Soft Wall: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for soft wall

Navigating the complexities of sourcing soft wall solutions can be a daunting task for international B2B buyers, especially when aiming to strike a balance between functionality, aesthetics, and sustainability. As businesses evolve, the need for adaptable, flexible space solutions has never been more pressing. Soft walls, with their innovative designs and modular capabilities, present a unique answer to the challenge of creating dynamic environments that can accommodate diverse needs.

This comprehensive guide delves into various types of soft walls, including acoustic fabric systems, freestanding partitions, and cleanroom applications, each tailored for specific market demands. B2B buyers will gain insights into the practical applications of these products, the importance of sustainable sourcing, and effective supplier vetting strategies. Furthermore, we provide a detailed analysis of cost factors and installation considerations, ensuring that businesses can make informed purchasing decisions that align with their operational goals.

By equipping international buyers from regions like Africa, South America, the Middle East, and Europe with actionable insights and expert recommendations, this guide aims to simplify the process of integrating soft wall solutions into their spaces. With the right information at hand, companies can confidently navigate the global market, choosing the optimal products that enhance their environments and meet their unique requirements.

Understanding soft wall Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Paper Softwall | Flexible, lightweight, freestanding, modular design | Event spaces, offices, temporary installations | Pros: Eco-friendly, customizable, portable. Cons: May not be suitable for long-term use. |

| Acoustic Fabric Wall Systems | Customizable edge profiles, absorbs sound, aesthetic flexibility | Offices, auditoriums, conference rooms | Pros: Enhances acoustics, visually appealing. Cons: Higher initial investment. |

| Softwall Cleanrooms | Portable, easy assembly, ideal for controlled environments | Pharmaceutical, semiconductor, research labs | Pros: Cost-effective, adaptable, compliant. Cons: Limited durability compared to permanent structures. |

| Textile Softwall | Soft, fabric-based, offers acoustic properties | Hospitality, retail, corporate environments | Pros: Softens space acoustics, attractive. Cons: Requires regular maintenance. |

| Modular Softwall Systems | Stackable, connectable, versatile for various configurations | Trade shows, flexible workspaces, educational use | Pros: Highly adaptable, space-efficient. Cons: Complexity in setup may require training. |

What Are the Key Characteristics of Paper Softwalls?

Paper softwalls are distinguished by their flexible and lightweight design, allowing them to be easily shaped into various configurations. Constructed from layers of paper with a honeycomb structure, they provide both visual and sound privacy, making them ideal for temporary installations in event spaces or offices. Buyers should consider their eco-friendliness, as they are made from responsibly sourced materials. However, their suitability for long-term use may be limited, making them more appropriate for transient needs.

How Do Acoustic Fabric Wall Systems Enhance B2B Spaces?

Acoustic fabric wall systems are characterized by their customizable edge profiles and ability to absorb sound, making them essential for creating serene environments in offices and auditoriums. These systems can be tailored to fit specific design aesthetics while effectively managing acoustics. B2B buyers should weigh the initial investment against the long-term benefits of improved sound quality and overall ambiance. While the upfront cost may be higher, the enhanced user experience often justifies the expense.

What Advantages Do Softwall Cleanrooms Offer for Regulated Industries?

Softwall cleanrooms provide a versatile and cost-effective solution for industries requiring controlled environments, such as pharmaceuticals and semiconductor manufacturing. Their portability and ease of assembly allow businesses to quickly adapt to changing needs, such as scaling up operations. When considering a purchase, buyers should evaluate compliance with industry standards and the potential for future expansion. However, these cleanrooms may not have the durability of traditional constructions, which could be a concern for some applications.

Why Choose Textile Softwalls for Hospitality and Retail?

Textile softwalls are made from fabric, offering not only aesthetic appeal but also acoustic properties that can enhance the ambiance of hospitality and retail environments. Their soft texture can create a welcoming atmosphere while effectively managing noise levels. Buyers should consider the maintenance requirements, as fabric walls may need regular cleaning to maintain their appearance. Despite this, the visual and acoustic benefits can significantly enhance customer experience in commercial settings.

What Are the Benefits of Modular Softwall Systems for Flexible Workspaces?

Modular softwall systems are designed for versatility, allowing for stacking and connecting to create various configurations. This adaptability makes them perfect for trade shows, educational settings, and flexible workspaces that require frequent reconfiguration. Buyers should assess the complexity of setup and whether staff will need training to maximize the system’s potential. The space efficiency and ability to quickly transform environments are significant advantages for businesses looking to optimize their operational flexibility.

Key Industrial Applications of soft wall

| Industry/Sector | Specific Application of soft wall | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Softwall Cleanrooms | Provides controlled environments for sensitive operations. | Compliance with health regulations, ease of transport, and assembly. |

| Event Management | Temporary Dividers for Events | Flexible space usage for diverse functions and privacy. | Aesthetic appeal, sound absorption capabilities, and portability. |

| Education | Classrooms and Collaborative Spaces | Enhances learning environments through adaptable layouts. | Durability, ease of reconfiguration, and sound control features. |

| Architecture & Design | Modular Office Spaces | Enables creative layouts and dynamic work environments. | Customization options, design flexibility, and material sustainability. |

| Retail | Visual Merchandising Displays | Creates engaging shopping experiences and brand storytelling. | Aesthetic versatility, ease of installation, and acoustic properties. |

How is Soft Wall Used in Healthcare Cleanrooms?

