Choosing Your Truck Wash Brush With A 10Ft Pole: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for truck wash brush with a 10ft pole

In the competitive world of logistics and transportation, maintaining the cleanliness of vehicles is essential for both aesthetics and operational efficiency. However, sourcing the right truck wash brush with a 10ft pole can pose a significant challenge for international B2B buyers. This guide addresses the complexities of selecting high-quality truck wash brushes, providing insights into various types, applications, and key features that contribute to effective cleaning solutions.

Throughout this comprehensive resource, we will explore the specifications of different brush designs, including soft bristles that prevent surface damage and durable materials that withstand rigorous use. Additionally, we will discuss the importance of supplier vetting, ensuring you partner with reputable manufacturers who prioritize quality and reliability in their products.

Cost considerations will also be outlined, helping buyers navigate pricing structures and identify the best value for their investment. By understanding these critical factors, B2B buyers from Africa, South America, the Middle East, and Europe—including markets like Vietnam and Germany—will be empowered to make informed purchasing decisions. This guide aims to streamline the procurement process, enabling you to enhance your vehicle maintenance operations while ensuring compliance with local standards and preferences.

Understanding truck wash brush with a 10ft pole Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| All-Direction Nyltex Brush | 10″ Nyltex bristles, all-direction cleaning design | Trucking companies, fleet services | Pros: Gentle on surfaces, efficient cleaning; Cons: May require more frequent replacements. |

| Dual Surface Wash Brush | Dual-sided design for varied cleaning surfaces | Car wash facilities, detailing | Pros: Versatile for multiple applications; Cons: Slightly heavier, may need additional storage. |

| Extendable Fiberglass Pole | Adjustable length (6′-12′), lightweight and durable | Industrial cleaning, maintenance | Pros: Versatile reach, easy to maneuver; Cons: Potentially less sturdy under heavy use. |

| Bi-Level Soft-Touch Brush | Crimped soft bristles for gentle scrubbing | Truck maintenance, detailing | Pros: Safe for delicate finishes, efficient dirt removal; Cons: Limited effectiveness on heavy grime. |

| Heavy-Duty Wash Brush | Sturdy construction with thick bristles | Heavy-duty transport, construction | Pros: Excellent for tough jobs, long-lasting; Cons: May be too abrasive for some surfaces. |

What Are the Characteristics of the All-Direction Nyltex Brush?

The All-Direction Nyltex Brush is designed with 10″ Nyltex bristles that provide a gentle yet effective cleaning experience. This brush is particularly suitable for trucking companies and fleet services that require thorough cleaning of various vehicle surfaces. Its all-direction design allows for easy maneuverability, ensuring that even hard-to-reach areas are cleaned efficiently. Buyers should consider the durability of the bristles and the frequency of replacements when investing in this product.

Why Choose a Dual Surface Wash Brush?

The Dual Surface Wash Brush features a unique dual-sided design, making it ideal for varying cleaning needs. This versatility makes it a popular choice among car wash facilities and detailing services. It allows users to switch between soft and firm bristles, accommodating different surfaces without needing multiple tools. However, its slightly heavier weight may require additional storage considerations. B2B buyers should evaluate their specific cleaning requirements and space availability before selecting this option.

How Does an Extendable Fiberglass Pole Enhance Cleaning?

An Extendable Fiberglass Pole allows for adjustable lengths ranging from 6 to 12 feet, making it perfect for industrial cleaning and maintenance tasks. Its lightweight yet durable construction makes it easy to handle while reaching high areas. This adaptability is crucial for businesses that need to clean large vehicles or equipment. However, buyers should be aware that while it is versatile, it may not withstand heavy-duty use as well as heavier materials.

What Are the Benefits of a Bi-Level Soft-Touch Brush?

The Bi-Level Soft-Touch Brush is designed with crimped soft bristles that effectively scrub surfaces without causing damage. This makes it particularly suitable for truck maintenance and detailing, where preserving the vehicle’s finish is paramount. Its gentle cleaning action is effective against dirt while being safe for delicate surfaces. Buyers should weigh the brush’s effectiveness against heavy grime, as it may not perform as well in such conditions.

When to Use a Heavy-Duty Wash Brush?

The Heavy-Duty Wash Brush is constructed with thick bristles that are ideal for tough cleaning jobs, making it suitable for heavy-duty transport and construction industries. Its sturdy design ensures long-lasting performance, even under rigorous conditions. While it excels in removing stubborn dirt and grime, buyers should consider whether its abrasive nature could potentially damage more sensitive surfaces. Evaluating the intended application will help in making an informed purchasing decision.

Key Industrial Applications of truck wash brush with a 10ft pole

| Industry/Sector | Specific Application of truck wash brush with a 10ft pole | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Regular cleaning of fleet vehicles, including trucks and trailers | Maintains fleet appearance, extends vehicle lifespan, and enhances brand image | Durability of bristles, compatibility with various vehicle sizes, and ease of use |

| Agriculture | Cleaning agricultural transport vehicles and equipment | Reduces the risk of contamination and equipment damage | Resistance to harsh chemicals, effective cleaning capabilities, and handle length |

| Mining & Construction | Washing heavy-duty trucks and machinery on-site | Ensures compliance with environmental regulations and improves safety | Robust construction, ability to handle tough grime, and ease of maneuverability |

| Waste Management | Cleaning waste collection trucks and containers | Promotes hygiene, prevents odors, and enhances public perception | Material quality, ease of attachment to poles, and size for maneuvering in tight spaces |

| Food & Beverage Distribution | Washing delivery trucks to maintain hygiene standards | Ensures compliance with health regulations and customer trust | Non-abrasive materials, compatibility with cleaning solutions, and effectiveness on various surfaces |

How is a truck wash brush with a 10ft pole used in the transportation and logistics sector?

