Everything You Need to Know About Hydraulic Spray Sourcing in 2025

Introduction: Navigating the Global Market for hydraulic spray

The hydraulic spray market is a crucial component for industries worldwide, offering solutions for applications ranging from cooling and coating to cleaning and lubrication. However, navigating this complex landscape can be daunting for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. The challenge lies in sourcing the right hydraulic spray solutions that not only meet operational needs but also align with budget constraints and local regulations.

This comprehensive guide serves as an essential resource for buyers seeking to understand the myriad types of hydraulic spray nozzles and systems available in the global marketplace. We will explore various applications, including industrial cleaning, fire protection, and agricultural use, while also providing insights on supplier vetting processes, cost considerations, and maintenance best practices. By equipping buyers with the knowledge to make informed decisions, this guide empowers businesses to enhance operational efficiency and sustainability through optimal hydraulic spray solutions.

Whether you’re a manufacturer in Nigeria looking to reduce water usage or a construction company in Germany aiming to improve insulation application, our guide will help you identify the right products and suppliers tailored to your unique needs. Join us as we delve into the intricacies of hydraulic spray systems and unlock the potential for greater productivity and cost savings in your operations.

Understanding hydraulic spray Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Cone Nozzles | Spray pattern forms a full cone; uniform distribution. | Cooling, coating, fire protection. | Pros: Excellent coverage; versatile. Cons: May require regular maintenance for optimal performance. |

| Hollow Cone Nozzles | Produces a hollow cone spray; ideal for targeted areas. | Agricultural applications, chemical spraying. | Pros: Efficient for specific applications; reduces material waste. Cons: Limited range; may need adjustments for optimal use. |

| Flat Spray Nozzles | Creates a flat spray pattern; adjustable angles. | Surface cleaning, lubrication, and cooling. | Pros: Customizable coverage; effective for large surfaces. Cons: Can lead to overspray if not properly calibrated. |

| Fine Spray Nozzles | Generates a fine mist; suitable for delicate applications. | Paint spraying, humidification, and cooling. | Pros: Precise application; minimizes waste. Cons: Sensitive to pressure changes; requires careful handling. |

| Hydraulic Spray Foam Machines | High-pressure operation; efficient for foam insulation. | Construction, roofing, and industrial coatings. | Pros: Long lifespan; high output efficiency. Cons: Higher initial investment; requires trained operators. |

What Are Full Cone Nozzles and Their Applications?

Full cone nozzles are designed to produce a spray pattern that resembles a full cone, providing uniform distribution across the targeted area. This type is commonly used in applications such as cooling and coating, where consistent coverage is crucial. B2B buyers should consider the nozzle’s flow rate and pressure requirements to ensure compatibility with their existing systems. Regular maintenance is essential to prevent clogging and ensure optimal performance over time.

How Do Hollow Cone Nozzles Work in Specific Industries?

Hollow cone nozzles create a spray pattern that is hollow in the center, making them ideal for applications that require targeted delivery of liquids, such as in agriculture for pesticide application or chemical spraying. Their efficiency in reducing material waste can lead to significant cost savings for businesses. When purchasing, buyers should evaluate the nozzle’s compatibility with their spray systems and consider the specific pressure and flow rate needed for their operations.

What Are the Benefits of Flat Spray Nozzles?

Flat spray nozzles produce a flat spray pattern and are highly adjustable, allowing users to customize the angle of the spray. They are widely used for surface cleaning, lubrication, and cooling applications. For B2B buyers, the ability to adjust the spray angle can enhance operational efficiency. However, proper calibration is necessary to avoid overspray, which can lead to increased costs and material waste.

Why Choose Fine Spray Nozzles for Sensitive Applications?

Fine spray nozzles generate a mist-like spray, making them suitable for applications that require delicate handling, such as paint spraying and humidification. Their precision helps minimize waste and ensures that the application is effective. Buyers should be aware that fine spray nozzles are sensitive to pressure changes and may require careful handling and maintenance to achieve optimal results.

What Are the Advantages of Hydraulic Spray Foam Machines?

