How to Source Brackets Flat Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for brackets flat

In the dynamic landscape of global construction and manufacturing, sourcing flat brackets can present a significant challenge for B2B buyers. These essential components are crucial for ensuring structural integrity in various applications, from furniture assembly to industrial projects. However, navigating the complexities of supplier options, material specifications, and pricing can be daunting, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Germany.

This comprehensive guide aims to equip B2B buyers with the knowledge and tools necessary to make informed purchasing decisions regarding flat brackets. It covers an extensive range of topics, including the different types of flat brackets available, their specific applications across industries, and best practices for vetting suppliers to ensure quality and reliability. Additionally, the guide will delve into cost considerations, helping buyers to optimize their budgets while securing the best products.

By providing actionable insights and practical advice, this guide empowers international B2B buyers to navigate the global market for flat brackets with confidence. Whether you are seeking to enhance your supply chain efficiency or ensure compliance with local standards, this resource is tailored to meet your needs and support your business objectives in an increasingly competitive environment.

Understanding brackets flat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flat Corner Brace | Simple L-shape design for reinforcing corners | Furniture assembly, cabinetry, shelving | Pros: Cost-effective, easy to install. Cons: Limited load capacity compared to heavier-duty options. |

| Flat Metal Bracket | Made from various metals, often galvanized for corrosion resistance | Industrial shelving, structural support | Pros: Durable, versatile. Cons: Heavier, may require more robust installation methods. |

| Concealed Flat Bracket | Hidden installation for a clean aesthetic | High-end furniture, cabinetry | Pros: Discreet, enhances design. Cons: More expensive, requires precise installation. |

| Flat L Bracket | L-shaped for corner and edge support, available in various sizes | Decks, outdoor structures, furniture | Pros: Strong support for larger structures. Cons: Bulkier design may not suit all applications. |

| Flat Pattern Bracket | Customizable shapes for specific applications | Robotics, machinery assembly | Pros: Tailored solutions for unique needs. Cons: Higher cost, longer lead times for custom orders. |

What Are Flat Corner Braces and Their Applications?

Flat corner braces are essential components for reinforcing corners in various furniture and construction applications. Their L-shaped design allows them to provide stability at right angles, making them ideal for shelving, cabinetry, and furniture assembly. When considering purchasing flat corner braces, businesses should evaluate the weight capacity and material type, as these factors influence durability and application suitability. They are generally cost-effective and easy to install, making them a popular choice for both DIY projects and professional setups.

How Do Flat Metal Brackets Differ from Other Types?

Flat metal brackets are fabricated from durable materials, often galvanized to resist corrosion, which makes them suitable for industrial applications. These brackets can support heavier loads compared to simpler designs, making them a go-to choice for structural support and shelving in warehouses and factories. B2B buyers should consider the weight ratings and installation requirements, as these can vary significantly based on the bracket’s thickness and material. While they offer robust support, their heavier nature may necessitate more intensive installation methods.

What Advantages Do Concealed Flat Brackets Offer?

Concealed flat brackets are designed for applications where aesthetics are paramount, as they can be hidden from view. This makes them particularly appealing in high-end furniture and cabinetry where a clean, modern look is desired. When purchasing concealed brackets, businesses must focus on precision in installation, as improper placement can undermine their effectiveness. Although they tend to be more expensive than standard brackets, the visual appeal and enhanced design can justify the investment, especially in premium markets.

Why Choose Flat L Brackets for Structural Support?

Flat L brackets are versatile and provide strong support for corners and edges in a variety of structures, including decks and outdoor furniture. Their robust design allows them to handle significant loads, making them suitable for both residential and commercial applications. Buyers should assess the size and material of flat L brackets to ensure they meet the specific requirements of their projects. While they are effective in providing support, their bulkier design may not be suitable for applications requiring a more discreet solution.

What Are Flat Pattern Brackets and Their Customization Potential?

Flat pattern brackets are specialized components designed for specific applications, often utilized in robotics and machinery assembly. Their customizable shapes allow for tailored solutions that meet unique project requirements. B2B buyers should consider the potential for longer lead times and higher costs associated with custom orders, but the benefits of having precisely fitting components can significantly enhance operational efficiency. These brackets are invaluable in industries where standard solutions may not suffice, underscoring the importance of flexibility in manufacturing and assembly processes.

Key Industrial Applications of brackets flat

| Industry/Sector | Specific Application of brackets flat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Building | Reinforcement of structural frameworks | Provides stability and durability to buildings and structures | Compliance with local building codes and material standards |

| Furniture Manufacturing | Assembly of furniture components | Enhances product longevity and design flexibility | Availability of various sizes and finishes to match design needs |

| Automotive Industry | Mounting components in vehicle assembly | Ensures secure and reliable assembly of automotive parts | High strength and corrosion resistance for safety and durability |

| Electronics & Appliances | Support for circuit boards and housing structures | Improves product reliability and ease of assembly | Precision manufacturing and compatibility with electronic components |

| Agricultural Equipment | Structural support for equipment and storage solutions | Increases efficiency and organization in agricultural settings | Material durability to withstand harsh environmental conditions |

How Are Flat Brackets Used in Construction and Building?

In the construction sector, flat brackets are essential for reinforcing structural frameworks, such as walls and roof systems. They provide crucial support at joints and corners, ensuring the overall stability and durability of buildings. For international buyers, especially in regions like Africa and the Middle East, sourcing brackets that comply with local building codes and material standards is vital to prevent structural failures and ensure safety. Additionally, options in various materials and finishes can cater to specific environmental conditions, enhancing longevity.

What Role Do Flat Brackets Play in Furniture Manufacturing?

In furniture manufacturing, flat brackets are commonly used to assemble various components, such as shelves, tables, and cabinets. They provide strong joints that enhance the overall durability of the furniture, allowing for intricate designs without compromising strength. For B2B buyers in Europe and South America, the availability of brackets in different sizes and finishes is crucial for matching diverse design aesthetics and ensuring easy integration into existing production lines. Sourcing from reputable suppliers can also guarantee consistent quality, which is vital for brand reputation.

How Are Flat Brackets Utilized in the Automotive Industry?

The automotive industry relies heavily on flat brackets for mounting components during vehicle assembly, including engine parts, frames, and interior fittings. Their role in ensuring secure and reliable connections is critical for vehicle safety and performance. For buyers in regions like Germany, where automotive standards are stringent, sourcing brackets made from high-strength, corrosion-resistant materials is essential to comply with industry regulations and enhance vehicle durability. Additionally, suppliers should provide detailed specifications to ensure compatibility with various vehicle models.

How Do Flat Brackets Support Electronics and Appliances?

