Class 5 Forklift Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for class 5 forklift

In the fast-evolving landscape of material handling, sourcing the right Class 5 forklift can be a formidable challenge for international B2B buyers. These forklifts, known for their robust performance in heavy-duty applications, are essential for industries ranging from construction to logistics. However, navigating the myriad of options, specifications, and supplier credentials can often lead to decision fatigue, especially for businesses operating across diverse regions such as Africa, South America, the Middle East, and Europe.

This comprehensive guide delves into the nuances of Class 5 forklifts, covering critical aspects such as types, applications, supplier vetting processes, and cost considerations. By providing in-depth insights into the unique features and capabilities of these forklifts, we empower buyers to make informed purchasing decisions tailored to their specific operational needs. Whether you are looking to optimize your supply chain efficiency or enhance productivity in your warehouse, this guide serves as a valuable resource to help you navigate the complexities of the global forklift market.

With practical tips and expert recommendations, you will gain a clearer understanding of how to evaluate potential suppliers, assess performance metrics, and ultimately select the right Class 5 forklift that aligns with your business goals. Prepare to elevate your material handling strategy as we explore the essential elements that drive successful procurement in today’s competitive marketplace.

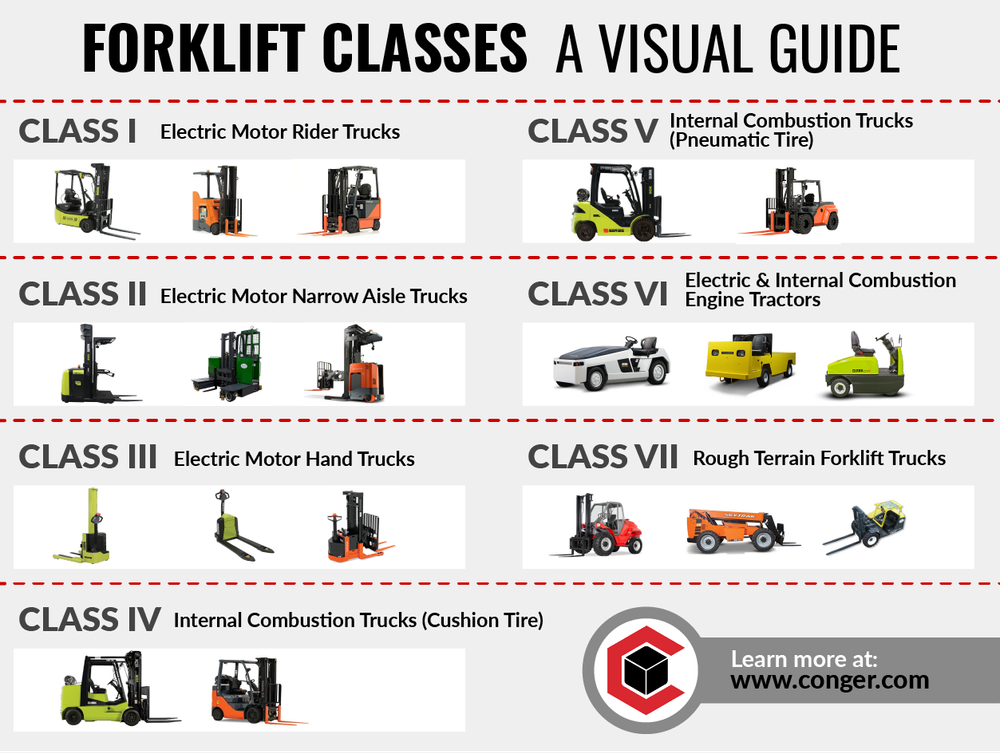

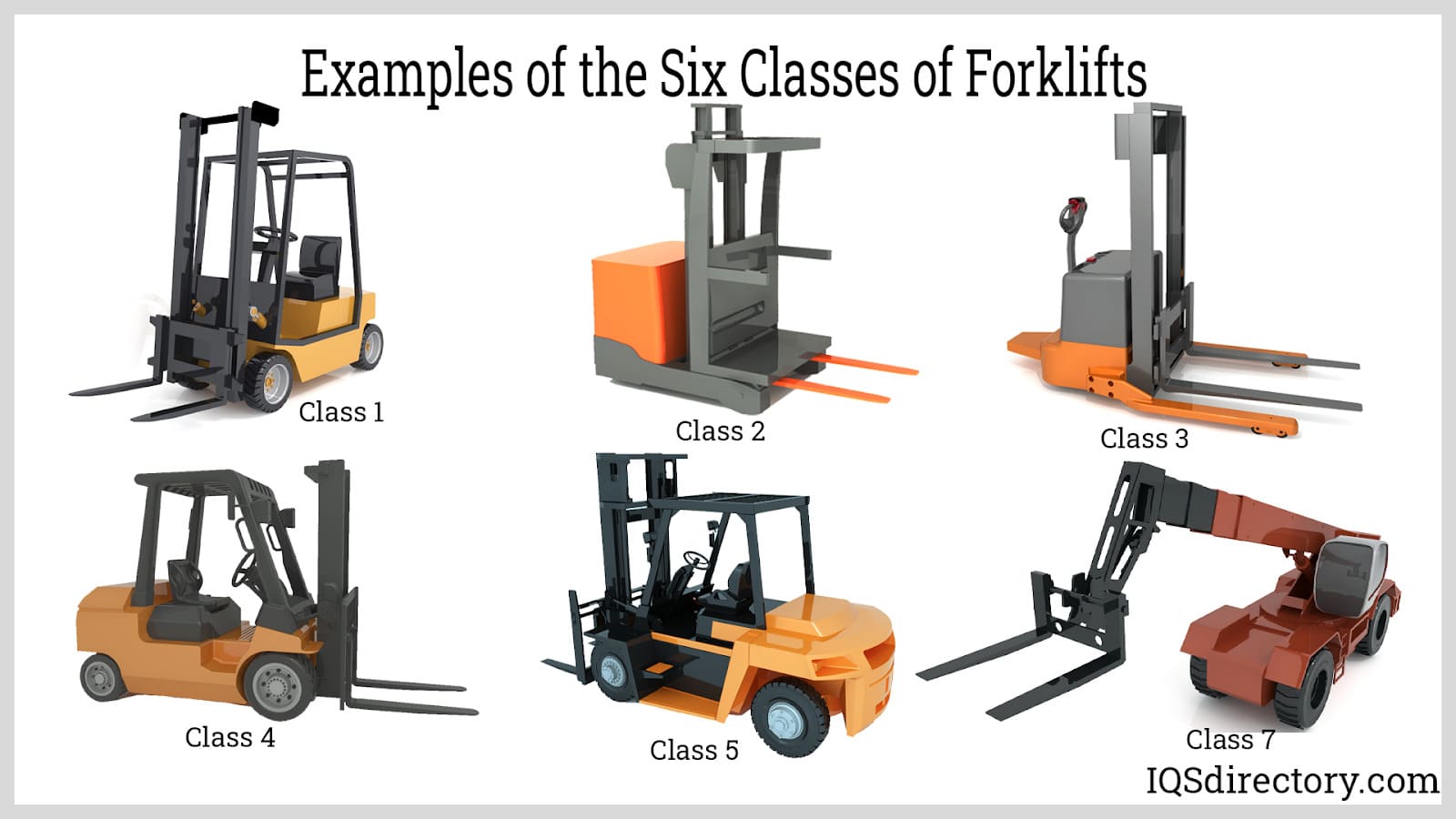

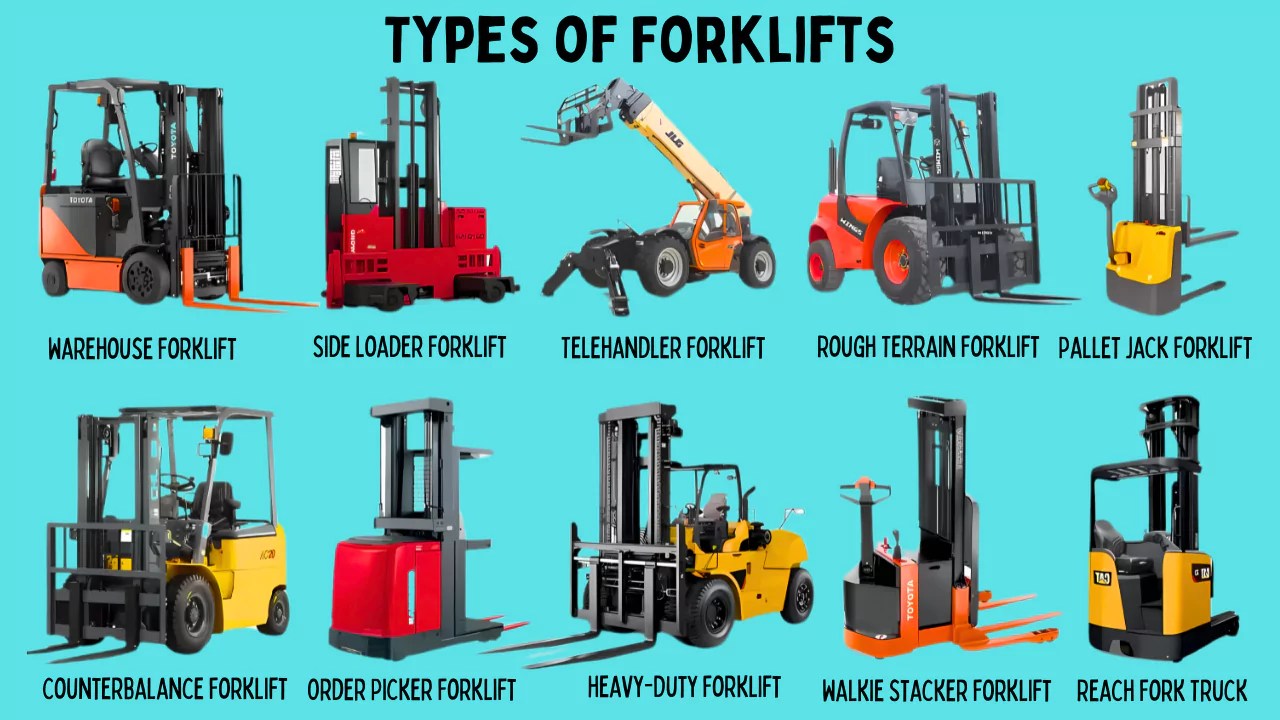

Understanding class 5 forklift Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Pneumatic | Air-filled tires for enhanced traction | Lumberyards, construction sites, outdoor warehousing | Pros: Excellent grip on uneven terrain; Cons: Higher maintenance costs due to tire wear. |

| Solid Pneumatic | Solid rubber tires for durability | Heavy-duty outdoor applications | Pros: No risk of punctures; Cons: Less cushioning compared to air-filled tires. |

| High-Capacity Forklift | Capable of lifting up to 55,000 lbs | Heavy manufacturing, steel mills | Pros: Ideal for handling large loads; Cons: Higher initial investment and operational costs. |

| All-Terrain Forklift | Designed for rough and uneven surfaces | Construction sites, landscaping, and mining | Pros: Versatile for various terrains; Cons: Can be slower on smooth surfaces. |

| Multi-Directional Forklift | Maneuvers in tight spaces with side-shifting capabilities | Warehousing, tight loading docks | Pros: Increased maneuverability; Cons: More complex operation and training required. |

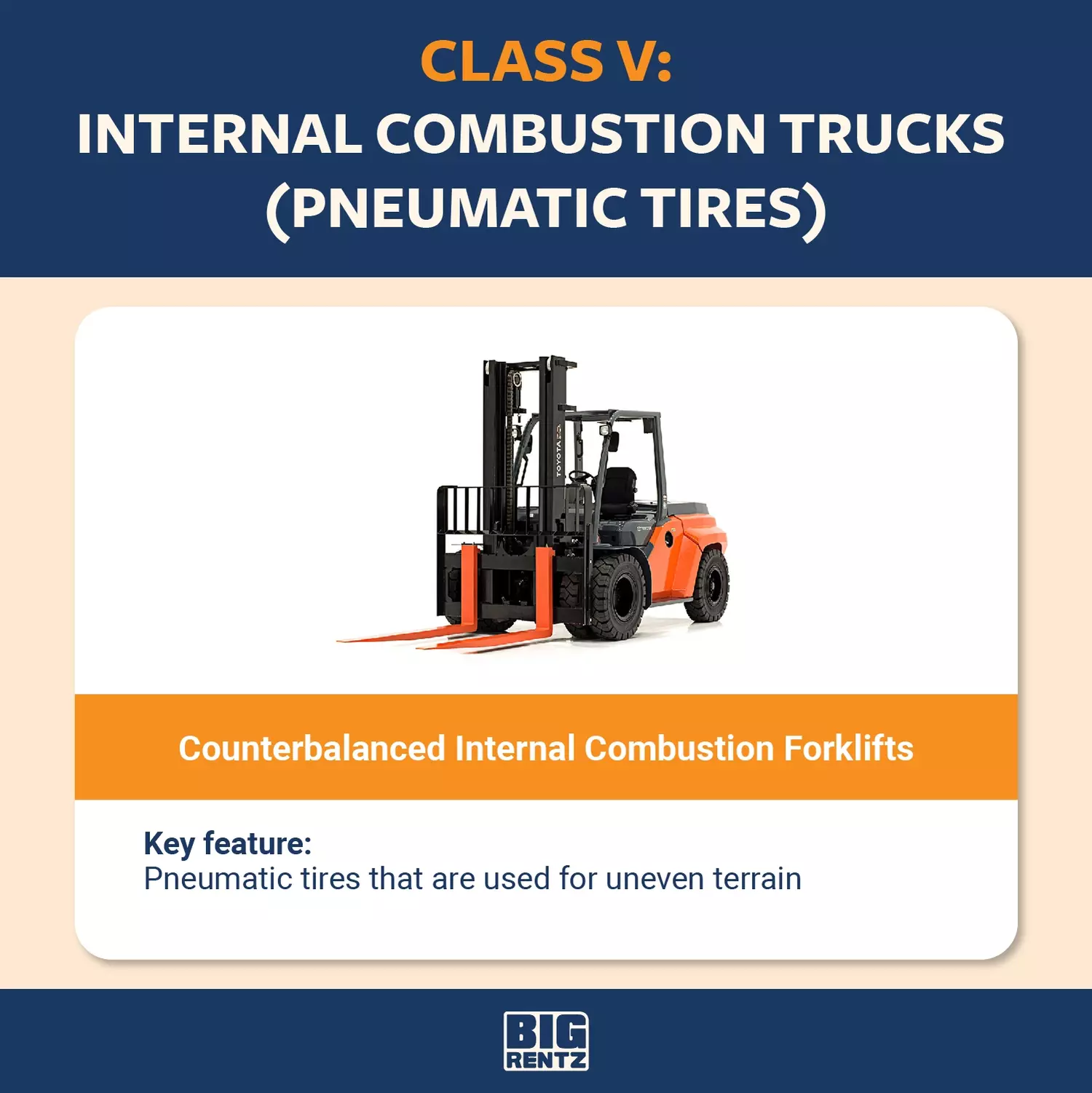

What Are the Key Features of Standard Pneumatic Forklifts?