In the transportation and logistics sector, a truck wash brush with a 10ft pole is crucial for maintaining the cleanliness of fleet vehicles. Regular cleaning prevents the buildup of dirt and grime, which can lead to corrosion and damage over time. This not only enhances the aesthetic appeal of vehicles but also contributes to their longevity. For international buyers, particularly in regions like Africa and South America, sourcing brushes that are durable and compatible with a variety of vehicle sizes is essential to ensure efficiency and effectiveness in their operations.

What role does a truck wash brush with a 10ft pole play in agriculture?

In agriculture, the brush is utilized for cleaning transport vehicles and equipment that may carry soil or contaminants. This is vital for preventing the spread of pests and diseases across different fields. A 10ft pole allows operators to reach high areas of larger vehicles easily. Buyers in the Middle East and Europe should focus on brushes resistant to harsh cleaning chemicals, as they may need to adhere to strict agricultural hygiene standards.

How does the mining and construction industry benefit from a truck wash brush with a 10ft pole?

In the mining and construction industries, a truck wash brush with a 10ft pole is essential for cleaning heavy-duty vehicles and machinery that accumulate substantial grime and dirt. Regular cleaning helps in compliance with environmental regulations and enhances safety by preventing the transfer of hazardous materials. Buyers in these sectors should prioritize robust brushes capable of handling tough grime while ensuring ease of maneuverability on job sites.

Why is a truck wash brush with a 10ft pole important for waste management?

For waste management operations, a truck wash brush with a 10ft pole is used to clean waste collection trucks and containers, promoting hygiene and preventing unpleasant odors. This is crucial for maintaining public perception and compliance with health regulations. Sourcing considerations for international buyers include the quality of materials to withstand frequent use and the brush’s ability to fit into tight spaces for effective cleaning.

How does the food and beverage distribution industry utilize a truck wash brush with a 10ft pole?

In the food and beverage distribution sector, maintaining hygiene standards is paramount, and a truck wash brush with a 10ft pole is instrumental in cleaning delivery trucks. This ensures compliance with health regulations and builds customer trust. Buyers should look for brushes made from non-abrasive materials that work effectively with various cleaning solutions to maintain the integrity of the vehicle surfaces.

3 Common User Pain Points for ‘truck wash brush with a 10ft pole’ & Their Solutions

Scenario 1: Difficulty Reaching High Areas on Trucks

The Problem:

B2B buyers, particularly those managing fleets of trucks, often face the challenge of cleaning hard-to-reach areas, such as the tops of trailers and cabs. These high spots can accumulate significant dirt and grime, affecting the overall appearance and potentially leading to corrosion if not properly maintained. Many cleaning solutions, including traditional brushes, simply do not provide the necessary reach, forcing operators to resort to unsafe practices like climbing on the trucks or using ladders, which can lead to accidents and injuries.

The Solution:

To effectively address this issue, sourcing a truck wash brush with a 10ft pole is essential. Such a brush allows operators to maintain a safe distance from the vehicle while effectively cleaning elevated surfaces. When selecting a brush, consider options with lightweight materials, such as fiberglass, which offer durability without adding excessive weight. The pole should also have a secure locking mechanism to ensure stability during use. Additionally, look for brushes with soft bristles that are gentle on surfaces yet tough on grime to avoid scratching paintwork while ensuring a thorough clean. Implementing a training program for staff on how to properly use the brush and pole can further enhance safety and efficiency.

Scenario 2: Inefficient Cleaning Process Leading to Increased Downtime

The Problem:

Fleet managers often struggle with inefficient cleaning processes that lead to extended downtime for vehicles. A lengthy wash cycle not only delays operations but can also frustrate drivers and negatively impact service delivery. Many traditional cleaning methods require multiple tools and significant manual effort, which can compound these inefficiencies. This issue is particularly pronounced in regions with harsher climates, where dirt and debris can accumulate quickly, necessitating more frequent washes.

The Solution:

Investing in a truck wash brush with a 10ft pole can streamline the cleaning process significantly. The brush’s design allows for an all-directional cleaning capability, which minimizes the time spent on each vehicle. To enhance efficiency, consider implementing a wash schedule that aligns with operational needs, ensuring that vehicles are cleaned during downtimes, such as overnight or during scheduled maintenance. Additionally, pairing the brush with a pressure washer can speed up the process without compromising on quality. Educating your team on the best techniques for using the brush, such as starting from the top and working downwards, can further reduce wash times and improve overall productivity.

Scenario 3: Damage to Truck Surfaces from Inadequate Cleaning Tools

The Problem:

Many B2B buyers encounter issues with damage to truck surfaces caused by using inappropriate cleaning tools. Brushes that are too stiff can scratch or damage paint finishes, leading to costly repairs and diminished resale value. This problem is particularly critical for companies that prioritize maintaining a professional appearance for their fleet, as a damaged exterior can negatively impact brand perception and customer trust.

