How to Source 75 Gallon Barrel Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for 75 gallon barrel

In today’s dynamic global market, sourcing a 75-gallon barrel can pose significant challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With varying regulations, material specifications, and supplier capabilities, navigating this landscape requires a strategic approach. This comprehensive guide aims to equip international buyers with essential insights into the various types of 75-gallon barrels available, including fiber, plastic, and steel options, as well as their specific applications across industries like chemicals, food, and pharmaceuticals.

Understanding the nuances of barrel sourcing goes beyond mere selection; it involves evaluating supplier reliability, assessing compliance with international standards, and negotiating costs effectively. This guide delves into these critical aspects, offering actionable strategies for vetting suppliers, understanding pricing structures, and ensuring that your sourcing decisions align with your operational needs. By providing a detailed exploration of these elements, we empower B2B buyers to make informed purchasing decisions that enhance efficiency and reduce risks.

Whether you are looking to streamline your supply chain or seeking reliable packaging solutions, this guide serves as a valuable resource to help you navigate the complexities of the global market for 75-gallon barrels. With the right information at your fingertips, you can confidently engage with suppliers and secure the best products for your business needs.

Understanding 75 gallon barrel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fiber Drum | Lightweight, made from fiberboard, open head design | Chemical, food, and pharmaceutical industries | Pros: Cost-effective, recyclable. Cons: Not UN rated for hazardous materials. |

| Plastic Drum | Durable, resistant to chemicals, closed head design | Oil, chemicals, and food storage | Pros: Lightweight, moisture-resistant. Cons: Limited temperature range. |

| Steel Drum | Heavy-duty, corrosion-resistant, available in open or closed head | Industrial chemicals, oils, and waste disposal | Pros: Robust, UN rated options available. Cons: Heavier, more expensive. |

| Composite Drum | Combination of materials for added strength and versatility | Hazardous materials, food-grade applications | Pros: Versatile, can be UN rated. Cons: Higher cost due to materials. |

| Reconditioned Drum | Used drums that have been cleaned and refurbished | Cost-effective storage solutions | Pros: Lower cost, environmentally friendly. Cons: May have limited availability. |

What are the Characteristics of Fiber Drums?

Fiber drums are primarily made from fiberboard, making them lightweight and easy to handle. Their open head design allows for easy filling and dispensing, making them ideal for industries such as food and pharmaceuticals. However, they are typically not UN rated, meaning they are unsuitable for transporting hazardous materials. B2B buyers should consider their specific storage and shipping needs when choosing fiber drums, especially regarding weight capacity and environmental regulations.

How Do Plastic Drums Stand Out?

Plastic drums are known for their durability and resistance to various chemicals, making them suitable for storing oils, chemicals, and food products. Their closed head design minimizes spills and contamination, which is crucial for food safety standards. While they are lightweight and moisture-resistant, buyers should note that plastic drums may have a limited temperature tolerance. For businesses in need of reliable, safe storage solutions, plastic drums are an excellent option.

What Advantages Do Steel Drums Offer?

Steel drums are recognized for their heavy-duty construction and corrosion resistance, which makes them ideal for industrial applications involving chemicals and waste disposal. They come in both open and closed head designs and can be UN rated, allowing for the safe transport of hazardous materials. However, their heavier weight and higher cost compared to other options may be a consideration for buyers. Steel drums are perfect for businesses requiring robust, long-lasting storage solutions.

Why Choose Composite Drums?

Composite drums combine various materials to enhance strength and versatility, making them suitable for a wide range of applications, including hazardous materials and food-grade storage. Many composite drums are UN rated, which is essential for transporting dangerous goods. While they offer significant advantages in terms of durability and compliance, the higher cost associated with composite drums may be a drawback for some buyers. Companies should weigh the benefits of compliance and safety against their budget constraints.

What Should Buyers Know About Reconditioned Drums?

Reconditioned drums are previously used containers that have been cleaned and refurbished for reuse. They present a cost-effective and environmentally friendly option for storage solutions. While they can be an excellent choice for businesses looking to reduce costs, buyers should be aware of the potential for limited availability and varying quality. Ensuring that reconditioned drums meet safety and regulatory standards is crucial for businesses in regulated industries.

Key Industrial Applications of 75 gallon barrel

| Industry/Sector | Specific Application of 75 gallon barrel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Manufacturing | Storage and transportation of chemicals | Ensures safe handling and compliance with regulations | Look for UN-rated options for hazardous materials, durability, and compatibility with chemicals. |

| Food and Beverage | Bulk storage of ingredients like grains or liquids | Maintains product integrity and freshness | Ensure food-grade certification, check for seal integrity, and assess transportation logistics. |

| Pharmaceuticals | Containment of raw materials and active ingredients | Supports regulatory compliance and product safety | Verify regulatory compliance, seek options with anti-contamination features, and assess ease of handling. |

| Agriculture | Storage of fertilizers and pesticides | Facilitates easy access and efficient inventory management | Source from suppliers familiar with agricultural regulations, and evaluate for UV resistance if stored outdoors. |

| Waste Management | Collection and transport of waste materials | Streamlines waste disposal processes | Consider options for leak-proof designs, assess compatibility with waste types, and inquire about recycling programs. |

How is the 75 Gallon Barrel Used in Chemical Manufacturing?

