Is Your Chengdu Fc1 Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for chengdu fc1

Navigating the global market for the Chengdu FC-1, also known as the JF-17 Thunder, presents a unique challenge for international B2B buyers seeking reliable and cost-effective military aircraft solutions. As geopolitical dynamics shift and defense budgets tighten, understanding the intricacies of sourcing this multirole fighter jet is crucial for stakeholders from regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide serves as an essential resource, detailing the various types of FC-1 aircraft, their applications in modern air forces, and the critical factors to consider when vetting suppliers.

In this guide, you will find in-depth analyses of the FC-1’s technical specifications, performance capabilities, and pricing structures, alongside insights into the manufacturing processes and potential partners in China and Pakistan. We will also explore the operational advantages of the FC-1 in different combat scenarios, helping you to assess its suitability for your specific needs. Additionally, this guide will equip you with actionable strategies for negotiating contracts and understanding the total cost of ownership, ensuring that you make informed purchasing decisions. By navigating the complexities of the Chengdu FC-1 market with this guide, international buyers can enhance their procurement strategies and secure a competitive edge in the defense sector.

Understanding chengdu fc1 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| FC-1 Xiaolong | Lightweight, single-engine multirole fighter | Military operations, defense contracts | Pros: Cost-effective, versatile; Cons: Limited export options, reliance on Chinese technology. |

| JF-17 Thunder | Jointly developed with Pakistan, advanced avionics | Air force modernization, regional defense | Pros: Proven combat capabilities; Cons: Potential geopolitical risks in procurement. |

| FC-1 Block 1 | Basic variant with standard avionics | Budget defense procurement | Pros: Affordable entry-level fighter; Cons: Limited advanced features compared to newer models. |

| FC-1 Block 2 | Enhanced avionics and weapons systems | Upgraded military capabilities | Pros: Improved performance and technology; Cons: Higher cost, longer lead time for delivery. |

| FC-1 Export Variant | Tailored for international markets | Global defense partnerships | Pros: Customizable features for specific needs; Cons: Complex negotiations and potential trade barriers. |

What Are the Key Characteristics of the FC-1 Xiaolong?

The FC-1 Xiaolong, also known as the JF-17, is a lightweight, single-engine multirole fighter that excels in versatility and cost-effectiveness. Designed primarily for air-to-air and air-to-ground combat, it features a relatively simple design that allows for easier maintenance and operational deployment. This model is particularly suitable for countries looking to modernize their air forces without incurring significant costs. B2B buyers should consider its operational capabilities against their specific defense requirements and budget constraints.

How Does the JF-17 Thunder Stand Out in Military Procurement?

The JF-17 Thunder is the result of a successful Sino-Pakistani collaboration, making it a unique offering in the global defense market. Its advanced avionics and combat systems provide a significant advantage in military operations. This aircraft is particularly appealing to nations looking to enhance their air force capabilities through proven technology. However, buyers must be aware of potential geopolitical implications and the need for supportive diplomatic relations, as these factors can influence procurement processes.

What Are the Advantages of the FC-1 Block 1 for Budget-Conscious Buyers?

The FC-1 Block 1 variant is designed with budget constraints in mind, offering a basic yet effective fighter aircraft option. It is particularly advantageous for countries with limited defense budgets seeking an entry-level fighter. While it lacks some of the advanced features found in newer models, it provides a reliable platform for basic military operations. Buyers should weigh the trade-offs between cost and capability when considering this variant for their air force needs.

What Enhancements Can Buyers Expect with the FC-1 Block 2?

The FC-1 Block 2 variant represents a significant upgrade over the Block 1, featuring enhanced avionics and weapon systems. This model is designed for nations looking to elevate their air combat capabilities with improved technology. While it comes at a higher price point, the advanced features can justify the investment for military modernization. B2B buyers should assess their long-term operational goals to determine if the Block 2’s enhancements align with their strategic defense objectives.

How Does the FC-1 Export Variant Cater to International Markets?

The FC-1 Export Variant is specifically tailored for international buyers, offering customizable features that cater to diverse operational needs. This model aims to facilitate defense partnerships and strengthen military cooperation between nations. However, potential buyers should be prepared for complex negotiations and possible trade barriers that may arise during the procurement process. Understanding the specific requirements of the target market can enhance the success of acquiring this aircraft for defense operations.

Key Industrial Applications of chengdu fc1

| Industry/Sector | Specific Application of chengdu fc1 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Defense and Security | Multirole combat operations | Enhanced national security through advanced aerial capabilities | Reliability of supply chain for parts and maintenance services |

| Aerospace Manufacturing | Training and simulation for pilots | Cost-effective training solutions for military personnel | Availability of training simulators and support for international standards |

| Counter-Terrorism Operations | Intelligence, surveillance, and reconnaissance (ISR) | Improved situational awareness and threat detection | Compliance with international regulations and export controls |

| International Defense Sales | Export to allied nations | Strengthening defense partnerships and military cooperation | Understanding regional defense needs and customization options |

| Emergency Response | Airborne support for disaster relief operations | Rapid deployment capabilities in crisis situations | Logistics for maintenance and operational readiness in remote areas |

How is the Chengdu FC-1 Used in Defense and Security Operations?

The Chengdu FC-1 serves as a multirole fighter jet, primarily employed in defense and security sectors to conduct combat operations. Its advanced avionics and weapon systems provide a tactical advantage in various conflict scenarios, enabling nations to enhance their aerial defense capabilities. For international buyers, particularly in regions like Africa and the Middle East, understanding the reliability of the supply chain for parts and maintenance services is critical to ensure operational readiness.

