Top 3 Oz Racing Rims Suppliers (And How to Choose)

Introduction: Navigating the Global Market for oz racing rims

In the competitive landscape of automotive accessories, sourcing high-quality OZ Racing rims can pose significant challenges for international B2B buyers. With a diverse range of products available, including lightweight alloy wheels designed for various applications—from motorsports to everyday driving—navigating the complexities of this market is essential. This guide provides a comprehensive overview of OZ Racing rims, detailing the various types and their respective applications, supplier vetting processes, pricing considerations, and the latest trends in the industry.

For buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Nigeria—understanding the nuances of sourcing OZ Racing rims is vital for making informed purchasing decisions. The guide empowers buyers by offering insights into how to evaluate suppliers, assess quality, and negotiate costs effectively. Furthermore, it highlights the importance of aligning product specifications with customer needs, ensuring that the chosen rims not only meet performance standards but also resonate with the cultural and aesthetic preferences of diverse markets.

By equipping B2B buyers with the necessary tools and knowledge, this guide aims to simplify the sourcing process, helping businesses enhance their offerings and drive customer satisfaction through superior product choices. The roads ahead are filled with opportunities, and with the right insights, buyers can confidently navigate the global market for OZ Racing rims.

Understanding oz racing rims Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Estrema Forgiata | Lightweight forged aluminum, high strength-to-weight ratio | Motorsports, performance vehicles | Pros: Superior performance, durable. Cons: Higher cost, may require specialized fitting. |

| Rally Legend | Designed for off-road and rally conditions, robust build | Rally racing, off-road vehicles | Pros: Excellent grip on varied terrains. Cons: Heavier than standard rims, limited aesthetic options. |

| Atelier Forged | Customizable designs, precision engineering | Luxury vehicles, bespoke builds | Pros: Tailored aesthetics, high-quality finish. Cons: Longer lead times for customization. |

| Ultraleggera | Ultra-lightweight design, aerodynamically optimized | High-performance sports cars | Pros: Enhanced speed and fuel efficiency. Cons: Less durability in extreme conditions. |

| Gass Series | Lightweight aluminum, street and racing applications | Everyday vehicles, racing | Pros: Versatile use, good balance of cost and performance. Cons: May not meet extreme performance needs. |

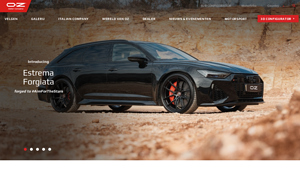

What Are the Key Characteristics of Estrema Forgiata Rims?

Estrema Forgiata rims are renowned for their lightweight yet robust construction, making them ideal for motorsports and high-performance vehicles. This type of rim is forged from high-grade aluminum, resulting in a superior strength-to-weight ratio. B2B buyers should consider the specific performance requirements of their vehicles, as these rims are designed for speed and agility but come at a premium price. Additionally, specialized fitting may be required, which can impact installation costs.

How Do Rally Legend Rims Stand Out in Off-Road Applications?

Rally Legend rims are engineered to withstand the rigors of off-road racing and rallying. Their robust build ensures excellent traction on diverse terrains, making them a preferred choice for rally teams and off-road enthusiasts. B2B buyers should assess the compatibility of these rims with their vehicles, as their heavier weight may not be suitable for all applications. While they offer unparalleled grip, the aesthetic options are limited compared to more performance-focused rims.

Why Choose Atelier Forged Rims for Bespoke Builds?

Atelier Forged rims allow for a high degree of customization, making them ideal for luxury vehicles and bespoke builds. These rims are precision-engineered, providing not just performance but also a unique aesthetic appeal. B2B buyers looking to enhance their brand’s luxury offerings should consider these rims, but they should also be prepared for longer lead times due to the customization process. The investment in these rims can significantly elevate a vehicle’s market appeal.

What Benefits Do Ultraleggera Rims Provide for High-Performance Vehicles?

Ultraleggera rims are designed with aerodynamics in mind, offering an ultra-lightweight profile that enhances speed and fuel efficiency. They are particularly suited for high-performance sports cars, where every ounce matters. B2B buyers should weigh the benefits of increased performance against the potential trade-offs in durability, especially under extreme driving conditions. While they can significantly improve a vehicle’s performance metrics, their fragility may pose risks in rugged environments.

How Do Gass Series Rims Offer Versatility for Everyday Use?

The Gass Series rims combine lightweight aluminum construction with versatility for both street and racing applications. These rims are an excellent choice for everyday vehicles, providing a good balance of performance and cost-effectiveness. B2B buyers should consider their target market; while these rims are suitable for a wide range of vehicles, those seeking extreme performance may need to explore other options. Their adaptability makes them a practical choice for businesses focusing on both everyday consumers and racing enthusiasts.

Key Industrial Applications of oz racing rims

| Industry/Sector | Specific Application of oz racing rims | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Racing | High-performance racing vehicles | Enhanced speed and handling, crucial for competitive edge | Compliance with FIA regulations, weight specifications |

| Luxury Vehicle Customization | Custom aftermarket wheels for luxury cars | Improved aesthetics and vehicle performance | Compatibility with various models, bespoke designs available |

| Off-Road and Rallying | Wheels for off-road and rally vehicles | Durability and stability on rough terrains | Resistance to harsh conditions, lightweight materials |

| Motorcycle Racing | Specialized rims for high-performance motorcycles | Reduced weight and improved maneuverability | Material specifications, certification for racing standards |

| Electric Vehicle (EV) Manufacturing | Rims designed for electric vehicles | Optimized for battery efficiency and reduced rolling resistance | Weight considerations, aerodynamics, and sustainability factors |

What Are the Key Industrial Applications of OZ Racing Rims in Automotive Racing?