The Solution:

To prevent damage, it is crucial to select a truck wash brush that combines effective cleaning with gentle bristles. A truck wash brush with a 10ft pole, featuring soft Nyltex or synthetic bristles, can provide the necessary cleaning power while being gentle on surfaces. When sourcing, look for brushes specifically designed for vehicle exteriors, as they are engineered to minimize scratching and damage. Additionally, consider integrating a two-step cleaning process: first, rinsing the vehicle with water to remove loose debris, followed by using the brush for a deeper clean. Regularly inspecting and maintaining the brush itself is also vital to ensure that bristles remain in good condition and do not become hardened over time, which could lead to unintentional damage during use.

Strategic Material Selection Guide for truck wash brush with a 10ft pole

What Are the Common Materials Used in Truck Wash Brushes with a 10ft Pole?

When selecting materials for truck wash brushes with a 10ft pole, it is essential to consider properties that enhance performance, durability, and suitability for various cleaning applications. Below, we analyze four common materials used in these products: Nylon, Polypropylene, Natural Fiber, and Aluminum.

How Does Nylon Impact the Performance of Truck Wash Brushes?

Nylon is a synthetic polymer known for its strength and flexibility. It has excellent temperature resistance, typically rated up to 180°F (82°C), and is resistant to many chemicals, making it suitable for various cleaning agents. The durability of nylon bristles allows them to maintain their shape even after extensive use, ensuring consistent performance.

Pros: Nylon is highly durable and resistant to abrasion, which helps in maintaining the brush’s integrity over time. It is also relatively cost-effective, making it a popular choice among manufacturers.

Cons: While nylon is resistant to many chemicals, it may not withstand prolonged exposure to certain solvents. Additionally, it can be less environmentally friendly compared to natural fibers.

Impact on Application: Nylon brushes are compatible with a wide range of cleaning media, including soaps and detergents, making them versatile for different truck cleaning operations.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that nylon products comply with local regulations regarding synthetic materials. Familiarity with ASTM standards can also assist in making informed choices.

What Role Does Polypropylene Play in Truck Wash Brush Construction?

Polypropylene is another synthetic material widely used in truck wash brushes. It is known for its lightweight nature and excellent resistance to moisture and chemicals, which makes it ideal for outdoor cleaning applications. Polypropylene bristles can withstand temperatures up to 200°F (93°C).

Pros: The lightweight nature of polypropylene makes it easy to handle, reducing fatigue during extended use. It is also resistant to mold and mildew, enhancing hygiene during cleaning.

Cons: Polypropylene can be less durable than nylon and may wear down faster, especially in high-abrasion scenarios. Its cost can vary depending on the quality, but it is generally considered a mid-range option.

Impact on Application: Polypropylene brushes are suitable for use with various cleaning solutions, but they may not perform as well with heavy-duty solvents.

Considerations for International Buyers: Buyers in Europe, such as Germany, should verify that polypropylene products meet EU regulations for plastic materials, including recycling and disposal standards.

How Do Natural Fibers Compare in Truck Wash Brush Manufacturing?

Natural fibers, such as horsehair or tampico, offer a biodegradable alternative to synthetic materials. They are known for their softness and ability to hold water, making them effective for gentle cleaning tasks.

Pros: Natural fiber brushes are gentle on surfaces, which is crucial for maintaining the finish of high-end trucks. They are also environmentally friendly, appealing to buyers focused on sustainability.

Cons: Natural fibers can be less durable than synthetic options and may degrade over time, especially when exposed to harsh chemicals or prolonged moisture.

Impact on Application: Natural fiber brushes are particularly effective for delicate surfaces and are often used in conjunction with gentle cleaning agents.

Considerations for International Buyers: Buyers from the Middle East may prefer natural fibers due to cultural preferences for sustainable products. Compliance with organic material regulations may also be necessary.

What Are the Benefits of Using Aluminum for the Brush Pole?

Aluminum is commonly used for the poles of truck wash brushes due to its lightweight and corrosion-resistant properties. It can withstand various environmental conditions, making it suitable for outdoor use.

Pros: Aluminum poles are strong yet lightweight, facilitating ease of use. They are also resistant to rust and corrosion, ensuring longevity.

Cons: While aluminum is generally durable, it can be prone to bending under excessive pressure. Additionally, it may be more expensive than other materials like fiberglass.

Impact on Application: Aluminum poles provide stability and ease of maneuverability, essential for reaching high areas during truck cleaning.

Considerations for International Buyers: Buyers from Europe should ensure that aluminum products comply with EU regulations regarding metal materials and recycling.

Summary Table of Material Selection for Truck Wash Brushes

| Material | Typical Use Case for truck wash brush with a 10ft pole | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Heavy-duty cleaning with various detergents | Highly durable and abrasion-resistant | May not withstand certain solvents | Medium |

| Polypropylene | General outdoor cleaning tasks | Lightweight and moisture-resistant | Less durable than nylon | Medium |

| Natural Fiber | Gentle cleaning for delicate surfaces | Environmentally friendly | Less durable, may degrade over time | Medium |

| Aluminum | Support for the brush pole | Lightweight and corrosion-resistant | Prone to bending under pressure | High |

This guide provides a comprehensive overview of material selection for truck wash brushes with a 10ft pole, catering to the needs of international B2B buyers. Understanding these materials will help in making informed purchasing decisions that align with operational requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for truck wash brush with a 10ft pole

What Are the Key Stages in the Manufacturing Process of a Truck Wash Brush with a 10ft Pole?

