Diesel Motor Boot: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for diesel motor boot

In the ever-evolving landscape of maritime transportation, sourcing the right diesel motor boot can pose significant challenges for international B2B buyers. With varying regulations, performance standards, and technological advancements across regions, ensuring the selection of a reliable diesel engine is critical for maintaining operational efficiency and compliance. This comprehensive guide delves into the multifaceted world of diesel motor boots, exploring diverse types, applications, and the intricacies of supplier vetting.

Buyers will gain insights into evaluating engine performance, understanding fuel efficiency, and assessing maintenance requirements, all tailored to the unique demands of markets in Africa, South America, the Middle East, and Europe, including Brazil and Vietnam. By providing an in-depth analysis of cost factors and available warranties, this guide equips decision-makers with the knowledge needed to navigate supplier negotiations and make informed purchases.

Furthermore, understanding the nuances of repowering and retrofitting options ensures that buyers can optimize their existing assets while embracing innovations in marine propulsion technology. This resource is designed to empower international B2B buyers to confidently select diesel motor boots that not only meet their operational needs but also enhance the overall boating experience, paving the way for sustainable growth in the maritime industry.

Understanding diesel motor boot Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Inboard Diesel Engines | Integrated within the hull, offering efficiency and power. | Commercial fishing, cargo vessels | Pros: High power-to-weight ratio, efficient. Cons: Complex installation, maintenance can be costly. |

| Outboard Diesel Engines | Mounted externally, providing flexibility and ease of use. | Recreational boats, small ferries | Pros: Easy to replace, lower initial cost. Cons: Less fuel-efficient, higher noise levels. |

| Hybrid Diesel Engines | Combines diesel and electric power for versatility. | Eco-friendly transportation, luxury yachts | Pros: Reduced emissions, fuel savings. Cons: Higher upfront cost, complex systems. |

| Marine Propulsion Systems | Comprehensive systems that include engines, drives, and controls. | Large vessels, military applications | Pros: Integrated solutions, optimized performance. Cons: Higher investment, requires specialized maintenance. |

| Repower Diesel Engines | Upgrading existing engines to enhance performance and efficiency. | Refitting older vessels | Pros: Extended vessel life, improved efficiency. Cons: Potential compatibility issues, higher initial costs. |

What Are Inboard Diesel Engines and Their Applications?

Inboard diesel engines are installed within the hull of the boat, providing a powerful and efficient propulsion system. They are ideal for commercial applications, such as fishing and cargo vessels, where reliability and performance are paramount. When purchasing, buyers should consider factors like engine size, fuel efficiency, and ease of maintenance, as these engines often require specialized service.

How Do Outboard Diesel Engines Differ from Inboard Options?

Outboard diesel engines are mounted externally, making them accessible and easy to replace. This type is commonly used in recreational boats and smaller ferries, where flexibility and lower initial costs are essential. Buyers should weigh the benefits of easy servicing against the potential downsides of higher noise levels and reduced fuel efficiency, especially for longer trips.

What Are the Advantages of Hybrid Diesel Engines?

Hybrid diesel engines combine traditional diesel power with electric propulsion, offering an eco-friendly alternative for luxury yachts and eco-conscious transport vessels. They provide reduced emissions and fuel savings, appealing to buyers focused on sustainability. However, the initial investment is higher, and the systems can be complex, necessitating careful consideration of long-term operational costs.

Why Choose Marine Propulsion Systems?

Marine propulsion systems encompass a holistic approach to boat propulsion, integrating engines, drives, and control systems. These systems are particularly suited for large vessels and military applications, where performance optimization is critical. Buyers should evaluate the total cost of ownership, including maintenance and compatibility with existing systems, as these setups can involve significant upfront investment.

What Does Repowering Entail for Diesel Engines?

Repowering involves upgrading an existing diesel engine to enhance performance and efficiency, often seen in older vessels. This process can significantly extend the life of the boat while improving fuel efficiency and reducing emissions. Buyers should consider compatibility with the existing vessel, potential downtime during installation, and overall cost-effectiveness when deciding to repower.

Key Industrial Applications of diesel motor boot

| Industry/Sector | Specific Application of diesel motor boot | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine Transportation | Commercial fishing vessels | Enhanced fuel efficiency and reliability for long trips | Engine power, fuel consumption, and maintenance support |

| Tourism and Leisure | Charter boats and yachts | Improved customer experience with quieter, efficient engines | Warranty options, service network, and ease of maintenance |

| Cargo and Freight Shipping | Cargo vessels | Robust performance under heavy loads and long distances | Engine durability, parts availability, and repowering options |

| Offshore Oil and Gas | Support vessels for offshore drilling | High power output and reliability in harsh environments | Compliance with marine standards and certifications |

| Aquaculture | Fish farming boats | Efficient operation for transport and feeding | Engine size, fuel efficiency, and adaptability to specific tasks |

How is Diesel Motor Boot Used in Marine Transportation?

In the marine transportation industry, diesel motor boats are vital for commercial fishing vessels. These engines provide the necessary power for long journeys, ensuring that fishing operations remain efficient and profitable. Diesel engines are preferred for their fuel efficiency, allowing vessels to cover larger distances without frequent refueling. Buyers in this sector should prioritize engines with a strong reputation for reliability and easy access to maintenance services, especially in remote fishing areas.

What Role Does Diesel Motor Boot Play in Tourism and Leisure?

