A Deep Dive into Split Stretcher Solution

Introduction: Navigating the Global Market for split stretcher

In the dynamic landscape of healthcare and fitness equipment, sourcing a reliable split stretcher can pose significant challenges for international B2B buyers. With an array of options available, businesses must navigate through varying quality standards, specific applications, and diverse supplier capabilities. This guide is designed to demystify the complexities of the split stretcher market, offering a comprehensive overview that includes different types, applications across sectors, and essential criteria for supplier vetting.

Whether you are in Africa, South America, the Middle East, or Europe—regions characterized by unique market demands and regulatory environments—this guide will empower you to make informed purchasing decisions. You will discover insights into cost considerations, warranty options, and the importance of choosing the right materials to ensure durability and safety. Additionally, we will highlight key features that enhance user experience and performance, essential for maximizing the effectiveness of your investment.

By equipping yourself with the knowledge contained in this guide, you can confidently approach suppliers, negotiate better terms, and ultimately enhance the value delivered to your organization. The information presented here is tailored to meet the needs of discerning buyers, ensuring you are well-prepared to select the ideal split stretcher for your operational requirements.

Understanding split stretcher Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Split Stretcher | Lightweight, portable, and easy to use without power requirements | Emergency medical services, sports teams, clinics | Pros: Cost-effective, versatile. Cons: Limited functionality, may require manual effort. |

| Electric Split Stretcher | Motorized adjustments for precise positioning | Hospitals, ambulances, specialized medical facilities | Pros: Effortless operation, adjustable settings. Cons: Higher cost, potential maintenance issues. |

| Foldable Split Stretcher | Compact design for easy storage and transport | Disaster response, outdoor medical services | Pros: Space-saving, easy to deploy. Cons: May sacrifice durability for portability. |

| Heavy-Duty Split Stretcher | Robust construction for high weight capacity | Military, rescue operations, industrial settings | Pros: High durability, suitable for diverse environments. Cons: Bulkier, may require more storage space. |

| Multi-Purpose Split Stretcher | Versatile design for various applications | Training facilities, rehabilitation centers | Pros: Adaptable for different uses, multifunctional. Cons: May not excel in specialized tasks. |

What Are the Key Characteristics of a Manual Split Stretcher?

Manual split stretchers are designed for ease of use and portability, making them a popular choice for emergency medical services and sports teams. These stretchers are lightweight and do not require electricity, allowing for quick deployment in various situations. When purchasing, consider the materials used for durability and ease of cleaning, as well as the stretcher’s weight capacity to ensure it meets your operational needs.

How Do Electric Split Stretchers Enhance Medical Operations?

Electric split stretchers offer motorized adjustments, allowing healthcare providers to position patients with precision and minimal physical strain. They are especially beneficial in hospital settings and ambulances where quick and safe patient transfer is essential. When considering an electric stretcher, evaluate the power source, battery life, and maintenance requirements to ensure reliability in critical situations.

Illustrative image related to split stretcher

What Makes Foldable Split Stretchers Ideal for Disaster Response?

Foldable split stretchers are designed for compact storage and rapid deployment, making them an excellent choice for disaster response teams and outdoor medical services. Their lightweight construction allows for easy transport, but buyers should assess the balance between portability and the stretcher’s durability. Look for models that maintain structural integrity while being easy to handle.

Why Choose a Heavy-Duty Split Stretcher for Challenging Environments?

Heavy-duty split stretchers are built to withstand the rigors of military and rescue operations, featuring robust construction that supports higher weight capacities. These stretchers are ideal for diverse environments, including rugged terrains. When purchasing, consider the stretcher’s weight, dimensions, and materials to ensure it can handle the demands of your specific applications without compromising safety.

How Can Multi-Purpose Split Stretchers Benefit Training Facilities?

Multi-purpose split stretchers are designed to accommodate a variety of applications, from training to rehabilitation. Their adaptability makes them suitable for different scenarios, appealing to institutions that require versatility. However, buyers should weigh the benefits of multifunctionality against the potential for reduced performance in specialized tasks, ensuring the stretcher meets their specific training or rehabilitation needs.

Key Industrial Applications of split stretcher

| Industry/Sector | Specific Application of split stretcher | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Emergency medical services | Facilitates rapid patient transport and stabilization | Ensure compliance with medical regulations and durability |

| Sports and Fitness | Athletic training and rehabilitation | Enhances flexibility and recovery for athletes | Look for adjustable features and comfort for users |

| Performing Arts | Dance and performance training | Aids in flexibility training for dancers and performers | Prioritize lightweight and portable models for easy transport |

| Education and Training | Physical education programs | Supports stretching routines in schools and institutions | Consider models that are easy to set up and store |

| Military and Defense | Tactical and field medical operations | Allows for efficient casualty evacuation in the field | Focus on rugged designs that withstand harsh environments |

How is a Split Stretcher Used in Healthcare Settings?

In healthcare, split stretchers are essential tools for emergency medical services (EMS) and hospitals. They allow for the safe and efficient transport of patients, especially those with spinal injuries or other critical conditions. The design enables healthcare professionals to stabilize patients while providing easy access for medical interventions. International B2B buyers should ensure that the stretchers comply with local medical regulations and standards, focusing on durability and ease of cleaning to maintain hygiene.

