A B2B Buyer’s Guide to Latch Pins: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for latch pins

Navigating the global market for latch pins presents unique challenges for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. As industries increasingly rely on these essential fasteners for securing movable parts in machinery, vehicles, and various applications, sourcing the right latch pins becomes critical. Buyers often face difficulties in identifying reliable suppliers, understanding the diversity of products available, and assessing the implications of cost and quality.

This comprehensive guide is designed to equip international buyers with the knowledge they need to make informed purchasing decisions. It covers a wide range of topics, including the different types of latch pins—such as cotter pins, clevis pins, and locking pins—alongside their specific applications across various industries. We delve into best practices for vetting suppliers, ensuring that you partner with trustworthy manufacturers who meet international standards. Additionally, the guide addresses pricing structures and factors that influence costs, helping you to budget effectively and negotiate favorable terms.

By leveraging the insights provided in this guide, B2B buyers from diverse markets can enhance their procurement strategies, ensuring they acquire high-quality latch pins that meet their operational requirements while optimizing supply chain efficiency. Whether you are in Germany, Nigeria, or any other part of the world, this resource aims to empower you to navigate the complexities of the latch pin market with confidence.

Understanding latch pins Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cotter Pin | Simple design with a split end for secure fastening. | Automotive, machinery, and construction. | Pros: Cost-effective and easy to use. Cons: Limited load capacity. |

| Clevis Pin | Cylindrical pin with a hole for a cotter pin or retaining ring. | Agricultural machinery, trailers, and gates. | Pros: Versatile and allows for quick assembly. Cons: May require additional components for security. |

| Locking Pin | Equipped with a latch mechanism for secure locking. | Industrial applications, heavy machinery. | Pros: Offers enhanced security and stability. Cons: Higher cost compared to simpler pins. |

| Dowel Pin | Cylindrical, solid pin used for alignment and fastening. | Furniture manufacturing, woodworking. | Pros: Provides strong alignment. Cons: Requires precise drilling for installation. |

| Spring-Loaded Pin | Automatically retracts and locks in place when released. | Automotive, aerospace, and equipment. | Pros: Quick engagement and disengagement. Cons: More complex mechanism may lead to higher failure rates. |

What Are the Key Characteristics of Cotter Pins?

Cotter pins are a straightforward fastening solution commonly used in various industries, including automotive and construction. Their design features a split end that, when inserted into a hole, can be bent to secure the pin in place. This simplicity makes them cost-effective and easy to use. However, they have a limited load capacity, which may not be suitable for high-stress applications.

How Do Clevis Pins Differ in Functionality?

Clevis pins are cylindrical fasteners with a hole at one end for a cotter pin or retaining ring, allowing for secure attachment of components. They are widely used in agricultural machinery and trailers due to their versatility and ease of assembly. While clevis pins facilitate quick assembly, they may require additional components for enhanced security, which can increase overall costs.

What Advantages Do Locking Pins Offer to B2B Buyers?

Locking pins are designed with a latch mechanism that provides enhanced security for applications in heavy machinery and industrial settings. These pins ensure that parts remain securely fastened, even under significant stress. Although they come at a higher price point compared to simpler pin types, their reliability and ability to prevent accidental disconnections make them a valuable investment for businesses prioritizing safety.

Why Are Dowel Pins Important in Manufacturing?

Dowel pins serve a critical role in furniture manufacturing and woodworking, providing alignment and fastening capabilities. Their solid cylindrical design allows for strong connections between components, ensuring structural integrity. However, the installation of dowel pins requires precise drilling, which can be a drawback if not executed correctly, potentially leading to alignment issues.

Illustrative image related to latch pins

What Makes Spring-Loaded Pins Unique?

Spring-loaded pins feature a mechanism that allows them to retract and lock into place automatically. This design is particularly beneficial in automotive and aerospace applications, where quick engagement and disengagement are essential. While their functionality offers convenience, the complexity of the mechanism can result in higher failure rates, making it crucial for buyers to consider the operational environment and usage frequency.

Key Industrial Applications of latch pins

| Industry/Sector | Specific Application of latch pins | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Securing implements and attachments on farm machinery | Enhances operational efficiency and safety | Consider corrosion resistance, load capacity, and ease of use. |

| Construction | Locking scaffolding components and temporary structures | Ensures stability and safety on job sites | Look for durability, ease of installation, and compliance with safety standards. |

| Automotive | Fastening components in vehicle assembly and repair | Improves assembly line efficiency and reliability | Prioritize material strength, weight, and compatibility with existing systems. |

| Transportation & Logistics | Securing cargo and equipment in trailers and containers | Reduces damage during transit and enhances security | Evaluate locking mechanisms, ease of operation, and weather resistance. |

| Manufacturing | Joining parts in machinery and production lines | Streamlines production processes and reduces downtime | Assess precision, material quality, and ability to withstand operational stresses. |

How are latch pins utilized in agriculture for securing implements?

In the agriculture sector, latch pins play a crucial role in securing various implements and attachments on farm machinery, such as plows, harrows, and trailers. They ensure that these components remain firmly attached during operation, thereby enhancing safety and operational efficiency. For international buyers, particularly in regions like Africa and South America, sourcing latch pins that are corrosion-resistant and capable of withstanding harsh environmental conditions is essential. Additionally, ease of use in attaching and detaching implements can significantly improve workflow on farms.

What role do latch pins play in construction for scaffolding safety?

In construction, latch pins are integral for locking scaffolding components and ensuring the stability of temporary structures. They provide a reliable means of securing parts together, which is vital for maintaining safety standards on job sites. B2B buyers in Europe, particularly in countries with stringent safety regulations like Germany, should focus on sourcing latch pins that comply with local safety standards and offer durability under various loads. The ability to quickly install and remove these pins can also enhance productivity, making them a valuable asset on construction sites.

How do latch pins enhance automotive assembly processes?

In the automotive industry, latch pins are used to fasten components during vehicle assembly and repair processes. Their reliable locking mechanism helps streamline assembly line operations, contributing to overall efficiency and reliability in vehicle production. For international automotive suppliers, particularly in emerging markets, it is crucial to select latch pins that offer high strength-to-weight ratios and compatibility with existing assembly systems. This ensures that the components can endure the stresses of operation while maintaining the integrity of the vehicle.

Why are latch pins important in transportation for securing cargo?

Latch pins are vital in the transportation and logistics sector for securing cargo and equipment within trailers and shipping containers. They help prevent damage during transit and enhance overall security, which is paramount for businesses dealing with high-value goods. International buyers should consider latch pins that offer robust locking mechanisms and are resistant to environmental wear, especially in regions prone to extreme weather conditions. The ease of operation is also a critical factor, as it can significantly impact loading and unloading efficiency.