In the automotive racing sector, OZ Racing rims are integral to high-performance vehicles. These rims are engineered for enhanced speed and precise handling, providing a competitive advantage on the track. The lightweight construction and advanced materials ensure that drivers can achieve optimal performance without compromising safety. International buyers, especially from regions like Europe and the Middle East, must consider compliance with FIA regulations and specific weight specifications when sourcing these rims.

How Do OZ Racing Rims Enhance Luxury Vehicle Customization?

For businesses involved in luxury vehicle customization, OZ Racing rims offer a unique opportunity to enhance both aesthetics and performance. These aftermarket wheels not only elevate the visual appeal of luxury cars but also contribute to improved handling and driving dynamics. Buyers looking to source these rims should focus on compatibility with various luxury models and the availability of bespoke designs that cater to the high expectations of discerning customers, particularly in affluent markets across Africa and South America.

Why Are OZ Racing Rims Essential for Off-Road and Rallying Applications?

In off-road and rallying applications, the durability and stability of OZ Racing rims are paramount. These wheels are designed to withstand the rigors of rough terrains while maintaining performance. Their lightweight nature reduces the overall vehicle weight, enhancing speed and maneuverability on challenging surfaces. Buyers in regions with diverse terrains, such as Nigeria and Saudi Arabia, should prioritize sourcing rims that exhibit resistance to harsh conditions, ensuring their vehicles can perform reliably under tough circumstances.

What Benefits Do OZ Racing Rims Provide in Motorcycle Racing?

Motorcycle racing demands precision and performance, making OZ Racing rims a valuable asset. These specialized rims are crafted to reduce weight and improve maneuverability, which is crucial for achieving high speeds and sharp handling. For motorcycle manufacturers and racing teams, sourcing these rims involves ensuring compliance with racing standards and understanding the specific material requirements that enhance performance. This is particularly relevant for buyers in Europe, where racing regulations are stringent.

How Are OZ Racing Rims Optimized for Electric Vehicle Manufacturing?

As the electric vehicle market grows, OZ Racing rims are being tailored to meet the unique requirements of EV manufacturing. These rims are designed to optimize battery efficiency and reduce rolling resistance, contributing to overall vehicle performance and range. International B2B buyers in the EV sector should consider weight specifications and aerodynamic designs that align with sustainability goals, especially in regions like Europe where environmental regulations are increasingly stringent.

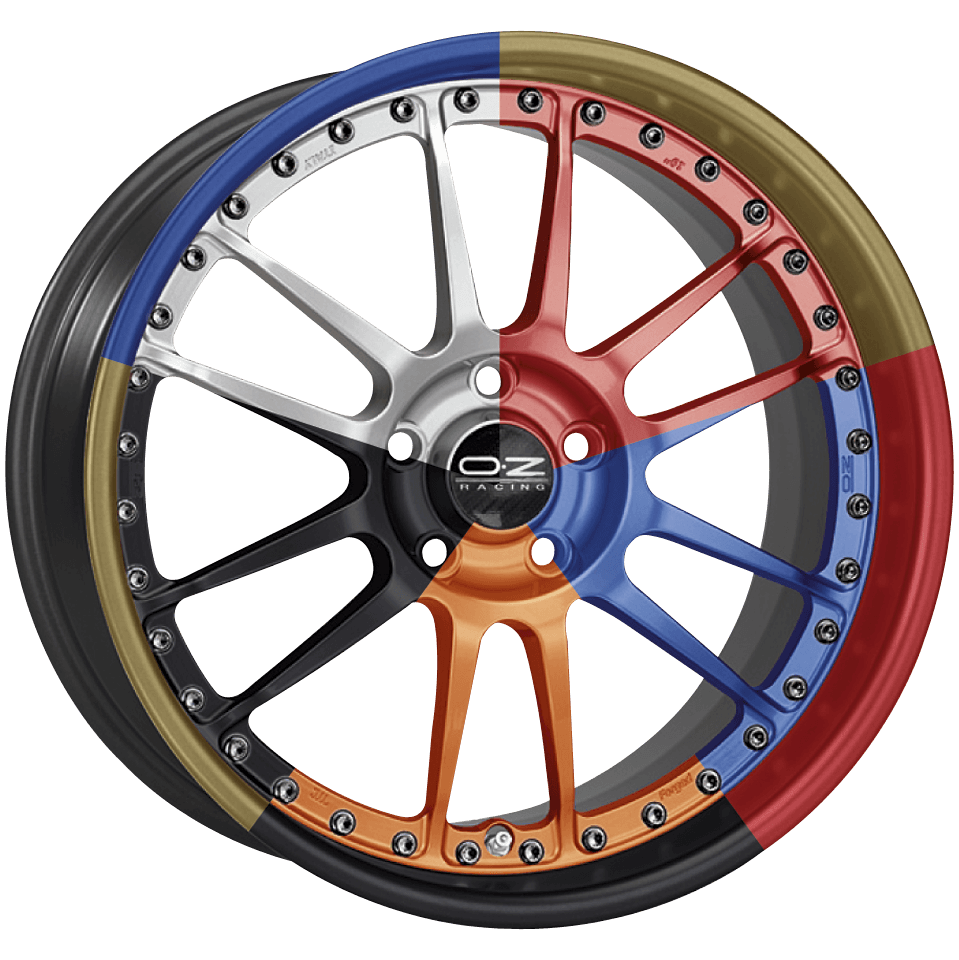

Illustrative image related to oz racing rims

3 Common User Pain Points for ‘oz racing rims’ & Their Solutions

Scenario 1: Sourcing Authentic OZ Racing Rims in Diverse Markets

The Problem: B2B buyers often struggle with sourcing genuine OZ Racing rims, especially in emerging markets such as Africa and South America. The proliferation of counterfeit products can lead to significant financial losses and reputational damage. Buyers may find themselves receiving substandard products that not only fail to meet performance expectations but could also jeopardize vehicle safety.