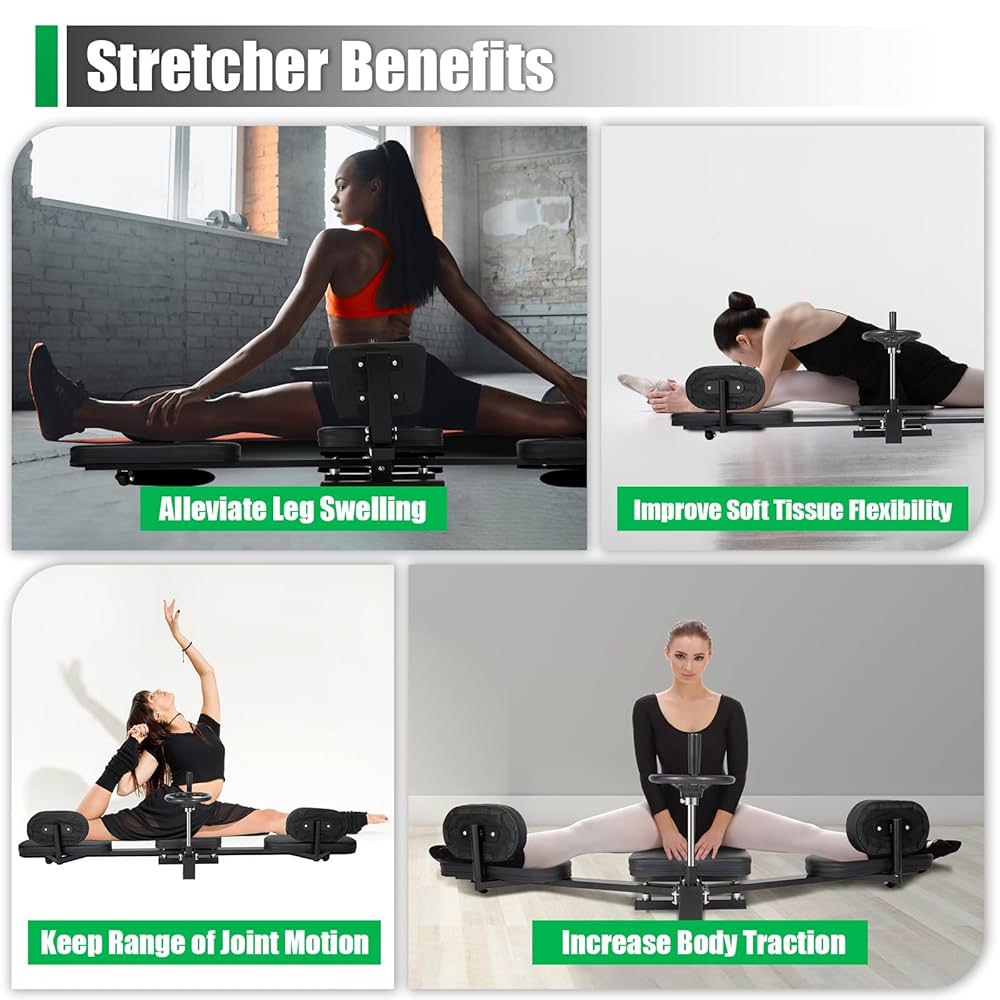

What Role Does a Split Stretcher Play in Sports and Fitness?

In the sports and fitness sector, split stretchers are used primarily for flexibility training and rehabilitation. Athletes utilize these machines to enhance their range of motion, which is crucial for performance and injury prevention. Buyers in this sector should look for models that offer adjustable settings to cater to different user needs and comfort levels. Additionally, a focus on ergonomic design will ensure that athletes can safely and effectively use the equipment during training sessions.

How Do Performing Arts Benefit from Split Stretchers?

For the performing arts, particularly in dance and theater, split stretchers are invaluable for training flexibility. Dancers and performers use these devices to stretch safely and improve their performance quality. B2B buyers in this industry should prioritize lightweight and portable models that can be easily transported to various rehearsal spaces. Additionally, the comfort of the equipment is crucial, as it directly impacts the performers’ ability to practice effectively.

Why are Split Stretchers Important in Educational Settings?

In educational institutions, particularly in physical education programs, split stretchers are utilized to promote physical fitness among students. They help in teaching proper stretching techniques, which can prevent injuries and improve overall physical health. Buyers from schools and universities should consider stretchers that are easy to set up and store, ensuring they can be efficiently used in multiple settings. Durability and safety features are also critical to withstand regular use by students.

What Are the Key Benefits of Split Stretchers in Military Operations?

In military and defense applications, split stretchers are crucial for tactical and field medical operations. They facilitate the rapid evacuation of injured personnel from combat zones, ensuring that medical support is delivered promptly. Buyers in this sector should focus on rugged designs that can withstand harsh environmental conditions and are easy to deploy. Additionally, weight considerations are important, as lightweight models enhance mobility and transport efficiency in the field.

3 Common User Pain Points for ‘split stretcher’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Split Stretchers for Diverse Needs

The Problem: B2B buyers often face challenges in sourcing high-quality split stretchers that meet the specific requirements of their operations. This is particularly true for businesses in the healthcare sector, where equipment must comply with stringent safety and quality standards. Buyers may find themselves overwhelmed by the variety of products available, each with different features, material quality, and durability. This can lead to uncertainty about whether they are making the right investment, especially when catering to diverse clientele, such as rehabilitation centers or fitness facilities.

The Solution: To mitigate these challenges, buyers should start by defining their specific needs based on the clientele they serve. Consider factors such as the weight capacity, material durability, and ease of cleaning, especially for medical or rehabilitation purposes. Conduct thorough research by requesting product samples and reviewing manufacturer certifications. Engage directly with suppliers who have a proven track record in the industry and can provide testimonials from similar businesses. Additionally, consider utilizing procurement platforms that specialize in medical and fitness equipment, allowing for side-by-side comparisons of specifications and pricing. This strategic approach ensures that buyers are not only sourcing quality products but also aligning them with the needs of their customers.

Scenario 2: Concerns Over Equipment Maintenance and Longevity

The Problem: Another common issue faced by B2B buyers is the long-term maintenance and durability of split stretchers. Many organizations worry about the costs associated with frequent repairs and replacements, especially in high-usage environments like gyms or hospitals. The fear of equipment failing during critical use can also lead to operational disruptions, impacting customer satisfaction and the overall business reputation.