What Role Does the Chengdu FC-1 Play in Aerospace Manufacturing?

In aerospace manufacturing, the FC-1 is utilized for training and simulation purposes, offering a cost-effective solution for pilot training. The aircraft’s design allows for realistic simulation of combat scenarios, ensuring pilots are well-prepared for real-world operations. Buyers should consider the availability of training simulators and support services that meet international standards to ensure comprehensive pilot readiness.

How is the Chengdu FC-1 Used in Counter-Terrorism Operations?

The FC-1 is instrumental in intelligence, surveillance, and reconnaissance (ISR) missions, providing critical data for counter-terrorism operations. Its capabilities enhance situational awareness, allowing military forces to detect and respond to threats more effectively. Buyers must be aware of compliance with international regulations and export controls, ensuring that the aircraft’s use aligns with global security frameworks.

What Benefits Does the Chengdu FC-1 Offer in International Defense Sales?

The Chengdu FC-1 is a key asset in international defense sales, enabling countries to bolster their military partnerships. By exporting this aircraft to allied nations, suppliers can strengthen defense cooperation and enhance regional security frameworks. Understanding the specific defense needs of different regions and customizing offerings accordingly is essential for success in this market.

How Can the Chengdu FC-1 Assist in Emergency Response Situations?

In emergency response scenarios, the FC-1 can provide airborne support for disaster relief operations. Its rapid deployment capabilities allow for quick response to crises, making it a valuable asset for governments and humanitarian organizations. Buyers should consider logistics for maintenance and operational readiness, especially in remote areas where timely assistance is crucial.

3 Common User Pain Points for ‘chengdu fc1’ & Their Solutions

Scenario 1: Difficulty in Assessing Total Cost of Ownership for Chengdu FC-1

The Problem:

Many B2B buyers, particularly from emerging markets in Africa and South America, face challenges in understanding the total cost of ownership (TCO) associated with acquiring the Chengdu FC-1. This includes not just the initial purchase price, which can be around $15 million, but also operational costs, maintenance, spare parts, and potential upgrades over the aircraft’s lifespan. The complexity of these costs can lead to unexpected financial burdens, affecting budgeting and financial planning for defense expenditures.

The Solution:

To effectively assess the total cost of ownership, buyers should engage in comprehensive financial modeling that accounts for all operational and maintenance costs. This involves gathering detailed information from the manufacturer, Chengdu Aircraft Industry Group, and current operators of the FC-1, such as the Pakistan Air Force. Buyers should request a breakdown of expected annual maintenance costs, fuel consumption rates, and the lifespan of key components. Additionally, establishing a partnership with local maintenance organizations can yield insights into the availability and pricing of spare parts. Utilizing simulation software to project costs over the aircraft’s expected service life can also provide clarity and assist in long-term budgeting.

Scenario 2: Navigating Regulatory and Export Compliance for Chengdu FC-1 Acquisition

The Problem:

International buyers may encounter significant hurdles related to regulatory and export compliance when looking to purchase the Chengdu FC-1. Many countries have stringent regulations governing the import of military equipment, which can vary widely between regions such as the Middle East, Europe, and Africa. This complexity can lead to delays in procurement processes and potential legal issues, creating uncertainty for defense procurement officers.

The Solution:

To navigate these regulatory challenges, buyers should engage legal experts with experience in international defense procurement. Conducting a thorough due diligence process to understand the specific regulations in their home country and any involved third-party nations is crucial. Buyers can also benefit from engaging with local defense ministries or regulatory bodies early in the procurement process to clarify requirements. Establishing a relationship with Chengdu Aircraft Industry Group can help facilitate compliance by ensuring that all necessary documentation and permits are in order. Leveraging the expertise of a consultant who specializes in defense contracts can streamline this process and minimize the risk of non-compliance.

Scenario 3: Ensuring Effective Integration of Chengdu FC-1 with Existing Military Systems

The Problem:

B2B buyers often struggle with the integration of new platforms like the Chengdu FC-1 into existing military systems. This is particularly challenging for countries that may have legacy systems or different technological standards. Without proper integration, the operational effectiveness of the FC-1 can be significantly compromised, leading to underutilization of the aircraft’s capabilities.

The Solution:

To ensure effective integration, buyers should conduct a thorough assessment of existing military systems and determine compatibility with the FC-1’s avionics and operational frameworks. This involves collaboration between military engineers and Chengdu Aircraft Industry Group’s technical teams to establish a clear integration roadmap. Buyers should consider investing in training programs for personnel to familiarize them with the FC-1’s systems and operational procedures. Additionally, conducting joint exercises with existing fleets can facilitate smoother operational transitions. Establishing a feedback loop with operators of the FC-1 can also provide valuable insights into best practices for integration and operational efficiency, ensuring that the aircraft can be deployed effectively within the broader defense strategy.

Strategic Material Selection Guide for chengdu fc1

What Are the Key Materials Used in the Chengdu FC-1 and Their Properties?

The Chengdu FC-1, also known as the JF-17 Thunder, employs a variety of materials that contribute to its performance, durability, and operational efficiency. Understanding these materials from a B2B perspective is crucial for international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe.

Which Aluminum Alloys Are Commonly Used in the Chengdu FC-1?

Aluminum alloys, particularly those in the 7000 series, are extensively used in aircraft structures due to their excellent strength-to-weight ratio and corrosion resistance. These alloys can withstand high temperatures and pressures, making them suitable for various components of the FC-1.

