Choosing Your Metal Perforation Patterns: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for metal perforation patterns

In the ever-evolving landscape of industrial manufacturing, sourcing metal perforation patterns can pose significant challenges for B2B buyers. Whether you are looking to enhance ventilation, achieve aesthetic appeal, or meet specific engineering requirements, the diversity of options available can be overwhelming. This comprehensive guide aims to simplify the process by providing detailed insights into various types of metal perforation patterns, their applications across industries, and essential factors for supplier vetting.

From standard round and square patterns to intricate custom designs, understanding the functionality and aesthetic value of these perforations is crucial for making informed purchasing decisions. Additionally, the guide covers cost considerations, allowing buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Saudi Arabia—to navigate financial implications effectively.

By equipping international B2B buyers with the necessary knowledge and strategies, this guide empowers you to confidently source the right metal perforation patterns tailored to your operational needs. You’ll gain the insights required to optimize your supply chain, enhance product quality, and ultimately drive business success in a competitive global market.

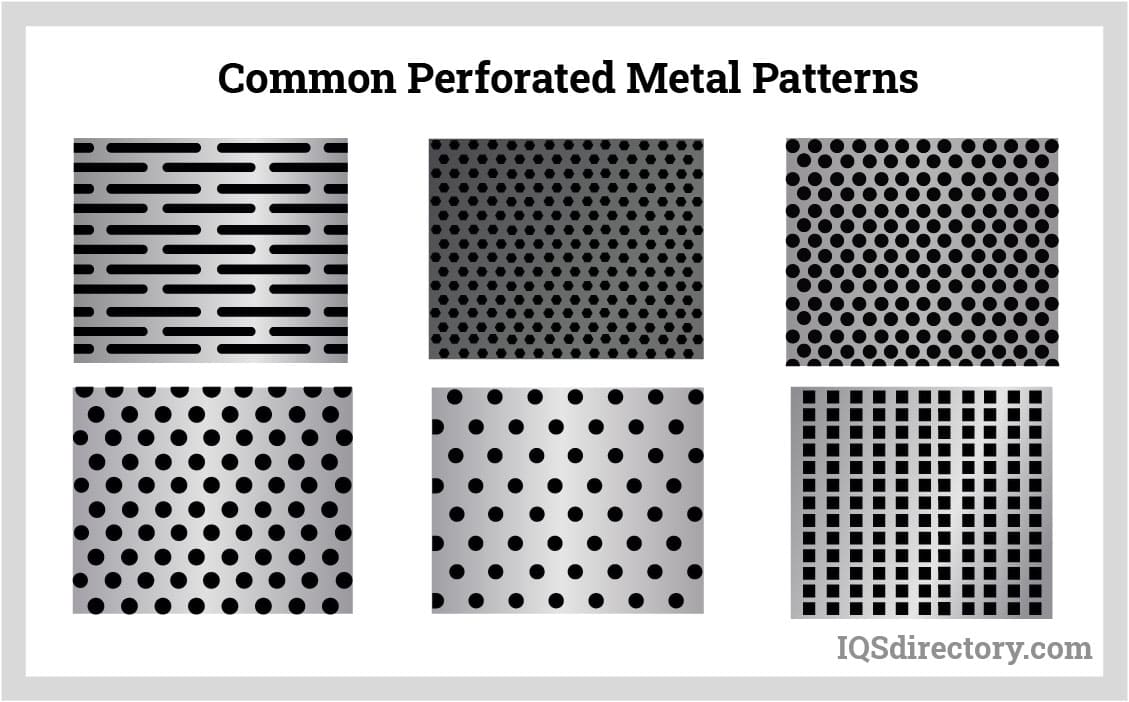

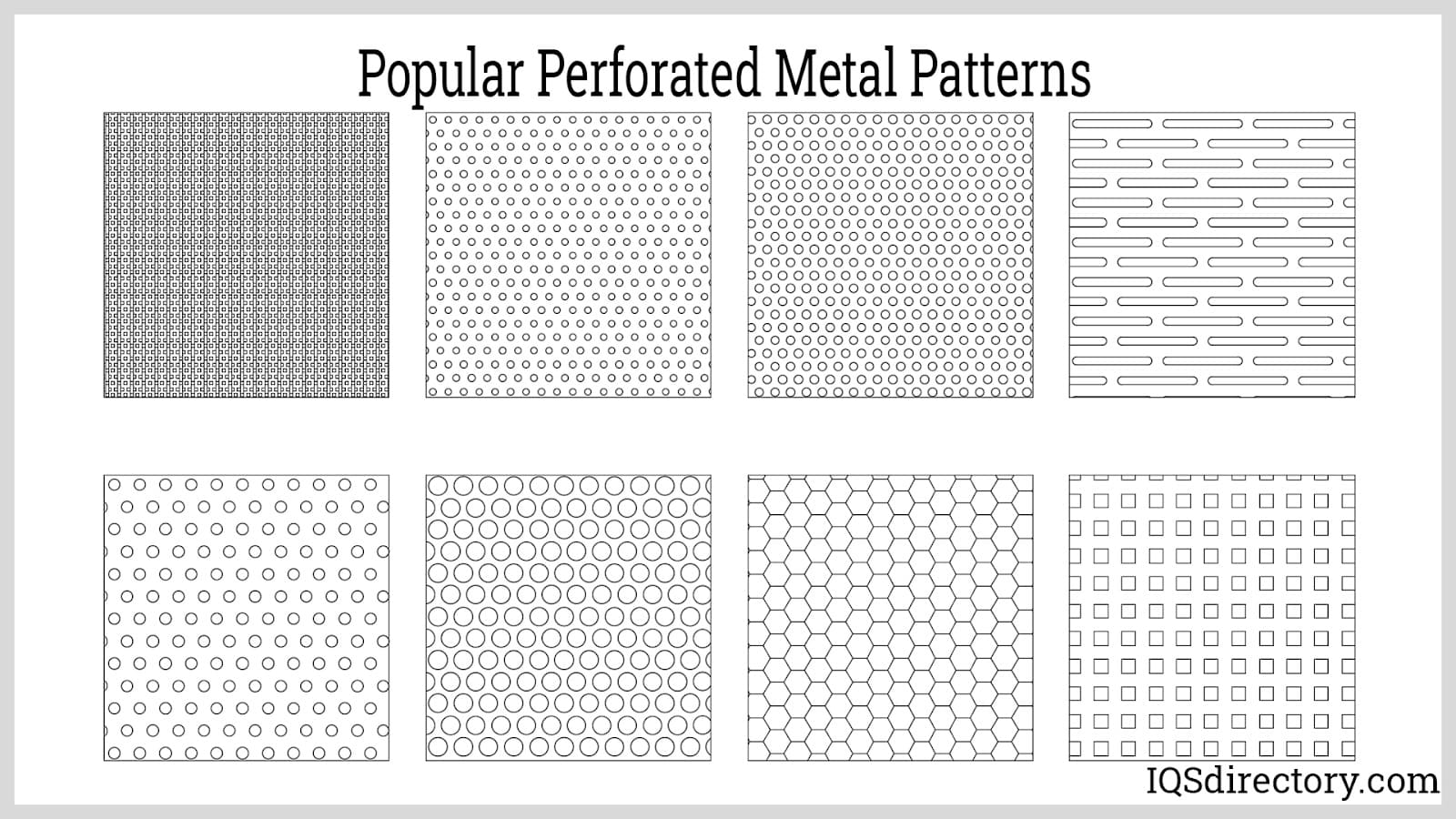

Understanding metal perforation patterns Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Round Perforations | Circular holes, various diameters, staggered or straight alignment | Architectural facades, filters, soundproofing | Pros: Versatile, aesthetically pleasing; Cons: Limited airflow in smaller sizes. |

