Is Your Raching Humidor Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for raching humidor

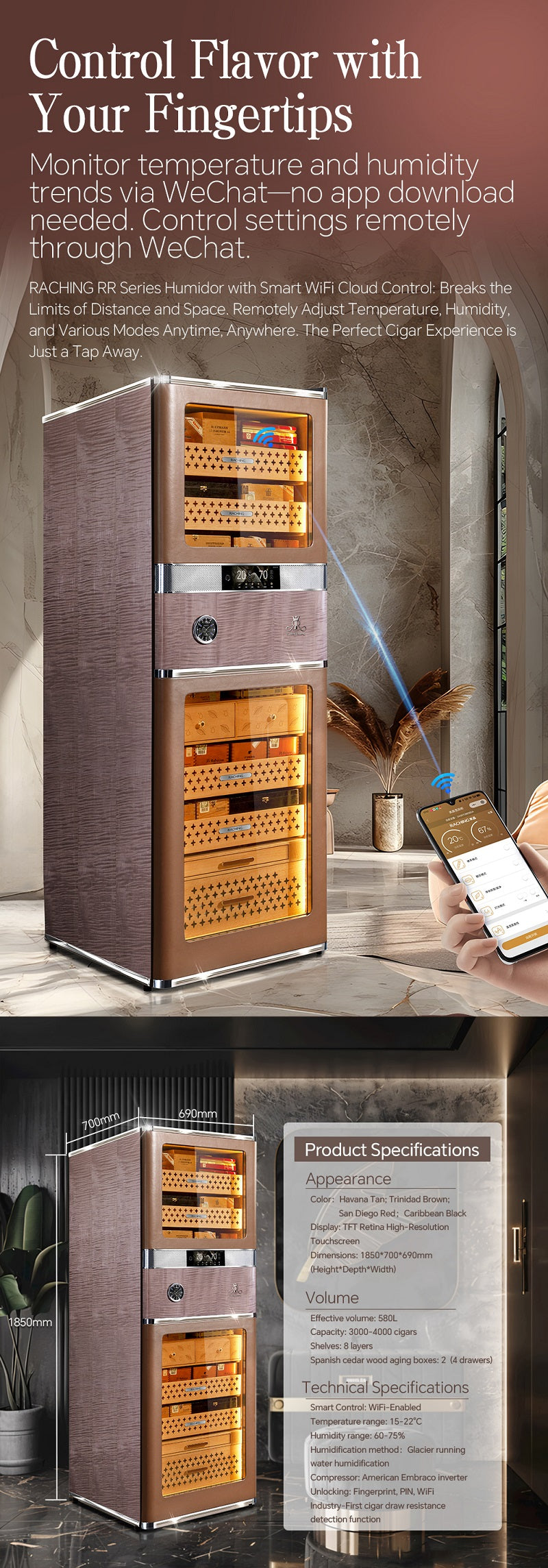

In today’s dynamic global market, sourcing high-quality raching humidors can pose significant challenges for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Germany. With the increasing demand for premium cigar storage solutions, it is essential for buyers to navigate a complex landscape filled with diverse product options, varying standards, and fluctuating prices. This comprehensive guide is designed to empower international buyers by providing insights into various types of raching humidors, their applications, and the critical aspects of supplier vetting.

Throughout this guide, we will explore the different categories of humidors available, including climate-controlled cabinets and innovative smart solutions. We will also address key considerations such as cost implications, shipping logistics, and compliance with regional regulations. Additionally, buyers will gain valuable knowledge on how to assess suppliers effectively, ensuring they choose partners that align with their quality and service expectations.

By the end of this guide, B2B buyers will be equipped with the essential tools and insights to make informed purchasing decisions, ultimately enhancing their product offerings and customer satisfaction in an increasingly competitive market. Whether you are a distributor, retailer, or an end-user, understanding the nuances of sourcing raching humidors will enable you to capitalize on the opportunities presented by this thriving industry.

Understanding raching humidor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Humidor | Durable, corrosion-resistant materials; modern aesthetic | Luxury cigar retailers, upscale lounges | Pros: Long-lasting, easy to clean. Cons: Higher initial cost. |

| Precision Electronic Humidor | Advanced humidity and temperature control; digital displays | High-end cigar shops, private collections | Pros: Accurate climate control, user-friendly. Cons: Requires power source. |

| Climate-Controlled Cabinet | Maintains optimal conditions for various cigar types | Cigar distributors, event venues | Pros: Versatile, accommodates diverse inventory. Cons: Larger footprint. |

| Cigar Aging Cabinet | Specialized for aging cigars to enhance flavor | Cigar manufacturers, specialty retailers | Pros: Improves cigar quality, tailored for aging. Cons: May require additional monitoring. |

| Travel Humidor | Portable design, often with built-in humidification | Retailers targeting on-the-go consumers | Pros: Convenient, lightweight. Cons: Limited storage capacity. |

What are the Key Characteristics of Stainless Steel Humidors?

Stainless steel humidors are designed for durability and aesthetic appeal, making them a preferred choice for luxury cigar retailers and upscale lounges. Their corrosion-resistant properties ensure longevity, while their modern design complements high-end environments. Buyers should consider the initial investment, as these models tend to be more expensive than traditional wood humidors. Additionally, the ease of cleaning and maintenance is a significant advantage, particularly in high-traffic retail settings.

How Do Precision Electronic Humidors Enhance Cigar Storage?

Precision electronic humidors utilize advanced technology to maintain optimal humidity and temperature levels, often featuring digital displays for easy monitoring. These are ideal for high-end cigar shops and private collections where maintaining the integrity of cigars is paramount. While they offer superior climate control, buyers must consider the need for a power source and potential electrical maintenance. The user-friendly interface is a strong selling point, enabling both novice and experienced users to manage their cigar storage effectively.

Why Choose Climate-Controlled Cabinets for Diverse Inventory?

Climate-controlled cabinets are versatile storage solutions that cater to various cigar types, making them suitable for cigar distributors and event venues. These cabinets maintain ideal conditions to preserve the quality of cigars, accommodating a wide range of products. However, their larger footprint may pose challenges in space-limited environments. Buyers should evaluate their inventory needs and available space to ensure a good fit. The ability to store multiple types of cigars in one unit can lead to significant operational efficiencies.

What Makes Cigar Aging Cabinets Unique for Manufacturers?