Pros: Aluminum alloys are lightweight, enhancing fuel efficiency and payload capacity. They are also cost-effective compared to other materials like titanium.

Cons: While they offer good durability, aluminum alloys may not perform as well under extreme conditions compared to higher-end materials. They can also be more susceptible to fatigue over time.

Impact on Application: The use of aluminum alloys allows for a lightweight structure that can handle the stresses of flight, but buyers should consider the potential need for regular inspections and maintenance.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers should ensure that the specific aluminum alloy grades meet the necessary specifications for military applications.

How Does Composite Material Contribute to the Chengdu FC-1’s Performance?

Composite materials, particularly carbon fiber reinforced polymers (CFRPs), are increasingly used in modern aircraft for their superior strength-to-weight ratio and resistance to corrosion. These materials are crucial in areas that require high structural integrity while minimizing weight.

Pros: Composites are highly durable and can withstand environmental stressors better than metals. They also allow for complex shapes, which can enhance aerodynamics.

Cons: The manufacturing process for composites can be more complex and costly than traditional materials. Additionally, repair processes for damaged composites can be more challenging.

Impact on Application: The integration of composite materials in the FC-1 enhances its overall performance and longevity, but buyers must be aware of the specialized skills required for maintenance and repair.

Considerations for International Buyers: Buyers from regions with varying levels of technological advancement should consider the availability of skilled labor for composite repairs. Compliance with international standards for composites is also critical.

What Role Does Titanium Play in the Chengdu FC-1’s Design?

Titanium is used in critical components of the FC-1 due to its excellent strength, low density, and high corrosion resistance. It is particularly useful in areas exposed to high temperatures and stresses, such as engine components and structural frames.

Pros: Titanium offers exceptional durability and can withstand extreme conditions, making it ideal for military applications. Its corrosion resistance extends the lifespan of components.

Cons: The primary drawback of titanium is its high cost and the complexity of its manufacturing processes. This can lead to increased overall costs for the aircraft.

Impact on Application: The use of titanium enhances the aircraft’s performance in harsh environments, but the cost implications must be factored into procurement decisions.

Considerations for International Buyers: Buyers should be aware of the specific titanium grades used and ensure they meet international standards. The high cost may influence budget considerations, especially for countries with limited defense budgets.

How Do Steel Alloys Fit into the Chengdu FC-1’s Material Selection?

Steel alloys, particularly high-strength steel, are used in the Chengdu FC-1 for components that require high tensile strength and durability. These materials are often employed in landing gear and other structural components.

Pros: Steel alloys are known for their toughness and ability to withstand impact, making them suitable for high-stress applications. They are also generally more affordable than titanium.

Cons: Steel alloys are heavier than aluminum or composites, which can impact the overall weight and fuel efficiency of the aircraft. They may also be more prone to corrosion if not properly treated.

Impact on Application: The use of steel alloys ensures that critical components can endure the rigors of operation, but the weight factor must be considered in overall design and performance.

Considerations for International Buyers: Compliance with international standards for steel alloys is essential, and buyers should consider the implications of weight on operational efficiency.

Summary Table of Strategic Material Selection for Chengdu FC-1

| Material | Typical Use Case for Chengdu FC-1 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Aircraft structure | Lightweight, cost-effective | Susceptible to fatigue | Medium |

| Composite Materials | Airframe components | High strength-to-weight ratio | Complex manufacturing process | High |

| Titanium | Engine components | Exceptional durability and corrosion resistance | High cost and complex manufacturing | High |

| Steel Alloys | Landing gear | Toughness and affordability | Heavier, prone to corrosion | Low |

This strategic material selection guide provides valuable insights for international B2B buyers considering the Chengdu FC-1, ensuring informed decisions aligned with operational requirements and budget constraints.

In-depth Look: Manufacturing Processes and Quality Assurance for chengdu fc1

What Are the Main Stages of Manufacturing Processes for the Chengdu FC-1?

The manufacturing of the Chengdu FC-1, also known as the JF-17 Thunder, involves several intricate stages to ensure high performance and reliability. The key stages in its manufacturing process include material preparation, forming, assembly, and finishing.

How is Material Prepared for the Chengdu FC-1?

Material preparation begins with sourcing high-quality raw materials, including advanced alloys and composites that meet stringent aerospace standards. The materials undergo rigorous inspection to verify their compliance with specifications, ensuring they can withstand the demanding conditions of flight.

What Forming Techniques Are Used in the Production of the FC-1?

The forming stage employs various advanced techniques such as precision machining, stamping, and forging. These processes are essential for shaping components like the airframe, wings, and control surfaces. The use of computer numerical control (CNC) machines ensures high precision and repeatability, which is crucial for the complex geometries of fighter aircraft.

How is Assembly Conducted for the Chengdu FC-1?

Assembly of the FC-1 involves the integration of numerous components, including avionics, propulsion systems, and structural elements. The assembly process is typically carried out in cleanroom environments to minimize contamination risks. Skilled technicians follow detailed assembly instructions and use specialized tools to ensure that each component fits perfectly.

What Finishing Processes Are Implemented for Quality and Performance?

Finishing processes include surface treatment, painting, and application of protective coatings. These not only enhance the aircraft’s aesthetics but also protect it from environmental factors. The finishing stage is critical for reducing drag and improving the overall aerodynamic performance of the FC-1.

What Quality Control Standards Are Relevant for the Chengdu FC-1?

Quality assurance in the manufacturing of the Chengdu FC-1 adheres to international standards such as ISO 9001, which establishes criteria for a quality management system. This ensures that the processes are consistently monitored and improved. Additionally, industry-specific certifications like CE and API may be relevant, depending on the components being manufactured.