In the chemical manufacturing industry, the 75-gallon barrel is predominantly used for storing and transporting various chemicals. These barrels are often UN-rated to ensure compliance with international safety standards, providing a reliable solution for hazardous materials. The durability of these barrels minimizes the risk of leaks or spills, which is critical for maintaining safety and environmental compliance. Buyers in regions such as the Middle East and Africa should ensure that their barrels are compatible with the specific chemicals they handle, as well as verify the suppliers’ certifications.

What Role Does the 75 Gallon Barrel Play in Food and Beverage Storage?

For the food and beverage sector, the 75-gallon barrel serves as an effective bulk storage solution for ingredients, such as grains, oils, and syrups. These barrels are typically food-grade certified, ensuring that they do not contaminate the contents. The design allows for easy access and minimizes the risk of spoilage, which is crucial for maintaining product quality. Buyers from South America and Europe should focus on sourcing barrels that meet local food safety regulations and consider features like airtight seals to enhance freshness.

Why is the 75 Gallon Barrel Essential in Pharmaceuticals?

In the pharmaceutical industry, the 75-gallon barrel is utilized for the containment of raw materials and active pharmaceutical ingredients (APIs). The barrels must meet stringent regulatory requirements to ensure product safety and efficacy. Features such as anti-contamination designs and easy handling mechanisms are essential for maintaining the integrity of sensitive materials. B2B buyers in this sector should prioritize sourcing from manufacturers with a proven track record of compliance and quality assurance.

How Does the 75 Gallon Barrel Benefit Agricultural Practices?

Agricultural businesses often use the 75-gallon barrel for storing fertilizers and pesticides. This capacity allows for efficient inventory management and easy access during planting and harvesting seasons. The barrels should be UV-resistant if stored outdoors to prevent degradation from sunlight. Buyers in regions like Africa should engage with suppliers who understand local agricultural regulations and can provide barrels that meet these specific needs.

What is the Importance of the 75 Gallon Barrel in Waste Management?

In waste management, the 75-gallon barrel is crucial for the collection and transport of various waste materials, including hazardous waste. These barrels are designed to be leak-proof, which is essential for preventing environmental contamination. Businesses benefit from streamlined waste disposal processes and compliance with local regulations. Buyers should consider sourcing barrels that are specifically designed for the type of waste they handle and inquire about recycling or disposal programs offered by suppliers.

3 Common User Pain Points for ’75 gallon barrel’ & Their Solutions

Scenario 1: Difficulty in Compliance with Shipping Regulations

The Problem: For B2B buyers in industries such as chemicals and pharmaceuticals, ensuring compliance with international shipping regulations is a significant concern. Many countries, including those in Africa and the Middle East, have strict guidelines regarding the transport of hazardous materials. The challenge lies in selecting a 75-gallon barrel that meets these regulatory standards while also being cost-effective and reliable. Buyers often face uncertainty about whether the chosen barrel complies with UN regulations, leading to potential fines, shipment delays, and reputational damage.

The Solution: To navigate this compliance issue, buyers should prioritize sourcing 75-gallon barrels that are clearly labeled as UN-rated for hazardous materials. It’s essential to work with reputable suppliers who provide detailed documentation regarding compliance certifications. Engaging a product sourcing team, like those offered by specialized packaging companies, can ensure buyers receive barrels that meet their specific needs and local regulations. Additionally, investing in training for staff on proper labeling and documentation practices can further mitigate compliance risks and streamline the shipping process.

Scenario 2: Challenges with Barrel Durability During Transport

The Problem: Transporting 75-gallon barrels often involves rigorous handling and exposure to various environmental conditions. Buyers may encounter issues with barrel durability, leading to leaks, spills, or even product contamination. This is particularly concerning for businesses operating in regions with extreme weather conditions, such as high humidity or temperature fluctuations. The cost implications of product loss and potential environmental damage can be significant, creating a pressing need for a reliable solution.

Illustrative image related to 75 gallon barrel

The Solution: To address durability concerns, B2B buyers should select barrels made from high-quality materials designed for harsh conditions. For instance, fiber drums with reinforced structures can offer increased strength and resistance to wear. Buyers should also consider using drum liners or protective covers to enhance durability during transport. Additionally, incorporating robust handling procedures, such as using proper lifting equipment and ensuring secure palletization, can minimize the risk of damage during shipping. Conducting thorough inspections before dispatch can also help identify any potential issues with the barrels.

Scenario 3: Inefficiencies in Storage Space Management

The Problem: As businesses scale, managing storage space for 75-gallon barrels can become increasingly complex. Buyers may find themselves struggling with inefficient use of warehouse space, leading to increased operational costs and logistical challenges. This situation is exacerbated when dealing with multiple barrel types or sizes, as it can complicate inventory management and disrupt workflow.

The Solution: To optimize storage space, B2B buyers should consider implementing a systematic inventory management system that tracks barrel dimensions and weights. Utilizing vertical storage solutions, such as shelving units designed for barrel storage, can maximize warehouse capacity. Additionally, standardizing on a specific type of 75-gallon barrel can simplify inventory management and reduce the complexity of handling various sizes. Collaborating with a logistics partner that specializes in industrial storage solutions can also provide insights into efficient storage practices, ensuring that space is utilized effectively while maintaining easy access to products.

Strategic Material Selection Guide for 75 gallon barrel

When selecting a 75-gallon barrel, the choice of material is critical for ensuring optimal performance, cost-effectiveness, and compliance with international standards. Here, we analyze four common materials used in the construction of 75-gallon barrels: fiber, plastic, steel, and stainless steel. Each material has distinct properties, advantages, and limitations that can significantly impact their suitability for various applications.

What are the Key Properties of Fiber Drums for 75 Gallon Barrels?

