Everything You Need to Know About Hot Air Dryer Sourcing in 2025

Introduction: Navigating the Global Market for hot air dryer

In the competitive landscape of manufacturing and processing, sourcing the right hot air dryer is a critical challenge for B2B buyers seeking efficiency and quality. The effectiveness of a hot air dryer significantly impacts production timelines and material integrity, making it essential for businesses, especially in regions like Africa, South America, the Middle East, and Europe, to make informed purchasing decisions. This comprehensive guide delves into the various types of hot air dryers, their diverse applications across industries, and essential considerations for supplier vetting and cost analysis.

Understanding the nuances of hot air dryer technology is crucial for maximizing operational efficiency. This guide aims to equip international B2B buyers with the knowledge needed to navigate the complexities of sourcing, ensuring they select the best solutions for their specific requirements. From evaluating energy efficiency and drying capacities to understanding the latest advancements in temperature control and safety features, this resource addresses the key factors that influence purchasing decisions.

By providing actionable insights and expert recommendations, this guide empowers buyers to confidently engage with suppliers and make decisions that enhance productivity and profitability. Whether you are in the plastics industry in Nigeria or the textile sector in Saudi Arabia, the information contained within this guide will serve as a valuable tool in your sourcing strategy, helping you to streamline operations and achieve your business goals.

Understanding hot air dryer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hot Air Dryers | Simple system with heater, blower, temperature controller | Plastics processing, food industry | Pros: Cost-effective, easy installation. Cons: Limited to non-hygroscopic materials. |

| Hopper Dryers | Integrated with a drying hopper, suitable for bulk materials | Injection molding, extrusion | Pros: Efficient for large volumes, compact design. Cons: Higher initial investment. |

| Desiccant Dryers | Uses desiccant materials for moisture removal | Electronics, pharmaceuticals | Pros: Effective for hygroscopic materials. Cons: Requires more maintenance and energy. |

| Hot Air Blowers | Focused airflow for surface drying | Textiles, woodworking | Pros: Versatile and portable. Cons: Less effective for bulk drying. |

| Hybrid Dryers | Combines hot air and other drying methods | Food processing, pharmaceuticals | Pros: High efficiency and flexibility. Cons: More complex and costly to maintain. |