Standard pneumatic forklifts are characterized by their air-filled tires, which provide superior traction on uneven surfaces. This makes them ideal for environments like lumberyards and construction sites, where grip is essential. Buyers should consider the terrain and load requirements, as these forklifts excel in outdoor applications but may incur higher maintenance costs due to tire wear.

How Do Solid Pneumatic Forklifts Differ from Standard Pneumatic Models?

Solid pneumatic forklifts utilize solid rubber tires, offering durability and eliminating the risk of punctures. This makes them suitable for heavy-duty outdoor applications where tire integrity is crucial. While they provide a stable ride, buyers should weigh the benefits of durability against the reduced cushioning effect, which can impact operator comfort over long shifts.

What Advantages Do High-Capacity Forklifts Offer for B2B Buyers?

High-capacity forklifts are designed to handle loads of up to 55,000 lbs, making them indispensable in heavy manufacturing settings or steel mills. Their robust construction allows for efficient handling of large materials, but buyers must consider the higher initial investment and ongoing operational costs associated with these powerful machines.

Why Choose an All-Terrain Forklift for Construction Projects?

All-terrain forklifts are engineered to navigate rough and uneven surfaces, making them ideal for construction sites, landscaping, and mining operations. Their versatility allows them to perform well in various environments, but potential buyers should note that these forklifts may operate more slowly on smooth surfaces, which could affect productivity in certain applications.

What Makes Multi-Directional Forklifts Suitable for Tight Spaces?

Multi-directional forklifts are designed with the ability to maneuver in tight spaces, utilizing side-shifting capabilities. This makes them particularly effective in warehouses and loading docks where space is limited. While they provide enhanced maneuverability, buyers should consider the additional complexity in operation and the potential need for specialized training for operators.

Key Industrial Applications of class 5 forklift

| Industry/Sector | Specific Application of class 5 forklift | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Moving heavy materials on site | Increases efficiency and reduces manual labor costs | Consider load capacity, terrain adaptability, and fuel type availability. |

| Lumber and Timber | Transporting logs and lumber within yards | Enhances operational speed and safety in rugged environments | Evaluate tire type (pneumatic), lift height, and maintenance support. |

| Warehousing | Loading and unloading freight at distribution centers | Improves turnaround time for shipments and inventory management | Focus on fuel efficiency, maneuverability, and compatibility with existing equipment. |

| Agriculture | Handling bulk materials like fertilizer and feed | Streamlines logistics and reduces product damage | Ensure suitability for outdoor use and robust design for agricultural settings. |

| Recycling and Waste Management | Moving heavy recyclables and waste materials | Supports sustainability initiatives and operational efficiency | Look for durability, ease of maintenance, and compliance with local regulations. |

How is Class 5 Forklift Used in Construction Projects?

In the construction industry, Class 5 forklifts are indispensable for moving heavy materials such as steel beams, concrete blocks, and equipment across job sites. Their robust design allows them to navigate rugged terrains, making them ideal for outdoor environments. By reducing the need for manual lifting and transportation, these forklifts enhance overall efficiency and safety. Buyers should prioritize factors such as load capacity, fuel type, and terrain adaptability to ensure they select the right forklift for their specific construction needs.

What Role Does Class 5 Forklift Play in the Lumber and Timber Sector?

Class 5 forklifts are crucial in the lumber and timber industry, where they transport logs and finished lumber products within yards. Their pneumatic tires provide excellent traction on uneven surfaces, allowing for safe and efficient operations. The ability to handle heavy loads reduces the time and labor associated with moving materials, directly impacting productivity. Buyers should consider the forklift’s lift height, load capacity, and maintenance support when sourcing equipment for this demanding sector.

Illustrative image related to class 5 forklift

How Do Class 5 Forklifts Enhance Warehousing Operations?

In warehousing, Class 5 forklifts are utilized for loading and unloading freight, which is critical for maintaining efficient supply chain operations. Their versatility allows them to operate both indoors and outdoors, making them suitable for various warehouse layouts. By speeding up the loading process, these forklifts minimize turnaround times for shipments, thereby improving inventory management. Buyers should focus on features such as fuel efficiency, maneuverability, and compatibility with existing warehouse systems to optimize their logistics.

What Benefits Do Class 5 Forklifts Provide in Agriculture?

In the agriculture sector, Class 5 forklifts facilitate the handling of bulk materials like fertilizer and animal feed, which are often heavy and cumbersome. Their ability to operate in outdoor conditions and traverse uneven terrain makes them ideal for farm environments. By streamlining logistics and reducing the risk of product damage during transport, these forklifts contribute to more efficient agricultural operations. Buyers should ensure that the forklifts are robust enough to handle agricultural demands and consider local fuel availability.

How Are Class 5 Forklifts Used in Recycling and Waste Management?

Class 5 forklifts play a vital role in recycling and waste management by moving heavy recyclables and waste materials efficiently. Their robust construction allows them to handle the rigors of waste facilities, where operational efficiency is paramount. By facilitating the quick transport of materials, these forklifts support sustainability initiatives while optimizing labor costs. When sourcing for this application, buyers should prioritize durability, ease of maintenance, and compliance with local environmental regulations to ensure long-term operational success.

3 Common User Pain Points for ‘class 5 forklift’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Class 5 Forklift for Diverse Applications

The Problem: Many B2B buyers struggle to choose the right Class 5 forklift that can handle various tasks across different environments, such as construction sites, lumberyards, and warehouses. This uncertainty can lead to purchasing the wrong model, resulting in operational inefficiencies, increased costs, and potential safety hazards. Buyers often find themselves overwhelmed by the wide range of specifications, load capacities, and fuel types available, leaving them unsure about the best fit for their specific needs.

The Solution: To effectively select the right Class 5 forklift, buyers should start by conducting a thorough analysis of their operational requirements. This includes assessing the types of loads to be lifted, the typical weight of materials, and the environments in which the forklift will operate. Buyers should also consider the terrain—whether it’s rugged outdoor conditions or smooth indoor surfaces. Once these factors are identified, it is crucial to consult with multiple suppliers to compare models that match the required specifications. Additionally, engaging in a rental program for a short period can provide firsthand experience with a specific forklift model before making a significant investment. This approach not only ensures the right choice but also optimizes cost-efficiency and productivity.

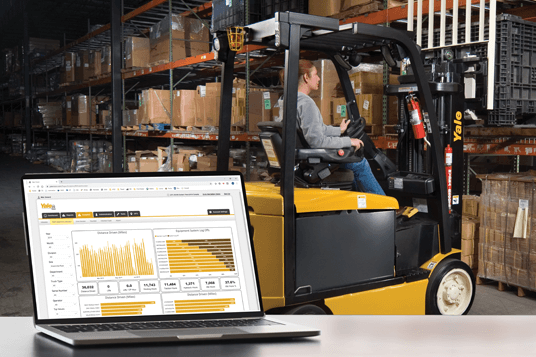

Illustrative image related to class 5 forklift

Scenario 2: Managing Maintenance and Downtime of Class 5 Forklifts

The Problem: A common pain point for B2B buyers is the unexpected maintenance and downtime associated with Class 5 forklifts. Frequent breakdowns can disrupt operations and lead to costly delays, especially in industries where timely material handling is critical. Buyers may struggle to find reliable service providers or may not have a clear understanding of the maintenance needs specific to their forklift models, resulting in inadequate upkeep.