Cigar aging cabinets are specifically designed to enhance the flavor profile of cigars over time, making them valuable for cigar manufacturers and specialty retailers. These cabinets create an environment that mimics the natural aging process, improving the overall quality of the cigars. However, they may require additional monitoring to ensure optimal conditions are maintained. Buyers should assess the potential return on investment through improved product quality and customer satisfaction when considering these cabinets.

How Do Travel Humidors Cater to On-the-Go Consumers?

Travel humidors provide a portable solution for cigar enthusiasts, featuring built-in humidification systems to keep cigars fresh while on the move. Retailers targeting on-the-go consumers can benefit from offering these models, which are lightweight and convenient for travel. However, buyers should note that travel humidors typically have limited storage capacity compared to larger models. When considering these products, businesses should focus on the convenience factor and the growing trend of mobile lifestyles among consumers.

Key Industrial Applications of raching humidor

| Industry/Sector | Specific Application of raching humidor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Cigar Retail | In-store cigar display and storage solutions | Enhances product quality and customer experience | Ensure humidity control, capacity, and aesthetic appeal |

| Hospitality | Cigar lounges and high-end bars | Attracts affluent clientele and enhances ambiance | Look for climate control features and design flexibility |

| Food and Beverage | Steak and sausage aging cabinets | Improves flavor profiles of premium meats | Consider temperature consistency and ease of cleaning |

| Events and Catering | Portable humidors for events and weddings | Ensures cigar quality during events | Evaluate portability, battery life, and humidity retention |

| Export and Distribution | Cigar preservation for international shipping | Maintains product integrity during transport | Focus on durability, insulation, and compliance with international standards |

How is Raching Humidor Utilized in the Cigar Retail Industry?

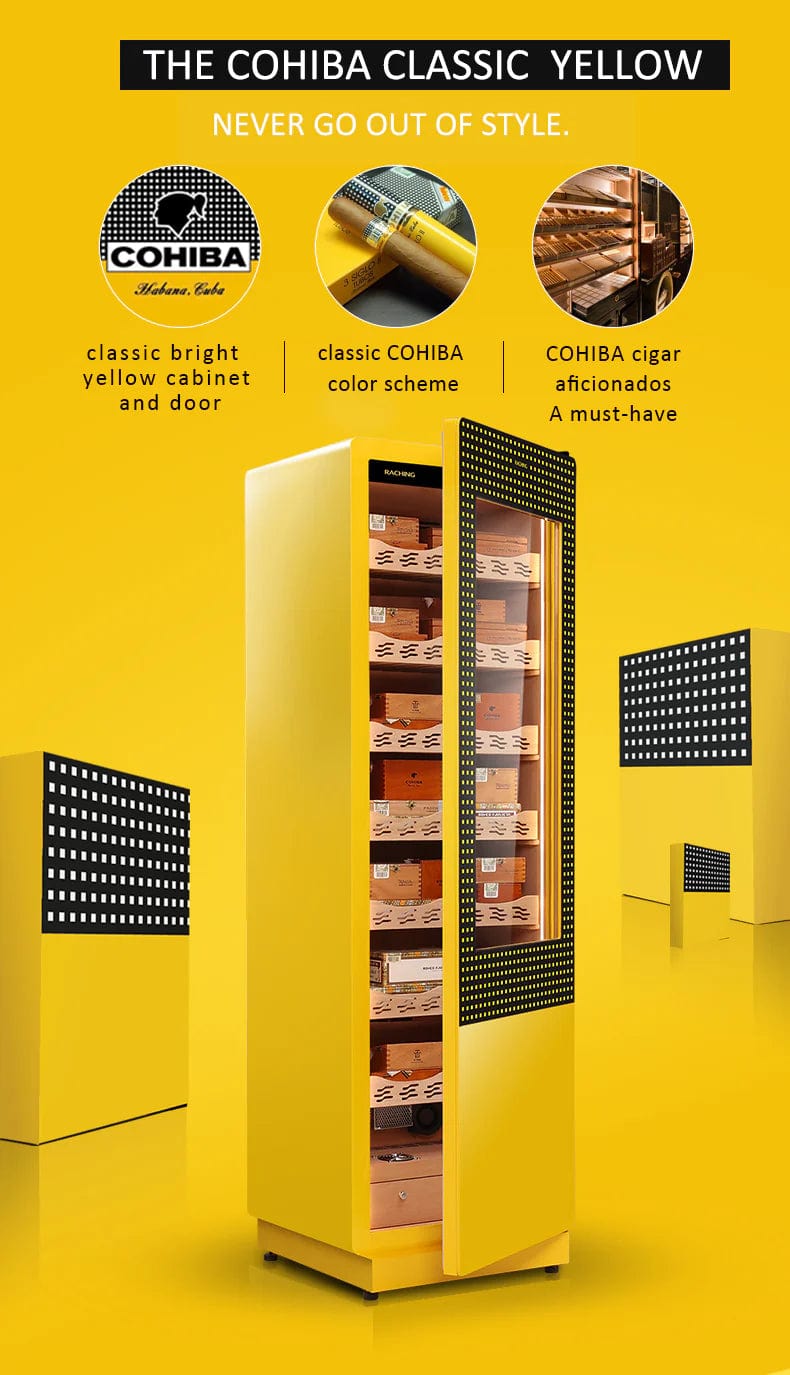

In the cigar retail sector, Raching humidors serve as essential storage and display units that maintain optimal humidity levels for cigars, ensuring they remain fresh and flavorful. Retailers benefit from an enhanced customer experience as they can showcase premium products without compromising quality. Buyers should consider the humidor’s capacity and aesthetic appeal, as these factors influence customer attraction and retention.

Why are Raching Humidors Important for the Hospitality Sector?

Cigar lounges and upscale bars utilize Raching humidors to create an inviting atmosphere for cigar enthusiasts. These units not only preserve the quality of cigars but also serve as stylish focal points within the establishment. For international buyers, features such as climate control and design flexibility are critical, as they must cater to varied climates and customer preferences.

What Role Do Raching Humidors Play in the Food and Beverage Industry?

In the food and beverage sector, Raching humidors are utilized for aging premium meats such as steak and sausage. The controlled environment enhances the flavor profiles, making the products more appealing to consumers. Buyers in this industry should prioritize temperature consistency and ease of cleaning, ensuring that the humidors meet food safety regulations while providing superior aging conditions.

How Can Portable Raching Humidors Benefit Events and Catering Services?