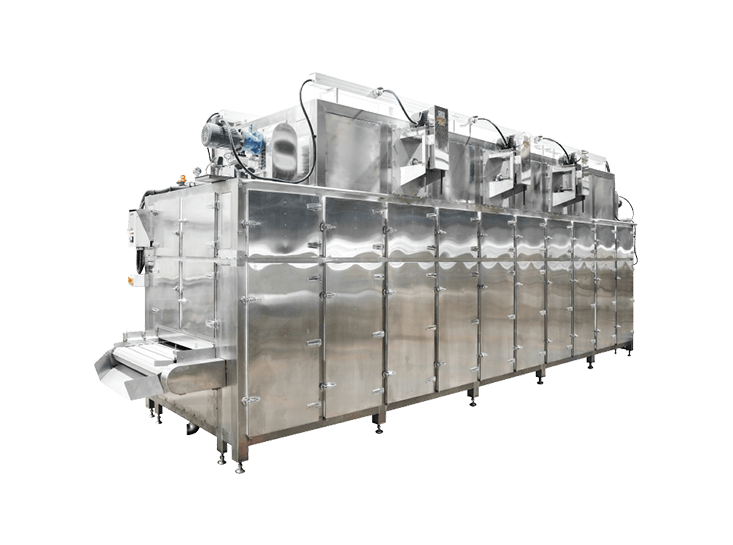

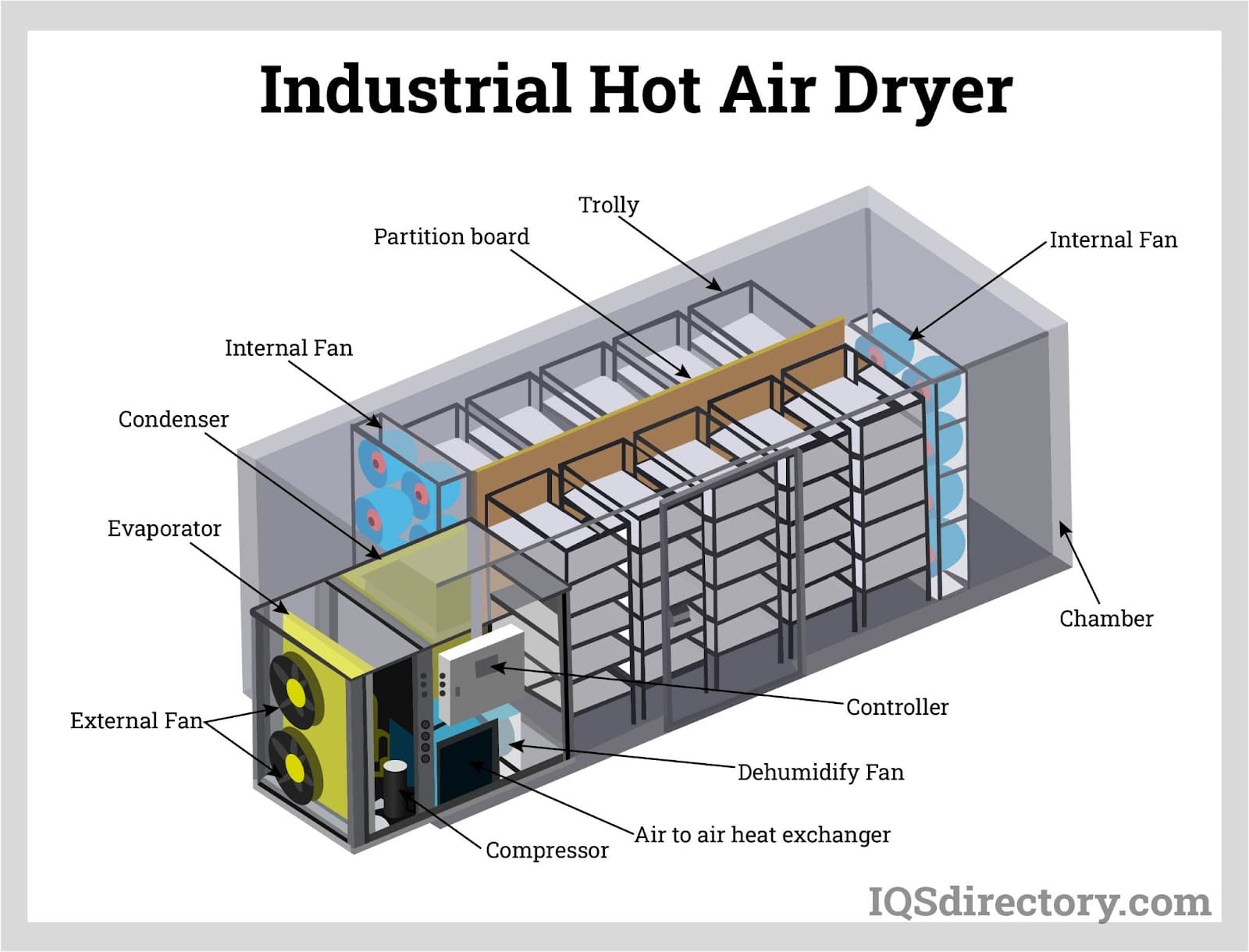

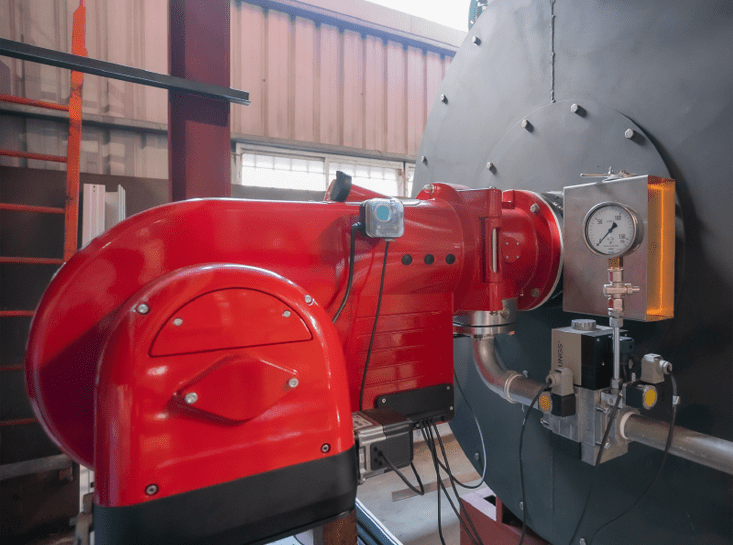

What Are Hot Air Dryers and Their Key Features?

Hot air dryers are essential for various industries, utilizing a simple system comprising a heater, blower, temperature controller, and filter. They are particularly effective for drying non-hygroscopic materials, making them popular in plastics processing and food industries. Buyers should consider the energy efficiency and installation requirements, as well as the volume of materials that need drying.

How Do Hopper Dryers Enhance Bulk Material Drying?

Hopper dryers are specifically designed for bulk materials and are often integrated directly with drying hoppers. This design allows for efficient drying of materials like resins used in injection molding and extrusion processes. They offer compact designs that save space but typically require a higher initial investment. Buyers should evaluate their production scale and drying needs to determine the suitability of hopper dryers.

Illustrative image related to hot air dryer

Why Choose Desiccant Dryers for Hygroscopic Materials?

Desiccant dryers are ideal for industries dealing with hygroscopic materials, such as electronics and pharmaceuticals. These dryers use desiccant materials to absorb moisture, ensuring optimal conditions for sensitive products. While they are highly effective, they require more maintenance and energy compared to hot air dryers. B2B buyers must assess the specific moisture control needs of their materials when considering desiccant dryers.

What Advantages Do Hot Air Blowers Offer?

Hot air blowers are versatile tools that provide focused airflow for surface drying applications, commonly used in textiles and woodworking. Their portability and ease of use make them suitable for various tasks. However, they may not be as effective for drying large volumes of material compared to other dryer types. Buyers should consider the specific drying tasks and environments when selecting hot air blowers.

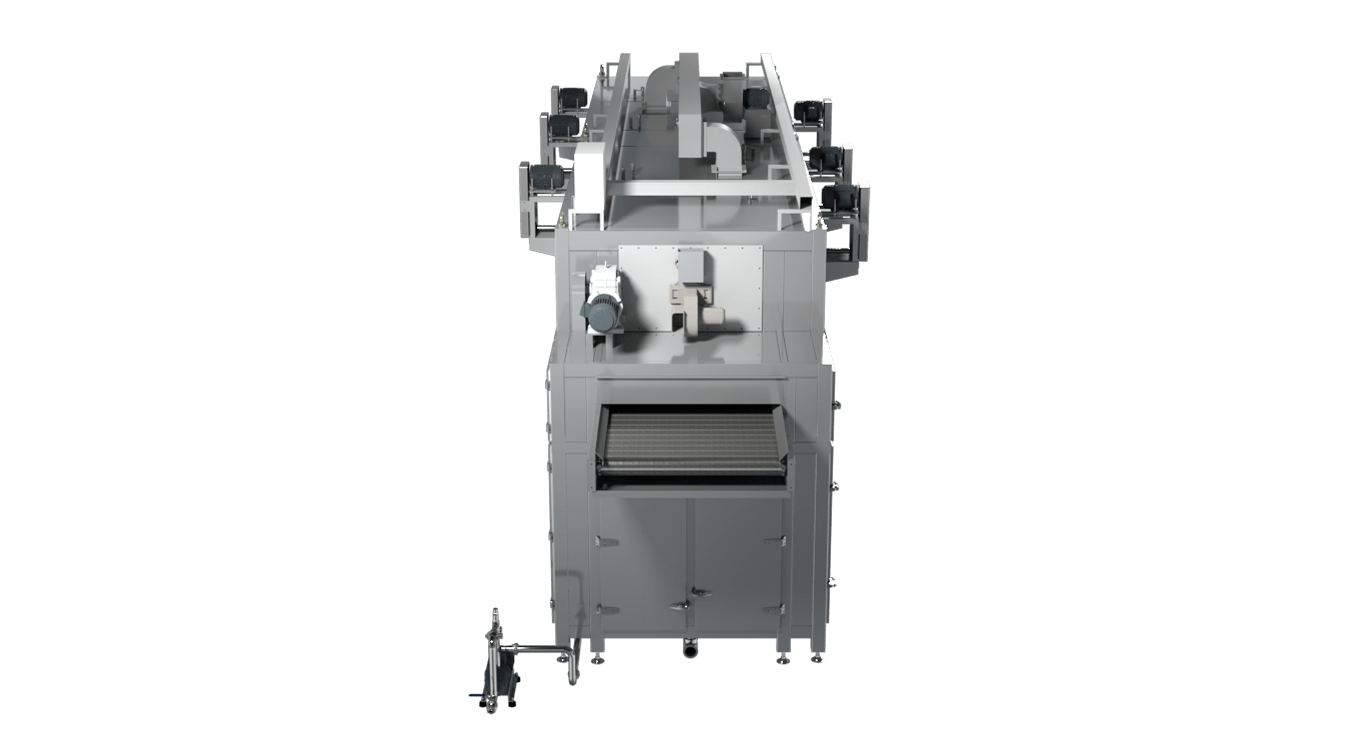

How Do Hybrid Dryers Provide Flexibility in Drying Processes?