What Are the Key Quality Control Checkpoints in the FC-1 Production Process?

Quality control checkpoints are crucial at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This phase involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing stages, continuous monitoring is conducted to identify and rectify any deviations from quality standards.

- Final Quality Control (FQC): The completed aircraft undergoes comprehensive testing to verify performance specifications, including flight tests and systems checks.

How Are Common Testing Methods Applied in the Quality Assurance of the Chengdu FC-1?

Common testing methods employed in the quality assurance of the FC-1 include non-destructive testing (NDT) techniques, such as ultrasonic and radiographic inspections. These methods help detect internal flaws without damaging the components. Additionally, functional testing of avionics and weapon systems is conducted to ensure that all systems operate as intended under various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential. This can be achieved through:

- Supplier Audits: Conducting on-site audits to assess the manufacturing processes, quality control systems, and compliance with international standards.

- Quality Reports: Requesting detailed quality reports that outline the testing and inspection results throughout the manufacturing process.

- Third-Party Inspections: Engaging third-party quality assurance firms to evaluate the supplier’s compliance with agreed standards and specifications.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers must navigate various quality control and certification nuances. Different regions may have specific regulatory requirements, and understanding these is critical for ensuring compliance. For example, European buyers may require CE marking, while buyers in other regions might prioritize ISO certifications.

Additionally, understanding the implications of export controls and military regulations is crucial for buyers in regions with varying levels of defense procurement policies. Establishing clear communication with suppliers regarding these requirements can help mitigate risks and ensure a smoother procurement process.

Conclusion

The manufacturing processes and quality assurance protocols for the Chengdu FC-1 are designed to meet the rigorous demands of modern military aviation. By understanding these processes, B2B buyers can make informed decisions and ensure they are sourcing high-quality aircraft that meet their operational needs. Engaging with suppliers who adhere to international quality standards and have robust quality control systems in place is paramount for successful procurement in the aerospace sector.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chengdu fc1’

The following practical sourcing guide is designed to assist international B2B buyers in navigating the procurement process for the Chengdu FC-1 (also known as JF-17 Thunder). This step-by-step checklist outlines essential actions to ensure a successful acquisition, focusing on the unique aspects of this multirole fighter jet.

Step 1: Define Your Technical Specifications

Begin by clearly outlining your specific operational requirements for the Chengdu FC-1. Consider the intended use, such as air superiority or ground attack capabilities, and the necessary avionics and armament. This step is crucial as it sets the foundation for your procurement process, ensuring that the aircraft meets your strategic needs.

- Key Considerations:

- Performance metrics: range, speed, and payload capacity.

- Required features: advanced avionics, weapon systems compatibility.

Step 2: Research Potential Suppliers

Identify and research manufacturers and suppliers of the Chengdu FC-1. Understanding the landscape of available suppliers is vital for making informed decisions. Look for companies with a proven track record in military aircraft manufacturing and a solid reputation in your region.

- What to Look For:

- Supplier certifications and compliance with international defense standards.

- Previous contracts and partnerships, particularly with your target countries.

Step 3: Evaluate Supplier Capabilities

Conduct a thorough evaluation of potential suppliers to assess their manufacturing capabilities and experience. This includes analyzing their production capacity, quality control processes, and after-sales support.

- Important Aspects:

- Supplier’s experience with the Chengdu FC-1 or similar aircraft.

- Availability of technical support and maintenance services post-purchase.

Step 4: Request Detailed Proposals

Once you have shortlisted suppliers, request detailed proposals that include pricing, delivery timelines, and terms of service. This is a critical step to compare offers and ensure transparency in the procurement process.

- Proposal Components:

- Breakdown of costs, including any potential hidden fees.

- Delivery schedules and payment terms.

Step 5: Verify Financial Stability

Assess the financial health of your selected suppliers. A financially stable supplier is more likely to deliver on time and provide ongoing support for the aircraft.

- Methods to Verify:

- Request financial statements or credit reports.

- Analyze their history of fulfilling contracts without default.

Step 6: Conduct Site Visits

If possible, arrange site visits to the manufacturing facilities of potential suppliers. This hands-on approach allows you to evaluate the production environment and meet key personnel, providing insight into their operational capabilities.

- What to Observe:

- Manufacturing processes and quality assurance measures.

- Overall facility condition and technological advancements.

Step 7: Negotiate Contracts Carefully

Finally, once you have selected a supplier, enter into contract negotiations with clear expectations. Ensure that all terms regarding warranties, support, and potential penalties for non-compliance are explicitly stated to protect your investment.

- Negotiation Focus Areas:

- Warranty terms and conditions.

- Clauses related to delivery delays or performance issues.

By following these steps, B2B buyers can navigate the complexities of sourcing the Chengdu FC-1 effectively, ensuring that they secure an aircraft that meets their operational needs while fostering a reliable supplier relationship.

Comprehensive Cost and Pricing Analysis for chengdu fc1 Sourcing

What Are the Key Cost Components for Chengdu FC-1 Sourcing?

When considering the sourcing of the Chengdu FC-1, a multifaceted cost structure comes into play. Key components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The primary materials involved in the production of the FC-1 include high-strength alloys, advanced composites, and avionics systems. The price of these materials can fluctuate based on global supply chains and geopolitical factors.

-

Labor: Labor costs vary significantly based on the region of production. For instance, sourcing from China may offer lower labor costs due to the availability of skilled workers in aerospace manufacturing. However, this may not always be the case in other regions like South America or Africa.