In the electronics and appliance sectors, flat brackets are used to support circuit boards and housing structures, facilitating efficient assembly and enhancing product reliability. These brackets help maintain the integrity of electronic components, which is crucial for performance and longevity. For international B2B buyers, especially those in emerging markets, sourcing precision-manufactured brackets that meet international quality standards is vital. Compatibility with different electronic designs and easy installation are key considerations to streamline production processes.

What Benefits Do Flat Brackets Offer in Agricultural Equipment?

Flat brackets serve as structural support in agricultural equipment and storage solutions, such as shelving units and machinery frames. They help organize tools and materials, increasing efficiency in agricultural operations. For buyers in regions like Africa and South America, where agricultural practices can be challenging, sourcing durable brackets that withstand harsh environmental conditions is crucial. Understanding the specific requirements for load-bearing capacity and weather resistance can significantly impact the effectiveness of agricultural solutions.

3 Common User Pain Points for ‘brackets flat’ & Their Solutions

Scenario 1: Sourcing Quality Flat Brackets for Durable Applications

The Problem: B2B buyers often face difficulties in sourcing high-quality flat brackets that can withstand heavy loads, particularly in construction and industrial applications. Many suppliers provide brackets that may look sturdy but fail to meet necessary safety standards or are made from subpar materials, leading to structural failures. This not only jeopardizes the integrity of projects but can also lead to costly delays and safety hazards.

The Solution: To ensure the quality and reliability of flat brackets, buyers should prioritize sourcing from reputable manufacturers that provide detailed specifications and certifications for their products. It’s crucial to request samples to assess the material quality and strength. Additionally, consider the intended application when specifying the type of bracket—whether for indoor or outdoor use—as materials like galvanized steel or stainless steel are better suited for environments exposed to moisture. Establishing a strong relationship with suppliers who offer transparency in their manufacturing processes can also lead to better product insights and a reliable supply chain.