Hybrid dryers combine hot air and other drying methods, offering high efficiency and flexibility for industries such as food processing and pharmaceuticals. This combination allows for tailored drying solutions that can adapt to varying material types and moisture levels. While they can be more complex and costly to maintain, their ability to handle diverse drying needs makes them a valuable investment for B2B buyers looking for advanced drying solutions.

Illustrative image related to hot air dryer

Key Industrial Applications of hot air dryer

| Industry/Sector | Specific Application of Hot Air Dryer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Plastics Manufacturing | Drying non-hygroscopic resins | Enhanced product quality and reduced production costs | Energy efficiency, capacity, and compatibility with existing machinery |

| Food Processing | Drying fruits and vegetables | Extended shelf life and improved flavor retention | Compliance with food safety standards and energy consumption |

| Textile Industry | Drying fabric and garments | Faster production cycles and improved fabric quality | Temperature control, material compatibility, and energy efficiency |

| Pharmaceutical Sector | Drying active pharmaceutical ingredients (APIs) | Consistent quality and enhanced shelf life of products | Precision in temperature and humidity control, regulatory compliance |

| Wood Processing | Drying timber and wood products | Improved product durability and reduced warping | Capacity to handle various wood sizes and moisture content control |

How Are Hot Air Dryers Used in Plastics Manufacturing?

In the plastics manufacturing sector, hot air dryers are crucial for drying non-hygroscopic resins before processing. This step is essential to remove surface moisture that can adversely affect the quality of molded parts. By ensuring that the resins are adequately dried, manufacturers can avoid defects, reduce waste, and enhance the overall quality of their products. Buyers in this sector should consider energy efficiency, drying capacity, and compatibility with their existing machinery to optimize production processes.

What Role Do Hot Air Dryers Play in Food Processing?

In food processing, hot air dryers are utilized to effectively dry fruits and vegetables, significantly enhancing their shelf life and retaining their flavor. This method of drying helps in preserving the nutritional value while preventing spoilage. For international buyers, particularly in regions with high humidity, sourcing equipment that complies with food safety standards and offers energy-efficient operation is paramount for maintaining product quality and reducing operational costs.

Why Are Hot Air Dryers Important in the Textile Industry?

The textile industry employs hot air dryers to dry fabrics and garments post-dyeing or washing. This process is vital for accelerating production cycles and ensuring that the finished products maintain high quality. A consistent drying temperature is crucial to prevent fabric damage and ensure color fastness. Buyers should prioritize equipment that offers precise temperature control and is energy-efficient, as these factors directly impact production costs and sustainability initiatives.

How Do Hot Air Dryers Benefit the Pharmaceutical Sector?

In the pharmaceutical sector, hot air dryers are essential for drying active pharmaceutical ingredients (APIs). This process ensures that the APIs maintain their integrity and stability, ultimately enhancing the shelf life of medications. Precision in temperature and humidity control is critical to meet regulatory compliance and ensure product safety. Buyers should focus on sourcing dryers that adhere to strict industry regulations and offer reliable performance to ensure consistent product quality.

What Advantages Do Hot Air Dryers Offer in Wood Processing?

Hot air dryers are widely used in wood processing to dry timber and other wood products efficiently. This drying process is vital to prevent warping and cracking, thus improving the durability and quality of the final product. For buyers in this sector, it’s essential to consider the dryer’s capacity to handle various wood sizes and its ability to control moisture content effectively. Investing in advanced drying technology can lead to significant cost savings and enhanced product quality.

3 Common User Pain Points for ‘hot air dryer’ & Their Solutions

Scenario 1: Inconsistent Drying Results in Production Processes

The Problem: B2B buyers often face the challenge of inconsistent drying results when utilizing hot air dryers, particularly in industries such as plastics processing. This inconsistency can lead to product defects, such as improper molding or finish, which ultimately affects the quality and reliability of the final product. For example, a manufacturer of plastic components may find that some batches are over-dried, leading to brittleness, while others are under-dried, resulting in moisture retention that compromises structural integrity. Such variability not only impacts production efficiency but also increases operational costs due to the need for reprocessing or scrapping defective items.

Illustrative image related to hot air dryer

The Solution: To address this issue, B2B buyers should invest in hot air dryers equipped with advanced temperature and humidity controls, such as those with microprocessor-based controllers. These systems allow for precise monitoring and adjustment of drying conditions, ensuring uniformity across batches. Additionally, integrating a drying hopper with the hot air dryer can enhance the drying process by providing a controlled environment for the material. It’s crucial to conduct thorough testing and calibration of the system before full-scale production to identify the optimal settings for specific materials. Furthermore, regular maintenance and periodic recalibration of equipment can help sustain consistent performance over time.

Scenario 2: High Energy Consumption and Operational Costs

The Problem: Another significant pain point for B2B buyers is the high energy consumption associated with running hot air dryers. In regions where energy costs are a concern, such as parts of Africa and South America, this can lead to inflated operational costs that eat into profit margins. Many buyers may not realize that traditional hot air dryers can be inefficient, leading to excessive energy usage without a corresponding increase in drying efficiency. This inefficiency not only impacts the bottom line but can also lead to dissatisfaction among stakeholders regarding sustainability efforts.

The Solution: Buyers should consider investing in energy-efficient hot air dryers that utilize advanced technologies, such as variable frequency drives (VFDs) and heat recovery systems. These technologies can significantly reduce energy consumption by optimizing airflow and temperature settings based on real-time processing needs. Additionally, sourcing dryers that are designed for specific materials—like non-hygroscopic resins—can enhance drying efficiency, thereby reducing energy costs. Implementing regular energy audits can also help identify inefficiencies within the drying process, allowing for targeted improvements that align with sustainability goals.

Scenario 3: Difficulty in Maintenance and Downtime

The Problem: Maintenance challenges and subsequent downtime can be a major concern for businesses relying on hot air dryers. Frequent breakdowns or difficulties in servicing equipment can lead to interruptions in production, which is particularly detrimental in fast-paced manufacturing environments. For instance, a company may struggle to find replacement parts or qualified technicians familiar with their specific dryer model, prolonging downtime and leading to lost revenue and frustrated customers.

The Solution: To mitigate these risks, B2B buyers should prioritize sourcing hot air dryers from reputable manufacturers that offer robust customer support and readily available spare parts. Opting for models with simplified designs that facilitate easy access for maintenance can also reduce downtime. Implementing a proactive maintenance schedule, including regular inspections and servicing, can help identify potential issues before they escalate into major problems. Furthermore, investing in training for in-house technicians on the specific equipment can empower the team to perform routine maintenance and minor repairs, thus minimizing reliance on external service providers and ensuring smoother operations.