The Solution: To mitigate maintenance issues, buyers should implement a proactive maintenance strategy that includes scheduled inspections and routine servicing based on the manufacturer’s guidelines. Establishing a partnership with a reliable service provider who specializes in Class 5 forklifts can ensure that maintenance is performed regularly and correctly. Buyers should also invest in training for their operators on basic troubleshooting and maintenance practices, which can help identify minor issues before they escalate into major problems. Additionally, investing in telematics technology can provide real-time data on the forklift’s performance, enabling managers to foresee potential mechanical failures and schedule maintenance accordingly, thus minimizing downtime and enhancing productivity.

Scenario 3: Ensuring Operator Safety and Compliance with Regulations

The Problem: Ensuring the safety of forklift operators while adhering to regulatory compliance is a major concern for B2B buyers. Class 5 forklifts, being heavy machinery, pose significant risks if not operated correctly. Buyers often face challenges in training their staff adequately and maintaining compliance with safety regulations, which can lead to accidents, injuries, and potential legal issues.

The Solution: To address safety concerns, buyers should prioritize comprehensive training programs for all forklift operators. This training should cover not only the operational aspects of using Class 5 forklifts but also safety protocols and compliance with OSHA regulations. Investing in certified training programs ensures that operators are well-equipped to handle the machinery safely. Furthermore, buyers should establish a culture of safety by regularly conducting safety audits and refresher courses to keep safety top of mind. Implementing operational guidelines, such as speed limits and load management practices, can also enhance safety. Lastly, utilizing safety features available in modern Class 5 forklifts—such as backup alarms, cameras, and stability systems—can further protect operators and improve overall workplace safety.

Strategic Material Selection Guide for class 5 forklift

What Are the Key Materials Used in Class 5 Forklifts?

Class 5 forklifts are designed for heavy-duty applications, often operating in challenging environments such as construction sites and lumberyards. The selection of materials used in their construction significantly impacts performance, durability, and cost-effectiveness. Here, we analyze four common materials used in Class 5 forklifts: steel, aluminum, rubber, and composite materials.

Illustrative image related to class 5 forklift

How Does Steel Contribute to Class 5 Forklift Performance?

Key Properties: Steel offers exceptional strength and durability, with high tensile strength and resistance to deformation under heavy loads. It can withstand extreme temperatures and pressures, making it suitable for various operational environments.

Pros & Cons: The primary advantage of steel is its robustness, which translates to longer service life and resistance to wear and tear. However, steel is relatively heavy, which can affect the forklift’s overall weight and fuel efficiency. Additionally, it is prone to corrosion if not properly treated, which may require additional maintenance costs.

Impact on Application: Steel is particularly effective in environments where heavy lifting is required, such as lumberyards and construction sites. Its strength ensures that the forklift can handle large loads without compromising safety.

Illustrative image related to class 5 forklift

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that the steel used meets local standards for corrosion resistance, especially in humid or saline environments. Compliance with international standards such as ASTM or DIN is crucial for ensuring quality and safety.

What Role Does Aluminum Play in Class 5 Forklift Design?

Key Properties: Aluminum is lightweight and resistant to corrosion, making it an attractive alternative to steel for certain components of Class 5 forklifts. It has a good strength-to-weight ratio, which can enhance fuel efficiency.

Pros & Cons: The lightweight nature of aluminum allows for better maneuverability and reduced energy consumption. However, it is generally less durable than steel and may not be suitable for high-impact applications. The cost of aluminum can also be higher than that of steel, which may affect overall project budgets.

Impact on Application: Aluminum components are often used in non-structural parts such as frames and panels, where weight reduction is beneficial. This can enhance the forklift’s performance in operations requiring agility and speed.

Considerations for International Buyers: Buyers should consider the availability and cost of aluminum in their region. Compliance with international standards for aluminum alloys is essential to ensure that the material will perform adequately under expected conditions.

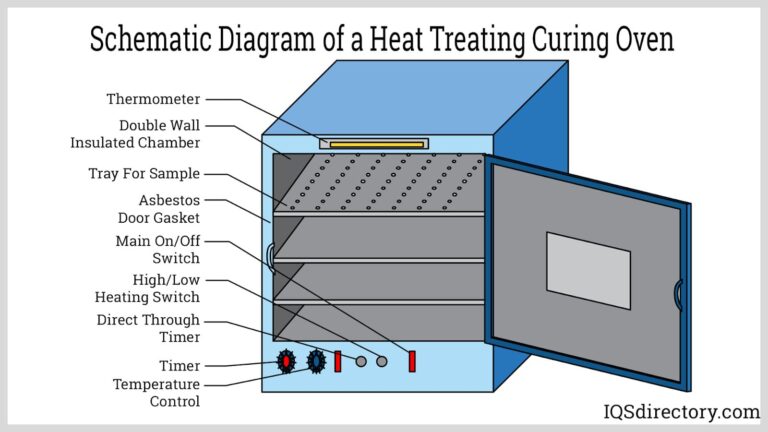

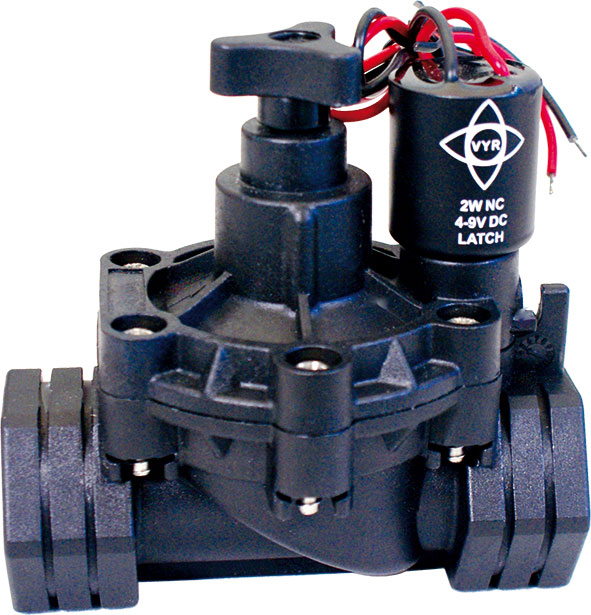

How Does Rubber Enhance Class 5 Forklift Functionality?

Key Properties: Rubber is primarily used in tires and seals due to its excellent elasticity and shock-absorbing properties. It can withstand various temperatures and provides good traction on multiple surfaces.

Illustrative image related to class 5 forklift

Pros & Cons: The primary advantage of rubber tires is their ability to absorb shocks and vibrations, which enhances operator comfort and reduces wear on the forklift. However, rubber can degrade over time due to exposure to UV light and harsh chemicals, leading to increased replacement costs.

Impact on Application: Rubber tires are essential for outdoor operations, providing the necessary grip and stability on uneven terrain. They are particularly beneficial in construction sites where terrain can change frequently.