The Solution: To ensure authenticity, buyers should establish relationships with authorized dealers and distributors. Conducting thorough research on the local market landscape is crucial. Utilize the OZ Racing official website to locate certified dealers in specific regions. Additionally, consider implementing a vendor verification process, which includes checking for product certifications, warranty options, and customer testimonials. It’s also beneficial to attend industry trade shows where OZ Racing is represented, as these events provide opportunities to connect directly with reputable suppliers.

Scenario 2: Understanding the Technical Specifications of OZ Racing Rims

The Problem: B2B buyers frequently encounter challenges in understanding the intricate technical specifications of OZ Racing rims, such as offset, bolt patterns, and load ratings. Misunderstanding these specifications can lead to incompatible wheel fitments, resulting in costly returns, delays in inventory turnover, and potential safety hazards during vehicle operation.

The Solution: To navigate the complexities of technical specifications, buyers should invest in comprehensive training for their purchasing and sales teams. This could include workshops led by OZ Racing experts or online training modules that focus on wheel dynamics and compatibility factors. Additionally, creating a detailed specification guide that includes visual aids and comparative charts can serve as a quick reference tool. When in doubt, always consult with OZ Racing’s technical support team for tailored advice on product selections based on specific vehicle models.

Illustrative image related to oz racing rims

Scenario 3: Addressing Concerns About Rim Durability and Performance

The Problem: Buyers in the automotive sector often face concerns about the durability and performance of OZ Racing rims, particularly in harsh driving conditions like those found in desert regions of the Middle East or rugged terrains in Africa. These concerns can stem from anecdotal experiences or a lack of information about the performance capabilities of the rims under extreme conditions.

The Solution: To alleviate these concerns, it’s essential to present data-backed evidence regarding the performance of OZ Racing rims. Buyers should request product testing reports and case studies that demonstrate how these rims have performed in similar environments. Additionally, conducting field trials with selected products can provide firsthand insights into their durability. It’s also advisable to communicate with existing users or fleet operators who have utilized OZ Racing rims in similar conditions; their testimonials can be invaluable in influencing purchasing decisions. Lastly, consider offering a trial period or satisfaction guarantee for clients hesitant to make a significant investment, as this can foster trust and encourage long-term partnerships.

Strategic Material Selection Guide for oz racing rims

What Materials Are Commonly Used in OZ Racing Rims?

When selecting materials for OZ Racing rims, several options are prevalent, each offering distinct properties that influence performance, durability, and cost. Below is an analysis of four common materials used in the manufacturing of these high-performance wheels.

How Does Aluminum Alloy Perform in OZ Racing Rims?

Aluminum alloys are a popular choice for OZ Racing rims due to their lightweight nature and excellent strength-to-weight ratio. Typically, these alloys can withstand temperatures up to 300°C and pressures associated with high-performance driving. They exhibit good corrosion resistance, especially when treated with protective coatings.

Pros: Aluminum alloys are relatively inexpensive compared to other materials, easy to manufacture, and suitable for a wide range of applications. Their lightweight nature enhances vehicle performance by improving acceleration and fuel efficiency.

Cons: While durable, aluminum alloys can be less resistant to impact damage compared to forged materials. Over time, they may also suffer from fatigue, especially under extreme driving conditions.

Impact on Application: Aluminum alloys are compatible with various media, including road salt and moisture, making them suitable for diverse environments. However, buyers in regions with high humidity or saline conditions, such as coastal areas in Africa and the Middle East, should consider additional protective treatments.

What Role Does Forged Aluminum Play in OZ Racing Rims?

Forged aluminum is another common material, known for its superior strength and durability. This material can handle higher temperatures and pressures than standard aluminum alloys, making it ideal for motorsport applications. Forged rims typically have a temperature rating exceeding 350°C and are resistant to corrosion.

Pros: The manufacturing process of forging enhances the material’s grain structure, resulting in a stronger and more resilient product. This makes forged aluminum rims suitable for high-performance applications where weight savings and strength are critical.

Cons: The cost of forged aluminum is significantly higher due to the complex manufacturing process. Additionally, the production of these rims requires specialized equipment and expertise.

Impact on Application: Forged aluminum rims are particularly beneficial for racing applications where performance is paramount. Buyers from regions with strict automotive standards, such as Europe, should ensure compliance with regulations like DIN standards for safety and performance.

Illustrative image related to oz racing rims

How Does Magnesium Alloy Compare for OZ Racing Rims?

Magnesium alloys are known for their exceptional lightweight properties and high strength. With a temperature rating similar to aluminum, magnesium rims can perform well under high-stress conditions. However, they are more susceptible to corrosion, requiring protective coatings.

Pros: The primary advantage of magnesium alloys is their weight reduction, which can significantly enhance vehicle performance. They are often preferred in motorsports for this reason.

Cons: Magnesium alloys are generally more expensive and can be challenging to manufacture. Their susceptibility to corrosion means they may not be suitable for all environments without adequate protection.

Impact on Application: Buyers in humid or coastal regions should be cautious when selecting magnesium rims, as they may require additional maintenance and protective measures. Compliance with international standards for corrosion resistance is also essential.

Illustrative image related to oz racing rims

What About Steel for OZ Racing Rims?

Steel is a less common choice for high-performance rims but is sometimes used for certain applications. Steel rims can handle high pressures and temperatures, making them durable. However, they are heavier than aluminum and magnesium options.

Pros: Steel rims are typically the most cost-effective option and can withstand significant wear and tear. They are less prone to bending or cracking under impact.