Portable Raching humidors are invaluable for events and catering, allowing organizers to maintain cigar quality throughout the occasion. These units ensure that cigars remain at the ideal humidity level, enhancing the overall experience for guests. Buyers should assess the portability, battery life, and humidity retention capabilities to ensure that the humidors can effectively serve their needs during various events.

Why is Raching Humidor Essential for Export and Distribution?

For businesses involved in the export and distribution of cigars, Raching humidors are crucial for preserving product integrity during transport. These humidors maintain ideal conditions that prevent damage and degradation, ensuring that cigars arrive in optimal condition. Buyers should focus on durability, insulation properties, and compliance with international shipping standards to safeguard their products in transit.

3 Common User Pain Points for ‘raching humidor’ & Their Solutions

Scenario 1: Ensuring Consistent Humidity Levels for Premium Cigar Storage

The Problem: A common challenge faced by B2B buyers, particularly those managing cigar lounges or retail outlets, is maintaining the appropriate humidity levels within their Raching humidors. Fluctuations in humidity can lead to dried-out cigars or overly moist conditions, resulting in mold growth or degradation of flavor. Buyers may struggle to find a reliable solution that guarantees consistent humidity control, especially in regions with extreme temperature variations.

The Solution: To address this issue, buyers should invest in Raching’s precision electronic humidors, which feature advanced climate control technology. These models are designed to automatically adjust humidity levels, ensuring a stable environment for cigar storage. When sourcing these humidors, it’s crucial to consider your specific climate and the volume of cigars you plan to store. Collaborating with Raching’s customer service can help tailor a solution that meets your needs. Additionally, regularly calibrating the built-in hygrometers and using high-quality distilled water for the humidification system will further enhance performance. This proactive approach minimizes risks and preserves the integrity of premium cigars.

Scenario 2: Navigating Supply Chain Challenges for Humidor Procurement

The Problem: B2B buyers often encounter supply chain disruptions that complicate the procurement of Raching humidors. Factors such as shipping delays, tariffs, and fluctuating costs can hinder timely delivery, impacting inventory levels and customer satisfaction. Buyers in regions like Africa and the Middle East may find it particularly difficult to navigate these challenges due to limited local suppliers and increased shipping times.

The Solution: To mitigate these supply chain issues, buyers should establish relationships with multiple distributors, including those that operate through platforms like Alibaba or Amazon. Diversifying suppliers not only increases reliability but also allows buyers to negotiate better terms and prices. It’s also advisable to maintain a safety stock of key models, particularly those that are high in demand. By forecasting sales and preparing for peak seasons, businesses can buffer against unforeseen delays. Additionally, leveraging Raching’s expertise in logistics can provide insights into best practices for shipping and inventory management.

Scenario 3: Addressing Maintenance and After-Sales Support for Humidors

The Problem: Many B2B buyers are concerned about the maintenance and longevity of their Raching humidors. After purchasing, they may realize that ongoing support for repairs, parts, or general inquiries is lacking, leading to frustration and operational downtime. This issue is especially critical for businesses that rely on humidors for daily operations, such as cigar shops or high-end restaurants.

The Solution: Buyers should prioritize selecting Raching models that come with robust warranties and readily available after-sales support. It is advisable to inquire about the specifics of the warranty and the availability of replacement parts during the purchasing process. Establishing a direct line of communication with Raching’s support team can facilitate quick resolutions to issues that arise. Furthermore, incorporating a scheduled maintenance routine into the operational plan can preemptively address potential problems. Regular cleaning, calibration, and checks on the humidification system will extend the lifespan of the humidor and ensure optimal performance. By taking these steps, businesses can minimize disruptions and maintain a premium cigar experience for their customers.

Strategic Material Selection Guide for raching humidor

What Are the Key Materials Used in Raching Humidors?

When selecting materials for raching humidors, it is essential to consider their properties, advantages, and limitations. The choice of material significantly impacts the performance, durability, and overall effectiveness of the humidor in maintaining optimal conditions for cigar storage. Here, we analyze four common materials used in the construction of raching humidors: wood, stainless steel, glass, and plastic.

How Does Wood Contribute to Humidor Performance?

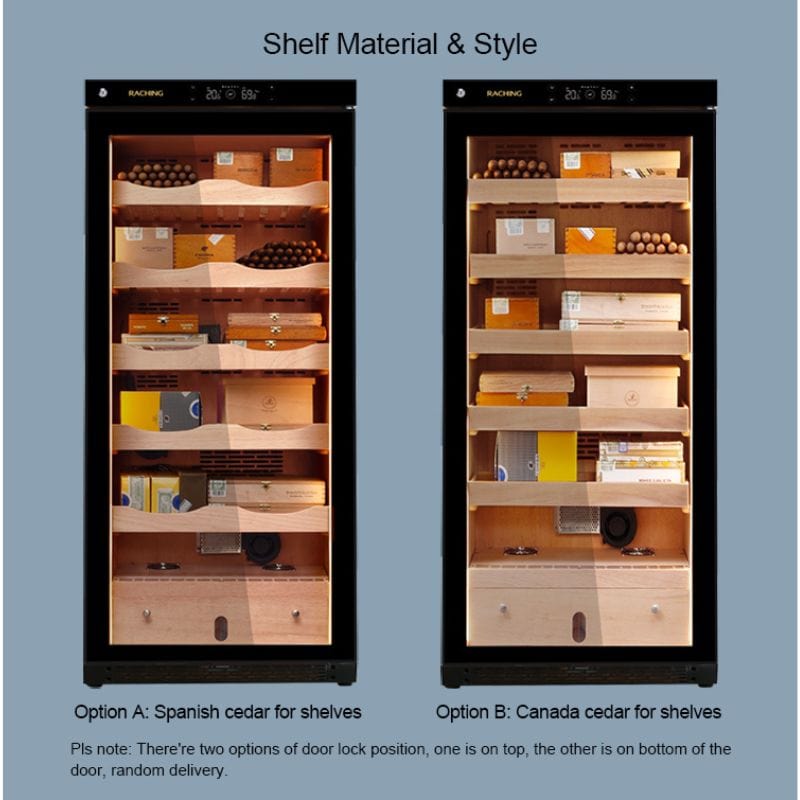

Wood, particularly Spanish cedar, is a traditional choice for humidors due to its natural properties. It has excellent moisture retention capabilities, which helps maintain the humidity levels necessary for cigar preservation. Furthermore, wood is aesthetically pleasing, providing a classic look that appeals to many cigar enthusiasts.