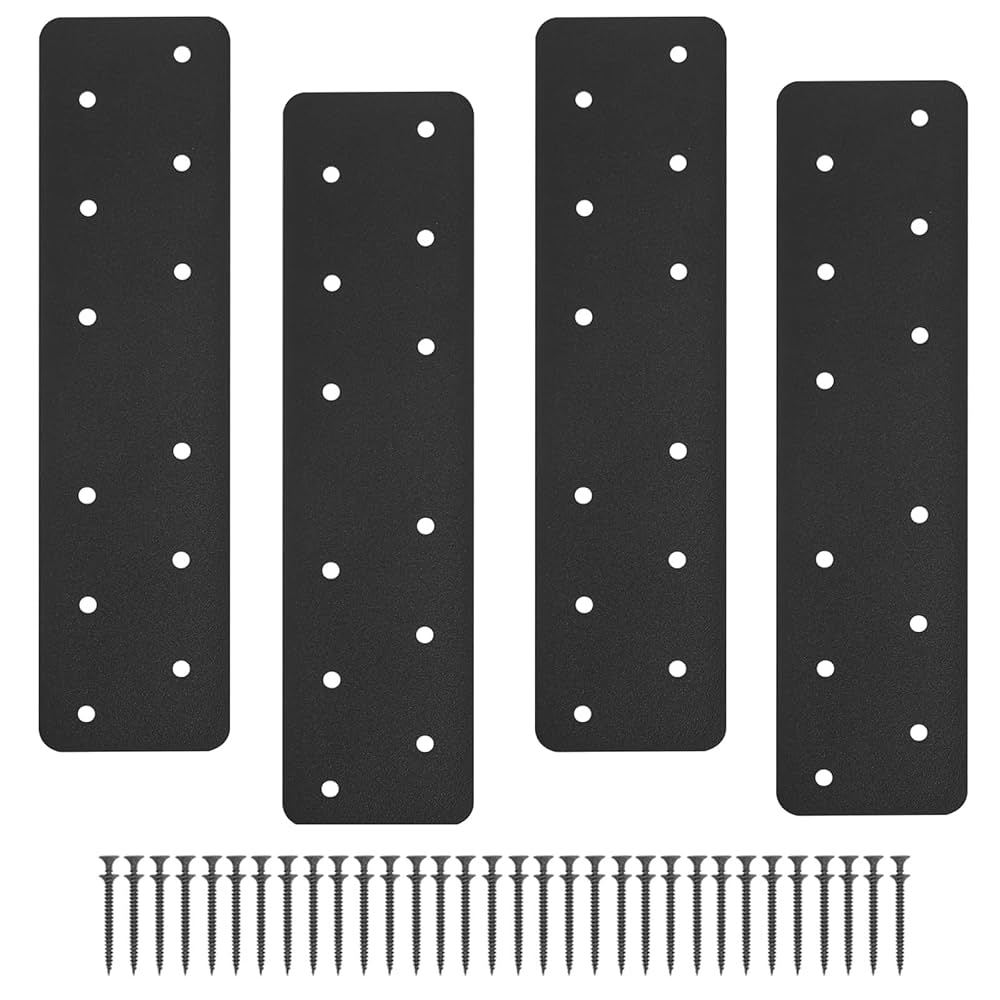

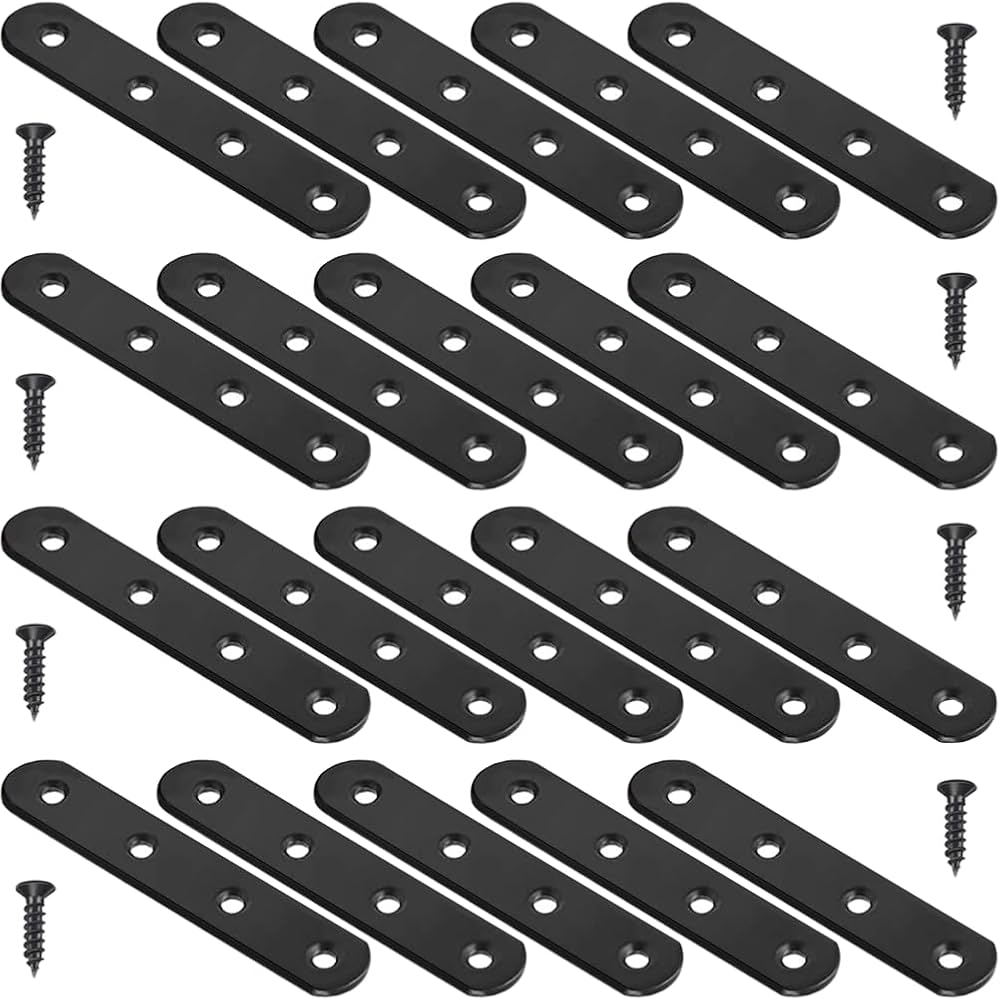

Illustrative image related to brackets flat

Scenario 2: Ensuring Compatibility in Structural Designs

The Problem: Another common issue faced by B2B buyers is ensuring that flat brackets are compatible with various structural designs and materials. Often, buyers encounter challenges when the brackets they select do not fit properly with the dimensions of beams, posts, or shelves, leading to inefficient installations and increased project costs.

The Solution: To avoid compatibility issues, buyers should meticulously measure the dimensions of the structural elements where the brackets will be installed. Create a detailed specification sheet that includes all necessary measurements, load requirements, and material types. When selecting flat brackets, opt for those that offer adjustable features or a range of sizes to accommodate different applications. Engaging with suppliers who provide customization options can also ensure that the brackets meet specific design requirements, facilitating a smoother installation process.

Scenario 3: Navigating Price Variability and Bulk Purchasing

The Problem: Price variability can be a significant concern for B2B buyers, especially when purchasing flat brackets in bulk. Fluctuations in pricing can arise from changes in material costs, shipping fees, or supplier pricing strategies. This uncertainty can complicate budgeting and financial forecasting for projects, leading to potential overruns.

The Solution: To navigate pricing challenges effectively, buyers should establish long-term contracts or agreements with suppliers to lock in prices over a defined period. This strategy not only helps in budgeting but also fosters better relationships with suppliers. Additionally, consider joining a buying group or consortium that allows for bulk purchasing across multiple businesses, which can lead to volume discounts. Monitoring market trends and being proactive in negotiations can also yield cost savings. Lastly, evaluating total cost of ownership, including shipping and handling, can provide a clearer picture of the overall expenses associated with flat brackets, ensuring that budgets remain intact.

Strategic Material Selection Guide for brackets flat

When selecting materials for flat brackets, it is essential to consider various factors such as performance characteristics, cost implications, and regional compliance standards. Below is an analysis of four common materials used in the manufacturing of flat brackets, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Steel Flat Brackets?

Steel is one of the most widely used materials for flat brackets due to its strength and versatility. Steel brackets can withstand high loads and are suitable for various applications, including construction and furniture assembly. Key properties include high tensile strength, good corrosion resistance when galvanized, and the ability to withstand elevated temperatures.

Pros of steel brackets include their durability and load-bearing capacity, making them suitable for heavy-duty applications. However, cons involve potential rusting if not treated properly, which may limit their use in humid or coastal environments. For international buyers, compliance with standards such as ASTM A36 for structural steel is crucial, particularly in regions like Germany and Nigeria, where quality assurance is paramount.

How Do Aluminum Flat Brackets Compare in Performance?

Aluminum is another popular choice for flat brackets, especially in applications where weight is a concern. It is lightweight, resistant to corrosion, and offers good thermal conductivity. Aluminum brackets are often used in automotive and aerospace applications due to their favorable strength-to-weight ratio.

The key advantage of aluminum brackets is their resistance to corrosion, which makes them suitable for outdoor applications. However, they can be less durable under heavy loads compared to steel. Additionally, the manufacturing complexity can lead to higher costs. For buyers in South America and the Middle East, ensuring compliance with international standards like JIS H 4000 for aluminum alloys is essential.