The Solution: To address these concerns, buyers should prioritize equipment that comes with robust warranties and support services. When evaluating potential purchases, inquire about the warranty coverage for parts and labor, especially for international buyers who may face additional challenges in accessing timely repairs. Look for manufacturers that offer comprehensive maintenance packages or training for staff on proper equipment care. Regular maintenance schedules should be implemented to prolong the lifespan of the equipment, coupled with proactive checks to identify wear and tear before they lead to equipment failure. Additionally, consider investing in equipment made from high-grade materials designed to withstand rigorous use, which will significantly reduce the frequency and cost of repairs.

Scenario 3: Navigating Compliance and Regulatory Standards

The Problem: For B2B buyers operating in the medical or rehabilitation sectors, navigating compliance with regulatory standards can be a daunting task. Different regions may have varying requirements for medical equipment, and failure to comply can result in legal issues and financial penalties. This complexity is especially pronounced for international buyers who must understand both local regulations and those of the countries they import from.

The Solution: To successfully navigate these regulatory landscapes, buyers should conduct thorough research on the specific compliance standards applicable to their market. Engage with local regulatory bodies or industry associations to obtain the most current guidelines. When selecting a split stretcher, ensure that the manufacturer provides documentation proving compliance with relevant standards, such as ISO certifications or CE marking in Europe. Establishing a relationship with a supplier that is knowledgeable about local regulations can also provide valuable support throughout the purchasing process. Furthermore, consider joining industry forums or groups where you can share insights and learn from the experiences of peers facing similar challenges. This proactive approach will not only ensure compliance but also enhance the credibility of your organization in the marketplace.

Strategic Material Selection Guide for split stretcher

What Are the Key Materials Used in Split Stretchers?

When selecting materials for split stretchers, it’s essential to consider their properties, advantages, and limitations. The choice of material can significantly impact the stretcher’s performance, durability, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of split stretchers: aluminum, stainless steel, high-density polyethylene (HDPE), and fiberglass.

How Does Aluminum Perform in Split Stretcher Applications?

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio. It typically has a temperature rating of up to 150°C and offers good corrosion resistance, making it suitable for various environments.

Pros: Aluminum is durable and resistant to rust, which is advantageous in humid or saline conditions often found in coastal regions. Its lightweight nature makes it easy to transport and maneuver, which is crucial in emergency situations.

Illustrative image related to split stretcher

Cons: While aluminum is strong, it can be less durable than steel under extreme loads. It may also be more expensive than other materials, impacting budget considerations for bulk purchases.

Impact on Application: Aluminum’s corrosion resistance makes it ideal for medical environments where hygiene is paramount. However, it may not be suitable for heavy-duty applications requiring higher load capacities.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure that aluminum stretchers meet standards such as EN 1865 for medical stretchers, which outlines safety and performance requirements.

What Are the Advantages of Stainless Steel in Split Stretchers?

Stainless steel is renowned for its strength, durability, and resistance to corrosion and staining. It can withstand temperatures up to 300°C, making it suitable for sterilization processes.

Pros: Stainless steel’s robustness ensures longevity and reliability, especially in high-use environments like hospitals and emergency services. Its aesthetic appeal also contributes to a professional appearance.

Cons: The primary drawback is its weight; stainless steel stretchers can be cumbersome, making them less ideal for rapid deployment scenarios. Additionally, the cost is generally higher than aluminum and plastic alternatives.

Impact on Application: Stainless steel is compatible with various cleaning agents, ensuring compliance with strict hygiene standards in medical settings. However, its weight may hinder quick transport.

Considerations for International Buyers: Compliance with international standards such as ASTM A240 for stainless steel is critical. Buyers should also consider the availability of parts and service in their region.

How Does High-Density Polyethylene (HDPE) Compare for Split Stretchers?

HDPE is a thermoplastic known for its high strength-to-density ratio and resistance to impact and chemicals. It typically performs well in temperatures ranging from -40°C to 80°C.

Pros: HDPE is lightweight, making it easy to handle and transport. Its resistance to chemicals and moisture makes it ideal for outdoor and rugged environments.

Cons: While HDPE is durable, it may not withstand extreme temperatures as effectively as metals. It can also be less aesthetically pleasing compared to aluminum or stainless steel.

Impact on Application: HDPE’s chemical resistance is beneficial in environments where exposure to various substances is common. However, it may not be suitable for applications requiring high structural integrity.

Considerations for International Buyers: Buyers in Africa and South America should ensure that HDPE stretchers comply with local regulations and standards, as material properties can vary by manufacturer.

Why Choose Fiberglass for Split Stretchers?

Fiberglass is a composite material known for its lightweight and high strength. It is resistant to corrosion and can withstand temperatures up to 100°C.

Pros: Fiberglass is incredibly strong yet lightweight, making it easy to transport. Its corrosion resistance is beneficial in moist or chemically aggressive environments.

Cons: Fiberglass can be more expensive to manufacture, and its brittleness may lead to cracking under certain conditions. Additionally, it requires careful handling during manufacturing and transport.

Impact on Application: Fiberglass stretchers are ideal for emergency services in harsh environments due to their durability and lightweight nature. However, they may not be as readily available in all markets.

Considerations for International Buyers: Compliance with international standards such as ISO 9001 for quality management systems is essential. Buyers should also consider the availability of replacement parts.

