How to Source Pneumatic Valve Diagram Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for pneumatic valve diagram

In an increasingly interconnected world, understanding the intricacies of pneumatic valve diagrams is crucial for businesses looking to optimize their pneumatic systems. For international B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe, sourcing the right pneumatic valve solutions can be a daunting task. The challenge lies not only in identifying the appropriate types and applications but also in navigating the complex specifications and supplier options available.

This comprehensive guide aims to demystify pneumatic valve diagrams, offering insights into various valve types, including their configurations and functionalities. We will explore practical applications across different industries, helping you understand how to leverage these components effectively. Additionally, we will provide critical information on supplier vetting processes, cost considerations, and best practices for maintaining pneumatic systems.

By equipping you with the knowledge to interpret pneumatic valve diagrams accurately, this guide empowers you to make informed purchasing decisions that align with your operational needs. Whether you are a manufacturer in Germany or a distributor in Nigeria, mastering these essential elements will enhance your ability to source reliable pneumatic solutions, ultimately driving efficiency and productivity in your operations.

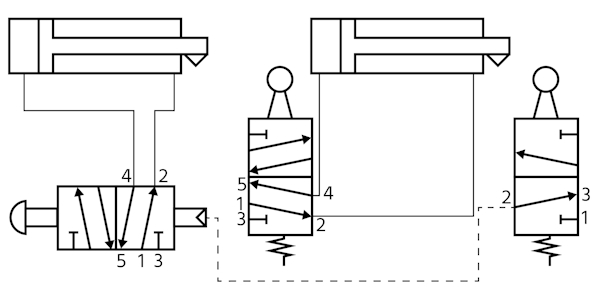

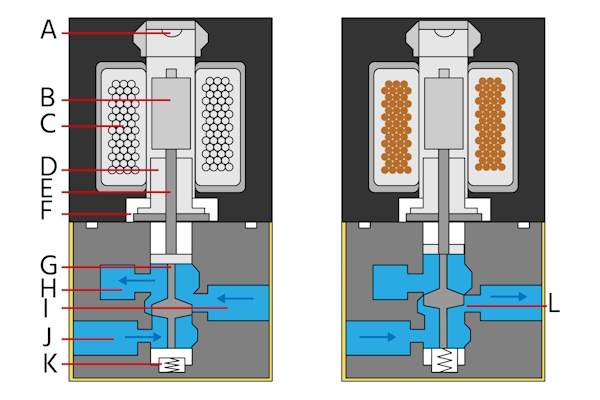

Understanding pneumatic valve diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 2/2-Way Valve | Two ports, two positions; simple on/off control | HVAC systems, pneumatic tools | Pros: Cost-effective, easy to install. Cons: Limited functionality. |

| 3/2-Way Valve | Three ports, two positions; allows for exhaust control | Automation, packaging machinery | Pros: Versatile, suitable for various applications. Cons: More complex than 2/2-way. |

| 4/2-Way Valve | Four ports, two positions; controls flow direction | Robotics, material handling | Pros: Efficient flow management. Cons: Higher cost and complexity. |

| 5/2-Way Valve | Five ports, two positions; commonly used for double-acting cylinders | Industrial automation, assembly lines | Pros: Supports dual action, flexible. Cons: Requires more space for installation. |

| 3-Position Valve | Three positions; can hold a cylinder in place | Sequential operations, conveyor systems | Pros: Allows precise control; can hold positions. Cons: More complicated to operate. |

What Are the Characteristics of a 2/2-Way Valve and Its Applications?

The 2/2-way valve is the most basic type of pneumatic valve, featuring two ports and two positions. It typically functions as an on/off switch for air flow, making it ideal for simple applications such as HVAC systems and pneumatic tools. Buyers should consider its cost-effectiveness and ease of installation, but they should also be aware of its limitations in functionality, as it cannot control flow direction or exhaust.

Illustrative image related to pneumatic valve diagram

How Does a 3/2-Way Valve Work and Where Is It Used?

The 3/2-way valve includes three ports and two positions, allowing for more flexibility than the 2/2-way valve. It can direct air flow to different paths and is often used in automation and packaging machinery. For B2B buyers, its versatility is a significant advantage, though its complexity may require additional training for operators, which could incur extra costs.

What Makes a 4/2-Way Valve Suitable for Robotics?

The 4/2-way valve has four ports and two positions, enabling it to control the direction of air flow effectively. This valve type is commonly utilized in robotics and material handling systems where precise control is essential. While it offers efficient flow management, B2B buyers should consider the higher cost and complexity involved in its operation compared to simpler valve types.

Why Choose a 5/2-Way Valve for Industrial Automation?

The 5/2-way valve consists of five ports and is designed for double-acting cylinders, making it a staple in industrial automation and assembly lines. Its ability to support dual action provides flexibility in application. However, buyers must keep in mind that the installation requires more space and can be more expensive than simpler valve types, which may affect budgeting and planning.

What Are the Benefits of Using a 3-Position Valve?

A 3-position valve can hold a cylinder in place, offering three distinct positions for precise control. This makes it particularly useful in sequential operations and conveyor systems where exact positioning is critical. While it allows for enhanced control, the added complexity may require specialized training for staff, impacting operational efficiency and costs for businesses.

Key Industrial Applications of pneumatic valve diagram

| Industry/Sector | Specific Application of pneumatic valve diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automation of assembly lines using pneumatic control systems | Increased efficiency and reduced labor costs | Compatibility with existing systems and maintenance support |

| Food and Beverage | Control of packaging machinery in production lines | Enhanced productivity and quality control | Compliance with food safety standards and reliability |

| Oil and Gas | Regulation of pressure in pipelines and drilling operations | Improved safety and operational efficiency | Durability and resistance to harsh environments |

| Automotive | Actuation of systems for vehicle assembly and testing | Streamlined production processes and reduced downtime | Precision in valve specifications and supplier reliability |

| Pharmaceuticals | Management of fluid systems in drug manufacturing | Consistency in production and adherence to regulations | Certifications and adaptability to various applications |

How Are Pneumatic Valve Diagrams Used in Manufacturing Automation?