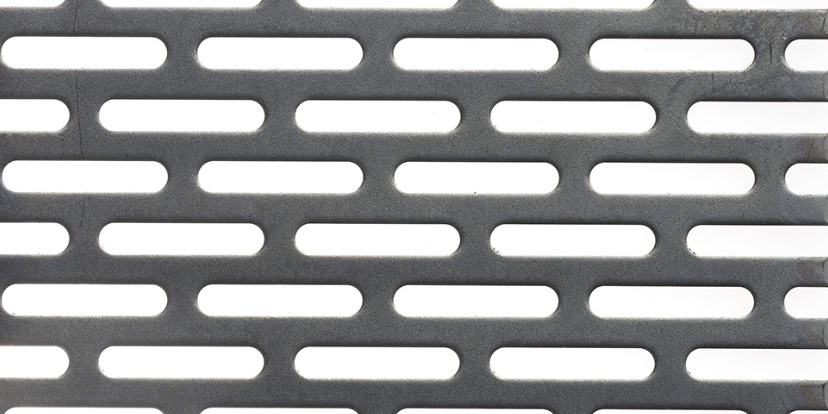

| Slot Perforations | Elongated holes, varying widths and lengths | Grilles, screens, and ventilation systems | Pros: High strength-to-weight ratio; Cons: Can be less visually appealing. |

| Square Perforations | Square-shaped holes, uniform spacing | Decorative panels, fencing, and partitions | Pros: Easy to manufacture; Cons: Less airflow compared to round holes. |

| Decorative Patterns | Customized shapes, intricate designs | Interior design, art installations, and branding | Pros: Unique aesthetics; Cons: Often higher cost and longer lead times. |

| Custom Patterns | Tailored designs based on specific needs | Specialized applications across industries | Pros: Exact fit for unique applications; Cons: May involve longer production times and higher costs. |

What Are the Key Characteristics of Round Perforations?

Round perforations are characterized by their circular holes, which can be produced in a variety of diameters and arrangements, including staggered or straight alignments. This type of perforation is widely used in architectural applications, such as facades and acoustic panels, due to its aesthetic appeal and functional benefits. Buyers should consider the open area percentage, as smaller holes may restrict airflow, impacting applications like filtration or ventilation.

How Do Slot Perforations Differ From Other Types?

Slot perforations feature elongated holes that vary in width and length, making them ideal for applications requiring structural integrity, such as grilles and screens. Their design allows for high strength-to-weight ratios, which is essential in industries like construction and manufacturing. While they offer practical benefits, buyers may find that slot perforations are less visually appealing compared to other types, which could be a consideration for decorative applications.

Why Choose Square Perforations for Specific Applications?

Square perforations are known for their uniform shape and spacing, making them easy to manufacture and integrate into various products. Common applications include decorative panels and fencing, where a clean, geometric look is desired. However, buyers should note that square perforations may provide less airflow compared to round perforations, which could be a critical factor in applications requiring ventilation.

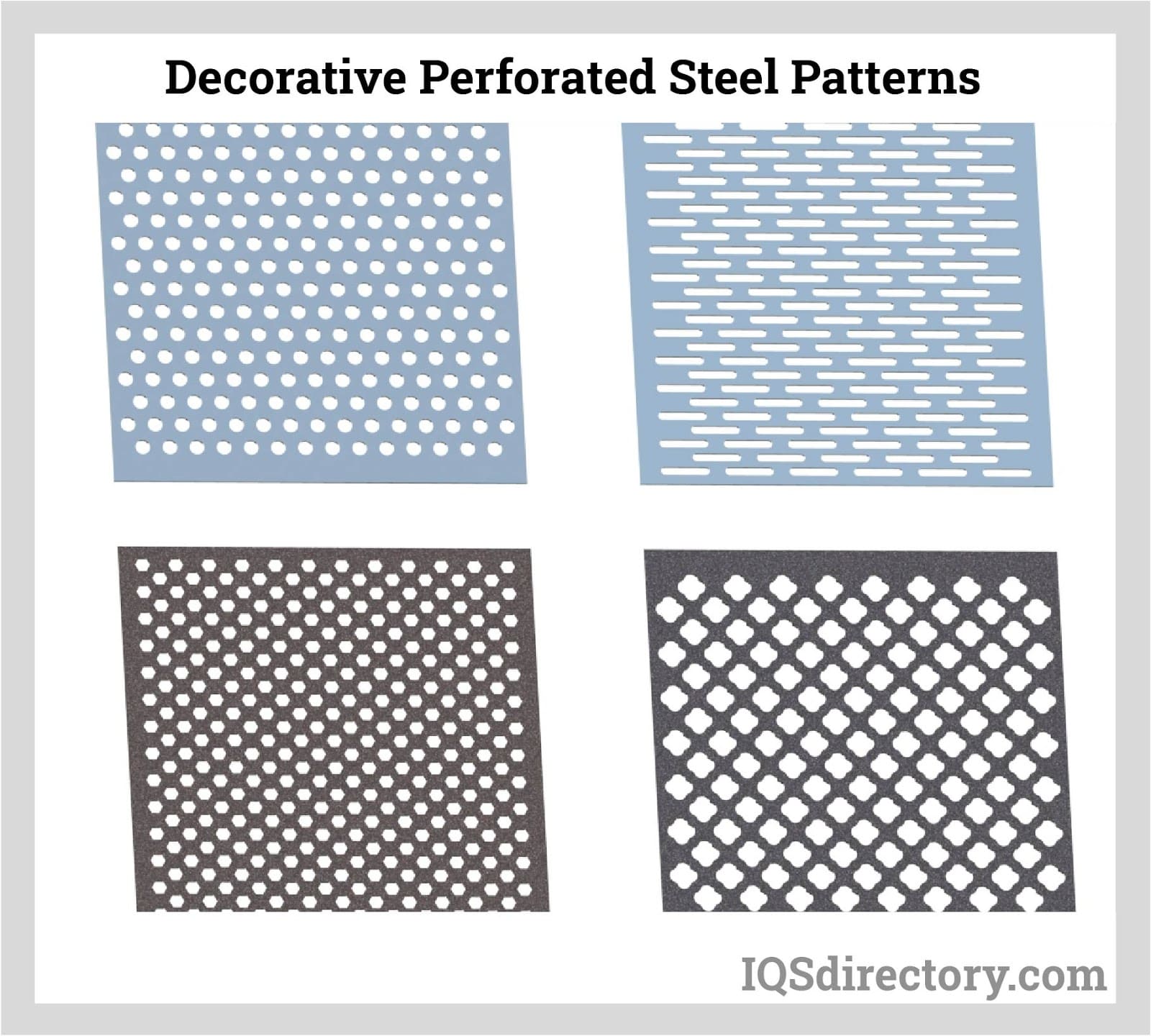

What Advantages Do Decorative Patterns Offer?

Decorative patterns are customized designs that can include intricate shapes and motifs, making them popular in interior design and branding. These patterns allow businesses to create unique visual elements that stand out. However, the customization process often comes with higher costs and longer lead times, so buyers should weigh the benefits of distinct aesthetics against their budget and timeline.

