Top 7 Plunger Switches Suppliers (And How to Choose)

Introduction: Navigating the Global Market for plunger switches

In the ever-evolving landscape of industrial equipment, sourcing reliable plunger switches poses significant challenges for B2B buyers across the globe. Whether you’re operating in the diverse markets of Africa, South America, the Middle East, or Europe, understanding the intricacies of these essential components is critical for maintaining operational efficiency and safety. This guide is designed to navigate you through the complexities of the global market for plunger switches, offering insights into various types, applications, and critical factors to consider when selecting a supplier.

Throughout this comprehensive resource, you will discover detailed information on the different configurations and specifications of plunger switches, including their performance ratings and durability standards. We delve into their diverse applications across industries such as automotive, marine, and manufacturing, ensuring you can identify the most suitable options for your specific needs. Additionally, we provide a framework for vetting suppliers, helping you to assess their reliability and capability in meeting your requirements.

By equipping you with actionable insights into pricing, quality standards, and supplier evaluation, this guide empowers international B2B buyers to make informed purchasing decisions. Understanding these critical components not only enhances your operational performance but also positions your business for sustained success in competitive markets.

Understanding plunger switches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Waterproof Plunger Switch | IP68 rating, stainless steel construction, customizable actuation parameters | Military vehicles, industrial equipment, marine systems | Pros: Durable, versatile, high performance. Cons: Higher cost due to robust design. |

| Mechanical Plunger Switch | Minimal physical force required for actuation, shock and vibration resistant | Conveyor systems, automotive, industrial machinery | Pros: Reliable, long lifespan. Cons: Limited to specific environments. |

| Sealed Plunger Switch | Designed for low current applications, effective against moisture and contaminants | Outdoor equipment, agricultural machinery, off-highway vehicles | Pros: Ensures contact cleanliness, long service life. Cons: May not handle high currents. |

| Electronic Plunger Switch | Direct connection to ECUs, multiple configuration options including NO/NC contacts | Automotive, robotics, industrial automation | Pros: High precision, customizable. Cons: More complex installation. |

| Foot Plunger Switch | Designed for foot actuation, available in various actuation forces and travel lengths | Industrial equipment, heavy machinery, safety systems | Pros: Ergonomic, versatile. Cons: May require additional space for installation. |

What are the Key Characteristics of Waterproof Plunger Switches?

Waterproof plunger switches are engineered to withstand harsh environments, featuring a robust IP68 rating that ensures complete submersion protection. Made from stainless steel, these switches are customizable in terms of actuator parameters, making them ideal for demanding applications like military vehicles and industrial equipment. When considering a purchase, buyers should evaluate the switch’s endurance ratings and environmental conditions to ensure compatibility with their specific use cases.

How Do Mechanical Plunger Switches Stand Out?

Mechanical plunger switches operate with minimal physical force, making them ideal for applications requiring reliability under shock and vibration. These switches are commonly used in conveyor systems and automotive applications. B2B buyers should focus on the mechanical cycle ratings and environmental resistance when selecting a mechanical plunger switch, as these factors significantly influence long-term performance and maintenance costs.

What Makes Sealed Plunger Switches Essential for Certain Applications?

Sealed plunger switches are specifically designed for low current applications and excel in environments exposed to moisture and contaminants. They are widely utilized in outdoor power equipment and agricultural machinery. Buyers should consider the switch’s current rating and expected lifespan, particularly if it will be used in rugged outdoor settings, where reliability is paramount.

Why Choose Electronic Plunger Switches for Advanced Applications?

Electronic plunger switches offer a direct connection to electronic control units (ECUs) and provide a range of configuration options, including normally open (NO) and normally closed (NC) contacts. These switches are suitable for advanced applications in robotics and industrial automation. Buyers should assess the complexity of installation and compatibility with existing systems, as these factors can impact overall operational efficiency.

What are the Advantages of Foot Plunger Switches in Industrial Settings?

Foot plunger switches are designed for ergonomic foot actuation and are available in various actuation forces and travel lengths. They are often used in heavy machinery and safety systems. When purchasing, buyers should consider the switch’s footprint and actuation force to ensure it meets the specific ergonomic and functional requirements of their applications.

Key Industrial Applications of plunger switches

| Industry/Sector | Specific Application of plunger switches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Valve position sensing in diesel turbochargers | Enhances operational reliability and safety | Ensure switches meet high-temperature and vibration resistance standards. |

| Military & Defense | Hatch and door interlock switches for amphibious vehicles | Improves personnel safety and equipment functionality | Look for waterproof and shock-resistant options. |

| Industrial Equipment | Position sensing in conveyor systems | Increases automation efficiency and reduces downtime | Verify compatibility with existing systems and environmental ratings. |

| Agricultural Machinery | Control levers in farming equipment | Optimizes machine performance and reduces maintenance needs | Assess for durability and resistance to contaminants like dust and moisture. |

| Marine Applications | Position sensing in marine vessels | Ensures operational integrity in harsh marine environments | Seek plunger switches with high corrosion resistance and IP ratings. |

How Are Plunger Switches Used in the Automotive Industry?