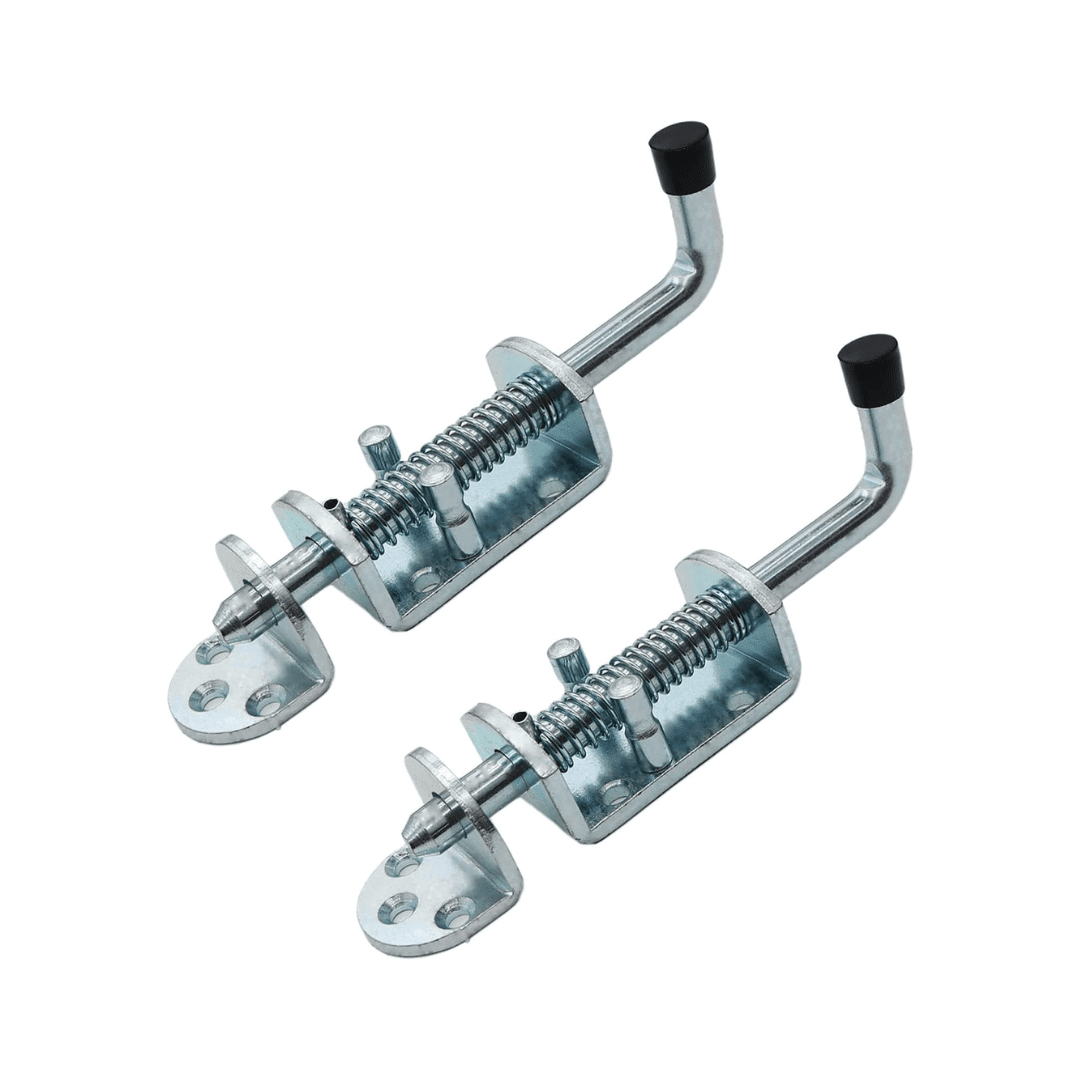

Illustrative image related to latch pins

What benefits do latch pins provide in manufacturing environments?

In manufacturing, latch pins are commonly used to join parts in machinery and along production lines. They help streamline operations, reduce downtime, and enhance the reliability of machinery. For B2B buyers, particularly in sectors focused on precision engineering, sourcing high-quality latch pins that can withstand operational stresses is essential. Additionally, considering the manufacturing process’s demands, such as temperature and load variations, can guide the selection of suitable materials and designs for latch pins.

3 Common User Pain Points for ‘latch pins’ & Their Solutions

Scenario 1: Challenges with Corrosion and Durability of Latch Pins in Harsh Environments

The Problem: In many industries, particularly in construction and agriculture, latch pins are often exposed to harsh environmental conditions. Buyers frequently encounter issues with corrosion, which leads to premature failure of these critical components. This not only results in increased maintenance costs but also impacts the operational efficiency of machinery and equipment. For instance, a construction firm in Nigeria found that their latch pins were failing due to rust after only a few months of use, leading to costly downtime and replacement expenses.

The Solution: To mitigate corrosion, buyers should prioritize sourcing latch pins made from corrosion-resistant materials, such as stainless steel or those with specialized coatings like zinc plating. When specifying latch pins, ensure they meet industry standards for durability and environmental resistance. It’s also beneficial to consider the operating environment when selecting latch pins. For example, using pins that are specifically designed for marine or outdoor applications can significantly enhance longevity. Regular maintenance checks should be scheduled to identify any signs of wear or corrosion early, allowing for timely replacements before they lead to equipment failure.

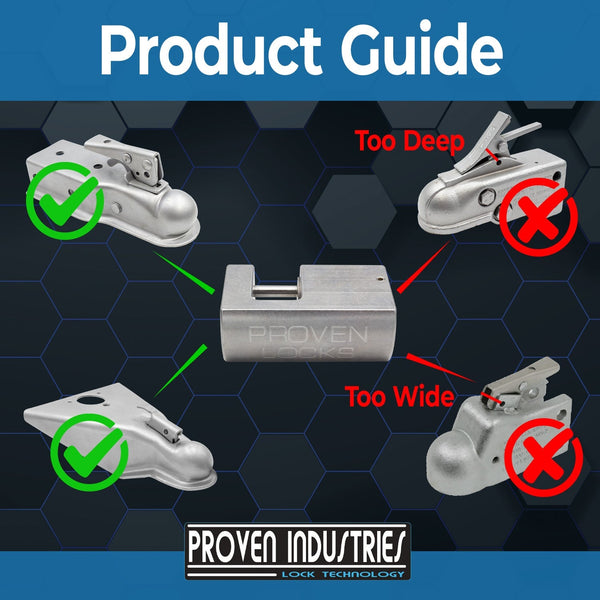

Scenario 2: Difficulty in Selecting the Right Size and Type of Latch Pin

The Problem: B2B buyers often struggle with selecting the appropriate size and type of latch pin for their specific applications. This can lead to improper fitment, which compromises the effectiveness and safety of the equipment. For instance, a manufacturing plant in Germany experienced frequent malfunctions in their machinery because the latch pins used were either too short or lacked the necessary locking mechanisms, resulting in parts becoming dislodged during operation.