Pros: Wood is durable and can withstand temperature fluctuations. It also has a natural aroma that enhances the flavor of cigars.

Cons: The main drawback is that wood can be susceptible to warping and cracking over time, especially in extreme humidity or temperature conditions. Additionally, it requires careful maintenance to prevent mold growth.

For international buyers, particularly in regions with high humidity like parts of Africa and South America, it is crucial to ensure that the wood used complies with local regulations regarding sustainability and treatment processes.

What Role Does Stainless Steel Play in Humidor Design?

Stainless steel is increasingly popular in modern humidor designs due to its durability and resistance to corrosion. This material is ideal for maintaining a stable internal environment, as it does not absorb moisture or odors, which can affect the quality of the cigars.

Pros: Stainless steel is highly durable and easy to clean, making it suitable for long-term use. It also offers a sleek, contemporary aesthetic that appeals to a modern market.

Cons: The primary downside is the higher cost compared to wood and plastic. Additionally, stainless steel does not provide the same level of moisture retention as wood, which may require additional humidity control mechanisms.

For B2B buyers in Europe, particularly Germany, compliance with EU regulations on materials and manufacturing processes is essential. Buyers should also consider the energy efficiency of climate control systems used in conjunction with stainless steel humidors.

How Does Glass Enhance Visibility and Functionality?

Glass is often used in humidor designs to provide visibility of the cigars inside while maintaining a controlled environment. Tempered glass is preferred for its strength and ability to withstand temperature changes without breaking.

Pros: Glass allows for easy viewing of the cigars, enhancing the user experience. It also provides a barrier against external elements while allowing light to enter, which can be visually appealing.

Cons: Glass can be fragile and may require additional support structures to prevent breakage. It also has lower insulation properties compared to wood or stainless steel, which can lead to fluctuations in humidity levels.

International buyers should consider the shipping and handling requirements for glass components, particularly in regions like the Middle East, where extreme temperatures may affect the integrity of the glass.

What Advantages Does Plastic Offer in Humidor Construction?

Plastic is often used in budget-friendly humidors due to its lightweight and cost-effective nature. High-density polyethylene (HDPE) and polycarbonate are common choices for their durability and resistance to impact.

Illustrative image related to raching humidor

Pros: Plastic is resistant to moisture and does not corrode, making it a practical choice for humidors. It is also lightweight and easy to transport, which is advantageous for international shipping.

Cons: The primary limitation of plastic is its aesthetic appeal, which may not meet the luxury expectations of high-end cigar enthusiasts. Additionally, it may not provide the same level of humidity control as wood or stainless steel.

For B2B buyers in regions like Africa and South America, the low cost of plastic humidors can make them an attractive option for entry-level markets. However, buyers should ensure that the plastic used meets local safety and environmental standards.

Summary Table of Material Selection for Raching Humidors

| Material | Typical Use Case for raching humidor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Traditional humidors | Excellent moisture retention | Susceptible to warping and mold | Medium |

| Stainless Steel | Modern, high-end humidors | Durable and corrosion-resistant | Higher cost and lower moisture retention | High |

| Glass | Display humidors | Provides visibility of contents | Fragile and lower insulation properties | Medium |

| Plastic | Budget-friendly humidors | Lightweight and moisture-resistant | Less aesthetic appeal and humidity control | Low |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for raching humidors, ensuring they make informed decisions that align with their market needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for raching humidor

What Are the Main Stages of Manufacturing Raching Humidors?

The manufacturing process of Raching humidors is a meticulous journey that emphasizes quality, precision, and innovation. The process can generally be broken down into four main stages: material preparation, forming, assembly, and finishing.

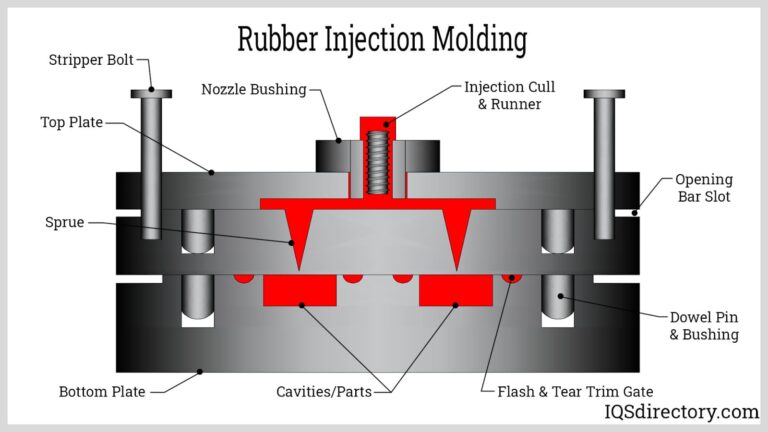

Illustrative image related to raching humidor

Material Preparation

The first stage involves sourcing high-quality materials. Raching prioritizes premium woods, stainless steel, and advanced electronic components, ensuring durability and functionality. The wood used for the humidors is often seasoned to maintain the ideal humidity levels and prevent warping. Stainless steel components are chosen for their corrosion resistance and aesthetic appeal. These materials are subjected to rigorous quality checks before they move into the production line, ensuring that only the best materials are utilized.

How Are Raching Humidors Formed?

In the forming stage, the prepared materials are cut and shaped according to design specifications. Advanced machinery is employed to achieve precise dimensions and intricate designs. For instance, the cabinets may feature sophisticated climate control systems, which require precise fittings to ensure efficiency. CNC machines and laser cutting technology are often used in this process to enhance accuracy and reduce waste.

What Does the Assembly Process Involve?

Once the components are formed, they move to the assembly stage. Skilled technicians assemble the various parts of the humidor, integrating electronic systems for humidity and temperature control. This stage is critical as it combines the craftsmanship of traditional methods with modern technology. Each humidor undergoes an initial quality control check (IQC) to ensure that all components meet the required specifications before proceeding to the next stage.