In the healthcare sector, softwall cleanrooms are essential for maintaining sterile environments required for medical device manufacturing and pharmaceutical development. These cleanrooms can be easily assembled and disassembled, providing flexibility for companies that may need to expand their operations. Buyers should ensure that the materials used meet health and safety regulations, are easy to clean, and are portable, especially for international operations in regions like Africa and South America where infrastructure may vary.

How Does Soft Wall Benefit Event Management?

For event management, soft walls serve as temporary dividers that can be configured to create different spaces within a venue. This flexibility allows event organizers to adapt the layout according to specific needs, whether for exhibitions, conferences, or private functions. The sound-absorbing properties of soft walls enhance the auditory experience, making them ideal for various events. B2B buyers should consider aesthetics, ease of transport, and the ability to customize colors and designs to fit the event theme.

What Role Does Soft Wall Play in Educational Settings?

In educational institutions, soft walls are used to create adaptable classroom environments that can be reconfigured for various teaching styles or group activities. This modular approach fosters collaboration and engagement among students. Buyers from educational sectors should focus on durability and acoustic control, ensuring that the partitions can withstand daily use while providing a conducive learning atmosphere. Importantly, sourcing from suppliers that offer sustainable materials can resonate well with eco-conscious institutions.

Why Choose Soft Wall for Modular Office Spaces?

In architecture and design, soft walls are increasingly utilized for creating modular office spaces. These partitions allow for innovative layouts that can evolve with the company’s needs, promoting a dynamic work environment. The ability to customize design and dimensions is crucial for architects and designers. Buyers should prioritize sourcing from manufacturers who offer a range of materials and finishes, ensuring that the soft walls align with the overall aesthetic and functional goals of the workspace.

How Can Soft Wall Enhance Retail Experiences?

In the retail industry, soft walls are effective for creating visually appealing merchandising displays that attract customers. By using these partitions, retailers can craft immersive shopping experiences that tell a story about their brand. The versatility in design and color allows for seasonal updates without significant investment. B2B buyers should look for suppliers who provide easy installation and removal options, as well as acoustic features that can help manage noise in busy retail environments.

3 Common User Pain Points for ‘soft wall’ & Their Solutions

Scenario 1: Navigating Acoustic Challenges in Open Spaces

The Problem: Many businesses operating in open-plan offices or event spaces face significant noise challenges. Without proper sound insulation, conversations, phone calls, and background noise can disrupt productivity and the overall atmosphere. For B2B buyers, this can lead to decreased employee satisfaction and potentially impact client interactions, particularly in environments like coworking spaces or conference rooms.

The Solution: To address these acoustic challenges effectively, consider sourcing soft wall systems specifically designed for sound absorption. Opt for modular acoustic fabric wall systems that can be tailored to fit the unique dimensions of your space. These systems not only enhance sound quality but also allow for aesthetic flexibility. When selecting a soft wall, ensure it features high-performance core materials that meet your specific acoustic needs. Additionally, integrating these walls with various edge profiles—like square, radius, or bevel edges—can provide a modern look while improving sound control. For maximum impact, strategically place these walls where noise is most problematic, such as near high-traffic areas or collaborative zones.

Scenario 2: Adapting Space for Evolving Business Needs

The Problem: In today’s fast-paced business environment, adaptability is crucial. Companies may need to frequently change their office layout or create temporary spaces for events, training sessions, or product launches. However, traditional fixed walls can be cumbersome and costly to modify or remove, leading to frustration for B2B buyers who require flexibility without long-term commitments.

The Solution: Consider investing in soft wall solutions that offer modularity and ease of reconfiguration. Products like freestanding paper soft walls can be expanded or compressed as needed, allowing for quick changes in layout without the need for tools or extensive labor. Look for options that can be easily flat-packed for storage, enabling seamless transitions between different uses of your space. When selecting these systems, evaluate the weight and ease of movement to ensure they can be rearranged effortlessly. Additionally, explore options that incorporate magnetic connectors, which enable swift assembly and disassembly, making it easier to adapt to changing requirements.

Scenario 3: Ensuring Compliance in Controlled Environments

The Problem: For businesses operating in sectors like pharmaceuticals, biotechnology, or electronics, maintaining a cleanroom environment is essential. Traditional cleanroom solutions can be expensive and difficult to install, creating barriers for businesses that need to adhere to strict regulatory standards while remaining budget-conscious. B2B buyers in these industries may struggle to find a cleanroom solution that balances cost, compliance, and functionality.

The Solution: Soft wall cleanrooms offer a cost-effective and versatile alternative for creating controlled environments. These structures can be assembled quickly and relocated as needed, which is particularly advantageous for businesses anticipating growth or changes in their cleanroom requirements. When selecting a soft wall cleanroom, ensure it meets industry standards for cleanliness and can accommodate necessary HVAC systems. Additionally, consider options that provide clear visibility and accessibility for monitoring and maintenance. By opting for soft wall systems made from non-toxic materials, you can ensure compliance with health and safety regulations while maintaining operational efficiency.

Strategic Material Selection Guide for soft wall

What Are the Key Properties of Common Materials Used in Soft Walls?

When selecting materials for soft walls, understanding the properties and characteristics of various options is essential for ensuring optimal performance in diverse applications. Below is an analysis of four common materials used in soft wall systems: paper, acoustic fabric, vinyl, and PVC.