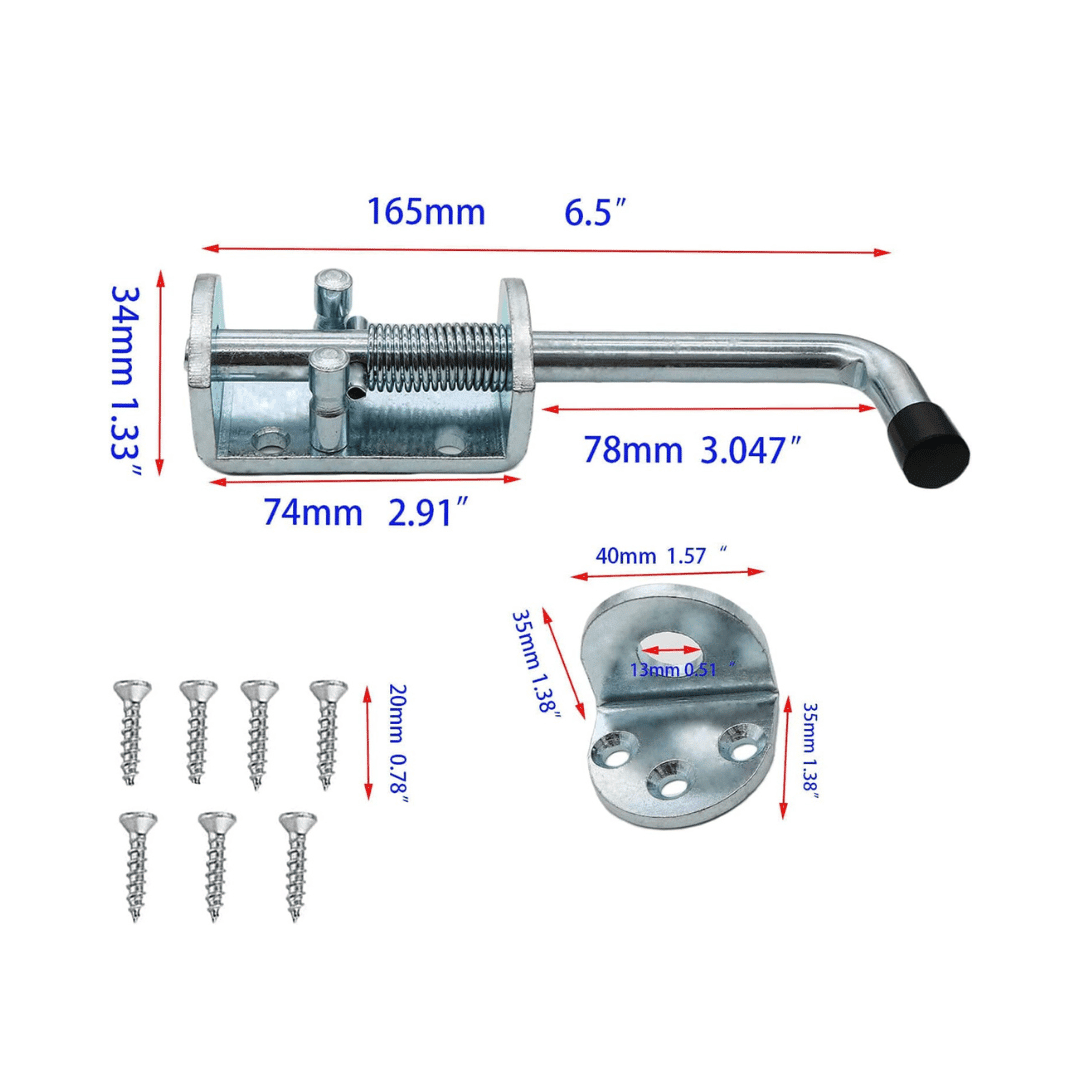

The Solution: To address this issue, it is critical for buyers to conduct a thorough assessment of their equipment and understand the specifications required for latch pins. This includes measuring the diameter and length of existing pins and determining the required locking mechanism—whether a cotter pin, clevis pin, or locking pin. Manufacturers often provide detailed specifications and application guides that can assist in making informed decisions. Additionally, engaging with suppliers who offer a wide range of latch pins and can provide expert advice on selection can streamline the sourcing process. Establishing a standardized process for selecting latch pins based on equipment specifications will also help reduce errors and improve operational reliability.

Scenario 3: Operational Inefficiencies Due to Manual Latching Mechanisms

The Problem: Many businesses face operational inefficiencies due to the reliance on manual latching mechanisms, which can slow down workflows and increase labor costs. For example, a logistics company in South America reported delays in loading and unloading shipments because workers spent excessive time manually securing trailer doors with latch pins that required significant effort to operate.

The Solution: To enhance operational efficiency, companies should consider transitioning to automatic or spring-loaded latch pins that allow for quicker and easier engagement. These types of latch pins reduce the physical effort needed to secure equipment, thus speeding up processes like loading and unloading. When evaluating latch pins, buyers should look for options that are designed for quick-release and easy operation, especially for high-volume applications. Furthermore, training personnel on the effective use of these enhanced latch systems can maximize efficiency and minimize downtime. Regular feedback from operators can also guide further improvements in latch design and operational practices.