In the tourism and leisure sector, diesel motor boats are commonly used for charter services and recreational activities. The quiet operation and smooth performance of modern diesel engines enhance the customer experience, making trips more enjoyable. Buyers should consider engines that offer low noise levels and exceptional fuel efficiency, as these features contribute to a better on-board experience. Additionally, a strong warranty and a global service network can help mitigate downtime during peak tourism seasons.

How is Diesel Motor Boot Essential for Cargo and Freight Shipping?

Cargo vessels rely heavily on diesel motor boats for their robust performance when transporting goods over long distances. Diesel engines are designed to handle heavy loads and provide the necessary power for efficient freight operations. For international buyers, sourcing engines that are durable and come with readily available parts is crucial to minimize operational disruptions. Consideration should also be given to the engine’s fuel consumption rates, as this impacts overall shipping costs.

What Benefits Does Diesel Motor Boot Offer in Offshore Oil and Gas Operations?

In the offshore oil and gas industry, diesel motor boats are essential for support vessels that operate in challenging environments. These engines are engineered for high power output and reliability, crucial for tasks such as transporting personnel and equipment to drilling sites. When sourcing engines for this sector, compliance with strict marine standards and certifications is imperative to ensure safety and reliability. Buyers should also assess the engine’s performance under various sea conditions to ensure operational efficiency.

How Does Diesel Motor Boot Support Aquaculture Operations?

In aquaculture, diesel motor boats play a critical role in the transport of feed and fish, as well as in maintaining the infrastructure of fish farms. The efficiency of diesel engines allows operators to optimize their operations while minimizing fuel costs. Buyers in this sector should focus on engine size and adaptability to specific aquaculture tasks, as well as fuel efficiency to ensure sustainable operations. Maintenance access and support are also key considerations, as downtime can significantly impact productivity.

3 Common User Pain Points for ‘diesel motor boot’ & Their Solutions

Scenario 1: Challenges in Sourcing Reliable Diesel Engines

The Problem: B2B buyers often face significant challenges when sourcing reliable diesel engines for marine applications. The availability of quality products can be inconsistent, especially in regions like Africa and South America, where local suppliers may not have access to reputable brands. Buyers might encounter engines that lack proper certification or do not meet international standards, leading to concerns about performance, safety, and regulatory compliance. This uncertainty can result in costly downtime and maintenance issues, which are critical factors for businesses operating in competitive maritime environments.