Cons: The weight of steel rims can negatively affect vehicle performance, particularly in racing contexts. Additionally, they are more prone to corrosion if not adequately treated.

Illustrative image related to oz racing rims

Impact on Application: Steel rims may be suitable for off-road or utility vehicles where durability is prioritized over performance. Buyers should ensure compliance with local regulations regarding material specifications.

Summary Table of Material Selection for OZ Racing Rims

| Material | Typical Use Case for oz racing rims | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy | General performance applications | Lightweight and cost-effective | Less impact resistance compared to forged | Medium |

| Forged Aluminum | High-performance racing | Superior strength and durability | Higher manufacturing costs | High |

| Magnesium Alloy | Motorsports and performance vehicles | Exceptional weight reduction | Susceptible to corrosion | High |

| Steel | Off-road and utility vehicles | Cost-effective and durable | Heavier, affecting performance | Low |

This guide serves as a strategic resource for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, to make informed decisions when selecting materials for OZ Racing rims.

In-depth Look: Manufacturing Processes and Quality Assurance for oz racing rims

OZ Racing rims are renowned for their quality, performance, and design, stemming from decades of expertise in motorsports. For B2B buyers, understanding the manufacturing processes and quality assurance measures is crucial in ensuring they invest in a product that meets their specifications and expectations. This guide provides an in-depth look into the typical manufacturing processes and quality control standards associated with OZ Racing rims.

Illustrative image related to oz racing rims

What Are the Main Stages of Manufacturing OZ Racing Rims?

How Is Material Prepared for OZ Racing Rims?

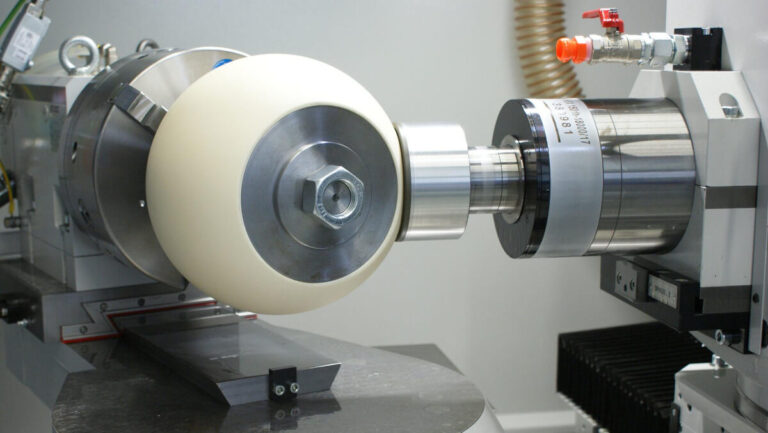

The manufacturing process of OZ Racing rims begins with the careful selection of high-grade aluminum alloys, which are chosen for their lightweight and strength properties. Once selected, the raw materials undergo a rigorous preparation phase that includes melting, alloying, and casting. This process ensures that the aluminum achieves the desired mechanical properties and purity levels necessary for high-performance applications. The prepared material is then shaped into billets, ready for the next stages of manufacturing.

What Techniques Are Used in Forming OZ Racing Rims?

The forming stage employs advanced techniques, primarily focusing on forging and casting methods. Forged rims are crafted by applying immense pressure to the aluminum billets, which aligns the metal’s grain structure, resulting in a stronger and lighter wheel. For OZ Racing, the Estrema Forgiata series exemplifies this forging technique, allowing for a design that meets high performance and aesthetic standards.

In contrast, cast rims utilize a pouring method where molten aluminum is poured into molds. While casting may not provide the same strength-to-weight ratio as forging, it allows for intricate designs and faster production times. Each method is chosen based on the specific performance requirements and design complexities of the rims being produced.

How Are OZ Racing Rims Assembled?

Once formed, the rims undergo an assembly process that includes the integration of components such as valve stems and fittings. This stage is crucial for ensuring that each wheel is not only structurally sound but also ready for installation on various vehicle models. Assembly is performed in controlled environments to minimize contamination and ensure precision.

What Finishing Processes Are Involved in OZ Racing Rim Manufacturing?

How Are OZ Racing Rims Finished for Aesthetic and Performance?

The finishing stage is essential for enhancing both the durability and appearance of OZ Racing rims. This typically involves surface treatments such as anodizing, powder coating, or painting. Anodizing increases corrosion resistance while providing a unique aesthetic, making it a popular choice for high-performance rims.

Additionally, OZ Racing may apply a clear coat to protect the finish from environmental elements. This step is crucial for international B2B buyers, as rims are often exposed to diverse climates and road conditions, making durability a top priority.

What Quality Assurance Measures Are Implemented in OZ Racing Rim Production?

How Does OZ Racing Comply with International Quality Standards?

OZ Racing adheres to internationally recognized quality standards, such as ISO 9001, which focuses on ensuring consistent quality management systems across manufacturing processes. Compliance with these standards assures B2B buyers that the rims produced are manufactured under stringent quality control measures.

In addition to ISO 9001, industry-specific certifications such as CE marking indicate compliance with European safety and environmental standards. This is particularly relevant for buyers in Europe, who may prioritize such certifications when sourcing products.

What Are the Key Quality Control Checkpoints in OZ Racing Rim Manufacturing?

Quality control is embedded at multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified requirements.

-

In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing stages, where parameters such as temperature, pressure, and material integrity are assessed.

-

Final Quality Control (FQC): Once production is completed, each rim undergoes a final inspection, including visual checks, dimensional accuracy, and performance testing.

These checkpoints help identify and rectify any issues early in the production process, minimizing waste and ensuring that only high-quality products reach the market.

What Testing Methods Are Commonly Used for OZ Racing Rims?

How Are OZ Racing Rims Tested for Performance and Safety?