Illustrative image related to hot air dryer

Strategic Material Selection Guide for hot air dryer

When selecting materials for hot air dryers, it is crucial to consider their properties, advantages, disadvantages, and how they align with the specific needs of international B2B buyers. The following analysis covers four common materials used in the construction of hot air dryers: stainless steel, aluminum, carbon steel, and high-temperature plastics.

What are the Key Properties of Stainless Steel for Hot Air Dryers?

Stainless steel is renowned for its excellent corrosion resistance, high-temperature tolerance, and durability. It typically withstands temperatures up to 1,600°F (870°C) and is resistant to oxidation, making it ideal for hot air dryer applications. The material’s mechanical strength ensures longevity and reliability, particularly in demanding environments.

Pros: Stainless steel offers outstanding durability and a long service life, minimizing the need for replacements. Its resistance to corrosion is particularly beneficial in humid environments, making it suitable for regions with high moisture levels.

Cons: The primary drawback is the higher cost compared to other materials, which may deter budget-conscious buyers. Additionally, manufacturing processes for stainless steel can be more complex, leading to longer lead times.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive materials, making it versatile for various applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Europe and the Middle East may prioritize materials that meet stringent safety regulations.

How Does Aluminum Perform as a Material for Hot Air Dryers?

Aluminum is lightweight and offers good thermal conductivity, making it an attractive option for hot air dryer components. It can withstand temperatures up to 1,200°F (650°C) and is less prone to rust than steel.

Pros: Aluminum is cost-effective and easier to manufacture, which can reduce overall production costs. Its lightweight nature allows for easier handling and installation.

Cons: However, aluminum has lower strength compared to stainless steel, which may limit its use in high-stress applications. It is also more susceptible to deformation under high temperatures.

Impact on Application: Aluminum is suitable for drying non-corrosive materials but may not be ideal for applications involving aggressive chemicals.

Considerations for International Buyers: Buyers should ensure that aluminum components comply with local regulations, particularly in the food and pharmaceutical industries, where safety and hygiene standards are critical.

What Role Does Carbon Steel Play in Hot Air Dryer Construction?

Carbon steel is a common choice for structural components due to its strength and affordability. It can handle moderate temperatures, generally up to 800°F (425°C), making it suitable for many hot air drying applications.

Pros: The primary advantage of carbon steel is its cost-effectiveness, which can significantly lower the overall manufacturing expenses. It also provides good mechanical properties and strength.

Cons: Carbon steel is prone to rust and corrosion, especially in humid environments, which can lead to increased maintenance costs over time. It may require additional coatings or treatments to enhance its durability.

Impact on Application: Carbon steel is best suited for applications where exposure to moisture is minimal.

Considerations for International Buyers: Buyers from regions with high humidity, such as parts of Africa and South America, should consider the implications of corrosion and may need to invest in protective coatings or opt for alternative materials.

Illustrative image related to hot air dryer

How Do High-Temperature Plastics Compare for Hot Air Dryers?

High-temperature plastics, such as polyimide and PTFE, are increasingly used in hot air dryers due to their lightweight and excellent thermal resistance, often exceeding 500°F (260°C).

Pros: These materials are resistant to chemical corrosion and provide excellent insulation, which can enhance energy efficiency. They are also easy to mold into complex shapes, allowing for innovative designs.

Cons: The main limitation is their higher cost compared to metals, and they may not offer the same mechanical strength, making them less suitable for load-bearing applications.

Impact on Application: High-temperature plastics are ideal for non-structural components and can be used in environments where chemical exposure is a concern.

Considerations for International Buyers: Compliance with industry-specific standards is crucial, especially in sectors like aerospace and automotive, where material specifications are stringent.

Summary Table of Material Selection for Hot Air Dryers

| Material | Typical Use Case for hot air dryer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Non-structural components | Lightweight and cost-effective | Lower strength and deformation risk | Medium |

| Carbon Steel | Structural components | Cost-effective and strong | Prone to rust and corrosion | Low |

| High-Temperature Plastics | Non-structural components | Chemical resistance and energy efficiency | Higher cost and lower mechanical strength | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance needs, environmental conditions, and regulatory compliance.

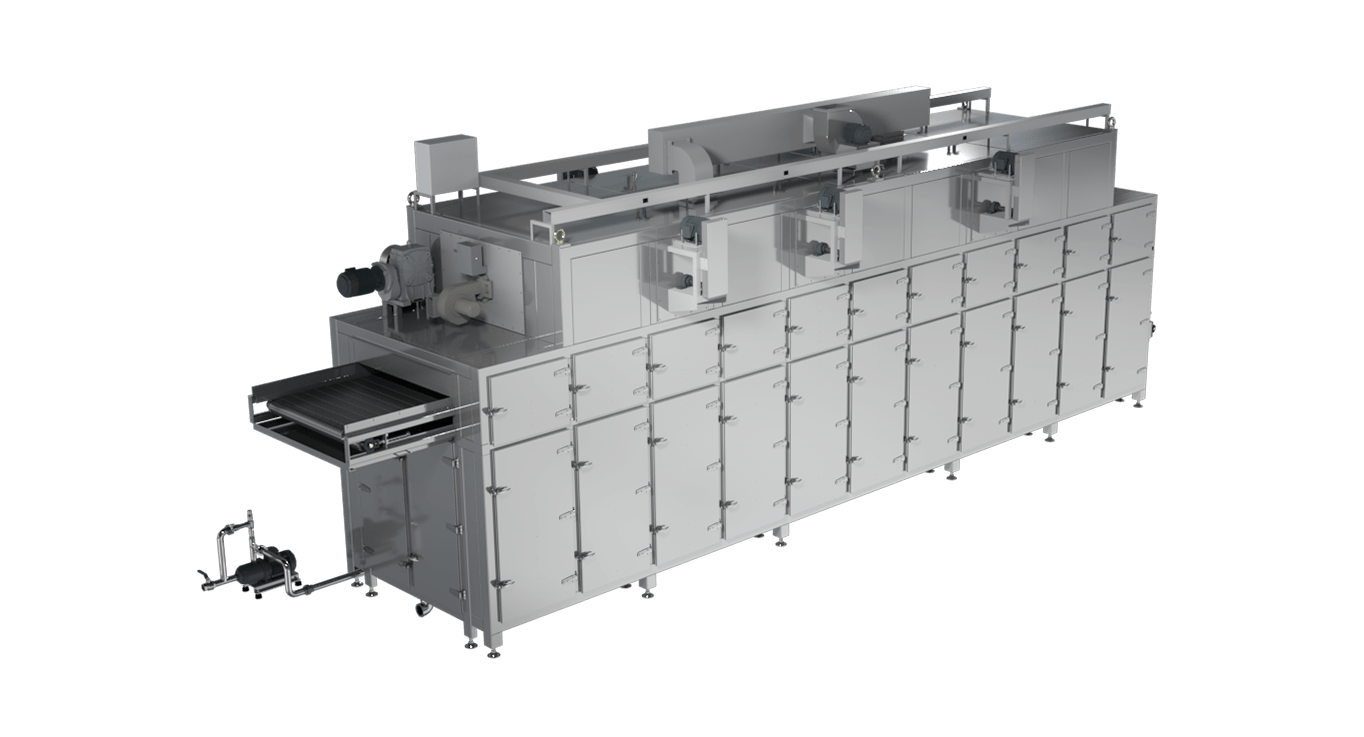

In-depth Look: Manufacturing Processes and Quality Assurance for hot air dryer

What Are the Main Stages in the Manufacturing Process of Hot Air Dryers?