Fiber drums are lightweight and made from compressed paperboard, making them an economical choice for many applications. They typically have a weight capacity of around 300 lbs and can withstand moderate temperatures and pressures. Fiber drums are not suitable for hazardous materials unless they are specifically designed to meet UN regulations.

Pros: Fiber drums are cost-effective, recyclable, and provide good protection against moisture and dust. They are ideal for storing dry goods and non-hazardous materials.

Cons: Their durability is lower compared to metal options, and they can be vulnerable to moisture damage if not properly treated. They also have limited temperature resistance.

Impact on Application: Fiber drums are best suited for dry products like grains, powders, or non-hazardous chemicals. Buyers in regions with high humidity, such as parts of Africa and South America, should consider moisture-resistant treatments.

How Do Plastic Drums Perform in 75 Gallon Applications?

Plastic drums, often made from high-density polyethylene (HDPE), offer excellent chemical resistance and can handle a wide range of temperatures. They are lightweight and can be manufactured in both open-head and tight-head designs, making them versatile for various applications.

Pros: Plastic drums are resistant to corrosion, lightweight, and can be produced in food-grade versions. They are also UV resistant, which is crucial for outdoor storage.

Cons: While generally durable, they can be susceptible to certain solvents and extreme temperatures. The cost can be higher than fiber drums.

Impact on Application: Plastic drums are suitable for storing liquids, including chemicals and food products. International buyers must ensure compliance with food safety standards, especially in regions like the Middle East and Europe, where regulations can be stringent.

What Advantages Do Steel Drums Offer for 75 Gallon Barrels?

Steel drums are robust and capable of withstanding high pressures and temperatures, making them ideal for hazardous materials and bulk storage. They are available in both open-head and closed-head designs and can be lined to protect against corrosion.

Pros: Steel drums are highly durable, reusable, and can be reconditioned, which can lower long-term costs. They also provide excellent protection against physical damage.

Cons: The weight of steel drums can increase shipping costs, and they are susceptible to rust if not properly coated. They may also require more complex manufacturing processes.

Impact on Application: Steel drums are ideal for chemicals, oils, and hazardous materials. Buyers must ensure compliance with UN standards for transporting hazardous materials, particularly in regions with strict regulations like Europe and the Middle East.

Why Choose Stainless Steel Drums for 75 Gallon Applications?

Stainless steel drums offer superior corrosion resistance and are ideal for high-purity applications. They can handle extreme temperatures and are often used in industries such as pharmaceuticals and food processing.

Pros: Stainless steel drums are highly durable, easy to clean, and resistant to a wide range of chemicals. They also do not leach harmful substances into stored products.

Cons: The initial cost is significantly higher than other materials, and they can be heavier, impacting transportation costs.

Impact on Application: Stainless steel drums are suitable for high-value products, including pharmaceuticals and food-grade applications. International buyers should verify compliance with specific standards such as ASTM or FDA regulations, especially in regions with rigorous quality controls.

Summary Table of Material Selection for 75 Gallon Barrels

| Material | Typical Use Case for 75 Gallon Barrel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fiber | Dry goods, non-hazardous materials | Cost-effective and recyclable | Vulnerable to moisture damage | Low |

| Plastic | Chemicals, food products | Excellent chemical resistance | Susceptible to certain solvents | Medium |

| Steel | Hazardous materials, bulk storage | Highly durable and reusable | Heavier and prone to rust | Medium |

| Stainless Steel | Pharmaceuticals, food processing | Superior corrosion resistance | High initial cost | High |

This guide should assist international B2B buyers in making informed decisions regarding the material selection for 75-gallon barrels, considering their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 75 gallon barrel

What Are the Main Stages of Manufacturing a 75 Gallon Barrel?

The manufacturing process of a 75-gallon barrel typically involves several key stages, including material preparation, forming, assembly, and finishing. Understanding these stages is crucial for B2B buyers looking for quality products that meet international standards.

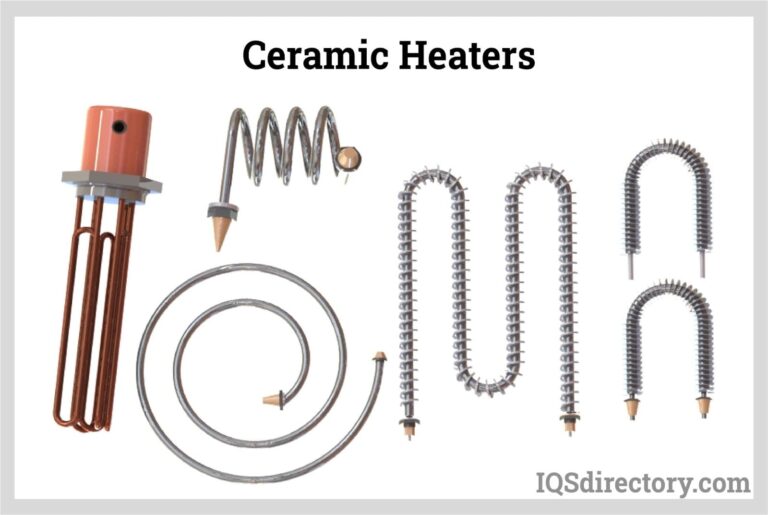

How Is Material Prepared for 75 Gallon Barrels?

The first step in manufacturing involves selecting the right materials, which can vary based on the type of barrel being produced—fiber, plastic, or steel. For fiber drums, kraft paper is often chosen for its strength and durability. In the case of steel barrels, manufacturers might use cold-rolled or stainless steel, depending on the intended application.