The manufacturing process of a truck wash brush with a 10ft pole involves several critical stages that ensure the final product meets durability and performance standards. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Manufacturing Truck Wash Brushes?

The process begins with the selection of high-quality materials. Commonly used materials include durable plastics for the brush head, such as polypropylene or nylon, and lightweight yet strong materials like fiberglass or aluminum for the pole. The raw materials undergo a series of treatments to enhance their properties, such as UV stabilization for resistance against sunlight and chemical treatments to withstand cleaning agents.

Once the materials are prepared, they are cut and shaped according to the specifications required for the brush and pole. This may involve extrusion or injection molding techniques for the brush heads and precision cutting for the poles.

What Techniques Are Used in Forming and Assembling Truck Wash Brushes?

Forming techniques vary based on the component being manufactured. For the brush head, a common method is the injection molding process, which allows for intricate designs and uniform bristle distribution. The bristles are often crimped or tufted into the head to ensure they remain securely in place during usage.

Assembly involves attaching the brush head to the pole. This is usually achieved through a threaded connection or a push-fit mechanism that allows for easy attachment and detachment. Quality assurance checks are conducted at this stage to ensure that the assembly meets design specifications.

How Is Finishing Applied to Enhance the Product Quality of Truck Wash Brushes?

The finishing stage focuses on enhancing the aesthetic appeal and functionality of the truck wash brush. Processes such as coating may be applied to the brush head to improve resistance against wear and tear. For the pole, anodization or powder coating may be used to prevent corrosion and enhance durability.

In addition, final inspections are performed to ensure that all components are free from defects and meet industry standards. The finished products are then packaged for distribution, ensuring that they are adequately protected during transportation.

What Are the Quality Assurance Standards Relevant to Truck Wash Brushes?

Quality assurance is crucial in ensuring that truck wash brushes perform effectively and are safe for use. International standards such as ISO 9001 outline the requirements for a quality management system, which manufacturers must adhere to in order to ensure consistency in production and quality.

How Do Industry-Specific Standards Impact Quality Control for Truck Wash Brushes?

In addition to ISO standards, industry-specific certifications such as CE marking for compliance with European safety standards, or API standards in the petroleum industry, may apply depending on the intended use of the brushes. These certifications often require rigorous testing and compliance with specific safety and performance criteria.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to ensure product integrity. These checkpoints typically include:

- Incoming Quality Control (IQC): Verification of raw materials upon receipt, ensuring they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing stages to identify and rectify any issues immediately.

- Final Quality Control (FQC): Comprehensive testing of the finished product to confirm it meets all design and performance specifications.

What Testing Methods Are Commonly Used for Truck Wash Brushes?

Common testing methods include:

- Durability Testing: Assessing the brush’s ability to withstand repeated use and exposure to cleaning chemicals.

- Performance Testing: Evaluating the brush’s cleaning effectiveness on various surface types.

- Safety Testing: Ensuring that the product does not pose any risks to users, such as sharp edges or unstable components.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to ensure that their suppliers adhere to robust quality control practices:

- Supplier Audits: Conducting on-site audits to assess the manufacturing processes and quality control systems in place.

- Requesting Quality Reports: Asking suppliers for documentation of their quality control procedures, including any certifications they hold.

- Third-Party Inspections: Engaging third-party inspection services to conduct independent evaluations of the manufacturing facilities and products.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers must be aware of the specific quality control requirements and certifications needed for their respective markets. For instance, products exported to Europe must comply with CE marking requirements, while those sold in the U.S. may need to meet ANSI standards.

Additionally, understanding the local regulations in regions such as Africa, South America, the Middle East, and Europe is essential. Buyers should inquire about the supplier’s experience with international shipping and compliance to ensure that all necessary documentation is provided.

Conclusion: Why Is Quality Assurance Critical for Truck Wash Brushes?

Quality assurance in the manufacturing of truck wash brushes with a 10ft pole is paramount to ensure that the products meet the high standards required in various markets. By understanding the manufacturing processes, quality control standards, and verification methods, B2B buyers can make informed decisions when sourcing these essential cleaning tools. This knowledge not only helps in selecting reliable suppliers but also in fostering long-term business relationships based on trust and quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘truck wash brush with a 10ft pole’

Introduction

This practical sourcing guide serves as a checklist for B2B buyers looking to procure a truck wash brush with a 10ft pole. The right equipment not only enhances cleaning efficiency but also ensures the longevity of your vehicles. By following this step-by-step guide, you can make informed decisions and secure the best products for your needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to clearly outline your technical specifications. Consider the type of vehicles you will be washing and the specific cleaning needs they have.

– Brush Material: Look for durable bristles, such as Nyltex or soft polystyrene, which can effectively remove grime without damaging surfaces.

– Pole Length: Ensure that the 10ft pole is extendable or fixed based on your operational requirements.

Step 2: Research Reliable Suppliers

Identify potential suppliers that specialize in truck washing equipment. Reliable suppliers will have a strong track record in the industry and positive reviews from customers.

– Industry Experience: Opt for suppliers with a history of providing high-quality truck wash brushes.

– Global Reach: Since your focus is on international procurement, ensure the supplier can ship to your region, whether it’s Africa, South America, the Middle East, or Europe.

Step 3: Evaluate Product Quality

Once you have shortlisted suppliers, assess the quality of their products. High-quality brushes will perform better and last longer, reducing the need for frequent replacements.