Manufacturing hot air dryers involves several critical stages, each ensuring that the final product meets the necessary performance and safety standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The manufacturing process begins with selecting high-quality materials, such as stainless steel for the housing and specialized alloys for heating elements. These materials are chosen for their durability and ability to withstand high temperatures and corrosion. Suppliers often conduct initial quality checks on these raw materials, ensuring they meet industry standards before they are used in production.

-

Forming: In this stage, materials are shaped into components using techniques such as stamping, bending, and machining. For instance, the outer casing of the hot air dryer may be formed through stamping processes, while the internal heating elements are often precision machined to ensure optimal performance. Advanced CNC (Computer Numerical Control) machines are typically used for high accuracy in forming components, reducing waste and improving product consistency.

-

Assembly: Once the individual components are prepared, they are assembled into the final product. This process may involve soldering or welding heating elements to circuit boards, installing fans, and integrating control panels. It is crucial that assembly workers follow standardized procedures to maintain quality and consistency. Automated assembly lines may be employed to enhance efficiency, especially for large-scale production.

-

Finishing: The final stage involves applying protective coatings and conducting thorough inspections. Coatings may include powder coating or anodizing to enhance corrosion resistance and improve the aesthetic appeal of the dryer. After finishing, each unit undergoes a series of quality checks to ensure it functions correctly and meets performance specifications.

How Is Quality Assurance Implemented in Hot Air Dryer Manufacturing?

Quality assurance (QA) is vital in the manufacturing of hot air dryers, ensuring that products are safe, reliable, and effective. Several international and industry-specific standards guide the QA process, including ISO 9001, CE marking, and various industry certifications.

-

Relevant International Standards: Adhering to ISO 9001 is essential for manufacturers targeting international markets. This standard focuses on a quality management system (QMS) that enhances customer satisfaction through consistent product quality. CE marking is also critical, particularly for products sold in Europe, indicating compliance with safety and environmental regulations.

-

Quality Control Checkpoints: Quality control (QC) checkpoints are integrated into the manufacturing process. These include:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet required specifications.

– In-Process Quality Control (IPQC): Regular inspections occur during assembly to identify defects early. This may include testing electrical components or verifying the assembly of moving parts.

– Final Quality Control (FQC): After assembly and finishing, each hot air dryer undergoes rigorous testing for functionality, safety, and performance. Common tests include temperature regulation checks, airflow measurements, and safety feature validations.

What Testing Methods Are Commonly Used in Hot Air Dryer Quality Assurance?

Testing is a critical component of the quality assurance process, ensuring that hot air dryers perform as expected under various conditions. Common methods include:

Illustrative image related to hot air dryer

- Thermal Efficiency Testing: This assesses the ability of the dryer to maintain a consistent temperature while minimizing energy consumption.

- Airflow Testing: Evaluates the volume and consistency of air delivered by the dryer, which is vital for effective drying.

- Safety Testing: Checks for electrical safety, ensuring that all components are properly insulated and that safety cut-off mechanisms function correctly.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are several methods to ensure that suppliers meet the necessary quality standards:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall compliance with industry standards. This firsthand evaluation can reveal much about a supplier’s commitment to quality.

-

Quality Reports and Certifications: Requesting documentation such as ISO certification and quality control reports can provide insight into a supplier’s quality management practices. These documents typically outline the QC processes and standards adhered to during production.

-

Third-Party Inspections: Engaging independent inspection agencies to evaluate products before shipment can provide an additional layer of assurance. These agencies can perform random inspections and testing, ensuring that the products meet specified standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When engaging with suppliers from different regions, it is essential to understand the nuances of quality control and certification processes. Here are a few key considerations:

-

Cultural Differences: Different regions may have varying approaches to quality management. Understanding these cultural differences can aid in building stronger relationships with suppliers and ensuring compliance with expectations.

-

Regulatory Compliance: Each region may have specific regulatory requirements for hot air dryers. Buyers should familiarize themselves with local regulations in target markets to ensure that products can be legally sold and used.

-

Language Barriers: Communication can sometimes be a barrier when dealing with international suppliers. Ensuring that all documentation is clear and available in the buyer’s primary language can help mitigate misunderstandings regarding quality expectations.

Conclusion

A comprehensive understanding of the manufacturing processes and quality assurance practices for hot air dryers is essential for B2B buyers. By knowing what to look for in terms of manufacturing stages, quality control checkpoints, testing methods, and supplier verification techniques, buyers can make informed decisions that align with their operational needs and market expectations. This knowledge not only helps in selecting reliable suppliers but also enhances product quality and customer satisfaction in the long run.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hot air dryer’

To assist B2B buyers in effectively sourcing hot air dryers, this guide outlines a practical step-by-step checklist. By following these steps, you can ensure a more streamlined procurement process, optimizing your investment in equipment that meets your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the right hot air dryer for your application. Consider factors such as drying capacity, temperature control range, and compatibility with the materials you intend to dry. This step helps avoid costly mistakes by ensuring that the equipment matches your production requirements.

- Capacity Requirements: Determine the volume of materials you need to dry per hour.

- Temperature Control: Specify the maximum temperature needed for your processes.

Step 2: Assess Energy Efficiency

Energy consumption is a significant operational cost, especially in regions with high energy prices. Look for hot air dryers that offer advanced energy-saving features, such as efficient heating elements and optimized airflow systems. This not only reduces your energy bills but also supports sustainability initiatives.

- Energy Ratings: Check for any energy efficiency certifications.

- Operational Costs: Estimate the long-term energy costs based on the unit’s specifications.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, vet potential suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. A reliable supplier should have a proven track record and be able to demonstrate their expertise and reliability.

- Supplier Background: Look for experience in your specific industry.

- Customer Testimonials: Seek feedback from previous clients about their satisfaction and support levels.

Step 4: Verify Compliance with International Standards

Ensuring that the hot air dryer meets international safety and quality standards is vital, especially for cross-border procurement. Check for certifications such as CE, ETL, or ISO, which indicate compliance with relevant regulations. This step protects your investment and ensures safe operation.

- Safety Certifications: Confirm that the product adheres to industry safety standards.

- Quality Assurance Processes: Inquire about the manufacturer’s quality control procedures.