Considerations for International Buyers: Buyers should ensure that the rubber used in tires meets local standards for durability and performance. In regions with extreme temperatures, selecting rubber compounds specifically designed for those conditions is crucial.

What Are the Benefits of Composite Materials in Class 5 Forklifts?

Key Properties: Composite materials combine different substances to create a lightweight yet strong material. They often exhibit excellent resistance to corrosion and fatigue.

Pros & Cons: The primary advantage of composites is their low weight, which can enhance fuel efficiency and reduce operating costs. However, they may be more expensive to manufacture and repair compared to traditional materials like steel and rubber.

Impact on Application: Composites are often used in specialized components where weight reduction is critical, such as in certain structural parts or panels. This can significantly improve the overall efficiency of the forklift.

Considerations for International Buyers: Buyers should evaluate the availability of composite materials in their region and ensure compliance with international standards for safety and performance.

Summary Table of Material Selection for Class 5 Forklifts

| Material | Typical Use Case for class 5 forklift | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, frames | High strength and durability | Heavy, prone to corrosion | Medium |

| Aluminum | Non-structural parts, frames | Lightweight, corrosion-resistant | Less durable than steel, higher cost | High |

| Rubber | Tires and seals | Excellent shock absorption | Degrades over time, UV sensitivity | Medium |

| Composite | Specialized components | Lightweight, corrosion-resistant | Higher manufacturing complexity | High |

This analysis provides B2B buyers with actionable insights into material selection for Class 5 forklifts, ensuring they make informed decisions that align with their operational needs and regional considerations.

Illustrative image related to class 5 forklift

In-depth Look: Manufacturing Processes and Quality Assurance for class 5 forklift

What Are the Main Stages in the Manufacturing Process of Class 5 Forklifts?

The manufacturing process of Class 5 forklifts, which are designed for heavy-duty applications such as lumberyards and construction sites, involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages can help B2B buyers assess the quality and durability of the forklifts they intend to purchase.

Material Preparation: What Raw Materials Are Used in Class 5 Forklift Production?

Material preparation is the foundational step in manufacturing Class 5 forklifts. The primary materials include high-strength steel for the chassis, various metals for hydraulic components, and durable rubber or composite materials for tires. Sourcing quality materials is crucial as they directly impact the forklift’s performance and longevity. Suppliers often conduct material inspections to ensure that the properties meet international standards, such as ASTM (American Society for Testing and Materials) specifications.

How Is the Forming Process Conducted for Class 5 Forklifts?

The forming stage involves shaping the raw materials into components that will make up the forklift. Techniques such as stamping, welding, and machining are commonly employed. For instance, steel sheets may be stamped into the desired shapes for the chassis, while welding is used to assemble these components into a robust frame. Precision in this stage is vital, as any deviations can affect the forklift’s structural integrity and safety. Advanced technologies like CNC (Computer Numerical Control) machining are increasingly used to enhance accuracy and efficiency in forming.

Illustrative image related to class 5 forklift

What Are the Key Steps in the Assembly Process of Class 5 Forklifts?

The assembly stage is where all the components come together. This process typically follows a sequential workflow, where parts are systematically added to the frame. Critical components such as the engine, transmission, and hydraulic systems are integrated during this phase. Each assembly line may include specific stations for different tasks, ensuring that all components are installed correctly and efficiently. Manufacturers often utilize lean manufacturing principles to minimize waste and optimize assembly time, which is particularly important for meeting the demands of B2B buyers who require timely deliveries.

How Is the Finishing Process Conducted to Ensure Quality?

The finishing process involves painting, coating, and final inspection of the forklift. This stage not only enhances the aesthetic appeal but also provides protection against corrosion and wear. High-quality finishes, such as powder coating, are commonly used for their durability. Following the application of finishes, each forklift undergoes a thorough inspection to ensure that it meets the design specifications and quality standards.

What Are the Quality Assurance Protocols for Class 5 Forklifts?

Quality assurance (QA) is a critical aspect of the manufacturing process for Class 5 forklifts, ensuring that they meet safety and performance standards. B2B buyers should be familiar with the relevant international and industry-specific standards that guide quality assurance practices.

Which International Standards Should Class 5 Forklift Manufacturers Comply With?

Manufacturers of Class 5 forklifts often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 indicates that a manufacturer has implemented effective quality management practices, ensuring consistent product quality. Additionally, specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for certain components may also apply.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process. These checkpoints typically include:

Illustrative image related to class 5 forklift

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch any defects early.

- Final Quality Control (FQC): Comprehensive testing of the completed forklift to verify that it meets all safety and operational standards.

B2B buyers should inquire about the QC processes employed by manufacturers to ensure adherence to these standards.

What Common Testing Methods Are Used to Ensure Forklift Performance?

Testing methods for Class 5 forklifts include load testing, stability testing, and performance assessments. Load testing is particularly crucial, as it verifies that the forklift can safely handle its rated capacity. Stability tests assess the forklift’s center of gravity and overall balance, while performance assessments evaluate speed, maneuverability, and braking effectiveness. Manufacturers may also conduct environmental tests to simulate real-world operating conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers should conduct thorough due diligence. Here are several strategies:

Illustrative image related to class 5 forklift

- Supplier Audits: Regular audits can help buyers assess a supplier’s adherence to quality standards and manufacturing processes. This can include on-site visits to observe operations and QC practices firsthand.

- Quality Reports: Requesting detailed QC reports can provide insights into the supplier’s testing methods, compliance with standards, and any issues encountered during production.

- Third-Party Inspections: Engaging independent third-party inspectors can offer an unbiased evaluation of the supplier’s quality control practices and product quality.

What Nuances Should International B2B Buyers Be Aware Of Regarding Quality Control?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. For instance, variations in regulatory requirements and quality expectations may exist between regions. Buyers should ensure that suppliers are familiar with the specific standards applicable in their target markets, such as CE marking for Europe or other regional certifications.

Additionally, logistical considerations, such as shipping and handling, can impact the condition of forklifts upon arrival. Buyers should discuss packaging and transportation methods with suppliers to ensure that products are delivered in optimal condition.

Conclusion: Ensuring Quality in Class 5 Forklift Procurement

Understanding the manufacturing processes and quality assurance protocols for Class 5 forklifts is crucial for B2B buyers. By familiarizing themselves with the stages of production, relevant standards, and effective verification methods, buyers can make informed decisions that ensure they procure high-quality, reliable forklifts tailored to their operational needs.

Illustrative image related to class 5 forklift

Practical Sourcing Guide: A Step-by-Step Checklist for ‘class 5 forklift’

When sourcing a Class 5 forklift, it’s essential to follow a structured approach to ensure you make an informed decision that aligns with your operational needs and budget constraints. This guide will provide a step-by-step checklist designed to help international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, effectively procure the right forklift.

Step 1: Define Your Technical Specifications

Begin by identifying the specific technical requirements for your Class 5 forklift. Consider factors such as load capacity, lift height, and power source (diesel, LP gas, or gasoline). Understanding these specifications will help narrow down your options and ensure the forklift can handle the intended applications, whether for outdoor use in lumberyards or construction sites.

Step 2: Assess Your Operational Environment

Evaluate the conditions in which the forklift will be used. Class 5 forklifts are versatile and can operate both indoors and outdoors, but their performance can be influenced by surface conditions and space constraints. Analyze the terrain, aisle widths, and any potential hazards to determine if additional features, such as enhanced traction or stability systems, are necessary.