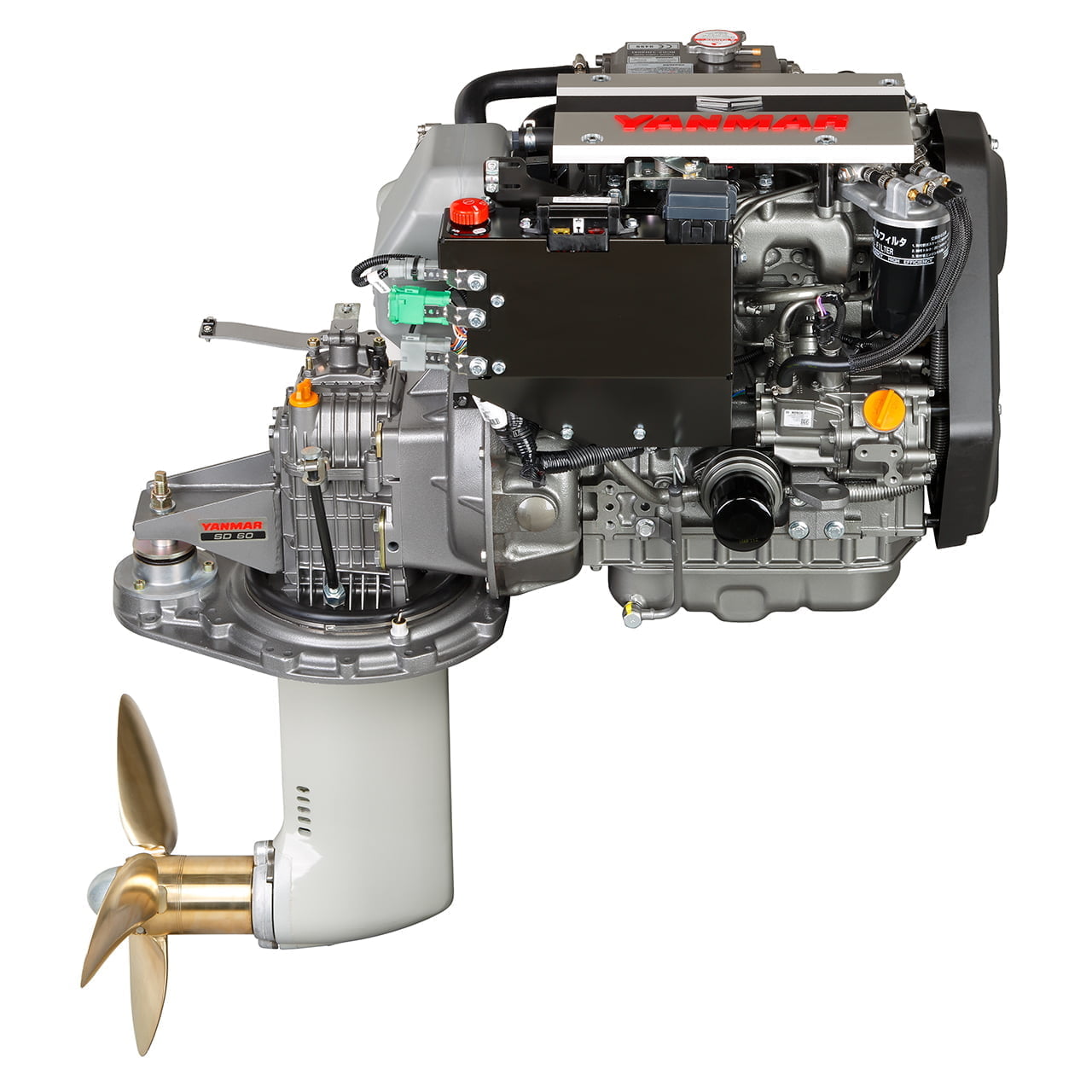

The Solution: To mitigate these sourcing challenges, buyers should prioritize establishing relationships with reputable manufacturers and suppliers who have a proven track record in the marine industry. Conduct thorough research on potential partners, focusing on their certifications, warranty offerings, and global support networks. For instance, opting for well-known brands like YANMAR or VETUS, which have extensive service networks and robust warranties, can provide peace of mind. Additionally, buyers should attend trade shows and industry seminars to network with manufacturers, gain insights into the latest technologies, and explore reliable supply chains. By focusing on reputable sources, buyers can ensure they acquire high-quality diesel engines that meet their operational needs.

Scenario 2: High Maintenance Costs and Downtime

The Problem: Another common pain point is the high maintenance costs associated with diesel motors, which can lead to significant downtime for businesses reliant on marine operations. Many diesel engines require regular servicing and parts replacement, which can be both time-consuming and expensive. In regions where skilled technicians are scarce, maintaining these engines becomes even more challenging, further exacerbating operational inefficiencies and increasing the risk of costly repairs.

Illustrative image related to diesel motor boot

The Solution: To reduce maintenance costs and downtime, buyers should consider investing in diesel engines designed for ease of maintenance. For example, engines like those from VETUS feature user-friendly designs that facilitate quick access to maintenance components, allowing for faster servicing and reduced labor costs. Furthermore, implementing a proactive maintenance schedule, which includes regular inspections and using genuine parts, can significantly extend the lifespan of the engine. Buyers can also explore training programs for their staff to enhance their maintenance capabilities, ensuring that they can address minor issues before they escalate into major problems. This approach not only saves money but also keeps vessels operational and profitable.

Scenario 3: Navigating Regulatory Compliance Challenges

The Problem: Regulatory compliance is a critical issue for B2B buyers in the marine sector, particularly concerning emissions standards and environmental regulations. Diesel engines are often scrutinized for their environmental impact, and failure to comply with local and international regulations can lead to hefty fines and operational restrictions. In regions with stringent regulations, such as Europe, buyers may find it challenging to select engines that meet these criteria without thorough knowledge of the specifications required.

The Solution: Buyers can overcome regulatory compliance challenges by partnering with manufacturers that prioritize environmental sustainability and offer engines certified to meet stringent emissions standards. For example, sourcing engines from companies that invest in innovative technologies, such as cleaner combustion systems, can help ensure compliance with regulations while enhancing operational efficiency. Buyers should also stay informed about local regulations and industry standards by participating in relevant workshops, seminars, and training sessions. By understanding the regulatory landscape and choosing compliant engines, buyers can minimize legal risks and contribute to environmental sustainability, positioning their businesses as responsible operators in the marine industry.

Strategic Material Selection Guide for diesel motor boot

What Are the Key Materials Used in Diesel Motor Boots?

When selecting materials for diesel motor boots, it’s crucial to consider properties that directly affect performance, durability, and maintenance. This guide analyzes four common materials: aluminum, stainless steel, fiberglass, and rubber. Each material has unique properties, advantages, and drawbacks that can influence the overall effectiveness and suitability for various applications.

How Does Aluminum Perform in Diesel Motor Boots?

Aluminum is widely used in marine applications due to its excellent strength-to-weight ratio and corrosion resistance. It typically withstands temperatures up to 150°C and is effective under moderate pressure conditions. The primary advantage of aluminum is its lightweight nature, which enhances the overall efficiency of the diesel motor. However, it can be susceptible to galvanic corrosion if not properly insulated from other metals.

For international B2B buyers, especially from regions like Africa and South America, the cost-effectiveness of aluminum is appealing. Compliance with standards such as ASTM and ISO ensures that the material meets global quality benchmarks. However, buyers should be aware of local environmental conditions that may accelerate corrosion.

What Are the Benefits of Stainless Steel in Diesel Motor Boots?

Stainless steel is another popular choice for diesel motor boots, known for its exceptional corrosion resistance and durability. It can handle higher temperatures (up to 800°C) and pressures, making it suitable for high-performance applications. Stainless steel components are less likely to degrade over time, resulting in lower long-term maintenance costs.

The downside of stainless steel is its higher cost and weight compared to aluminum. For buyers in Europe, where quality and longevity are prioritized, the investment in stainless steel may be justified. Compliance with standards like DIN and JIS is essential for ensuring that the material meets the specific requirements of marine applications.

Why Choose Fiberglass for Diesel Motor Boots?

Fiberglass offers a unique combination of lightweight properties and excellent corrosion resistance, making it a suitable choice for diesel motor boots. It can withstand moderate temperatures and pressures, although it is generally not as strong as metals. Fiberglass is also non-conductive, which reduces the risk of electrical interference.

The primary disadvantage is that fiberglass can be more challenging to repair and may require specialized skills for manufacturing. For buyers in the Middle East, where heat and humidity can affect material performance, fiberglass’s resistance to environmental factors is a significant advantage. However, ensuring compliance with local regulations regarding composite materials is crucial.

How Does Rubber Fit into Diesel Motor Boot Applications?