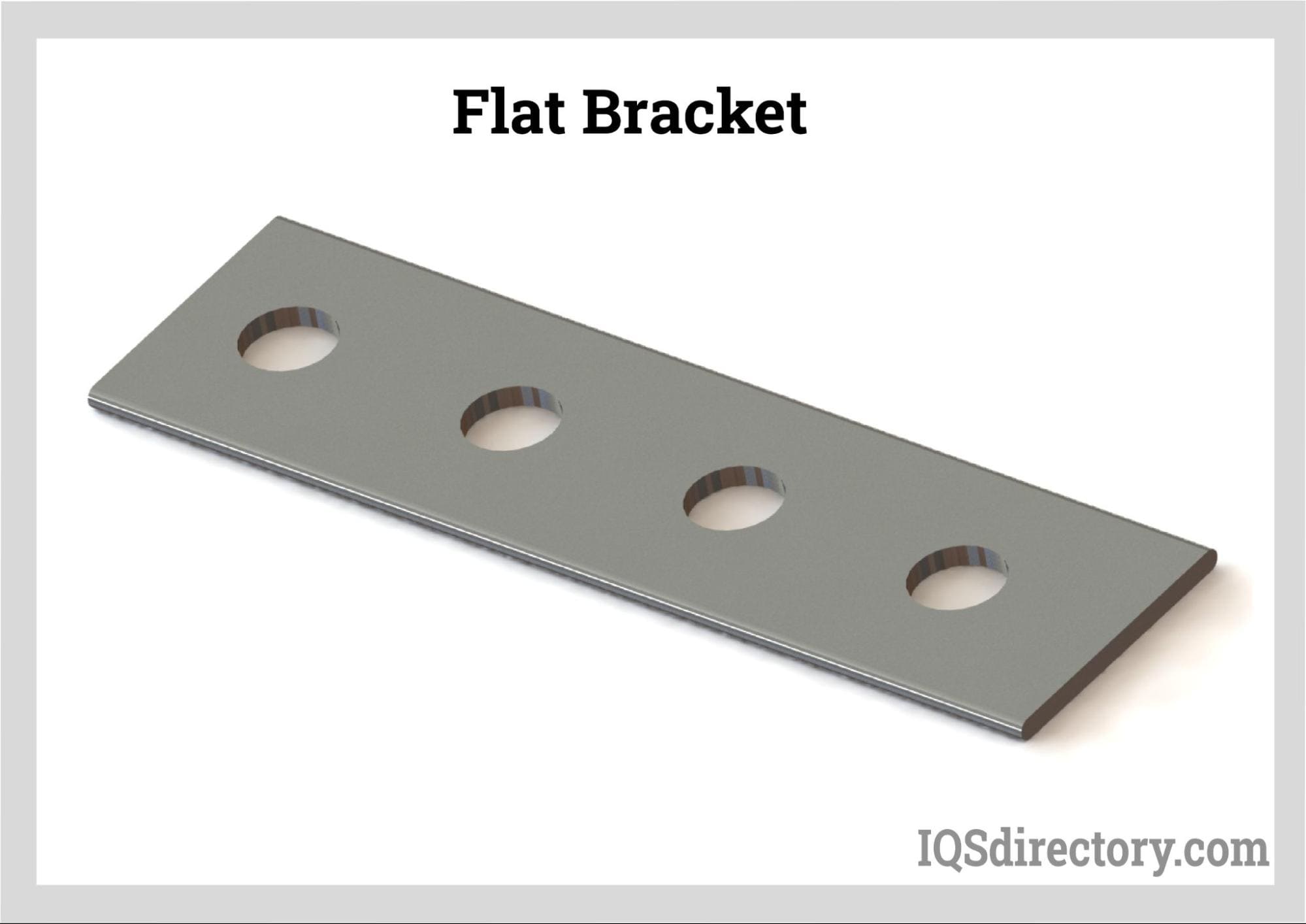

Illustrative image related to brackets flat

What Are the Benefits of Using Plastic Flat Brackets?

Plastic brackets, often made from high-density polyethylene (HDPE) or polyvinyl chloride (PVC), are lightweight and resistant to moisture and chemicals. They are commonly used in applications where corrosion resistance is critical, such as in plumbing and outdoor furniture.

The key advantage of plastic brackets is their resistance to corrosion and chemicals, making them ideal for specific environments. However, they may not support heavy loads as effectively as metal brackets. Additionally, plastic brackets may not meet the same structural standards as metal options, which can be a concern for buyers in Europe and Africa who require compliance with stringent regulations.

What Role Does Stainless Steel Play in Flat Bracket Applications?

Stainless steel is an excellent choice for flat brackets that require both strength and corrosion resistance. With a composition that includes chromium, stainless steel resists rust and staining, making it suitable for applications in marine environments or areas with high humidity.

The key advantage of stainless steel brackets is their longevity and aesthetic appeal, as they maintain their appearance over time. However, they tend to be more expensive than other materials, which can impact budget considerations. For international buyers, understanding compliance with standards such as DIN EN 10088 for stainless steel is vital, especially in regions like Germany where quality standards are strictly enforced.

Summary Table of Material Selection for Flat Brackets

| Material | Typical Use Case for brackets flat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty construction | High tensile strength | Prone to rust without treatment | Medium |

| Aluminum | Automotive, aerospace applications | Lightweight and corrosion-resistant | Lower load capacity than steel | High |

| Plastic | Plumbing, outdoor furniture | Corrosion and chemical resistance | Limited load-bearing capability | Low |

| Stainless Steel | Marine, high-humidity environments | Excellent corrosion resistance | Higher cost compared to other metals | High |

This guide provides a comprehensive overview of material selection for flat brackets, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for brackets flat

What Are the Main Stages of Manufacturing Flat Brackets?

The manufacturing process of flat brackets involves several key stages, each critical to producing high-quality components that meet industry standards.

Material Preparation

The journey begins with material selection. Flat brackets are typically made from metals such as steel, stainless steel, or aluminum, chosen based on the application’s specific requirements, including strength, corrosion resistance, and weight. The selected materials undergo cutting and shearing to achieve the desired dimensions. This initial stage is crucial, as any defects in the raw materials can lead to issues down the line.

Illustrative image related to brackets flat

Forming Techniques for Flat Brackets

Following material preparation, the next stage is forming. This involves shaping the flat metal into the required form through processes such as stamping, bending, or laser cutting. Advanced techniques like CNC (Computer Numerical Control) machining are often employed to ensure precision and repeatability. Stamping is particularly popular for mass production, allowing for quick and efficient shaping while maintaining tight tolerances.

Assembly Process for Flat Brackets

Once formed, the brackets may require assembly, especially if they incorporate additional features like gussets or support plates. This stage can involve welding, riveting, or using mechanical fasteners. Automated assembly lines are increasingly common in modern manufacturing, enhancing consistency and reducing labor costs. For B2B buyers, understanding the assembly process can provide insights into the product’s strength and durability.

Finishing Touches: What Processes Are Used?

The final stage of manufacturing involves finishing processes, which can include coating, painting, or galvanizing. These treatments not only enhance the aesthetic appeal of the brackets but also provide protection against environmental factors such as moisture and UV radiation. Electroplating and powder coating are popular choices, as they significantly increase the lifespan of the products. Buyers should inquire about the finishing techniques used, as they can impact both performance and longevity.

How Is Quality Assurance Implemented in Flat Bracket Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the final product meets specified standards and customer expectations.

What International Standards Are Relevant for Flat Bracket Quality?

International standards such as ISO 9001 provide a framework for establishing effective quality management systems. This certification requires manufacturers to demonstrate consistent quality in their products and services. Additionally, industry-specific certifications, such as CE marking for European markets or API for oil and gas applications, can further validate a supplier’s commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early. These include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the production process helps identify any deviations from quality standards.

- Final Quality Control (FQC): The final inspection before shipping ensures that all products meet the required specifications.

Employing these checkpoints helps to minimize defects and ensures consistent product quality.

What Testing Methods Are Commonly Used?

Various testing methods are employed to ensure the integrity and performance of flat brackets. These can include tensile tests to assess strength, fatigue tests to evaluate endurance, and corrosion resistance tests to determine longevity. Non-destructive testing (NDT) methods, such as ultrasonic or magnetic particle inspections, may also be used to detect internal flaws without compromising the product.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must be proactive in verifying a supplier’s quality control measures to ensure they receive reliable products. Here are some strategies:

What Should Buyers Look for in Supplier Audits and Reports?

Requesting audits and quality reports from suppliers can provide valuable insights into their quality management practices. Buyers should look for documentation of compliance with international standards, results from previous inspections, and any corrective actions taken in response to identified issues.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can add an extra layer of assurance. These independent evaluations can verify that suppliers adhere to specified quality standards and manufacturing processes. This is particularly important for international buyers who may not be able to conduct on-site inspections.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regulatory Compliance: Different regions have varying regulations that may affect product specifications. Understanding these requirements is essential for compliance and market entry.