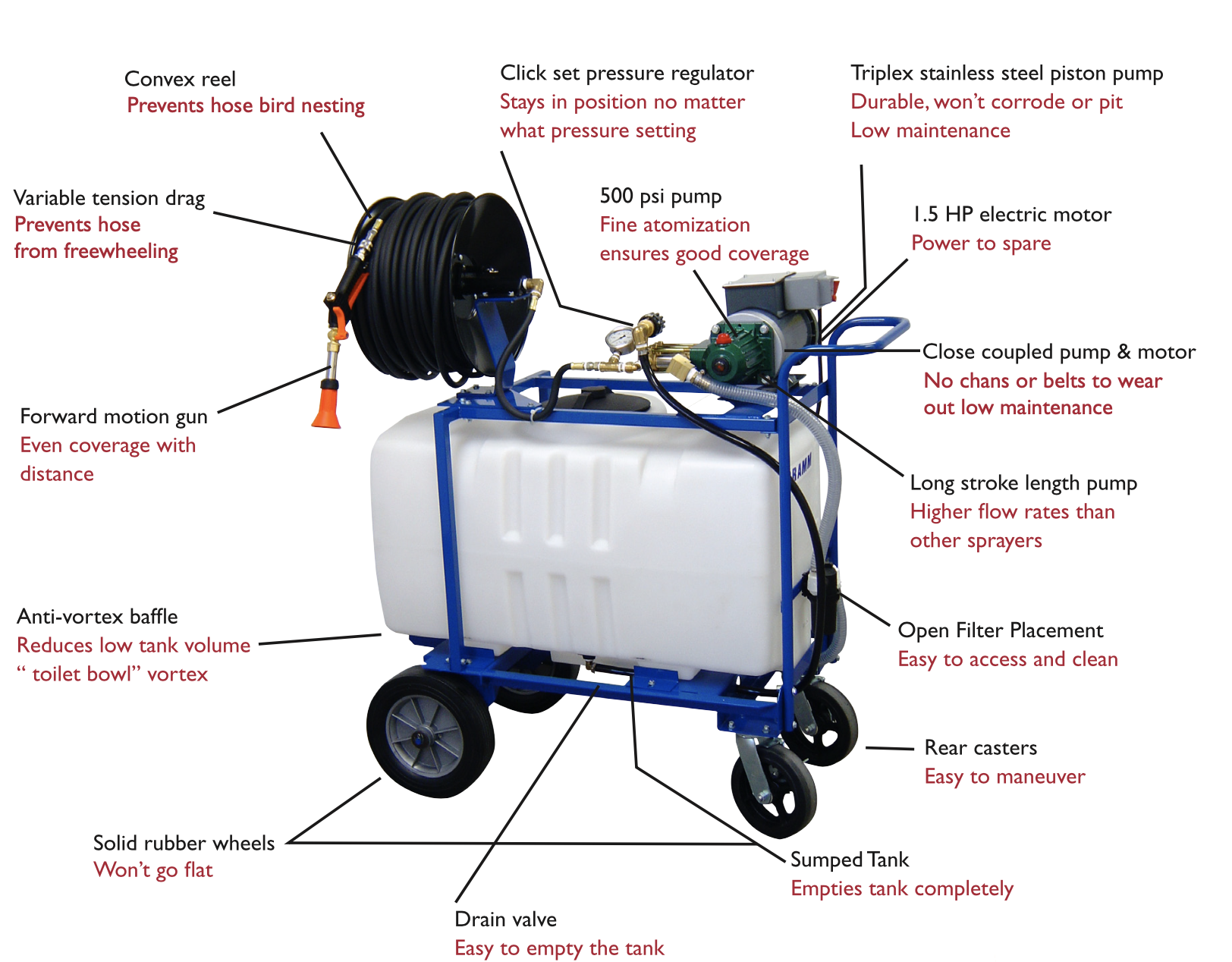

Hydraulic spray foam machines operate at high pressure and are particularly efficient for insulation in construction and industrial coatings. Known for their longevity, these machines can last up to 12 years with proper maintenance. B2B buyers should consider the initial investment and ensure that operators are trained to maximize the machine’s capabilities and efficiency. The high output can significantly improve project timelines, making them a valuable asset for contractors and construction firms.

Key Industrial Applications of hydraulic spray

| Industry/Sector | Specific Application of hydraulic spray | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Cooling and coating of food products | Reduces water usage and enhances product quality | Need for precise flow rates and nozzle types for hygiene |

| Automotive Manufacturing | Lubrication of machinery and metal forming processes | Increases equipment lifespan and reduces downtime | Requirement for corrosion-resistant materials and easy maintenance |

| Construction and Insulation | Application of spray foam insulation | Improved energy efficiency and reduced material waste | Need for high-pressure systems and reliable heating elements |

| Chemical Processing | Dust control and chemical spraying | Enhances safety and compliance with environmental standards | Importance of chemical resistance and nozzle adaptability |

| Fire Protection | Fire suppression systems using hydraulic spray | Protects assets and ensures safety compliance | Consideration for pressure ratings and nozzle coverage area |

How is Hydraulic Spray Used in Food Processing?

In the food processing industry, hydraulic spray is primarily utilized for cooling and coating food products, such as meats and baked goods. This method not only conserves water—an essential resource in regions like Africa and South America—but also improves product quality by ensuring even distribution of coatings. Buyers should prioritize nozzles that offer specific spray patterns and flow rates to maintain hygiene standards and meet local regulatory requirements.

What Role Does Hydraulic Spray Play in Automotive Manufacturing?

Hydraulic spray systems are integral to the automotive sector, particularly for lubrication in machinery and metal forming processes. By delivering a controlled spray of lubricants, these systems minimize wear and tear on equipment, leading to longer service life and reduced maintenance costs. B2B buyers must consider the material durability of nozzles, as well as their compatibility with various lubricants, to ensure optimal performance in harsh manufacturing environments.

How is Hydraulic Spray Applied in Construction and Insulation?

In construction, hydraulic spray is crucial for the application of spray foam insulation, which provides superior thermal resistance and energy efficiency. This application is particularly beneficial for large commercial projects, as it reduces material waste and labor costs. Buyers should focus on sourcing high-pressure hydraulic systems that can efficiently handle the mixing and application of foam, ensuring consistent performance across diverse building materials.

What Benefits Does Hydraulic Spray Provide in Chemical Processing?

Hydraulic spray technology is essential in chemical processing for tasks such as dust control and the application of chemicals. These systems enhance workplace safety by minimizing airborne particles and ensuring even chemical distribution, which is vital for compliance with environmental regulations. When sourcing for this application, buyers should look for nozzles that are resistant to corrosive substances and can accommodate varying flow rates for different chemical types.

How Does Hydraulic Spray Contribute to Fire Protection Systems?

In fire protection, hydraulic spray systems are employed for fire suppression, utilizing high-pressure sprays to extinguish flames effectively. This application is critical for safeguarding valuable assets and ensuring safety compliance in industrial settings. Buyers must consider the nozzle’s coverage area and pressure ratings to ensure adequate fire suppression capabilities, especially in high-risk environments across diverse geographic regions.

3 Common User Pain Points for ‘hydraulic spray’ & Their Solutions

Scenario 1: Inefficient Spray Coverage Leading to Waste

The Problem: Many B2B buyers in industries such as food processing or manufacturing often encounter challenges with inefficient spray coverage. This can lead to significant waste of materials, whether it’s water, chemicals, or lubricants. For instance, a beverage manufacturer might struggle with uneven cooling or cleaning processes, which not only affects product quality but also increases operational costs. When spray nozzles do not deliver the required pattern or flow rate, it can result in over-application or under-application, causing inefficiencies that are costly to rectify.

The Solution: To address this issue, buyers should prioritize sourcing hydraulic spray nozzles that are specifically designed for their application needs. It is crucial to consult with spray technology experts who can provide guidance on selecting the right nozzle type—whether it be full cone, flat spray, or hollow cone—based on the specific requirements of coverage, flow rate, and pressure. Utilizing advanced options like the Maximum Free Passage FullJet nozzles can optimize material usage by ensuring that spray patterns are uniform and effective. Additionally, implementing a maintenance schedule for regular cleaning and inspection of nozzles can help maintain optimal performance, reducing the risk of clogs and ensuring consistent spray delivery.

Scenario 2: High Maintenance Costs Due to Frequent Failures

The Problem: Businesses that utilize hydraulic spray systems often face high maintenance costs stemming from frequent nozzle failures. This is particularly common in environments exposed to harsh chemicals or extreme temperatures, where equipment can degrade rapidly. For example, a mining operation using hydraulic spray for dust suppression may find that their nozzles fail prematurely, leading to increased downtime and the need for costly replacements, which can disrupt production schedules.

The Solution: To mitigate these issues, it is essential to invest in high-performance nozzles made from durable materials that can withstand specific environmental conditions. Buyers should consider nozzles crafted from high-performance alloys or those that offer corrosion resistance. In addition, selecting clog-resistant designs can significantly extend the life of the nozzles. It is also advisable to implement a predictive maintenance strategy that utilizes data analytics to monitor nozzle performance and anticipate failures before they occur. This proactive approach not only minimizes unexpected downtime but also enhances the overall efficiency of operations.