Testing methods for OZ Racing rims are comprehensive and include both static and dynamic tests. Static tests assess the structural integrity of the rim under load, while dynamic tests evaluate performance under real-world conditions, simulating driving scenarios. Common testing methods include:

- Impact Tests: Evaluating the rim’s ability to withstand sudden impacts.

- Fatigue Tests: Assessing durability over extended use under various loads.

- Tensile Tests: Measuring the strength and elongation of the material.

These rigorous testing protocols ensure that each rim meets performance and safety standards, providing peace of mind for B2B buyers.

How Can B2B Buyers Verify Supplier Quality Control?

What Steps Should Buyers Take to Ensure Supplier Compliance with QC Standards?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is paramount. Here are actionable steps to ensure compliance:

-

Conduct Audits: Regular audits of suppliers can help assess their adherence to quality standards. Buyers should request access to audit reports and certifications.

-

Request Documentation: Buyers should ask for quality assurance documentation, including test reports, compliance certificates, and details of their manufacturing processes.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control measures and product quality.

-

Engage in Direct Communication: Establishing a direct line of communication with suppliers can facilitate transparency and foster a collaborative relationship focused on quality.

By taking these steps, B2B buyers can mitigate risks and ensure they are sourcing high-quality OZ Racing rims that meet their specific needs and expectations.

Conclusion

Understanding the manufacturing processes and quality assurance measures associated with OZ Racing rims is essential for B2B buyers. By familiarizing themselves with these aspects, buyers can make informed decisions, ensuring they invest in products that offer both performance and reliability. With a focus on quality and rigorous testing protocols, OZ Racing rims stand out as a top choice for those seeking superior alloy wheels in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘oz racing rims’

To ensure a successful procurement process for OZ Racing rims, this practical sourcing guide outlines essential steps to follow. This checklist is designed for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe. Each step emphasizes critical actions to enhance your sourcing strategy and mitigate risks.

Step 1: Define Your Technical Specifications

Before diving into the procurement process, clearly outline the technical specifications required for your OZ Racing rims. This includes details such as diameter, width, offset, and bolt pattern, which are crucial for compatibility with your vehicles. Ensuring that you have precise specifications will streamline your search and help prevent costly mistakes down the line.

Step 2: Research Reputable Suppliers

Identify and compile a list of reputable suppliers and authorized dealers of OZ Racing rims. Research their background, market presence, and customer reviews to ensure they have a solid track record. Look for suppliers who specialize in aftermarket wheels and have experience in your target market, as this can influence product availability and support.

Step 3: Evaluate Supplier Certifications

Verifying the certifications of potential suppliers is essential for ensuring product quality and compliance with industry standards. Check for ISO certifications or other relevant quality assurances that demonstrate the supplier’s commitment to manufacturing excellence. This step can significantly reduce the risk of receiving subpar products that may not meet safety standards.

Step 4: Request Samples or Product Catalogs

Before making a bulk order, request samples or detailed product catalogs from your shortlisted suppliers. This allows you to assess the quality and craftsmanship of the OZ Racing rims firsthand. Pay attention to the material, finish, and overall design, as these factors can impact both aesthetics and performance.

Step 5: Negotiate Pricing and Terms

Once you have selected a potential supplier, initiate discussions around pricing, payment terms, and delivery timelines. Ensure that you understand all cost components, including shipping and potential tariffs, especially when dealing with international suppliers. Negotiating favorable terms can lead to significant cost savings and a more sustainable partnership.

Step 6: Verify After-Sales Support and Warranty Policies

Assess the after-sales support and warranty policies offered by the supplier. A reliable supplier should provide comprehensive support for installation, maintenance, and any potential issues that may arise. Understanding warranty terms is critical for protecting your investment and ensuring long-term satisfaction with your purchase.

Step 7: Finalize the Purchase Agreement

Before concluding the transaction, ensure that all agreed-upon terms are documented in a formal purchase agreement. This should include product specifications, pricing, delivery schedules, and warranty information. A well-drafted agreement protects both parties and serves as a reference point in case of disputes.

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for OZ Racing rims, ensuring a successful procurement experience that meets their specific needs and expectations.

Illustrative image related to oz racing rims

Comprehensive Cost and Pricing Analysis for oz racing rims Sourcing

What Are the Key Cost Components in Sourcing OZ Racing Rims?

When sourcing OZ Racing rims, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and supplier margins.

-

Materials: The production of high-quality alloy wheels typically utilizes lightweight aluminum and magnesium alloys. The cost of these raw materials fluctuates based on market conditions, impacting the final price. Specialty materials or finishes can further increase costs.

-

Labor: Skilled labor is required for the manufacturing of OZ Racing rims, especially given the precision involved in producing high-performance wheels. Labor costs vary by region, so it’s essential to consider the location of the manufacturing facility.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, maintenance, and indirect labor. Efficient manufacturing processes can help reduce these costs, but they still contribute significantly to the overall price.

-

Tooling: The initial investment in specialized tooling and machinery can be substantial. This cost is often amortized over a larger production run, meaning that larger orders can benefit from reduced per-unit costs.

-

Quality Control (QC): Rigorous testing and quality assurance processes are crucial for ensuring that the rims meet safety and performance standards. QC costs are essential to factor in, as they can influence both the reliability of the product and the potential for returns or defects.

-

Logistics: Shipping and handling costs can vary significantly based on the destination. International shipping, in particular, may involve additional fees, customs duties, and handling charges that can impact the total cost.

-

Margin: Suppliers typically add a margin to cover their operational costs and desired profits. This margin can vary based on the supplier’s business model and market conditions.

How Do Price Influencers Affect the Cost of OZ Racing Rims?