In the manufacturing sector, pneumatic valve diagrams are essential for automating assembly lines. These diagrams help engineers design and implement pneumatic control systems that efficiently manage air flow to various actuators and machinery. By utilizing these diagrams, manufacturers can troubleshoot and maintain their systems effectively, leading to increased efficiency and reduced labor costs. International buyers, particularly in regions like Africa and South America, should consider compatibility with existing systems and the availability of maintenance support when sourcing these components.

What Role Do Pneumatic Valve Diagrams Play in the Food and Beverage Industry?

In the food and beverage industry, pneumatic valve diagrams are crucial for controlling packaging machinery. These diagrams enable precise control of air flow, which is vital for maintaining high productivity and quality standards. By ensuring accurate actuation of machinery, companies can significantly reduce waste and enhance the efficiency of their production lines. Buyers in this sector must prioritize suppliers who comply with food safety standards and can guarantee the reliability of their products to avoid costly downtimes.

How Are Pneumatic Valve Diagrams Important for Oil and Gas Operations?

Pneumatic valve diagrams are pivotal in the oil and gas industry for regulating pressure in pipelines and drilling operations. These diagrams facilitate the design of systems that ensure safe and efficient flow control, which is essential in high-stakes environments. By utilizing these diagrams, companies can enhance safety and operational efficiency, minimizing the risk of accidents. Buyers should focus on sourcing durable valves that can withstand harsh environmental conditions, as well as ensuring that suppliers provide robust technical support.

In What Ways Are Pneumatic Valve Diagrams Utilized in Automotive Production?

In the automotive industry, pneumatic valve diagrams are employed to actuate various systems used in vehicle assembly and testing. These diagrams help streamline production processes, leading to reduced downtime and increased output. Accurate valve specifications are critical in this sector, as they directly impact the performance of assembly line equipment. International buyers should consider the precision of valve specifications and the reliability of suppliers to ensure smooth operations in their manufacturing processes.

How Do Pneumatic Valve Diagrams Support Pharmaceutical Manufacturing?

In pharmaceuticals, pneumatic valve diagrams are used to manage fluid systems essential for drug manufacturing. These diagrams allow for precise control of air flow, which is necessary for maintaining consistency in production and adhering to strict regulatory standards. Businesses in this sector benefit from improved quality control and operational efficiency. Buyers should look for suppliers that hold relevant certifications and can adapt their products to various applications, ensuring compliance with industry regulations.

3 Common User Pain Points for ‘pneumatic valve diagram’ & Their Solutions

Scenario 1: Difficulty in Interpreting Complex Pneumatic Valve Diagrams

The Problem:

B2B buyers, particularly engineers and technicians, often encounter intricate pneumatic valve diagrams that can be overwhelming. The complexity arises from various symbols and notations that represent different valve positions, flow paths, and actuation methods. Misinterpretation can lead to improper installations, costly downtime, or even safety hazards in industrial environments. This challenge is particularly pronounced for teams who may not have extensive experience with pneumatic systems or who are working with new equipment.

The Solution:

To navigate these complexities, it is essential to invest in training and resources that enhance diagram literacy. Start by sourcing comprehensive guides that break down pneumatic circuit symbols in a user-friendly format. Manufacturers often provide detailed legend documents that explain each symbol’s meaning, including common valve types and their functions. Additionally, consider utilizing interactive online tools or software that allow users to visualize and manipulate pneumatic diagrams, making it easier to understand how different components interact. Regular workshops and hands-on training can further solidify this knowledge, ensuring that all team members can confidently interpret and apply pneumatic valve diagrams in real-world applications.

Scenario 2: Inadequate Sourcing of the Right Pneumatic Valves Based on Diagrams

The Problem:

When attempting to source pneumatic valves, B2B buyers frequently struggle to find the right components that match the specifications outlined in the diagrams. This issue is exacerbated when suppliers offer limited product lines or fail to provide adequate technical documentation. Misalignment between the valve’s capabilities as depicted in the diagram and the actual performance can result in operational inefficiencies and increased costs for businesses.

The Solution:

To mitigate this challenge, establish a structured sourcing process that prioritizes collaboration with reputable suppliers who provide detailed product specifications aligned with pneumatic valve diagrams. Before making any purchases, create a checklist based on the diagram that includes critical factors such as the number of ports, actuation type, and flow direction. Engage in open discussions with suppliers about your specific application needs, and request samples or trial periods for critical components. Additionally, leveraging online platforms that aggregate various manufacturers’ products can help streamline the comparison process, ensuring that the valves sourced meet the requirements depicted in your diagrams.

Scenario 3: Inefficient Troubleshooting and Maintenance Procedures

The Problem:

B2B buyers often face challenges when troubleshooting pneumatic systems due to a lack of clear understanding of the valve diagrams. In environments where multiple valves are interconnected, pinpointing the source of a malfunction can be time-consuming and frustrating. This inefficiency not only affects productivity but can also lead to increased repair costs if the wrong components are replaced.

The Solution:

To enhance troubleshooting efficiency, create a centralized documentation repository that includes all pneumatic valve diagrams used in your systems, annotated with operational notes and maintenance history. Implement a standardized troubleshooting protocol that utilizes these diagrams to guide technicians step-by-step through the diagnostic process. Encourage the use of digital tools that can overlay real-time data onto valve diagrams, providing insights into performance metrics and alerts for potential issues. Investing in maintenance training that emphasizes the importance of understanding diagrammatic representations can empower your team to quickly identify and resolve issues, minimizing downtime and associated costs.

Strategic Material Selection Guide for pneumatic valve diagram

What Are the Key Materials Used in Pneumatic Valve Diagrams?