-

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, maintenance, and depreciation of manufacturing equipment. Efficient overhead management is crucial to keep overall costs competitive.

-

Tooling: Initial tooling costs can be substantial, especially for specialized components. Buyers should consider whether the supplier has the necessary tooling already in place or if new investments are required.

-

Quality Control (QC): Implementing stringent QC processes is vital for ensuring the aircraft meets international safety and performance standards. This can add to the overall cost but is essential for maintaining quality assurance.

-

Logistics: Shipping costs can vary based on the chosen Incoterms and the distance to the buyer’s location. Understanding these terms is crucial for anticipating total shipping costs and timelines.

-

Margin: Supplier margins can vary significantly based on market competition and the supplier’s reputation. Buyers should assess the total value offered by suppliers, including after-sales support and warranty services.

How Do Pricing Influencers Affect Chengdu FC-1 Costs?

Various factors influence the pricing of the Chengdu FC-1, which can significantly impact the overall cost for international buyers.

-

Volume/MOQ: Larger orders typically result in lower per-unit costs. Understanding the minimum order quantity (MOQ) can help buyers negotiate better pricing.

-

Specifications/Customization: Customizing the aircraft according to specific operational needs can lead to increased costs. Buyers should weigh the benefits of customization against the added expense.

-

Materials: The choice of materials impacts both performance and cost. High-performance materials may raise the initial price but can lead to lower maintenance costs over the aircraft’s lifecycle.

-

Quality/Certifications: Aircraft must meet various international certifications, which can influence pricing. Ensure that the supplier has the necessary certifications to avoid future compliance issues.

-

Supplier Factors: Consider the supplier’s reliability, reputation, and past performance. A well-established supplier may charge a premium but can provide greater assurance of quality and support.

-

Incoterms: The selected Incoterms will determine who is responsible for various costs and risks during shipping. Buyers should choose terms that align with their logistical capabilities and risk tolerance.

What Tips Can Buyers Use to Enhance Cost Efficiency in Chengdu FC-1 Sourcing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, leveraging cost-efficiency strategies can make a significant difference in the sourcing process.

-

Negotiate Terms: Always negotiate payment terms, delivery schedules, and warranty conditions. Flexible terms can lead to significant savings.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase price, consider long-term costs associated with maintenance, operation, and potential upgrades.

-

Research Market Prices: Stay informed about market trends and pricing benchmarks for the FC-1 to negotiate effectively. This knowledge empowers buyers to make informed decisions.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, priority service, and access to exclusive offers.

-

Consider Regional Factors: Understand the geopolitical and economic conditions in both the supplier’s and buyer’s regions. This knowledge can aid in anticipating potential cost fluctuations.

Disclaimer

The indicative pricing for the Chengdu FC-1 is based on available data and may vary due to market conditions, currency fluctuations, and changes in supplier pricing strategies. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing chengdu fc1 With Other Solutions

Understanding Alternatives in Military Aircraft Selection

When evaluating military aircraft options, it is essential to consider various alternatives that meet operational requirements while also aligning with budgetary constraints and maintenance capabilities. The Chengdu FC-1, known for its multirole capabilities and affordability, stands as a strong contender in the market. However, international B2B buyers should explore comparable solutions to make informed decisions.

Comparison Table

| Comparison Aspect | Chengdu FC-1 | JF-17 Thunder | MiG-29 Fulcrum |

|---|---|---|---|

| Performance | Max Speed: 734 knots | Max Speed: 1,500 km/h | Max Speed: 2,400 km/h |

| Cost | Approx. $15 million | Approx. $25 million | Approx. $30 million |

| Ease of Implementation | Moderate | Moderate | High |

| Maintenance | Moderate | Moderate | High |

| Best Use Case | Budget-conscious air forces | Versatile multirole operations | Air superiority missions |

Detailed Breakdown of Alternatives

JF-17 Thunder

The JF-17 Thunder, developed as a collaborative effort between China and Pakistan, offers enhanced performance with a maximum speed that exceeds that of the Chengdu FC-1. Priced around $25 million, it remains a cost-effective choice, albeit slightly higher than the FC-1. Its moderate ease of implementation and maintenance needs make it suitable for air forces looking to bolster their capabilities without excessive operational burdens. However, it may require more advanced logistics and training, particularly for newer operators.

MiG-29 Fulcrum

The MiG-29 Fulcrum is a well-known fighter jet with outstanding air superiority capabilities and a maximum speed of 2,400 km/h. Although it is priced higher at approximately $30 million, its performance and combat capabilities are robust, making it ideal for air forces that prioritize air dominance. However, the MiG-29’s complexity means it has higher maintenance demands and requires significant operational expertise. This can be a downside for smaller or less experienced air forces looking to maintain affordability and ease of use.

Conclusion: How to Choose the Right Military Aircraft Solution

When selecting the right military aircraft, B2B buyers must assess their specific operational needs, budget constraints, and the logistical capabilities of their air forces. The Chengdu FC-1 offers a balanced solution for those prioritizing cost and ease of use. In contrast, the JF-17 Thunder provides slightly better performance for a higher price, making it ideal for air forces prepared for moderate investment. Meanwhile, the MiG-29 Fulcrum is suited for those seeking superior performance and air superiority, albeit at a significantly higher cost and maintenance demand. Ultimately, the choice should align with the buyer’s strategic objectives, operational readiness, and financial considerations.