Illustrative image related to split stretcher

Summary Table of Material Selection for Split Stretchers

| Material | Typical Use Case for split stretcher | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight medical transport | Excellent strength-to-weight ratio | Less durable under extreme loads | Medium |

| Stainless Steel | Hospital and emergency services | High durability and corrosion resistance | Heavier than alternatives | High |

| High-Density Polyethylene (HDPE) | Outdoor and rugged environments | Lightweight and chemically resistant | Limited temperature resistance | Low |

| Fiberglass | Harsh environments and emergency use | Strong and lightweight | Can be brittle and expensive | Medium |

In summary, the selection of materials for split stretchers requires careful consideration of their properties, advantages, and limitations, particularly in the context of international standards and regional requirements. B2B buyers should evaluate their specific needs and compliance requirements to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for split stretcher

What Are the Main Stages in the Manufacturing Process of Split Stretchers?

The manufacturing process of split stretchers typically involves several key stages, each crucial for ensuring the final product meets the necessary quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing a split stretcher involves selecting the appropriate materials, which often include high-strength steel or aluminum for the frame, as well as durable fabrics for padding and support. These materials are carefully sourced to ensure they meet international quality standards. Once selected, the materials undergo cutting and treatment processes to prepare them for further manufacturing stages. This might include processes like anodizing for aluminum components, which enhances corrosion resistance.

Forming

After preparation, the next stage is forming, where the materials are shaped into the various components of the stretcher. This can involve processes such as bending, welding, and stamping. Advanced machinery is often used to ensure precision in shaping, which is critical for the stretcher’s functionality and safety. Computer Numerical Control (CNC) machines may be employed to achieve high levels of accuracy and repeatability, especially for complex shapes.

Assembly

Once the components are formed, they are assembled. This stage involves combining the frame, padding, and any additional features such as adjustable straps or hinges. Quality control is critical during assembly; parts must fit together seamlessly to ensure the stretcher operates as intended. Skilled technicians often conduct this assembly, ensuring that each unit is built to the specifications outlined in the design phase.

Finishing

The final stage of the manufacturing process is finishing, which includes painting, coating, or applying any other surface treatments. This not only enhances the aesthetic appeal of the stretcher but also adds an extra layer of protection against wear and environmental factors. Quality checks are conducted to ensure that the finish is consistent and meets the standards required for commercial use.

What Quality Control Practices Are Essential for Split Stretchers?

Quality assurance in the manufacturing of split stretchers is pivotal for ensuring safety, reliability, and compliance with international standards. The following quality control (QC) practices are commonly implemented:

Illustrative image related to split stretcher

International Standards and Certifications

Manufacturers of split stretchers should adhere to internationally recognized standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with CE marking is also essential, particularly for products sold in Europe, as it signifies conformity with health, safety, and environmental protection standards. Other relevant certifications might include API for medical equipment, depending on the intended use of the stretcher.

Quality Control Checkpoints

To maintain high-quality standards throughout the manufacturing process, several quality control checkpoints are established:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon delivery to ensure they meet predefined specifications. Testing may include material strength assessments and dimensional checks.

-

In-Process Quality Control (IPQC): During the manufacturing stages, in-process checks are performed to monitor the quality of components as they are formed and assembled. This might involve visual inspections and measurements to detect any deviations from specifications.

-

Final Quality Control (FQC): Once assembly is complete, final inspections are conducted. This includes functional testing of the stretcher, checking for weight capacity, durability, and safety features. Any non-conformities identified at this stage can result in rework or rejection of the product.

What Testing Methods Are Commonly Used for Quality Assurance in Split Stretchers?

Testing methods employed in the quality assurance of split stretchers can vary but generally include:

-

Static Load Testing: This method evaluates the load-bearing capacity of the stretcher by applying a predetermined weight to ensure it can withstand the pressures it will encounter in real-world use.

-

Dynamic Testing: This involves simulating actual usage conditions, such as moving the stretcher under load, to assess its stability and durability over time.

-

Material Testing: Various tests may be performed on the materials used, such as tensile strength tests for metals and abrasion tests for fabrics, to ensure they meet the necessary safety and performance standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is critical. Here are several strategies to ensure supplier compliance:

-

Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes and quality control measures. This allows buyers to assess whether the supplier adheres to the required standards.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can help buyers understand the testing methods used and the results obtained. These reports should include information on compliance with international standards and any certifications held by the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing and quality control processes. These inspections can be scheduled at various stages of the production process to ensure compliance with agreed specifications.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

B2B buyers operating in international markets should be aware of several nuances related to quality control:

-

Regulatory Compliance: Different regions may have varying regulatory requirements for medical equipment. Buyers should ensure that their suppliers are compliant with local regulations, especially when importing products into regions like Europe or the Middle East.

-

Cultural Differences: Understanding cultural attitudes towards quality and safety can impact supplier relationships. Buyers should communicate their quality expectations clearly and establish mutual understanding.

-

Post-Purchase Support: Quality assurance doesn’t end with the purchase. Buyers should inquire about the supplier’s policies on after-sales support, warranty claims, and how they handle defective products. This can greatly affect the long-term relationship and satisfaction with the purchased equipment.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for split stretchers is essential for B2B buyers to ensure they select reliable suppliers that meet their quality standards and regulatory requirements. By leveraging audits, quality reports, and third-party inspections, buyers can confidently navigate the complexities of international procurement.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘split stretcher’

In the fast-paced world of international trade, sourcing a split stretcher requires careful consideration and strategic planning. This guide provides a practical checklist for B2B buyers focused on procuring split stretchers, ensuring you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Before engaging suppliers, it is essential to clearly outline the technical specifications of the split stretcher you require. Consider factors such as dimensions, weight capacity, material, and intended use (e.g., medical transport, fitness training). This clarity will help you communicate effectively with suppliers and avoid misunderstandings later in the procurement process.

Step 2: Identify Reputable Suppliers

Next, research and identify potential suppliers who specialize in split stretchers. Focus on suppliers with a solid reputation in your target markets, such as Africa, South America, the Middle East, and Europe. Look for suppliers that have been in the industry for several years, as longevity often indicates reliability and experience.