In the automotive sector, plunger switches are critical for applications such as valve position sensing in diesel turbochargers. These switches provide real-time feedback on valve positions, enabling precise control of engine functions. This is essential for optimizing performance and ensuring compliance with emissions regulations. Buyers in this sector should prioritize switches with high-temperature resistance and durability to withstand the demanding conditions typical in automotive environments.

What Role Do Plunger Switches Play in Military and Defense Applications?

In military applications, plunger switches are often employed as hatch and door interlock switches in amphibious vehicles. These switches enhance safety by preventing accidental openings during critical operations. The rugged design and waterproof features are vital, particularly in combat scenarios. Buyers should focus on sourcing switches that meet stringent military specifications, including shock and vibration resistance to ensure functionality in extreme conditions.

How Are Plunger Switches Beneficial for Industrial Equipment?

Within industrial settings, plunger switches are widely used for position sensing in conveyor systems. They automate the operation of machinery, significantly improving efficiency and minimizing downtime. The ability to provide accurate position feedback allows for better control over production processes. When sourcing these switches, buyers should ensure compatibility with existing systems and verify their environmental ratings, especially if used in harsh conditions.

Why Are Plunger Switches Important in Agricultural Machinery?

In the agricultural sector, plunger switches are integral to controlling levers in various farming equipment. They help optimize machine performance, leading to increased productivity and reduced maintenance costs. Given the exposure to dirt and moisture in agricultural environments, buyers should look for switches designed for durability and resistance to contaminants, ensuring reliable operation over time.

What Are the Key Considerations for Marine Applications Using Plunger Switches?

In marine applications, plunger switches are utilized for position sensing in vessels, ensuring operational integrity in challenging environments. The switches must be resistant to corrosion and have high IP ratings to withstand exposure to saltwater and moisture. Buyers in this sector should prioritize sourcing switches that offer robust sealing and high durability to ensure long-term performance in marine conditions.

3 Common User Pain Points for ‘plunger switches’ & Their Solutions

Scenario 1: Inconsistent Performance Under Harsh Conditions

The Problem: B2B buyers often face challenges when sourcing plunger switches for equipment used in extreme environments, such as agricultural machinery or outdoor power equipment. These environments expose switches to dust, moisture, and temperature fluctuations, leading to inconsistent performance and premature failure. Buyers may find that standard switches do not meet the durability or reliability required for their specific applications, leading to increased maintenance costs and downtime.

The Solution: To overcome this issue, it is crucial to source plunger switches specifically designed for harsh conditions. Look for switches with high ingress protection ratings (IP67 or IP68) that indicate their resistance to dust and water. Additionally, consider models with stainless steel construction or specialized coatings that enhance corrosion resistance. When specifying these switches, consult with manufacturers to understand the environmental ratings and ensure they meet the operational requirements of your equipment. Moreover, investing in seals and wipers can help maintain contact cleanliness, further extending the life of the switch in rugged applications.

Scenario 2: Complexity in Integration with Existing Systems

The Problem: Many businesses struggle with integrating new plunger switches into existing systems, especially when dealing with custom machinery or legacy equipment. The complexity arises from the need for compatibility with electrical systems, varying actuation forces, and plunger travel distances. This can lead to additional costs associated with redesigning systems or modifying components, ultimately delaying project timelines.

The Solution: To streamline integration, begin by conducting a thorough assessment of your current system requirements. Identify the electrical specifications, actuation needs, and mounting configurations necessary for seamless compatibility. When selecting plunger switches, opt for those with customizable features, such as variable plunger lengths and actuator shapes. Many manufacturers offer design consultations; take advantage of this resource to ensure the selected switches can be effectively integrated into your systems. Additionally, consider purchasing samples for field testing to validate compatibility before committing to larger orders.

Scenario 3: Limited Understanding of Switching Capabilities and Specifications

The Problem: B2B buyers often find themselves overwhelmed by the technical specifications of plunger switches, including contact configurations, electrical ratings, and endurance cycles. This lack of understanding can lead to incorrect purchasing decisions, resulting in switches that do not meet the operational demands of their applications. Missteps in selecting the right switch can cause functionality issues, safety hazards, and unnecessary replacement costs.

The Solution: To mitigate this problem, invest time in educating your procurement team about the critical specifications of plunger switches. Focus on understanding contact configurations (normally open vs. normally closed), electrical ratings, and mechanical endurance. Utilize manufacturer resources, such as datasheets and application guides, to gain insights into how these specifications impact performance. Additionally, engaging directly with supplier technical support can provide clarity and assistance in aligning product choices with application requirements. Consider creating a checklist based on your specific needs to simplify the decision-making process and ensure you select the most suitable plunger switches for your projects.

Strategic Material Selection Guide for plunger switches

What Are the Key Materials Used in Plunger Switches?