Illustrative image related to class 5 forklift

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request detailed company profiles, customer testimonials, and case studies that demonstrate their expertise and reliability in your industry. Pay attention to their experience with international shipping and after-sales support, as these factors are crucial for a smooth procurement process.

Step 4: Verify Compliance and Certifications

Ensure that the forklifts meet the required safety and regulatory standards relevant to your region. Check for certifications from organizations like OSHA or CE marking in Europe, which indicate compliance with safety regulations. This step is vital for ensuring that the equipment adheres to the necessary operational standards and reduces liability risks.

Step 5: Request Quotes and Compare Pricing

Solicit quotes from multiple suppliers to compare pricing effectively. Be transparent about your requirements and any additional services you may need, such as training or maintenance packages. Look beyond the initial purchase price; consider the total cost of ownership, including fuel efficiency, maintenance costs, and warranty offerings.

Step 6: Conduct a Site Visit or Inspection

If possible, arrange a site visit to inspect the forklift in operation. This will allow you to assess its performance and suitability for your specific applications firsthand. During the inspection, evaluate the build quality, ease of use, and any additional features that may enhance productivity, such as ergonomic controls or advanced safety systems.

Step 7: Finalize the Purchase Agreement

Once you’ve selected a supplier, carefully review and finalize the purchase agreement. Ensure that all terms, including delivery timelines, warranty conditions, and after-sales support, are clearly defined. This step is crucial to avoid misunderstandings and ensure a smooth transaction process.

Illustrative image related to class 5 forklift

By following this checklist, you can make a well-informed decision when sourcing a Class 5 forklift, ensuring that it meets your operational needs while also providing value for your investment.

Comprehensive Cost and Pricing Analysis for class 5 forklift Sourcing

What Are the Key Cost Components of Class 5 Forklift Sourcing?

When sourcing Class 5 forklifts, it is crucial to understand the cost structure that underpins their pricing. The primary components include:

-

Materials: The cost of raw materials such as steel, aluminum, and plastics directly affects the overall pricing. Forklifts also incorporate various electronic components, hydraulic systems, and engines, which add to material costs.

-

Labor: Labor costs encompass not only the wages of assembly workers but also skilled technicians involved in design and quality assurance. In regions with higher labor costs, such as Western Europe, this can significantly influence pricing.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help mitigate these expenses.

-

Tooling: Custom tooling for specific forklift designs or features can be a significant upfront cost. Buyers should inquire about tooling expenses, especially if they are considering a custom model.

-

Quality Control (QC): Investing in rigorous QC processes ensures that each forklift meets safety and performance standards. This can increase the upfront cost but is essential for long-term reliability.

-

Logistics: Transportation costs from the manufacturing site to the end-user can vary greatly, influenced by distance, shipping method, and tariffs. International buyers must account for these variables when calculating total costs.

-

Margin: Supplier profit margins will vary based on market positioning and competition. Understanding the competitive landscape can help buyers negotiate better deals.

How Do Price Influencers Affect Class 5 Forklift Costs?

Several factors can influence the pricing of Class 5 forklifts beyond the basic cost components:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk can lead to significant discounts. Suppliers often have tiered pricing structures, so negotiating a higher MOQ can lower the per-unit cost.

-

Specifications and Customization: Custom features or modifications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials Quality and Certifications: High-quality materials and certifications (such as ISO or CE) can add to the cost but often lead to better performance and longevity. Buyers should weigh the benefits of premium options against budget constraints.

-

Supplier Factors: The reputation, reliability, and experience of the supplier can impact pricing. Established suppliers may charge a premium for their expertise and service quality.

-

Incoterms: The terms of trade (e.g., FOB, CIF) dictate who bears the cost of shipping and insurance, which can significantly affect the final pricing. Understanding these terms is vital for international transactions.

What Are the Best Buyer Tips for Sourcing Class 5 Forklifts?

Navigating the complexities of Class 5 forklift sourcing requires strategic approaches:

-

Negotiation: Always negotiate pricing and terms. Understanding the cost structure allows buyers to identify areas where suppliers might have flexibility.

-

Cost-Efficiency: Look beyond the initial purchase price. Consider total cost of ownership (TCO), which includes maintenance, fuel, and operational costs over the forklift’s lifespan.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional market conditions, including currency fluctuations and local economic factors that can influence pricing.

-

Request for Quotations (RFQs): Sending detailed RFQs to multiple suppliers can yield competitive pricing. Ensure RFQs include specifications, quantities, and desired delivery timelines.

-

Evaluate After-Sales Support: Consider the level of after-sales service and support offered by suppliers. Good support can significantly enhance the value of your investment.

Disclaimer on Indicative Prices

Prices for Class 5 forklifts can vary widely based on specifications, supplier, and market conditions. It is advisable to request quotes from multiple suppliers to obtain the most accurate pricing for your specific needs. Always consider local economic factors and logistics when evaluating costs.

Alternatives Analysis: Comparing class 5 forklift With Other Solutions

Understanding Alternative Solutions to Class 5 Forklifts

In the competitive landscape of material handling, businesses often seek alternatives to Class 5 forklifts to optimize their operations. Class 5 forklifts, known for their versatility and high load capacity, are excellent for various environments, particularly outdoor and rough terrain applications. However, depending on specific operational needs, other solutions may offer advantages in performance, cost, or ease of use. This section provides a comparative analysis of Class 5 forklifts against two alternative solutions: Electric Pallet Jacks and Automated Guided Vehicles (AGVs).

Illustrative image related to class 5 forklift

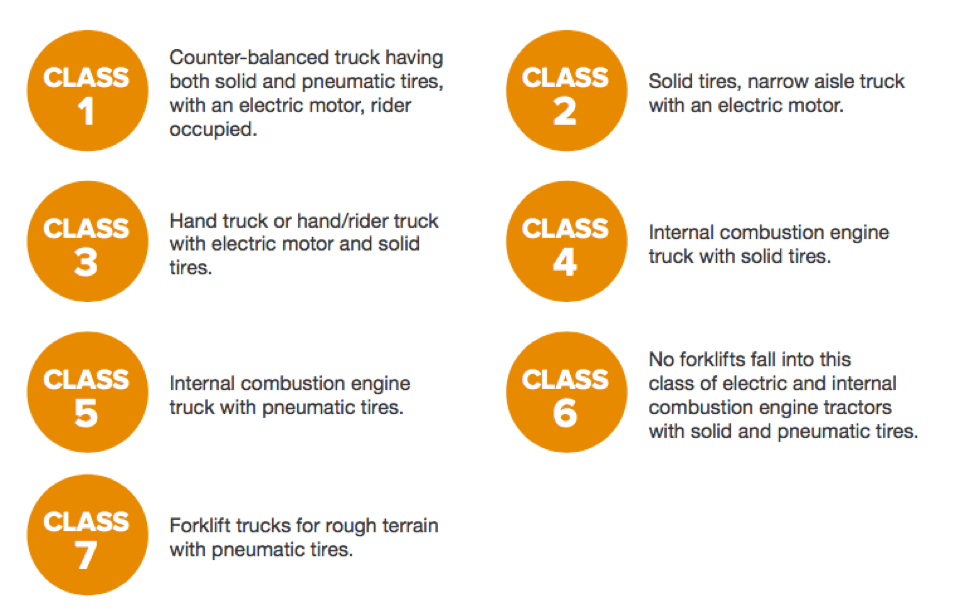

Comparison Table

| Comparison Aspect | Class 5 Forklift | Electric Pallet Jack | Automated Guided Vehicle (AGV) |

|---|---|---|---|

| Performance | High load capacity (3,000-36,000 lbs) and versatility in various terrains | Moderate load capacity (up to 5,500 lbs), ideal for flat surfaces | Variable load capacity, typically suited for repetitive tasks |

| Cost | Higher upfront and operating costs due to fuel and maintenance | Lower initial cost; electric power reduces ongoing expenses | High initial investment but can lower labor costs over time |

| Ease of Implementation | Requires operator training and certification | Easy to use with minimal training | Initial setup can be complex, but low operator intervention needed |

| Maintenance | Regular maintenance required for engine and components | Minimal maintenance; battery replacement needed | Low maintenance; software updates and battery management are key |

| Best Use Case | Construction sites, lumberyards, outdoor operations | Warehouses and retail environments for pallet handling | Automated warehouses, repetitive transport tasks |