Scenario 3: Inconsistent Spray Quality Affecting Product Integrity

The Problem: In industries such as automotive or electronics manufacturing, inconsistent spray quality can severely impact product integrity. For instance, when applying coatings or lubricants, variations in spray quality can lead to defects, such as uneven finishes or inadequate lubrication, which could compromise the functionality of the final product. This inconsistency can result in higher rejection rates and increased rework costs, ultimately affecting profitability.

The Solution: Buyers should focus on sourcing hydraulic spray systems that offer precise control over spray parameters such as pressure, flow rate, and spray pattern. Investing in advanced hydraulic spray machines that allow for adjustable settings can ensure consistent application. Additionally, implementing rigorous training for operators on how to correctly set up and adjust the spray equipment can lead to improved outcomes. Regular calibration of spray equipment and ongoing quality checks can further ensure that the spray application meets required standards. Leveraging technology, such as automated systems that monitor and adjust spray conditions in real time, can also greatly enhance the consistency and quality of the output, reducing waste and improving overall product integrity.

Strategic Material Selection Guide for hydraulic spray

What Are the Key Materials Used in Hydraulic Spray Applications?

Hydraulic spray systems rely on various materials to ensure optimal performance, durability, and compatibility with specific applications. Below are analyses of four common materials used in hydraulic spray systems, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Stainless Steel Perform in Hydraulic Spray Applications?

Stainless steel is a popular choice for hydraulic spray components due to its excellent corrosion resistance and strength. Key properties include a high-temperature rating (up to 800°F or 427°C) and the ability to withstand high pressures (up to 3000 psi or 207 bar).

Pros: Stainless steel is highly durable, resistant to rust and corrosion, and can handle a wide range of chemicals, making it suitable for various applications, including food processing and chemical manufacturing.

Cons: The primary disadvantage is its cost; stainless steel is more expensive than other materials, which may impact budget-sensitive projects. Additionally, manufacturing complexity can be higher due to the need for specialized welding and machining.

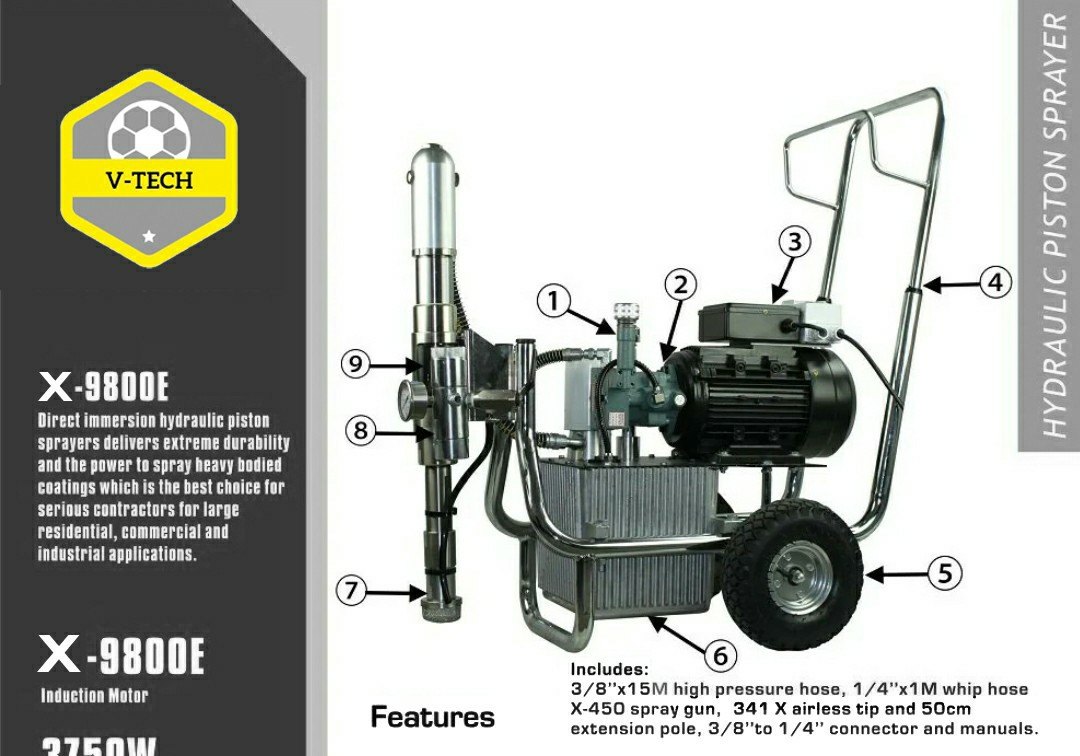

Illustrative image related to hydraulic spray

Impact on Application: Stainless steel is compatible with a wide range of media, from water to aggressive chemicals, making it versatile for different industries.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A312 for stainless steel pipes and fittings. Preference for stainless steel may vary by region, with European markets often favoring high-grade alloys.

What Role Does Brass Play in Hydraulic Spray Systems?

Brass is another common material used in hydraulic spray nozzles and fittings. It offers good corrosion resistance and can handle moderate temperatures (up to 400°F or 204°C) and pressures (up to 1500 psi or 103 bar).

Pros: Brass is relatively inexpensive compared to stainless steel and offers excellent machinability. It is also resistant to corrosion, particularly in water-based applications.

Cons: However, brass can be susceptible to dezincification, especially in saltwater environments, which can compromise its integrity. Its lower temperature and pressure ratings may limit its use in high-demand applications.

Impact on Application: Brass is suitable for applications involving water and light oils but may not be ideal for aggressive chemicals or high-temperature environments.

Considerations for International Buyers: Buyers should be aware of regional preferences for brass alloys, as some regions may have specific standards, such as DIN 17660 in Europe, which governs the quality of brass used in hydraulic applications.

How Do Plastics Compare for Hydraulic Spray Applications?

High-performance plastics, such as polypropylene and PTFE (Teflon), are increasingly used in hydraulic spray systems due to their lightweight nature and chemical resistance. These materials can typically withstand temperatures up to 200°F (93°C) and pressures around 1500 psi (103 bar).

Pros: Plastics are cost-effective, lightweight, and resistant to a wide range of chemicals, making them ideal for specific applications, including agricultural and cleaning solutions.

Cons: On the downside, plastics may have lower mechanical strength compared to metals, which can limit their use in high-pressure applications. They can also degrade under UV exposure unless treated.

Impact on Application: Plastics are well-suited for applications involving corrosive chemicals but may not perform well in high-temperature or high-pressure environments.

Considerations for International Buyers: Compliance with standards such as ASTM D638 for plastic materials is crucial. Buyers should also consider the specific chemical compatibility of plastics with the media being sprayed.

What Advantages Do High-Performance Alloys Offer in Hydraulic Spray Systems?

High-performance alloys, such as Hastelloy and Inconel, are engineered for extreme conditions. These materials can handle temperatures exceeding 1000°F (538°C) and pressures up to 5000 psi (345 bar).