Once the materials are selected, they undergo preparation, which may include processes like cutting, coating, or treating to enhance resistance against corrosion or chemical reactions. This step is essential to ensure that the final product meets specific industry requirements, especially for sectors like chemicals or food production.

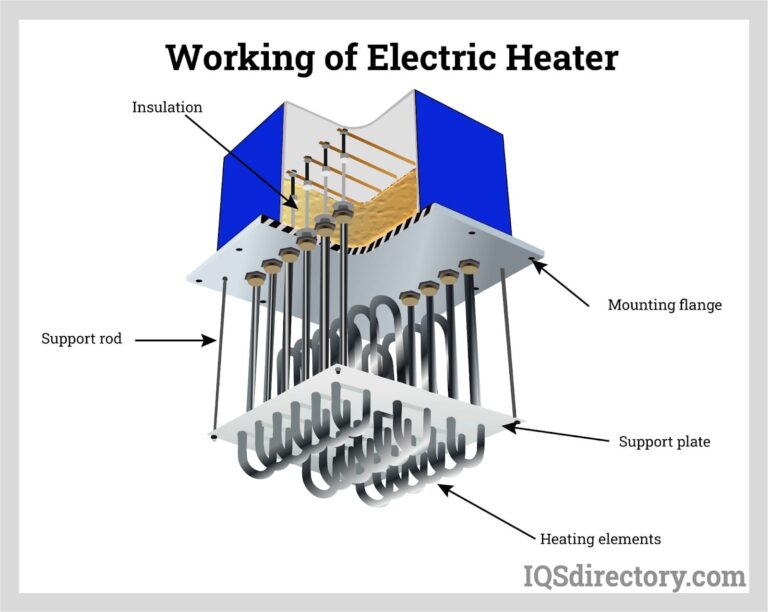

What Techniques Are Used to Form the Barrels?

The forming stage involves shaping the prepared materials into the desired barrel structure. For fiber drums, this typically includes rolling and bonding layers of kraft paper to create a cylindrical shape. In contrast, steel barrels are produced through processes such as deep drawing or hydroforming, where steel sheets are transformed into cylindrical shapes under high pressure.

Plastic barrels are manufactured using blow molding or injection molding techniques, allowing for precise shapes and sizes. Each of these techniques requires specialized machinery and skilled operators, ensuring consistency and quality throughout the production process.

How Are 75 Gallon Barrels Assembled and Finished?

After forming, the next stage is assembly, where components such as lids, seals, and closures are added. For example, fiber drums often feature ring-lock lids, while steel drums might have lever-lock closures. The assembly process may also include the application of gaskets or liners to improve leak resistance and maintain product integrity.

Finishing involves surface treatments and coatings that enhance durability and protect against environmental factors. This may include applying a protective lacquer on steel barrels or waterproofing treatments on fiber drums. Quality control checks during this stage help ensure that the barrels meet the required specifications.

What Quality Assurance Standards Are Relevant for 75 Gallon Barrels?

Quality assurance (QA) is critical in the barrel manufacturing process, particularly for B2B buyers who require consistent quality and compliance with international standards. Key standards include ISO 9001, which outlines a framework for quality management systems, and industry-specific certifications such as CE marking for safety compliance in Europe.

How Are Quality Control Checkpoints Implemented?

The quality control process typically includes several checkpoints throughout the manufacturing stages:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they are used in production. B2B buyers should ensure that suppliers maintain stringent IQC processes to mitigate risks.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections and tests are conducted to ensure that each stage meets quality standards. This includes monitoring the forming and assembly processes.

-

Final Quality Control (FQC): Before the barrels are packaged and shipped, a final inspection is performed to verify that the products meet all specifications and are free from defects. This stage may involve dimensional checks, leakage tests, and surface inspections.

What Testing Methods Are Commonly Used for Quality Assurance?

Various testing methods are employed to ensure the integrity and safety of 75-gallon barrels. Common tests include:

-

Hydrostatic Testing: Used primarily for steel barrels, this test assesses the barrel’s ability to withstand internal pressure without leaking.

-

Impact Resistance Testing: This evaluates how well the barrel can withstand physical impacts, particularly important for barrels used in transportation.

-

Chemical Compatibility Testing: For barrels intended for chemical storage, compatibility tests ensure that the materials can safely contain the substances without degrading.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are some actionable steps:

Illustrative image related to 75 gallon barrel

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing practices and quality control systems. Buyers should request access to audit reports and certifications.

-

Request Quality Control Reports: Suppliers should be able to provide documentation that outlines their quality control processes, test results, and compliance with international standards.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the barrels before shipment, ensuring they meet quality and safety standards.

What Are the Nuances of Quality Control for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of the specific quality control nuances that may impact their purchasing decisions. For instance, certain countries may have unique regulatory requirements that dictate the types of materials or certifications needed for import.

Additionally, cultural factors may influence communication and negotiation processes. Establishing clear expectations regarding quality standards upfront can help prevent misunderstandings and ensure a smooth transaction.

In conclusion, understanding the manufacturing processes and quality assurance measures associated with 75-gallon barrels is vital for B2B buyers. By focusing on these aspects, buyers can make informed purchasing decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ’75 gallon barrel’

In this sourcing guide, we aim to provide a structured approach for B2B buyers looking to procure 75-gallon barrels. This checklist will help you navigate the complexities of sourcing, ensuring that you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clarify the technical requirements for the 75-gallon barrel. Consider factors such as material type (fiberboard, plastic, or steel), weight capacity, and intended use (liquids, solids, or hazardous materials). Having a detailed specification helps suppliers provide accurate quotes and ensures the product meets your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in your target regions, such as Africa, South America, the Middle East, and Europe. Look for companies that specialize in industrial packaging and have a proven track record. Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers.