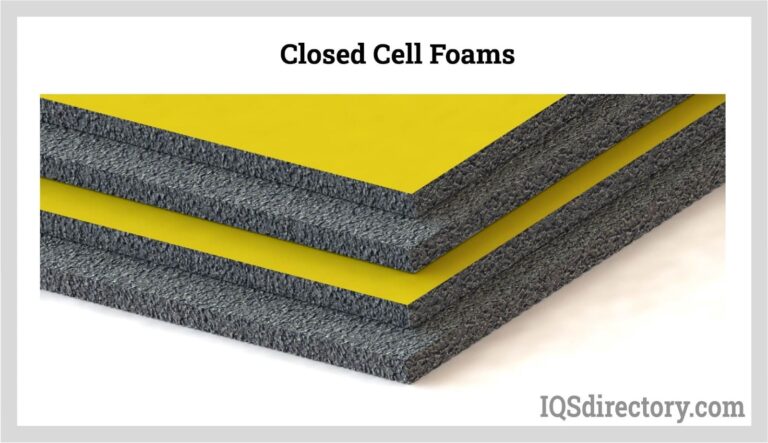

Illustrative image related to raching humidor

How Is the Finishing Touch Applied to Raching Humidors?

The final stage is finishing, where each humidor is sanded, polished, and treated with protective coatings. This not only enhances the aesthetic appeal but also adds an extra layer of durability. Humidors may also undergo a final inspection to ensure that they meet both functional and visual standards. Once the finishing is complete, the products are prepared for packaging and distribution.

What Quality Assurance Standards Are Followed in Raching Humidors Manufacturing?

Quality assurance is paramount in the manufacturing of Raching humidors, with adherence to both international and industry-specific standards. The company primarily follows ISO 9001 standards, which focus on quality management systems to enhance customer satisfaction through effective process control.

Which International Standards Are Relevant to Humidor Production?

In addition to ISO 9001, Raching complies with CE (Conformité Européenne) marking, ensuring that the products meet European safety and environmental protection standards. Furthermore, industry-specific certifications such as API (American Petroleum Institute) may apply to certain components, especially those involving electronic controls.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process at various checkpoints:

-

Incoming Quality Control (IQC): This initial inspection ensures that all raw materials meet Raching’s quality standards before entering production. Materials that do not pass this stage are rejected, minimizing defects in the final product.

-

In-Process Quality Control (IPQC): During the assembly process, technicians conduct regular checks to verify that the assembly aligns with design specifications. This ongoing scrutiny helps identify potential issues early, allowing for timely corrections.

-

Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is performed to ensure that the humidor operates correctly and meets all aesthetic and functional requirements. This includes testing the climate control system and verifying that humidity levels are within acceptable ranges.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several actionable steps:

-

Request Documentation: Buyers should ask for detailed documentation of the quality assurance processes, including IQC, IPQC, and FQC records. This documentation should outline the procedures and standards followed during production.

-

Conduct Audits: On-site audits can provide valuable insights into a supplier’s manufacturing capabilities and quality control processes. During these audits, buyers can assess compliance with international standards and evaluate the overall production environment.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These services can conduct unbiased evaluations of the manufacturing process and final products, providing reports on compliance with quality standards.

-

Review Certifications: Buyers should verify that the supplier holds relevant certifications, such as ISO 9001 and CE. These certifications not only reflect adherence to quality standards but also demonstrate a commitment to continuous improvement.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers must be aware of certain nuances related to quality control when dealing with manufacturers like Raching. One critical factor is understanding the implications of different regulatory environments across regions. For instance, standards that are acceptable in Europe may differ from those in the Middle East or Africa.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Buyers should ensure that they have clear, documented agreements on quality standards and specifications to mitigate any misunderstandings.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance in Raching Humidors

Understanding the manufacturing processes and quality assurance mechanisms behind Raching humidors is essential for B2B buyers. By focusing on meticulous manufacturing stages, adherence to international standards, and robust quality control checkpoints, Raching ensures that its products meet the highest quality standards. Buyers who engage with Raching can expect not only superior products but also a commitment to quality that aligns with their own business needs. This understanding empowers buyers to make informed decisions, fostering long-term partnerships that can thrive in the competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘raching humidor’

When sourcing a Raching humidor for your business, it’s essential to follow a structured approach to ensure you select the best product that meets your needs. This guide provides a checklist of actionable steps to help you navigate the procurement process effectively.

Illustrative image related to raching humidor

Step 1: Define Your Technical Specifications

Begin by outlining the specific features and functionalities you require in a humidor. This includes the size, capacity, climate control capabilities, and materials used in construction. Understanding your needs will help you narrow down options and communicate effectively with suppliers.

- Capacity Requirements: Consider how many cigars you need to store and whether you anticipate future growth.

- Climate Control Features: Determine if you need advanced features like humidity control or ammonia removal, which are crucial for preserving cigar quality.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of Raching humidors. Look for companies with a strong track record in the industry and positive reviews from previous customers.

- Supplier Background: Investigate how long the supplier has been in business and their experience with similar products.

- Product Range: Ensure they offer a variety of models to meet different needs, such as the Raching CT48A or MA50.

Step 3: Evaluate Supplier Certifications

Before making any decisions, verify that potential suppliers have the necessary certifications and adhere to international standards. This step is critical for ensuring product quality and compliance with regulations.

- Quality Certifications: Look for ISO certifications or other relevant standards that demonstrate a commitment to quality.

- Product Testing: Inquire about any testing procedures the supplier employs to guarantee product reliability.

Step 4: Request Product Samples

Obtaining samples of the Raching humidors you are considering allows you to evaluate their quality firsthand. This step can help avoid costly mistakes down the line.

- Assessment of Build Quality: Examine the materials, craftsmanship, and overall design.

- Functional Testing: Check features like humidity control and temperature settings to ensure they meet your specifications.

Step 5: Compare Pricing and Terms

Once you have a shortlist of suppliers, compare their pricing structures and terms of sale. This includes not just the unit price but also shipping costs, payment terms, and warranty options.

Illustrative image related to raching humidor

- Bulk Discounts: Inquire if the supplier offers discounts for bulk purchases, which can significantly reduce costs.

- Warranty and Support: Understand the warranty terms and the level of after-sales support provided.

Step 6: Assess Delivery and Logistics

Confirm the supplier’s ability to meet your delivery timelines and logistics requirements. Timely delivery is crucial for maintaining your inventory and meeting customer demands.

- Shipping Options: Evaluate the available shipping methods and associated costs.

- Lead Times: Understand how long it will take for your order to be processed and shipped.

Step 7: Finalize Your Order and Establish Communication

After selecting your supplier, finalize the order while ensuring clear communication regarding all terms. Establish a point of contact for ongoing support and queries.