Pros: Their exceptional resistance to corrosion and high temperatures makes them ideal for harsh environments, such as oil and gas or chemical processing.

Cons: The significant drawback is their high cost and manufacturing complexity, which can be prohibitive for many applications.

Impact on Application: High-performance alloys are essential for applications involving aggressive chemicals or extreme temperatures, ensuring reliability and longevity.

Illustrative image related to hydraulic spray

Considerations for International Buyers: Buyers must ensure compliance with international standards like ASTM B575 for alloy specifications. The preference for these materials may be more pronounced in regions with stringent environmental regulations, such as Europe.

Summary Table of Material Selection for Hydraulic Spray

| Material | Typical Use Case for hydraulic spray | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, chemical manufacturing | Excellent corrosion resistance | High cost and manufacturing complexity | High |

| Brass | Water-based applications | Cost-effective and machinable | Susceptible to dezincification | Medium |

| High-Performance Plastics | Agricultural spraying, cleaning solutions | Lightweight and chemical resistant | Lower mechanical strength | Low |

| High-Performance Alloys | Oil and gas, chemical processing | Exceptional temperature and corrosion resistance | Very high cost and complexity | High |

This guide provides a comprehensive overview of the materials used in hydraulic spray applications, assisting international B2B buyers in making informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hydraulic spray

What are the Main Stages of Manufacturing Hydraulic Spray Components?

Manufacturing hydraulic spray components involves a series of precise and well-defined stages that ensure high-quality output. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection and preparation of raw materials. Common materials for hydraulic spray components include high-performance alloys, plastics, and metals that provide resistance to wear, corrosion, and high temperatures. Suppliers often source these materials from certified vendors to ensure quality. The preparation stage may involve cutting, machining, or chemical treatment to achieve the desired specifications for each component.

Forming Techniques

Forming techniques are critical in shaping the hydraulic spray components. Common methods include casting, forging, and machining. For instance, nozzles are often produced using precision machining to achieve exact spray patterns and flow rates. Advanced CNC (Computer Numerical Control) machines are frequently employed to ensure accuracy and repeatability. Additionally, forming techniques must adhere to international standards to meet the stringent requirements of various industries.

Assembly Processes

Once the individual components are formed, they move to the assembly stage. This involves the careful integration of various parts such as nozzles, valves, and seals. Assembly can be manual or automated, depending on the complexity of the product and the manufacturer’s capabilities. Quality checks during assembly are crucial to ensure that all components fit perfectly and function as intended.

Finishing Techniques

The final stage in manufacturing hydraulic spray components is finishing. This includes processes such as surface treatment, coating, and polishing, aimed at enhancing durability and aesthetic appeal. Techniques like anodizing or applying protective coatings can significantly extend the lifespan of components, especially in harsh environments.

How is Quality Assurance Implemented in Hydraulic Spray Manufacturing?

Quality assurance (QA) is a critical aspect of hydraulic spray manufacturing, ensuring that products meet both international and industry-specific standards. Implementing a robust QA framework involves several checkpoints and testing methods.

International Standards for Quality Assurance

Manufacturers of hydraulic spray components typically adhere to international quality standards such as ISO 9001. This certification ensures a consistent quality management system that enhances customer satisfaction and operational efficiency. Additional certifications relevant to specific industries, such as CE for compliance with European safety standards or API for oil and gas applications, may also be required.

Key Quality Control Checkpoints

Quality control in hydraulic spray manufacturing involves multiple checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint verifies that the raw materials meet specified standards before production begins. It involves inspections and testing of materials to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC involves monitoring the production process to identify any deviations from quality standards in real-time. This can include regular measurements of dimensions, spray patterns, and flow rates.

-

Final Quality Control (FQC): Upon completion, finished products undergo comprehensive testing to ensure they meet all specifications and standards. This may include pressure testing, flow rate measurement, and performance evaluations under simulated operating conditions.

What Testing Methods are Commonly Used in Hydraulic Spray Quality Control?

Testing methods employed in the quality control of hydraulic spray components are vital for ensuring performance and reliability. Common methods include:

-

Hydrostatic Testing: This method tests the strength and leak integrity of components by subjecting them to high-pressure water. It is essential for ensuring that the nozzles and other parts can withstand operational pressures.

-

Flow Rate Testing: This involves measuring the flow rate of fluids through the nozzles to ensure they meet the specified performance criteria. Accurate flow rate testing is crucial for applications that require precise spraying capabilities.

-

Spray Pattern Analysis: Utilizing advanced imaging techniques, manufacturers can analyze the spray pattern produced by nozzles to ensure it meets design specifications. This is particularly important for applications requiring specific coverage or distribution.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, especially those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control practices of potential suppliers.

Conducting Supplier Audits

One effective way to verify a supplier’s quality control practices is through on-site audits. These audits allow buyers to assess the manufacturing processes, equipment, and adherence to quality standards firsthand. It also provides an opportunity to review documentation related to quality management systems and certifications.

Requesting Quality Reports

Buyers should request detailed quality reports that outline the testing methods used, results obtained, and any corrective actions taken for non-conformities. These reports can offer insights into the supplier’s commitment to quality and their ability to meet international standards.

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can cover various aspects, from incoming materials to final products, ensuring that the supplied components meet the buyer’s specifications.

Illustrative image related to hydraulic spray

What are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control in different regions is essential for successful sourcing. Factors such as local regulations, certification requirements, and cultural differences can impact quality assurance processes.

Regulatory Compliance

Buyers should be aware of the regulatory landscape in the supplier’s country. For example, European buyers might require CE certification for products sold in the EU, while buyers from the Middle East may need to consider local standards specific to their industry.

Cultural Considerations

Cultural attitudes toward quality and compliance can vary significantly across regions. Buyers should foster relationships with suppliers that prioritize quality assurance and are willing to engage in transparent communication regarding their processes.

Continuous Improvement

Finally, B2B buyers should look for suppliers that demonstrate a commitment to continuous improvement in their quality control practices. This includes regular training for employees, investment in new technologies, and an openness to feedback from clients.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing hydraulic spray components, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hydraulic spray’

In the competitive landscape of hydraulic spray procurement, having a well-defined sourcing strategy is essential for ensuring optimal performance and efficiency. This guide will provide you with a practical checklist to navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Before initiating your search for hydraulic spray solutions, it’s vital to establish clear technical specifications. Identify the required spray patterns (e.g., full cone, flat spray), flow rates, and pressure requirements that align with your operational needs. This clarity will help you narrow down your options and ensure that the products you consider are fit for purpose.

- Key Considerations:

- Determine the specific applications for which you need hydraulic spray (e.g., cooling, coating, cleaning).