When selecting materials for pneumatic valve diagrams, it is essential to consider the properties, advantages, disadvantages, and application impacts of various materials. Below, we analyze four common materials used in the manufacturing of pneumatic valves: aluminum, brass, stainless steel, and plastic.

Illustrative image related to pneumatic valve diagram

How Does Aluminum Perform in Pneumatic Valve Applications?

Aluminum is a lightweight and corrosion-resistant material commonly used in pneumatic valves. It typically has a temperature rating of up to 150°C and can withstand moderate pressures. The key advantages of aluminum include its low weight, which facilitates easier handling and installation, and its resistance to corrosion, making it suitable for various environments.

However, aluminum’s lower strength compared to metals like stainless steel can be a limitation in high-pressure applications. Additionally, while it is generally cost-effective, the manufacturing complexity can increase if specialized coatings are required for enhanced durability. For international buyers, particularly in regions like Africa and South America, aluminum valves may meet local standards, but compliance with international standards such as ASTM or DIN should be verified.

What Are the Benefits of Using Brass in Pneumatic Valves?

Brass is another popular material for pneumatic valves, known for its excellent machinability and corrosion resistance. It can handle temperatures up to 200°C and is suitable for moderate to high-pressure applications. The primary advantage of brass is its durability and resistance to wear, making it ideal for long-term use in various industrial settings.

On the downside, brass can be more expensive than aluminum, and its weight may pose challenges in applications where weight reduction is critical. Additionally, brass is susceptible to dezincification in certain environments, which can compromise its integrity. Buyers in Europe, particularly Germany, should ensure that the brass used complies with relevant material standards to avoid issues related to quality and performance.

Why Choose Stainless Steel for Pneumatic Valves?

Stainless steel is renowned for its exceptional strength, corrosion resistance, and high-temperature tolerance, making it suitable for demanding applications. It can withstand temperatures exceeding 300°C and high pressures, which makes it ideal for heavy-duty industrial environments. The key advantage of stainless steel is its longevity and reliability, reducing the need for frequent replacements.

However, the higher cost of stainless steel compared to other materials can be a significant drawback for budget-conscious projects. Additionally, its weight can complicate installation. For international buyers, especially in the Middle East, compliance with standards such as JIS and ASTM is crucial, as the material’s quality can directly impact operational safety and efficiency.

When Is Plastic the Right Choice for Pneumatic Valves?

Plastic materials, such as polycarbonate and nylon, are increasingly used in pneumatic valves due to their lightweight nature and resistance to corrosion. They are typically rated for temperatures up to 80°C and are suitable for low-pressure applications. The primary advantage of plastic is its cost-effectiveness and versatility in various environments.

However, plastics generally have lower strength and temperature resistance compared to metals, limiting their use in high-pressure or high-temperature applications. Additionally, compatibility with specific media must be assessed, as certain chemicals can degrade plastic materials. For buyers from Africa and South America, understanding local regulations regarding plastic use in industrial applications is critical to ensure compliance.

Summary of Material Selection for Pneumatic Valve Diagrams

| Material | Typical Use Case for pneumatic valve diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight valves in moderate pressure applications | Corrosion resistance and low weight | Lower strength than metals | Low |

| Brass | Industrial valves requiring durability | Excellent machinability and wear resistance | Higher cost and dezincification risk | Medium |

| Stainless Steel | Heavy-duty valves in high-pressure environments | Exceptional strength and longevity | Higher cost and weight | High |

| Plastic | Low-pressure applications in various environments | Cost-effective and versatile | Lower strength and temperature limits | Low |

This analysis provides B2B buyers with a comprehensive overview of the materials used in pneumatic valve diagrams, enabling informed decisions based on application requirements and regional considerations.

Illustrative image related to pneumatic valve diagram

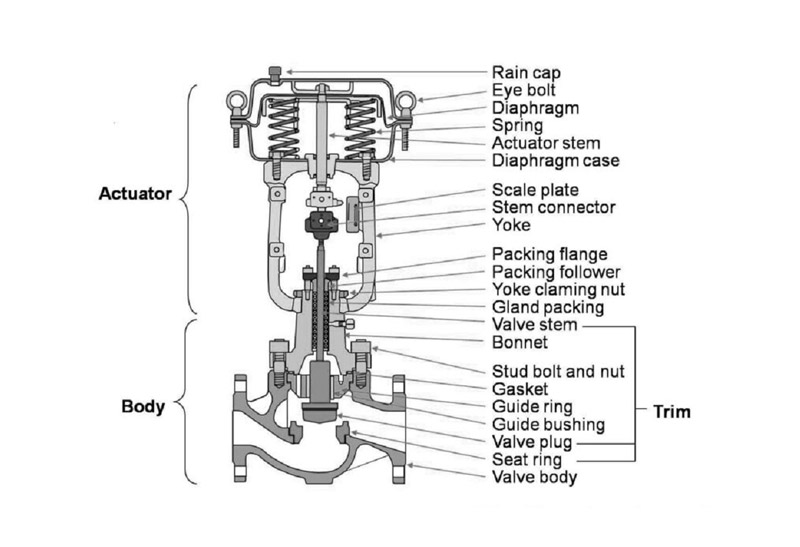

In-depth Look: Manufacturing Processes and Quality Assurance for pneumatic valve diagram

What Are the Main Stages of Manufacturing Pneumatic Valves?

Manufacturing pneumatic valves involves a series of well-defined stages, each critical to ensuring the final product meets industry standards and customer expectations. The primary stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Pneumatic Valve Manufacturing?

The manufacturing process begins with material selection, where manufacturers typically choose high-quality metals like aluminum, brass, or stainless steel, depending on the valve’s application. The selected materials undergo rigorous testing for tensile strength, corrosion resistance, and compatibility with the gases or fluids they will control.

