″ x 48″ wood pallet, facilitate compatibility with forklifts and storage systems. Knowing the standard dimensions helps businesses optimize space in warehouses and shipping containers, ensuring efficient logistics and reducing costs associated with wasted space.

What Are Common Trade Terms Related to Freight Pallets?

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the pallet industry, OEMs may create custom pallets tailored to specific client needs, ensuring that the pallets meet industry standards and operational requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management. For businesses looking to procure pallets, knowing the MOQ can help in negotiating better terms and ensuring that the order size aligns with shipping and storage capacities.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price offers from suppliers. This process is essential for comparing costs and ensuring competitive pricing for pallets. An RFQ allows businesses to evaluate different options and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping. Understanding these terms is essential for ensuring compliance with international shipping regulations and for determining who bears the cost and risk at various stages of the shipping process.

5. Pallet Pooling

Pallet pooling involves the use of a shared inventory of pallets among multiple companies. This practice can reduce costs associated with purchasing and maintaining pallets and is especially beneficial for businesses engaged in frequent shipping.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions regarding freight pallets, optimizing their shipping strategies and ensuring product safety throughout the supply chain.

Navigating Market Dynamics and Sourcing Trends in the freight pallets Sector

What Are the Key Market Drivers Influencing the Freight Pallets Sector?

The freight pallets sector is experiencing significant growth, driven by the globalization of supply chains and the increasing demand for efficient logistics solutions. Key trends include the rise of e-commerce, which has accelerated the need for reliable and standardized shipping methods. Emerging technologies such as RFID tracking and automated inventory management systems are revolutionizing how businesses manage their palletized goods, making operations more transparent and efficient. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. Buyers must consider local market conditions, including regulatory requirements and transportation infrastructure, which can greatly impact sourcing decisions.

Additionally, the current emphasis on cost efficiency is pushing companies to explore alternative pallet materials and designs. Wood pallets remain the most widely used due to their strength and cost-effectiveness, but plastic pallets are gaining traction for their durability and recyclability. As environmental awareness grows, buyers are also gravitating towards suppliers who can offer innovative solutions that meet their operational needs while being mindful of sustainability.

How Does Sustainability Impact Sourcing Decisions for Freight Pallets?

Sustainability is becoming a critical consideration in the sourcing of freight pallets. The environmental impact of pallet production and disposal can no longer be overlooked, prompting buyers to seek out suppliers who prioritize ethical sourcing practices. This shift is particularly pertinent for international buyers who are increasingly held accountable for their supply chain choices, especially in markets sensitive to environmental concerns.

Illustrative image related to freight pallets

Ethical supply chains that incorporate sustainable materials, such as recycled plastics or sustainably sourced wood, are gaining popularity. Certifications such as FSC (Forest Stewardship Council) for wood pallets or recycling certifications for plastic pallets are becoming essential for businesses aiming to enhance their sustainability profiles. These certifications not only mitigate environmental risks but also appeal to consumers who are increasingly making purchasing decisions based on a company’s environmental impact.

Moreover, investing in sustainable pallets can lead to long-term cost savings. Reusable pallets reduce waste and minimize the need for new materials, making them a more economical choice over time. Buyers should prioritize suppliers who demonstrate a commitment to sustainable practices, ensuring that their logistics operations are both efficient and responsible.

What Is the Historical Context of the Freight Pallets Industry?

The freight pallets industry has evolved significantly over the past century, reflecting broader changes in manufacturing, transportation, and logistics. Initially, pallets were simple wooden platforms used primarily in warehouses. However, the post-World War II boom in consumer goods and the rise of global trade necessitated more sophisticated pallet designs and materials.

The introduction of standardized pallet sizes, particularly the 40″ x 48″ wooden pallet, revolutionized shipping efficiency, allowing for easier stacking, storage, and transport. As global trade expanded, so did the complexity of supply chains, leading to innovations in pallet materials such as plastic and composite options. Today, the focus on sustainability and technology integration continues to shape the industry, making it essential for B2B buyers to stay informed about historical trends that influence current market dynamics.

By understanding these key aspects of the freight pallets sector, international B2B buyers can make informed sourcing decisions that align with their operational needs and ethical standards.