When Are Custom Patterns the Right Choice for Businesses?

Custom perforation patterns are tailored to meet specific requirements, making them ideal for specialized applications across various industries. This flexibility allows businesses to achieve precise functionality and design. However, buyers should be prepared for potentially longer production times and higher costs associated with custom orders, making it essential to plan ahead when considering this option.

Key Industrial Applications of metal perforation patterns

| Industry/Sector | Specific Application of metal perforation patterns | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Facades and Cladding Systems | Enhances aesthetic appeal and ventilation | Material durability, corrosion resistance, and design flexibility |

| Automotive | Interior Components and Grilles | Lightweight design, noise reduction | Compliance with safety standards and customization options |

| Filtration and Separation | Industrial Filters and Screens | Improved filtration efficiency | Mesh size, open area percentage, and ease of maintenance |

| HVAC | Air Distribution Grilles | Energy efficiency and airflow optimization | Resistance to environmental factors and compatibility with systems |

| Architecture | Decorative Wall Panels | Unique design elements and light diffusion | Custom pattern capabilities and material selection |

How Are Metal Perforation Patterns Used in Construction?

In the construction industry, metal perforation patterns are extensively used in facades and cladding systems. These patterns not only enhance the aesthetic appeal of buildings but also facilitate ventilation, allowing for better airflow and temperature regulation. Buyers in regions like Africa and the Middle East often seek materials that can withstand harsh weather conditions, emphasizing the need for corrosion-resistant metals. Additionally, the ability to customize patterns to meet specific architectural designs is a crucial consideration for buyers.

What Role Do Metal Perforation Patterns Play in Automotive Applications?

In the automotive sector, metal perforation patterns are employed in various interior components, including grilles and sound-dampening panels. These patterns contribute to lightweight designs, which enhance fuel efficiency, while also reducing noise inside vehicles. International buyers, particularly from Europe and South America, need to ensure that their suppliers meet stringent safety standards and offer customization to fit specific vehicle models, making sourcing decisions critical for competitive advantage.

How Are Metal Perforation Patterns Essential for Filtration and Separation?

Metal perforation patterns are vital in the filtration and separation industry, where they are used to create industrial filters and screens. The open area percentage and mesh size are crucial for achieving optimal filtration efficiency, making it essential for buyers to specify these requirements clearly. In regions with diverse industrial needs, such as Brazil and Saudi Arabia, sourcing partners must demonstrate expertise in producing patterns that meet specific operational demands while ensuring easy maintenance and durability.

How Do HVAC Systems Benefit from Metal Perforation Patterns?

In HVAC applications, metal perforation patterns are utilized in air distribution grilles, playing a significant role in energy efficiency and airflow optimization. Buyers need to consider the materials’ resistance to environmental factors, especially in areas with extreme temperatures. Compatibility with existing HVAC systems is also a key factor for international buyers, who often seek suppliers that can deliver tailored solutions that enhance system performance while maintaining aesthetic appeal.

Why Are Metal Perforation Patterns Important in Architecture?

In architecture, metal perforation patterns are increasingly popular for decorative wall panels that provide unique design elements and light diffusion. Buyers value the ability to customize these patterns to create visually striking interiors or exteriors. Sourcing considerations include the capability to produce complex designs and the selection of materials that align with sustainability goals, particularly relevant in European markets where green building practices are prioritized.

3 Common User Pain Points for ‘metal perforation patterns’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Metal Perforation Pattern for Specific Applications

The Problem: B2B buyers often struggle to identify the correct metal perforation patterns that fit their specific project needs. With a plethora of options available, it can be overwhelming to determine which pattern will provide the necessary functional benefits, such as air flow, light diffusion, or aesthetic appeal. This challenge can lead to costly mistakes, as selecting an inappropriate pattern may compromise the product’s performance or increase manufacturing costs due to rework or redesign. Additionally, for international buyers, variations in standards and practices across regions can complicate the selection process further.

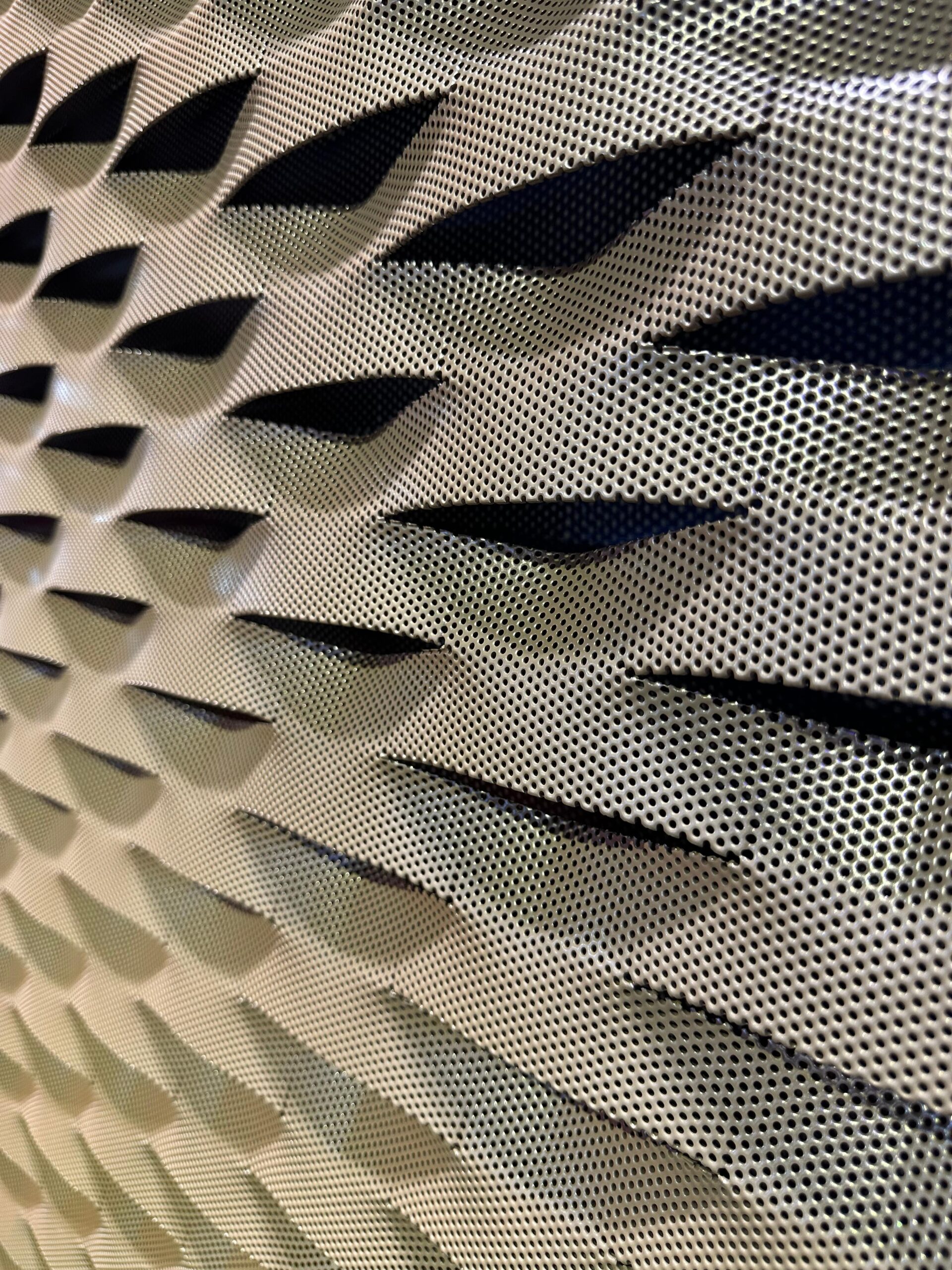

Illustrative image related to metal perforation patterns

The Solution: To effectively source the right metal perforation pattern, buyers should begin by conducting a thorough assessment of their project requirements. This includes understanding the desired open area percentage, hole size, and pattern type, whether it be round, square, or decorative. Engaging with suppliers who offer extensive libraries of perforated patterns can significantly ease this process. Buyers should take advantage of resources such as pattern design tools or sample kits that allow for real-world testing of patterns. Additionally, collaborating with the supplier during the design phase can lead to the creation of custom patterns that meet specific functional and aesthetic needs, ensuring both performance and visual appeal.