- Assess environmental factors, such as temperature and chemical exposure, that may affect nozzle material choices.

Step 2: Research Available Products and Technologies

Conduct thorough research to understand the types of hydraulic spray nozzles and machines available in the market. Familiarize yourself with different brands, models, and technologies that can meet your specifications. Look for innovations that enhance efficiency, such as clog-resistant designs or adjustable spray patterns.

Illustrative image related to hydraulic spray

- Action Items:

- Review product catalogs and technical datasheets from multiple manufacturers.

- Explore case studies demonstrating successful implementations in similar industries.

Step 3: Evaluate Potential Suppliers

It’s crucial to vet suppliers thoroughly before making a commitment. Request detailed company profiles, case studies, and references from buyers in your industry or region. Ensure that the suppliers have a proven track record of reliability and quality in their products.

- Important Checks:

- Verify their manufacturing capabilities and quality control processes.

- Assess the supplier’s customer service support, including technical assistance and warranty policies.

Step 4: Request Samples and Demonstrations

Once you have shortlisted potential suppliers, request samples or demonstrations of their hydraulic spray products. This step allows you to evaluate performance in real-world conditions and ensure that the nozzles meet your specific requirements.

- What to Look For:

- Performance consistency under varying pressure and flow rates.

- Ease of installation and maintenance.

Step 5: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers comply with industry standards and regulations relevant to hydraulic spray systems. Look for certifications such as ISO or equivalent, which indicate adherence to quality management practices.

- Compliance Checklist:

- Check if the products meet local and international safety and environmental regulations.

- Confirm any specific certifications required for your industry, particularly in sectors like food processing or pharmaceuticals.

Step 6: Assess Total Cost of Ownership

Beyond the initial purchase price, evaluate the total cost of ownership of the hydraulic spray systems you are considering. Factor in maintenance costs, expected lifespan, and efficiency savings over time.

- Cost Evaluation:

- Analyze the energy consumption of hydraulic machines versus alternatives.

- Consider the long-term savings from reduced downtime and maintenance needs.

Step 7: Finalize Contract Terms and Conditions

Once you have selected a supplier, ensure that all terms and conditions are clearly outlined in the contract. Pay close attention to warranty coverage, delivery timelines, and support services.

- Contract Essentials:

- Specify the terms of service and maintenance agreements.

- Outline penalties for non-compliance or delays to protect your business interests.

By following this structured checklist, you can streamline your sourcing process for hydraulic spray systems, ensuring that you make informed decisions that align with your operational goals.

Comprehensive Cost and Pricing Analysis for hydraulic spray Sourcing

What Are the Key Cost Components in Hydraulic Spray Sourcing?

When sourcing hydraulic spray systems, understanding the cost structure is essential for informed decision-making. Key components influencing the overall cost include:

-

Materials: The choice of materials significantly affects pricing. High-performance alloys, plastics, and metals vary in cost based on availability and properties such as corrosion resistance and durability. For instance, specialized nozzles designed for high-temperature applications may require more expensive materials.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembly, and quality control. Regions with higher labor costs may impact the final price, making it crucial for buyers to consider sourcing from areas with competitive labor rates.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and indirect labor associated with production. Efficient production processes can help mitigate overhead costs, ultimately lowering prices.

-

Tooling: Custom tooling for specific spray nozzle designs can be a significant upfront investment. However, it’s often necessary for achieving the desired precision and performance in hydraulic sprays.

-

Quality Control (QC): Rigorous QC processes ensure that products meet specifications and industry standards. While this adds to costs, it is essential for maintaining product reliability and minimizing returns.

-

Logistics: Shipping and handling expenses can vary based on the supplier’s location and the destination. Import duties, tariffs, and transportation fees can considerably influence the total landed cost.

-

Margin: Supplier profit margins will also play a role in the pricing. Established manufacturers with a strong reputation may charge a premium, reflecting their investment in quality and service.

How Do Pricing Influencers Affect Hydraulic Spray Costs?

Several factors can influence the pricing of hydraulic spray systems, including:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities often results in reduced unit prices. Suppliers frequently offer discounts for bulk orders, making it beneficial for buyers to negotiate MOQs that align with their needs.

-

Specifications and Customization: Customized hydraulic spray solutions tailored to specific applications may incur additional costs. Buyers should weigh the benefits of customization against standard options to determine the best fit for their operational needs.

-

Material Choices: The selected material not only impacts performance but also cost. Buyers should consider the long-term benefits of higher-quality materials against their initial expense.

-

Quality Certifications: Products certified to international quality standards may come at a higher cost, but they can provide assurance of reliability and performance, particularly in critical applications.

-

Supplier Factors: The reputation, reliability, and service level of suppliers can also affect pricing. A supplier known for high-quality products and exceptional customer support may command higher prices, which can be justified by the overall value provided.

-

Incoterms: Understanding the terms of shipping and responsibility for costs is crucial. Depending on the Incoterms agreed upon, buyers may incur additional expenses for customs clearance, insurance, and freight.

What Buyer Tips Can Enhance Cost-Efficiency in Hydraulic Spray Sourcing?

To maximize cost-efficiency in hydraulic spray sourcing, international buyers, especially those from Africa, South America, the Middle East, and Europe, should consider the following tips:

-

Negotiate Wisely: Leverage your purchasing power by negotiating prices, especially when ordering in bulk. Establishing long-term relationships with suppliers can also yield better pricing over time.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price to evaluate the TCO, which includes maintenance, operational efficiency, and replacement costs. Investing in higher-quality products may reduce long-term expenses.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, potential tariffs, and international shipping costs that can affect pricing. Engaging with local suppliers may help mitigate some of these costs.

-

Consider Local Suppliers: Sourcing from local suppliers can reduce logistics costs and improve lead times, making it easier to manage inventory and respond to market demands.

-

Stay Informed on Market Trends: Keeping abreast of industry trends and market dynamics can provide insights into pricing patterns and help buyers make strategic sourcing decisions.

Disclaimer on Indicative Prices

Prices for hydraulic spray systems can vary widely based on the factors discussed above. It is advisable for buyers to obtain multiple quotes and conduct thorough research to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing hydraulic spray With Other Solutions

Introduction to Alternative Solutions for Hydraulic Spray

In the industrial landscape, hydraulic spray systems are a popular choice for various applications, including cooling, coating, and cleaning. However, businesses often seek alternatives that may offer specific advantages based on their operational needs, budget constraints, or environmental considerations. This section evaluates hydraulic spray against two viable alternatives: pneumatic spray systems and electrostatic spray technology. Each option presents unique benefits and challenges that B2B buyers should consider when making informed purchasing decisions.