Illustrative image related to freight pallets

Frequently Asked Questions (FAQs) for B2B Buyers of freight pallets

-

1. How do I solve issues related to pallet damage during international shipping?

To mitigate pallet damage during international shipping, choose durable materials and appropriate pallet types, such as new wood or high-quality plastic pallets. Ensure your pallets are properly loaded and secured using methods like column stacking and stretch wrap. Additionally, consider environmental factors like humidity and temperature fluctuations when selecting pallets. Regularly inspect your pallets for damage before use and implement a quality assurance process to catch issues early. Lastly, partnering with reliable freight carriers experienced in international logistics can further reduce the risk of damage during transit. -

2. What is the best type of pallet for shipping heavy machinery?

For shipping heavy machinery, standard wooden pallets with reinforced designs are typically the best choice. These pallets should have a higher load capacity and offer four-way entry for easy handling. Consider using pallets with thicker deck boards and additional stringers for enhanced stiffness and durability. If your machinery is particularly heavy or valuable, you might also explore custom pallets designed specifically for your equipment. Ensure that any pallet you select complies with international shipping regulations, especially if exporting to regions with stringent quality standards. -

3. How can I ensure the quality of pallets when sourcing from international suppliers?

To ensure the quality of pallets from international suppliers, start by verifying their certifications and compliance with industry standards such as ISPM 15 for wood packaging materials. Request samples to assess the quality firsthand, and inquire about their manufacturing processes. Establish clear quality assurance guidelines and consider conducting on-site inspections if feasible. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations, helping to ensure that the pallets meet your specific shipping requirements. -

4. What are the minimum order quantities (MOQs) for freight pallets?

Minimum order quantities (MOQs) for freight pallets can vary significantly based on the supplier and the type of pallets being ordered. Generally, wood pallets may have MOQs ranging from 50 to 500 units, while plastic pallets may require higher MOQs due to their manufacturing processes. When sourcing internationally, it’s essential to communicate your needs clearly and explore options for smaller initial orders or trial shipments. Some suppliers may offer flexibility in MOQs, especially for long-term partnerships or larger contracts. -

5. What payment terms should I negotiate when purchasing pallets internationally?

When purchasing pallets internationally, it’s crucial to negotiate payment terms that protect your interests while remaining fair to the supplier. Common terms include a deposit upfront (20-30%) with the balance due upon delivery or after inspection. Explore options for letter of credit (LC) or payment through escrow services to ensure security in transactions. Additionally, consider negotiating for payment terms that allow for partial payments based on milestone deliveries, especially for larger orders, to maintain cash flow while minimizing risk. -

6. How do I customize pallets to fit my specific shipping needs?

Customizing pallets to fit specific shipping needs involves collaborating closely with your supplier to define requirements such as dimensions, load capacity, and materials. Discuss your product specifications and how they impact pallet design, such as weight distribution and stacking methods. Consider features like non-slip surfaces, additional reinforcement for heavy loads, or specific treatment processes to comply with international regulations. Many suppliers can provide design prototypes or CAD drawings to help visualize your custom pallet before production. -

7. What logistics considerations should I keep in mind when shipping pallets internationally?

When shipping pallets internationally, consider logistics factors such as transportation modes (sea, air, or land), customs regulations, and potential tariffs. Ensure that your pallets comply with packaging and labeling requirements specific to each destination country to avoid delays. Collaborate with a freight forwarder who understands the complexities of international shipping and can help navigate documentation and compliance. Additionally, plan for warehousing and distribution needs at the destination to ensure a smooth transition upon arrival. -

8. How can I verify the reliability of a pallet supplier?

To verify the reliability of a pallet supplier, start by checking their industry certifications and reputation through customer reviews and testimonials. Request references from previous clients and inquire about their experience with the supplier’s product quality and service. Conduct background research on their operational history and financial stability, as well as their compliance with international shipping standards. Establish clear communication and set expectations upfront; a reliable supplier will be transparent about their processes and willing to address your concerns.

Top 8 Freight Pallets Manufacturers & Suppliers List

1. FedEx – Pallet Selection Guide

Domain: fedex.com

Registered: 1991 (34 years)

Introduction: Pallets are portable platforms used for handling, storing, and shipping products. Key considerations when choosing a pallet include: 1. Strength – must support the weight of the load; 2. Stiffness – should resist bending and deformation; 3. Durability – needs to withstand shipping conditions; 4. Functionality – must conform to industry standards for transport; 5. Price – balance cost and quality. …