Rubber is often used for seals, gaskets, and vibration dampening in diesel motor boots. Its flexibility and excellent resistance to oil and fuel make it ideal for maintaining airtight seals. Rubber typically performs well under a range of temperatures, but it can degrade over time if exposed to harsh UV light or extreme temperatures.

While rubber is cost-effective, its lifespan can be shorter compared to metals and composites. For buyers in Brazil and Vietnam, where environmental conditions can vary significantly, selecting the right type of rubber that meets ASTM standards for resilience is essential to ensure longevity and performance.

Summary of Material Selection for Diesel Motor Boots

| Material | Typical Use Case for diesel motor boot | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine housing and structural parts | Lightweight and corrosion-resistant | Susceptible to galvanic corrosion | Medium |

| Stainless Steel | High-performance engine components | Exceptional durability and corrosion resistance | Higher cost and weight | High |

| Fiberglass | Non-structural components and enclosures | Lightweight and non-conductive | Difficult to repair | Medium |

| Rubber | Seals and gaskets | Excellent oil resistance and flexibility | Shorter lifespan compared to metals | Low |

This strategic material selection guide aims to equip international B2B buyers with the insights needed to make informed decisions regarding diesel motor boots. By understanding the properties, advantages, and limitations of each material, buyers can ensure optimal performance and longevity for their marine applications.

In-depth Look: Manufacturing Processes and Quality Assurance for diesel motor boot

What Are the Main Stages of Manufacturing Diesel Motor Boots?

The manufacturing process for diesel motor boots involves several critical stages that ensure the final product meets performance and reliability standards. Understanding these stages is vital for B2B buyers looking to source high-quality diesel engines.

Material Preparation: What Materials Are Used?

The first step in the manufacturing process is material preparation. High-quality materials are essential for the durability and performance of diesel motor boots. Common materials include:

- Cast Iron and Aluminum Alloys: Used for engine blocks due to their strength and heat resistance.

- Steel: Often employed for components like crankshafts and camshafts.

- Composites and Plastics: Utilized in non-structural parts for weight reduction and corrosion resistance.

Materials undergo rigorous inspections to verify their properties and ensure they meet international standards.

How Are Diesel Motor Boots Formed?

The forming stage involves various techniques to shape the prepared materials into engine components. Key techniques include:

- Casting: Molten metal is poured into molds to create complex shapes for engine blocks and heads.

- Machining: Components are precisely cut and shaped using CNC machines to achieve the required tolerances.

- Forging: Steel parts are shaped under high pressure, enhancing their strength and durability.

Each forming method is selected based on the component’s specifications and the desired mechanical properties.

What Does the Assembly Process Involve?

During the assembly stage, individual components are brought together to create the complete diesel motor boot. This process includes:

- Sub-Assembly: Smaller parts, such as fuel injectors and pumps, are assembled separately before being integrated into the main engine.

- Main Assembly: The engine block is combined with the crankshaft, camshaft, and other major components. Careful alignment and fitting are essential to ensure operational efficiency.

- Integration of Electrical Systems: Wiring and electronic control units are installed, ensuring that all systems work in harmony.

Quality control measures are employed at each step to prevent defects.

How Is the Finishing Stage Performed?

Finishing involves the application of protective coatings and final adjustments to ensure optimal performance. Techniques used include:

Illustrative image related to diesel motor boot

- Surface Treatments: Processes like anodizing or powder coating are employed to enhance corrosion resistance.

- Balancing and Testing: Engines are balanced to minimize vibrations, and initial tests are conducted to verify functionality.

The finishing stage is crucial for delivering a product that meets the aesthetic and functional expectations of buyers.

What Quality Assurance Measures Are Implemented?

Quality assurance is a critical component of the manufacturing process, particularly for B2B buyers who require reliable products. Key aspects of quality assurance include adherence to international and industry-specific standards.

Which International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 are essential for ensuring consistent quality across manufacturing processes. ISO 9001 focuses on effective quality management systems, emphasizing continuous improvement and customer satisfaction. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for products sold in specific regions, particularly in Europe and North America.

What Are the Key QC Checkpoints in Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during production to identify and correct defects early.

- Final Quality Control (FQC): Comprehensive testing of the final product to ensure it meets performance and safety standards.

These checkpoints help maintain product integrity and reliability.

What Common Testing Methods Are Used in Diesel Motor Boot Manufacturing?

Various testing methods are employed to verify the quality and performance of diesel motor boots. Common methods include:

- Performance Testing: Engines are subjected to load testing to assess power output and efficiency under simulated operating conditions.

- Durability Testing: Components are tested for wear and tear over time, often involving accelerated life testing.

- Leak Testing: Systems are checked for leaks in fuel, oil, and coolant lines to ensure safe operation.

These tests provide critical data that help manufacturers improve their processes and products.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers maintain high-quality standards. Here are ways to verify supplier QC:

- Conducting Audits: Regular audits of the manufacturing facilities can provide insights into the supplier’s processes and adherence to quality standards.

- Reviewing Quality Reports: Suppliers should provide detailed quality reports that outline their testing methods, results, and any corrective actions taken.

- Third-Party Inspections: Engaging independent inspectors can provide an unbiased assessment of the supplier’s quality control measures.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. These include:

- Regulatory Compliance: Different regions have varying regulations regarding emissions and safety standards. Buyers must ensure that products comply with local regulations.

- Cultural Considerations: Understanding the cultural context of suppliers can impact communication and expectations regarding quality.