Once materials are confirmed, they are cut into appropriate sizes using CNC machines or laser cutting techniques, ensuring precision and reducing waste. This stage may also include surface treatments such as anodizing or galvanizing to enhance durability and resistance against environmental factors.

What Forming Techniques Are Used in Pneumatic Valve Production?

Forming is a crucial stage where the prepared materials are shaped into the required components of the pneumatic valve. Techniques such as machining, forging, and stamping are commonly employed.

- Machining: Involves removing material from a solid block to create intricate valve designs. CNC (Computer Numerical Control) machines are often used for high precision.

- Forging: This technique uses compressive forces to shape the metal, resulting in a stronger component due to the alignment of the metal grains.

- Stamping: Utilized for creating flat components, stamping is efficient for high-volume production and offers cost advantages.

After forming, components are inspected for dimensional accuracy and surface integrity, ensuring they meet the specifications outlined in the design phase.

How Are Pneumatic Valves Assembled?

The assembly stage is where the individual components come together to form a complete pneumatic valve. This process can be manual or automated, depending on the complexity of the valve and production volume.

Illustrative image related to pneumatic valve diagram

During assembly, careful attention is paid to aligning components and ensuring seals and gaskets are properly fitted to prevent leaks. Each valve is typically tested for functionality at this stage, with operators checking for correct actuation and flow paths according to the valve diagram specifications.

What Finishing Processes Are Applied to Pneumatic Valves?

Finishing processes enhance both the aesthetic and functional properties of pneumatic valves. Common finishing techniques include:

- Painting and Coating: Protective coatings are applied to prevent corrosion and wear.

- Polishing: Enhances the appearance and smoothness of the valve surfaces, which can reduce friction and improve performance.

- Final Inspection: Each finished valve undergoes a thorough inspection to verify that it meets all specifications and is free from defects before packaging and shipping.

What Quality Assurance Practices Are Essential for Pneumatic Valve Manufacturing?

Quality assurance (QA) is critical in the manufacturing of pneumatic valves, especially for B2B buyers who require reliable and high-performing products. Implementing a robust QA system helps ensure compliance with international standards and enhances customer trust.

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers of pneumatic valves typically adhere to various international quality standards to ensure product reliability and safety. Key standards include:

- ISO 9001: This standard focuses on quality management systems, emphasizing continuous improvement and customer satisfaction.

- CE Marking: Required for products sold within the European Economic Area (EEA), it indicates compliance with safety, health, and environmental protection standards.

- API (American Petroleum Institute): Relevant for valves used in the oil and gas industry, these standards ensure that products meet specific performance and safety requirements.

Understanding these standards helps B2B buyers assess the credibility of suppliers and their commitment to quality.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure adherence to specifications. Key checkpoints include:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon delivery, ensuring they meet required specifications before use.

- In-Process Quality Control (IPQC): Conducted at various stages of the manufacturing process, IPQC involves monitoring production to identify any deviations from quality standards.

- Final Quality Control (FQC): A comprehensive inspection of the finished product before it is shipped to customers. This includes functional testing, dimensional verification, and visual inspections.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying the quality control processes of suppliers is essential to ensure they are receiving reliable products. Here are some effective methods:

What Role Do Audits and Reports Play in Supplier Quality Verification?

Conducting audits of suppliers allows buyers to assess their manufacturing processes and quality control systems directly. During an audit, buyers can review documentation, observe manufacturing practices, and verify compliance with international standards.

Additionally, suppliers should provide quality assurance reports, detailing inspection results, test data, and certifications. This transparency helps buyers confirm that the supplier adheres to necessary quality standards.

How Can Third-Party Inspections Enhance Supplier Reliability?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspections can be scheduled at various stages of production, offering an additional layer of assurance that the products meet specified standards.

Third-party inspectors can also provide valuable insights and recommendations for improvement, further enhancing the supplier’s quality assurance practices.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate additional complexities in quality control.

How Do Regional Regulations Impact Quality Assurance?

Different regions may have specific regulations and standards that affect pneumatic valve manufacturing. Buyers must be aware of local requirements and ensure that suppliers comply with them. This may involve additional certifications or testing that are specific to the region.

What Should Buyers Consider Regarding Supply Chain Transparency?

Supply chain transparency is crucial for international buyers to ensure ethical sourcing and quality assurance. Buyers should inquire about the origins of materials, labor practices, and the environmental impact of the manufacturing processes.

By addressing these factors, B2B buyers can make informed decisions and foster long-term partnerships with suppliers committed to quality and sustainability.

In conclusion, understanding the manufacturing processes and quality assurance measures for pneumatic valves equips B2B buyers with the insights needed to select reliable suppliers and ensure they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pneumatic valve diagram’

In the competitive landscape of industrial automation, understanding and procuring pneumatic valve diagrams is essential for optimizing system design and maintenance. This guide will equip B2B buyers with a practical checklist to ensure they source the right pneumatic valve diagrams effectively, facilitating enhanced operational efficiency and reliability.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements for pneumatic valve diagrams. Identify the specific types of valves needed (e.g., 2/2-way, 3/2-way) and their applications in your systems. This clarity will help you communicate effectively with suppliers and ensure they provide diagrams that meet your operational needs.

Step 2: Research Trusted Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the industry. Look for companies that specialize in pneumatic components and have a track record of providing high-quality diagrams. Prioritize suppliers who demonstrate expertise through certifications, industry standards compliance, and positive customer testimonials.

- Consider regional expertise: Suppliers with experience in your market (e.g., Africa, South America, Europe) may better understand local regulations and operational challenges.

Step 3: Evaluate Supplier Credentials

Before committing, it’s crucial to vet potential suppliers thoroughly. Request company profiles, product portfolios, and case studies that showcase their expertise in pneumatic systems. Ensure they have relevant certifications, such as ISO or equivalent, which indicate adherence to quality and safety standards.

- Ask for references: Speak with other businesses in your industry to gauge their experiences with the supplier.