Comparison Table

| Comparison Aspect | Hydraulic Spray | Pneumatic Spray System | Electrostatic Spray Technology |

|---|---|---|---|

| Performance | High pressure, precise application | Moderate pressure, less precise | Highly efficient, excellent coverage |

| Cost | Moderate initial investment | Lower initial cost, higher operating cost | High initial investment, low operating cost |

| Ease of Implementation | Requires specialized setup and maintenance | Easier setup, but requires air supply | Complex setup, needs skilled operators |

| Maintenance | Requires regular maintenance | Low maintenance needs | Requires specialized maintenance |

| Best Use Case | Heavy-duty industrial applications | General-purpose spraying | Coating applications needing even coverage |

Detailed Breakdown of Alternatives

Pneumatic Spray Systems

Pneumatic spray systems utilize compressed air to atomize and propel liquids, making them a cost-effective alternative to hydraulic sprays. They are simpler to set up and maintain, requiring only a compressed air supply. However, their performance can be less precise, leading to overspray and waste in some applications. This method is best suited for general-purpose spraying tasks where high precision is not critical, such as in painting or light coatings.

Electrostatic Spray Technology

Electrostatic spray technology employs electrical charges to ensure that paint or coating particles adhere more effectively to surfaces. This method is particularly advantageous in applications requiring uniform coverage, such as automotive painting or furniture finishing. While it offers significant material savings and reduces overspray, the initial investment is relatively high. Additionally, the technology necessitates skilled operators for optimal results and maintenance, which may be a consideration for businesses with limited technical expertise.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating which spraying technology to adopt, B2B buyers must consider specific operational requirements, budgetary constraints, and the desired application outcomes. Hydraulic spray systems are ideal for heavy-duty industrial applications requiring high pressure and precision. In contrast, pneumatic systems may be better suited for less critical tasks where cost savings are prioritized. Electrostatic spray technology stands out for applications needing superior coverage and material efficiency, albeit at a higher initial cost. By aligning the chosen solution with operational needs and available resources, businesses can optimize their processes and achieve greater efficiency.

Essential Technical Properties and Trade Terminology for hydraulic spray

What Are the Key Technical Properties of Hydraulic Spray?

Understanding the technical properties of hydraulic spray systems is crucial for B2B buyers looking to optimize performance, ensure reliability, and enhance efficiency in their operations. Here are some critical specifications:

1. Flow Rate

Flow rate, measured in gallons per minute (gpm) or liters per minute (lpm), indicates the volume of fluid that can be delivered by the nozzle within a specified time. For hydraulic sprays, flow rates can range from as low as 0.025 gpm to over 2500 gpm. Selecting the right flow rate is vital for applications like cooling, coating, and cleaning, as it directly affects the uniformity of spray coverage and operational efficiency.

2. Operating Pressure

Operating pressure, expressed in pounds per square inch (psi) or bar, determines the force with which the fluid is expelled from the nozzle. Hydraulic spray systems can handle pressures ranging from 0 to 4000 psi. Higher pressures allow for finer spray patterns and better penetration of the fluid, which is essential in applications such as fire protection and industrial cleaning.

3. Material Compatibility

The materials used in hydraulic spray systems—ranging from metals and plastics to specialized alloys—must withstand the chemical and thermal conditions of the application. Material compatibility is critical to prevent corrosion, wear, and degradation over time. Choosing the right materials helps ensure longevity and reduces maintenance costs, making it an important consideration for B2B buyers.

4. Spray Pattern

Spray patterns can significantly impact the effectiveness of the application. Options include flat spray, full cone, hollow cone, and fine spray, with angles varying from 0° to 170°. The choice of spray pattern affects coverage area and application precision. Understanding these patterns enables buyers to select the right nozzles for their specific operational needs.

5. Design Features

Design features such as clog resistance and ease of maintenance can enhance the operational efficiency of hydraulic spray systems. Features like quick-connect nozzles allow for rapid replacement and maintenance without the need for tools. These attributes can minimize downtime and improve productivity, making them essential considerations for B2B buyers.

What Are Common Trade Terms in Hydraulic Spray?

Familiarity with industry jargon is crucial for effective communication and decision-making in the hydraulic spray market. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the hydraulic spray industry, buyers may seek OEM components to ensure compatibility and performance, which can be particularly important for maintaining warranty coverage.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory costs effectively and negotiate better terms with suppliers, especially when considering bulk purchases.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing information for specific products or services. This process is crucial in B2B transactions, allowing buyers to compare offers and select the best option based on cost, delivery time, and specifications.

Illustrative image related to hydraulic spray

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for international B2B transactions to avoid misunderstandings and ensure smooth logistics.

5. Lead Time

Lead time refers to the duration from the placement of an order to its delivery. In the hydraulic spray market, lead times can vary based on product availability, customization, and supplier efficiency. Knowing lead times helps buyers plan their operations and manage project timelines effectively.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and enhance their procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the hydraulic spray Sector

What Are the Current Market Dynamics and Key Trends in the Hydraulic Spray Sector?

The hydraulic spray sector is undergoing transformative changes driven by technological advancements and increasing demand for efficiency across various industries. Global drivers such as the need for precision in application, enhanced automation, and the push for reduced operational costs are shaping the market landscape. Notably, industries such as agriculture, manufacturing, and construction are leveraging hydraulic spray systems to optimize processes ranging from lubrication to coating and cleaning.

Emerging B2B technology trends include the adoption of smart nozzles equipped with IoT capabilities that allow for real-time monitoring and adjustments, leading to improved accuracy and reduced waste. Furthermore, the development of hybrid systems that combine hydraulic and pneumatic technologies is gaining traction, offering versatility and enhanced performance. International buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking suppliers that can provide customized solutions to meet specific operational requirements. This trend underscores the importance of supplier collaboration and the ability to adapt offerings based on local market needs.

Additionally, the focus on efficiency has prompted companies to consider not only the initial purchase price but also the total cost of ownership, which encompasses maintenance, durability, and energy consumption. As buyers become more discerning, they are prioritizing suppliers that can demonstrate long-term value and sustainability in their hydraulic spray solutions.

How Is Sustainability and Ethical Sourcing Influencing Hydraulic Spray Procurement?

In today’s business environment, sustainability and ethical sourcing have become paramount for B2B buyers in the hydraulic spray sector. The environmental impact of hydraulic systems, particularly concerning energy consumption and waste generation, is under scrutiny. As a result, companies are increasingly looking to partner with suppliers who prioritize eco-friendly practices, such as utilizing materials that are recyclable or have a lower carbon footprint.

The importance of ethical supply chains cannot be overstated; buyers are seeking manufacturers who comply with international labor standards and demonstrate a commitment to social responsibility. Certifications such as ISO 14001 for environmental management and other ‘green’ credentials are becoming essential benchmarks for supplier selection. Furthermore, as regulations regarding environmental impact become stricter, suppliers who can provide proof of sustainable practices will have a competitive edge.