How Does Paper as a Material Perform in Soft Wall Applications?

Paper soft walls, like those produced by Molo Design, are composed of layers structured in a honeycomb geometry, providing flexibility and strength. This material is lightweight yet durable, making it easy to move and reconfigure. Additionally, it is made from FSC-certified wood, ensuring sustainability.

Pros: Paper soft walls are highly customizable, allowing for various shapes and sizes. They are also recyclable and have a low environmental impact, appealing to eco-conscious buyers. Their ability to absorb sound makes them suitable for environments requiring acoustic control.

Illustrative image related to soft wall

Cons: While they are durable, paper soft walls may not withstand extreme weather conditions or heavy physical impacts. They also require careful handling to avoid moisture damage, which can limit their use in humid environments.

Impact on Application: Paper soft walls are ideal for temporary installations, such as event spaces and exhibitions. However, they may not be suitable for permanent structures in harsh climates.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local building codes and standards, such as ASTM for fire safety. The lightweight nature of paper soft walls makes them cost-effective for shipping, especially for international orders.

What Are the Benefits of Using Acoustic Fabric in Soft Walls?

Acoustic fabric systems, such as those offered by SoftWalls Inc., are designed to enhance sound control while providing aesthetic appeal. These systems can be tailored with various edge profiles and fabric finishes, making them versatile for different environments.

Pros: Acoustic fabrics are effective in reducing noise levels, making them suitable for offices, schools, and healthcare facilities. They offer a modern appearance and can be customized to fit specific design needs.

Illustrative image related to soft wall

Cons: The initial investment can be higher compared to simpler materials. Additionally, the fabric can require regular maintenance to keep it clean and looking new, which may incur additional costs over time.

Impact on Application: These systems are particularly beneficial in environments where sound quality is paramount, such as conference rooms or performance spaces. They can also be used in residential settings for home theaters.

Considerations for International Buyers: Buyers should be aware of local regulations regarding acoustic performance and fire safety standards. The availability of specific fabric types may vary by region, so sourcing should be carefully planned.

How Does Vinyl Contribute to Soft Wall Solutions?

Vinyl soft walls are known for their durability and resistance to moisture, making them suitable for various applications, including healthcare and cleanroom environments. They are easy to clean and maintain, which is a significant advantage in high-traffic areas.

Pros: Vinyl is highly resistant to water, stains, and chemicals, making it ideal for environments that require frequent cleaning. Its durability ensures a longer lifespan compared to other materials.

Cons: Vinyl can be less environmentally friendly due to its petroleum-based composition. Additionally, it may not offer the same level of acoustic performance as other materials, which could be a drawback in noise-sensitive areas.

Impact on Application: Vinyl soft walls are particularly effective in cleanrooms and medical facilities where hygiene is critical. However, they may not be the best choice for spaces where aesthetics are a primary concern.

Considerations for International Buyers: Buyers should check for compliance with health and safety regulations, especially in the medical field. The cost of vinyl may vary significantly based on regional availability and import tariffs.

What Role Does PVC Play in Soft Wall Systems?

PVC (polyvinyl chloride) is another common material used in soft wall applications, known for its strength and versatility. It can be manufactured in various thicknesses and finishes, catering to different aesthetic and functional requirements.

Pros: PVC is lightweight, durable, and resistant to corrosion, making it suitable for a wide range of environments. Its flexibility allows for innovative designs, and it can be produced in various colors and textures.

Cons: Similar to vinyl, PVC is not the most sustainable option due to its environmental impact during production and disposal. It may also emit volatile organic compounds (VOCs), which can be a concern in indoor air quality.

Impact on Application: PVC soft walls are effective in environments requiring durability and resistance to wear and tear, such as warehouses and industrial settings. However, they may not be ideal for high-end commercial spaces where aesthetics are crucial.

Considerations for International Buyers: Buyers should ensure that PVC products meet local environmental regulations and standards. The cost-effectiveness of PVC can vary depending on regional manufacturing capabilities and import duties.

Summary Table of Material Selection for Soft Walls

| Material | Typical Use Case for soft wall | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Paper | Temporary installations, event spaces | Eco-friendly, customizable | Vulnerable to moisture damage | Low |

| Acoustic Fabric | Offices, schools, healthcare facilities | Excellent sound absorption | Higher initial investment | Medium |

| Vinyl | Cleanrooms, healthcare environments | Durable, easy to clean | Less environmentally friendly | Medium |

| PVC | Industrial settings, warehouses | Lightweight, corrosion-resistant | Emits VOCs, less aesthetic appeal | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for soft wall

The manufacturing processes and quality assurance measures for soft walls are essential for international B2B buyers, particularly those in diverse markets such as Africa, South America, the Middle East, and Europe. Understanding these processes can help buyers make informed decisions when sourcing soft walls for various applications, from flexible partitions to cleanroom environments.

What Are the Main Stages of Manufacturing Soft Walls?

Material Preparation: What Materials Are Used in Soft Wall Production?

The initial stage of manufacturing soft walls involves material selection and preparation. Soft walls are typically made from sustainable materials such as paper with a honeycomb structure, which provides lightweight strength and flexibility. For example, Molo Design uses FSC® certified paper that is non-toxic and treated with fire retardants.