2. Uline – Pallets

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Pallets available include: Plastic Pallets, Shipping Pallets, Export Pallets, New Wood Pallets, Rackable Pallets, Economy Plastic Pallets, Industrial Plastic Pallets, Heavy Duty Nestable Pallets, Solid Top Rackable Pallets, Heavy Duty Export Pallets, Rackable Export Pallet, Closed Deck Export Pallet, Stackable Pallets, Extended Pallet, Plastic Drum Pallets, Aluminum Pallets, Galvanized Steel Palle…

3. Satco – Air Cargo Pallets

Domain: satco-inc.com

Registered: 1999 (26 years)

Introduction: Satco air cargo pallets are durable and cost-effective, introduced in 1968 as the international standard for pallet and container base applications. They are made of all-aluminum, featuring heavy-duty construction for heavy and oversized loads. The pallets utilize top and bottom 7075-T6 aluminum sheets fastened to a patented stringer core for maximum rigidity at the lowest tare weight. They are me…

4. FreightQuote – Pallet Sizes and Types

Domain: freightquote.com

Registered: 1998 (27 years)

Introduction: Standard pallet sizes include 48″ x 40″, 42″ x 42″, and 48″ x 48″. The most common type is the GMA pallet (48″ x 40″). There are five common types of pallets: Stringer pallets (two-way or four-way), Block pallets (four-way with cylindrical posts), Solid Deck pallets (fully connected top surface), Double Face pallets (decks on both top and bottom), and Double Wing pallets (extended deck boards). Pa…

5. Oneway Solutions – 40 x 48 Stackable Light Duty Plastic Pallet

Domain: oneway-solutions.com

Registered: 2002 (23 years)

Introduction: [{‘name’: ’40 x 48 Stackable Light Duty Plastic Pallet – 3 Runner – Unassembled’, ‘sku’: ‘PP-O-40-SL7’, ‘price’: ‘$31.19’, ‘dynamic_load_capacity_lbs’: 2800, ‘height_in’: 5, ‘dimensions’: ’40 x 48′, ‘weight_lbs’: 18}, {‘name’: ’40 x 48 Stackable Light Duty Plastic Pallet – 3 Runner – Assembled’, ‘sku’: ‘PP-O-40-SL7A’, ‘price’: ‘$32.39’, ‘dynamic_load_capacity_lbs’: 2800, ‘height_in’: 5, ‘dimension…

6. Pack Kontrol® – Heavy Duty Closed Deck Pallet

Domain: cabletiesandmore.com

Registered: 2006 (19 years)

Introduction: This company, Pack Kontrol® – Heavy Duty Closed Deck Pallet, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Shipping Solutions – Liftgate Delivery for Electronic Equipment

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Shipping a pallet of electronic equipment, approximately 4′ square and 475-500 pounds, from a facility with a loading dock to a residential address without a loading dock. Requires liftgate delivery. Shipping distance is about 2600 miles from the west coast to the east coast of the US. Initial quotes from UPS and FedEx were $1650 and over $2200 respectively. A quote of $675 was obtained from R&L C…

8. A-1 Auto Transport – Pallet Shipping Services

Domain: a1autotransport.com

Registered: 2001 (24 years)

Introduction: Pallet Shipping Services – Affordable & Easy with A-1 Auto Transport. Average shipping rates: $0.50–$0.90 per pound. Standard transit times: 2–7 business days, with expedited LTL options available. Compliance with FMCSA and DOT packaging standards required. Cost-effective for transporting goods in large quantities. Plastic pallets cost $25 to $50; wooden pallets cost $5 to $25. Economy ground carr…

Strategic Sourcing Conclusion and Outlook for freight pallets

In conclusion, the strategic sourcing of freight pallets is essential for optimizing logistics and enhancing supply chain efficiency. By carefully considering factors such as strength, durability, and cost, businesses can select pallets that not only protect their products but also streamline shipping processes. The choice between wood, plastic, or alternative materials should align with specific operational needs and environmental conditions, particularly for international shipments where varying regulations and standards apply.

As B2B buyers from regions like Africa, South America, the Middle East, and Europe assess their pallet sourcing strategies, it’s crucial to prioritize quality and functionality to mitigate risks associated with product damage and inefficiencies. Engaging with reliable suppliers who understand local market dynamics can provide significant advantages, ensuring compliance and reducing lead times.

Looking ahead, the demand for sustainable and reusable pallet solutions is likely to grow, driven by global supply chain pressures and environmental concerns. Companies should remain proactive in exploring innovative pallet options and collaborate with logistics partners to enhance their competitive edge. Embrace this opportunity to refine your pallet strategy today for a more resilient tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to freight pallets

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.