Hydraulic spray technologies are also evolving, with innovations focused on reducing water usage and improving chemical efficiency. For instance, nozzles designed for optimal spray patterns can significantly minimize waste while maximizing effectiveness in applications like cooling and cleaning. As companies strive to meet corporate sustainability goals, the demand for such technologies is expected to grow, influencing procurement strategies across various sectors.

What Is the Historical Evolution of Hydraulic Spray Technology?

The evolution of hydraulic spray technology can be traced back to the early 20th century when the need for efficient liquid application methods began to emerge in agricultural practices. Initially, mechanical sprayers were developed, but they lacked the precision and efficiency required for larger-scale applications. As technology progressed, the introduction of hydraulic systems allowed for more controlled and effective spraying mechanisms.

By the late 20th century, advancements in materials science and engineering led to the development of specialized nozzles and pumps, enhancing the performance and durability of hydraulic spray systems. The rise of automation and digital technologies in the 21st century further revolutionized the sector, introducing smart spraying solutions that provide real-time data and feedback to operators.

Today, hydraulic spray technology is integral to various industries, from agricultural applications to industrial manufacturing, reflecting a continuous journey of innovation aimed at improving efficiency, sustainability, and user experience. As this technology continues to evolve, it will undoubtedly play a crucial role in shaping the future of B2B procurement and operational excellence.

Frequently Asked Questions (FAQs) for B2B Buyers of hydraulic spray

-

How do I solve issues with inconsistent spray patterns in hydraulic nozzles?

Inconsistent spray patterns can be caused by clogged nozzles, incorrect pressure settings, or improper nozzle selection. To resolve this, first, inspect and clean the nozzles regularly to prevent blockages. Ensure that your system maintains the recommended pressure and flow rates specified by the manufacturer. Additionally, consult with a spray technology expert to determine if the nozzle type and design are suitable for your application, as different patterns (e.g., full cone, hollow cone) serve distinct purposes. -

What is the best hydraulic spray nozzle for industrial coating applications?

The best hydraulic spray nozzle for industrial coating depends on the specific requirements of your application, such as the viscosity of the coating and the desired finish. Full cone nozzles are often ideal for wide coverage areas, while hollow cone nozzles are suitable for finer applications. It is essential to evaluate factors like flow rate, pressure, and material compatibility when choosing your nozzle. Consulting with a supplier can help you select the optimal nozzle for your coating needs. -

How can I ensure the quality of hydraulic spray products from international suppliers?

To ensure quality when sourcing hydraulic spray products internationally, start by vetting suppliers thoroughly. Look for certifications, such as ISO 9001, which indicate adherence to quality management standards. Request product samples to evaluate performance and durability before making large orders. Additionally, consider suppliers with a proven track record in your industry and check for customer testimonials or case studies showcasing their success with similar applications. -

What are the typical minimum order quantities (MOQ) for hydraulic spray products?

Minimum order quantities for hydraulic spray products can vary significantly by supplier and product type. Generally, MOQs range from 50 to several hundred units, depending on the complexity of the product and the manufacturer’s capabilities. For custom or specialized nozzles, MOQs might be higher. Always discuss MOQs upfront with potential suppliers to ensure they align with your purchasing needs and budget. -

What payment terms should I negotiate when sourcing hydraulic spray equipment internationally?

When negotiating payment terms for international purchases of hydraulic spray equipment, consider options like letters of credit, advance payments, or net 30/60 terms. Ensure that the terms protect both parties and facilitate a smooth transaction. Additionally, inquire about any discounts for early payment or bulk orders, as these can significantly reduce costs. Always clarify currency exchange rates and potential fees associated with international transactions to avoid unexpected expenses. -

How do I handle logistics and shipping for hydraulic spray products?

Effective logistics and shipping are crucial when sourcing hydraulic spray products internationally. Start by choosing a reliable freight forwarder familiar with customs regulations in your destination country. Discuss packaging options with your supplier to ensure products are protected during transit. Determine whether you prefer air or sea freight based on urgency and cost. Lastly, ensure that all documentation, such as invoices and certificates of origin, is correctly prepared to facilitate smooth customs clearance. -

What customization options are available for hydraulic spray nozzles?

Many suppliers offer customization options for hydraulic spray nozzles to meet specific application needs. Customizations may include variations in spray patterns, flow rates, materials, and connection types. You can also request specific sizes and shapes to fit your equipment. Engaging in a detailed discussion with your supplier about your unique requirements can lead to tailored solutions that enhance efficiency and effectiveness in your operations. -

How can I maintain hydraulic spray equipment to extend its lifespan?

Regular maintenance is key to extending the lifespan of hydraulic spray equipment. Implement a routine cleaning schedule to remove buildup and prevent clogs, particularly in nozzles. Inspect seals, hoses, and fittings for wear or damage, replacing parts as necessary. Follow the manufacturer’s guidelines for operational parameters, including pressure and temperature, to avoid stress on the equipment. Additionally, consider training your team on proper handling and maintenance procedures to ensure optimal performance.

Top 6 Hydraulic Spray Manufacturers & Suppliers List

1. Spraying Systems Co. – Hydraulic Atomizing Nozzles

Domain: spray.com

Registered: 1995 (30 years)

Introduction: Hydraulic Atomizing Nozzles from Spraying Systems Co. include a wide range of options optimized for industrial applications such as cooling, coating, cleaning, lubricating, dust control, and fire protection. Key features include:

– Spray patterns: flat spray, solid stream, full cone, hollow cone, fine spray, oval, and square spray with angles from 0° to 170°.