Step 3: Evaluate Supplier Certifications

Supplier certifications are critical, especially if you’re handling hazardous materials. Ensure that potential suppliers hold relevant certifications such as ISO, UN ratings, or other industry-specific credentials. These certifications indicate compliance with safety and quality standards, which can mitigate risks associated with sourcing.

Step 4: Request Samples and Test Quality

Before making bulk purchases, request samples of the 75-gallon barrels for testing. Assess the quality of the barrels in terms of durability, closure mechanisms, and suitability for your specific applications. Testing samples can reveal potential issues that may not be apparent in product descriptions or specifications.

Illustrative image related to 75 gallon barrel

Step 5: Negotiate Pricing and Terms

Once you’ve identified suitable suppliers, engage in negotiations regarding pricing, minimum order quantities, and payment terms. Be aware of any additional costs such as shipping, customs duties, or handling fees, especially when sourcing internationally. Clear terms can help avoid misunderstandings and ensure a smooth procurement process.

Step 6: Verify Delivery Capabilities

Confirm the supplier’s ability to meet your delivery timelines and logistics requirements. Inquire about their shipping methods, lead times, and options for bulk orders. Reliable delivery is crucial to maintaining your supply chain and operational efficiency.

Step 7: Establish Communication Channels

Maintain open lines of communication with your chosen supplier. Regular updates and feedback loops can help address any concerns promptly and foster a stronger business relationship. Establishing a rapport can lead to better service and potential discounts for future orders.

By following this checklist, B2B buyers can streamline their procurement process for 75-gallon barrels, ensuring they select the right products and suppliers to meet their business needs effectively.

Comprehensive Cost and Pricing Analysis for 75 gallon barrel Sourcing

When sourcing 75-gallon barrels, understanding the comprehensive cost structure is crucial for making informed purchasing decisions. Several components contribute to the overall cost, including materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

What Are the Key Cost Components in 75-Gallon Barrel Production?

-

Materials: The choice of materials significantly affects pricing. Common options for 75-gallon barrels include fiber, plastic, and steel. Fiber drums, for instance, are generally less expensive but may not offer the same durability as steel. The price range for fiber barrels can start around $55, while steel options may vary significantly based on certification and specifications.

-

Labor and Manufacturing Overhead: Labor costs can vary based on the region and the complexity of the manufacturing process. In regions like Africa or South America, labor might be less expensive, potentially lowering overall costs. However, efficient production requires trained personnel, and overhead costs must also be factored in.

-

Tooling and Quality Control: Initial tooling costs can be significant, especially for custom designs. Quality control measures ensure that barrels meet industry standards, which can add to the overall cost but are crucial for compliance and safety, particularly in regulated industries.

-

Logistics: Shipping costs are a critical consideration, especially for international buyers. Factors such as distance, mode of transport, and local tariffs can impact logistics expenses. Understanding Incoterms is vital, as they dictate who bears the costs and risks during transportation.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary widely depending on the supplier’s position in the market and the demand for specific barrel types.

How Do Volume and Customization Influence Pricing?

Volume and minimum order quantities (MOQ) play a significant role in pricing. Suppliers often provide discounts for bulk purchases, which can lead to substantial savings. For example, purchasing in pallet quantities may lower the per-unit price significantly. Customization, such as adding specific certifications or features (like UN ratings), can increase costs but may be necessary for compliance in certain industries.

What Factors Should Buyers Consider When Sourcing Barrels Internationally?

-

Quality and Certifications: International buyers should prioritize suppliers that offer quality certifications, especially when sourcing barrels for hazardous materials. The cost of non-compliance can far exceed the savings from choosing a cheaper option.

-

Negotiation Strategies: Building a relationship with suppliers can lead to better pricing and terms. Consider negotiating for volume discounts or flexible payment terms to improve cash flow.

-

Total Cost of Ownership (TCO): Beyond the initial purchase price, TCO includes shipping, handling, storage, and potential disposal costs. Analyzing these factors can help buyers make more informed decisions.

-

Pricing Nuances by Region: Different regions may have varying price points due to local economic conditions, availability of materials, and competition. For instance, buyers in Europe may face higher prices due to stricter environmental regulations compared to those in less regulated markets.

What Are the Best Practices for International Sourcing?

- Research Multiple Suppliers: Gather quotes from different suppliers to understand the market range. This can help identify the best value for your specific needs.

- Evaluate Supplier Reliability: Look for reviews or testimonials from other B2B buyers to gauge the reliability and service quality of potential suppliers.

- Consider Local Regulations: Familiarize yourself with import/export regulations and tariffs in your country, as these can significantly impact overall costs.

In summary, a thorough understanding of the cost components and pricing influencers associated with 75-gallon barrels is essential for making strategic purchasing decisions. By considering these factors and employing effective negotiation strategies, international B2B buyers can optimize their sourcing processes and achieve better value.