Step 3: Evaluate Supplier Certifications

It’s critical to verify that your chosen suppliers have the necessary certifications and compliance with international standards. Certifications such as ISO 9001 for quality management or CE marking for medical devices can indicate that the supplier adheres to strict quality control processes. This step ensures that you are sourcing safe and effective products.

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the split stretcher. Assess the quality, durability, and functionality of the product firsthand. This step allows you to ensure that the stretcher meets your specifications and expectations, reducing the risk of dissatisfaction after a large order.

Illustrative image related to split stretcher

Step 5: Review Warranty and Support Terms

Examine the warranty and after-sales support provided by the supplier. A robust warranty can protect your investment and cover potential defects or issues. Ensure that the supplier offers adequate technical support and service options, especially if you are sourcing for a market where quick response times are critical.

Step 6: Compare Pricing and Payment Terms

Conduct a thorough comparison of pricing among different suppliers, but don’t solely focus on the lowest price. Consider the total cost of ownership, including shipping, taxes, and potential tariffs. Discuss payment terms and conditions to ensure they align with your cash flow requirements and negotiate favorable terms if necessary.

Step 7: Establish a Communication Plan

Effective communication is vital throughout the procurement process. Set up a communication plan with your supplier that outlines how you will stay in touch, the frequency of updates, and points of contact. This proactive approach helps manage expectations and fosters a strong partnership.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing split stretchers with confidence, ensuring they select the right products and suppliers to meet their operational needs.

Comprehensive Cost and Pricing Analysis for split stretcher Sourcing

What Are the Key Cost Components in Split Stretcher Manufacturing?

When sourcing split stretchers, understanding the cost structure is critical for effective budgeting and negotiation. The primary cost components include:

-

Materials: The type and quality of materials directly impact the cost. High-strength steel or aluminum may be more expensive but offer better durability and safety features. The inclusion of additional features, like padding or adjustable settings, can also increase material costs.

-

Labor: Labor costs can vary significantly depending on the region and the level of expertise required. Skilled labor in regions with higher living costs, such as parts of Europe, may drive up prices compared to regions with lower wage standards.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, maintenance, and factory management. Efficient manufacturing processes can help minimize overhead and, consequently, overall costs.

-

Tooling: Initial tooling costs for specialized equipment or molds can be significant, particularly for custom designs. However, these costs can be amortized over larger production runs, making them less burdensome per unit.

-

Quality Control (QC): Ensuring that each unit meets safety and performance standards is vital, especially for medical or emergency equipment. QC processes can add to the cost but are essential for maintaining a reputable brand.

-

Logistics: Transportation costs can fluctuate based on the origin and destination, shipping methods, and current fuel prices. These costs are particularly relevant for international buyers, who must consider tariffs and duties as well.

-

Margin: Suppliers typically include a profit margin in their pricing, which can range from 10% to 30%, depending on the market demand and competition.

How Do Pricing Influencers Affect Split Stretcher Costs?

Various factors can influence pricing when sourcing split stretchers, including:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom features can significantly raise costs. Buyers should weigh the benefits of customization against the additional expense. Standard models are often more cost-effective.

-

Material Quality and Certifications: Stretcher models that meet international safety standards or have additional certifications may come with a higher price tag. Buyers should consider the value of compliance against potential liabilities.

-

Supplier Factors: The reliability and reputation of the supplier can impact pricing. Established suppliers may charge a premium for their products due to their proven track record.

-

Incoterms: Understanding Incoterms can help buyers evaluate total logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping and insurance, affecting overall pricing.

What Are the Best Practices for Negotiating Split Stretcher Prices?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, the following tips can enhance negotiation outcomes:

-

Conduct Thorough Market Research: Understanding market prices and competitor offerings can provide leverage during negotiations.

-

Build Relationships: Establishing a rapport with suppliers can lead to better terms and pricing flexibility over time.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, logistics, and potential downtime costs. A higher upfront cost may be justified if it leads to lower long-term expenses.

-

Be Transparent About Needs: Clearly communicate specifications and needs to suppliers. This can lead to tailored solutions that may offer better value.

-

Leverage Local Knowledge: Engage local representatives who understand regional market dynamics and can negotiate effectively on your behalf.

Conclusion: What Should Buyers Remember About Pricing Nuances?

While this analysis provides a framework for understanding the costs and pricing structure of split stretchers, buyers should remember that prices can fluctuate based on market conditions and specific supplier circumstances. Therefore, it is essential to approach negotiations with flexibility and a clear understanding of your total cost considerations. Always seek multiple quotes and be prepared to discuss various options to achieve the best possible deal for your organization.

Alternatives Analysis: Comparing split stretcher With Other Solutions

Exploring Alternatives to Split Stretchers in Stretching Solutions

In the realm of physical therapy and fitness, the need for effective stretching solutions is paramount. While split stretchers have gained popularity for their targeted approach to leg flexibility, there are several viable alternatives that serve similar purposes. This analysis will compare split stretchers with other stretching technologies, allowing B2B buyers to make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Split Stretcher | Leg Stretching Machine | Partner-Assisted Stretching |

|---|---|---|---|

| Performance | Highly effective for splits | Versatile, adjusts for various stretches | Personalized, adaptable to user needs |

| Cost | Moderate (typically $200-$500) | Higher ($300-$800) | Low (primarily labor cost) |

| Ease of Implementation | Simple setup, easy to use | Requires space and assembly | Requires trained personnel |

| Maintenance | Low maintenance | Moderate maintenance | Minimal, depends on personnel |

| Best Use Case | Individual stretch sessions | Gym settings, rehabilitation centers | Group classes, personalized sessions |

Detailed Breakdown of Alternatives

Leg Stretching Machine

Leg stretching machines are designed to offer a broader range of stretches compared to split stretchers. These machines often come equipped with adjustable backrests and resistance settings, enabling users to target various muscle groups effectively. However, their higher cost and larger footprint can be a disadvantage for smaller facilities. They are ideal for gyms and rehabilitation centers where space and budget allow, providing a versatile solution for a variety of stretching needs.