- Cultural Differences: Approaches to quality management can vary by region. Building strong communication channels with suppliers can help mitigate misunderstandings regarding quality expectations.

- Logistical Challenges: Shipping and handling can impact product quality. Buyers should ensure that suppliers have robust packaging and transport methods to protect products during transit.

By understanding the manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing flat brackets. This knowledge not only aids in selecting reliable suppliers but also ensures that the products meet the necessary performance standards for their specific applications.

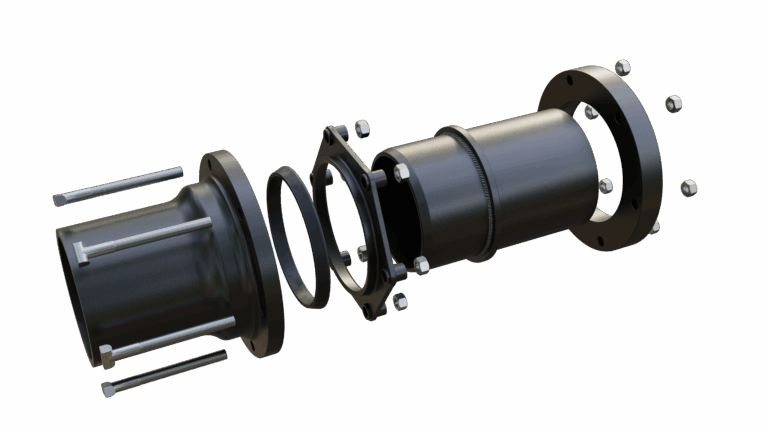

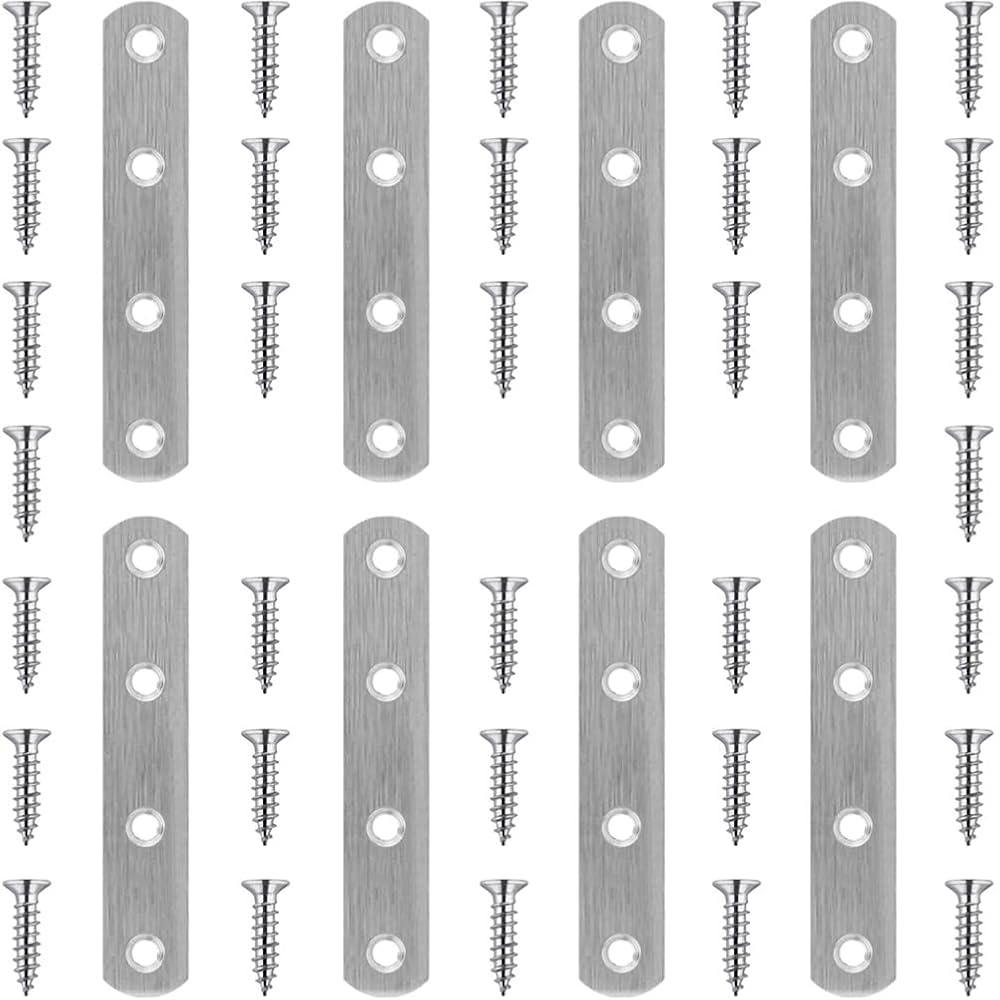

Illustrative image related to brackets flat

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brackets flat’

In today’s competitive landscape, acquiring high-quality flat brackets is essential for ensuring the structural integrity of various applications, from furniture assembly to construction projects. This practical sourcing guide provides B2B buyers with a systematic checklist to streamline the procurement process and secure the best products for their needs.

Step 1: Define Your Technical Specifications

Before initiating your sourcing journey, it’s crucial to establish clear technical specifications for the flat brackets you need. Consider factors such as size, material (e.g., steel, zinc-plated, or galvanized), load capacity, and application environment (indoor or outdoor). These specifications will guide your supplier search and help ensure you acquire brackets that meet your operational requirements.

Step 2: Research Potential Suppliers

Engage in comprehensive research to identify potential suppliers that specialize in flat brackets. Look for suppliers with a robust online presence, positive customer reviews, and a history of reliability. Pay attention to their experience in your specific industry, as this can indicate their understanding of your unique needs.

- Key resources: Supplier directories, trade shows, and industry forums.

- Check their product range: Ensure they offer a variety of sizes and materials.

Step 3: Evaluate Supplier Certifications and Compliance

Verifying supplier certifications is vital to ensure the quality and safety of the products you are sourcing. Look for certifications such as ISO 9001 or specific industry standards relevant to your application. This step minimizes risks associated with substandard products that could compromise your projects.

- Request documentation: Ask for compliance certificates and quality assurance processes.

- Understand regional regulations: Different regions may have specific requirements for construction materials.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the flat brackets you are considering. Assess the quality, finish, and dimensions to ensure they align with your specifications. This hands-on evaluation can prevent costly mistakes and ensure that the products will perform as expected in real-world applications.

Illustrative image related to brackets flat

- Inspect for durability: Check for rust resistance or coating quality, especially for outdoor applications.

- Verify dimensions: Ensure that the samples match the required specifications accurately.