- Order Confirmation: Ensure all details are confirmed in writing, including specifications, pricing, and delivery schedules.

- Ongoing Communication: Maintain regular contact to address any issues that may arise during the fulfillment process.

By following this checklist, you can effectively navigate the procurement of Raching humidors and ensure a successful partnership with your chosen supplier.

Comprehensive Cost and Pricing Analysis for raching humidor Sourcing

What Are the Key Cost Components in Raching Humidor Sourcing?

When sourcing Raching humidors, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The choice of materials significantly impacts the cost. Raching humidors often utilize high-quality woods, stainless steel, and advanced electronic components for climate control. The selection of premium materials enhances durability and aesthetic appeal but also raises the overall price.

Labor: Labor costs can vary based on the region of production. In China, where Raching is based, labor costs are generally lower than in Europe or the Middle East. However, skilled labor is essential for the intricate assembly of humidors, particularly for models that feature advanced technology.

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Raching’s commitment to quality means investing in advanced manufacturing technologies, which can increase overhead costs but also improve efficiency and product quality.

Illustrative image related to raching humidor

Tooling: Custom tooling may be necessary for specific designs or features, contributing to initial setup costs. Buyers should consider these costs when requesting customized humidors.

Quality Control: Rigorous QC processes ensure that each unit meets international standards. This involves additional testing and inspections, which contribute to the overall cost but are vital for maintaining brand integrity.

Logistics: Shipping costs are influenced by the Incoterms agreed upon, shipping volume, and destination. International buyers should factor in customs duties and tariffs, particularly for imports into regions like Africa and South America.

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on competition and demand. Understanding this margin helps buyers negotiate better deals.

Illustrative image related to raching humidor

How Do Price Influencers Affect Raching Humidor Costs?

Several price influencers can affect the total cost of Raching humidors, including order volume, specifications, materials, and supplier factors.

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs. Buyers should assess their demand to negotiate favorable pricing based on volume.

Specifications and Customization: Custom features, such as advanced climate control options or unique designs, can significantly increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

Illustrative image related to raching humidor

Materials and Quality Certifications: The use of certified materials, such as eco-friendly woods or high-grade electronic components, can elevate costs. Buyers should inquire about certifications to ensure quality without compromising on price.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers like Raching may offer premium products at a higher price, reflecting their brand reputation and product reliability.

Incoterms: Understanding shipping terms is essential. DDP (Delivered Duty Paid) terms may involve higher upfront costs but simplify logistics for buyers, while FOB (Free on Board) may require buyers to manage shipping and customs.

Illustrative image related to raching humidor

What Are the Best Tips for B2B Buyers When Sourcing Raching Humidors?

International B2B buyers should adopt strategic approaches to enhance cost-efficiency in sourcing Raching humidors.

Negotiation: Engage suppliers in discussions about pricing, especially for bulk purchases. Highlight your potential as a long-term partner to leverage better terms.

Cost-Efficiency: Evaluate total cost of ownership, including maintenance and operational costs, when assessing the price of humidors. A higher initial investment in quality humidors can lead to savings in the long run.

Pricing Nuances: Be aware of fluctuating exchange rates and regional market conditions that may affect pricing. Buyers from Europe, the Middle East, or Africa should consider these factors in their purchasing strategy.

Illustrative image related to raching humidor

Research and Benchmarking: Conduct market research to benchmark prices across different suppliers. Understanding the competitive landscape can empower buyers during negotiations.

Shipping and Customs: Factor in all logistics costs, including potential delays and customs fees, to avoid surprises. Engage a reliable freight forwarder familiar with the region for smoother transactions.

Conclusion

Sourcing Raching humidors involves navigating a complex landscape of costs and pricing influencers. By understanding the cost components, recognizing the price influencers, and employing strategic negotiation techniques, international B2B buyers can make informed decisions that lead to successful procurement. Always remember that pricing can vary, so it’s advisable to obtain multiple quotes and ensure transparency throughout the sourcing process.

Alternatives Analysis: Comparing raching humidor With Other Solutions

Understanding Alternatives in Cigar Humidification Solutions

In the world of cigar storage, maintaining optimal humidity and temperature is essential to preserve flavor and freshness. While Raching humidors are a popular choice, various alternatives exist that cater to different needs and preferences. This analysis compares Raching humidors with two viable alternatives: traditional wooden humidors and electronic humidity control systems. By evaluating these options, international B2B buyers can make informed decisions tailored to their specific requirements.

Illustrative image related to raching humidor

Comparison Table

| Comparison Aspect | Raching Humidor | Traditional Wooden Humidor | Electronic Humidity Control System |

|---|---|---|---|

| Performance | Maintains precise humidity and temperature levels | Varies based on quality; may fluctuate | Highly accurate and adjustable settings |

| Cost | $1,299 – $7,399 USD | $200 – $1,500 USD | $300 – $2,000 USD |

| Ease of Implementation | Plug-and-play setup | Simple setup; requires manual monitoring | May require installation and calibration |

| Maintenance | Low maintenance; periodic checks | Requires regular seasoning and monitoring | Moderate; periodic component replacement needed |

| Best Use Case | Large collections; climate-sensitive cigars | Casual users; occasional storage | Professional settings; high-value collections |

Detailed Breakdown of Alternatives

Traditional Wooden Humidors

Traditional wooden humidors, often made from Spanish cedar, are a classic choice for cigar enthusiasts. They naturally regulate humidity through the wood’s moisture-retaining properties. However, their performance can be inconsistent based on the quality of construction and the ambient environment. While they are generally more affordable, ranging from $200 to $1,500, they require regular maintenance, such as seasoning and humidity monitoring. This option is best suited for casual users or those with smaller collections who appreciate the aesthetic appeal of wooden designs.

Electronic Humidity Control Systems

Electronic humidity control systems offer advanced features for precise humidity and temperature management. These systems typically include sensors and digital displays, allowing users to adjust settings according to specific needs. While they tend to be more expensive than traditional wooden humidors, costing between $300 and $2,000, they provide a high level of accuracy and require moderate maintenance, including periodic replacement of components. Ideal for professional settings or high-value collections, these systems ensure optimal conditions for cigar preservation, minimizing risks of damage due to fluctuating environmental factors.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate humidification solution depends on various factors, including budget, collection size, and user expertise. Raching humidors excel in performance and convenience, making them suitable for serious collectors and businesses focused on quality assurance. In contrast, traditional wooden humidors offer a nostalgic charm with lower costs, ideal for casual users. Meanwhile, electronic humidity control systems cater to professionals seeking precision and reliability. By carefully evaluating these aspects, B2B buyers can make an informed choice that aligns with their operational goals and enhances their cigar preservation strategy.