Step 4: Request Detailed Diagrams

Once you’ve shortlisted potential suppliers, request samples of their pneumatic valve diagrams. Assess these diagrams for clarity, accuracy, and comprehensiveness. Ensure they include essential details such as actuating methods, flow paths, and port labeling, which are crucial for installation and maintenance.

- Check for compatibility: Confirm that the diagrams align with the specific valves you plan to use in your systems.

Step 5: Clarify Support and Documentation

Inquire about the level of technical support and documentation provided with the pneumatic valve diagrams. Quality suppliers should offer detailed explanations, troubleshooting guides, and installation manuals. This support is invaluable for ensuring proper implementation and maintenance of pneumatic systems.

- Look for additional resources: Suppliers who provide training or workshops can help your team better understand the diagrams and their applications.

Step 6: Negotiate Terms and Pricing

Discuss pricing structures and payment terms with your selected suppliers. Be clear about your budget constraints and seek to understand the value offered, not just the cost. A supplier that provides comprehensive support and high-quality diagrams may justify a higher price point.

- Consider long-term partnerships: Building a relationship with a reliable supplier can lead to better pricing and service over time.

Step 7: Finalize Your Order with Care

After evaluating all aspects, finalize your order with the chosen supplier. Ensure that all agreements regarding delivery timelines, warranty terms, and after-sales support are documented. This precaution helps mitigate risks associated with procurement and ensures a smoother implementation process.

By following this practical checklist, B2B buyers can effectively navigate the procurement of pneumatic valve diagrams, ensuring they choose suppliers that meet their technical needs while fostering operational efficiency in their automation systems.

Comprehensive Cost and Pricing Analysis for pneumatic valve diagram Sourcing

Understanding the cost structure and pricing dynamics of pneumatic valve diagrams is crucial for international B2B buyers, especially those operating in regions such as Africa, South America, the Middle East, and Europe. The following analysis breaks down the various components that influence costs and pricing in this niche market.

What Are the Key Cost Components in Pneumatic Valve Diagram Sourcing?

Materials

The choice of materials significantly impacts the overall cost of pneumatic valves. Common materials include aluminum, brass, and various plastics. High-quality materials often come at a premium but can enhance durability and performance, making them a better long-term investment.

Labor

Labor costs vary by region and depend on the complexity of the manufacturing process. Skilled labor is often required for assembly and quality control, especially for custom valves that need precise specifications. Countries with higher labor costs may lead to increased pricing, while regions with lower labor costs can offer competitive pricing.

Illustrative image related to pneumatic valve diagram

Manufacturing Overhead

This encompasses indirect costs associated with production, including utilities, facility maintenance, and administrative expenses. Companies with efficient operations may pass savings onto buyers, making it essential to evaluate potential suppliers’ operational efficiencies.

Tooling

Initial tooling costs can be substantial, especially for custom designs. Buyers should inquire about tooling fees, as these costs can be amortized over larger orders, reducing the per-unit price in high-volume purchases.

Quality Control (QC)

Investing in robust quality control processes can add to upfront costs but ultimately ensures product reliability and compliance with industry standards. Certifications like ISO 9001 can enhance a supplier’s credibility and justify higher prices.

Logistics

Shipping costs, including freight and insurance, can significantly influence the total cost of procurement. Factors such as Incoterms, shipping distance, and mode of transport (air vs. sea) should be considered. Buyers should assess logistics capabilities when evaluating suppliers, particularly for international shipments.

Margin

Suppliers typically mark up their prices to cover costs and ensure profit margins. Understanding the average margin in the industry can help buyers negotiate better deals.

What Influences Pricing for Pneumatic Valve Diagrams?

Volume/MOQ (Minimum Order Quantity)

Pricing often reflects the volume of the order. Suppliers may offer discounts for larger orders, which can lead to significant cost savings. However, buyers should carefully assess their needs to avoid overcommitting.

Specifications and Customization

Custom designs or specific features will typically come at a higher price point. Buyers should clearly communicate their requirements to avoid unexpected costs and ensure the supplier can meet their specifications.

Quality and Certifications

High-quality valves that meet international standards may command higher prices. Buyers in regulated industries or those seeking long-term reliability should prioritize suppliers with recognized certifications.

Supplier Factors

The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record and service levels, while newer entrants might offer competitive pricing to gain market share.

Incoterms

Understanding Incoterms is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine who bears the cost and risk at different stages of shipping, affecting the overall price.

Illustrative image related to pneumatic valve diagram

What Negotiation Strategies Can Buyers Employ?

Buyers should approach negotiations with a clear understanding of their total cost of ownership, which includes purchase price, logistics, and potential future maintenance costs. Engaging in discussions about volume discounts, payment terms, and delivery schedules can yield favorable terms. Additionally, establishing long-term relationships with suppliers can lead to better pricing over time.

What Pricing Nuances Should International Buyers Consider?

International buyers must be aware of currency fluctuations, tariffs, and trade regulations that can impact pricing. In regions such as Africa and South America, where trade dynamics may differ from Europe, understanding local market conditions is crucial. It’s advisable to conduct thorough market research and possibly consult local experts to navigate these complexities effectively.

Disclaimer for Indicative Prices

Prices for pneumatic valve diagrams can vary widely based on the factors mentioned above. This analysis provides a general framework but may not reflect specific market conditions or pricing strategies. Buyers should seek quotes directly from suppliers for accurate pricing tailored to their needs.