– Product Reviews: Look for testimonials or case studies from other businesses that have used the products.

– Material Testing: Inquire if the brushes undergo quality testing to ensure they meet performance standards.

Step 4: Request Samples

Before finalizing your order, request samples of the truck wash brush and pole. This hands-on approach allows you to evaluate the product’s effectiveness in real-world conditions.

– Testing Performance: Use the samples on different vehicle types to assess cleaning efficiency.

– Comfort and Usability: Check the ergonomics of the pole and brush to ensure ease of use during extended cleaning sessions.

Step 5: Verify Supplier Certifications

Confirm that your chosen suppliers possess the necessary certifications and comply with industry standards. This step is crucial for ensuring product safety and quality.

– ISO Certifications: Look for suppliers that hold ISO or equivalent certifications, which indicate adherence to international quality standards.

– Environmental Compliance: Ensure that the products meet environmental regulations, especially if you operate in regions with strict guidelines.

Step 6: Assess Pricing and Terms

Compare pricing from different suppliers to ensure you are getting the best value for your investment. However, be cautious of prices that seem too low, as they may indicate inferior quality.

– Bulk Discounts: Inquire about pricing structures for bulk purchases, which can significantly reduce your overall costs.

– Payment Terms: Review the payment terms and conditions, including any warranties or return policies that may apply.

Step 7: Finalize Your Order and Logistics

After completing all previous steps, it’s time to finalize your order. Pay attention to logistics to ensure timely delivery and proper handling of your products.

– Shipping Options: Discuss shipping methods and timelines with your supplier to avoid delays.

– Customs and Duties: Be aware of any customs regulations or duties that may apply when importing goods to your country.

By following this checklist, you can streamline your sourcing process and ensure that you acquire high-quality truck wash brushes with a 10ft pole that meet your business needs effectively.

Comprehensive Cost and Pricing Analysis for truck wash brush with a 10ft pole Sourcing

What Are the Key Cost Components in Sourcing a Truck Wash Brush with a 10ft Pole?

When sourcing a truck wash brush with a 10ft pole, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

- Materials: The type of bristles (e.g., Nyltex, synthetic) and pole material (e.g., fiberglass, aluminum) significantly impact costs. Higher-quality materials typically lead to increased durability and effectiveness but also raise the initial investment.

- Labor: Labor costs vary based on location and manufacturing processes. Regions with lower labor costs may offer more competitive pricing, but this can also affect quality.

- Manufacturing Overhead: This includes utilities, rent, and equipment maintenance that contribute to the overall production costs. A well-optimized manufacturing facility may reduce overhead, allowing for better pricing.

- Tooling: The initial costs of molds and equipment for producing specific brush designs can be substantial. These costs are often amortized over larger production runs.

- Quality Control: Implementing rigorous QC processes ensures product reliability, which may incur additional costs but is crucial for maintaining brand reputation.

- Logistics: Transportation and warehousing costs can vary widely based on shipping distances and methods. International buyers need to consider customs duties and taxes as part of the logistics cost.

- Margin: Supplier profit margins can range significantly based on the supplier’s market positioning and brand value, influencing the final price offered to buyers.

How Do Price Influencers Affect the Cost of a Truck Wash Brush with a 10ft Pole?

Several factors influence the pricing of truck wash brushes, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

- Volume/MOQ: Larger orders typically yield lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) to optimize pricing.

- Specifications/Customization: Custom designs or features may increase costs. Buyers should evaluate the necessity of customization versus standard offerings.

- Materials and Quality/Certifications: Brushes made from high-quality, certified materials often command higher prices. Certifications for safety and environmental standards can also add to costs.

- Supplier Factors: The reputation, reliability, and location of suppliers play a significant role in pricing. Established suppliers may charge a premium for their products but often offer better service and quality assurance.

- Incoterms: Understanding the Incoterms (International Commercial Terms) is vital for clarifying shipping responsibilities and costs. Different terms can significantly impact the total landed cost.

What Tips Can B2B Buyers Use to Negotiate Better Prices?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider several strategies to enhance cost efficiency.

- Negotiation: Establish a clear understanding of your needs and leverage multiple suppliers to negotiate better terms. Highlighting long-term partnerships can incentivize suppliers to offer discounts.

- Total Cost of Ownership (TCO): Assessing TCO—factoring in purchase price, maintenance, and operational costs—can lead to more informed purchasing decisions. Sometimes, a higher upfront cost may translate into lower lifetime costs due to durability and efficiency.

- Pricing Nuances for International Buyers: Be aware of currency fluctuations and international shipping costs that could affect pricing. Consider securing fixed pricing agreements to mitigate these risks.

Disclaimer on Indicative Prices

Prices for truck wash brushes with a 10ft pole can vary widely based on the factors discussed. It’s essential for buyers to conduct thorough market research and supplier evaluations to arrive at an accurate pricing strategy tailored to their specific needs. Always consult multiple sources and consider local market conditions when determining budget and pricing expectations.