Scenario 2: Inconsistent Quality and Specifications Across Suppliers

The Problem: Another common pain point for B2B buyers is the inconsistency in quality and specifications when sourcing metal perforation patterns from multiple suppliers. This variability can lead to issues such as mismatched dimensions, subpar material quality, or even performance discrepancies in finished products. Such inconsistencies can result in delays in production, increased costs, and dissatisfaction among end customers, ultimately damaging the buyer’s reputation and business relationships.

The Solution: To combat quality inconsistencies, buyers should establish strong relationships with a select group of trusted suppliers who are known for their reliability and quality assurance processes. It is crucial to request detailed specifications, including material certifications and tolerances, for every order. Implementing a quality control process that includes pre-production samples and on-site inspections can help ensure that products meet the necessary standards before they reach the production line. Additionally, leveraging digital tools for tracking order history and quality metrics can provide insights into supplier performance, allowing buyers to make informed decisions based on past experiences.

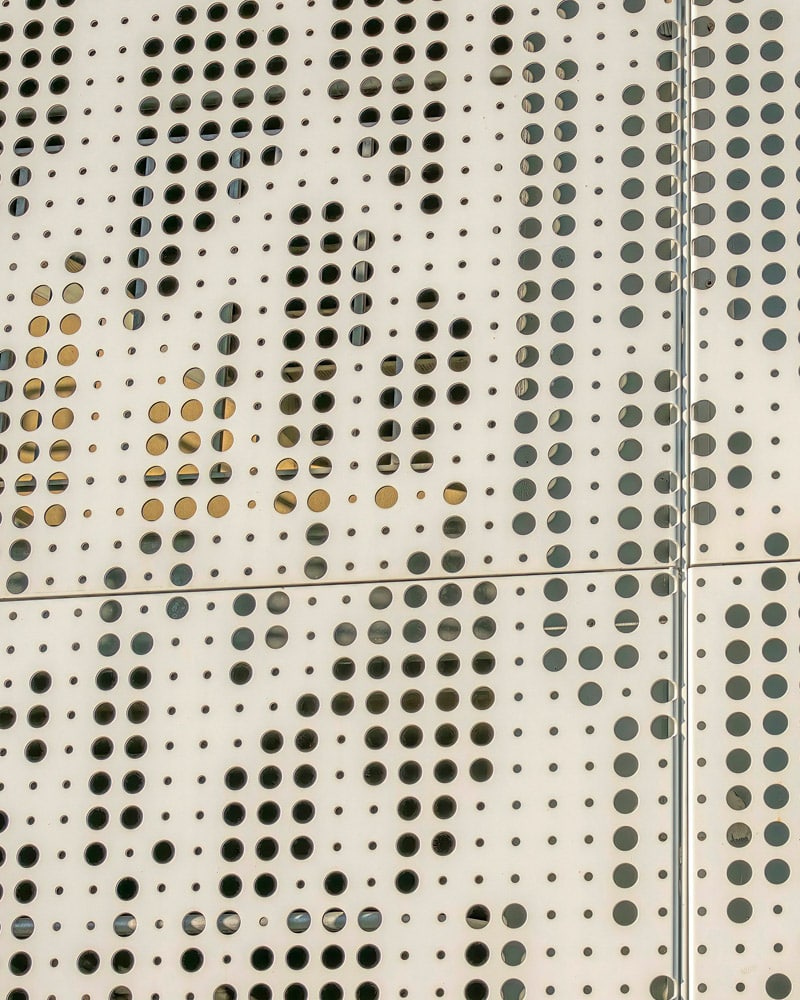

Illustrative image related to metal perforation patterns

Scenario 3: High Costs Due to Inefficient Ordering Processes

The Problem: B2B buyers frequently encounter high costs stemming from inefficient ordering processes for metal perforation patterns. This inefficiency can arise from multiple factors, including unclear specifications, lengthy lead times, or unexpected shipping costs, especially for international orders. These issues not only inflate costs but can also disrupt project timelines and cause frustration among teams who rely on timely deliveries to keep projects on track.

The Solution: To streamline the ordering process and reduce costs, buyers should invest in creating clear and concise specifications for their orders. Utilizing standardized templates for order requests can help eliminate ambiguity and ensure that suppliers understand the requirements from the outset. Moreover, implementing a just-in-time inventory system can minimize holding costs and reduce the risk of over-ordering. Buyers should also consider negotiating long-term contracts with suppliers to secure better pricing and more predictable lead times. Establishing a digital procurement system can further enhance efficiency by automating order placement and tracking, allowing buyers to focus on strategic initiatives rather than logistical challenges.

Strategic Material Selection Guide for metal perforation patterns

What Are the Key Properties of Common Materials Used for Metal Perforation Patterns?

When selecting materials for metal perforation patterns, it is essential to understand the unique properties of each material, as they significantly influence product performance. The most common materials include stainless steel, aluminum, carbon steel, and brass.

Stainless Steel

Stainless steel is renowned for its excellent corrosion resistance and durability, making it suitable for a wide range of applications, including architectural and industrial uses. It can withstand high temperatures and pressures, which is crucial for environments that experience thermal fluctuations. However, the manufacturing complexity of stainless steel can lead to higher costs compared to other materials. For international buyers, compliance with standards such as ASTM A240 or DIN 1.4301 is essential to ensure quality and performance.