Step 5: Consider After-Sales Support and Warranty

Robust after-sales support is essential for maintaining equipment efficiency and longevity. Evaluate the warranty terms and the availability of spare parts, as well as technical support services. A good warranty can safeguard your investment against unforeseen issues.

- Warranty Length: Look for warranties that cover significant components for multiple years.

- Technical Assistance: Ensure that the supplier offers prompt technical support and service.

Step 6: Request Quotes and Compare Costs

Gather quotes from multiple suppliers to compare prices and features. Be wary of prices that seem too good to be true; they may indicate compromised quality or hidden costs. A comprehensive cost analysis should include not only the purchase price but also installation, maintenance, and operational costs.

- Transparent Pricing: Ensure quotes break down all costs involved.

- Total Cost of Ownership: Consider long-term costs, including maintenance and energy consumption.

Step 7: Finalize Your Purchase and Delivery Terms

Once you have selected a supplier, clearly define the purchase agreement, including delivery terms and installation timelines. Establishing these details upfront minimizes potential disputes and ensures a smoother procurement process.

- Delivery Schedule: Agree on realistic timelines for delivery and installation.

- Payment Terms: Clarify payment schedules and conditions to avoid misunderstandings.

By following this checklist, B2B buyers can make informed decisions when sourcing hot air dryers, ensuring that they choose equipment that is reliable, efficient, and suitable for their specific operational needs.

Comprehensive Cost and Pricing Analysis for hot air dryer Sourcing

What Are the Key Cost Components in Hot Air Dryer Sourcing?

When sourcing hot air dryers, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The quality of materials used in manufacturing hot air dryers significantly impacts costs. Stainless steel components, for instance, provide durability and corrosion resistance, but they are more expensive than plastic alternatives.

-

Labor: Labor costs can vary based on geographic location and the complexity of the manufacturing process. Skilled labor may be required for assembly and quality checks, which can increase overall costs.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Custom tooling may be necessary for specific designs or specifications, adding to the initial investment. However, investing in high-quality tooling can improve production efficiency and product quality.

-

Quality Control (QC): Ensuring that hot air dryers meet industry standards requires a robust QC process, which can increase costs but is crucial for minimizing defects and ensuring customer satisfaction.

-

Logistics: Shipping and handling costs can vary significantly depending on the destination, shipping methods, and whether the product is being imported or exported.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Margins can vary based on market competition and product demand.

How Do Price Influencers Affect Hot Air Dryer Costs?

Several factors influence the pricing of hot air dryers, which B2B buyers should consider:

-

Volume/MOQ: Purchasing in bulk often leads to lower per-unit costs. Suppliers frequently offer discounts for larger orders, making it beneficial for businesses with high demand.

-

Specifications and Customization: Custom features or specifications can lead to higher costs. Buyers should evaluate whether these customizations are necessary for their operations.

-

Materials and Quality Certifications: High-quality materials and certifications (like ISO or CE) can increase costs but are often essential for compliance and safety in specific industries.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of trade, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is crucial as they determine who is responsible for shipping costs and risks.

What Are Effective Buyer Tips for Cost-Efficiency?

To ensure cost-efficiency when sourcing hot air dryers, international B2B buyers should consider the following tips:

Illustrative image related to hot air dryer

-

Negotiate Prices: Don’t hesitate to negotiate prices with suppliers. Building a good relationship can lead to better terms and discounts.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs, including maintenance, energy consumption, and potential downtime.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local tariffs, taxes, and import duties that can affect overall costs.

-

Request Detailed Quotes: Ensure that quotes include all potential costs, including shipping, customs, and any other fees. This will help avoid unexpected expenses.

-

Consider Local Suppliers: Sourcing from local manufacturers can reduce shipping costs and lead times, providing a competitive edge in pricing.

Disclaimer on Indicative Prices

Prices for hot air dryers can vary widely based on the aforementioned factors. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are getting the best value for their investment. Always account for potential fluctuations in material costs and other economic factors that could impact pricing over time.

Alternatives Analysis: Comparing hot air dryer With Other Solutions

Understanding Alternative Solutions to Hot Air Dryers in Industrial Applications

In the industrial landscape, selecting the right drying solution is crucial for efficiency and product quality. While hot air dryers are a popular choice for drying materials, various alternative technologies also exist. This section compares hot air dryers with two notable alternatives: desiccant dryers and infrared (IR) dryers. Each option has unique benefits and considerations that can impact the decision-making process for international B2B buyers.

Comparison of Hot Air Dryers and Alternative Solutions

| Comparison Aspect | Hot Air Dryer | Desiccant Dryer | Infrared Dryer |

|---|---|---|---|

| Performance | Effective for non-hygroscopic resins with good airflow | Excellent moisture removal, especially for hygroscopic materials | Rapid drying with targeted heat application |

| Cost | Moderate initial investment; lower operational costs | Higher initial costs; energy-efficient in the long run | Moderate to high initial cost; energy-efficient |

| Ease of Implementation | Relatively easy to set up and integrate into existing systems | Requires careful installation and calibration | Simple setup, but may require specific infrastructure |

| Maintenance | Low maintenance with regular checks | Moderate; requires routine desiccant replacement | Low maintenance, but needs regular cleaning of IR panels |

| Best Use Case | Ideal for plastics and non-hygroscopic materials | Best for hygroscopic materials like PET | Suitable for quick drying applications, such as thin films and coatings |

Detailed Breakdown of Alternatives

Desiccant Dryer

Desiccant dryers utilize a drying agent to absorb moisture from the air before it comes into contact with the material. This method is particularly effective for hygroscopic materials, making it suitable for industries such as plastics and pharmaceuticals. The main advantage of desiccant dryers is their ability to achieve lower humidity levels, resulting in high-quality outputs. However, the initial investment is generally higher due to the cost of the desiccant material and the need for a more complex installation. Regular replacement of the desiccant can also increase maintenance efforts and costs.

Infrared Dryer

Infrared dryers operate by emitting infrared radiation, which directly heats the surface of the material, leading to rapid moisture evaporation. This technology is excellent for applications requiring quick drying times, such as coatings and films. The primary benefits include energy efficiency and reduced drying times compared to traditional methods. However, infrared dryers may have limitations in uniform drying if the material thickness varies, and they can be costlier upfront. Additionally, specific infrastructure adjustments may be necessary to accommodate the equipment.

Conclusion: Choosing the Right Drying Solution for Your Business Needs

When selecting a drying solution, B2B buyers must consider their specific operational requirements, including the type of material, production volume, and budget constraints. Hot air dryers are versatile and cost-effective for many applications, particularly for non-hygroscopic materials. However, if your operations involve hygroscopic materials, investing in a desiccant dryer may yield better results. Conversely, for applications demanding speed and efficiency, infrared dryers could be the best choice. Ultimately, understanding the strengths and weaknesses of each solution will empower businesses to make informed decisions that align with their production goals and financial capabilities.