When selecting plunger switches for various applications, the choice of materials is crucial. Different materials offer distinct properties that can significantly influence the performance, durability, and suitability of the switches for specific environments. Below, we analyze four common materials used in plunger switches, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance and high strength. It can withstand extreme temperatures, making it suitable for harsh environments. Common grades used include 304 and 316, which offer varying levels of resistance to oxidation and corrosion.

Pros & Cons: The durability of stainless steel is a significant advantage, particularly in applications exposed to moisture or chemicals. However, it can be more expensive than other materials and may require additional machining, increasing manufacturing complexity.

Impact on Application: Stainless steel is ideal for applications in marine environments or industries where exposure to corrosive substances is common, such as oil and gas.

Considerations for International Buyers: Buyers from regions like the Middle East, where high temperatures and humidity are prevalent, should ensure compliance with local standards such as ASTM and JIS for material quality.

2. Plastic (Polycarbonate or Nylon)

Key Properties: Plastics like polycarbonate and nylon are lightweight and provide good electrical insulation. They have decent resistance to chemicals and can be molded into complex shapes.

Pros & Cons: The primary advantage of plastic materials is their cost-effectiveness and ease of manufacturing. However, they may not withstand high temperatures or mechanical stress as well as metals, leading to potential failure in demanding applications.

Impact on Application: Plastic plunger switches are commonly used in consumer electronics and low-power applications, where weight and cost are critical factors.

Considerations for International Buyers: Buyers should verify that the plastics used meet relevant safety and environmental standards, especially in Europe where regulations like REACH are stringent.

3. Brass

Key Properties: Brass is an alloy of copper and zinc known for its good electrical conductivity and corrosion resistance. It is often used in environments that require reliable electrical connections.

Pros & Cons: Brass is relatively easy to machine and offers a balance between cost and performance. However, it may be susceptible to dezincification in certain environments, which can compromise its integrity over time.

Impact on Application: Brass is suitable for applications in electrical systems, such as in automotive or industrial machinery, where reliable conductivity is essential.

Considerations for International Buyers: In regions like Africa and South America, where environmental factors can vary, it is essential to ensure that brass components comply with local corrosion resistance standards.

4. Aluminum

Key Properties: Aluminum is lightweight, resistant to corrosion, and possesses good thermal and electrical conductivity. It can be anodized to enhance its surface properties.

Pros & Cons: The lightweight nature of aluminum makes it advantageous for applications where weight is a concern. However, it is generally less durable than stainless steel and may require protective coatings to prevent corrosion in harsh environments.

Impact on Application: Aluminum plunger switches are often used in aerospace and automotive applications, where weight savings can lead to improved fuel efficiency.

Considerations for International Buyers: Buyers should consider the local climate and potential exposure to corrosive elements when selecting aluminum components, particularly in coastal areas.

Summary Table of Material Properties

| Material | Typical Use Case for plunger switches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine and chemical environments | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Consumer electronics, low-power apps | Cost-effective and lightweight | Limited temperature and stress resistance | Low |

| Brass | Electrical systems in machinery | Good conductivity and easy to machine | Susceptible to dezincification | Medium |

| Aluminum | Aerospace and automotive applications | Lightweight and corrosion-resistant | Less durable than stainless steel | Medium |

This strategic material selection guide provides essential insights for B2B buyers looking to make informed decisions regarding plunger switches. Understanding the properties and implications of different materials ensures that the selected switches will meet the specific requirements of their applications.

In-depth Look: Manufacturing Processes and Quality Assurance for plunger switches

What Are the Key Stages in the Manufacturing Process of Plunger Switches?

The manufacturing process of plunger switches involves several critical stages that ensure the final product meets the required specifications and quality standards. Understanding these stages can help B2B buyers make informed decisions when sourcing plunger switches.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing plunger switches is the selection and preparation of raw materials. Typically, high-grade materials such as stainless steel, brass, and various plastics are used to ensure durability and resistance to environmental factors. Materials are sourced from certified suppliers to guarantee quality.

Once selected, the materials undergo rigorous inspections to ensure they meet predefined specifications. This includes checking for impurities and verifying material grades. The preparation phase may also involve cutting and shaping raw materials into usable forms, which are crucial for the subsequent forming and assembly stages.

What Techniques Are Used for Forming Plunger Switch Components?

After material preparation, the forming stage begins. This phase typically employs various techniques such as stamping, machining, and injection molding to create individual components of the plunger switch.

-

Stamping and Machining: These methods are commonly used for metal components, allowing for precise cuts and shapes that are essential for the switch’s functionality. High-speed presses and CNC machines are often utilized to achieve the required tolerances.

-

Injection Molding: For plastic parts, injection molding is a prevalent technique. This process involves injecting molten plastic into a mold, where it cools and solidifies into the desired shape.

The choice of technique depends on the component’s design, material properties, and the volume of production required. Each method must ensure that the components are produced consistently and meet design specifications.

How Are Plunger Switches Assembled for Optimal Functionality?