Essential Technical Properties and Trade Terminology for chengdu fc1

What Are the Key Technical Specifications of the Chengdu FC-1?

Understanding the Chengdu FC-1, also known as the JF-17 Thunder, is crucial for B2B buyers in the aerospace and defense sectors. Below are some of its essential technical properties:

-

Engine Type and Performance

– Specification: The FC-1 is powered by a Klimov RD-93 afterburning turbofan engine, delivering approximately 19,000 pound-force.

– B2B Importance: The engine’s performance impacts operational capabilities, including speed and range. Buyers should consider how engine efficiency and thrust-to-weight ratio influence mission profiles and overall operational costs. -

Max Takeoff Weight (MTOW)

– Specification: The maximum takeoff weight of the FC-1 is 12,700 kg (27,998 lbs).

– B2B Importance: MTOW is vital for understanding the aircraft’s load-carrying capacity. This impacts the number of weapons or equipment it can carry, which is a key consideration for air forces looking to maximize combat effectiveness. -

Service Ceiling

– Specification: The FC-1 can operate at a service ceiling of 55,000 feet.

– B2B Importance: A higher service ceiling allows the aircraft to engage targets at greater altitudes, providing strategic advantages in air superiority missions. Buyers need to evaluate how this capability aligns with their operational requirements. -

Combat Radius

– Specification: The aircraft has a combat radius of approximately 1,300 nautical miles (2,408 km).

– B2B Importance: The combat radius determines how far the aircraft can travel from its base to conduct operations. This metric is critical for assessing the strategic reach and versatility of the aircraft in various conflict scenarios. -

Avionics Systems

– Specification: Equipped with advanced avionics like Aselsan ASELPOD and KLJ-7V2 radar.

– B2B Importance: The quality of avionics directly affects situational awareness, targeting accuracy, and overall mission success. Buyers should prioritize avionics that meet their specific operational needs and technology standards.

What Are Common Trade Terms Used in the Chengdu FC-1 Market?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B aerospace market. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: The company that produces the original parts or equipment for the aircraft.

– Importance: Understanding who the OEM is can help buyers assess product quality, warranty terms, and support services. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their procurement strategies and manage inventory costs effectively. -

RFQ (Request for Quotation)

– Definition: A formal request sent to suppliers asking for pricing and availability on specific products.

– Importance: RFQs are crucial for comparative analysis and budgeting, allowing buyers to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international shipping and freight.

– Importance: Understanding Incoterms is essential for clarifying the responsibilities of buyers and sellers regarding shipping costs, risk transfer, and delivery points. -

Lead Time

– Definition: The amount of time that passes from the initiation of a process until its completion.

– Importance: Knowing the lead time for parts and aircraft delivery is vital for planning and operational readiness. -

Aftermarket Support

– Definition: Services provided after the sale of the aircraft, including maintenance, parts replacement, and upgrades.

– Importance: Robust aftermarket support is essential for maintaining operational capability and extending the lifecycle of the aircraft, making it a key consideration for buyers.

By understanding these technical specifications and trade terminologies, B2B buyers can make more informed decisions when considering the Chengdu FC-1 for their defense needs.

Navigating Market Dynamics and Sourcing Trends in the chengdu fc1 Sector

What Are the Key Trends Influencing the Chengdu FC-1 Market for International Buyers?

The Chengdu FC-1, also known as the JF-17 Thunder, represents a significant advancement in multirole fighter technology, appealing to international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe. A primary driver for the growing interest in the FC-1 is its competitive pricing, estimated at approximately $15 million per unit, which positions it as a cost-effective alternative to more expensive Western fighter jets. Additionally, the collaborative development between China and Pakistan underlines its strategic significance and potential for broader market penetration.

Emerging B2B technology trends, including advancements in avionics and weapon systems, are enhancing the FC-1’s capabilities. The integration of systems like the Aselsan ASELPOD and advanced fire-control radar systems enhances operational effectiveness, making it an attractive option for nations seeking to modernize their air forces. Furthermore, the trend towards joint defense production agreements is gaining traction, as countries aim to establish local production facilities to reduce dependency on foreign technologies and increase self-sufficiency.

The geopolitical landscape is also influencing market dynamics. Countries in Africa and the Middle East, facing security challenges, are increasingly considering the FC-1 as a viable solution to bolster their defense capabilities without incurring exorbitant costs. As these regions continue to invest in military modernization, the FC-1 is poised to capture a significant share of the market, driven by its blend of affordability, performance, and local production options.

How Can Sustainability and Ethical Sourcing Impact the Chengdu FC-1 Supply Chain?

In today’s global marketplace, sustainability and ethical sourcing are paramount considerations for B2B buyers, particularly in the defense sector. The environmental impact of military aircraft, including the Chengdu FC-1, is a growing concern, prompting manufacturers to prioritize sustainable practices in their production processes. Buyers are increasingly seeking suppliers who adhere to strict environmental regulations and demonstrate a commitment to minimizing their carbon footprint.

Ethical supply chains are equally important, as international buyers face scrutiny regarding human rights and labor practices in manufacturing. The Chengdu Aircraft Industry Group and its partners must ensure transparency in their sourcing practices, promoting fair labor conditions and ethical treatment of workers involved in the production of the FC-1. This commitment not only enhances brand reputation but also aligns with the values of many buyers in Africa, South America, the Middle East, and Europe, who prioritize ethical considerations in their procurement processes.

Additionally, the adoption of ‘green’ certifications and materials in the production of the FC-1 can further enhance its appeal. Manufacturers that invest in sustainable materials and technologies are likely to attract buyers looking for environmentally friendly options, thereby creating a competitive advantage in the market.