Alternatives Analysis: Comparing truck wash brush with a 10ft pole With Other Solutions

Exploring Alternative Solutions for Truck Washing

In the realm of truck washing, the choice of tools can significantly impact efficiency and effectiveness. While the truck wash brush with a 10ft pole is a popular option for many businesses, it’s essential to consider other viable alternatives that may better suit specific operational needs. This analysis provides a comparative overview of the truck wash brush against other solutions, helping B2B buyers make informed decisions.

| Comparison Aspect | Truck Wash Brush With A 10Ft Pole | Automatic Truck Wash System | High-Pressure Washer |

|---|---|---|---|

| Performance | Excellent for manual detailing and hard-to-reach areas | Consistent and thorough wash; less manual effort | Effective at removing heavy grime; quick cleaning |

| Cost | Moderate initial investment, low long-term costs | High initial investment, potential ongoing maintenance fees | Moderate initial cost, possible high water and energy costs |

| Ease of Implementation | Simple setup; requires manual labor | Requires installation and space; minimal manual effort | Easy to set up, but needs water supply and power |

| Maintenance | Low maintenance; occasional brush replacement | Requires regular maintenance and inspections | Moderate maintenance; regular cleaning of equipment necessary |

| Best Use Case | Ideal for detailed cleaning, fleet maintenance | Best for high-volume operations needing consistent results | Suitable for heavy-duty cleaning tasks, less ideal for delicate surfaces |

What Are the Advantages and Disadvantages of Automatic Truck Wash Systems?

Automatic truck wash systems are designed for high efficiency and consistent results. These systems can handle multiple trucks in a short period, making them ideal for businesses with high wash volumes. However, the initial investment is significant, and ongoing maintenance can add to operational costs. Additionally, they may not provide the same level of detail in cleaning as a manual brush system, particularly in tight or intricate areas.

How Does a High-Pressure Washer Compare to a Truck Wash Brush?

High-pressure washers are known for their ability to remove tough grime and dirt quickly. They are versatile and can be used for various cleaning tasks beyond just truck washing. However, they can be harsh on surfaces, potentially damaging paint or finishes if not used correctly. Moreover, the operational costs associated with water and energy use can accumulate over time. While they offer speed, they may not be as effective for detailed cleaning compared to a truck wash brush.

Conclusion: How to Choose the Right Truck Washing Solution?

When selecting the ideal truck washing solution, B2B buyers should consider their specific operational needs, including the volume of trucks, budget constraints, and the desired level of cleanliness. For businesses focused on detailed maintenance and care, a truck wash brush with a 10ft pole may be the best choice. Conversely, for high-volume operations, an automatic truck wash system could provide the necessary efficiency. High-pressure washers are suitable for those needing quick, heavy-duty cleaning but require careful handling to avoid damaging surfaces. By carefully evaluating these options, businesses can ensure they invest in a solution that enhances their operational efficiency and meets their cleaning standards.

Essential Technical Properties and Trade Terminology for truck wash brush with a 10ft pole

What Are the Key Technical Properties of a Truck Wash Brush with a 10ft Pole?

When selecting a truck wash brush with a 10ft pole, understanding its technical properties is crucial for ensuring optimal performance and durability. Here are several critical specifications to consider:

-

Material Composition

The materials used in the brush and pole construction significantly impact durability and cleaning efficacy. Common materials include high-density polyethylene (HDPE) for the brush head and fiberglass or aluminum for the pole. HDPE offers resistance to chemicals and UV light, prolonging the life of the brush. Fiberglass is lightweight yet strong, while aluminum provides corrosion resistance, making it ideal for outdoor use. -

Bristle Type and Density

The bristles can be made from various materials such as Nyltex, polystyrene, or natural fibers. Nyltex bristles are known for their durability and softness, allowing for effective cleaning without scratching surfaces. The density of the bristles affects the brush’s ability to trap dirt and grime; a denser arrangement typically enhances cleaning efficiency. -

Head Width

A 10-inch brush head width is standard for truck wash brushes, striking a balance between maneuverability and coverage. A wider brush head allows for more surface area to be cleaned in a single pass, thus improving efficiency. However, it should be noted that a wider head may also require more effort to navigate around tight spaces. -

Pole Length and Adjustability

The pole length, typically extending from 10 to 12 feet, is essential for reaching high surfaces, such as truck roofs. An extendable or telescoping pole adds versatility, allowing users to adjust the height based on specific cleaning needs. This adaptability is particularly important for businesses with various vehicle sizes. -

Flow-Through Design

Many truck wash brushes feature a flow-through design, enabling water to flow directly through the brush head. This feature enhances cleaning effectiveness by allowing soap and water to be applied while brushing, reducing the number of required passes and saving time. -

Weight Capacity

The weight capacity of the brush and pole is important for ensuring they can withstand the rigors of heavy-duty cleaning. A robust construction will prevent breakage during use, which is vital for maintaining operational efficiency in a commercial setting.

What Are Common Trade Terms Associated with Truck Wash Brushes?

Familiarity with industry jargon can greatly enhance communication and negotiation with suppliers. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s product. In the context of truck wash brushes, an OEM might provide the brush heads or poles that are then sold under another brand name. Understanding OEM relationships can help businesses identify quality products and secure reliable supply chains. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is critical for budgeting and inventory management. Suppliers often set MOQs to ensure profitability and reduce shipping costs. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request price quotes for specific products or services. This process is vital for comparing prices and terms from multiple vendors, allowing businesses to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, insurance, and risk transfer, which are crucial for B2B agreements involving cross-border transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the goods are received. Understanding lead times helps businesses plan their inventory and operational schedules effectively, minimizing disruptions in service. -

Warranty Period

The warranty period is the time frame during which a manufacturer will repair or replace defective products. A longer warranty can indicate higher quality and provide peace of mind for B2B buyers, reducing the risk associated with their investment.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions, ensuring they select the right truck wash brush with a 10ft pole for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the truck wash brush with a 10ft pole Sector

What Are the Current Market Dynamics and Key Trends in the Truck Wash Brush Sector?