– Flow rates: from 0.025 to 2500 gpm (…

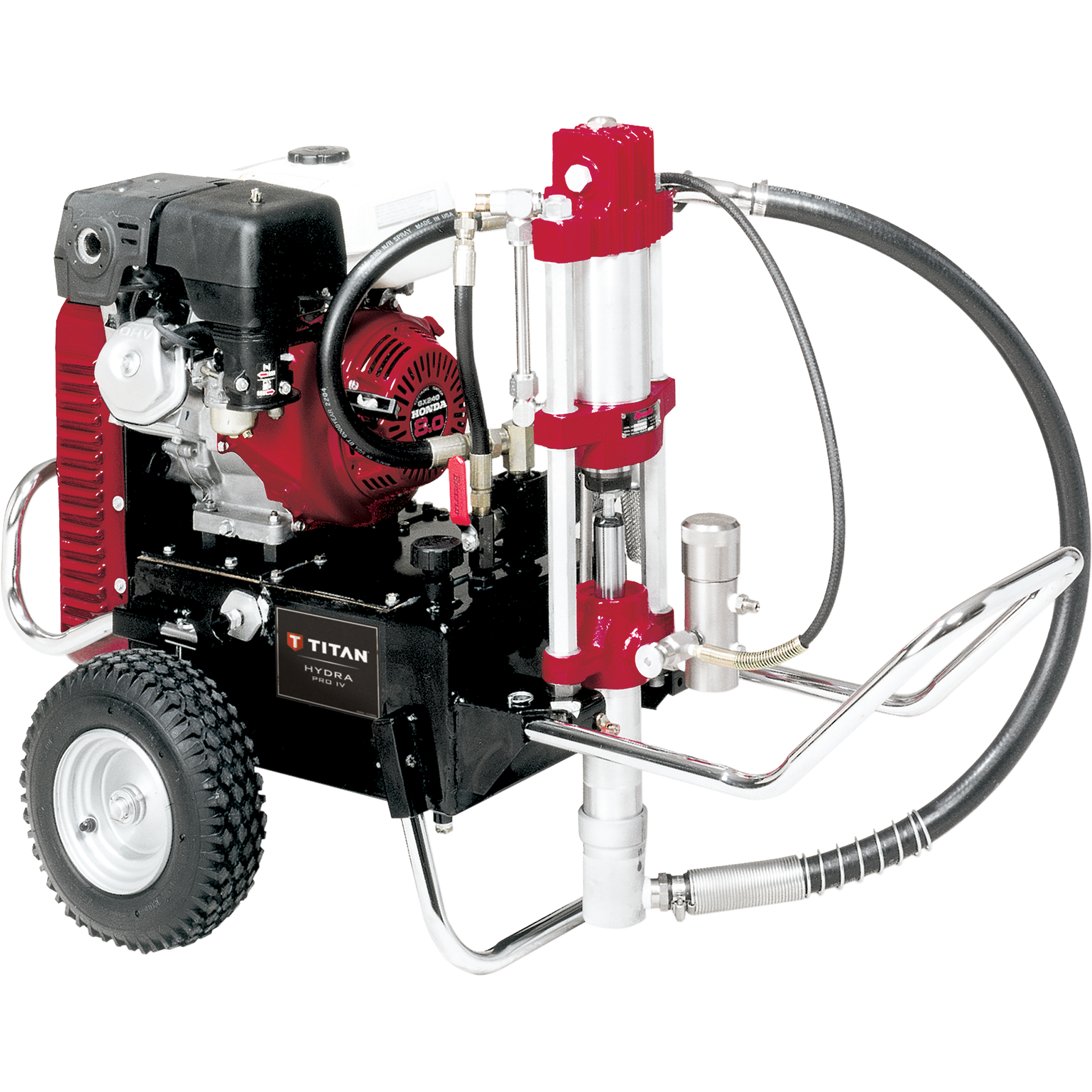

2. SprayWorks Equipment – Hydraulic Spray Foam Machines

Domain: sprayworksequipment.com

Registered: 2008 (17 years)

Introduction: Hydraulic Spray Foam Machines from SprayWorks Equipment include various models suitable for different applications. Key details include:

– **Gusmer GH-20/35**: Hydraulic, 2,000 psi, 28 lbs/minute, max hose length 320 ft, max fluid temp 190°F.

– **PMC PH2**: Hydraulic, 2,000 psi, 28 lbs/min, hose length 210 – 410 ft, fluid temp 190°F.

– **PMC PH25**: Hydraulic, 2,000 psi, 30 lbs/min, hose length…

3. JET-SET – Hydraulic & Lubrication Spray Nozzles

Domain: jetsetspray.com

Registered: 2015 (10 years)

Introduction: Hydraulic & Lubrication Spray Nozzles from JET-SET provide controlled lubrication application. Key features include adjustable spray displacement from zero to full capacity via a volume control knob, and adjustable spray velocity from gentle to strong by regulating air supply pressure. Standard nozzles come with an 80015 flat spray tip, with a variety of spray tips and mounting accessories availab…

4. Graco – Spray Foam Machines

Domain: graco.com

Registered: 1994 (31 years)

Introduction: Electric, Hydraulic or Air-Driven Spray Foam Machine by Graco. Suitable for various applications including spray foam insulation, roof coating, and surface preparation. Offers options for electric, hydraulic, or air-driven operation to meet different project needs.

5. Sprayer Supplies – Hydraulic Pumps

Domain: sprayersupplies.com

Registered: 2003 (22 years)

Introduction: Hydraulic Pumps available in various types and models including 115 / 230 Volt Pumps, 12 Volt Pumps, Belt Driven Pumps, Briggs & Stratton Pumps, Centrifugal Pumps, Diaphragm Pumps, Electric Pumps, Gas Engine Pumps, Irrigation Injection Pumps, Piston Pumps, PTO Driven Pumps, Roller Pumps, Self Priming Pumps, Transfer Pumps, Water Pumps, Honda Pumps, Ace Pumps, Banjo Pumps, Delavan Pumps, Everflo Pu…

6. Access Truck Parts – Hydraulic Spray Head Valve

Domain: accesstruckparts.com

Registered: 2008 (17 years)

Introduction: {“product_name”: “Hydraulic Spray Head Valve”, “SKU”: “194-025610”, “price”: “$775.00”, “availability”: “In Stock”, “description”: “Heavy Duty Hydraulic Spray Head Valve. Suitable replacement for AGM type hydraulic spray head valves.”, “rebuild_kit_available”: “Heavy Duty Hydraulic Spray Head Valve Rebuild Kit available!”, “rebuild_kit_sku”: “1931-300KIT”, “rebuild_kit_price”: “$87.50”, “weight”: …

Strategic Sourcing Conclusion and Outlook for hydraulic spray

In the competitive landscape of hydraulic spray applications, strategic sourcing is essential for international B2B buyers aiming to optimize performance while reducing costs. By leveraging advanced technologies like hydraulic atomizing nozzles and efficient spray foam machines, companies can achieve improved operational efficiency, enhance product quality, and minimize resource consumption. The ability to customize spray patterns, flow rates, and materials ensures that buyers can meet specific industry needs, whether in manufacturing, construction, or agricultural sectors.

Illustrative image related to hydraulic spray

Investing in high-quality hydraulic spray solutions not only contributes to sustainability by reducing water usage and waste but also drives significant cost savings, as evidenced by successful case studies across various industries. As markets continue to evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, companies must remain agile and informed about the latest innovations and best practices in hydraulic spray technology.

Looking ahead, buyers are encouraged to engage with suppliers and experts in the field to explore tailored solutions that align with their operational goals. Embracing strategic sourcing will be pivotal in navigating future challenges and seizing new opportunities in the hydraulic spray market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.