Essential Technical Properties and Trade Terminology for raching humidor

What Are the Key Technical Properties of a Raching Humidor?

When selecting a Raching humidor, several technical properties play a crucial role in ensuring optimal storage conditions for cigars. Understanding these specifications can help buyers make informed decisions that align with their business needs.

-

Material Grade:

Raching humidors are typically constructed from high-grade materials like stainless steel and premium woods. Stainless steel offers durability and resistance to corrosion, while wood, particularly Spanish cedar, is favored for its moisture retention and aroma-enhancing properties. For B2B buyers, the material grade affects not only the longevity of the product but also its aesthetic appeal, crucial for retail environments. -

Temperature Control Range:

A critical specification for any humidor is its ability to maintain a consistent temperature, typically between 65°F and 75°F (18°C to 24°C). This feature is vital for preserving the quality of cigars, as temperature fluctuations can lead to spoilage. For businesses, reliable temperature control means reduced losses and enhanced customer satisfaction. -

Humidity Control Mechanism:

Raching humidors often incorporate advanced humidity control systems, such as electronic humidifiers, which maintain optimal humidity levels of 65% to 75%. Maintaining proper humidity is essential to prevent cigars from drying out or becoming too moist, which can compromise flavor. For distributors, understanding the humidity control technology can facilitate better inventory management and customer education. -

Capacity:

The storage capacity of a humidor is measured in the number of cigars it can hold, ranging from smaller models (holding around 50 cigars) to larger cabinets (holding over 1,200). Capacity is a critical consideration for retailers and wholesalers, as it directly impacts inventory management and sales potential. -

Energy Efficiency:

With growing environmental concerns, energy efficiency is becoming increasingly important. Raching humidors are designed to consume less energy while maintaining optimal conditions. This property is not only beneficial for reducing operational costs but also aligns with sustainability goals, making it a selling point for environmentally conscious buyers.

What Are Common Trade Terms in the Raching Humidor Industry?

Understanding industry terminology is essential for navigating the B2B landscape, especially when dealing with international suppliers and customers. Here are some common terms relevant to Raching humidors:

Illustrative image related to raching humidor

-

OEM (Original Equipment Manufacturer):

This term refers to companies that manufacture products based on specifications provided by another company, typically for resale under the latter’s brand. For businesses sourcing Raching humidors, understanding OEM arrangements can lead to customized products that meet specific market demands. -

MOQ (Minimum Order Quantity):

MOQ is the smallest quantity of a product that a supplier is willing to sell. It’s crucial for B2B buyers to be aware of the MOQ, as it affects inventory costs and cash flow. Negotiating MOQs can lead to more favorable purchasing terms and better inventory management. -

RFQ (Request for Quotation):

An RFQ is a formal document used to solicit price quotes from suppliers. In the context of Raching humidors, an RFQ helps businesses compare pricing, terms, and conditions from multiple suppliers, ensuring they secure the best deal. -

Incoterms:

These are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping costs, insurance, and risk management when importing Raching humidors from manufacturers. -

Lead Time:

Lead time refers to the time it takes from placing an order to receiving the product. For businesses, understanding lead times is crucial for planning inventory levels and ensuring timely deliveries to customers. -

Warranty Period:

This term refers to the duration during which a product is guaranteed against defects. Knowing the warranty period for Raching humidors can provide peace of mind and protect against unexpected costs, making it an essential factor for B2B buyers when evaluating suppliers.

By grasping these technical properties and trade terms, B2B buyers can navigate the Raching humidor market more effectively, ensuring they make informed purchasing decisions that align with their operational goals.

Navigating Market Dynamics and Sourcing Trends in the raching humidor Sector

Market Overview & Key Trends in the Raching Humidor Sector

The global humidor market is experiencing a dynamic transformation, driven by rising disposable incomes, growing cigar consumption, and an increasing appreciation for premium tobacco products. In regions like Africa, South America, the Middle East, and Europe, particularly in markets such as Saudi Arabia and Germany, the demand for high-quality storage solutions is surging. B2B buyers are increasingly seeking advanced technology in humidors, including climate control systems and smart features that ensure optimal storage conditions for cigars.

Emerging trends indicate a shift towards customization and personalization in product offerings. International buyers are not only looking for functionality but also for unique designs that reflect their brand identity. The integration of technology, such as humidity sensors and automated monitoring, is becoming essential. Additionally, e-commerce platforms are playing a pivotal role in sourcing, enabling buyers to access a wider range of products and suppliers with greater ease.

The market dynamics also reflect a competitive landscape where manufacturers like Raching are leveraging their production capabilities and technological advancements to meet the diverse needs of international buyers. Partnerships with logistics providers and distributors are crucial for ensuring timely deliveries and maintaining supply chain efficiency, which are key considerations for B2B buyers in this sector.

How Does Sustainability & Ethical Sourcing Impact B2B in the Raching Humidor Sector?

As environmental consciousness grows, sustainability is becoming a critical factor in the purchasing decisions of B2B buyers. The humidor industry is no exception, with buyers increasingly prioritizing products that are made from sustainable materials and produced through ethical practices. This shift is driven by both regulatory pressures and consumer demand for environmentally friendly products.

Illustrative image related to raching humidor

For Raching and similar manufacturers, adopting eco-friendly materials, such as sustainably sourced woods and recyclable components, can enhance their market appeal. Furthermore, obtaining green certifications can provide a competitive advantage, as these credentials assure buyers of the product’s environmental integrity.

Establishing ethical supply chains is also paramount. This includes ensuring fair labor practices, minimizing carbon footprints, and adopting responsible sourcing strategies. B2B buyers are more likely to engage with suppliers who demonstrate a commitment to sustainability, as this aligns with the increasing demand for corporate social responsibility in business operations.

What is the Brief Evolution and History of the Raching Humidor Sector?

Raching Technology Co., Ltd. was established in 2004 and has since evolved into a leader in the humidor and wine cooler market. Initially focusing on basic storage solutions, the company has expanded its product line to include advanced climate-controlled humidors and smart technology integrations. This evolution reflects broader industry trends towards automation and precision in storage solutions.