- Logistics and Supply Chain Management: Timely delivery of quality products is crucial. Buyers should assess the supplier’s logistics capabilities and their impact on quality assurance.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for diesel motor boots is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions and establish long-lasting partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diesel motor boot’

This guide provides B2B buyers with a structured checklist for sourcing diesel motors for boats, ensuring that procurement aligns with operational needs and industry standards. By following these steps, buyers can make informed decisions, minimizing risks and maximizing performance.

Illustrative image related to diesel motor boot

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the diesel motor meets the unique requirements of your vessel. Consider factors such as power output, engine size, fuel efficiency, and compatibility with existing systems. Additionally, evaluate the intended use of the boat—commercial, recreational, or industrial—as this will influence your choice of motor.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers with a strong market presence. Look for companies that specialize in marine diesel engines and have a track record of reliability and performance. Utilize industry directories, trade shows, and online reviews to gather information on potential partners.

- Key Considerations:

- Supplier reputation within the marine industry.

- Availability of customer support and service networks.

- Range of products offered, including warranties and spare parts.

Step 3: Evaluate Supplier Certifications and Compliance

Before finalizing a supplier, verify their certifications and compliance with international standards. Certifications such as ISO 9001 for quality management systems and specific marine safety standards indicate a commitment to quality and safety.

- What to Look For:

- Compliance with emission regulations (e.g., EPA or IMO standards).

- Quality assurance processes in place.

- Documentation of past performance and reliability.

Step 4: Request Detailed Quotes and Proposals

Solicit detailed quotes from shortlisted suppliers, ensuring that they include all relevant costs, such as shipping, installation, and after-sales service. A comprehensive proposal should outline the specifications, warranty terms, and expected delivery timelines.

- Important Aspects:

- Compare quotes on a like-for-like basis to ensure transparency.

- Look for any hidden costs that may affect the overall budget.

- Ensure clarity on warranty coverage and support services.

Step 5: Conduct Supplier Audits and Site Visits

If feasible, perform site visits to suppliers’ manufacturing facilities or service centers. This step allows you to assess their operational standards, quality control processes, and overall capability to meet your requirements.

Illustrative image related to diesel motor boot

- What to Assess:

- Cleanliness and organization of the production area.

- Availability of skilled technicians and engineers.

- Responsiveness of the team to inquiries and concerns.

Step 6: Negotiate Terms and Finalize Contracts

Once a suitable supplier is identified, engage in negotiations to finalize terms that align with your budget and operational needs. Ensure that all agreements regarding delivery schedules, payment terms, and after-sales support are clearly documented in the contract.

- Negotiation Tips:

- Be clear about expectations and requirements.

- Discuss potential penalties for non-compliance or delays.

- Build in performance metrics to measure supplier accountability.

Step 7: Plan for After-Sales Support and Maintenance

A successful procurement process doesn’t end with the purchase. Establish a plan for after-sales support, including maintenance schedules and access to spare parts. This ensures the longevity and efficiency of the diesel motor.

- Considerations:

- Availability of local service centers and technicians.

- Training programs for your crew on maintenance and operation.

- Access to a supply chain for spare parts and accessories.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing diesel motors for boats, ensuring that their investment leads to enhanced performance and reliability on the water.

Comprehensive Cost and Pricing Analysis for diesel motor boot Sourcing

What Are the Key Cost Components in Diesel Motor Boot Sourcing?

When sourcing diesel motors for boats, understanding the cost structure is crucial for international B2B buyers. The main components include:

-

Materials: The choice of materials significantly influences the cost. High-quality metals, composites, and specialized components (such as cooling systems and soundproofing materials) can increase expenses. Buyers should consider durable, corrosion-resistant materials suitable for marine environments.

-

Labor: Labor costs vary based on the manufacturing location. Regions with higher labor costs may produce engines with more intricate craftsmanship and quality assurance, while lower-cost regions might offer more budget-friendly options but potentially at the expense of quality.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help minimize these overheads, ultimately impacting the final price.

-

Tooling: The initial investment in tooling for production can be substantial. Custom designs or specifications may require unique tooling, increasing the initial costs. However, bulk orders can amortize these costs effectively.

-

Quality Control (QC): Rigorous QC processes ensure that the engines meet safety and performance standards, especially for marine applications. While this might add to the cost, it is essential for maintaining reliability and reducing long-term maintenance expenses.

-

Logistics: Transportation costs can fluctuate based on distance, shipping methods, and current fuel prices. Factors like Incoterms also play a role in determining who bears the logistics costs, which can affect overall pricing.

-

Margin: Suppliers’ profit margins can vary widely based on market dynamics, brand reputation, and demand. Understanding the typical margins in the industry can help buyers gauge the fairness of the pricing.

What Influences Pricing in Diesel Motor Boot Sourcing?

Several factors can influence the pricing of diesel motors for boats:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer better pricing for larger orders. Buyers should consider their needs and potential for future growth when negotiating volumes.

-

Specifications and Customization: Customized engines tailored to specific performance needs may command higher prices. Buyers should weigh the benefits of customization against the associated costs.

-

Materials and Quality Certifications: The quality of materials and certifications (e.g., ISO, CE) can significantly affect pricing. Engines with higher quality materials and certifications may cost more upfront but can reduce Total Cost of Ownership (TCO) through lower maintenance and operational costs.

-

Supplier Factors: Established suppliers with a strong reputation may charge a premium for their products due to perceived quality and reliability. Conversely, emerging suppliers may offer competitive pricing to gain market share.

-

Incoterms: The choice of Incoterms affects the responsibilities and costs related to shipping. Understanding these terms can help buyers manage logistics costs effectively.

How Can Buyers Negotiate for Better Pricing in Diesel Motor Boot Sourcing?