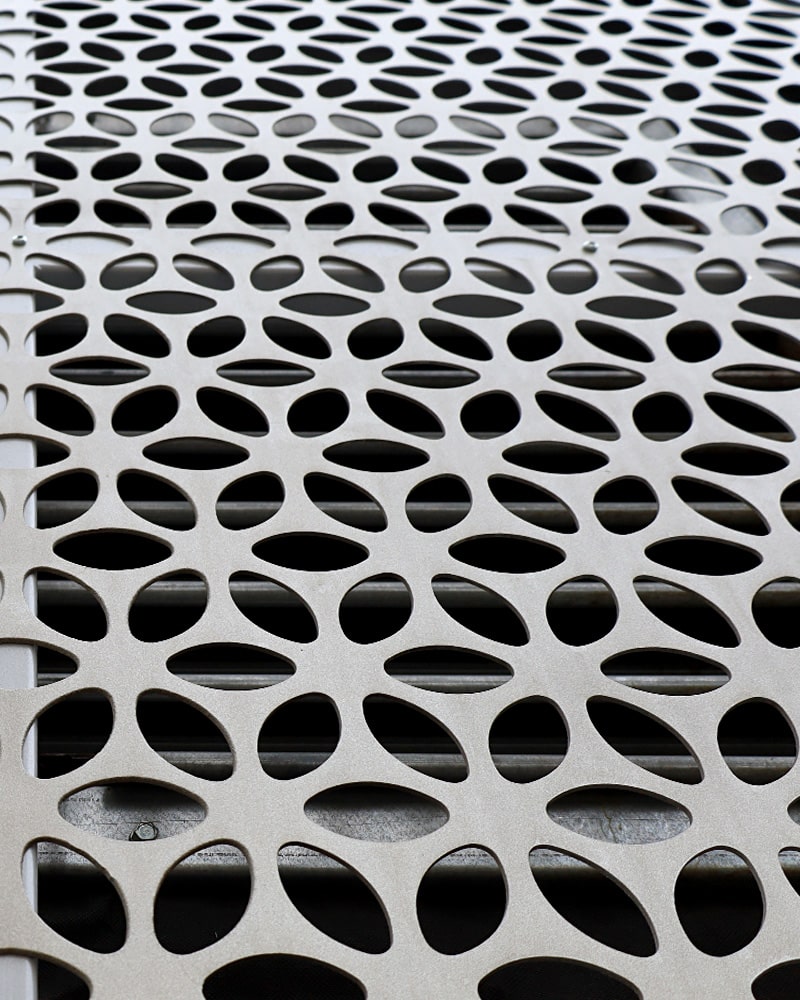

Illustrative image related to metal perforation patterns

Aluminum

Aluminum is lightweight and offers good corrosion resistance, making it a popular choice for decorative and functional applications. Its low density allows for easy handling and installation, which is advantageous in construction and automotive industries. However, aluminum has a lower strength compared to stainless steel and can be more susceptible to denting and deformation under heavy loads. Buyers in regions like Brazil and Saudi Arabia should consider the local climate, as extreme temperatures can affect aluminum’s performance.

Carbon Steel

Carbon steel is a cost-effective material that provides high strength and durability. It is commonly used in industrial applications where strength is paramount. However, carbon steel is prone to rust and corrosion unless properly coated or treated, which can increase maintenance costs over time. For buyers in the Middle East, where humidity levels can be high, selecting a protective coating is crucial to prolong the material’s lifespan. Compliance with standards like ASTM A36 is also necessary to ensure the material meets specific performance criteria.

Brass

Brass is often chosen for its aesthetic appeal and good machinability. It has excellent corrosion resistance, particularly in marine environments, making it suitable for applications involving water and moisture. However, brass can be more expensive than carbon steel and may not provide the same level of strength. For international buyers, understanding the specific applications and ensuring compliance with standards such as ASTM B36 is important to ensure the material’s suitability for their needs.

What Should International B2B Buyers Consider When Selecting Materials for Metal Perforation Patterns?

When selecting materials for metal perforation patterns, international B2B buyers should consider various factors, including compliance with local and international standards, the specific application requirements, and the environmental conditions of their region. Understanding these factors can help ensure that the selected material not only meets performance criteria but also aligns with budget constraints and logistical considerations.

Illustrative image related to metal perforation patterns

| Material | Typical Use Case for metal perforation patterns | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial, architectural, and food processing | Excellent corrosion resistance | Higher manufacturing complexity | High |

| Aluminum | Decorative panels, automotive, and construction | Lightweight and easy to handle | Lower strength compared to steel | Medium |

| Carbon Steel | Heavy-duty industrial applications | Cost-effective and high strength | Prone to rust without protective coating | Low |

| Brass | Marine applications and decorative uses | Good corrosion resistance and machinability | Higher cost and lower strength | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for metal perforation patterns

What Are the Key Stages in the Manufacturing Process of Metal Perforation Patterns?

The manufacturing of metal perforation patterns involves several critical stages that ensure both functionality and aesthetic appeal. Understanding these stages is vital for B2B buyers who are looking to procure high-quality products.

-

Material Preparation: This initial stage involves selecting the appropriate type of metal, typically sheets of steel, aluminum, or other alloys. The chosen material must meet specific strength and corrosion resistance criteria based on the intended application. Suppliers often utilize advanced software to optimize material usage, minimizing waste and costs.

-

Forming Techniques: The core of the perforation process is forming, where holes are created in the metal sheets. Common techniques include:

– Punching: A mechanical or hydraulic press uses a punch and die to create holes in the metal. This method is efficient for high-volume production and can create a variety of shapes and sizes.

– Laser Cutting: A more versatile method, laser cutting allows for intricate designs and patterns with precision. It is particularly useful for complex patterns that require high accuracy.

– Water Jet Cutting: This technique uses high-pressure water mixed with abrasives to cut through metal. It is advantageous for thicker materials and produces no heat-affected zones, preserving the integrity of the metal. -

Assembly and Finishing: After perforation, the metal sheets may undergo further processing, including bending, shaping, or welding, depending on the final product requirements. Finishing processes may include:

– Deburring: Removing sharp edges and burrs to ensure safety and improve aesthetics.

– Coating: Applying protective coatings such as powder coating or anodizing to enhance corrosion resistance and appearance.

How Is Quality Assurance Implemented in Metal Perforation?

Quality assurance (QA) is integral to ensuring that perforated metal patterns meet the required standards for durability, safety, and performance. For international B2B buyers, understanding QA protocols is essential.

-

International Standards Compliance: Suppliers should adhere to recognized international standards such as ISO 9001, which outlines the requirements for a quality management system. Other industry-specific certifications may include CE marking for products sold in Europe and API certifications for oil and gas applications.

-

Quality Control Checkpoints: Throughout the manufacturing process, several quality control (QC) checkpoints are established:

– Incoming Quality Control (IQC): This initial phase involves inspecting raw materials for compliance with specifications before production begins.

– In-Process Quality Control (IPQC): During the manufacturing process, regular inspections and tests are conducted to ensure that the production meets quality standards. This includes monitoring the precision of hole placement and dimensions.

– Final Quality Control (FQC): Once production is complete, the final products undergo comprehensive testing, which may include dimensional checks, visual inspections, and performance tests to verify they meet all specified requirements.

What Testing Methods Are Commonly Used for Metal Perforation Patterns?

B2B buyers should be aware of the various testing methods employed to ensure the quality of perforated metal patterns. These methods help verify the integrity and functionality of the final products.

-

Dimensional Inspection: This involves using calipers, gauges, and laser measurement systems to ensure that all dimensions are within specified tolerances.

-

Visual Inspection: A thorough visual examination for any defects, such as misalignment or irregularities in the perforation pattern, is performed to ensure aesthetic and functional quality.

-

Mechanical Testing: Depending on the application, mechanical properties such as tensile strength, yield strength, and hardness may be tested to ensure the material can withstand operational stresses.

-

Corrosion Testing: For applications in harsh environments, corrosion resistance tests, including salt spray tests, are essential to ensure longevity.

How Can B2B Buyers Verify Supplier Quality Control Procedures?

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, ensuring that suppliers adhere to robust quality control procedures is crucial. Here are effective methods to verify supplier QC:

Illustrative image related to metal perforation patterns

-

Supplier Audits: Conducting regular audits of suppliers’ facilities provides insights into their manufacturing processes, adherence to standards, and overall quality management systems. It’s advisable to have a checklist based on relevant international standards.