Several factors influence the pricing of OZ Racing rims, making it essential for buyers to understand these dynamics:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to significant discounts, while smaller orders may incur higher per-unit costs. Negotiating favorable terms can enhance cost-efficiency.

-

Specifications and Customization: Custom designs or specific specifications can increase costs due to the need for specialized production processes. Buyers should balance their need for customization with budget constraints.

-

Material Quality and Certifications: High-performance rims often come with certifications that ensure they meet specific safety and quality standards. While these certifications add value, they can also increase costs.

-

Supplier Factors: The reliability and reputation of the supplier can affect pricing. Established suppliers may charge a premium for their brand and assurance of quality, while newer suppliers may offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms associated with the purchase can impact the overall cost. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will dictate who bears the responsibility for shipping costs and risks.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing OZ Racing Rims?

To ensure a successful purchasing experience, B2B buyers should consider the following tips:

-

Negotiate Effectively: Engage in discussions regarding pricing, especially for bulk orders. Suppliers may be willing to offer discounts or better terms to secure a larger volume sale.

-

Assess Total Cost of Ownership (TCO): Rather than focusing solely on the upfront price, consider the long-term costs associated with the rims, including maintenance, potential defects, and resale value.

-

Understand Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations, import duties, and taxes that can affect the final landed cost of the rims. Working with local partners or consultants can provide insights into navigating these complexities.

-

Request Samples: Before making a large purchase, requesting samples can help assess quality and suitability. This step can prevent costly mistakes and ensure alignment with expectations.

-

Stay Informed: Keeping abreast of market trends and material costs can empower buyers to make informed decisions and potentially capitalize on favorable purchasing conditions.

Disclaimer on Indicative Prices

Prices for OZ Racing rims can vary widely based on the factors discussed above. This analysis serves as a guideline, and actual costs may differ based on specific circumstances and supplier negotiations. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing oz racing rims With Other Solutions

When evaluating the best options for alloy wheels, particularly for high-performance vehicles, it’s essential to consider various alternatives to OZ Racing rims. This comparison will help international B2B buyers identify the most suitable solution for their specific needs, whether they are in Africa, South America, the Middle East, or Europe.

Illustrative image related to oz racing rims

| Comparison Aspect | Oz Racing Rims | BBS Wheels | HRE Wheels |

|---|---|---|---|

| Performance | High-performance, lightweight, designed for motorsports | Excellent grip and handling, known for track performance | Custom high-performance options, exceptional quality |

| Cost | Mid to high range (typically $2,500 – $6,000) | High range (typically $2,500 – $5,000) | Premium pricing (often exceeding $5,000) |

| Ease of Implementation | Available through numerous authorized dealers, customization options | Widely available, installation is straightforward | Custom orders can complicate the process |

| Maintenance | Low maintenance, durable materials | Requires regular inspections for track use | High durability, but custom designs may need more care |

| Best Use Case | Ideal for both everyday driving and motorsport | Best for track enthusiasts and performance vehicles | Tailored for luxury and high-performance applications |

What Are the Key Advantages and Disadvantages of BBS Wheels?

BBS Wheels are renowned for their exceptional grip and handling capabilities. They are especially favored in racing and performance applications. The downside, however, is their higher price point compared to some alternatives, which may deter budget-conscious buyers. Additionally, while they are widely available, the need for regular inspections is essential for those who frequently engage in track use, which can lead to increased maintenance costs.

How Do HRE Wheels Compare to Oz Racing Rims?

HRE Wheels are a premium option known for their customizability and exceptional quality. They are often the choice of luxury and high-performance vehicle owners looking for tailored solutions. However, this level of customization comes with a higher price tag, often exceeding $5,000. The bespoke nature of HRE Wheels can also complicate the purchasing process, as they typically require a custom order, which may lead to longer lead times.

What Should B2B Buyers Consider When Choosing Between These Options?

When selecting the right alloy wheel for their needs, B2B buyers should assess several factors, including performance requirements, budget constraints, and the intended use of the vehicle. For those prioritizing high performance and durability, OZ Racing rims present an excellent balance of cost and functionality. In contrast, BBS Wheels are ideal for track-focused applications, while HRE Wheels cater to those seeking a luxury and customized experience. Understanding these distinctions will enable buyers to make informed decisions that align with their specific operational needs and market demands.

Essential Technical Properties and Trade Terminology for oz racing rims

What Are the Key Technical Properties of OZ Racing Rims?

When considering OZ Racing rims, understanding the critical technical properties is essential for making informed purchasing decisions. Here are some key specifications:

1. Material Grade

OZ Racing rims are primarily made from high-grade aluminum alloys, specifically those that balance strength and weight. The use of materials like 6061-T6 aluminum ensures that the rims are lightweight yet durable, which is crucial for performance vehicles. For B2B buyers, this means lower wear and tear on tires and improved fuel efficiency, making it a cost-effective choice in the long run.

Illustrative image related to oz racing rims

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. For OZ Racing rims, maintaining precise tolerances is critical for ensuring fitment and performance. A typical tolerance range might be ±0.1 mm. In the B2B context, high tolerance levels translate to improved safety and performance, which can significantly impact customer satisfaction and brand reputation.

3. Load Rating

The load rating of a rim indicates the maximum weight it can safely support. OZ Racing rims often feature load ratings that meet or exceed industry standards, making them suitable for various vehicle types, from everyday cars to high-performance racing vehicles. For buyers, this ensures that the rims will perform reliably under different conditions, reducing liability and maintenance costs.

4. Offset

Offset is the distance from the wheel’s mounting surface to its centerline. OZ Racing rims come with various offset options to accommodate different vehicle designs. Understanding offset is crucial for ensuring proper handling and alignment. For B2B buyers, selecting the correct offset can prevent costly installation errors and ensure the rims enhance vehicle performance.