Step 5: Compare Pricing and Terms

Once you have identified suitable suppliers and evaluated their samples, it’s time to compare pricing and terms. Look beyond just the unit price; consider shipping costs, payment terms, and any bulk purchase discounts. Understanding the total cost of ownership will help you make an informed decision.

- Negotiate terms: Don’t hesitate to negotiate better pricing or payment conditions based on your volume needs.

- Evaluate lead times: Ensure that the supplier can meet your delivery deadlines.

Step 6: Check References and Customer Feedback

Before finalizing your supplier choice, check references and gather feedback from their previous customers. This step provides insights into the supplier’s reliability, product quality, and customer service. Look for testimonials or case studies that illustrate their capability in meeting client expectations.

- Ask specific questions: Inquire about the supplier’s response to issues or delays.

- Seek industry-specific references: This can give you a clearer picture of their performance in your field.

Step 7: Finalize the Purchase Agreement

After thorough evaluation and due diligence, finalize the purchase agreement with the selected supplier. Clearly outline the terms of the agreement, including product specifications, quantities, pricing, delivery timelines, and warranty information. A well-documented agreement protects both parties and sets clear expectations.

- Include performance clauses: Consider adding clauses that address potential quality issues or delays.

- Review payment terms: Ensure that the payment schedule aligns with your financial planning.

Following this checklist will empower B2B buyers to make informed decisions when sourcing flat brackets, ultimately leading to enhanced project outcomes and operational efficiency.

Comprehensive Cost and Pricing Analysis for brackets flat Sourcing

When sourcing flat brackets, international B2B buyers must navigate a complex cost structure that encompasses various components essential for accurate pricing. Understanding these components will empower buyers to make informed purchasing decisions and optimize their supply chain.

What Are the Key Cost Components for Flat Bracket Sourcing?

The cost structure for flat brackets typically includes several key components:

-

Materials: The choice of materials, such as steel, aluminum, or galvanized finishes, significantly impacts the cost. High-quality materials can enhance durability but may raise the price. Buyers should evaluate the material requirements based on the intended application to balance cost and quality.

-

Labor: Labor costs can vary depending on the region of production and the complexity of manufacturing processes. Skilled labor may command higher wages, but it often results in better craftsmanship and quality.

-

Manufacturing Overhead: This includes costs associated with the production facility, utilities, and indirect labor. Efficient manufacturers may pass on savings to buyers, making it essential to consider the production environment when assessing pricing.

-

Tooling: Custom designs or specifications may require specialized tooling, which can increase initial costs. Buyers should inquire about tooling fees, especially for low-volume orders.

-

Quality Control (QC): Implementing QC processes to ensure product integrity adds to overall costs. Certifications such as ISO can enhance product credibility but may also reflect higher prices.

-

Logistics: Shipping costs can vary significantly based on distance, mode of transport, and handling fees. Incoterms play a critical role in determining who bears these costs, affecting the total landed price.

-

Margin: Supplier margins can fluctuate based on competition, demand, and market conditions. Understanding the typical margin in your sector can help in negotiating better deals.

How Do Price Influencers Affect Flat Bracket Costs?

Several factors influence the pricing of flat brackets, particularly in an international B2B context:

-

Volume/MOQ: Bulk orders typically yield lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom designs may incur additional costs. Buyers should evaluate whether standard options meet their requirements to avoid unnecessary expenditures.

-

Material Quality and Certifications: Higher quality materials or certified products generally command higher prices. However, investing in superior products can reduce long-term costs related to maintenance and replacements.

-

Supplier Factors: The supplier’s reputation, reliability, and experience can influence pricing. Established suppliers may offer better quality assurance, justifying a higher price point.

-

Incoterms: Different Incoterms can shift cost responsibilities between buyers and sellers, impacting the overall cost structure. Familiarity with these terms is crucial for accurate budgeting.

What Buyer Tips Can Help Optimize Flat Bracket Sourcing Costs?

To achieve cost efficiency in sourcing flat brackets, international buyers should consider the following strategies:

-

Negotiate Terms: Engage in negotiations to secure favorable pricing and terms. Leveraging volume purchases can lead to discounts.

-

Evaluate Total Cost of Ownership: Look beyond initial purchase prices. Consider factors like durability, maintenance, and potential downtime when assessing the total cost of ownership.

-

Understand Pricing Nuances: Be aware of regional pricing differences, particularly in emerging markets in Africa and South America. Currency fluctuations and local demand can impact costs.

-

Research Suppliers: Conduct thorough due diligence on suppliers. Assess their capabilities, quality standards, and customer reviews to ensure alignment with your expectations.

-

Plan for Logistics: Factor in logistics costs early in the sourcing process. Working with suppliers who have established logistics networks can streamline the supply chain and reduce costs.

Conclusion

While sourcing flat brackets involves navigating a multifaceted cost structure, understanding the key components and price influencers can lead to more strategic purchasing decisions. By applying effective negotiation tactics and focusing on total cost considerations, international B2B buyers can enhance their sourcing strategies and achieve greater value from their investments.

Illustrative image related to brackets flat

Alternatives Analysis: Comparing brackets flat With Other Solutions

Exploring Alternatives to Brackets Flat: A Comparative Analysis

In the realm of structural and furniture hardware, ‘brackets flat’ serve a critical function in providing stability and support. However, B2B buyers often seek various solutions that can fulfill similar roles. This analysis compares brackets flat against two viable alternatives: Corner Braces and Concealed Brackets. Each option has its own strengths and weaknesses, which can influence purchasing decisions based on specific project needs.

| Comparison Aspect | Brackets Flat | Corner Braces | Concealed Brackets |

|---|---|---|---|

| Performance | High load-bearing capacity, versatile in application | Excellent for right-angle joints, provides strong support | Aesthetic appeal, hides hardware from view |

| Cost | Generally low cost, varies by material | Typically affordable, bulk pricing available | Higher initial cost due to design and materials |

| Ease of Implementation | Simple installation, requires basic tools | Easy to install, often comes with fasteners | Installation can be more complex, may require specialized tools |

| Maintenance | Minimal maintenance required | Durable, low maintenance | Occasional checks for stability needed |

| Best Use Case | Ideal for general support in furniture and construction | Best suited for structural reinforcement at corners | Preferred for cabinetry and design-focused projects |

What Are the Advantages and Disadvantages of Corner Braces?

Corner braces are widely used in construction and furniture assembly, particularly where right angles are critical. Their primary advantage lies in their robust design, which allows them to handle significant stress and weight. They typically come in various materials, including galvanized steel and zinc, making them suitable for both indoor and outdoor applications. However, their visibility can be a drawback in design-focused projects, as they may detract from aesthetic appeal.

How Do Concealed Brackets Offer Unique Benefits?