In this stage, raw materials are sourced from responsible suppliers, and quality checks are performed to ensure compliance with sustainability standards. This is particularly important for B2B buyers who prioritize eco-friendly products. Other materials might include specialized acoustic fabrics or polymers for sound insulation and aesthetic appeal.

How Are Soft Walls Formed and Assembled?

The forming process involves shaping the selected materials into the desired wall configurations. For paper soft walls, the honeycomb structure is formed through layering techniques that enhance both strength and flexibility. The assembly stage often employs advanced techniques such as magnetic connectors, allowing for easy assembly and reconfiguration of the partitions.

These modular systems are designed to be easily manipulated without requiring tools, which adds value for buyers looking for versatile solutions in dynamic environments. In contrast, acoustic fabric wall systems may involve sewing or bonding techniques to create panels that effectively manage sound.

What Finishing Processes Are Involved?

Finishing processes include surface treatments, dyeing, and coating to enhance the aesthetic qualities and durability of the soft walls. For instance, soft walls may be coated with non-toxic inks and fire retardants to meet safety standards. These finishing touches ensure that the products not only perform well but also appeal visually to end-users.

The final product is then subjected to quality checks before being packaged for shipment. Proper finishing is crucial for maintaining the integrity of the product during transportation and installation.

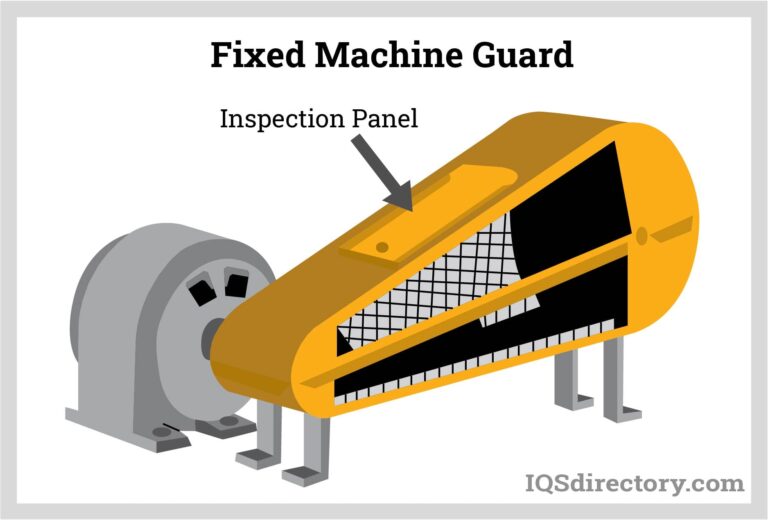

What Quality Control Measures Are Implemented During Production?

What International Standards Apply to Soft Wall Manufacturing?

Quality assurance in soft wall manufacturing is governed by several international standards, with ISO 9001 being a cornerstone for quality management systems. This certification ensures that manufacturers consistently meet customer and regulatory requirements, which is vital for B2B buyers.

Illustrative image related to soft wall

Additionally, industry-specific certifications such as CE marking for products sold within the European Economic Area or API standards for cleanroom applications may also apply, depending on the intended use of the soft walls.

What Are the Key Quality Control Checkpoints in Soft Wall Production?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to ensure product integrity. These typically include:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter the production line. Suppliers should provide documentation proving compliance with applicable standards.

-

In-Process Quality Control (IPQC): During production, ongoing checks are performed to monitor processes and materials, ensuring that any deviations from quality standards are immediately addressed.

-

Final Quality Control (FQC): Once the soft walls are assembled and finished, they undergo final inspections to ensure they meet design specifications and quality standards. This may involve functional testing, such as acoustic performance evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. This can include:

Illustrative image related to soft wall

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturer’s quality management systems and adherence to international standards.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports, including test results and compliance certifications, to ensure that the products meet their specifications.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the manufacturing processes and final products. This is particularly beneficial for buyers in international markets, where regulatory compliance may vary.

What Are the Quality Control Nuances for International Buyers?

How Do Regional Standards Affect Quality Assurance?

When sourcing soft walls from international suppliers, B2B buyers must be aware of regional standards that may differ significantly from their own. For instance, European buyers may require CE marking, while buyers in the Middle East may need to comply with local building codes and safety regulations.

Understanding these nuances is crucial for ensuring that products meet the necessary legal and safety standards in the buyer’s market. Buyers should communicate clearly with suppliers about their specific requirements to avoid potential compliance issues.

What Should Buyers Consider About Sustainability and Eco-Friendliness?

Sustainability is increasingly becoming a priority for B2B buyers, especially those in regions like Europe and South America, where eco-friendly practices are highly valued. Buyers should inquire about the sustainability certifications of materials used in soft wall production, such as FSC® certification for wood products.

Illustrative image related to soft wall

Additionally, manufacturers that adopt sustainable practices in their production processes not only appeal to environmentally conscious buyers but also often have more robust quality assurance systems in place.

Conclusion: How to Choose a Reliable Soft Wall Supplier

In summary, understanding the manufacturing processes and quality assurance measures for soft walls is essential for B2B buyers seeking reliable and high-quality products. By focusing on material selection, manufacturing techniques, and stringent quality control measures, buyers can ensure they source products that meet their specific needs. Furthermore, verifying supplier quality through audits, reports, and third-party inspections will enhance confidence in the procurement process. As the market for soft walls continues to grow, informed buyers will be better positioned to make strategic purchasing decisions that align with their business objectives.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘soft wall’

Introduction

This practical sourcing guide aims to assist B2B buyers in navigating the procurement of soft wall systems. As versatile and innovative solutions for space division, soft walls offer flexibility in design and functionality. By following this checklist, buyers can ensure they make informed decisions that align with their specific needs and industry standards.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your soft wall solution. Consider factors such as dimensions, acoustic properties, and material preferences. Clearly defined specifications will help you communicate your needs effectively to potential suppliers.