Buyers can adopt several strategies to negotiate favorable terms:

-

Research and Compare: Conduct thorough market research to compare prices and understand the range of offerings. This knowledge empowers buyers during negotiations.

-

Leverage Volume Discounts: If planning to make large purchases, use the potential for volume as a negotiation tool. Suppliers are often willing to provide discounts for bulk orders.

-

Assess Total Cost of Ownership: Emphasize the importance of TCO in discussions. A higher initial cost may be justified if the engine offers lower fuel consumption, reduced maintenance, and longer lifespan.

-

Explore Flexible Payment Terms: Negotiating payment terms can improve cash flow and reduce upfront costs. Consider options like staggered payments based on delivery milestones.

-

Build Relationships: Establishing a long-term relationship with suppliers can lead to better pricing and preferential treatment in future transactions.

What Pricing Nuances Should International Buyers Consider?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can impact the overall cost. Buyers should monitor currency trends and consider hedging strategies when necessary.

-

Tariffs and Duties: Import tariffs can add significant costs. Understanding the trade agreements and tariffs applicable to their region can help buyers estimate total expenses accurately.

-

Logistical Challenges: Shipping to remote areas may incur additional logistics costs. Buyers should factor in these potential expenses when budgeting for diesel motor purchases.

-

Local Regulations: Compliance with local maritime regulations and standards may require additional features or certifications, influencing the overall cost.

Disclaimer

Prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier pricing strategies, and individual negotiation outcomes. Buyers should conduct their own due diligence to obtain accurate and current pricing information.

Alternatives Analysis: Comparing diesel motor boot With Other Solutions

Exploring Alternative Solutions to Diesel Motor Boats

When considering the propulsion systems for marine vessels, it is essential to evaluate various alternatives to diesel motor boats. While diesel engines have long been favored for their robustness and efficiency, emerging technologies and methods may offer compelling advantages. This analysis provides a comprehensive comparison of diesel motor boats against electric propulsion systems and hybrid solutions, helping international B2B buyers make informed decisions.

| Comparison Aspect | Diesel Motor Boat | Electric Propulsion System | Hybrid Propulsion System |

|---|---|---|---|

| Performance | High torque and reliability | Limited range, but instant torque | Combines benefits of both systems |

| Cost | Higher initial purchase cost | Lower operational costs | Moderate initial cost, variable operational costs |

| Ease of Implementation | Requires complex installation | Simpler installation, fewer components | More complex due to dual systems |

| Maintenance | Higher maintenance needs | Minimal maintenance required | Moderate maintenance required |

| Best Use Case | Long-distance voyages | Short trips, eco-conscious buyers | Versatile use cases, including long and short trips |

In-Depth Analysis of Alternatives

Electric Propulsion Systems: A Sustainable Choice

Electric propulsion systems are gaining traction due to their eco-friendliness and lower operational costs. These systems utilize battery power to drive electric motors, resulting in zero emissions and significantly reduced noise levels. The simplicity of installation and minimal maintenance requirements make electric systems appealing for short trips and recreational vessels. However, the limited range remains a significant drawback, making them less suitable for long-distance voyages where battery life may constrain performance.

Illustrative image related to diesel motor boot

Hybrid Propulsion Systems: The Best of Both Worlds

Hybrid propulsion systems combine traditional diesel engines with electric motors, offering flexibility and improved fuel efficiency. These systems are designed to operate in various modes, allowing vessels to switch between diesel and electric power depending on the operational demands. The versatility of hybrid systems makes them suitable for diverse applications, from commercial shipping to leisure boating. However, the complexity of having two propulsion systems can lead to increased maintenance challenges and costs compared to purely diesel or electric options.

Making the Right Choice for Your Marine Needs

When evaluating the best propulsion system for a marine vessel, B2B buyers should consider their specific operational requirements, budget constraints, and environmental impact goals. Diesel motor boats remain a reliable choice for long voyages and heavy-duty applications, while electric and hybrid systems present innovative alternatives for those prioritizing sustainability and lower operational costs. Ultimately, the decision should align with the vessel’s intended use, ensuring optimal performance and cost-effectiveness in the long run.

Essential Technical Properties and Trade Terminology for diesel motor boot

What Are the Key Technical Properties of a Diesel Motor Boot?

When considering the procurement of a diesel motor boot, understanding critical technical specifications is essential for making informed decisions. Here are several key properties to consider:

-

Engine Power Rating (HP or kW)

The power rating of a diesel engine is a crucial factor that determines its ability to propel the boat effectively. Measured in horsepower (HP) or kilowatts (kW), this rating informs buyers about the engine’s performance capabilities. Higher power ratings typically translate to better acceleration and speed, making it vital for applications requiring swift maneuvers. -

Fuel Efficiency (g/kWh)

Fuel efficiency indicates how much fuel the engine consumes to produce a specific amount of power. It is expressed in grams per kilowatt-hour (g/kWh). For B2B buyers, fuel efficiency directly impacts operational costs, especially in regions where fuel prices are high. Investing in engines with better fuel efficiency can lead to substantial cost savings over time. -

Weight and Dimensions

The weight and physical dimensions of the engine are critical for ensuring that it fits within the boat’s design specifications. Heavy engines may affect the boat’s balance and performance. Understanding these specifications helps buyers assess compatibility with their vessels and ensures compliance with maritime regulations. -

Material Composition

The materials used in the construction of the diesel engine affect durability and performance. Common materials include cast iron for the engine block and aluminum for components like cylinder heads. High-quality materials enhance the engine’s lifespan and performance, making it essential for buyers to inquire about material grades and their implications for maintenance and longevity. -

Cooling System Type

Diesel engines can utilize various cooling systems, such as freshwater or seawater cooling. The type of cooling system affects maintenance requirements and operational reliability. Buyers should consider the local operating conditions and the availability of cooling water when selecting an engine, as these factors will influence performance and longevity. -

Emission Standards Compliance

Compliance with local and international emission regulations is increasingly important. Diesel engines must meet specific standards to reduce environmental impact. Understanding the engine’s compliance with these regulations can prevent costly fines and ensure operational viability in various markets.