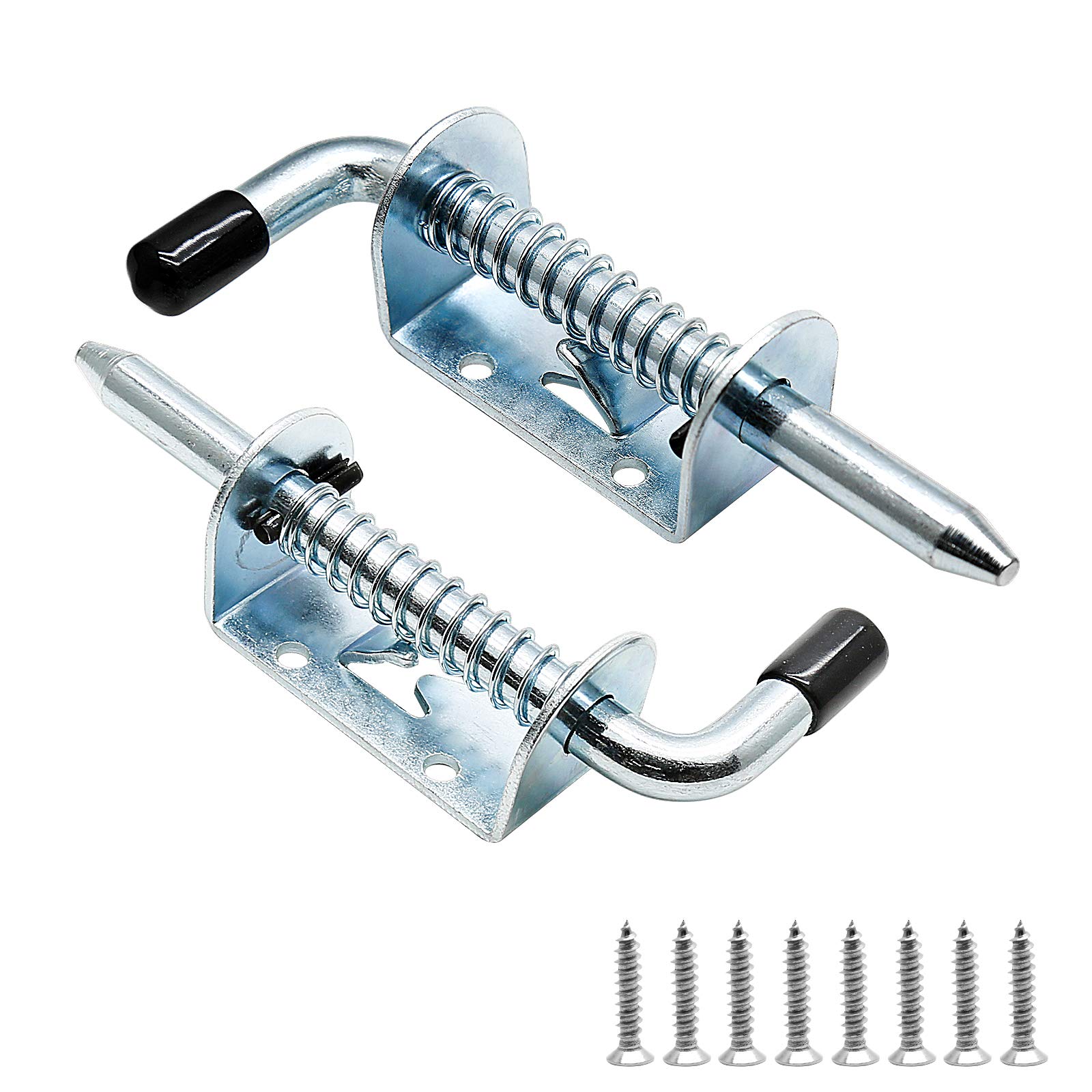

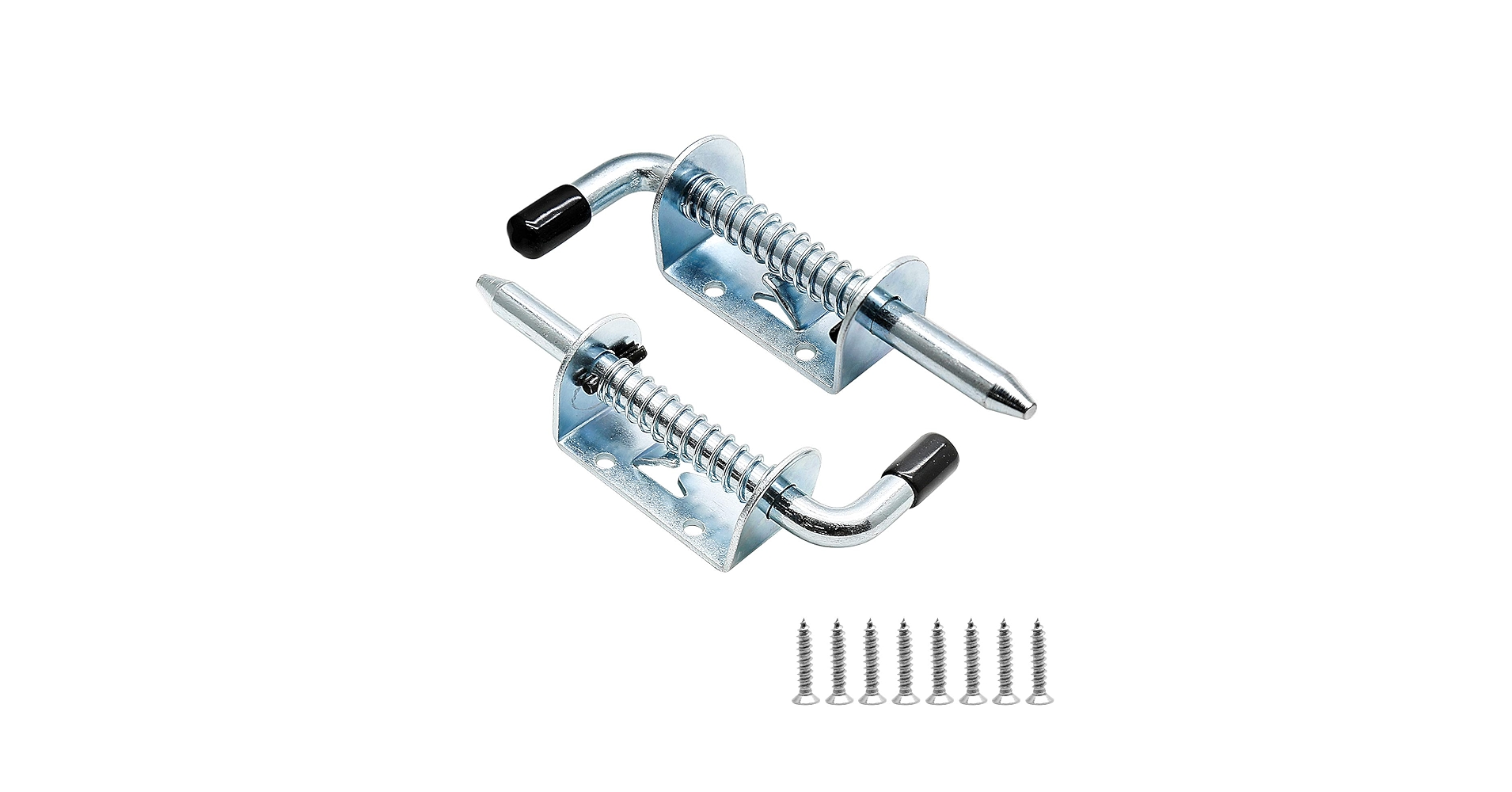

Illustrative image related to latch pins

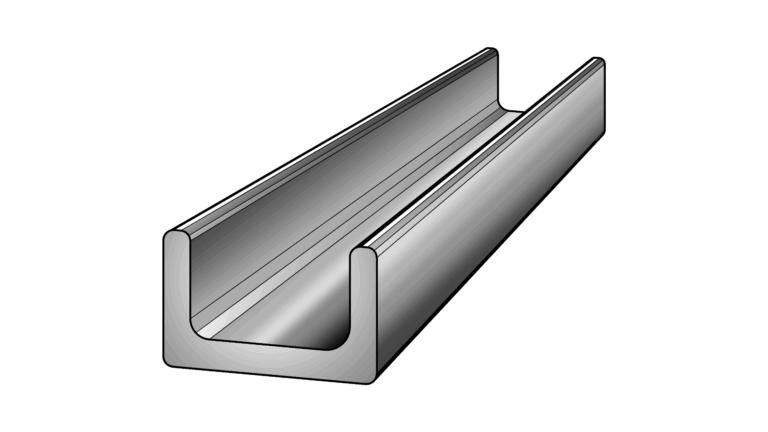

Strategic Material Selection Guide for latch pins

When selecting materials for latch pins, it is essential to consider the specific requirements of the application, including environmental conditions, load-bearing capacities, and compatibility with other components. Below is an analysis of four common materials used in the manufacturing of latch pins, along with their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Steel Latch Pins?