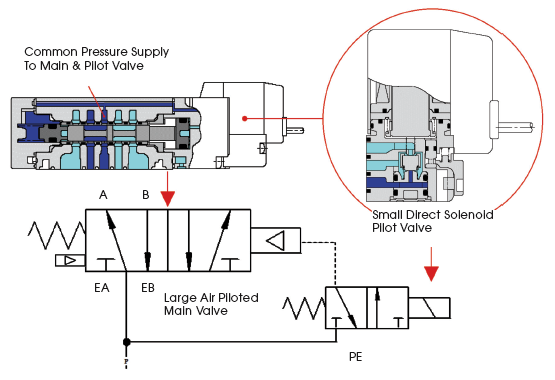

Alternatives Analysis: Comparing pneumatic valve diagram With Other Solutions

Exploring Alternatives to Pneumatic Valve Diagrams

In the realm of pneumatic control systems, understanding and interpreting valve diagrams is crucial for effective design and operation. However, there are alternative methods and technologies that can also facilitate similar objectives, such as controlling air flow and automating processes. This analysis will compare pneumatic valve diagrams with two viable alternatives: hydraulic valve diagrams and electronic control systems, each offering unique advantages and drawbacks.

Comparison Table

| Comparison Aspect | Pneumatic Valve Diagram | Hydraulic Valve Diagram | Electronic Control Systems |

|---|---|---|---|

| Performance | Efficient for air flow control; limited to pneumatic applications | High force output; suitable for heavy loads | High precision; can control various parameters |

| Cost | Generally lower cost; requires less maintenance | Higher cost due to hydraulic components | Variable cost; can be high due to complexity |

| Ease of Implementation | Straightforward for pneumatic systems | Requires specialized knowledge for setup | Complex; requires programming and integration |

| Maintenance | Lower maintenance requirements; easier troubleshooting | Higher maintenance due to fluid management | Variable; depends on system complexity |

| Best Use Case | Ideal for light to medium applications | Best for heavy machinery and industrial applications | Suitable for advanced automation and integration |

Detailed Breakdown of Alternatives

Hydraulic Valve Diagrams

Hydraulic valve diagrams serve as a representation for fluid power systems, showcasing how hydraulic fluid is controlled within machinery. The primary advantage of hydraulic systems is their ability to generate significant force, making them ideal for heavy-duty applications like construction and manufacturing. However, they come with higher costs due to the complexity of hydraulic components and require specialized knowledge for effective implementation and maintenance. While they excel in power output, they may not be as efficient in energy consumption compared to pneumatic systems.

Electronic Control Systems

Electronic control systems utilize advanced technology to manage pneumatic or hydraulic operations through software and sensors. These systems offer high precision and flexibility, allowing for real-time monitoring and adjustments. They can integrate with other systems and provide comprehensive data analytics, which is beneficial for optimizing performance. However, the initial setup costs can be substantial, and the complexity of programming may require skilled personnel. For businesses looking for automation and data-driven decision-making, electronic control systems provide robust solutions but at a higher investment.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a control system for your business, it’s essential to consider the specific requirements of your applications. Pneumatic valve diagrams are best suited for straightforward, cost-effective solutions in environments where air pressure is the primary medium. In contrast, hydraulic valve diagrams may be preferable for tasks requiring significant force, while electronic control systems are ideal for organizations seeking advanced automation and data insights. Evaluating factors such as performance needs, budget constraints, and implementation complexity will guide B2B buyers in making informed decisions that align with their operational objectives.

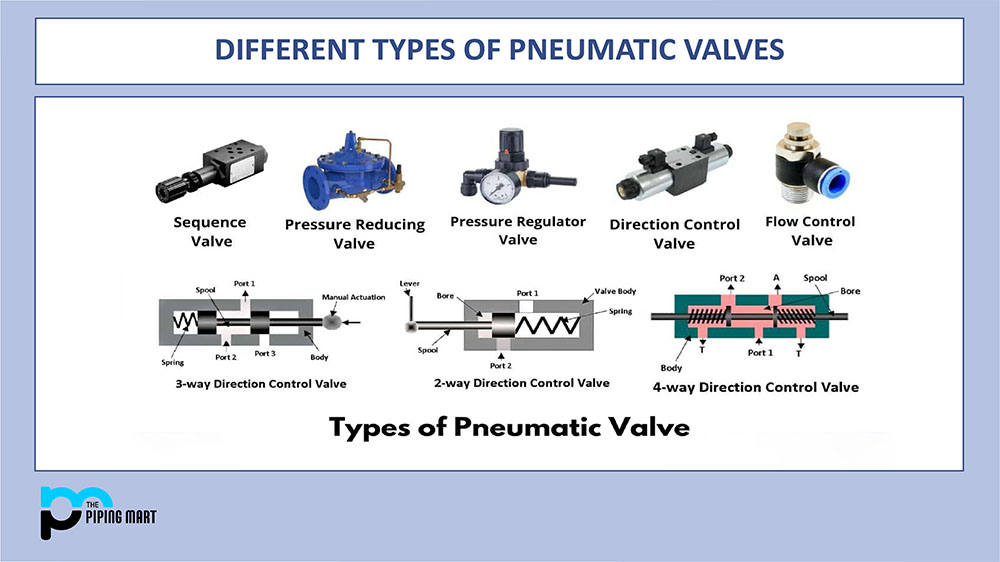

Essential Technical Properties and Trade Terminology for pneumatic valve diagram

What Are the Critical Technical Properties of Pneumatic Valve Diagrams?

Understanding the technical properties of pneumatic valve diagrams is crucial for B2B buyers engaged in the procurement of pneumatic components. Here are some key specifications that should be considered:

1. Material Grade

The materials used in pneumatic valves significantly influence their performance and durability. Common materials include aluminum, brass, and stainless steel. Each material has different properties, such as corrosion resistance and weight, which can affect the overall application. For example, stainless steel is ideal for harsh environments, whereas aluminum is lightweight and suitable for less demanding applications. Selecting the right material can reduce maintenance costs and increase the lifespan of the valve.

2. Pressure Rating

The pressure rating of a valve indicates the maximum pressure it can safely handle without failure. This is typically expressed in bar or psi. For B2B buyers, understanding the pressure requirements of the specific application is essential for ensuring safety and functionality. Choosing a valve with an adequate pressure rating can prevent catastrophic failures and costly downtime.