Illustrative image related to soft wall

- Space Requirements: Determine the area where the soft wall will be installed. Measure height, width, and any architectural features that may affect installation.

- Functionality: Decide whether you need the wall for sound absorption, visual privacy, or aesthetic purposes.

Step 2: Research Available Materials and Designs

Different soft wall systems utilize various materials that can affect performance and aesthetics. Investigate options like paper, fabric, or modular systems to find the best fit for your application.

- Sustainability: Consider materials that are recyclable or sourced responsibly, such as FSC-certified wood products.

- Acoustic Performance: Look for materials that offer sound-dampening properties, especially if the wall will be used in environments requiring noise control.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. A reliable supplier can significantly impact your project’s success, so it’s essential to check their credentials and past performance.

- Company Profile: Request information about the supplier’s history, expertise, and product range.

- Client References: Ask for case studies or testimonials from clients in similar industries or regions to gauge their reliability and service quality.

Step 4: Verify Compliance with Industry Standards

Ensure that the soft wall systems you are considering comply with relevant industry regulations and standards. This step is crucial for safety, especially in specialized environments like cleanrooms or medical facilities.

- Fire Ratings: Confirm that the materials meet fire safety regulations applicable in your region.

- Acoustic Standards: Check for certifications that indicate the sound absorption capabilities of the products.

Step 5: Assess Customization Options

Customization can enhance the functionality and aesthetic appeal of soft wall systems. Evaluate how flexible suppliers are in accommodating specific design requests.

- Design Flexibility: Inquire whether the supplier offers customizable features such as color, finish, or configuration.

- Modular Systems: Look for systems that allow for easy reconfiguration and expansion to adapt to future needs.

Step 6: Request Samples and Conduct Quality Checks

Before finalizing your order, request samples to assess the quality of the materials and construction. This will help ensure that the products meet your expectations and project requirements.

- Material Inspection: Evaluate the physical properties of samples, including durability, texture, and finish.

- Acoustic Testing: If possible, conduct tests to verify the acoustic performance claims of the materials.

Step 7: Review Terms and Conditions

Finally, thoroughly review the terms and conditions of the purchase agreement. Understanding the fine print can prevent potential issues down the line.

- Warranties and Support: Check for warranties on the products and inquire about post-purchase support.

- Return Policies: Familiarize yourself with the return and exchange policies in case the products do not meet your needs.

By following this checklist, B2B buyers can confidently source soft wall systems that align with their functional, aesthetic, and regulatory requirements.

Illustrative image related to soft wall

Comprehensive Cost and Pricing Analysis for soft wall Sourcing

What Are the Key Cost Components in Soft Wall Sourcing?

When sourcing soft wall products, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of materials used significantly impacts the cost. For instance, eco-friendly options such as FSC-certified paper or high-quality acoustic fabrics may carry a premium. Buyers should consider the trade-off between sustainability and cost when selecting materials.

-

Labor: Labor costs vary depending on the region and complexity of the production process. Skilled labor for installation or customization can increase overall costs, especially if sourcing from regions with higher wage standards.

-

Manufacturing Overhead: This encompasses the indirect costs of production, including utilities, rent, and administrative expenses. Efficient manufacturing processes and economies of scale can reduce overhead costs, benefitting buyers.

-

Tooling: Initial tooling costs can be significant, particularly for custom designs. Buyers should inquire about any one-time setup fees and how these might affect pricing.

-

Quality Control (QC): Ensuring that products meet specific standards is essential. Rigorous QC processes may add to costs, but they are vital for maintaining product integrity, especially in sensitive applications like cleanrooms.

-

Logistics: Shipping costs can vary widely based on distance, mode of transportation, and volume. Buyers should factor in freight costs, potential customs duties, and handling fees to understand the total landed cost.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on competition, brand positioning, and market demand.

How Do Price Influencers Affect Soft Wall Procurement?

Several factors can influence the pricing of soft wall products, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk pricing discounts. Buyers should assess their needs to determine optimal order quantities.

-

Specifications and Customization: Custom designs or specific acoustic requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses later in the process.

-

Materials Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., fire safety ratings) typically command higher prices. Buyers must balance quality with budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established brands may charge more for their products due to perceived quality and service levels.

-

Incoterms: Understanding shipping terms is essential for cost management. Different Incoterms (e.g., FOB, CIF) can affect who bears the shipping costs and risks, which in turn impacts the total cost of acquisition.

What Are the Best Buyer Tips for Cost-Efficiency in Soft Wall Sourcing?

To ensure a cost-effective procurement process for soft wall products, consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing and payment terms. Establishing long-term relationships can lead to better deals and flexibility in future orders.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, shipping, installation, maintenance, and eventual disposal costs. Understanding the full lifecycle cost can lead to more informed purchasing decisions.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should consider currency fluctuations, local taxes, and import duties. These factors can significantly affect the final price.