Steel is one of the most widely used materials for latch pins due to its excellent mechanical properties. Steel latch pins typically exhibit high tensile strength, making them suitable for applications requiring significant load-bearing capacity. They can withstand high temperatures and pressures, which is crucial in industrial settings. Additionally, steel can be treated for improved corrosion resistance through processes such as galvanization or powder coating.

Pros and Cons: The primary advantage of steel latch pins is their durability and strength. However, they can be prone to rust if not properly treated, which may limit their use in humid or corrosive environments. The cost of steel is generally moderate, but manufacturing complexity can increase with the need for additional coatings or treatments.

How Does Stainless Steel Compare for Latch Pin Applications?

Stainless Steel offers similar mechanical properties to carbon steel but with enhanced corrosion resistance due to its chromium content. This makes stainless steel latch pins ideal for applications in marine environments or areas with high humidity. They also have a higher temperature tolerance, making them suitable for applications involving heat exposure.

Illustrative image related to latch pins

Pros and Cons: The main advantage of stainless steel is its resistance to corrosion and staining, which extends the lifespan of the latch pin. However, stainless steel is typically more expensive than carbon steel, which can be a consideration for budget-conscious buyers. Additionally, the manufacturing process can be more complex, potentially leading to higher production costs.

What Role Does Plastic Play in Latch Pin Manufacturing?

Plastic latch pins, often made from materials like nylon or polycarbonate, are lightweight and resistant to corrosion. They are particularly useful in applications where metal might corrode or where weight is a critical factor, such as in automotive or aerospace applications. Plastic latch pins can also be manufactured in various colors and shapes, providing aesthetic flexibility.

Pros and Cons: The primary advantage of plastic latch pins is their lightweight nature and resistance to corrosion. However, they generally have lower tensile strength compared to metal options, which may limit their use in high-load applications. Additionally, the cost of high-performance plastics can be high, but they often offset this with lower manufacturing complexity.

Are There Unique Benefits to Using Aluminum for Latch Pins?

Aluminum is another material that is increasingly being used for latch pins due to its favorable strength-to-weight ratio and corrosion resistance. Aluminum latch pins are lightweight, making them ideal for applications where reducing weight is essential, such as in the aerospace and automotive industries. Additionally, aluminum can be anodized for additional corrosion protection.

Pros and Cons: The key advantage of aluminum is its lightweight nature, which can significantly reduce the overall weight of the assembly. However, aluminum may not be as strong as steel or stainless steel, which can limit its use in high-stress applications. The cost of aluminum is typically moderate, but its manufacturing processes can be complex, especially when anodizing is involved.

Summary Table of Material Selection for Latch Pins

| Material | Typical Use Case for latch pins | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, construction equipment | High strength and durability | Prone to corrosion without treatment | Medium |

| Stainless Steel | Marine applications, food processing | Excellent corrosion resistance | Higher cost than carbon steel | High |

| Plastic | Lightweight applications, automotive | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Aluminum | Aerospace, automotive components | Lightweight with good corrosion resistance | Not as strong as steel | Medium |

This material selection guide provides a comprehensive overview for B2B buyers, enabling them to make informed decisions based on application requirements, environmental conditions, and cost considerations. Understanding these factors is crucial for ensuring the reliability and longevity of latch pins in various industrial applications.

In-depth Look: Manufacturing Processes and Quality Assurance for latch pins

What Are the Key Manufacturing Processes for Latch Pins?

The production of latch pins involves several crucial manufacturing stages, each designed to ensure the final product meets stringent quality and functionality standards. Understanding these processes can help B2B buyers evaluate potential suppliers effectively.

How Is Material Prepared for Latch Pin Manufacturing?

The first step in the manufacturing process is material preparation. Common materials used for latch pins include stainless steel, carbon steel, and zinc-plated steel, which provide durability and corrosion resistance. Suppliers often source raw materials that comply with international standards, such as ASTM or ISO specifications, ensuring consistent quality.

Before fabrication, the raw materials undergo a series of inspections to verify their chemical and physical properties. This step is critical as it influences the performance of the final product. For instance, low-carbon steel may be chosen for its malleability, while stainless steel may be preferred for its resistance to rust and environmental factors.

What Forming Techniques Are Used in Latch Pin Production?

Once materials are prepared, the next phase is forming. Latch pins are typically manufactured through processes such as:

- Stamping: This technique involves cutting and shaping the material into the desired pin shape using a die. It’s efficient for high-volume production and provides precise dimensions.

- Machining: For more complex designs, machining processes such as turning and milling are employed. This method is ideal for custom latch pins with specific tolerances.

- Cold Heading: This process involves shaping metal at room temperature, which increases the material’s strength without compromising its integrity.

Each forming technique has its advantages, and suppliers may choose based on the volume of production, material type, and required specifications.

What Assembly Processes Are Involved in Latch Pin Manufacturing?

After forming, the next step is assembly, particularly for latch pins that have multiple components, such as those with locking mechanisms or springs. This may include:

Illustrative image related to latch pins

- Component Assembly: If the latch pin consists of various parts, such as a pin and a latch, these components are brought together using methods like welding, riveting, or mechanical fastening.

- Spring Insertion: For spring-loaded latch pins, the springs must be inserted with precision to ensure proper functionality. Automated machines often assist in this stage to enhance efficiency and accuracy.

Quality control during assembly is critical to ensure that all components fit together seamlessly, which directly affects the latch pin’s performance.

How Is Finishing Applied to Latch Pins?

Finishing is the final manufacturing stage and plays a vital role in protecting the latch pins from environmental damage. Common finishing processes include:

- Electroplating: This process involves coating the latch pin with a thin layer of metal, such as zinc or nickel, to improve corrosion resistance and aesthetic appeal.

- Powder Coating: For additional protection and color options, powder coating is applied, providing a durable finish that can withstand harsh conditions.

- Surface Treatment: Techniques such as polishing or shot blasting may be employed to enhance surface smoothness and reduce friction during operation.

The finishing process not only improves the product’s durability but also its marketability, especially for B2B buyers looking for high-quality, reliable components.

What Quality Assurance Standards Are Relevant for Latch Pins?

Quality assurance (QA) is a cornerstone of the manufacturing process for latch pins, ensuring that products meet both industry-specific and international standards. B2B buyers should be aware of these standards to make informed decisions.

Which International Standards Should B2B Buyers Consider?

One of the most recognized quality management standards is ISO 9001, which outlines the criteria for a quality management system. Suppliers certified in ISO 9001 demonstrate their commitment to consistent quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications may include:

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Certification: Relevant for latch pins used in the oil and gas industry, API standards ensure that products meet specific performance and safety criteria.

What Are the Key Quality Control Checkpoints in Latch Pin Manufacturing?