Alternatives Analysis: Comparing 75 gallon barrel With Other Solutions

When evaluating packaging solutions for industrial applications, the 75-gallon barrel stands out, but it’s essential to consider viable alternatives that may better meet specific operational requirements. This section compares the 75-gallon barrel with two alternatives: fiber drums and IBC (Intermediate Bulk Containers). Each solution has unique attributes that influence performance, cost, and suitability for various applications.

| Comparison Aspect | 75 Gallon Barrel | Fiber Drum | IBC Container |

|---|---|---|---|

| Performance | High durability for liquids; moderate weight capacity (300 lbs) | Good for dry and liquid goods; lightweight | Excellent for bulk liquids; high weight capacity (up to 2,000 lbs) |

| Cost | Mid-range price point (approx. $55) | Generally lower cost (approx. $50) | Higher upfront cost (approx. $150-$300) |

| Ease of Implementation | Requires proper handling; may need specific equipment for loading/unloading | Lightweight, easy to handle; no special equipment needed | Requires forklifts or pallet jacks; more complex to handle |

| Maintenance | Minimal maintenance; durable | Limited reuse; may need replacement after single use | Requires cleaning and inspection for reuse; more maintenance needed |

| Best Use Case | Ideal for transporting liquids or bulk materials | Suitable for lightweight goods and dry products | Best for large volume liquid transport and storage |

What Are the Advantages and Disadvantages of Using Fiber Drums?

Fiber drums serve as an effective alternative to the 75-gallon barrel, particularly for businesses looking to reduce packaging weight and costs. Weighing significantly less, fiber drums are easier to handle and transport, making them an attractive option for companies focused on efficiency. However, they are less durable than metal or plastic options and may not be suitable for high-pressure applications or the transport of hazardous materials. Their weight capacity is generally lower, making them better suited for lighter goods.

How Do IBC Containers Compare to 75 Gallon Barrels?

IBC containers are designed for the bulk transport of liquids and offer substantial capacity, often accommodating up to 2,000 lbs. This makes them ideal for industries that require the transport of large volumes, such as chemicals or food products. While their upfront cost is higher compared to the 75-gallon barrel, IBCs can be more economical in the long run due to their reusability and durability. However, they necessitate specialized handling equipment, which may complicate implementation for smaller operations.

Conclusion: How Can B2B Buyers Choose the Right Packaging Solution?

Selecting the right packaging solution is critical for optimizing logistics and operational efficiency. B2B buyers should evaluate their specific needs, including the nature of the materials being transported, budget constraints, and handling capabilities. For operations focusing on lightweight, non-hazardous materials, fiber drums may be the best choice. Conversely, if high-capacity liquid transport is needed, investing in IBC containers could yield greater long-term benefits. Ultimately, understanding the unique attributes of each option will empower buyers to make informed decisions that align with their business goals.

Essential Technical Properties and Trade Terminology for 75 gallon barrel

What Are the Key Technical Properties of a 75 Gallon Barrel?

When sourcing a 75 gallon barrel, understanding its essential technical properties is crucial for ensuring it meets your specific operational requirements. Here are several critical specifications that B2B buyers should consider:

-

Material Type

The most common materials for 75 gallon barrels include fiberboard, plastic, and steel. Fiberboard barrels are lightweight and suitable for dry goods, while plastic barrels offer excellent chemical resistance, making them ideal for liquids. Steel barrels provide durability and strength, often required for hazardous materials. Choosing the right material impacts shipping costs, storage conditions, and product safety. -

Weight Capacity

A 75 gallon barrel typically has a weight capacity of around 300 pounds. This specification is vital for determining how much product can be safely stored and transported. Overloading a barrel can lead to structural failure, posing safety risks and potential financial losses. -

Dimensions

Standard dimensions for a 75 gallon barrel are approximately 23 inches in diameter and 42 inches in height. These dimensions are critical for ensuring compatibility with storage facilities and shipping containers. Buyers should consider whether the barrel fits within their existing logistics and warehouse space. -

Closure Type

Barrels can feature various closure types, including lever lock, ring lock, or screw tops. The closure type affects the ease of access and the barrel’s ability to maintain an airtight seal, which is essential for preserving the integrity of the contents. Understanding the closure mechanism helps in selecting barrels that align with handling and dispensing needs. -

UN Rating

The United Nations (UN) rating indicates whether a barrel is suitable for transporting hazardous materials. A barrel with a UN rating is designed to meet stringent safety standards. For businesses dealing with chemicals or other regulated substances, this rating is critical to ensure compliance with local and international shipping regulations. -

Palletization and Shipping Guidelines

Knowing how many barrels fit on a standard pallet (usually four for 75 gallon barrels) can help in planning shipments and storage. Additionally, understanding shipping guidelines, such as weight limits and carrier restrictions, is essential for optimizing logistics and minimizing costs.

What Trade Terminology Should B2B Buyers Understand for 75 Gallon Barrels?

Navigating the procurement of 75 gallon barrels involves familiarizing yourself with specific industry terminology. Here are key terms that will enhance your purchasing process:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are sold under another company’s brand. Understanding OEM relationships can help buyers negotiate better pricing and ensure product quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, especially for businesses that may not require large quantities. -

RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests price quotes from suppliers for specific products. This process is essential for comparing costs and ensuring that you are getting the best value for your investment. -

Incoterms (International Commercial Terms)

These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping. Understanding Incoterms helps in managing shipping costs and risk, ensuring that both parties are clear on obligations. -

Lead Time

This refers to the amount of time it takes from placing an order to receiving it. Knowing the lead time is crucial for inventory planning and ensuring that your supply chain remains uninterrupted. -

Certification

This term refers to the documentation that verifies a barrel meets specific safety and quality standards. For example, barrels used for food storage may require FDA certification. Understanding certification requirements is essential for compliance and product safety.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, streamline procurement processes, and enhance operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the 75 gallon barrel Sector

What Are the Key Market Drivers and Trends Influencing the 75 Gallon Barrel Sector?