Assembly is a pivotal stage where the individual components are brought together to create the final plunger switch. This stage often involves both manual and automated processes, depending on the complexity of the switch design.

During assembly, components such as the actuator, spring, and housing are meticulously fitted together. Quality control measures are implemented at this stage to check for proper alignment and functionality. Automated systems may be used for tasks like soldering or wiring, enhancing efficiency while maintaining consistency.

What Finishing Processes Enhance Durability and Performance?

Finishing processes are crucial for enhancing the durability and performance of plunger switches. Common techniques include surface treatments such as plating, coating, and polishing.

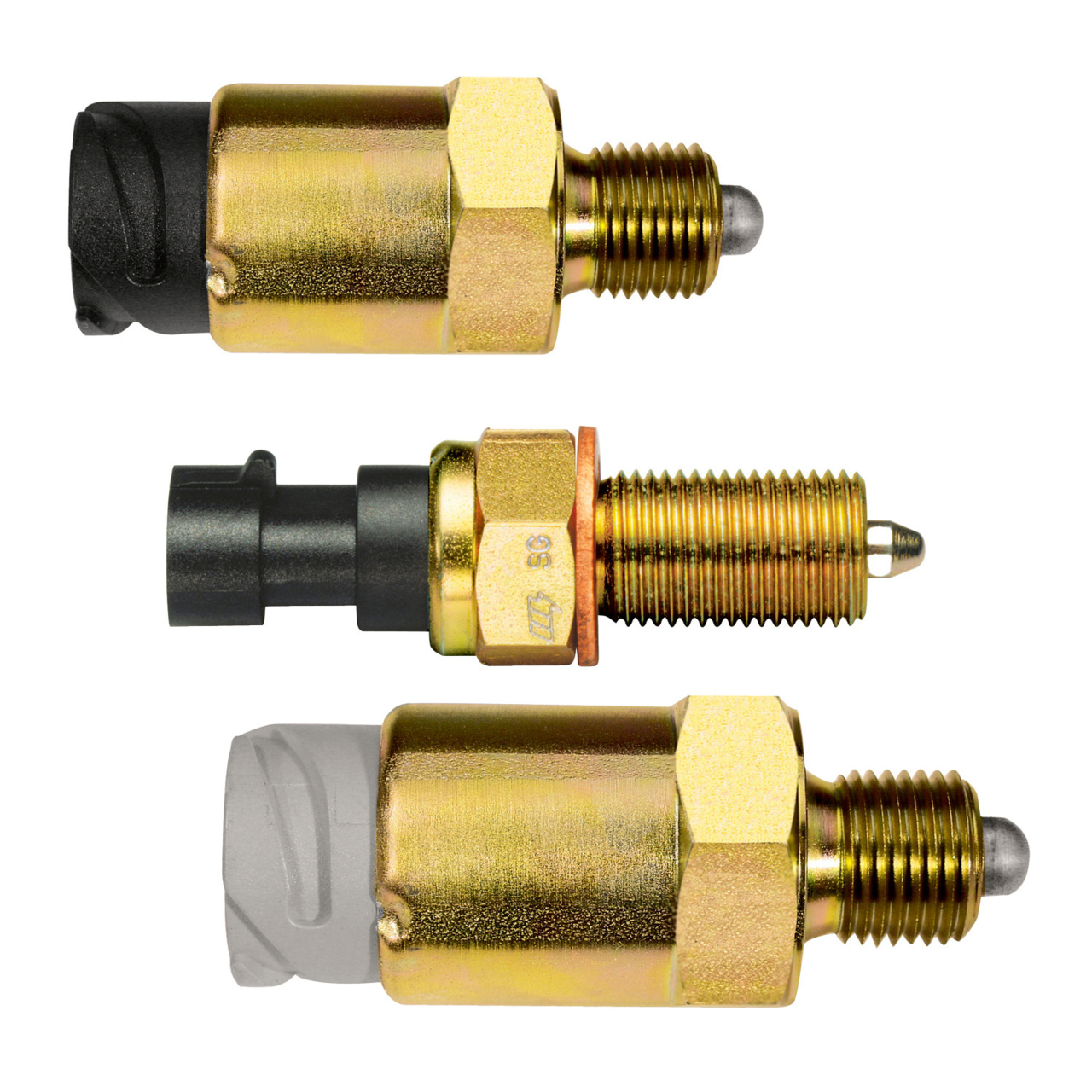