Quality control checkpoints are critical to ensuring that latch pins meet established standards throughout the manufacturing process. Key checkpoints typically include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to ensure that processes are being followed correctly and that any deviations are promptly addressed.

- Final Quality Control (FQC): Once manufacturing is complete, final inspections are performed to verify that the finished products meet all specifications and standards before shipping.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should employ several strategies to verify the quality control practices of potential suppliers:

- Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes and quality management systems. This direct observation allows buyers to assess compliance with international standards.

- Quality Reports: Requesting detailed quality reports can help buyers understand a supplier’s QA practices and historical performance. These reports should include information on defect rates, corrective actions taken, and compliance with industry standards.

- Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These independent organizations can evaluate the manufacturing processes and final products, providing unbiased assessments of quality.

What Are the Unique Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control. Understanding these nuances can help buyers navigate the complexities of global sourcing.

- Regulatory Compliance: Different regions may have varying regulations regarding material safety and product standards. Buyers must ensure that suppliers comply with the specific regulations applicable in their target markets.

- Cultural Considerations: Communication barriers and cultural differences can impact quality assurance practices. Establishing clear expectations and maintaining open lines of communication with suppliers is essential for overcoming these challenges.

- Logistics and Supply Chain Management: International shipping can introduce risks related to damage or loss of quality during transit. Buyers should work with suppliers who have robust logistics solutions and can provide guarantees regarding product integrity.

By understanding the manufacturing processes and quality assurance measures for latch pins, B2B buyers can make informed decisions, ensuring that they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘latch pins’

To streamline the procurement process for latch pins, this guide provides actionable steps for B2B buyers. The objective is to ensure that you source high-quality products that meet your specific requirements while minimizing risks associated with international procurement.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications required for the latch pins you need. This includes material type (e.g., stainless steel, zinc-plated), dimensions (length, diameter), and load capacity. Defining these parameters upfront helps avoid costly mistakes and ensures that the products meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in latch pins. Look for manufacturers with a strong reputation and experience in your industry. Utilize online platforms, trade shows, and industry directories to compile a list of potential suppliers.

Illustrative image related to latch pins

- Tip: Pay attention to suppliers who offer detailed product catalogs and technical support, as these can be indicators of reliability.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers hold necessary certifications that ensure product quality and safety. Look for certifications such as ISO 9001, which indicates a commitment to quality management. This step is crucial for minimizing risks associated with product defects and ensuring compliance with international standards.

Step 4: Request Samples for Testing

Before making a bulk order, request samples of the latch pins from your selected suppliers. Testing samples allows you to evaluate the quality, durability, and suitability of the pins for your specific applications. It also gives you a chance to assess the supplier’s responsiveness and customer service.

- Considerations: Check for corrosion resistance, ease of use, and compatibility with existing equipment.

Step 5: Analyze Pricing and Terms of Sale

Review the pricing structures and terms of sale offered by each supplier. Compare not only the cost per unit but also consider shipping fees, payment terms, and bulk order discounts. Understanding the total cost of procurement is vital for budget planning and ensuring you receive value for your investment.

Step 6: Assess Logistics and Delivery Capabilities

Evaluate the logistics capabilities of your suppliers, including shipping times and methods. Ensure that they can meet your delivery timelines, especially if you are operating under tight schedules. Discuss potential customs requirements and shipping documentation to avoid delays.

Step 7: Establish a Communication Plan

Finally, establish a clear communication plan with your chosen supplier. Set expectations regarding regular updates on order status, potential delays, and any changes in specifications. Effective communication helps foster a strong partnership and ensures that any issues are addressed promptly.

By following this checklist, B2B buyers can make informed decisions when sourcing latch pins, ensuring that they acquire the right products for their operational needs while building reliable supplier relationships.

Comprehensive Cost and Pricing Analysis for latch pins Sourcing

What Are the Key Cost Components in Latch Pins Manufacturing?

When sourcing latch pins, understanding the cost structure is crucial for B2B buyers. The primary components include:

-

Materials: The choice of materials significantly impacts costs. Common materials for latch pins include stainless steel, zinc-plated steel, and sometimes plastic. High-quality materials often lead to higher prices but provide better durability and resistance to corrosion.

-

Labor: Labor costs can vary greatly depending on the region of production. In regions with higher labor costs, such as Europe, the overall price of latch pins may be elevated. Conversely, sourcing from countries with lower labor costs, such as some parts of Africa or South America, may offer savings.

-

Manufacturing Overhead: This includes costs associated with factory operation, equipment maintenance, and utilities. Efficient manufacturing processes can lower overhead, making it essential for buyers to consider the supplier’s operational efficiencies.

-

Tooling: Custom latch pins often require specialized tooling, which can increase initial costs. For bulk orders, however, these costs can be amortized over a larger number of units, reducing the per-unit price.

-

Quality Control (QC): Ensuring that latch pins meet specified standards involves QC processes, which can add to costs. Buyers should inquire about the QC measures taken by suppliers, as this impacts product reliability.

-

Logistics: Shipping and handling costs are crucial, especially for international transactions. Consideration of shipping methods, distance, and import tariffs can significantly affect the total cost.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding the competitive landscape can help buyers negotiate better prices.

How Do Price Influencers Affect Latch Pin Costs?

Several factors influence the pricing of latch pins, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit prices due to economies of scale. Negotiating MOQs can be beneficial for buyers looking to maximize cost efficiency.

-

Specifications and Customization: Custom latch pins tailored to specific applications may incur additional costs. Standardized products usually have more competitive pricing.

-

Quality and Certifications: Higher quality standards and certifications (e.g., ISO, CE) may result in increased costs but can ensure better performance and compliance, particularly in regulated industries.

-

Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Established suppliers may charge more due to their reliability, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: The terms of shipment (e.g., FOB, CIF) can significantly influence the total cost. Understanding these terms is essential for budgeting and financial planning.

What Tips Can Help Buyers Negotiate Better Prices for Latch Pins?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several negotiation strategies and considerations to keep in mind:

Illustrative image related to latch pins

-

Leverage Volume Discounts: If your company regularly purchases latch pins, consider negotiating for bulk purchase discounts. Suppliers are often willing to provide better rates for committed long-term orders.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like durability, maintenance, and potential failure rates to evaluate the long-term value of your purchase.

-

Be Aware of Currency Fluctuations: International transactions may involve currency risks. Locking in prices or using forward contracts can mitigate this risk.

-

Research Local Market Prices: Understanding what similar products cost in your region can provide leverage during negotiations.

-

Build Relationships with Suppliers: Establishing a good rapport can lead to better terms and preferential pricing. Suppliers are often more willing to negotiate with trusted partners.