What Is the Historical Context of the Chengdu FC-1 Development?

The Chengdu FC-1 has its roots in a joint Sino-Pakistani development program initiated in 1999, aimed at creating a modern multirole fighter that could meet the needs of both countries’ air forces. With each country contributing equally to the development costs, the project aimed to produce an aircraft that would be not only technologically advanced but also cost-effective. The first prototype was unveiled in 2003, and by 2007, the aircraft entered service with the Pakistan Air Force.

This collaborative effort has facilitated the transfer of technology and expertise, enabling Pakistan to engage in local production and maintenance of the aircraft. Over the years, the FC-1 has evolved to incorporate advanced avionics and weaponry, solidifying its position in the global defense market. Its development reflects a broader trend in international defense procurement, where countries seek collaborative ventures to enhance their military capabilities while fostering local industries.

Frequently Asked Questions (FAQs) for B2B Buyers of chengdu fc1

-

How do I assess the reliability of a supplier for Chengdu FC-1?

To evaluate a supplier’s reliability for the Chengdu FC-1, start by conducting comprehensive background checks, including their history, financial stability, and previous client feedback. Request references from other businesses that have engaged with them, and consider visiting their facilities if possible. Additionally, verify their compliance with international aviation standards and certifications. Engaging a third-party audit can also provide an unbiased perspective on their operational capabilities and reliability. -

What are the key specifications of the Chengdu FC-1?

The Chengdu FC-1, also known as the JF-17 Thunder, features a single-engine design powered by the Klimov RD-93 turbofan, with a maximum cruise speed of 734 knots and a service ceiling of 55,000 feet. It has a combat range of 1,300 nautical miles and can carry a payload of up to 3,000 kg. The aircraft is equipped with advanced avionics, including the KLJ-7V2 radar, making it suitable for various combat roles. Understanding these specifications can help buyers determine its suitability for specific defense needs. -

What customization options are available for the Chengdu FC-1?

Customization options for the Chengdu FC-1 can vary based on the buyer’s specific requirements and agreements with the manufacturer. Potential modifications may include avionics upgrades, armament configurations, and enhancements to electronic warfare systems. Engaging in discussions with Chengdu Aircraft Industry Group or authorized representatives can clarify available options and any associated costs. It’s essential to communicate your operational needs clearly to ensure the aircraft meets your strategic objectives. -

What is the minimum order quantity (MOQ) for the Chengdu FC-1?

The minimum order quantity for the Chengdu FC-1 typically depends on the buyer’s negotiations with the supplier and the specific terms of the contract. Historically, initial orders have included batches of eight to ten aircraft for countries like Pakistan. Buyers should be prepared to discuss their budget, anticipated requirements, and potential for future orders to negotiate favorable terms effectively. -

What payment terms can I expect when purchasing the Chengdu FC-1?

Payment terms for acquiring the Chengdu FC-1 can vary widely based on the contractual agreement. Typically, buyers may encounter terms such as a deposit upfront, followed by milestone payments aligned with production phases. It’s advisable to negotiate clear terms regarding payment schedules, including any provisions for financing or credit terms. Consulting with legal and financial advisors can help ensure that the payment structure aligns with your organization’s cash flow and budgeting capabilities. -

How is quality assurance managed for the Chengdu FC-1?

Quality assurance for the Chengdu FC-1 is typically overseen by the Chengdu Aircraft Industry Group, which adheres to rigorous international aviation standards. Buyers should inquire about the quality control processes in place, including testing protocols, compliance with military specifications, and post-sale support. Establishing a clear understanding of the QA processes can help ensure that the delivered aircraft meet operational and safety standards. -

What logistical considerations should I keep in mind when importing the Chengdu FC-1?

Importing the Chengdu FC-1 involves several logistical considerations, including compliance with international trade regulations, customs clearance processes, and transportation arrangements. Ensure that you understand the import duties, taxes, and any specific documentation required for military aircraft. Collaborating with a logistics partner experienced in defense procurement can streamline this process and help mitigate potential delays or legal issues. -

What are the typical delivery timelines for the Chengdu FC-1?

Delivery timelines for the Chengdu FC-1 can vary based on factors such as order size, customization requirements, and production capacity. Generally, once an order is placed, it may take several months to years for delivery, depending on the complexity of the order and the manufacturer’s current workload. Buyers should establish a clear timeline during negotiations and maintain regular communication with the supplier to stay informed about any changes or delays in the production schedule.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Chengdu Fc1 Manufacturers & Suppliers List

1. Chengdu – FC-1 Fierce Dragon

Domain: aerocorner.com

Registered: 2020 (5 years)

Introduction: {‘name’: ‘Chengdu FC-1 Fierce Dragon’, ‘price’: ‘$15 million (2016)’, ‘manufacturer’: ‘Chengdu Aircraft Industry Group’, ‘country’: ‘China’, ‘manufactured’: ‘2007 to Present’, ‘ICAO’: ‘FC1’, ‘performance’: {‘engine’: ‘1 x Klimov RD-93 afterburning turbofan’, ‘power’: ‘19,000 pound-force’, ‘max_cruise_speed’: ‘734 knots (1,359 Km/h)’, ‘travel_range’: ‘1,300 Nautical Miles (2,408 Kilometers)’, ‘fuel…

2. Chengdu FC-1 Xiaolong – Multirole Fighter

Domain: military-history.fandom.com

Registered: 1996 (29 years)

Introduction: Chengdu FC-1 Xiaolong (JF-17 Thunder) is a multirole fighter developed through a joint Sino-Pakistani program initiated in 1999. Key details include:

– Development Cost: Estimated at US$150 million, with China and Pakistan each contributing 50%.