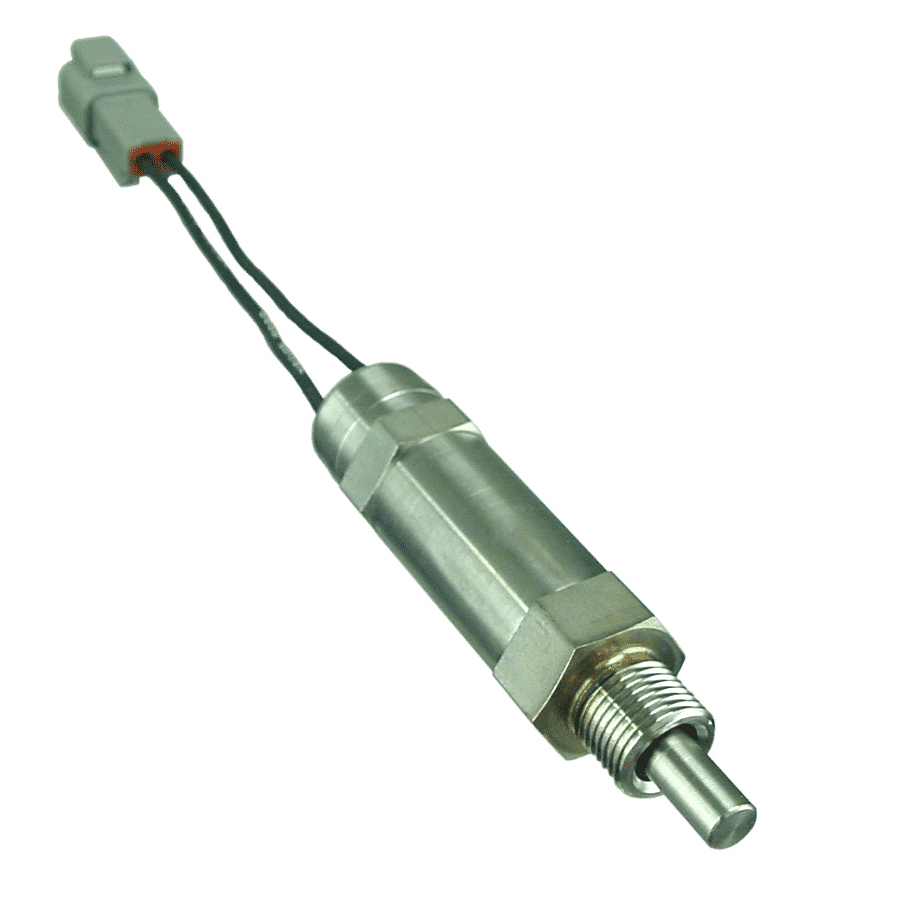

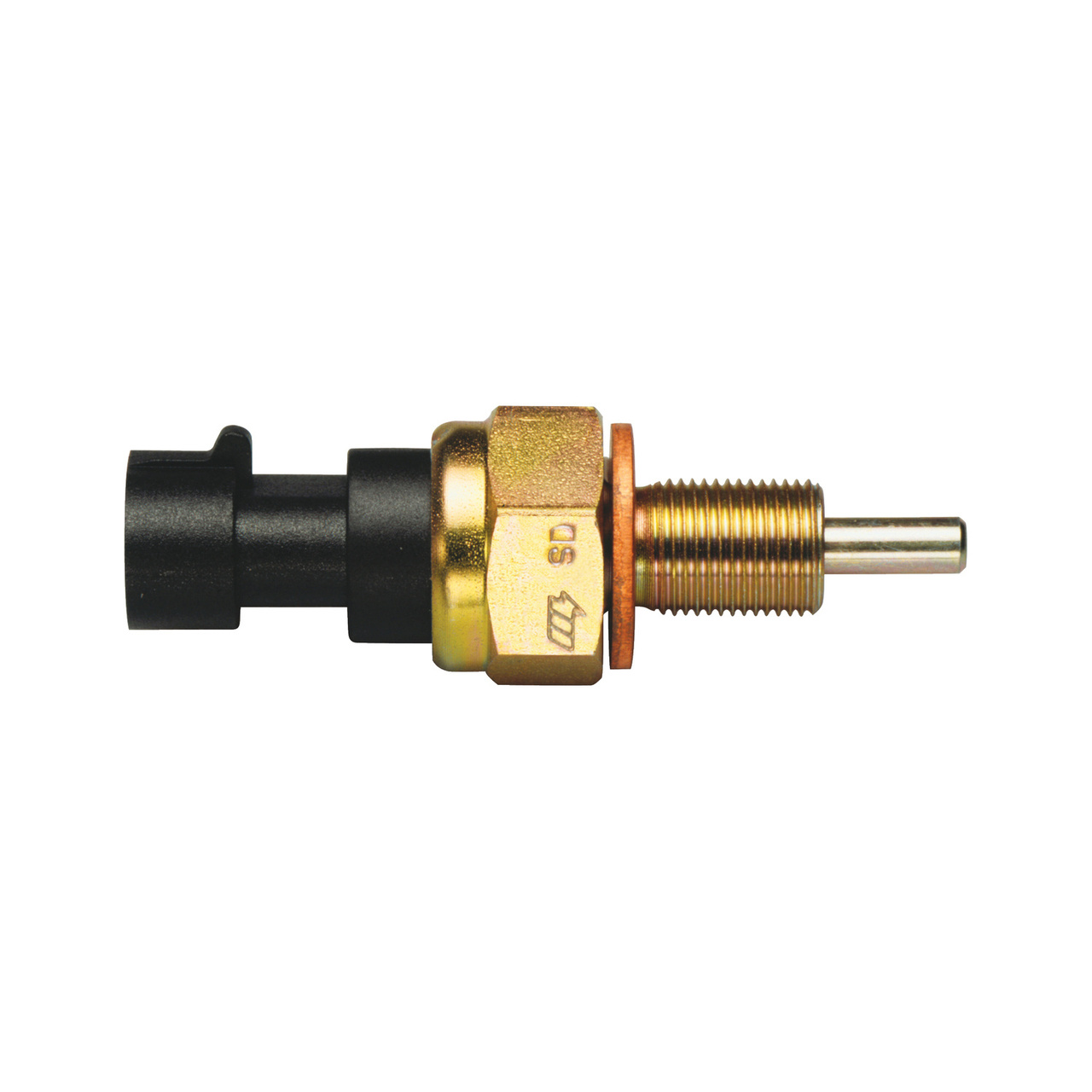

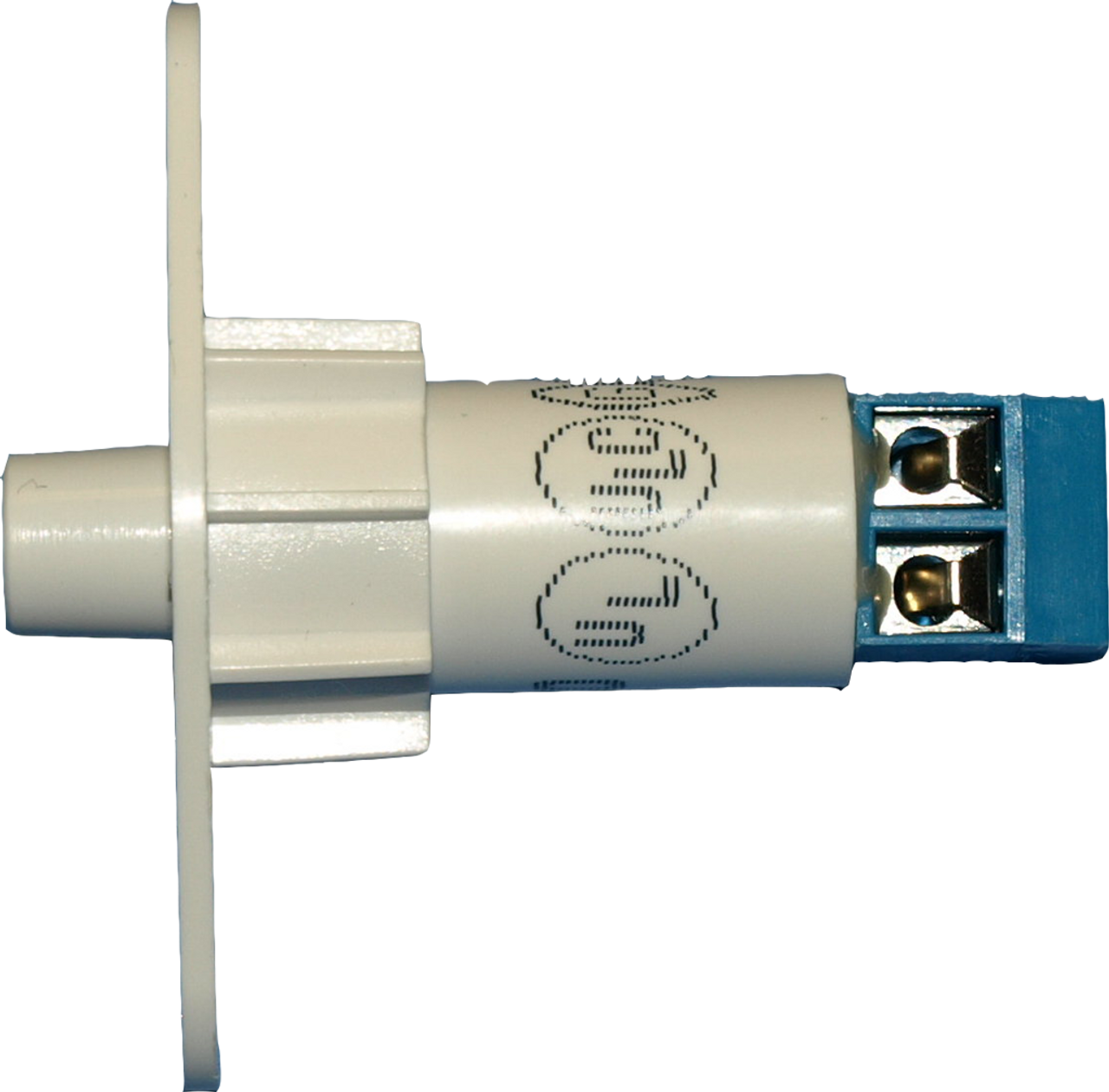

Illustrative image related to plunger switches

-

Plating and Coating: These processes are often applied to metal components to enhance corrosion resistance and aesthetics. For instance, a nickel or chrome plating may be applied to provide a protective layer against environmental factors.