5. Finish

The finish of a rim affects both aesthetics and durability. OZ Racing offers various finishes, such as anodized or powder-coated, which enhance resistance to corrosion and wear. This is particularly important for buyers in regions with harsh climates, as a high-quality finish can prolong the lifespan of the rims, leading to lower replacement costs.

6. Weight

Weight is a critical factor in rim performance, affecting acceleration, braking, and fuel efficiency. OZ Racing rims are designed to be lightweight without compromising strength, often weighing significantly less than standard steel rims. For B2B customers, investing in lightweight rims can lead to noticeable improvements in vehicle performance and efficiency.

What Are Common Trade Terms Associated with OZ Racing Rims?

Familiarity with industry terminology is vital for effective communication and negotiation. Here are some common terms related to OZ Racing rims:

1. OEM (Original Equipment Manufacturer)

OEM refers to components made by the original manufacturer of a vehicle. In the context of OZ Racing rims, this term is essential for buyers looking to upgrade or replace their vehicle’s wheels with high-quality, compatible options. OEM parts often guarantee fitment and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial for budgeting and inventory management. If you are a retailer or distributor, knowing the MOQ for OZ Racing rims can help in planning purchases and stock levels.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for a specific quantity of products. B2B buyers should utilize RFQs when sourcing OZ Racing rims to ensure they receive competitive pricing and terms, aiding in effective procurement strategies.

Illustrative image related to oz racing rims

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in a transaction. For instance, terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who is responsible for shipping costs and risks. Understanding these terms is vital for B2B buyers to avoid unexpected costs and ensure smooth logistics.

5. Aftermarket

The aftermarket refers to parts and accessories sold for vehicles after their initial sale. OZ Racing rims are a popular choice in the aftermarket for performance upgrades. B2B buyers in this sector should recognize the significance of aftermarket products in enhancing vehicle performance and aesthetics.

6. Certification

Certification indicates that a product meets specific industry standards, such as safety and performance benchmarks. OZ Racing rims often hold certifications from organizations like the FIA, enhancing their credibility. For B2B buyers, purchasing certified products ensures compliance with local regulations and boosts customer trust.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing OZ Racing rims, ensuring they meet the specific needs of their customers while maximizing profitability.

Navigating Market Dynamics and Sourcing Trends in the oz racing rims Sector

What Are the Key Trends Driving the Global Market for OZ Racing Rims?

The global market for OZ Racing rims is shaped by several key drivers. Firstly, the increasing demand for lightweight, high-performance alloy wheels is being propelled by advancements in automotive technology and the push for enhanced fuel efficiency. As manufacturers innovate, B2B buyers are looking for products that not only deliver superior performance but also contribute to overall vehicle efficiency.

Emerging trends in B2B sourcing include the rise of e-commerce platforms, enabling buyers from regions like Africa, South America, and the Middle East to access a broader range of OZ Racing products. Additionally, the integration of digital tools such as augmented reality for virtual product trials is gaining traction, allowing buyers to visualize how specific rims will look on different vehicle models.

Another dynamic is the increasing focus on customization, with B2B buyers seeking unique designs that cater to regional preferences. This trend is particularly relevant in markets like Saudi Arabia and Nigeria, where cultural aesthetics play a significant role in purchasing decisions. As buyers become more discerning, the demand for high-quality, bespoke solutions will likely drive competition among manufacturers.

How Is Sustainability Shaping the Sourcing of OZ Racing Rims?

Sustainability is becoming a critical factor for B2B buyers in the OZ Racing rims sector. Environmental concerns are prompting companies to prioritize ethical sourcing and sustainable production methods. The impact of manufacturing processes on the environment is under scrutiny, leading to increased demand for rims made from recycled or eco-friendly materials.

Buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainable practices, such as using green certifications like ISO 14001, which indicates effective environmental management systems. Additionally, transparent supply chains that ensure ethical labor practices are becoming a prerequisite for many B2B transactions. As a result, suppliers that can showcase their sustainability credentials will be better positioned to attract international buyers.

Illustrative image related to oz racing rims

Moreover, the use of advanced materials, such as forged aluminum, not only enhances performance but also reduces the overall carbon footprint. B2B buyers should consider these aspects when sourcing OZ Racing rims, as they align with the growing consumer demand for environmentally responsible products.

What Is the Historical Context of OZ Racing Rims and Its Relevance for Today’s Buyers?

OZ Racing has a rich heritage dating back to its establishment in Italy, where it has built a reputation for high-quality alloy wheels designed for both motorsport and everyday driving. The brand’s commitment to innovation is reflected in its extensive research and development efforts, which have led to the creation of cutting-edge products that meet the rigorous demands of professional racing and casual driving alike.

Over the years, OZ Racing has evolved from a niche manufacturer to a globally recognized brand, gaining traction in diverse markets such as Europe, the Middle East, and South America. This historical context is significant for B2B buyers, as it underscores the brand’s reliability and expertise in wheel manufacturing. Understanding the evolution of OZ Racing not only provides insights into the quality and performance standards buyers can expect but also highlights the brand’s adaptability to changing market demands, making it a trustworthy partner in the competitive landscape of alloy wheels.

In summary, the OZ Racing rims sector is characterized by dynamic market trends, a strong focus on sustainability, and a rich history that adds credibility to its products. B2B buyers should leverage these insights to make informed sourcing decisions that align with their operational goals and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of oz racing rims

1. How can I ensure the quality of OZ Racing rims when sourcing?

To ensure the quality of OZ Racing rims, consider working with authorized distributors or directly with OZ Racing representatives. Verify that the supplier provides certifications and quality assurance documentation, confirming compliance with international safety standards. Request samples if possible to evaluate the rims’ craftsmanship and performance. Additionally, reviewing customer testimonials and feedback from other B2B buyers can provide insights into the supplier’s reliability and the product’s quality.