The 75 gallon barrel sector is experiencing dynamic changes driven by various global factors, including an increase in industrial activity, growth in e-commerce, and heightened environmental awareness. In regions such as Africa and South America, the expanding manufacturing and agricultural sectors are increasing demand for versatile packaging solutions. For international B2B buyers, understanding these trends is crucial for making informed purchasing decisions.

Emerging technologies are also reshaping sourcing strategies. Digital platforms enable buyers to access a wider range of suppliers and products, allowing for more competitive pricing and streamlined procurement processes. Innovations in materials, such as the development of lightweight, durable fiber drums, are further enhancing operational efficiencies. Additionally, as industries adopt just-in-time inventory practices, suppliers are adapting to meet the need for faster delivery times and lower minimum order quantities.

Furthermore, market dynamics are influenced by regulatory changes, particularly in the chemical and food sectors, where compliance with safety standards is paramount. Buyers from Europe and the Middle East must navigate these regulations carefully to ensure their supply chains remain compliant while optimizing costs. In summary, staying abreast of these market drivers and trends can provide B2B buyers with a significant edge in sourcing decisions.

Illustrative image related to 75 gallon barrel

How Is Sustainability Shaping the Sourcing of 75 Gallon Barrels?

Sustainability has become a key consideration in the sourcing of 75 gallon barrels, reflecting a broader shift towards environmentally responsible practices in B2B transactions. The environmental impact of packaging materials is under scrutiny, prompting buyers to seek barrels made from recycled or sustainably sourced materials. For instance, fiber drums, which can be manufactured from recycled paper, are increasingly favored for their lower carbon footprint compared to traditional plastic or metal options.

The importance of ethical supply chains cannot be overstated. Buyers are now prioritizing suppliers who demonstrate transparency in their sourcing practices and commitment to social responsibility. This includes ensuring fair labor practices and reducing waste throughout the production process. Certifications such as FSC (Forest Stewardship Council) for wood-based products or ISO 14001 for environmental management systems can serve as indicators of a supplier’s commitment to sustainability.

As consumers demand more environmentally friendly products, B2B buyers in regions like the Middle East and Europe should align their sourcing strategies with these expectations. By choosing suppliers who prioritize sustainability, businesses can not only enhance their brand reputation but also contribute to a more sustainable future.

What Is the Historical Context Behind the 75 Gallon Barrel Sector?

The evolution of the 75 gallon barrel sector reflects broader changes in manufacturing and packaging practices over the decades. Initially, barrels were predominantly made from wood and used for storing liquids such as oil, wine, and chemicals. However, with the advent of modern materials and manufacturing techniques, the industry began to diversify.

Illustrative image related to 75 gallon barrel

The introduction of fiber drums in the mid-20th century marked a significant turning point, offering a lightweight, cost-effective alternative to traditional metal barrels. This innovation expanded the use of 75 gallon barrels beyond hazardous materials to include food products and pharmaceuticals, catering to a wider range of industries. As the global economy has grown and environmental concerns have become more pressing, the demand for sustainable packaging solutions has driven further innovation in the sector.

Today, the 75 gallon barrel stands as a testament to the industry’s adaptability, responding to both market demands and environmental challenges. Understanding this historical context can provide B2B buyers with valuable insights into current sourcing trends and future opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of 75 gallon barrel

-

How do I ensure the quality of a 75-gallon barrel before purchase?

To ensure the quality of a 75-gallon barrel, it’s essential to vet suppliers thoroughly. Request samples or certifications that verify the barrel’s specifications, such as material type, weight capacity, and compliance with international standards (e.g., UN ratings for hazardous materials). Additionally, consider conducting factory visits or audits if possible, and check reviews or testimonials from previous clients to gauge their reliability and product quality. -

What is the best material for a 75-gallon barrel for storing chemicals?

For storing chemicals, the best material for a 75-gallon barrel is typically high-density polyethylene (HDPE) or steel, depending on the chemical’s properties. HDPE offers excellent corrosion resistance and is lightweight, making it suitable for many non-hazardous liquids. Steel barrels are more durable and can withstand higher pressures, making them ideal for hazardous materials. Always confirm compatibility with the specific chemicals to be stored to prevent reactions or leaks. -

What are common customization options available for 75-gallon barrels?

Common customization options for 75-gallon barrels include different lid types (e.g., screw tops, lever locks), colors, labeling, and additional fittings such as spouts or taps. Some suppliers may offer custom branding or printing on the barrel. Discuss your specific needs with suppliers to explore available options that meet your operational requirements and enhance product identification. -

What are typical minimum order quantities (MOQ) for 75-gallon barrels?

Minimum order quantities for 75-gallon barrels can vary significantly by supplier and material type. Generally, you can expect MOQs to range from 4 to 10 barrels for standard orders. However, some suppliers may offer flexibility for larger orders or specific regional demands. Always inquire directly with suppliers to negotiate terms that align with your purchasing needs. -

What payment terms should I expect when sourcing 75-gallon barrels internationally?

Payment terms for international purchases of 75-gallon barrels typically include options like advance payment, letter of credit, or payment upon delivery, depending on the supplier’s policies and your relationship with them. It’s crucial to clarify these terms upfront to avoid any misunderstandings. Additionally, consider discussing currency exchange risks and payment methods that are secure and convenient for both parties. -

What logistics considerations should I keep in mind when importing 75-gallon barrels?