Detailed Breakdown of Alternatives

Electric Pallet Jack

Electric pallet jacks are compact and efficient for transporting pallets over short distances, especially in indoor settings. They are user-friendly, with a simple design that requires minimal training, making them an attractive option for businesses looking to streamline operations quickly. The lower initial cost compared to Class 5 forklifts is a significant advantage, particularly for smaller operations or those with budget constraints. However, their moderate load capacity and limited performance in rough terrains mean they are not suitable for all applications, especially where heavy lifting and outdoor maneuverability are required.

Automated Guided Vehicle (AGV)

AGVs represent a cutting-edge solution for material handling, designed to automate the transportation of goods within a facility. They can efficiently handle repetitive tasks and reduce the need for human operators, potentially lowering long-term labor costs. While the initial investment in AGVs can be substantial, they offer scalability and flexibility as businesses grow. The primary drawback is the complexity of setup and integration into existing systems, which may require significant time and resources. Additionally, AGVs may not perform well in environments with variable layouts or require frequent changes in routes.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating the right material handling solution, B2B buyers must consider their specific operational requirements, including load capacities, terrain types, and budget constraints. Class 5 forklifts excel in heavy-duty and outdoor applications, making them ideal for industries such as construction and lumber. Conversely, electric pallet jacks are perfect for indoor environments where maneuverability and cost-efficiency are priorities. For businesses looking to embrace automation, AGVs can offer long-term savings and efficiency, albeit with a higher upfront investment and complexity. By carefully assessing these factors, buyers can make informed decisions that align with their operational goals and financial capabilities.

Illustrative image related to class 5 forklift

Essential Technical Properties and Trade Terminology for class 5 forklift

What Are the Key Technical Properties of Class 5 Forklifts?

When evaluating Class 5 forklifts, it’s crucial to understand specific technical properties that directly impact performance, safety, and cost-effectiveness. Here are several critical specifications to consider:

-

Load Capacity

Class 5 forklifts generally have a load capacity ranging from 3,000 to 36,000 lbs. This specification is pivotal for businesses needing to transport heavy materials, such as in construction sites or lumber yards. Understanding load capacity ensures that the forklift can handle the intended loads without compromising safety or efficiency. -

Power Type

These forklifts typically operate on internal combustion engines fueled by diesel, LP gas, or gasoline. The choice of power type affects operational costs, fuel availability, and performance characteristics. For instance, diesel engines often provide more torque for heavy lifting but may require more stringent emissions compliance, especially in urban areas. -

Lift Height

Class 5 forklifts can achieve lift heights of up to 147 inches (approximately 12 feet). This is critical for businesses that need to stack materials in warehouses or construction sites. A higher lift height allows for better space utilization and can reduce the need for additional handling equipment. -

Tire Type

The pneumatic tires are designed for both indoor and outdoor use, providing stability and traction on rough terrains. Choosing the right tire type can significantly affect operational efficiency, especially in environments where ground conditions vary. Businesses must consider the trade-off between tire durability and the type of surfaces they operate on. -

Turning Radius

A tighter turning radius enhances maneuverability in confined spaces. This is especially important in warehouses or construction sites where space is limited. Understanding the turning radius can help businesses optimize their operations and improve productivity.

What Common Trade Terms Should You Know When Buying Class 5 Forklifts?

Familiarity with industry terminology can streamline the purchasing process and ensure that buyers make informed decisions. Here are several essential trade terms relevant to Class 5 forklifts:

-

OEM (Original Equipment Manufacturer)

This term refers to the company that manufactures the forklift or its components. Understanding OEM specifications helps buyers identify quality and compatibility, especially when sourcing parts or planning maintenance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for businesses aiming to maintain inventory levels without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This is a critical step in the procurement process, allowing businesses to compare costs and negotiate terms effectively. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms helps businesses navigate international transactions with confidence. -

TCO (Total Cost of Ownership)

TCO encompasses all costs associated with purchasing and operating a forklift, including purchase price, maintenance, fuel, and training. Evaluating TCO allows businesses to make holistic financial decisions that align with long-term operational goals. -

Warranty Period

This term refers to the duration for which the manufacturer guarantees the forklift against defects. A comprehensive warranty can be a significant factor in purchasing decisions, as it reflects the manufacturer’s confidence in their product and provides peace of mind to buyers.

Understanding these technical properties and trade terms will empower B2B buyers in making informed decisions about Class 5 forklifts, ensuring they select the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the class 5 forklift Sector

What Are the Current Market Dynamics and Key Trends Affecting Class 5 Forklifts?

The class 5 forklift sector is experiencing significant growth, driven by increasing demand across various industries, including construction, logistics, and manufacturing. As global supply chains expand, the need for versatile and robust material handling solutions becomes crucial. Class 5 forklifts, with their high load capacity ranging from 3,000 to 36,000 lbs, are particularly sought after for outdoor applications in diverse environments, from lumberyards to construction sites.

Emerging technologies are reshaping the sourcing landscape, with advancements such as telematics and automation gaining traction. These technologies allow operators to monitor performance metrics in real time, enhancing operational efficiency and safety. Furthermore, the rise of e-commerce is driving demand for more efficient material handling solutions, pushing companies to invest in modern class 5 forklifts equipped with smart features.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should pay attention to the local market dynamics. Factors such as economic stability, regulatory frameworks, and infrastructure development can significantly impact sourcing decisions. For instance, countries in the Middle East may prioritize heavy-duty forklifts due to ongoing construction projects, while European markets might focus on sustainability and innovation.

How Can Sustainability and Ethical Sourcing Impact Class 5 Forklift Procurement?

Sustainability is increasingly becoming a priority in the B2B procurement process for class 5 forklifts. The environmental impact of heavy machinery, particularly in terms of emissions and fuel consumption, is under scrutiny as companies strive to meet corporate social responsibility goals. Buyers are now looking for options that offer lower emissions, such as forklifts powered by alternative fuels or hybrid technology.

Illustrative image related to class 5 forklift

Ethical sourcing is also gaining prominence. Buyers are encouraged to seek suppliers who adhere to sustainable practices, ensuring that the materials used in manufacturing class 5 forklifts are responsibly sourced. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) can serve as indicators of a supplier’s commitment to sustainability. Additionally, utilizing recycled materials in the production of forklifts can further enhance a company’s green credentials.

Investing in class 5 forklifts that meet stringent environmental standards not only helps in reducing a company’s carbon footprint but can also lead to cost savings in the long run through improved fuel efficiency and reduced maintenance needs.