Over the years, Raching has participated in various international trade shows, such as IPCPR and InterTabac, showcasing its commitment to innovation and quality. The company’s ability to adapt to market demands has positioned it as a trusted partner for B2B buyers looking for high-quality humidors that not only preserve the integrity of cigars but also enhance the overall user experience. As the market continues to grow, Raching is poised to lead with its commitment to quality, innovation, and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of raching humidor

-

How do I ensure the quality of Raching humidors before purchasing?

To ensure the quality of Raching humidors, consider requesting product samples or visiting the manufacturer’s facility if feasible. Conduct thorough research on the supplier’s reputation through trade shows, reviews, and testimonials from other B2B buyers. Additionally, inquire about their quality assurance processes, including certifications and standards they adhere to, which can help verify the reliability and craftsmanship of their products. -

What is the best humidor model for commercial use?

The Raching C380A and CT48A models are highly recommended for commercial use due to their large capacities and advanced climate control features. These models maintain optimal humidity and temperature levels, essential for preserving cigar quality. Moreover, they are designed for high-volume storage, making them suitable for retail environments or cigar lounges, where consistent quality is paramount. -

What customization options are available for Raching humidors?

Raching offers various customization options, including size, material, and internal configuration tailored to your specific needs. You can also request branding options for a more personalized touch. It’s advisable to contact Raching directly to discuss your requirements and explore available customization features that align with your business objectives. -

What are the minimum order quantities (MOQ) for Raching humidors?

The MOQ for Raching humidors typically varies depending on the model and your location. For international buyers, it is common to see MOQs ranging from 10 to 50 units. To get precise details, it’s best to contact Raching’s sales team directly, who can provide information tailored to your specific order and shipping requirements. -

What payment terms are offered for international purchases of Raching humidors?

Raching generally offers flexible payment terms for international buyers, including options like T/T (Telegraphic Transfer), PayPal, and letters of credit. Payment terms may vary based on the order size and relationship with the supplier. It’s advisable to discuss and negotiate these terms upfront to ensure a smooth transaction process. -

How can I effectively vet a supplier of Raching humidors?

Vetting a supplier involves checking their business credentials, such as registration, years in operation, and industry certifications. Additionally, request references from previous clients and evaluate their customer service responsiveness. Visiting their facility or attending trade shows where they exhibit can also provide insights into their manufacturing capabilities and quality standards. -

What logistics options are available for shipping Raching humidors internationally?

Raching provides various logistics options, including air freight and sea freight, depending on your urgency and budget. They typically work with reliable shipping partners to ensure safe and timely delivery. It’s important to discuss logistics during the order process, including customs clearance and any import duties applicable in your country. -

What after-sales support does Raching provide for their humidors?

Raching offers comprehensive after-sales support, including warranty services and technical assistance. They have a dedicated customer service team available to address any issues or questions you may have post-purchase. Ensure to inquire about the specifics of the warranty coverage and the process for service requests to facilitate a seamless support experience.

Top 5 Raching Humidor Manufacturers & Suppliers List

1. Raching – Premium Cigar Humidors

Domain: rachinghumidor.com

Registered: 2023 (2 years)

Introduction: Raching offers a variety of cigar humidors and cabinets including:

1. Raching Cigar Humidor MA50 – Price: $1,399.00 USD

2. Raching C330A Humidor – Price: $2,399.00 USD

3. Raching C380A Humidor – Price: $2,999.00 USD

4. Raching CD1200 Double Door Humidor – Price: $7,399.00 USD

5. Raching CT48A Cabinet Humidor – Price: $4,949.00 USD

6. Raching MON1800 Humidor with Ammonia Removal – Price: $3,5…

2. Raching Global – Premium Cigar Humidors & Wine Coolers

Domain: rachingglobal.com

Registered: 2019 (6 years)

Introduction: Stainless steel series cigar humidor, Precision electronic cigar humidor, Climate controlled cigar humidor, Cigar humidor, Smart wine cooler, Simple wine cooler, Artistic wine cooler, Customization series, Sausage & Steak Dry-Age Cabinet, Other Cigar Accessories.

3. Raching – Electric Cigar Humidor MA50

Domain: rachinghumidor.net

Registered: 2024 (1 years)

Introduction: Raching Cigar Humidor models include: 1. Raching Electric Cigar Humidor, Cigar Climate Control Cabinet, MA50 – Price: $1,299.00 USD 2. ZIEUN stainless steel cigar humidor – Sale Price: $1,249.00 USD (Regular Price: $1,399.00 USD) 3. Raching MON800 Humidor Climate Control Cabinet with Ammonia Removal – Price: $2,599.00 USD 4. Raching MON1800 Humidor with Ammonia Removal – Price: $3,599.00 USD (Regu…

4. Reddit – User Experience with Product

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – User Experience with Product, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Raching – Cigar Humidor MON5800A

Domain: winecoolersempire.com

Registered: 2018 (7 years)

Introduction: Raching Humidors (11 products) – Cigar Humidors (11) – Indoor/Outdoor: Indoor (11) – Temperature Zone: Dual Zone (1), Single Zone (10) – Price Range: From $1,999.00 to $4,799.00 – Products include: Raching Cigar Humidor MON5800A, Raching Cabinet Cigar Humidor COH300A, Raching Climate Controlled Cigar Humidor C230A, Raching Precision Electronic Cigar Humidor MON800A.

Strategic Sourcing Conclusion and Outlook for raching humidor

In the ever-evolving landscape of luxury cigar storage, Raching humidors stand out for their innovative design and robust functionality. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe evaluate sourcing options, it is crucial to recognize the significance of quality and reliability in humidors. Raching’s commitment to high-tech solutions, like climate control and moisture regulation, ensures that cigars are preserved in optimal conditions, thus enhancing their flavor and longevity.

Strategic sourcing of Raching humidors not only provides a competitive edge in the luxury market but also supports building a sustainable supply chain. By partnering with a trusted manufacturer like Raching, businesses can access a wide range of products tailored to meet diverse customer needs, from precision electronic models to customizable options.

Looking ahead, the demand for quality cigar storage solutions is projected to grow, driven by an expanding global market for premium cigars. Now is the time for buyers to engage with Raching, leveraging their expertise and innovative offerings to enhance their product portfolio and meet the evolving preferences of cigar enthusiasts worldwide. Embrace the opportunity to elevate your business by sourcing Raching humidors today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.