-

Research and Compare Suppliers: Take time to compare multiple suppliers, looking at their offerings, pricing structures, and customer reviews. This can provide insights into market standards and help identify the best value.

-

Stay Informed About Market Trends: Keeping abreast of industry trends and innovations can help buyers make informed decisions about materials and technologies that may offer better performance at competitive prices.

Disclaimer on Pricing

Please note that prices for soft wall products can vary widely based on the factors outlined above. The information provided here is indicative and should be verified with specific suppliers for accurate pricing tailored to your unique requirements.

Alternatives Analysis: Comparing soft wall With Other Solutions

Introduction to Alternative Solutions for Space Partitioning

In the evolving landscape of workspace design and functionality, the need for versatile and efficient space partitioning solutions has gained prominence. As businesses across various sectors look to optimize their environments, understanding alternatives to soft wall systems becomes crucial. This analysis compares soft walls to two viable alternatives: acoustic fabric wall systems and modular drywall partitions, highlighting their performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to soft wall

Comparison Table

| Comparison Aspect | Soft Wall | Acoustic Fabric Wall Systems | Modular Drywall Partitions |

|---|---|---|---|

| Performance | Excellent sound absorption; flexible design | Customizable acoustics; aesthetic appeal | High durability; effective for permanent structures |

| Cost | Moderate initial investment; economical storage | Higher initial cost; long-term durability | Generally lower upfront cost; higher installation costs |

| Ease of Implementation | Quick setup; no tools required | Moderate complexity; professional installation often needed | Complex installation; requires skilled labor |

| Maintenance | Low maintenance; recyclable material | Moderate maintenance; fabric replacement necessary | Low maintenance; durable materials |

| Best Use Case | Temporary or flexible spaces; events and exhibitions | Offices needing sound control; aesthetic environments | Permanent office walls; high-traffic areas |

In-Depth Analysis of Alternatives

Acoustic Fabric Wall Systems

Acoustic fabric wall systems offer a sophisticated approach to sound management in various environments. These systems can be tailored with different edge profiles and fabric finishes, allowing businesses to achieve both acoustic performance and aesthetic appeal. While they excel in sound absorption and customization, they generally come with a higher initial cost compared to soft walls. Additionally, the installation process can be complex, often requiring professional assistance. Maintenance is moderate, as the fabric may need to be replaced over time, but the overall durability makes them a long-term investment.

Modular Drywall Partitions

Modular drywall partitions represent a more traditional approach to space division. They are highly durable and suitable for permanent installations, making them ideal for high-traffic areas or long-term office layouts. The initial cost is generally lower, but the installation can be more complex and labor-intensive, requiring skilled professionals. Additionally, while they provide effective sound insulation, they lack the flexibility offered by soft walls. Maintenance is minimal once installed, but any modifications or repairs can be labor-intensive and costly.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right partitioning solution depends on the specific requirements of your business environment. If flexibility and temporary setups are priorities, soft walls provide an innovative and efficient option. On the other hand, if aesthetic appeal combined with sound control is crucial, acoustic fabric wall systems may be more suitable. For businesses seeking a long-term, durable solution, modular drywall partitions offer a reliable choice, albeit with a more complex installation process. Ultimately, understanding the unique needs of your workspace will guide you in making an informed decision that aligns with your operational goals.

Illustrative image related to soft wall

Essential Technical Properties and Trade Terminology for soft wall

What are the Key Technical Properties of Soft Walls?

When considering soft walls for various applications, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that B2B buyers should consider:

-

Material Composition

Soft walls are typically made from eco-friendly materials such as recycled paper or fabric. For instance, the use of FSC-certified paper ensures sustainability and responsible sourcing. This property is significant for companies aiming to enhance their environmental credentials and comply with regulations. -

Acoustic Performance

Soft walls often incorporate sound-absorbing materials, which can significantly reduce noise pollution in open spaces. The effectiveness of these walls is usually measured in terms of Noise Reduction Coefficient (NRC) ratings. High NRC values indicate superior sound dampening, making soft walls essential for environments like offices, schools, and auditoriums. -

Fire Rating

Fire safety is a critical aspect of any construction material. Soft walls are subjected to various fire rating standards, such as NFPA 701 in the USA or B1 in Germany. Understanding these ratings helps buyers ensure compliance with local safety regulations, thereby minimizing risk. -

Modularity and Flexibility

One of the standout features of soft walls is their modular design, allowing for easy reconfiguration and customization. This property is vital for businesses that require versatile space solutions that can adapt to changing needs, such as pop-up events or co-working spaces. -

Weight and Portability

Soft walls are typically lightweight, making them easy to transport and install. This feature is particularly important for businesses that need temporary solutions, as it reduces logistical costs and installation time. -

Durability and Maintenance

Durability varies between products, but soft walls are often designed to withstand frequent use while maintaining their appearance. Easy-to-clean surfaces can significantly reduce maintenance costs over time, making them a practical choice for high-traffic areas.

What are Common Trade Terms Associated with Soft Walls?