Essential Technical Properties and Trade Terminology for hot air dryer

What Are the Key Technical Properties of Hot Air Dryers?

When evaluating hot air dryers, several technical properties stand out as critical for ensuring optimal performance and efficiency in industrial applications. Understanding these specifications can significantly influence purchasing decisions.

1. Heating Capacity (KW)

The heating capacity, measured in kilowatts (KW), indicates the amount of heat the dryer can produce. This parameter is crucial for determining the drying speed and efficiency. A higher KW rating typically translates to faster drying times, which is essential in high-demand production environments. Buyers should assess their production needs and choose a dryer with adequate heating capacity to maintain throughput without sacrificing quality.

2. Blower Capacity (KW)

Blower capacity, also expressed in kilowatts, refers to the power of the blower that circulates heated air through the drying chamber. Efficient airflow is vital for uniform drying and preventing material clumping. Buyers must consider the specific requirements of the materials they are drying, as different materials may need varying airflow rates for effective moisture removal.

3. Temperature Control

Advanced temperature control systems are essential for maintaining consistent drying conditions. Many hot air dryers feature micro PLC (Programmable Logic Controller) systems that allow precise adjustments to temperature settings. This capability is particularly important when working with sensitive materials that require specific drying temperatures to avoid degradation. Buyers should prioritize systems with reliable temperature control to enhance product quality and reduce waste.

4. Material Construction

The durability of a hot air dryer is often determined by its material construction. Common materials include stainless steel for heating elements and aluminum for casings. These materials not only provide longevity but also resistance to corrosion and heat. Buyers should evaluate the construction materials to ensure that the dryer can withstand the operational environment, particularly in industries where exposure to moisture and chemicals is common.

5. Drying Capacity

Drying capacity, typically measured in kilograms per hour (kg/hr), indicates the volume of material that the dryer can process within a specific timeframe. This specification is critical for businesses looking to match their dryer’s output with production demands. Selecting a dryer with the appropriate capacity helps optimize operational efficiency and minimizes bottlenecks in the production line.

What Are Common Trade Terms Used in the Hot Air Dryer Industry?

Understanding industry terminology is essential for effective communication and negotiation in B2B transactions involving hot air dryers.

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of hot air dryers, understanding OEM partnerships can help buyers identify reputable suppliers and ensure they are purchasing quality equipment that meets industry standards.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest number of units a supplier is willing to sell. This term is crucial for buyers as it impacts inventory management and cost efficiency. Understanding the MOQ can help businesses negotiate better terms and avoid overstocking or understocking issues.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products, including hot air dryers. This process allows buyers to compare options and make informed purchasing decisions. Providing detailed specifications in an RFQ can lead to more accurate and competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms widely used in international trade. They define the responsibilities of buyers and sellers in shipping and logistics. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, ensuring smooth transactions across borders.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. This term is crucial for production planning, especially in industries where timing is critical. Understanding lead times can help businesses synchronize their supply chain and avoid delays in production schedules.

By grasping these essential properties and terminology, B2B buyers can make more informed decisions when investing in hot air dryers, ultimately enhancing operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the hot air dryer Sector

Market Overview & Key Trends in the Hot Air Dryer Sector

The hot air dryer market is experiencing robust growth, driven by increasing demand across various industries including plastics processing, food, and textiles. In regions like Africa, South America, the Middle East, and Europe, businesses are seeking efficient drying solutions that can enhance productivity and reduce operational costs. Key trends include the adoption of advanced technologies such as Industry 4.0, which integrates automation and data exchange in manufacturing processes. This shift allows for real-time monitoring and optimization of drying parameters, leading to improved product quality and reduced energy consumption.

Illustrative image related to hot air dryer

Emerging players are also focusing on developing energy-efficient models that minimize environmental impact while maximizing performance. For instance, hot air dryers equipped with micro PLC temperature controllers are gaining traction, allowing for precise control of drying conditions. Additionally, the trend towards modular designs enables businesses to scale their operations flexibly, adapting to varying production needs without significant capital investment.

International B2B buyers are increasingly prioritizing suppliers who offer not only high-quality products but also reliable after-sales support and maintenance services. The ability to provide customized solutions that cater to specific industry requirements is becoming a critical differentiator in the competitive landscape. As a result, understanding local market dynamics, including regulatory requirements and cultural preferences, is essential for successful sourcing in these diverse regions.

How is Sustainability Influencing the Sourcing of Hot Air Dryers?

Sustainability has emerged as a pivotal factor in the sourcing of hot air dryers. Businesses are under growing pressure to reduce their environmental footprint, which is driving the demand for eco-friendly drying solutions. Hot air dryers that utilize renewable energy sources or incorporate energy-efficient technologies not only align with corporate sustainability goals but also lead to significant cost savings over time.

Moreover, the importance of ethical supply chains is gaining prominence among B2B buyers. Companies are increasingly scrutinizing the sourcing practices of their suppliers, favoring those who demonstrate a commitment to ethical labor practices and environmental stewardship. Certifications such as ISO 14001 for environmental management systems and ENERGY STAR for energy efficiency are becoming critical benchmarks for evaluating potential suppliers.

Investing in ‘green’ materials and technologies not only enhances brand reputation but also meets the growing consumer demand for sustainable products. B2B buyers are encouraged to engage with manufacturers who can provide transparency in their sourcing practices and demonstrate compliance with international sustainability standards. This approach not only mitigates risks associated with supply chain disruptions but also fosters long-term partnerships built on shared values.

What is the Evolution of Hot Air Dryers and Their Impact on Modern B2B Practices?

The evolution of hot air dryers has significantly transformed industrial drying processes. Initially, these dryers were simple, conventional units used primarily in the food industry. Over the decades, technological advancements have led to the development of sophisticated models equipped with features such as temperature control, energy efficiency, and automation.

The introduction of microprocessor controls and advanced materials has enhanced the performance and reliability of hot air dryers, making them integral to various manufacturing processes. Today, these dryers are essential not only for drying but also for improving product quality by ensuring uniform moisture content and reducing processing time.

As industries increasingly adopt lean manufacturing principles, the role of hot air dryers in optimizing production efficiency cannot be overstated. B2B buyers are now more inclined to invest in high-quality, technologically advanced dryers that promise reliability and efficiency, ultimately contributing to their competitive advantage in the global marketplace. This historical context underscores the importance of selecting the right hot air dryer, as it directly impacts operational efficiency and product quality in today’s fast-paced industrial landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of hot air dryer

-

How do I solve issues with inadequate drying performance in my hot air dryer?