-

Requesting Quality Reports: Suppliers should provide detailed quality assurance reports, including results from IQC, IPQC, and FQC stages. These reports should outline any deviations from standards and corrective actions taken.

-

Third-party Inspections: Engaging third-party inspection agencies can add an additional layer of assurance. These agencies can conduct independent audits and testing, providing unbiased evaluations of the supplier’s quality control measures.

What Are the Nuances of Quality Certification for International B2B Buyers?

Navigating the complexities of quality certifications can be challenging for international B2B buyers. Here are key considerations:

-

Understanding Regional Standards: Different regions may have varying standards and certifications. Buyers must familiarize themselves with the relevant regulations in their target markets, such as CE marking in Europe or ANSI standards in the U.S.

-

Cultural and Regulatory Differences: Factors such as local regulations, cultural perceptions of quality, and market expectations can influence the type of certifications that are most valued in different regions.

-

Supplier Transparency: Buyers should seek suppliers who are open about their quality control processes and certifications. Transparency fosters trust and ensures that all parties are aligned on quality expectations.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing metal perforation patterns, ensuring they receive products that meet their high standards for quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal perforation patterns’

Introduction

Sourcing metal perforation patterns effectively requires a structured approach to ensure that the chosen designs meet both aesthetic and functional needs. This checklist is designed to guide international B2B buyers through the critical steps of procurement, emphasizing the importance of technical specifications, supplier evaluation, and quality assurance.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the metal perforation patterns you require. This includes the type of material, hole sizes, spacing, and the overall application (decorative vs. functional). Understanding these requirements will help you communicate effectively with suppliers and ensure that the products meet your needs.

Illustrative image related to metal perforation patterns

- Material Considerations: Different metals (e.g., aluminum, stainless steel) offer various benefits, such as corrosion resistance or weight.

- Functionality: Determine whether the patterns need to provide ventilation, light filtration, or aesthetic appeal.

Step 2: Research Available Patterns

Explore the various perforation patterns that are available in the market. Familiarize yourself with standard designs, such as round, square, and decorative patterns, as well as custom options. This knowledge will empower you to make informed decisions and request specific patterns from suppliers.

- Pattern Libraries: Utilize resources like perforated pattern libraries to view available options and their applications.

- Customization: Don’t hesitate to inquire about custom patterns if your project requires unique specifications.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet potential suppliers to ensure they can meet your needs. Request company profiles, product samples, and references from other clients, particularly those within your industry or region.

- Supplier Reputation: Look for reviews and testimonials that reflect the supplier’s reliability and quality.

- Experience: Consider suppliers with experience in delivering similar projects to yours.

Step 4: Verify Quality Standards and Certifications

Ensure that your suppliers adhere to relevant quality standards and certifications. This is crucial for maintaining product consistency and compliance with industry regulations.

- ISO Certifications: Check for ISO certifications that indicate adherence to international quality management standards.

- Material Certifications: Confirm that the materials used meet industry specifications, especially for specific applications like construction or automotive.

Step 5: Request Samples and Prototypes

Always request samples or prototypes before finalizing your order. This allows you to evaluate the quality and suitability of the perforation patterns firsthand.

Illustrative image related to metal perforation patterns

- Testing for Fit: Assess how the samples fit into your intended application.

- Quality Assurance: Look for any inconsistencies in hole sizes and spacing that may affect performance.

Step 6: Negotiate Terms and Conditions

Before finalizing your purchase, negotiate the terms and conditions with your supplier. This includes pricing, lead times, shipping costs, and payment terms.

- Volume Discounts: Discuss bulk purchasing options to take advantage of cost savings.

- Delivery Timelines: Ensure that the supplier can meet your deadlines, particularly for time-sensitive projects.

Step 7: Establish a Communication Plan

Set up a clear communication plan with your chosen supplier. Effective communication is vital for addressing any issues that may arise during production or delivery.

- Regular Updates: Schedule regular check-ins to monitor the status of your order.

- Feedback Loop: Establish a process for providing feedback on samples and discussing any modifications needed.

By following this checklist, B2B buyers can enhance their procurement process for metal perforation patterns, ensuring they select the right products to meet their specific requirements.

Comprehensive Cost and Pricing Analysis for metal perforation patterns Sourcing

Understanding the cost structure and pricing dynamics for sourcing metal perforation patterns is essential for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will cover the various cost components that affect pricing, the influencers that can sway costs, and actionable tips for buyers to optimize their purchasing strategy.

What Are the Key Cost Components in Metal Perforation Patterns?

The cost structure for metal perforation patterns generally comprises several components:

-

Materials: The choice of base metal—such as stainless steel, aluminum, or carbon steel—significantly influences costs. Specialty alloys or treated materials can drive prices higher due to their enhanced properties.

-

Labor: Labor costs vary widely based on geographic location, with regions like Europe often having higher labor rates compared to parts of Africa or South America. Skilled labor for intricate perforation patterns can also add to the overall cost.

-

Manufacturing Overhead: This includes costs associated with utilities, maintenance of machinery, and administrative expenses. Efficient production processes can help mitigate these costs.

-

Tooling: The initial investment in tooling for custom patterns can be substantial. Buyers should consider whether the tooling costs can be amortized over a large volume of orders.

-

Quality Control (QC): Ensuring that products meet required specifications involves testing and inspection, which can add to costs. Certifications such as ISO or ASTM can further elevate expenses but provide assurance of quality.

-

Logistics: Shipping costs are influenced by distance, weight, and volume. International buyers must also consider tariffs, duties, and compliance with local regulations.

-

Margin: Suppliers typically apply a profit margin based on the complexity and demand for the product. Understanding the market can help buyers gauge reasonable margins.

How Do Price Influencers Impact Metal Perforation Patterns?

Several factors can influence the pricing of metal perforation patterns:

-

Volume/MOQ: Bulk orders often result in lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom patterns or intricate designs can increase costs. Buyers should clarify their requirements upfront to avoid unexpected price hikes.

-

Materials: The choice of material directly affects pricing. High-quality or specialty materials will inherently be more expensive.

-

Quality and Certifications: Products that meet higher standards or possess relevant certifications are typically priced higher but offer better assurance of performance and compliance.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence pricing. Established suppliers may charge a premium for their reliability and quality.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can significantly affect total costs. Buyers should negotiate Incoterms that minimize their exposure to unexpected freight and insurance costs.

What Tips Can Buyers Use to Negotiate Better Prices for Metal Perforation Patterns?

-

Negotiate: Engage in open discussions with suppliers about pricing structures. Understanding their cost components can provide leverage in negotiations.

-

Focus on Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, maintenance, and potential downtimes.

-

Consider Long-Term Relationships: Establishing long-term partnerships can lead to more favorable pricing and terms. Suppliers often reward loyalty with better deals.

-

Research Local Market Conditions: Understanding regional pricing trends can help buyers negotiate effectively. Knowledge of local supply and demand dynamics is crucial.

-

Evaluate Alternatives: Explore multiple suppliers and compare their offerings. This can provide insights into competitive pricing and help identify the best value for your needs.

Disclaimer for Indicative Prices

Prices for metal perforation patterns can fluctuate based on market conditions, material availability, and specific customer requirements. It is advisable for buyers to request quotes from multiple suppliers and conduct thorough due diligence before making procurement decisions.