Concealed brackets provide a sleek and unobtrusive look, making them an excellent choice for high-end cabinetry and furniture where design is a priority. They allow for clean lines and a minimalist appearance, which can enhance the overall aesthetic of a project. However, their installation can be more complex and may require specialized tools or skills, making them less accessible for DIY projects. Additionally, the cost is typically higher, which may be a consideration for budget-conscious buyers.

Making the Right Choice: How Should B2B Buyers Decide?

When choosing between brackets flat, corner braces, and concealed brackets, B2B buyers should consider the specific requirements of their projects. Factors such as load-bearing needs, aesthetic preferences, installation complexity, and budget constraints will significantly influence the decision. For projects prioritizing functionality and ease of use, brackets flat or corner braces may be the best choice. Conversely, for high-end applications where design is crucial, concealed brackets could provide the desired aesthetic and functionality.

Ultimately, understanding the strengths and weaknesses of each option will empower buyers to make informed decisions that align with their project goals.

Illustrative image related to brackets flat

Essential Technical Properties and Trade Terminology for brackets flat

What Are the Essential Technical Properties of Flat Brackets?

1. Material Composition

Flat brackets are typically made from materials like steel, zinc, or galvanized steel. The material affects the bracket’s strength, durability, and corrosion resistance. For instance, galvanized steel offers enhanced protection against rust, making it suitable for outdoor applications. Understanding the material composition helps buyers select the right brackets for specific environments, ensuring longevity and reliability in their projects.

2. Load Capacity

The load capacity of a flat bracket indicates how much weight it can support without failure. This specification is crucial for B2B buyers, as it directly impacts the structural integrity of the application, whether in furniture, shelving, or construction. Knowing the load capacity allows businesses to choose the appropriate brackets for their needs, preventing potential safety hazards and costly failures.

3. Dimensions and Tolerances

Dimensions refer to the size of the bracket, including length, width, and thickness, while tolerances denote the allowable variations in these dimensions. Accurate dimensions are vital for ensuring a proper fit in assembly applications. For international buyers, understanding tolerances is essential to prevent discrepancies during manufacturing and to ensure that components align correctly.

4. Finish Type

The finish type, such as powder-coated, zinc-plated, or galvanized, affects the aesthetic and functional properties of flat brackets. A specific finish can enhance corrosion resistance and provide a more appealing appearance. Buyers should consider the finish type based on the intended use, whether for indoor decorative applications or rugged outdoor settings.

5. Fastening Mechanism

The fastening mechanism refers to how the bracket attaches to other components, which can include screws, bolts, or adhesives. Different fastening methods can provide varying levels of stability and ease of installation. Understanding the fastening mechanism helps buyers select brackets that will work seamlessly with their existing systems and facilitate easier assembly.

What Are Common Trade Terms Associated with Flat Brackets?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of flat brackets, this term is significant for buyers looking to source high-quality components for their products. Understanding OEM relationships can lead to better pricing and product consistency.

Illustrative image related to brackets flat

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier requires a buyer to purchase. This term is essential for B2B transactions as it affects inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases effectively and avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. For flat brackets, submitting an RFQ allows buyers to compare offers from different suppliers, ensuring they receive the best value for their purchase. Understanding how to create an effective RFQ can streamline the procurement process.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms is crucial for B2B buyers involved in international trade, as they clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms helps avoid disputes and ensures a smoother transaction process.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In the context of flat brackets, understanding lead times can help businesses manage their project timelines and inventory levels. Being aware of lead times allows for better planning and can prevent delays in production or construction.

These technical properties and trade terms equip B2B buyers with the knowledge necessary to make informed decisions regarding flat brackets, ultimately enhancing their purchasing strategies and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the brackets flat Sector

What Are the Key Market Trends Influencing the Brackets Flat Sector?

The global brackets flat market is witnessing significant transformation driven by various factors, including increasing demand for construction and DIY projects, technological advancements, and evolving consumer preferences. Countries in Africa, South America, the Middle East, and Europe are particularly relevant markets, as urbanization and infrastructural development accelerate. For instance, Nigeria’s booming construction sector and Germany’s emphasis on high-quality manufacturing are indicative of the diverse opportunities for international buyers.

Emerging B2B technology trends, such as e-commerce platforms and digital supply chain management, are reshaping how buyers source flat brackets. These technologies facilitate real-time inventory management, enhance procurement processes, and allow for a broader selection of products. Additionally, trends towards customization and modular designs are gaining traction, as businesses look for tailored solutions that meet specific project requirements. The increasing popularity of sustainable construction materials is also influencing sourcing decisions, prompting manufacturers to innovate and adapt their product lines.

With the ongoing challenges posed by supply chain disruptions, international B2B buyers must remain agile. Collaborating with suppliers that demonstrate flexibility and responsiveness can mitigate risks associated with sourcing delays or quality inconsistencies. Understanding regional market dynamics, including local regulations and material availability, is crucial for making informed purchasing decisions.

How Can Sustainability and Ethical Sourcing Impact the Brackets Flat Sector?

Sustainability is becoming a paramount concern for B2B buyers, particularly as environmental regulations tighten and consumer awareness grows. The brackets flat sector is not exempt from this trend, as manufacturers are increasingly pressured to adopt eco-friendly practices. This includes using recycled materials, reducing energy consumption in production, and minimizing waste. Buyers should prioritize suppliers who implement sustainable practices, as this can enhance their brand reputation and align with their corporate social responsibility goals.

Ethical sourcing is equally important, as it ensures that materials are obtained through fair labor practices and responsible environmental stewardship. Buyers should inquire about certifications such as ISO 14001 for environmental management and Fair Trade certifications to validate their suppliers’ commitments to ethical practices. Furthermore, integrating sustainability into procurement strategies can provide a competitive edge, as clients increasingly favor businesses that prioritize eco-friendly solutions.

Investing in ‘green’ materials, such as brackets made from recycled steel or sustainably sourced wood, can further enhance a company’s sustainability profile. By aligning sourcing strategies with sustainability goals, B2B buyers can not only meet regulatory requirements but also attract a growing segment of environmentally conscious consumers.

Illustrative image related to brackets flat

What Is the Historical Context of the Brackets Flat Sector?

The brackets flat sector has evolved significantly over the years, transitioning from simple metal fasteners to sophisticated structural components integral to modern construction and DIY projects. Historically, brackets were primarily made from iron and steel, focusing on functionality and strength. However, as construction techniques advanced and the demand for aesthetics increased, manufacturers began exploring various materials and designs.

The introduction of galvanized and powder-coated finishes marked a turning point, improving corrosion resistance and enhancing the visual appeal of brackets. As global markets expanded, so did the variety of bracket designs available, catering to diverse consumer needs and preferences. Today, the sector is characterized by innovation, with manufacturers focusing on sustainability and customization to meet the demands of a rapidly changing market landscape. For international B2B buyers, understanding this historical context can provide valuable insights into product development trends and sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of brackets flat

-

How do I choose the right flat brackets for my project?