Partner-Assisted Stretching

Partner-assisted stretching relies on the involvement of a trained professional who helps clients achieve deeper stretches. This method is highly effective because it allows for personalized adjustments based on the individual’s flexibility and comfort levels. The primary drawback is that it can be labor-intensive and may not be feasible in all settings, especially for larger groups. However, it is excellent for one-on-one sessions in personal training or rehabilitation contexts where customized attention is beneficial.

Conclusion: Choosing the Right Stretching Solution for Your Needs

When selecting a stretching solution, B2B buyers should consider their specific operational needs and budget constraints. Split stretchers are a cost-effective and straightforward option for facilities focused on individual flexibility training. In contrast, leg stretching machines offer versatility for diverse stretching routines but come at a higher price point and require more space. Partner-assisted stretching can provide personalized care but necessitates trained personnel, making it ideal for environments that prioritize individualized attention. By evaluating these factors, buyers can determine the most suitable stretching solution for their target audience, ultimately enhancing their service offerings and client satisfaction.

Essential Technical Properties and Trade Terminology for split stretcher

What Are the Key Technical Properties of a Split Stretcher?

When considering a split stretcher for B2B procurement, understanding its technical specifications is crucial for ensuring it meets the operational needs of your business. Here are some essential properties to evaluate:

-

Material Composition

The material used in a split stretcher can significantly impact its durability, weight capacity, and comfort. Common materials include high-grade steel for the frame and heavy-duty fabric for the surface. Opting for corrosion-resistant materials is essential for longevity, especially in humid environments or regions with variable weather conditions. -

Weight Capacity

A split stretcher’s weight capacity is a critical specification that determines its suitability for various applications, particularly in emergency medical services. Most stretchers can support weights ranging from 200 to 600 pounds. It’s vital to choose a model that accommodates the maximum expected load to ensure safety and compliance with industry standards. -

Dimensions and Foldability

The overall dimensions of the stretcher, along with its ability to fold for storage, are important for space management, especially in vehicles or small facilities. Standard dimensions typically range from 70 to 80 inches in length when unfolded. A foldable design aids in transportability and ease of storage, making it a practical choice for businesses with limited space. -

Adjustability Features

Many split stretchers come with adjustable backrests and leg rests, allowing for customized patient positioning. This feature is particularly beneficial in medical settings, as it enhances patient comfort and accessibility during transportation. Ensure the adjustability mechanisms are intuitive and robust to withstand frequent use. -

Safety Features

Look for safety features such as reinforced straps, locking mechanisms, and anti-slip surfaces. These attributes are vital for preventing accidents during transport, especially in emergency situations. Compliance with safety standards and certifications is also a key consideration when evaluating potential suppliers. -

Warranty and Support

Understanding the warranty terms can offer peace of mind regarding the investment. Many manufacturers provide warranties ranging from one to ten years, covering parts and labor. Ensure that the warranty is comprehensive and that the supplier offers adequate support for maintenance and repairs.

What Are Common Trade Terms Related to Split Stretchers?

Familiarity with industry jargon can streamline procurement processes and improve communication with suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. When purchasing split stretchers, knowing whether a product is OEM can indicate quality and compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is essential for budgeting and inventory management, as it can affect your overall procurement strategy. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing, terms, and conditions for specific products. Issuing an RFQ for split stretchers can help you compare offers and negotiate better deals. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarizing yourself with Incoterms can prevent misunderstandings regarding delivery and cost responsibilities. -

Lead Time

Lead time is the duration it takes from placing an order to receiving the goods. Understanding lead times is crucial for planning and ensuring that your supply chain remains uninterrupted, particularly in urgent medical situations. -

Certification Standards

This term refers to industry-specific standards that products must meet to ensure quality and safety. For split stretchers, certifications from bodies like ISO or CE can be indicators of compliance with international safety and quality standards.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and safety in their organizations.

Navigating Market Dynamics and Sourcing Trends in the split stretcher Sector

What Are the Key Market Dynamics and Trends in the Split Stretcher Sector?

The global market for split stretchers is experiencing significant growth driven by increasing demands in healthcare, sports, and rehabilitation sectors. Key factors include the rising prevalence of sports injuries and a growing emphasis on physical therapy, particularly in regions such as Africa, South America, the Middle East, and Europe. For instance, countries like Brazil and Germany are investing heavily in healthcare infrastructure, which includes advanced medical equipment like split stretchers.

Illustrative image related to split stretcher

Emerging B2B tech trends include the integration of smart technologies into stretcher designs, such as built-in sensors that provide real-time data on patient positioning and comfort levels. Additionally, the demand for customizability in product features is on the rise, as international buyers seek solutions tailored to their unique operational environments. This trend is particularly pronounced in the Middle East, where hospitals are often equipped with high-tech facilities.

Sourcing dynamics are also evolving, with a shift toward direct partnerships with manufacturers to enhance supply chain efficiency. Many buyers are looking for suppliers who can provide not just products but also comprehensive support services, including training and maintenance. This is especially important in regions with developing markets, where expertise and after-sales support can significantly impact operational success.

How Important Are Sustainability and Ethical Sourcing in the Split Stretcher Market?

Sustainability and ethical sourcing are becoming pivotal considerations for B2B buyers in the split stretcher market. As environmental concerns grow globally, companies are increasingly scrutinizing their supply chains to ensure they minimize ecological impact. This is particularly relevant in Africa and South America, where regulatory frameworks are evolving to enforce stricter environmental standards.