-

Polishing: This finishing technique is essential for ensuring smooth operation of the plunger mechanism, reducing friction, and extending the switch’s lifespan.

Finishing not only improves the product’s appearance but also its functional capabilities, making it more suitable for demanding applications.

What Quality Assurance Measures Are Critical for Plunger Switches?

Quality assurance (QA) is integral to the manufacturing process, ensuring that plunger switches meet international standards and customer expectations.

Which International Standards Should Buyers Be Aware Of?

B2B buyers should look for manufacturers that comply with international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with industry-specific standards like CE marking (for European markets) and API specifications (for oil and gas applications) is also crucial, as these certifications indicate that the products have been tested for safety and performance.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control in the manufacturing of plunger switches involves several checkpoints, including:

-

Incoming Quality Control (IQC): This initial inspection phase focuses on raw materials and components before they enter the production process. It ensures that only materials meeting quality standards are used.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are conducted to ensure that each stage adheres to quality specifications. This may involve monitoring machine settings, component tolerances, and assembly accuracy.

-

Final Quality Control (FQC): Once the plunger switches are fully assembled, they undergo rigorous testing to verify their functionality and durability. This includes electrical testing, mechanical cycling tests, and environmental simulations to ensure they perform under various conditions.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

B2B buyers can verify a supplier’s quality assurance practices through several methods:

-

Audits: Conducting on-site audits of manufacturing facilities can provide valuable insights into the supplier’s processes, compliance with standards, and overall quality management systems.

-

Quality Reports: Requesting detailed quality reports, including test results and compliance certifications, can help buyers assess a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control practices, ensuring that the products meet the required standards before shipment.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, must be aware of specific quality control nuances:

Illustrative image related to plunger switches

-

Regulatory Compliance: Different regions have varying regulations and standards. It is essential for buyers to understand these regulations and ensure that their suppliers comply with local laws.

-

Cultural and Logistical Challenges: Language barriers and logistical issues can complicate communication regarding quality standards. Establishing clear channels for communication and documentation is vital to avoid misunderstandings.

-

Supply Chain Transparency: Buyers should seek suppliers who provide transparency in their supply chain processes, enabling them to trace the origin of materials and the history of quality checks.

By understanding the manufacturing processes and quality assurance measures specific to plunger switches, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plunger switches’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to source plunger switches effectively. Understanding the critical aspects of selecting the right plunger switch can significantly impact operational efficiency and product reliability. Following these steps will help ensure that you procure switches that meet your specific needs while minimizing risks associated with sourcing.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for identifying the right plunger switch for your application. Consider factors such as electrical ratings (voltage and current), environmental conditions (temperature and moisture exposure), and required actuation force. This ensures that the selected switch will perform reliably in its intended environment.

- Electrical Ratings: Determine the voltage and current requirements to avoid overloading the switch.

- Environmental Conditions: Assess whether the switch needs to be waterproof or resistant to dust and other contaminants.

Step 2: Assess Application Requirements

Understanding the specific application for which the plunger switch will be used is crucial. Different industries may have unique demands, such as high durability for outdoor equipment or precision in industrial machinery. Evaluate the mechanical and electrical demands of your application to ensure compatibility.

- Industry Standards: Familiarize yourself with industry-specific standards that the switch must meet, such as IP ratings for water and dust resistance.

- Life Cycle Expectations: Consider the expected life cycle and switching cycles required for your application to select a reliable switch.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers to ensure they can meet your needs. Request detailed company profiles, case studies, and references from clients in similar industries. A strong supplier history can indicate reliability and quality.

- Certifications: Check for industry certifications (e.g., ISO, UL) that demonstrate the supplier’s commitment to quality and safety.

- Customer Feedback: Seek testimonials or reviews from other buyers to gauge supplier performance and reliability.

Step 4: Verify Product Customization Options

Many applications may require customized plunger switches to fit specific requirements. Inquire about the range of customization options available, including actuator size, mounting style, and contact configurations. Custom solutions can optimize performance and integration within your systems.

- Modifications: Ask about the feasibility of modifying existing designs to meet your specifications.

- Lead Times: Understand how custom requests may affect lead times and delivery schedules.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the plunger switches you are considering. Testing these samples in your application will provide insights into their performance and compatibility. This step is vital to ensure that the switches will operate as expected in real-world conditions.

Illustrative image related to plunger switches

- Performance Testing: Evaluate the samples under actual operating conditions to assess durability and functionality.

- Compatibility Checks: Ensure that the samples fit within your existing systems and meet all technical requirements.

Step 6: Negotiate Pricing and Terms

Once you have identified the right supplier and product, negotiate pricing and payment terms to secure a favorable deal. Consider factors such as volume discounts, payment schedules, and warranty terms. This step can lead to significant cost savings and better purchasing conditions.