Conclusion

While indicative pricing for latch pins can range from as low as $2 for basic models to upwards of $45 for specialized designs, these prices can fluctuate based on the factors outlined above. Buyers should approach sourcing with a comprehensive understanding of the cost structure and price influencers to make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing latch pins With Other Solutions

In the realm of fasteners and securing mechanisms, latch pins are a popular choice due to their reliability and versatility. However, as with any component, it’s essential to consider viable alternatives that may better suit specific applications or requirements. This section delves into a comparative analysis of latch pins against alternative fastening solutions, providing B2B buyers with the insights needed to make informed decisions.

| Comparison Aspect | Latch Pins | Locking Pins (with Folding Latch) | Cotter Pins |

|---|---|---|---|

| Performance | High strength; quick release | Secure under pressure; durable | Basic fastening; limited use |

| Cost | Moderate ($15 – $45) | Moderate ($18) | Low ($3 – $10) |

| Ease of Implementation | Simple installation | Requires alignment for locking | Quick to use |

| Maintenance | Low maintenance | Moderate (occasional lubrication) | Low maintenance |

| Best Use Case | General applications | Permanent joins under pressure | Temporary fastening |

How Do Locking Pins with Folding Latches Compare to Latch Pins?

Locking pins with folding latches offer a robust alternative to latch pins, especially in applications requiring a secure hold under pressure. Made from durable materials, these pins are designed to withstand axial forces and provide a definitive locking mechanism, making them ideal for heavy-duty applications. However, their installation may require more precision due to the need for proper alignment, which could slow down the assembly process in high-volume manufacturing settings.

What Are the Advantages of Using Cotter Pins Over Latch Pins?

Cotter pins serve as a simpler, cost-effective alternative for fastening applications, especially in scenarios where a temporary hold is acceptable. Priced lower than latch pins, they are easy to install and remove, making them suitable for quick fixes or less demanding environments. However, cotter pins may not provide the same level of strength or security as latch pins, limiting their use in critical applications where durability is paramount.

Conclusion: Which Fastening Solution Should a B2B Buyer Choose?

When selecting between latch pins and their alternatives, B2B buyers should assess their specific application requirements. If the application demands quick release and versatility, latch pins are an excellent choice. However, for scenarios that require a more secure fastening under load, locking pins with folding latches might be preferable. Cotter pins, while economical, are best suited for temporary solutions. By understanding the strengths and weaknesses of each option, buyers can make more informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for latch pins

What Are the Essential Technical Properties of Latch Pins?

When selecting latch pins for various applications, several technical properties should be prioritized to ensure product reliability and performance. Here are some critical specifications:

-

Material Grade

Latch pins are typically made from various materials, including stainless steel, carbon steel, and zinc-plated steel. The material grade affects the pin’s strength, corrosion resistance, and overall durability. For instance, stainless steel offers excellent resistance to rust and is ideal for outdoor applications, while carbon steel is often more cost-effective for indoor use. B2B buyers must consider the environment where the latch pin will be used to select the appropriate material. -

Diameter and Length Specifications

The diameter and length of latch pins are crucial for their fit and functionality. These dimensions must align with the specifications of the components they are securing. Tolerance levels in these measurements ensure that latch pins fit snugly without excessive force. A mismatch can lead to operational failures, making it vital for buyers to verify these specifications against their application requirements. -

Load Capacity

Each latch pin has a defined load capacity, indicating how much weight it can support without failure. This property is especially important in industrial and agricultural settings where latch pins may be subjected to significant forces. Buyers should assess the expected load conditions to choose latch pins that can safely handle the required weight. -

Corrosion Resistance

Corrosion resistance is a significant property, especially for latch pins exposed to moisture or harsh chemicals. Different finishes, such as galvanization or powder coating, enhance a pin’s resistance to environmental factors. Selecting a latch pin with adequate corrosion resistance can extend its lifespan and reduce maintenance costs. -

Spring Action Mechanism

Many latch pins feature a spring action mechanism that allows for quick engagement and disengagement. This feature is particularly beneficial in applications where frequent access is required. Buyers should evaluate whether a spring-loaded design aligns with their operational needs for efficiency and convenience.

What Are Common Trade Terms Related to Latch Pins?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are several common terms associated with latch pins:

Illustrative image related to latch pins

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are sold under another company’s brand name. Buyers should consider whether they are purchasing latch pins directly from OEMs, as this can affect product quality and warranty. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is crucial for B2B transactions as it impacts inventory management and purchasing strategies. Buyers must assess their needs against the MOQ to avoid overstocking or running short. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. This process allows buyers to compare options from different suppliers and negotiate better terms. An effective RFQ can lead to significant cost savings and improved supplier relationships. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Understanding these terms is vital for logistics and shipping arrangements, ensuring that both parties are aware of their obligations regarding costs, risks, and delivery. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving it. This is a critical factor in supply chain management. Buyers should inquire about lead times when sourcing latch pins to ensure they can meet their project timelines.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions when sourcing latch pins, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the latch pins Sector

What Are the Key Market Dynamics and Trends Influencing the Latch Pins Sector?

The latch pins sector is experiencing notable shifts driven by globalization, technological advancements, and evolving buyer expectations. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly influenced by demand for high-quality, durable fasteners. As industries such as automotive, construction, and manufacturing expand, the need for reliable components like latch pins becomes critical. Emerging technologies, such as automation and IoT, are reshaping production processes, leading to faster turnaround times and improved quality control.

Moreover, the shift towards online procurement platforms is making it easier for international buyers to source latch pins from diverse suppliers. These platforms provide real-time data on pricing, availability, and specifications, allowing buyers to make informed decisions. Additionally, a growing emphasis on just-in-time inventory management is prompting companies to seek suppliers who can offer flexible order quantities and rapid delivery options.

Another significant trend is the increasing demand for customized latch pins. As industries strive for greater efficiency, the ability to tailor products to specific applications is becoming paramount. This customization trend is especially prevalent in sectors like agriculture and heavy machinery, where latch pins must meet unique operational requirements.

How Important Is Sustainability and Ethical Sourcing in the Latch Pins Market?

Sustainability and ethical sourcing have emerged as critical considerations for B2B buyers in the latch pins sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt more responsible practices. Suppliers are increasingly held accountable for their production methods, and buyers are prioritizing partnerships with manufacturers that demonstrate a commitment to sustainability.

This shift is reflected in the growing demand for “green” certifications and materials. Buyers are looking for latch pins made from recycled or environmentally friendly materials, as well as those produced using energy-efficient processes. Certifications such as ISO 14001 (Environmental Management) and the use of eco-friendly coatings are becoming significant differentiators in the market.

Illustrative image related to latch pins

Furthermore, ethical supply chains are gaining traction, with buyers seeking assurance that their suppliers adhere to fair labor practices and responsible sourcing. Transparency in sourcing and production processes is becoming a key requirement, as companies aim to enhance their corporate social responsibility (CSR) profiles. By aligning with suppliers who prioritize ethical practices, businesses can not only mitigate risks but also bolster their brand reputation in an increasingly conscious marketplace.

How Have Latch Pins Evolved Over Time?

The evolution of latch pins reflects broader technological and industrial advancements. Historically, latch pins were simple mechanical devices used in various applications, primarily in agriculture and basic machinery. However, as manufacturing techniques have advanced, so too have the designs and materials used in latch pin production.