What Are Common Trade Terms Related to Diesel Motor Boots?

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B landscape. Below are some common terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of diesel engines, purchasing from OEMs ensures that parts are genuine, meeting quality standards that enhance reliability and performance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers, especially in regions where inventory management is critical. It helps in budgeting and ensures that procurement aligns with demand forecasts. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific products or services. It is a vital step in the procurement process, enabling buyers to compare costs and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms helps in understanding shipping costs, insurance obligations, and risk management, crucial for smooth international transactions. -

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. This metric is critical for supply chain management, allowing buyers to plan their operations and minimize downtime. -

Warranty Period

The warranty period is the duration during which the manufacturer guarantees the performance of the engine and covers repairs or replacements for defects. Understanding warranty terms is essential for assessing the long-term value of the investment and the manufacturer’s commitment to quality.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions when investing in diesel motor boots, ensuring they meet their operational needs and budget constraints effectively.

Navigating Market Dynamics and Sourcing Trends in the diesel motor boot Sector

What Are the Current Market Dynamics and Key Trends in the Diesel Motor Boot Sector?

The diesel motor boot sector is experiencing a transformative phase driven by various global factors. The demand for marine diesel engines is largely influenced by the growth of the shipping and leisure boating industries, particularly in regions such as Africa, South America, the Middle East, and Europe. Emerging markets are witnessing increased recreational boating activities, spurring demand for reliable and efficient diesel engines. Technological advancements, such as enhanced fuel efficiency and reduced emissions, are becoming vital selling points. Manufacturers are increasingly focusing on integrating smart technologies into their engines, including IoT capabilities for real-time monitoring and predictive maintenance, which resonates well with B2B buyers seeking long-term operational efficiency.

Moreover, international buyers are prioritizing sourcing from suppliers that demonstrate robust global support networks, as seen with companies like YANMAR and VETUS. These brands offer not just products but also extensive service and parts availability, which is crucial for maintaining operational uptime. The trend towards repowering older vessels with new, more efficient engines is also gaining traction, driven by the need for compliance with stricter environmental regulations and the desire to reduce overall operational costs.

How Are Sustainability and Ethical Sourcing Influencing the Diesel Motor Boot Market?

Sustainability is no longer just a buzzword; it has become an essential criterion for B2B buyers in the diesel motor boot sector. The environmental impact of diesel engines, particularly concerning emissions, is prompting manufacturers to adopt greener technologies and materials. Buyers are increasingly seeking suppliers that offer ‘green’ certifications and environmentally friendly manufacturing processes. For instance, innovations in air filtering and sound-reducing technologies are not only enhancing user experience but also contributing to lower environmental footprints.

Illustrative image related to diesel motor boot

Ethical sourcing is becoming equally important, as businesses recognize the need to support supply chains that prioritize fair labor practices and minimal environmental impact. Manufacturers are responding by ensuring transparency in their sourcing processes and providing documentation that verifies compliance with environmental regulations. This trend aligns well with the growing consumer preference for sustainable products, compelling B2B buyers to collaborate with partners who share their commitment to ethical practices.

How Has the Diesel Motor Boot Sector Evolved Over Time?

The evolution of the diesel motor boot sector has been marked by significant advancements in technology and design. Initially, diesel engines were primarily valued for their durability and power, making them the preferred choice for larger vessels. However, as environmental awareness increased, the industry began to shift towards more efficient and cleaner technologies. The introduction of marinization techniques and the development of sophisticated engine management systems have drastically improved performance and reliability.

Today, the sector is characterized by a blend of traditional engineering and cutting-edge technology. Manufacturers are focusing on creating engines that not only meet power demands but also adhere to stringent emissions standards. This shift is crucial for attracting international B2B buyers who are increasingly aware of the environmental implications of their purchasing decisions. As the industry continues to innovate, the focus will remain on enhancing efficiency, reducing emissions, and providing comprehensive support to buyers across diverse markets.

Frequently Asked Questions (FAQs) for B2B Buyers of diesel motor boot

-

How do I ensure I am sourcing a reliable diesel motor boot supplier?

To identify a reliable supplier for diesel motor boots, conduct thorough research by checking their industry reputation, customer reviews, and certifications. Verify their experience in the marine sector and their ability to meet international standards. Additionally, request references from previous clients and assess their customer service responsiveness. Consider visiting their facilities if possible or engaging in video calls to gauge their operations and professionalism. Establishing a clear communication channel will also help ensure a fruitful partnership. -

What are the key specifications I should look for in a diesel motor boot?

When sourcing a diesel motor boot, focus on specifications such as engine power output, fuel efficiency, and compliance with environmental regulations. Evaluate the engine’s noise and vibration levels, as these can affect the overall boating experience. Additionally, consider the size and weight of the engine to ensure compatibility with your vessel. Look for features that enhance reliability, such as advanced cooling systems and easy access for maintenance. Lastly, check the warranty and support options offered by the manufacturer. -

What are the typical payment terms for purchasing diesel motor boots in B2B transactions?