3. Flow Rate

Flow rate, measured in liters per minute (L/min) or cubic feet per minute (CFM), indicates how much air can pass through the valve in a given time. This property is vital for applications requiring specific air volumes for optimal performance. Buyers must match the flow rate of the valve to the requirements of the pneumatic system to ensure efficiency and effectiveness.

4. Port Configuration

The port configuration specifies the number of ports and their arrangement. Common configurations include 2/2-way and 3/2-way valves, which refer to the number of ports and positions available for air flow. Understanding the port configuration is critical for proper installation and integration into existing systems. A mismatch can lead to inefficient operation or the inability to connect to other components.

5. Actuation Method

Pneumatic valves can be actuated manually, electrically, or pneumatically. The choice of actuation method affects how the valve operates within the system. For instance, electrically actuated valves offer precision and automation, while manual valves are often used for simpler, direct control. B2B buyers should consider the operational requirements and automation level of their systems when selecting the actuation method.

What Are Common Trade Terms in the Pneumatic Valve Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of pneumatic valves, understanding OEM specifications can help buyers ensure compatibility and quality in their systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. This term is crucial for buyers as it can impact inventory levels and cost per unit. Understanding the MOQ helps in budgeting and planning procurement strategies.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests price quotes from suppliers. This process allows buyers to compare prices and terms, ensuring they make informed purchasing decisions. An effective RFQ can lead to better negotiation outcomes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for understanding shipping responsibilities, risk management, and delivery timelines, which can significantly affect the total cost of procurement.

5. Pneumatic Circuit Symbols

These symbols represent various pneumatic components, including valves, in diagrams. Understanding these symbols is essential for engineers and technicians involved in the design and maintenance of pneumatic systems. It allows for accurate communication of system layouts and functionality, ultimately leading to better project outcomes.

By grasping both the technical properties and trade terminology associated with pneumatic valve diagrams, B2B buyers can make informed decisions that enhance the efficiency and effectiveness of their pneumatic systems.

Navigating Market Dynamics and Sourcing Trends in the pneumatic valve diagram Sector

What Are the Key Market Dynamics and Trends Influencing the Pneumatic Valve Diagram Sector?

The pneumatic valve diagram market is experiencing robust growth, driven primarily by the increasing demand for automation across various industries, including manufacturing, automotive, and energy sectors. The global push for efficiency and precision in operations is propelling investments in pneumatic systems, where valve diagrams play a crucial role in design and functionality. For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of pneumatic valve diagrams is essential for optimizing system performance.

Emerging technologies such as Industry 4.0 and the Internet of Things (IoT) are shaping sourcing trends, with a growing emphasis on smart pneumatic systems that offer real-time monitoring and control. This trend is particularly relevant for buyers in technologically advanced markets like Germany, where automation is integral to industrial processes. Moreover, the integration of AI-driven analytics into pneumatic systems is enabling predictive maintenance, thus reducing downtime and enhancing operational efficiency.

In addition to technological advancements, sustainability is becoming a focal point in sourcing decisions. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmentally friendly practices and materials. This shift is particularly pronounced in regions like Europe, where stringent regulations and consumer preferences are driving demand for sustainable pneumatic solutions.

How Is Sustainability and Ethical Sourcing Shaping the Pneumatic Valve Diagram Market?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the pneumatic valve diagram sector. The environmental impact of pneumatic systems, including energy consumption and waste generation, necessitates a focus on sustainable practices. Buyers are increasingly seeking suppliers who utilize eco-friendly materials and manufacturing processes, as well as those who hold certifications such as ISO 14001, which denotes a commitment to effective environmental management.

Ethical supply chains are not only about reducing environmental footprints; they also encompass fair labor practices and transparency in sourcing. Buyers are advised to conduct thorough due diligence on potential suppliers to ensure adherence to ethical standards. This is particularly relevant in emerging markets where regulatory frameworks may be less stringent. By prioritizing suppliers who align with sustainability goals, B2B buyers can enhance their brand reputation and meet the expectations of environmentally conscious customers.

Furthermore, the adoption of “green” certifications for pneumatic components is becoming a competitive differentiator. Suppliers who can demonstrate compliance with sustainability standards are likely to gain favor with buyers who prioritize long-term partnerships based on shared values.

What Is the Historical Context of Pneumatic Valve Diagrams in B2B Sourcing?

The evolution of pneumatic valve diagrams dates back to the early 20th century, with the advent of pneumatic systems designed for industrial automation. Initially, these diagrams served primarily as technical illustrations for engineers and technicians, facilitating the understanding of valve functions and flow paths. Over the decades, advancements in materials and technology have significantly enhanced the complexity and efficiency of pneumatic systems.

In the late 20th century, the introduction of computer-aided design (CAD) tools revolutionized how pneumatic valve diagrams are created and interpreted, allowing for greater precision and customization. Today, these diagrams are indispensable in designing, maintaining, and troubleshooting pneumatic systems, playing a pivotal role in ensuring operational efficiency and safety.

For B2B buyers, this historical context underscores the importance of staying informed about the latest developments in pneumatic valve technology and sourcing practices. Understanding the evolution of pneumatic valve diagrams can aid buyers in making informed decisions that align with current industry standards and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of pneumatic valve diagram

-

How do I solve issues with interpreting pneumatic valve diagrams?

To effectively interpret pneumatic valve diagrams, familiarize yourself with the standard symbols and their meanings, such as the actuation methods, positions, and flow paths. Start by identifying the actuator type—manual, solenoid, or pilot-operated—and check the flow direction indicated by arrows. Additionally, refer to manufacturer-specific documentation or online resources that provide interactive diagrams to enhance your understanding. If problems persist, consulting with a technical expert can help clarify any remaining uncertainties. -

What is the best pneumatic valve diagram for specific applications?