– Prime Contractor: Chengdu Aircraft Corporation (CAC) of China.

– Partner: Pakistani Aeronautical Complex (PAC) responsible for post-sale service and …

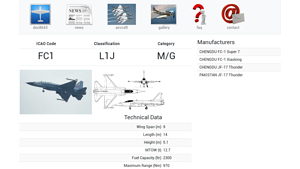

3. FC1 – M/G Model Specifications

Domain: doc8643.com

Registered: 2012 (13 years)

Introduction: {‘ICAO_Code’: ”, ‘Classification’: ”, ‘Category’: ”, ‘Model’: ‘FC1 L1J M/G’, ‘Wing_Span_m’: 9, ‘Length_m’: 14, ‘Height_m’: 5.1, ‘MTOW_t’: 12.7, ‘Fuel_Capacity_ltr’: 2300, ‘Maximum_Range_Nm’: 970, ‘Persons_On_Board’: 1, ‘Take_Off_Distance_m’: 500, ‘Landing_Distance_m’: 700, ‘Absolute_Ceiling_x100ft’: 550, ‘Optimum_Ceiling_x100ft’: ”, ‘Maximum_Speed_kts_M’: 1.6, ‘Optimum_Speed_kts_M’: ”, ‘Maxim…

4. FlightAware – AeroAPI, Firehose, Foresight

Domain: flightaware.com

Registered: 2005 (20 years)

Introduction: CHENGDU Xiaolong (single-jet) (FC1) – FlightAware Products: AeroAPI (Flight data API with on-demand flight status and flight tracking data), FlightAware Firehose (Streaming flight data feed for enterprise integrations with real-time, historical and predictive flight data), FlightAware Foresight (Predictive technology to strengthen customer trust in operations), Rapid Reports (Quickly purchase hist…

5. Aviation Week – Chengdu FC-1/JF-17 Fighter

Domain: aviationweek.com

Registered: 1995 (30 years)

Introduction: The Chengdu Aircraft FC-1, also known as the JF-17 in Pakistan, is a lightweight fighter program initiated by Chengdu in 1991 after the U.S. withdrew from the Grumman/Chengdu Super 7 effort. The joint development and production agreement between Pakistan and China was signed in 1998, with the first prototype flying in 2003.

6. Chengdu – FC-1 Fighter

Domain: flightglobal.com

Registered: 2005 (20 years)

Introduction: Chengdu FC-1 lightweight fighter, redesigned fourth prototype, first flight on April 28, 2006, features JSF-style diverterless engine inlets, larger wing leading-edge root extensions, longer ventral strakes, taller fin, powered by Klimov RD-93 afterburning turbofan, improved electronics and weapon systems, Pakistan plans to buy up to 150 units, initial order of 16 fighters, assembly split between …

7. Flashscore USA – Chengdu Rongcheng Live Scores

Domain: flashscoreusa.com

Registered: 2023 (2 years)

Introduction: Chengdu Rongcheng live scores, results, fixtures; Stadium: Chengdu Phoenix Hill Sports Park (Chengdu); Capacity: 60,000; Competitions: Super League, FA Cup, AFC Champions League; Player details: Goalkeepers – Jian Tao (24), Liu Dianzuo (35); Defenders – Dong Yanfeng (29), Gurfinkel Yahav (27), Han Pengfei (32), Hu Hetao (21), Li Yang (28), Tang Xin (34), Wang Dongsheng (28), Yang Shuai (28), Yuan …

8. Chengdu Rongcheng – 2025 Squad Overview

Domain: espn.com

Introduction: Chengdu Rongcheng 2025 Squad details: 1st in Chinese Super League. Goalkeepers: Tao Jian (24, 6’1″, 179 lbs, China PR, 2 apps, 7 SV, 2 GA), Ran Weifeng (23, 6’1″, 172 lbs, –), Liu Dianzuo (35, 6’2″, 190 lbs, China PR, 21 apps, 43 SV, 16 GA), Peng Haochen (20, 5’9″, 130 lbs, –), Tang Zicheng (17, 6’1″, 163 lbs, –). Outfield players: Hu Hetao (21, D, 5’9″, 152 lbs, –, 14 apps, 1 G, 3 A), Tang Xi…

Strategic Sourcing Conclusion and Outlook for chengdu fc1

The Chengdu FC-1, also known as the JF-17 Thunder, exemplifies a strategic opportunity for international B2B buyers seeking advanced military capabilities at a competitive price point. With a development rooted in collaboration between China and Pakistan, the FC-1 offers robust performance specifications, including a maximum cruise speed of 734 knots and a range of 1,300 nautical miles, making it a versatile choice for air forces looking to enhance their operational capabilities without incurring excessive costs.

Strategic sourcing of the FC-1 not only provides access to a technologically advanced fighter jet but also facilitates partnerships within the defense sector, enabling countries to bolster their military readiness while fostering economic ties. The aircraft’s affordability—approximately USD 15 million—alongside its proven track record with operators like the Pakistan Air Force, positions it as a compelling option for nations in Africa, South America, the Middle East, and Europe.

Looking ahead, international buyers are encouraged to explore the potential of the FC-1 as a strategic asset in their defense procurement strategies. Engaging with Chengdu Aircraft Industry Group could unlock further collaboration opportunities, ensuring that your air force is equipped with cutting-edge technology to meet future challenges.