Understanding industry jargon can facilitate smoother transactions and better communication with suppliers. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

In the context of soft walls, an OEM refers to a company that manufactures products that can be rebranded by another firm. Understanding OEM relationships can help buyers identify quality sources and negotiate better terms. -

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps businesses gauge their purchasing capacity and manage inventory levels effectively. -

RFQ (Request for Quotation)

An RFQ is a document that businesses use to solicit pricing information from suppliers. This is particularly useful for comparing costs and ensuring that you get the best deal when sourcing soft walls. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and handling costs. Familiarity with these terms is essential for B2B buyers to avoid unexpected fees and delays. -

Lead Time

Lead time refers to the time taken from placing an order until its delivery. Understanding lead times is crucial for project planning, particularly in industries where time-sensitive delivery is critical. -

Customization

This term refers to the ability to tailor products to specific requirements. In the context of soft walls, customization can include size, color, and acoustic properties, allowing businesses to meet their unique design and functional needs.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when purchasing soft walls, ensuring they choose the right solutions for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the soft wall Sector

What Are the Key Market Drivers and Trends in the Soft Wall Sector?

The soft wall sector is experiencing significant growth driven by a combination of flexibility in design, sustainability, and the increasing demand for adaptable spaces across various industries. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly looking for solutions that not only enhance aesthetic appeal but also contribute to functional versatility. The rise of remote work and hybrid office environments has further accelerated the need for dynamic space solutions, making soft walls an attractive option for businesses seeking to create multipurpose areas.

Emerging technologies in manufacturing and design are also shaping the market. Innovations in materials—such as lightweight, eco-friendly composites—allow for the creation of partitions that are not only portable but also sustainable. Additionally, the integration of acoustic performance in soft walls is gaining traction, addressing the growing concern over noise control in open office layouts and public spaces. This trend is particularly relevant for sectors such as education, healthcare, and hospitality, where sound management is crucial.

Illustrative image related to soft wall

As global supply chains become more interconnected, international B2B buyers are increasingly seeking suppliers who can provide customized solutions tailored to specific market needs. This includes preferences for modular designs that can be easily reconfigured and expanded as business needs change. The focus on local sourcing and reduced lead times is also becoming more pronounced, as companies aim to enhance their operational agility and reduce their environmental footprint.

How Is Sustainability and Ethical Sourcing Influencing the Soft Wall Market?

Sustainability is at the forefront of purchasing decisions in the soft wall sector. Buyers are increasingly aware of the environmental impact of their choices, prompting a demand for products made from responsibly sourced materials. Soft walls constructed from FSC-certified paper and other eco-friendly materials are gaining popularity, as they not only offer aesthetic benefits but also contribute to a circular economy.

The importance of ethical supply chains cannot be overstated. B2B buyers are looking for partners who prioritize transparency and sustainability in their sourcing practices. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 for environmental management systems are becoming essential criteria for selecting suppliers. These certifications assure buyers that the materials used in soft wall products are sourced responsibly and that the production processes adhere to environmentally friendly practices.

Moreover, the trend towards ‘green’ products is not merely a marketing strategy; it reflects a deeper commitment to corporate social responsibility. Companies that prioritize sustainable practices are likely to enhance their brand reputation and customer loyalty, which is particularly relevant in competitive markets. For international buyers, aligning with suppliers who share these values can lead to better market positioning and long-term success.

What Is the Historical Context of Soft Wall Development?

The evolution of soft walls can be traced back to the early 20th century, when the need for flexible and temporary space solutions began to emerge in response to changing work environments. Initially used in theatrical settings for sound and visual management, soft wall designs have since transitioned into mainstream architectural applications. The 1960s and 1970s saw an increased focus on modular and adaptable designs, driven by the rise of open-plan offices and collaborative workspaces.

In recent decades, the soft wall sector has witnessed a significant transformation due to advancements in material science and manufacturing technologies. This has enabled the creation of lightweight, durable, and aesthetically versatile products that cater to a diverse range of industries, from healthcare to hospitality. As the demand for sustainable and flexible solutions continues to grow, the soft wall market is poised for further innovation, making it a compelling area for international B2B buyers to explore.

Frequently Asked Questions (FAQs) for B2B Buyers of soft wall

-

How do I select the right soft wall system for my business needs?

Choosing the right soft wall system involves assessing your specific requirements such as the intended use, acoustic performance, and aesthetic preferences. Consider factors like flexibility, portability, and ease of assembly, especially if your space needs frequent reconfiguration. Evaluate materials for durability and sustainability, and ensure compliance with local regulations. Engaging with suppliers to discuss customization options can also help tailor the solution to your operational needs. -

What are the key benefits of using soft walls in a commercial setting?

Soft walls offer numerous advantages, including flexibility in space management, sound absorption, and ease of installation. They are lightweight and can be easily moved or reconfigured, making them ideal for dynamic environments. Their modular nature allows for the creation of custom layouts, enhancing visual appeal while maintaining acoustic comfort. Additionally, many soft wall products are made from sustainable materials, aligning with eco-friendly business practices. -

What customization options are available for soft wall products?

Most manufacturers provide various customization options, including size, color, material, and acoustic properties. You can choose from different edge profiles and finishes that align with your design vision. Discussing your specific requirements with suppliers can lead to tailored solutions that meet both functional and aesthetic needs. Be sure to inquire about lead times and any additional costs associated with custom orders. -

What is the minimum order quantity (MOQ) for soft wall systems?

Minimum order quantities can vary significantly among suppliers. Some may allow small orders for prototype or sample purposes, while others might require larger quantities to fulfill production runs. It’s advisable to directly communicate with potential suppliers to understand their MOQ policies. This is particularly important for international buyers who may need to factor in logistics and shipping costs when placing larger orders. -

How can I ensure the quality of the soft wall systems I purchase?