Choosing the right flat brackets involves assessing the specific requirements of your project, including the weight and type of materials you will be supporting. Consider factors such as bracket material (e.g., steel or zinc-plated), size, and load capacity. Look for suppliers that offer detailed specifications and load ratings. Additionally, ensure the brackets are suitable for the intended environment (indoor vs. outdoor) to avoid corrosion or wear. -

What is the best flat bracket for outdoor applications?

For outdoor applications, galvanized steel or powder-coated flat brackets are ideal due to their resistance to rust and corrosion. Look for brackets specifically designed for outdoor use, as they typically feature protective finishes. Consider the load requirements and ensure the bracket can handle the stress of outdoor conditions, such as wind or moisture. Brands that specialize in outdoor hardware often provide detailed guidelines on their products’ suitability. -

What customization options are available for flat brackets?

Many manufacturers offer customization options for flat brackets, including size, material, and finish. Depending on your needs, you can request specific dimensions or load capacities. Some suppliers may also provide branding options, such as logo engraving. Be sure to communicate your requirements clearly to potential suppliers and inquire about minimum order quantities (MOQs) for customized products. -

How do I vet suppliers for flat brackets?

To vet suppliers, start by researching their reputation within the industry. Look for customer reviews, case studies, and their history of international trade. Request samples to assess product quality and check for relevant certifications (e.g., ISO standards). It’s also beneficial to have direct communication with the supplier to gauge their responsiveness and willingness to accommodate your needs. -

What are the typical minimum order quantities (MOQs) for flat brackets?

Minimum order quantities for flat brackets can vary significantly based on the supplier and the specific product. Generally, MOQs can range from as low as 50 units to several hundred. When discussing MOQs, consider your project requirements and budget. Some suppliers may offer flexibility on MOQs for first-time buyers or larger, ongoing orders. -

What payment terms should I expect when sourcing flat brackets internationally?

Payment terms can vary by supplier and region, but common options include payment in advance, letter of credit, or payment upon delivery. For international transactions, consider using secure payment methods like PayPal or escrow services that protect both parties. It’s essential to clarify payment terms upfront to avoid misunderstandings and ensure a smooth transaction. -

How do I ensure quality assurance for flat brackets?

To ensure quality assurance, request certifications and quality control documentation from the supplier. Many reputable manufacturers follow strict quality management systems and can provide proof of compliance. You may also consider third-party inspections before shipment, particularly for large orders. Establishing clear quality standards in your contract can help ensure that the products meet your expectations. -

What logistics considerations should I be aware of when importing flat brackets?

When importing flat brackets, consider shipping costs, lead times, and customs regulations in your country. Choose a reliable logistics provider familiar with international shipping to handle your orders efficiently. Ensure that all documentation, such as invoices and packing lists, is accurate to avoid delays at customs. Understanding the import duties and taxes applicable in your region will also help you budget effectively for your purchase.

Top 5 Brackets Flat Manufacturers & Suppliers List

1. GoBilda – Steel Flat Brackets

Domain: gobilda.com

Registered: 2015 (10 years)

Introduction: {“brackets”: [{“name”: “1126 Series Steel Flat Bracket (1-1)”, “type”: “2 Pack”, “price”: “$2.99”}, {“name”: “1108 Series Flat Pattern Bracket (2-1)”, “type”: “1 Pack”, “price”: “$2.99”}, {“name”: “1137 Series Steel Flat Grid Bracket (1-1)”, “type”: “2 Pack”, “price”: “$4.49”}, {“name”: “1137 Series Steel Flat Grid Bracket (1-2)”, “type”: “2 Pack”, “price”: “$4.49”}, {“name”: “1126-0090-0001 Steel…

2. Häfele – Concealed Brackets

Domain: hafele.com

Registered: 1997 (28 years)

Introduction: Concealed Brackets, Flat Design for attachment to wall studs. Available sizes: 9″ x 12″, 12″ x 12″, 12″ x 15″, 18″ x 18″, 18″ x 21″, 18″ x 24″. Color options: Black (powder coated) and White (powder coated). Item numbers: 287.80.330 (Black 9×12″), 287.80.331 (Black 12×12″), 287.80.332 (Black 12×15″), 287.80.333 (Black 18×18″), 287.80.334 (Black 18×21″), 287.80.335 (Black 18×24″), 287.80.730 (White…

3. PostHugger™ – Flat L Brackets for 4×4 Posts

Domain: posthugger.com

Registered: 2021 (4 years)

Introduction: {“product_name”: “PostHugger™ Flat L Brackets For 4×4 Posts”, “price_range”: “$15.00 – $18.00”, “material_finish”: [“1/8\” Thick Steel”, “1/8\” Thick Steel with Black Powder Coating”], “dimensions”: “6 × 6 × 4 in”, “weight”: “1.25 lbs”, “description”: “These brackets are designed for standard 4×4 posts and beams (3.5” x 3.5”). Made from 1/8″ thick steel, each bracket weighs over 2 pounds, providin…

4. McMaster – Flat Brackets

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Flat Brackets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Unistrut Store – Flat Brackets & Fittings

Domain: unistrutstore.com

Registered: 2018 (7 years)

Introduction: Flat brackets, including splice plates and square washers, are essential Unistrut fittings used to join sections of Unistrut Channel, enabling secure and unique weldless connections. Available configurations include 2-hole, 3-hole, and 4-hole options. Various finishes are offered for these fittings.

Strategic Sourcing Conclusion and Outlook for brackets flat

As businesses globally continue to adapt to an evolving marketplace, the strategic sourcing of flat brackets emerges as a critical factor for success. This essential hardware not only provides structural integrity but also enhances efficiency in various applications, from construction to furniture assembly. By prioritizing quality and reliability in sourcing flat brackets, international B2B buyers can secure competitive advantages, particularly in fast-growing markets across Africa, South America, the Middle East, and Europe.

Understanding regional preferences and material specifications will be vital in making informed purchasing decisions. Buyers should leverage partnerships with reputable suppliers who offer a range of products tailored to specific needs, ensuring compliance with local standards and sustainability practices. This proactive approach can lead to improved supply chain resilience and cost savings.

Looking ahead, the demand for innovative and durable flat brackets is poised to rise. B2B buyers are encouraged to explore new sourcing strategies that incorporate advanced materials and sustainable practices. By doing so, businesses can not only meet current market demands but also position themselves as leaders in a rapidly changing industry landscape. Engage with suppliers today to discover the latest offerings and elevate your sourcing strategy to new heights.

Illustrative image related to brackets flat

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to brackets flat