Inadequate drying performance can often be traced back to several factors, including incorrect temperature settings, insufficient airflow, or a clogged filter. Start by checking the temperature settings against the material specifications and ensure that the heater is functioning optimally. Inspect the blower and ensure it’s providing sufficient airflow; any blockages should be cleared. Regular maintenance, including cleaning or replacing filters, is crucial to maintaining performance. If issues persist, consult with the manufacturer for troubleshooting or consider professional servicing. -

What is the best hot air dryer for processing non-hygroscopic resins?

For processing non-hygroscopic resins, a hot air dryer with a high-capacity blower and precise temperature control is ideal. Models such as the Bry-Air EcoDry series are designed specifically for this purpose, offering capacities ranging from 13 to 400 kg/hr. Look for features like stainless steel heaters for durability, an automatic temperature controller for consistent drying, and the option for machine mounting. These specifications ensure efficient drying and improved product quality, making them suitable for various industrial applications. -

What factors should I consider when selecting a hot air dryer supplier?

When selecting a hot air dryer supplier, consider their experience in the industry, product quality, and after-sales support. Verify their reputation by reviewing client testimonials and case studies. Ensure they offer comprehensive technical support, including installation and maintenance services. Additionally, evaluate their ability to customize products to meet specific requirements and check their compliance with international standards for safety and efficiency. Lastly, assess their logistics capabilities to ensure timely delivery to your region. -

What are the typical minimum order quantities (MOQ) for hot air dryers?

Minimum order quantities for hot air dryers can vary significantly by supplier and product type. Generally, MOQs range from one unit for small-scale suppliers to several units for larger manufacturers. It’s essential to discuss your needs directly with potential suppliers to negotiate MOQs that fit your purchasing strategy. Some suppliers may offer flexibility for first-time buyers or bulk orders, so it’s worth exploring options to optimize your investment and minimize storage costs. -

What payment terms are standard for international purchases of hot air dryers?

Standard payment terms for international purchases typically include options such as letters of credit, advance payments, or payment upon delivery. Many suppliers may require a deposit (often 30-50%) before production, with the balance due prior to shipment or upon receipt of the goods. It’s crucial to clarify payment terms upfront to avoid any misunderstandings. Additionally, consider the implications of currency exchange rates and international transaction fees when negotiating payment arrangements. -

How can I ensure quality assurance (QA) for my hot air dryer?

To ensure quality assurance for your hot air dryer, request detailed product specifications and certifications from the supplier. Look for compliance with international standards such as ISO or CE marking, which indicates adherence to safety and performance criteria. Consider conducting factory visits or audits if feasible, or request third-party inspections before shipment. Furthermore, establish clear QA protocols that include testing for performance and reliability upon receipt, ensuring the equipment meets your operational requirements. -

What logistics considerations should I keep in mind when sourcing hot air dryers internationally?

When sourcing hot air dryers internationally, consider shipping methods, lead times, and customs regulations. Discuss with your supplier the most efficient shipping options based on your location, weighing cost against delivery speed. Ensure you understand any import duties, taxes, and compliance documentation required for customs clearance in your country. It’s advisable to work with a logistics partner experienced in handling industrial equipment to facilitate a smooth shipping process and mitigate potential delays. -

Can hot air dryers be customized for specific applications?

Yes, many manufacturers offer customization options for hot air dryers to suit specific applications and operational needs. Customizations may include adjustments in size, heating capacity, and control systems to match unique processing requirements. When engaging with suppliers, provide detailed specifications of your application, including materials to be dried and desired throughput. This will help the supplier recommend the best modifications to enhance efficiency and ensure optimal performance in your production environment.

Top 5 Hot Air Dryer Manufacturers & Suppliers List

1. Revlon – One-Step™ Hair Dryer and Volumizer

Domain: revlonhairtools.com

Registered: 2010 (15 years)

Introduction: Salon One-Step™ Hair Dryer and Volumizer features: Original REVLON One-Step™ Volumizer Hot Air Brush with new features, designed with Nylon Pin & Tufted Bristles for detangling, improved volume and control. Unique Oval Brush Design for smoothing hair, while round edges create volume. 1100-Watt power for optimal heat, can be placed closer to the scalp for lift. 3 Heat/Speed Settings for styling fle…

2. Conair – Hot Air Dryers for Plastics Processing

Domain: conairgroup.com

Registered: 1996 (29 years)

Introduction: Hot Air Dryers for Plastics Processing by Conair include models ranging from 600 to 5000. They are designed to remove surface moisture using a simple system that consists of a heater, blower, temperature controller, and a filter. These dryers are effective for drying non-hygroscopic resins when paired with a drying hopper.

3. AEC – Hot Air Dryer

Domain: aecinternet.com

Registered: 1996 (29 years)

Introduction: AEC offers a hot air dryer featuring a single blower that provides heated air to dry non-hygroscopic materials. The hot air dryer is available with a regenerative or centrifugal blower.

4. RevAir – Reverse-Air Hair Dryer

Domain: myrevair.com

Registered: 2017 (8 years)

Introduction: RevAir Reverse-Air Hair Dryer with friction-free technology, 3 heat settings, 7 tension settings. 70% faster dry time compared to traditional blow dryers. Suitable for all hair types, including extensions, twist outs, braids, locs, and wigs. Variable tension settings and internal temperature sensors to reduce damage and breakage. Preserves curl pattern, keeping hair healthier, shinier, and stronge…

5. Bryair – Hot Air Dryer (HAD Series)

Domain: bryair.com

Registered: 1999 (26 years)

Introduction: Hot Air Dryer – HAD Series

– Capacity: 13-400 kg/hr for non-hygroscopic resins; larger models available for above 400 kg/hr.

– Features: Compact and rugged design, includes blower, stainless steel tubular heaters, automatic temperature controller.

– Installation: Can be machine mounted or installed beside the moulding machine.

– Loading: Supports manual loading or can be paired with Bry-Air Auto L…

Strategic Sourcing Conclusion and Outlook for hot air dryer

In today’s competitive landscape, the strategic sourcing of hot air dryers offers significant advantages for businesses across various sectors. By prioritizing quality, efficiency, and cost-effectiveness, international buyers can enhance their operational capabilities while ensuring optimal performance in drying applications. The integration of advanced technologies, such as automatic temperature controls and energy-efficient designs, not only maximizes productivity but also minimizes operational costs—an essential consideration for companies in regions like Africa, South America, the Middle East, and Europe.

Investing in reliable hot air dryers can lead to improved product quality and reduced waste, translating to higher profitability and customer satisfaction. As the market evolves, suppliers are increasingly innovating to meet diverse industrial needs, paving the way for tailored solutions that address specific challenges faced by manufacturers.

Looking ahead, it is crucial for B2B buyers to leverage strategic partnerships with reputable suppliers, ensuring access to the latest technologies and best practices. By doing so, businesses can position themselves to thrive in an ever-changing market landscape. Engage with industry experts today to explore how the right hot air dryer solutions can elevate your operations and drive sustainable growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.