The truck wash brush market, particularly those equipped with a 10ft pole, is experiencing significant growth driven by increasing demand for vehicle cleanliness and maintenance across various regions, including Africa, South America, the Middle East, and Europe. The global logistics and transportation sectors are expanding, resulting in a higher number of commercial vehicles that require regular cleaning. Key trends influencing this market include the adoption of ergonomic designs that enhance usability and reduce physical strain during operation. Innovations in materials, such as durable Nyltex bristles that are gentle on surfaces while effectively removing grime, are also gaining traction.

Moreover, the rise of e-commerce has streamlined the purchasing process for B2B buyers, allowing them to source high-quality truck wash brushes easily. Companies are increasingly leveraging digital platforms to compare products, prices, and suppliers, resulting in a more competitive marketplace. As international trade regulations evolve, buyers must also navigate complexities related to import/export tariffs and compliance with local standards, particularly in regions like Germany and Vietnam, where quality standards are stringent.

How Are Sustainability and Ethical Sourcing Influencing the Truck Wash Brush Industry?

Sustainability is becoming a cornerstone of purchasing decisions in the truck wash brush sector. As global awareness of environmental issues rises, buyers are increasingly seeking products that minimize ecological impact. This includes sourcing brushes made from recycled materials or those that comply with ‘green’ certifications. Ethical supply chains are gaining importance, with businesses prioritizing vendors who maintain fair labor practices and sustainable production methods.

B2B buyers should consider suppliers that offer transparent sourcing information and demonstrate a commitment to sustainability. For instance, brushes featuring biodegradable components or those manufactured using energy-efficient processes not only contribute to reducing carbon footprints but also enhance brand image in a market that values corporate responsibility. Moreover, eco-friendly products often attract a broader customer base, as end-users increasingly prefer to engage with environmentally conscious brands.

What Is the Brief Evolution and History of Truck Wash Brushes?

The evolution of truck wash brushes can be traced back to the early days of motorized transport when basic cleaning tools were utilized to maintain vehicle hygiene. Over the decades, advancements in materials and design have transformed these brushes into specialized tools tailored for heavy-duty applications. The introduction of longer poles allowed users to reach higher areas of trucks and trailers, making the cleaning process more efficient and effective.

In recent years, manufacturers have focused on developing brushes with innovative bristle technologies that enhance cleaning performance without damaging vehicle surfaces. The integration of ergonomic designs has also become a focal point, addressing the physical demands placed on users during prolonged cleaning tasks. Today, the truck wash brush with a 10ft pole stands as a testament to the industry’s commitment to providing effective, user-friendly solutions that meet the evolving needs of the transportation sector.

In conclusion, navigating the truck wash brush market requires a keen understanding of current trends, sustainability practices, and the historical context that shapes today’s offerings. By prioritizing quality and ethical sourcing, international B2B buyers can make informed purchasing decisions that align with their operational goals and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of truck wash brush with a 10ft pole

-

1. How do I solve challenges with cleaning hard-to-reach areas on trucks?

Utilizing a truck wash brush with a 10ft pole is an effective solution for cleaning hard-to-reach areas. The extended reach allows operators to clean the tops of trailers and other elevated surfaces without the need for ladders or scaffolding, thus enhancing safety. Additionally, selecting a brush with soft bristles will ensure that surfaces are cleaned without scratching the paint or finish, preserving the vehicle’s aesthetic and value. Regular maintenance of the brush and pole will further ensure optimal performance and longevity. -

2. What is the best type of brush for cleaning trucks?

The ideal brush for truck cleaning is one with durable, soft bristles, such as Nyltex, which effectively removes grime without damaging the surface. A 10-inch wide brush head is recommended as it provides a broader cleaning area, reducing wash time while ensuring thorough coverage. Additionally, brushes designed with an all-direction feature enhance maneuverability, making it easier to reach various angles and tight spots. It’s crucial to choose a brush that fits securely onto a compatible extendable pole for maximum efficiency. -

3. How can I vet suppliers for truck wash brushes?

Vetting suppliers involves assessing their reputation, product quality, and reliability. Start by checking customer reviews and ratings on platforms like Alibaba or industry-specific forums. Request samples to evaluate the brush’s durability and effectiveness. Additionally, inquire about their manufacturing processes, quality assurance measures, and certifications, such as ISO standards. A reliable supplier should provide transparent information regarding their production capacity and delivery timelines, ensuring they can meet your business needs consistently. -

4. What are common payment terms for international orders of truck wash brushes?

Common payment terms in international B2B transactions typically include options like 30% upfront payment and 70% upon delivery, or payment via letter of credit (LC) to ensure security for both parties. Some suppliers may also accept PayPal or escrow services for smaller transactions. It’s crucial to clarify payment terms before placing an order and to ensure they are documented in a purchase agreement to avoid disputes. Understanding currency exchange rates and potential transaction fees is also essential. -