The best pneumatic valve diagram depends on your application requirements. For simple on/off control, a 2/2-way valve is typically sufficient. For more complex tasks, such as controlling double-acting cylinders or sequential operations, consider 3/2-way or 5/2-way valves. Always evaluate the flow requirements, pressure ratings, and specific functionalities needed for your machinery. Consulting with a knowledgeable supplier can help you select the most suitable valve type and diagram for your system. -

What should I consider when sourcing pneumatic valve diagrams internationally?

When sourcing pneumatic valve diagrams internationally, consider factors such as compliance with local regulations and standards, the supplier’s reputation, and their ability to provide detailed technical documentation. It’s essential to verify if the diagrams align with your specific application needs and whether the supplier can offer customization options. Additionally, assess logistics, shipping costs, and delivery timelines to ensure timely project execution. -

How can I vet suppliers for pneumatic valve diagrams?

To vet suppliers, begin by checking their industry certifications and customer reviews. Request references from previous clients to gauge reliability and product quality. It’s also beneficial to assess their technical expertise—ensure they can provide comprehensive diagrams and support. Engage in direct communication to discuss your specific needs and evaluate their responsiveness. Finally, consider suppliers with established distribution networks in your region to facilitate smoother transactions. -

What are the minimum order quantities (MOQ) for pneumatic valve diagrams?

Minimum order quantities (MOQ) can vary significantly among suppliers, often depending on the complexity of the diagrams and the valve types. Some suppliers may offer low MOQs for standard products, while customized diagrams might require larger orders. When negotiating, be clear about your project needs and explore options for flexibility in MOQs, especially if you’re testing new suppliers or products. -

What payment terms should I expect when purchasing pneumatic valve diagrams?

Payment terms can vary widely depending on the supplier and your relationship with them. Common arrangements include upfront payments, partial payments upon order confirmation, or payment upon delivery. International transactions may involve letters of credit or escrow services for added security. Always clarify payment terms before finalizing the agreement to avoid misunderstandings and ensure a smooth purchasing process. -

How do quality assurance measures impact pneumatic valve diagrams?

Quality assurance (QA) measures are critical in ensuring that pneumatic valve diagrams accurately reflect the product’s functionality and reliability. Look for suppliers that adhere to international quality standards, such as ISO certifications. QA processes should include thorough testing of the valves and their corresponding diagrams to prevent operational failures. Request documentation that demonstrates the supplier’s commitment to quality, including test results and compliance certifications. -

What logistics considerations should I keep in mind for importing pneumatic valve diagrams?

When importing pneumatic valve diagrams, consider the logistics aspects such as shipping methods, lead times, and customs regulations in your country. Collaborate with suppliers who have experience in international shipping to mitigate potential delays. Ensure that all necessary documentation, including commercial invoices and customs declarations, is prepared correctly. Additionally, factor in shipping costs and potential tariffs, which can significantly impact your overall project budget.

Top 4 Pneumatic Valve Diagram Manufacturers & Suppliers List

1. AutomationDirect – Pneumatic Circuit Symbols

Domain: library.automationdirect.com

Registered: 1999 (26 years)

Introduction: Pneumatic circuit symbols represent directional air control valves, indicating methods of actuation, number of positions, flow paths, and number of ports. Valve symbols consist of actuators, position and flow boxes, and flow direction arrows. Each valve has at least two positions and flow boxes. The number of ports is shown by endpoints in flow boxes, with standard port labels including ‘P’ for pr…

2. Reddit – Pneumatic Valves Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Pneumatic valves are used in pneumatic systems and can include types such as 4-position 2-way valves. Resources for understanding pneumatic valves include technical documentation from companies like Festo and SMC, which provide guides on pneumatic basics and schematic diagrams. Important considerations in pneumatic systems include minimum flow rates and pressure drops.

3. Airline Hyd – Pneumatic Symbols Guide

Domain: blog.airlinehyd.com

Registered: 1996 (29 years)

Introduction: Pneumatic symbols are standardized shapes used to represent components in pneumatic systems, facilitating understanding, design, and troubleshooting. They follow ISO standards (like ISO 1219) and include symbols for directional control valves, flow control valves, and actuators. Directional control valves are essential for airflow direction, while flow control valves manage actuator speed. Underst…

4. NITRA Pneumatics – Directional Air Control Valves

Domain: automationdirect.com

Registered: 1999 (26 years)

Introduction: NITRA Pneumatics offers a variety of pneumatic components including directional air control valves. These valves are represented by symbols that provide information about their actuation methods, number of positions, flow paths, and ports. Each valve symbol consists of multiple parts, including actuators that shift the valve between positions, and position and flow boxes that indicate the valve’s …

Strategic Sourcing Conclusion and Outlook for pneumatic valve diagram

How Can Strategic Sourcing Enhance Your Pneumatic Valve Procurement?

In the rapidly evolving landscape of pneumatic systems, understanding pneumatic valve diagrams is essential for optimizing operational efficiency and ensuring safety. Key takeaways for international B2B buyers include the importance of selecting the right valve types based on their application needs—whether it’s a 2/2-way valve for simple control or a more complex 3/2-way valve for nuanced operations. Additionally, familiarizing oneself with valve symbols and their functions can significantly streamline design, installation, and maintenance processes.

Strategic sourcing plays a pivotal role in this context, enabling companies to leverage supplier relationships, negotiate favorable terms, and ensure the procurement of high-quality components that meet global standards. By focusing on strategic sourcing, businesses can minimize costs while maximizing performance and reliability in their pneumatic systems.

As you navigate the complexities of sourcing pneumatic valves, consider the diverse markets across Africa, South America, the Middle East, and Europe. Embrace the opportunity to forge partnerships with reputable suppliers and manufacturers who understand regional demands. Equip your organization with the knowledge and tools to make informed decisions, positioning yourself for success in the competitive landscape of pneumatic technology.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.