When importing 75-gallon barrels, consider logistics factors such as shipping methods, lead times, and customs regulations specific to your destination country. Evaluate whether you need to arrange for freight forwarders or customs brokers to handle paperwork and compliance. Additionally, assess the cost of shipping, which can vary based on barrel weight and volume, and factor in any potential tariffs or duties. -

How can I verify a supplier’s credibility when sourcing 75-gallon barrels?

To verify a supplier’s credibility, research their business history, industry certifications, and customer reviews. Check for memberships in recognized industry associations and request references from previous clients. Utilizing platforms like Alibaba or ThomasNet can also provide insights into supplier ratings. Conducting a background check can further ensure that you engage with a reputable supplier. -

What are the best practices for maintaining 75-gallon barrels after purchase?

Maintaining 75-gallon barrels involves proper storage and regular inspections. Ensure that barrels are stored in a cool, dry place away from direct sunlight and extreme temperatures. Conduct routine checks for leaks, corrosion, or damage, especially if they contain hazardous materials. For barrels used for food-grade applications, ensure they are cleaned and sanitized regularly to prevent contamination.

Top 5 75 Gallon Barrel Manufacturers & Suppliers List

1. Uline – Fiber Drum – 75 Gallon

Domain: uline.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Fiber Drum – 75 Gallon”, “Model Number”: “S-17006”, “Capacity”: “75 Gallon (284 L)”, “Weight Capacity”: “400 lbs (181 Kg)”, “UN Rating”: “1G/X120/S”, “Unit Weight”: “19 lbs (9 Kg)”, “Dimensions”: {“Circumference”: “73.79 inches”, “Diameter”: {“Opening (Inside)”: “22 1/2 inches”, “Inside”: “22 7/8 inches”, “Outside”: “23 1/2 inches”}, “Height”: {“Inside”: “42 1/4 inches”, “Outside…

2. Air Sea Containers – 75 Gallon Open Head Fiberboard Drum

Domain: airseacontainers.com

Registered: 1997 (28 years)

Introduction: {“item_number”:”1G2-N-75-A”,”product_name”:”75 Gallon Open Head (Non-UN) Fiberboard Drum with Ring Lock Lid”,”capacity”:”300 lbs”,”dimensions”:”23” diameter x 42””,”weight”:”17 lbs”,”minimum_quantity”:”4″,”shipping_info”:”Ships within 24 – 48 hours”,”pallet_quantity”:”4″,”pallet_dimensions”:”48″ x 45″ x 49″”,”estimated_pallet_weight”:”107 lbs”,”max_quantity_per_pallet”:”8″,”max_pallet_dimensions”:…

3. The Cary Company – Drums & Barrels

Domain: thecarycompany.com

Registered: 1999 (26 years)

Introduction: Drums & Barrels | Bulk & Wholesale, 55 Gallon Drum, Steel Drums, Plastic Drums, Fiber Drums, Carbon Steel Drums, Open Head Steel Drums, Tight Head Steel Drums, Stainless Steel Drums, Open Head Stainless Steel Drums, Tight Head Stainless Steel Drums, Plastic Drums, Open Head Plastic Drums, Tight Head Plastic Drums, Fiber Drums, Composite Drums, Salvage & Overpack Drums, Steel Salvage Drums, Plastic…

4. AquaBarrel – RainBox 75 Gallon Rain Barrel

Domain: aquabarrel.com

Registered: 2006 (19 years)

Introduction: {“name”: “RainBox, 75 Gallon Rain Barrel”, “capacity”: “75 gallons”, “color”: “Black”, “dimensions”: “20” x 24″ x 42″”, “features”: [“2″ OD diameter overflow port on each side”, “2” OD diameter bottom port on each side”, “Built-in debris filter”, “Garden hose shut off valve”, “Child safe design”, “100% recycled plastic”, “UV-resistant polyethylene”, “Multiple units can be connected in series”], “i…

5. Lewis Container – 75 Gallon Plastic Drum

Domain: lewiscontainer.com

Registered: 2005 (20 years)

Introduction: {“products”:[{“name”:”75 gallon plastic drum”,”description”:”The jumbo plastic drum is the most common drum used for shipping to the Caribbean. It is more durable and has more ways to be reused once down on the island.”},{“name”:”75 gallon fiber drum”,”description”:”The jumbo fiber is the cost-effective alternative for shipping to the Caribbean. Accepted by most shippers, this less expensive drum …

Strategic Sourcing Conclusion and Outlook for 75 gallon barrel

In the rapidly evolving landscape of industrial packaging, the strategic sourcing of 75-gallon barrels presents significant opportunities for businesses across Africa, South America, the Middle East, and Europe. By understanding the diverse applications and materials available—ranging from fiber to steel—buyers can make informed decisions that align with their operational needs and sustainability goals. The cost-effectiveness of bulk purchasing, coupled with the ability to source tailored solutions, enhances supply chain efficiency and reduces downtime.

Collaboration with suppliers who prioritize transparency and responsiveness can further streamline procurement processes. As highlighted in various case studies, clear communication and trust are essential components for long-term partnerships, ensuring that the quality and specifications of barrels meet industry standards.

Looking ahead, international buyers are encouraged to leverage digital platforms and market insights to navigate the complexities of sourcing. As global supply chains become more interconnected, the ability to adapt and innovate will be key to maintaining a competitive edge. Engage with reputable suppliers today to explore customized solutions that not only meet your immediate needs but also contribute to sustainable practices in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.