Buyers are increasingly favoring suppliers that utilize eco-friendly materials and processes, such as recyclable metals and sustainable manufacturing practices. Certifications such as ISO 14001 for environmental management and those indicating the use of low-impact materials are becoming essential for suppliers to demonstrate their commitment to sustainability.

Illustrative image related to split stretcher

Moreover, an ethical supply chain is vital for maintaining brand reputation and customer trust. International buyers are now more inclined to partner with manufacturers who adhere to fair labor practices and ensure safe working conditions. This trend not only enhances corporate responsibility but also attracts socially conscious consumers and clients who prioritize ethical business practices.

How Has the Split Stretcher Market Evolved Over Time?

The split stretcher market has evolved significantly over the past few decades, transitioning from simple, manually operated devices to advanced, multifunctional equipment. Initially designed primarily for emergency medical services, modern split stretchers are now integral to physical therapy and rehabilitation settings. Innovations such as adjustable frames and ergonomic designs have enhanced usability and comfort for both patients and healthcare providers.

The rise of fitness culture and increased awareness of physical health have also contributed to the diversification of products available in the market. Today, buyers can choose from a wide range of options, including those designed specifically for athletes or tailored for use in rehabilitation centers. This evolution reflects broader trends in healthcare and wellness, emphasizing the importance of specialized equipment in enhancing patient outcomes and overall satisfaction.

Illustrative image related to split stretcher

Frequently Asked Questions (FAQs) for B2B Buyers of split stretcher

-

How do I choose the right split stretcher for my needs?

Choosing the right split stretcher involves considering factors such as the intended use (e.g., medical emergencies, sports, or fitness), weight capacity, material quality, and ease of transport. Assess whether you need a lightweight model for portability or a more robust option for heavy-duty use. Additionally, check for features like adjustable components and comfort padding, which can enhance usability and user experience. Consulting with manufacturers or suppliers can also provide insights tailored to your specific requirements. -

What are the benefits of using a split stretcher in emergency medical situations?

Split stretchers are designed for efficient patient transport in emergencies. They allow for easy loading and unloading, which is crucial in time-sensitive scenarios. The split design helps immobilize patients securely while providing the flexibility to adapt to various environments, such as uneven terrain. Additionally, many models are compatible with other emergency equipment, enhancing their utility in medical response settings. -

What should I consider when sourcing split stretchers internationally?

When sourcing split stretchers internationally, consider factors like compliance with local regulations, quality certifications, and supplier reliability. It’s essential to evaluate the manufacturer’s reputation through reviews and testimonials. Additionally, verify logistics capabilities to ensure timely delivery and assess potential tariffs or customs duties that may affect the overall cost. Establishing clear communication regarding specifications and after-sales support is also crucial for a successful procurement process. -

What are the minimum order quantities (MOQs) for split stretchers?

Minimum order quantities (MOQs) for split stretchers can vary significantly among suppliers. Some manufacturers may require MOQs as low as 10 units, while others might set higher thresholds based on production capabilities. It’s advisable to discuss MOQs directly with suppliers to understand their flexibility and any potential for smaller test orders. Negotiating terms can often lead to customized agreements that fit your purchasing strategy. -

How can I ensure the quality of the split stretchers I purchase?

Ensuring quality in your split stretcher purchases involves selecting suppliers with established quality management systems and certifications, such as ISO 9001. Request samples to evaluate the materials and construction firsthand. Additionally, inquire about the quality assurance processes they have in place, such as inspections and testing. Establishing a solid relationship with your supplier can also facilitate ongoing quality checks and improvements. -

What payment terms are typically offered by suppliers of split stretchers?

Payment terms for split stretchers can vary based on the supplier and order size. Common arrangements include upfront payments, deposits followed by balance payments upon delivery, or net payment terms (e.g., 30, 60, or 90 days). It’s crucial to clarify these terms before finalizing your order to avoid misunderstandings. Consider using secure payment methods and establish agreements that offer buyer protection, especially for large transactions. -

What logistics considerations should I keep in mind when importing split stretchers?

When importing split stretchers, consider logistics factors such as shipping methods, lead times, and costs. Determine whether air or sea freight is more cost-effective based on your timeline and budget. Ensure that your supplier can provide necessary shipping documentation and understand any customs regulations specific to your region. Partnering with a reliable freight forwarder can streamline the import process and help navigate any potential challenges. -

Can I customize split stretchers to meet specific requirements?

Many manufacturers offer customization options for split stretchers, allowing you to tailor features such as size, color, and additional accessories based on your needs. Discuss your specific requirements with potential suppliers to explore available options. Customization can enhance the functionality of the product for your intended use, whether for medical, fitness, or emergency services. Be mindful that custom orders may involve longer lead times and potentially higher costs.