Alternatives Analysis: Comparing metal perforation patterns With Other Solutions

In the ever-evolving landscape of industrial applications, buyers often seek the most effective solutions to meet their specific needs. Metal perforation patterns are well-regarded for their versatility and functionality, but understanding viable alternatives is crucial for informed decision-making. Below, we compare metal perforation patterns with two noteworthy alternatives: expanded metal and laser cutting.

| Comparison Aspect | Metal Perforation Patterns | Expanded Metal | Laser Cutting |

|---|---|---|---|

| Performance | High structural integrity; customizable designs; excellent airflow | Good strength-to-weight ratio; limited design options | Precise cuts; intricate designs; high versatility |

| Cost | Moderate; varies by complexity and material | Generally lower; depends on thickness and size | Higher initial costs due to machinery and setup |

| Ease of Implementation | Requires specialized equipment for perforation; moderate lead times | Easier to manufacture; widely available | High complexity; requires skilled operators |

| Maintenance | Low maintenance; durable materials | Low maintenance; can be susceptible to corrosion | Moderate; depends on the material used |

| Best Use Case | Architectural applications, filtration systems, and decorative elements | Security fencing, grating, and flooring | Prototyping, custom parts, and artistic applications |

What Are the Advantages and Disadvantages of Expanded Metal?

Expanded metal is produced by cutting and stretching sheets of metal to create a mesh-like structure. One of its primary advantages is the lower cost compared to perforated metal. It offers good strength-to-weight ratios, making it ideal for applications like security fencing and grating. However, its design options are limited, which may not meet the aesthetic or functional needs for specific projects. Additionally, while it’s generally low maintenance, it can be susceptible to corrosion if not treated properly.

How Does Laser Cutting Compare to Metal Perforation Patterns?

Laser cutting employs high-powered lasers to cut through materials with exceptional precision. This method allows for intricate designs and custom shapes that may be impossible with traditional perforation. While laser cutting offers unparalleled flexibility, it comes with a higher initial cost due to the machinery required and the skilled labor necessary to operate it. Maintenance levels can vary based on the type of material being cut, and the process may involve longer lead times, especially for complex designs.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right solution requires a careful assessment of specific project requirements. Buyers should consider factors such as the desired performance characteristics, budget constraints, and the level of customization needed. Metal perforation patterns excel in applications requiring structural integrity and aesthetic appeal, while expanded metal provides a cost-effective solution for simpler needs. For projects demanding intricate designs and precision, laser cutting may be the best choice despite its higher costs. Ultimately, understanding the unique advantages and limitations of each option will empower B2B buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for metal perforation patterns

What Are the Essential Technical Properties of Metal Perforation Patterns?

Understanding the technical specifications of metal perforation patterns is crucial for B2B buyers, especially when selecting materials that meet both functional and aesthetic needs. Below are some key properties that should be considered:

1. Material Grade

The grade of the metal used in perforation patterns significantly affects durability and performance. Common materials include stainless steel, aluminum, and carbon steel, each offering unique benefits. For instance, stainless steel provides excellent corrosion resistance, making it ideal for outdoor applications. Selecting the appropriate material grade ensures that the perforated metal meets industry standards and operational demands.

Illustrative image related to metal perforation patterns

2. Hole Diameter

The diameter of the holes in a perforated pattern is a critical specification that influences airflow, light transmission, and aesthetic appeal. Common hole sizes range from small (less than 1 mm) to large (over 25 mm). The choice of hole diameter affects the open area percentage, which directly impacts the material’s structural integrity and functionality. Buyers must align hole diameter choices with their specific application requirements, such as filtration, ventilation, or decorative purposes.

3. Open Area Percentage

Open area refers to the ratio of the total area of the holes to the overall area of the sheet. This percentage is crucial for applications requiring air or liquid passage. A higher open area percentage (e.g., over 50%) is desirable for ventilation, while lower percentages may be suitable for sound absorption or security screens. Understanding the open area helps buyers gauge performance in their intended applications.

4. Tolerance

Tolerance defines the allowable deviation from specified dimensions. In perforated metals, tight tolerances are essential for applications requiring precise fit and function. For example, in industries like aerospace or automotive, where components must align perfectly, maintaining tight tolerances ensures operational efficiency and safety. Buyers should inquire about the manufacturer’s tolerances to ensure they meet their project specifications.

Illustrative image related to metal perforation patterns

5. Pattern Type

Different perforation patterns—such as round, square, or decorative—offer various functional and aesthetic benefits. The choice of pattern can influence structural strength and visual appeal. For example, staggered patterns may improve airflow while adding a unique design element. Understanding the implications of different patterns allows buyers to make informed decisions based on their specific needs.

What Are Common Trade Terminologies in Metal Perforation?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In metal perforation, understanding OEM relationships can help buyers identify quality and reliability in the components they purchase.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers as it affects budgeting and inventory management. Knowing the MOQ can help buyers plan their purchases effectively.

3. RFQ (Request for Quotation)

An RFQ is a standard business process for soliciting price quotes from suppliers. It outlines specific requirements for the perforated metal, including dimensions, material, and quantity. Submitting an RFQ enables buyers to compare offers and negotiate better terms.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and risks in international transactions.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is critical for project planning and inventory control, especially in industries where timing is essential. Buyers should always inquire about lead times when negotiating orders.

By grasping these essential properties and trade terminologies, B2B buyers can navigate the metal perforation landscape more effectively, ensuring that they select products that meet their operational needs while enhancing overall project efficiency.

Navigating Market Dynamics and Sourcing Trends in the metal perforation patterns Sector

What Are the Key Trends Driving the Metal Perforation Patterns Market?

The global metal perforation patterns market is witnessing significant growth driven by multiple factors, including increased demand for customized solutions and advancements in manufacturing technologies. The rise of automation and digital fabrication techniques has enabled manufacturers to produce complex and tailored perforated patterns that cater to specific applications, from architectural designs to filtration systems. In emerging markets such as Africa and South America, infrastructural development projects are propelling the need for diverse metal perforation solutions, particularly in construction and transportation sectors.

Moreover, the shift towards lightweight materials in industries like automotive and aerospace is driving innovation in perforation techniques. International B2B buyers, particularly from regions like Brazil and Saudi Arabia, are increasingly looking for suppliers who can offer both standard and custom perforation options. As sustainability becomes a priority, suppliers are also focusing on eco-friendly manufacturing processes, which aligns with the broader trend of responsible sourcing.

How Are Sustainability and Ethical Sourcing Shaping B2B Practices?

Sustainability has emerged as a crucial consideration in the metal perforation patterns sector, influencing purchasing decisions among B2B buyers. The environmental impact of metal production and perforation processes has prompted companies to seek suppliers who prioritize sustainable practices. This includes the use of recycled materials and energy-efficient manufacturing methods.

Ethical sourcing practices are also gaining traction, with businesses increasingly demanding transparency in their supply chains. Certifications such as ISO 14001 for environmental management and LEED for sustainable building materials are becoming essential for suppliers aiming to establish credibility in the market. Buyers from Europe and the Middle East, in particular, are keen on partnering with manufacturers who can demonstrate commitment to sustainability through certifications and eco-friendly practices. This focus not only mitigates environmental impact but also enhances brand reputation and customer loyalty.

What Is the Historical Context of Metal Perforation Patterns in B2B Markets?

The evolution of metal perforation patterns can be traced back to the early industrial age, where perforated metals began to gain traction for their functional benefits in ventilation and aesthetics. Initially limited to basic designs, the technology has significantly advanced over the decades. The introduction of CNC (computer numerical control) machinery in the late 20th century revolutionized the industry, allowing for precision and customization that were previously unattainable.