In recent decades, the introduction of high-strength materials and precision engineering has led to the development of more durable and reliable latch pins. Modern latch pins are now designed to withstand extreme conditions, including high pressure and corrosive environments, making them essential components in sectors such as automotive, aerospace, and construction. Furthermore, the integration of smart technologies has paved the way for innovations in latch pin design, with features such as locking mechanisms that enhance security and ease of use.

Illustrative image related to latch pins

As the market continues to evolve, latch pins are expected to become even more specialized, catering to the unique needs of diverse industries and applications. This evolution presents significant opportunities for B2B buyers to leverage advanced products that enhance operational efficiency and safety in their respective sectors.

Frequently Asked Questions (FAQs) for B2B Buyers of latch pins

-

How do I solve issues with latch pins not securing properly?

To resolve problems with latch pins not securing properly, first ensure that the latch pin is the correct size and type for your application. Inspect the pin for wear or damage, as a defective pin can fail to engage properly. Additionally, verify that the mounting holes are aligned and free from debris. If the latch pin is meant to bear load, consider switching to a heavy-duty option or one with a locking mechanism for added security. If problems persist, consulting with the supplier for recommendations on compatible products may be beneficial. -

What is the best latch pin for heavy-duty applications?

For heavy-duty applications, look for latch pins made from high-strength materials such as stainless steel or zinc-plated steel, which offer enhanced durability and corrosion resistance. Heavy-duty spring-loaded latch pins with a locking mechanism are ideal for applications that require secure fastening under load. Brands that specialize in industrial fasteners, like KIPP or Everbilt, provide reliable options. It’s also important to consider the pin diameter and length to ensure compatibility with your specific application. -

What customization options are available for latch pins?

Many manufacturers offer customization options for latch pins, including size, material, and finish. You can request specific dimensions to fit unique applications or select materials that meet environmental conditions, such as corrosion-resistant coatings for outdoor use. Additionally, some suppliers provide the option to add features like locking mechanisms or specific color finishes for easy identification. Engaging with suppliers early in the sourcing process can help you understand the full range of customization options available. -

What are the minimum order quantities (MOQ) for latch pins?

Minimum order quantities (MOQ) for latch pins can vary significantly depending on the supplier and the specific product. Generally, MOQs can range from 50 to 500 units. For customized products, MOQs may be higher due to the production setup. It’s advisable to discuss your needs with suppliers, as some may offer flexibility in MOQs, especially for first-time orders or ongoing partnerships. Consider consolidating orders with other components to meet MOQ requirements efficiently. -

How can I vet suppliers of latch pins effectively?

To vet suppliers effectively, start by researching their reputation within the industry. Look for reviews, testimonials, and case studies from other B2B buyers. Check if the supplier holds relevant certifications, such as ISO, which indicate adherence to quality standards. Request samples of the latch pins to evaluate their quality firsthand. Additionally, assess their communication responsiveness and willingness to engage in discussions about your specific requirements, as this can reflect their customer service ethos. -

What payment terms are common when sourcing latch pins internationally?

Common payment terms for international sourcing of latch pins include options such as advance payment, letter of credit, and net 30 or 60 days after shipment. Many suppliers may require a deposit upfront, particularly for custom orders. It’s essential to clarify these terms before placing an order and to consider using secure payment methods, such as PayPal or bank transfers, to protect your financial interests. Establishing a good relationship with the supplier can also lead to more favorable payment terms over time. -

What quality assurance measures should I expect from latch pin suppliers?

Reputable latch pin suppliers typically implement rigorous quality assurance measures, including material testing, dimensional inspections, and functionality tests to ensure product reliability. They should provide certifications for the materials used and be willing to share their quality control processes. When sourcing, inquire about their return policy and warranty options, as these can provide additional assurance regarding product quality and supplier accountability. -

How do logistics and shipping impact the sourcing of latch pins?

Logistics and shipping play a crucial role in the sourcing of latch pins, particularly for international buyers. Factors such as shipping costs, delivery times, and customs regulations can significantly impact the overall procurement process. It’s important to discuss shipping options with your supplier, including freight forwarders they recommend. Additionally, consider potential delays due to customs clearance, especially in regions with strict regulations. Planning for these logistics challenges in advance can help ensure timely delivery and minimize disruptions to your operations.

Top 4 Latch Pins Manufacturers & Suppliers List

1. Kipp – Locking Pins with Folding Latch

Domain: kippusa.com

Registered: 2012 (13 years)

Introduction: {“productId”:”agid.32729″,”price”:18.03,”name”:”Locking pins, steel with folding latch”,”material”:”Steel electro zinc-plated”,”description”:”Locking pins with folding latch are used for fast and easy fixing as well as for permanent joining of movable parts and workpieces. The wide folding latch secures parts over a large cross section and can work under pressure in the axial direction. Indexing s…

2. John Deere – PF Parts Latch Pin

Domain: pfparts.com

Registered: 2004 (21 years)

Introduction: {“name”: “PF Parts Latch Pin”, “price”: “15.00 USD”, “sku”: “PF210894-1”, “category”: “Combine Upgrades”, “brands”: “John Deere”, “series”: “S/STS”, “condition”: “New”, “company_name”: “Precision Farm Parts, Inc.”, “address”: “305 Main Street, Sherwood, ND 58782”, “contact_number”: “701-459-2771”, “operating_hours”: {“Monday”: “8:00AM – 5:00PM”, “Tuesday”: “8:00AM – 5:00PM”, “Wednesday”: “8:00AM –…

3. McMaster – Spring Loaded Latch Pins

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Spring Loaded Latch Pins, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Hay Chix® – Quick Latch Pin

Domain: haychix.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “Hay Chix® Quick Latch Pin”, “regular_price”: “$3.00”, “sale_price”: “$3.00”, “description”: “Use this pin to ‘lock up’ your Quick Latch! This pin was made specifically for the Hay Chix® Quick Latch.”, “note”: “This product does not include the Hay Chix® Quick Latch.”}

Strategic Sourcing Conclusion and Outlook for latch pins

In conclusion, the strategic sourcing of latch pins is vital for international B2B buyers seeking reliability and efficiency in their operations. By understanding the diverse range of latch pins available—from cotter pins to heavy-duty spring-loaded options—companies can select products that not only meet their specific needs but also enhance operational efficiency.

Investing in quality latch pins ensures durability and performance, reducing the risk of equipment failure and subsequent downtime. Moreover, sourcing from reputable suppliers can lead to cost savings and improved supply chain stability, especially for businesses in emerging markets in Africa and South America.

As we look to the future, it is essential for buyers to engage in proactive sourcing strategies that prioritize quality, supplier relationships, and innovation. Embrace the opportunity to explore new markets and technologies, and consider integrating sustainable practices into your sourcing processes. By doing so, your business can thrive in an increasingly competitive landscape. Take the next step in optimizing your supply chain and ensure you have the right latch pins to support your growth and success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.