Payment terms for diesel motor boots can vary widely among suppliers, but common practices include 30% upfront payment with the balance due upon delivery or a net 30-60 days payment term after receipt of goods. Some suppliers may offer financing options or letters of credit, especially for larger orders. It’s essential to clarify these terms before finalizing contracts to avoid misunderstandings. Ensure that payment methods are secure and that you receive a detailed invoice for transparency. -

What is the Minimum Order Quantity (MOQ) when sourcing diesel motor boots?

Minimum Order Quantity (MOQ) can significantly differ based on the supplier and specific engine model. Some manufacturers may have an MOQ of one unit, while others might require multiple units to justify production costs. It’s advisable to discuss your needs with potential suppliers and negotiate MOQs that suit your business model. Consider the potential for bulk purchasing discounts if you anticipate future demand, as this can reduce costs in the long run. -

How do I handle logistics and shipping for diesel motor boots?

Logistics for shipping diesel motor boots involve several key steps, including selecting a reliable freight forwarder experienced in handling heavy machinery. Confirm the shipping method (air, sea, or land) based on urgency and budget. Ensure all necessary documentation, such as customs clearance papers and import licenses, is prepared to avoid delays. Discuss insurance options to cover potential damages during transit. Establish clear communication with your supplier to coordinate shipping schedules and tracking. -

What quality assurance measures should I expect from diesel motor boot suppliers?

Reputable suppliers should provide comprehensive quality assurance measures, including adherence to international standards such as ISO certifications. Look for suppliers that conduct rigorous testing on their engines, including performance and durability assessments. They should also provide warranty coverage and after-sales support, which can be indicative of their commitment to quality. Request detailed documentation of quality control processes and any certifications they hold to ensure the engines meet your expectations. -

Can I customize diesel motor boots to suit my specific needs?

Many manufacturers offer customization options for diesel motor boots to accommodate specific performance requirements or installation constraints. Customizations may include adjustments to engine power output, modifications for space constraints, or enhancements for noise reduction. Discuss your needs with potential suppliers early in the sourcing process to determine what options are available. Be clear about your specifications and any regulatory requirements to ensure compliance and optimal performance. -

What after-sales support should I expect when purchasing a diesel motor boot?

After-sales support is critical in maintaining your diesel motor boot’s performance and longevity. Expect suppliers to offer warranty services, technical support, and access to spare parts. A robust service network is essential, especially for international buyers, to ensure timely assistance. Inquire about training for your team on maintenance and troubleshooting, as well as resources for ongoing support. A supplier committed to customer service will enhance your overall experience and minimize downtime for your vessel.

Top 3 Diesel Motor Boot Manufacturers & Suppliers List

1. VETUS – Marine Diesel Engine

Domain: vetus.com

Registered: 1997 (28 years)

Introduction: Marine Diesel Engine by VETUS offers improved boating experience with powerful and efficient performance. Key features include:

– Cleaner, smoother, quieter operation with reduced engine sound levels (up to 5 dB(A)).

– Unique water-cooled aluminum top cover that lowers engine-room temperature by up to 15ºC, enhancing combustion efficiency.

– Designed for easy installation and minimal maintenanc…

2. Boot Motor Seminar – Practical Engine Maintenance

Domain: boot.com

Registered: 1995 (30 years)

Introduction: boot Motor Seminar 2026 on January 21, 2026, from 14:30 to 17:30. Speakers: Dr. Robert Möckel (Marine mechanical engineer) and Sönke Roever (Editor-in-chief and founder of BLAUWASSER.DE). Focus on practical handling and maintenance of boat motors, specifically Volvo Penta and Yanmar engines. Price: EUR 79. Language: English. Location: Seminar rooms of Hall 10 at the boot trade fair.

3. DIESELSITE – 1994-2003 Ford 7.3L Intake Plenum Boot Kit

Domain: dieselsite.com

Registered: 2000 (25 years)

Introduction: Product Name: 1994-2003 Ford 7.3L DIESELSITE Intake Plenum Boot Kit

Price: From $89.00 to $99.00

Compatibility: 1994-2003 Ford 7.3L Powerstroke

Includes: Two boots connecting the intake manifold to the cylinder heads and clamps

Boot Specifications:

– 1994-1997: (2) Engine Valley Boots measuring 2″ Inner Diameter, (4) Worm-Gear Style Clamps

– 1999 Early: (2) Engine Valley Boots measuring 2″/2.35″ (…

Strategic Sourcing Conclusion and Outlook for diesel motor boot

In summary, strategic sourcing of diesel motor boats is crucial for international B2B buyers aiming to enhance their marine operations. Key takeaways include the importance of partnering with reliable manufacturers that offer robust warranties, a global service network, and innovative technologies. Companies like YANMAR and VETUS exemplify this, providing not only high-performance engines but also comprehensive support for maintenance and repowering needs.

Understanding the specific requirements of regional markets in Africa, South America, the Middle East, and Europe can further inform sourcing decisions. Buyers should prioritize suppliers that demonstrate a commitment to efficiency, sustainability, and user comfort, as these factors are increasingly significant in today’s marine industry.

As the global demand for diesel engines continues to evolve, staying informed about the latest innovations and market trends will position businesses for long-term success. We encourage B2B buyers to take proactive steps in exploring strategic sourcing opportunities to ensure they are equipped with the best diesel motor solutions tailored to their operational needs. Engage with trusted suppliers, attend industry seminars, and leverage global networks to optimize your sourcing strategy for diesel motor boats.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.