What Is the Brief Evolution and History of Class 5 Forklifts in the B2B Market?

Class 5 forklifts have evolved significantly since their inception, adapting to the changing needs of industries worldwide. Initially designed for basic material handling tasks, these forklifts have incorporated advanced technology over the years, enhancing their functionality and efficiency. The introduction of pneumatic tires allowed these forklifts to operate effectively in rough terrains, making them suitable for outdoor applications.

Illustrative image related to class 5 forklift

In the last few decades, the focus has shifted toward improving safety features and operator comfort. Innovations such as ergonomic designs, advanced visibility, and automated systems have become standard, addressing the growing emphasis on workplace safety and operator productivity. As global supply chains continue to evolve, class 5 forklifts are likely to undergo further advancements, integrating smart technologies to meet the demands of modern logistics and manufacturing environments.

By understanding these trends, B2B buyers can make informed decisions when sourcing class 5 forklifts, ensuring they choose equipment that aligns with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of class 5 forklift

-

How do I choose the right Class 5 forklift for my needs?

Selecting the right Class 5 forklift involves assessing your specific application requirements. Consider the load capacity (ranging from 3,000 to 36,000 lbs) and the nature of your work environment, whether it’s outdoors or in a warehouse. Evaluate the terrain—pneumatic tires are ideal for rough surfaces, while cushion tires work better on smooth floors. Additionally, assess your vertical lift needs, as Class 5 forklifts can reach heights of up to 12 feet. Engaging with suppliers for recommendations based on your operational demands can also streamline your decision-making process. -

What are the typical applications for a Class 5 forklift?

Class 5 forklifts are versatile, suitable for various applications including construction sites, lumberyards, and warehouses. Their robust design allows them to handle heavy loads in both outdoor and indoor settings. Common tasks include transporting pallets, lifting construction materials, and managing logistics in distribution centers. Given their capacity and durability, these forklifts are particularly beneficial in industries requiring heavy-duty lifting and maneuverability across different terrains. -

What should I consider when vetting suppliers for Class 5 forklifts?

When vetting suppliers, assess their reputation, experience, and customer reviews. Look for suppliers with a proven track record in your region, especially if sourcing from Africa, South America, the Middle East, or Europe. Verify their compliance with international standards and regulations. Request information on warranty terms, after-sales support, and maintenance services. Additionally, consider suppliers who offer customization options tailored to your specific needs, as this can significantly enhance your operational efficiency. -

What are the payment terms commonly offered for Class 5 forklifts?

Payment terms can vary by supplier, but typical arrangements include upfront payment, financing options, or leasing agreements. Some suppliers may require a deposit followed by payment upon delivery. It’s essential to clarify these terms before finalizing a purchase to avoid misunderstandings. Additionally, inquire about potential discounts for bulk purchases or long-term contracts, which can provide significant savings for businesses looking to invest in multiple units. -

Are there customization options available for Class 5 forklifts?

Many suppliers offer customization options for Class 5 forklifts to meet specific operational requirements. Customizations can include modifications to the lift height, attachment options (like forks or clamps), and ergonomic features for operator comfort. Discuss your needs with potential suppliers, as they can provide insights on available upgrades and modifications that align with your application. Tailoring your forklift can enhance productivity and ensure it meets the unique challenges of your work environment. -

What are the logistics considerations when importing Class 5 forklifts?

When importing Class 5 forklifts, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Engage with freight forwarders familiar with machinery imports to navigate customs clearance efficiently. Ensure all documentation, including bills of lading and import permits, is in order. Additionally, factor in the costs of transportation, insurance, and potential tariffs when budgeting for your purchase. Proper planning in logistics can prevent delays and unforeseen expenses. -

What quality assurance measures should I expect with my forklift purchase?

Reputable suppliers should provide quality assurance through rigorous testing and certification processes. Look for suppliers who adhere to industry standards, such as ISO certifications, which indicate compliance with international quality norms. Ensure that the forklifts come with warranties that cover defects and performance issues. Additionally, inquire about the supplier’s maintenance and inspection protocols, as regular quality checks are crucial for long-term performance and safety. -

How can I assess the total cost of ownership for a Class 5 forklift?

To assess the total cost of ownership (TCO), consider not just the initial purchase price but also ongoing expenses such as maintenance, fuel, insurance, and operator training. Evaluate the forklift’s fuel efficiency and durability, as these factors directly impact operational costs. Additionally, consider the resale value of the forklift, as some models retain value better than others. By calculating these elements, you can make a more informed decision that aligns with your budget and operational goals.

Top 3 Class 5 Forklift Manufacturers & Suppliers List

1. Crown – C-5 Internal Combustion Pneumatic Tire Forklift

Domain: crown.com

Registered: 1998 (27 years)

Introduction: C-5 Internal Combustion Pneumatic Tire Forklift

– Load Capacity: 4,000 – 6,500 lb

– Max Lift Height: 294 in (Quad Mast)

– Engine Options: 2.4 liter LPG engine or 2.5 liter diesel engine

– Features: D4 armrest for ergonomic comfort, wide brake pedal, dual radiator cooling system, Crown Power Brake System, On-Demand Cooling option

– Applications: Suitable for indoor and outdoor use, rugged terrain

-…

2. Logisnext Americas – Forklift Class Overview

Domain: logisnextamericas.com

Registered: 2020 (5 years)

Introduction: There are seven basic types of forklift classes ranging from class I to class VII, classified based on fuel type, application, and features.

Class I: Electric Motor Rider Trucks – Electric motor, operators can stand or sit, heavy battery acts as counterweight, versatile, available in 3 or 4 wheels, quieter, reduced fuel costs, low maintenance, suitable for strict air quality standards.

Class I…

3. CertifyMe – OSHA Forklift Certification Classes

Domain: certifyme.net

Registered: 1999 (26 years)

Introduction: CertifyMe.net offers online OSHA compliant forklift certification classes for $59.95, taking approximately two hours to complete. Classes are available in English and Spanish and include various types of forklift training: Class 1 (Electric Motor Rider Trucks), Class 4 (Internal Combustion Engine Forklifts – Cushion Tires), Class 5 (Internal Combustion Engine Forklifts – Pneumatic Tires), Class 2 …

Strategic Sourcing Conclusion and Outlook for class 5 forklift

What Are the Key Takeaways for Sourcing Class 5 Forklifts?

In conclusion, the Class 5 forklift, with its robust load capacity ranging from 3,000 to 36,000 lbs, is a versatile asset for businesses operating in diverse environments, from construction sites to lumberyards. Its internal combustion engine, capable of using diesel, LP gas, or gasoline, provides the reliability and endurance needed for heavy-duty tasks. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the unique operational requirements of Class 5 forklifts is essential for optimizing performance and reducing operational costs.

How Can Strategic Sourcing Enhance Your Forklift Acquisition?

Emphasizing strategic sourcing can significantly streamline your procurement process. By establishing partnerships with reputable suppliers, you can ensure access to high-quality machinery, competitive pricing, and excellent after-sales support. This proactive approach not only mitigates risks associated with equipment failure but also aligns with your long-term operational goals.

Illustrative image related to class 5 forklift

What’s Next for International Buyers?

As you consider your options, keep an eye on advancements in technology and sustainability in forklift design, which may influence future purchasing decisions. Engage with suppliers who are committed to innovation and can offer tailored solutions to meet your specific needs. Take the next step in enhancing your operational efficiency by exploring the best Class 5 forklift options available today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to class 5 forklift