As industries evolved, so did the applications of perforated metals, expanding into sectors such as construction, automotive, and consumer goods. Today, the combination of traditional craftsmanship and modern technology continues to shape the market, enabling manufacturers to meet the diverse needs of international B2B buyers while adhering to evolving standards of quality and sustainability. This historical context is essential for understanding current market dynamics and sourcing trends, particularly as global buyers seek innovative solutions that align with both functionality and ethical considerations.

Conclusion

In summary, the metal perforation patterns market is characterized by a blend of innovation, sustainability, and evolving buyer expectations. For B2B buyers across Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions that not only meet operational requirements but also align with broader environmental and ethical standards. The ongoing trends in customization, sustainability, and technological advancement present unique opportunities for buyers to leverage competitive advantages in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of metal perforation patterns

-

1. How do I choose the right metal perforation pattern for my application?

Choosing the right metal perforation pattern depends on your specific application requirements, such as airflow, light transmission, and aesthetics. Start by considering the functional needs, like the percentage of open area required for ventilation or filtration. Next, assess the material type and thickness, as these factors influence the durability and structural integrity of the perforation. Finally, review aesthetic considerations if the pattern will be visible in finished products. Consulting with a supplier who offers a diverse range of patterns can provide insights into the best options for your project. -

2. What factors should I consider when sourcing a supplier for metal perforation patterns?

When sourcing a supplier, evaluate their experience in the industry, product range, and customization capabilities. Look for suppliers with a robust portfolio and proven track record in fulfilling orders for businesses similar to yours. Quality assurance processes are crucial, so inquire about their certifications and testing methods. Additionally, consider their logistics capabilities, including shipping options and delivery times, especially if you are located in regions like Africa or South America, where supply chain efficiency can vary. -

3. What is the minimum order quantity (MOQ) for custom metal perforation patterns?

Minimum order quantities can vary significantly among suppliers. Many manufacturers have a standard MOQ for custom patterns, often ranging from 100 to 1,000 pieces, depending on the complexity and production costs. It’s advisable to discuss your specific needs with potential suppliers, as some may be willing to accommodate lower MOQs for initial orders or trial runs. This flexibility can be particularly beneficial for businesses testing new products in markets like the Middle East or Europe. -

4. Can I request a sample of a metal perforation pattern before placing a bulk order?

Yes, most reputable suppliers will provide samples of their perforated metal patterns upon request. Sampling allows you to assess the quality, dimensions, and suitability of the patterns for your application before committing to a larger order. Be sure to specify the material and pattern type you are interested in, and inquire about any associated costs or lead times for sample production. This step is essential for ensuring that the final product meets your expectations. -

5. What payment terms should I expect when ordering metal perforation patterns internationally?

Payment terms can vary based on the supplier and the nature of the transaction. Common arrangements include upfront payment, a deposit with the balance due before shipping, or net terms (e.g., net 30 days). For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Always clarify payment terms upfront and ensure they align with your cash flow and budgeting strategies, especially when importing from suppliers in regions like Europe or the Middle East. -

6. How does customization work for metal perforation patterns?

Customization typically involves working closely with the supplier to define the specific dimensions, hole shapes, and arrangements that suit your needs. This process may include providing design files or collaborating on design concepts. Be prepared to discuss factors like material type, thickness, and any additional finishes required. Many suppliers offer CAD drawings for review before production begins, ensuring the final product aligns with your specifications. Establish clear communication and timelines to facilitate a smooth customization process. -

7. What quality assurance measures should I look for in a metal perforation supplier?

Quality assurance measures can include certifications like ISO standards, which indicate adherence to international quality management practices. Inquire about the supplier’s testing protocols, including inspections during production and final product evaluations. A reputable supplier should also have a return policy or warranty in place to address any defects or discrepancies in the order. Understanding these measures helps ensure you receive high-quality products that meet your specifications and performance requirements. -

8. How can I ensure timely delivery of my metal perforation order?

To ensure timely delivery, establish clear timelines with your supplier from the outset. Discuss production lead times, shipping methods, and potential customs delays if importing internationally. It’s beneficial to have a contingency plan in case of unforeseen delays. Regular communication throughout the production and shipping process can help keep you informed about your order status. If you operate in regions like Africa or South America, consider suppliers with established logistics networks to enhance reliability.

Top 4 Metal Perforation Patterns Manufacturers & Suppliers List

1. Hendrick Manufacturing – Perforated Metal Patterns

Domain: hendrickcorp.com

Registered: 2015 (10 years)

Introduction: Hendrick Manufacturing offers a variety of perforated metal patterns suitable for numerous applications. Key product details include:

– Patterns available: Round, Hexagon, Slotted, Square, Diamond, Ellipse, Custom Shapes, and Designer Series.

– Open area percentages: Options range from <=20% to >=61%.

– Specific patterns include:

– Standard .045″ Diameter Round on .265″ Centers (3% Open Area…

2. ATAS International – Perforation Options

Domain: atas.com

Registered: 1996 (29 years)

Introduction: ATAS International, Inc. offers perforation options as part of their product line, featuring six available patterns. The architectural systems are designed for various applications including decorative applications, signage, panel infills, ornamental contrast, ceilings, walls, grills, dividers, and acoustical surfaces. The functional systems are designed for applications such as ventilation, acous…

3. Marco Specialty Steel – Perforated Metal Solutions

Domain: marcospecialtysteel.com

Registered: 1999 (26 years)

Introduction: Perforated Metal Hole Patterns: Standard patterns include Round, Square, and Ornamental/Decorative holes. Custom perforation available. Round hole sizes range from .020″ to 1″ diameter with varying center distances and open areas (e.g., .020″ Dia, .043″ Ctrs, 20% Open Area; 1/2″ Dia, 11/16″ Ctrs, 48% Open Area). Square hole sizes range from 1/8″ to 3/4″ with different center distances and open are…

4. RMIG Solutions – Perforated Metal Patterns

Domain: rmigsolutions.com

Registered: 2023 (2 years)

Introduction: RMIG Solutions offers a wide selection of perforated metal patterns suitable for various applications, including technical and decorative designs. Their pattern catalogue serves as a reference for different perforated patterns and expanded metal. Key features include:

– Round hole perforation: Most commonly used type.

– Square hole perforation: Attractive alternative to round holes.

– Slot hole…

Strategic Sourcing Conclusion and Outlook for metal perforation patterns

As the demand for metal perforation patterns continues to evolve, strategic sourcing emerges as a pivotal approach for international buyers looking to optimize their procurement processes. By understanding the diverse range of perforated patterns available—from standard designs to custom solutions—businesses can align their product specifications with specific functional and aesthetic requirements. This strategic alignment not only enhances product performance but also contributes to cost efficiency and sustainability in operations.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, leveraging local suppliers while also exploring global partnerships can provide a competitive advantage. As industries increasingly focus on innovation and adaptability, sourcing high-quality metal perforation patterns will be crucial in meeting emerging market demands.

Looking ahead, it is essential for businesses to stay informed about trends and advancements in metal perforation technologies. Engaging with trusted suppliers and participating in industry discussions will empower buyers to make informed decisions that drive growth and sustainability. Take the next step in your sourcing strategy today—explore the possibilities of metal perforation patterns and position your business for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.