Top 4 Split Stretcher Manufacturers & Suppliers List

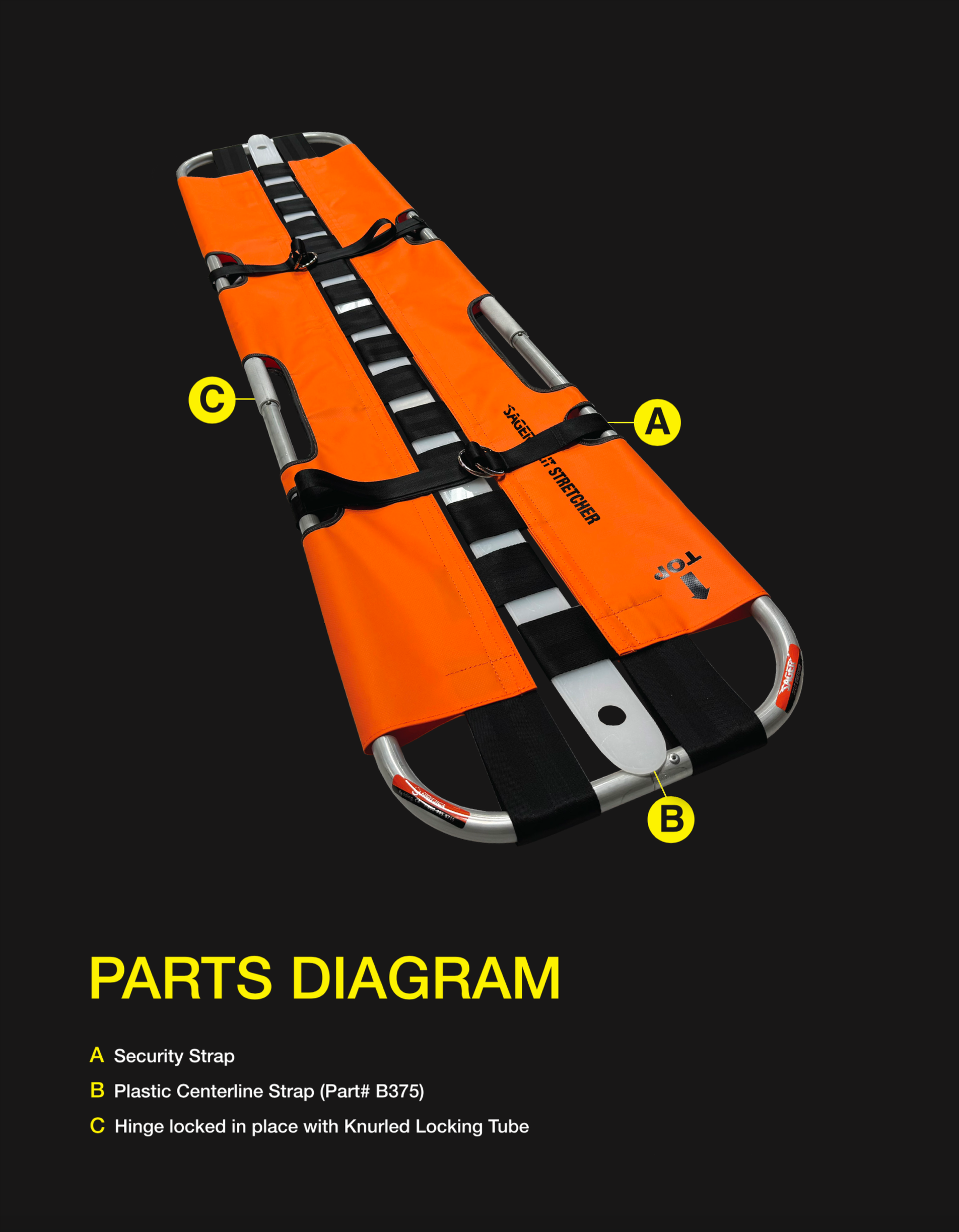

1. Sunmedica – D-B101-100 Sager Split Stretcher

Domain: sunmedica.com

Registered: 1999 (26 years)

Introduction: Product Name: D-B101-100 Sager Split Stretcher (Formerly “Breakaway Flat”)

Price: $980.03

Description: The Sager Split Stretcher is designed for first responders to transport injured patients from accident scenes to emergency facilities. It is lightweight, folds for convenient storage, and can be split into two halves for easy removal of the stretcher without rolling the patient.

Benefits:

– Lig…

2. Reddit – Stretching Machine for Flexibility

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The device in question is a stretching machine that allows users to control the degree of stretch. It is designed to help improve flexibility, particularly for achieving side splits. Some users find it beneficial for relaxing into stretches and performing PNF (Proprioceptive Neuromuscular Facilitation) techniques safely, while others consider it unnecessary and prefer active flexibility drills ins…

3. Leg Split Machine – Heavy Duty & MMA Models

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Leg Split Machine listings on eBay include various models with key details such as: 1. 330LBS Leg Stretcher, Heavy Duty Split Machine, priced at $104.99 (originally $149.99) with free delivery from Fontana, CA. 2. Leg Stretcher MMA Stretching Machine, priced at $124.24 with free delivery in 2-4 days from Monroe Township, NJ. 3. Fitness Stretching Machine for martial arts, priced at $85.37 (origina…

4. HolaHatha – Leg Stretcher Split Machine

Domain: target.com

Registered: 1997 (28 years)

Introduction: HolaHatha Leg Stretcher Split Machine for Full Split Flexibility Training, Adjustable, Stainless Steel, Dance Exercise Equipment for Home Gym, Color: Black, Sold & shipped by Spreetail, Free & easy returns within 30 days for a full refund, Eligible for registries and wish lists.

Strategic Sourcing Conclusion and Outlook for split stretcher

In conclusion, strategic sourcing for split stretchers presents a significant opportunity for international B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. By focusing on quality, durability, and adaptability of these products, businesses can enhance their operational efficiency and meet varied client needs. The demand for reliable and innovative stretchers, like the Sager® Split Stretcher and French Fitness models, underscores the importance of selecting suppliers that prioritize both functionality and comfort.

Investing in high-quality split stretchers not only improves user experience but also reduces long-term operational costs through decreased maintenance needs and enhanced product longevity. As global health standards continue to evolve, ensuring that your sourcing strategy aligns with these changes will keep your business competitive.

Looking ahead, international buyers are encouraged to engage with reputable manufacturers and distributors that can offer tailored solutions and robust support. By doing so, you can position your business to thrive in an increasingly competitive landscape. Embrace the future of sourcing by exploring innovative products that align with your strategic goals and meet the demands of your clientele.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.