Illustrative image related to oz racing rims

2. What are the customization options available for OZ Racing rims?

OZ Racing offers a variety of customization options to meet specific customer needs, including different sizes, finishes, and designs. Buyers can inquire about bespoke specifications tailored to particular vehicle models or performance requirements. It’s essential to communicate your needs clearly to the supplier and confirm any additional costs associated with custom designs. Keep in mind that lead times may vary based on the complexity of the customization.

3. What is the minimum order quantity (MOQ) for OZ Racing rims?

The minimum order quantity (MOQ) for OZ Racing rims can vary depending on the supplier and the specific product line. Typically, MOQs range from a few sets to larger bulk orders. When negotiating, it’s advisable to discuss your purchasing capacity and explore potential flexibility in MOQs. This can help in establishing a mutually beneficial arrangement, especially if you are looking to test the market with a smaller initial order.

4. What payment terms should I expect when sourcing OZ Racing rims?

Payment terms for sourcing OZ Racing rims generally vary by supplier and region. Common practices include upfront payments, letters of credit, or payment upon delivery. It’s crucial to negotiate terms that align with your business cash flow and risk management strategies. Ensure that all payment terms are clearly outlined in the purchase agreement to avoid any misunderstandings.

5. How can I vet suppliers of OZ Racing rims effectively?

To vet suppliers of OZ Racing rims, start by researching their reputation within the industry. Look for reviews, ratings, and feedback from previous customers. Assess their experience in international trade, particularly with businesses in your region, as this can indicate their understanding of local regulations and logistics. Additionally, request references and verify their business licenses and certifications to ensure they meet industry standards.

6. What logistics considerations should I keep in mind when importing OZ Racing rims?

When importing OZ Racing rims, consider shipping methods, customs regulations, and potential tariffs in your country. It’s advisable to work with a freight forwarder experienced in handling automotive parts to navigate the complexities of international shipping. Ensure that the rims are packaged securely to prevent damage during transit, and confirm that all necessary documentation, such as invoices and packing lists, is prepared to facilitate a smooth customs clearance process.

7. What are the warranty options for OZ Racing rims?

OZ Racing typically offers warranties on their rims that cover manufacturing defects and performance issues. The specifics of the warranty, including duration and coverage, may vary by product line and region. It’s essential to inquire about the warranty details before making a purchase, as this can provide peace of mind and protect your investment. Ensure that you understand the warranty claim process in case you encounter any issues.

8. How do I handle quality assurance (QA) for OZ Racing rims upon receipt?

Upon receipt of OZ Racing rims, conduct a thorough inspection to ensure they meet your quality standards. Check for any visible damage, defects, or inconsistencies in the specifications compared to what was ordered. It’s advisable to have a checklist based on the supplier’s quality assurance standards. If any issues are found, document them with photographs and contact the supplier promptly to discuss possible resolutions, such as replacements or refunds.

Top 3 Oz Racing Rims Manufacturers & Suppliers List

1. OZ Racing – Lightweight Alloy Wheels

Domain: ozracing.com

Registered: 1996 (29 years)

Introduction: Made in Italy light weight Alloy Wheels; Designed, handcrafted and tested in Italy; Perfect combination of performance, construction quality, and design; Focus on safety, stability, and readiness for any route; Suitable for various car brands including Alfa Romeo, Audi, BMW, Fiat, Ford, Hyundai, Kia, Mercedes, Mini, Nissan, Opel, Peugeot, Porsche, Renault, Skoda, Smart, Volkswagen, Volvo; Features…

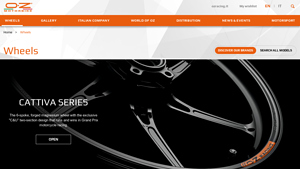

2. OZ – Cattiva Series 6-Spoke Magnesium Wheels

Domain: ozmotorbike.com

Registered: 2009 (16 years)

Introduction: {“Cattiva Series”: {“type”: “6-spoke, forged magnesium wheel”, “design”: “exclusive ‘C&U’ two-section design”, “usage”: “Grand Prix motorcycle racing”, “available_colours”: 3}, “Piega Series”: {“type”: “forged wheels”, “usage”: “derived from OZ racing experience”, “available_colours”: {“front”: 3, “rear”: 3, “rear_monoarm”: 3}}, “Piega R Series”: {“available_colours”: {“front”: 2, “rear”: 2, “rear…

3. OZ Racing – Motorsport & Performance Products

Domain: demon-tweeks.com

Registered: 1999 (26 years)

Introduction: This company, OZ Racing – Motorsport & Performance Products, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for oz racing rims

As the demand for high-performance automotive components continues to grow globally, strategic sourcing of OZ Racing rims presents an invaluable opportunity for international B2B buyers. Key takeaways include the brand’s commitment to quality, with products handcrafted in Italy and designed for both aesthetic appeal and superior performance. The diverse range of offerings—from lightweight alloy wheels to specialized forged options—caters to various market segments, including motorsports and everyday driving.

Investing in OZ Racing rims not only enhances vehicle performance but also aligns with the increasing consumer preference for premium automotive accessories. For buyers in regions such as Africa, South America, the Middle East, and Europe, establishing partnerships with authorized dealers and distributors can facilitate access to these high-quality products, ensuring a competitive edge in the marketplace.

Looking ahead, the outlook for OZ Racing rims is promising, driven by innovation and a focus on customer satisfaction. B2B buyers are encouraged to leverage this momentum by exploring collaborations that can enhance their product offerings and meet the evolving demands of their clientele. The roads of opportunity are wide open; now is the time to engage with OZ Racing and elevate your business to new heights.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.