5. What is the minimum order quantity (MOQ) for truck wash brushes?

Minimum order quantities (MOQ) for truck wash brushes can vary significantly by supplier, often ranging from 100 to 500 units. Factors influencing MOQ include the manufacturer’s production capabilities and the specific materials used. When negotiating with suppliers, consider your storage capacity and sales projections to determine a suitable order quantity that meets your needs without overcommitting resources. Suppliers may offer lower MOQs for first-time buyers or larger orders, so it’s beneficial to discuss flexibility. -

6. Are customization options available for truck wash brushes?

Many suppliers offer customization options for truck wash brushes, allowing you to tailor features such as brush size, bristle material, and handle length to meet specific cleaning needs. Custom branding, such as logos or colors, may also be available. When exploring customization, provide detailed specifications and inquire about any additional costs or minimum order requirements. Custom solutions can enhance brand visibility and ensure the product aligns with your operational requirements. -

7. How can I ensure quality assurance for my truck wash brush order?

To ensure quality assurance, request documentation from the supplier detailing their quality control processes, including inspection protocols and testing standards. It’s advisable to establish clear specifications in your purchase agreement, including material standards and performance criteria. Consider conducting pre-shipment inspections or third-party audits to verify product quality before shipment. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations and potential issues. -

8. What are the logistics considerations for importing truck wash brushes?

When importing truck wash brushes, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder who can navigate international shipping complexities and provide options like air or sea freight based on your urgency and budget. Familiarize yourself with import duties and taxes applicable to your products in your country to avoid unexpected costs. Planning for warehousing and distribution upon arrival will also streamline your supply chain management.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Truck Wash Brush With A 10Ft Pole Manufacturers & Suppliers List

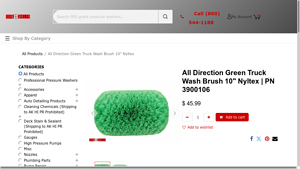

1. Dirt Killer – All Direction Green Truck Wash Brush

Domain: dirtkiller.com

Registered: 1995 (30 years)

Introduction: All Direction Green Truck Wash Brush 10″ Nyltex | Commercial grade | Price: $45.99 | Features: Effortless Cleaning, Durable Nyltex Bristles, All-Direction Design, 10″ Wide Brush Head, Time-Saving.

2. Reddit – Pole Washing Brushes

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Pole washing brushes are being discussed for their use in exterior contact washing of vehicles. Users express concerns about potential scratches caused by brushes, while some suggest alternatives like microfiber sponges or mitts on sticks for cleaning hard-to-reach areas, particularly the tops of larger vehicles like SUVs. The conversation indicates a preference for tools that minimize the risk of…

3. Iowa80 – Stack Brush

Domain: iowa80.com

Registered: 1999 (26 years)

Introduction: [{‘name’: ‘Stack Brush’, ‘item_number’: ‘286515’, ‘price’: ‘$47.99’, ‘sizes’: [‘7 and 8 inch dia.’, ‘5 and 6 inch dia.’]}, {‘name’: ‘Sym-Mat Door Step Mat’, ‘item_number’: ‘53900’, ‘price’: ‘$25.99’, ‘dimensions’: ’24″L x 5″W’}, {‘name’: ‘Jumbo Tank Brush’, ‘item_number’: ‘266832’, ‘price’: ‘$52.99’}, {‘name’: ‘Reefer Trailer Push Broom’, ‘item_number’: ‘263762’, ‘price’: ‘$51.99’}, {‘name’: ‘Sym-…

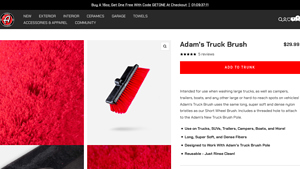

4. Adam’s – Truck Brush

Domain: adamspolishes.com

Registered: 2002 (23 years)

Introduction: Adam’s Truck Brush

– Sale Price: $29.99

– Intended Use: Washing large trucks, campers, trailers, boats, and hard-to-reach spots on vehicles.

– Bristle Type: Long, super soft, and dense nylon bristles.

– Compatibility: Designed to work with Adam’s Truck Brush Pole (sold separately).

– Reusable: Just rinse clean after use.

– Caution: Not intended for show vehicles; potential for light marring or swi…

Strategic Sourcing Conclusion and Outlook for truck wash brush with a 10ft pole

What Are the Key Takeaways for Sourcing Truck Wash Brushes with a 10ft Pole?

In the competitive landscape of B2B procurement, strategic sourcing of truck wash brushes with a 10ft pole can significantly impact operational efficiency and cost-effectiveness. Buyers should prioritize products featuring durable materials like Nyltex for long-lasting performance and soft bristles to prevent surface damage. The versatility of a 10-inch brush head allows for comprehensive cleaning, essential for maintaining the professional appearance of fleets across diverse industries.

How Does Strategic Sourcing Enhance Business Operations?

Implementing a strategic sourcing approach not only streamlines procurement processes but also fosters supplier relationships that can lead to better pricing, quality assurance, and timely deliveries. International buyers, particularly from Africa, South America, the Middle East, and Europe, should leverage local and global suppliers to ensure access to a variety of high-quality products that meet their specific needs.

What’s Next for International B2B Buyers?

As the demand for efficient and effective truck cleaning solutions grows, it is crucial for businesses to stay ahead of market trends and invest in reliable equipment. By focusing on strategic sourcing, companies can enhance their operational capabilities and ensure the longevity of their assets. Engage with trusted suppliers today to explore innovative solutions that will keep your fleet looking pristine and performing at its best.