To ensure quality, request samples and certifications from suppliers, such as fire ratings and material safety data. Engage in discussions about their manufacturing processes and quality control measures. Reviews and case studies from other businesses can also provide insights into product performance. Establishing a good rapport with suppliers and asking for warranties can further secure your investment. -

What payment terms should I expect when sourcing soft walls internationally?

Payment terms can vary by supplier and region, but common options include upfront payment, partial payments, or net terms (e.g., net 30 or net 60). It’s essential to clarify these terms before finalizing an order. Consider using secure payment methods and inquire about any financing options that may be available. Additionally, be aware of currency exchange rates and potential fees when dealing with international transactions. -

What logistics considerations should I keep in mind when importing soft walls?

When importing soft walls, consider shipping methods, costs, and delivery timelines. Understand the import regulations and tariffs applicable in your country, as these can affect your overall expenses. Collaborate with logistics providers who specialize in international shipping to ensure smooth customs clearance. Additionally, plan for storage requirements upon arrival, especially if your order size is significant. -

How do I evaluate and vet suppliers for soft wall systems?

To effectively evaluate suppliers, start by researching their reputation and customer reviews. Request references and case studies to gauge their experience and reliability. Consider visiting their facilities if feasible or conducting virtual meetings to assess their operations. Verify certifications related to quality and sustainability standards, and ensure they have robust customer support and after-sales service. A thorough vetting process can mitigate risks and ensure a successful partnership.

Top 5 Soft Wall Manufacturers & Suppliers List

1. Molodesign – Paper Softwall Folding Wall Partition

Domain: molodesign.com

Registered: 2003 (22 years)

Introduction: Product Name: Paper Softwall Folding Wall Partition

Type: Portable Folding Room Divider

Availability: In stock, ready to ship within 2 – 5 business days

Shipping: All taxes & duties included for shipments within the United States

Colors: Brown Paper, Black Paper

Sizes:

– 5ft tall x 9.25in wide (152.5 x 23.5cm)

– 6ft tall x 9.25in wide (183 x 23.5cm)

– 8ft tall x 9.25in wide (244 x 23.5cm)

Handles…

2. SoftWalls Inc. – Customizable Acoustic Fabric Wall Systems

Domain: softwalls.com

Registered: 2001 (24 years)

Introduction: Customizable Acoustic Fabric Wall Systems from SoftWalls Inc. include various profiles: Square Edge Profiles for a monolithic appearance, Radius Edge Profiles for a subtle curvature, and Bevel Edge Profiles for unique angled cuts. The systems are designed to address both aesthetic and functional acoustic needs, utilizing a range of core materials and finish fabrics, from standard polyesters to fin…

3. NGS Cleanrooms – Softwall Cleanrooms

Domain: ngscleanrooms.com

Registered: 2019 (6 years)

Introduction: Softwall Cleanrooms provide an economical and versatile solution for cleanroom construction, suitable for materials development, medical devices, semiconductors, and other industries requiring cleanroom conditions. Key features include:

– Portable and easy to assemble, extend, or modify

– Simple air management system

– Minimal environmental change when accessing the cleanroom

– Recommended for ISO…

4. Taylor Creative – 8’ Softwall White Textile

Domain: taylorcreativeinc.com

Registered: 2004 (21 years)

Introduction: {“name”: “8’ Softwall White Textile”, “collection”: “Softwall Collection”, “description”: “A freestanding space partition, molo’s textile softwall room divider is a modern partition design and folding wall that has the flexibility to be shaped in any curved or linear formation.”, “maximum_length”: “15 feet”, “dimensions”: {“height”: “8′”, “depth”: “11 ½””, “length”: “15′”}, “weight”: “50 lbs”, “pr…

5. Modular Cleanrooms – Econo-Tent

Domain: modularcleanrooms.com

Registered: 1999 (26 years)

Introduction: Modular Softwall Cleanrooms are an affordable solution for cleanroom design and implementation. The Econo-Tent is a portable, modular cleanroom that can be used with ceiling grids or as a stand-alone unit. It is customizable, versatile, and can be easily expanded or reduced in size. Key features include: prefabricated for quick installation, almost 100% reusable, and self-contained. The frames are…

Strategic Sourcing Conclusion and Outlook for soft wall

How Can Strategic Sourcing Enhance Your Soft Wall Procurement?

In today’s dynamic business environment, strategic sourcing is essential for international buyers seeking soft wall solutions. The versatility of soft walls—whether for acoustic control, spatial reconfiguration, or cleanroom applications—offers significant advantages. Their modular design and lightweight materials facilitate easy transport and installation, meeting the evolving needs of businesses across various sectors.

By prioritizing sustainable sourcing practices, such as selecting products made from FSC-certified materials, buyers can align with global sustainability goals while ensuring high-quality standards. The innovative features of soft walls, including customizable designs and acoustic properties, enable companies to create functional and aesthetically pleasing environments, thus enhancing productivity and employee satisfaction.

Looking ahead, the demand for flexible, eco-friendly solutions in workspace design is set to rise, particularly in emerging markets like Africa and South America, as well as established regions in Europe and the Middle East. Now is the time for B2B buyers to explore partnerships with leading suppliers to leverage these benefits. Take the next step in your sourcing strategy by investing in soft wall solutions that not only meet your current needs but also adapt to future challenges.

Illustrative image related to soft wall

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to soft wall