- Bulk Discounts: Inquire about pricing breaks for larger orders to maximize your budget.

- Warranty and Support: Clarify warranty terms and post-purchase support to ensure long-term reliability and assistance.

Step 7: Finalize Your Order and Monitor Delivery

After agreeing on terms, finalize your order and ensure that you have a clear understanding of the delivery timeline. Monitoring the delivery process is crucial to address any potential issues proactively.

- Tracking: Utilize tracking systems to monitor the shipment and ensure timely arrival.

- Quality Assurance: Plan for a quality check upon receipt to verify that the products meet your specifications.

By following this checklist, B2B buyers can navigate the complexities of sourcing plunger switches, ensuring they select the right products for their operational needs.

Comprehensive Cost and Pricing Analysis for plunger switches Sourcing

What Are the Key Cost Components in Plunger Switch Manufacturing?

Understanding the cost structure of plunger switches is crucial for international B2B buyers, particularly in emerging markets such as Africa and South America. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Commonly used materials include stainless steel for durability and plastics for lighter applications. Advanced options like IP68-rated seals and high-temperature resistant components can increase material costs.

-

Labor: Labor costs vary widely by region. In markets like Europe, labor costs are typically higher due to stringent labor laws and higher wage standards. Conversely, regions with lower labor costs may offer competitive pricing, but potential trade-offs in quality may arise.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and administrative expenses. Efficient production processes can help minimize overhead, but investments in automation may be required to achieve cost-effectiveness.

-

Tooling: The initial investment in tooling for customized plunger switches can be substantial. Buyers should consider the tooling costs when placing large orders for specialized products, as these costs can be amortized over higher volumes.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the switches meet necessary specifications and certifications. While this adds to the cost, it protects against potential failures and recalls, which can be far more expensive.

-

Logistics: Shipping costs can vary based on the destination, shipping method, and Incoterms agreed upon. Buyers must factor in these costs when evaluating supplier proposals.

-

Margin: Supplier margins can fluctuate based on market demand, competition, and the complexity of the switch design. Understanding these margins can provide insight into the pricing structure.

How Do Price Influencers Affect Plunger Switch Sourcing?

Several factors influence the pricing of plunger switches, which international buyers should be aware of:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Suppliers may offer better rates for larger orders, making it essential for buyers to assess their needs and negotiate accordingly.

-

Specifications and Customization: Custom-designed switches typically command higher prices due to the added complexity in manufacturing. Buyers should weigh the benefits of customization against the costs.

-

Quality and Certifications: Products that meet international standards (such as IP ratings or industry-specific certifications) often come at a premium. Buyers should verify that suppliers can provide relevant certifications to ensure compliance with local regulations.

-

Supplier Factors: The reliability and reputation of a supplier can impact pricing. Established suppliers may charge more due to perceived quality and trust, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms and responsibilities is vital. Costs can vary significantly depending on whether the buyer or seller assumes responsibility for shipping, insurance, and duties.

What Tips Can Help Buyers Negotiate Better Prices for Plunger Switches?

For B2B buyers, particularly those operating in diverse markets, effective negotiation strategies can lead to cost savings:

-

Conduct Market Research: Understand the average pricing for different plunger switch models and specifications. This knowledge arms buyers with leverage in negotiations.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the lifecycle costs, including maintenance, reliability, and potential downtime. Cheaper switches may result in higher TCO due to frequent replacements or failures.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow. Discussing payment options can sometimes lead to better pricing or discounts.

-

Leverage Long-Term Relationships: Building a long-term relationship with suppliers can lead to better pricing and terms over time. Regular communication and feedback can foster trust and loyalty.

-

Be Cautious of Hidden Costs: Always clarify the total price, including shipping, duties, and any additional fees. Transparency is key to avoiding unexpected expenses.

In summary, understanding the cost structure, price influencers, and negotiation tactics can empower B2B buyers in sourcing plunger switches effectively. By strategically evaluating these factors, buyers can achieve better pricing and ensure that they are receiving high-quality products tailored to their specific needs.

Alternatives Analysis: Comparing plunger switches With Other Solutions

When evaluating switching solutions in industrial applications, it is essential to consider various alternatives to plunger switches. Plunger switches are widely used for their reliability and versatility, but several other technologies can also fulfill similar roles in different contexts. This analysis will explore two viable alternatives: reed switches and proximity sensors, highlighting their strengths and weaknesses in comparison to plunger switches.

| Comparison Aspect | Plunger Switches | Reed Switches | Proximity Sensors |

|---|---|---|---|

| Performance | High durability, suitable for harsh environments; mechanical action leads to reliable switching. | Limited to low-power applications; susceptible to environmental interference. | High sensitivity; can detect objects without contact, suitable for various materials. |

| Cost | Moderate initial investment; long lifespan reduces overall cost. | Generally low-cost; however, limited functionality may require additional components. | Higher upfront costs; installation complexity may add to expenses. |

| Ease of Implementation | Straightforward installation with multiple mounting options; adaptable to various applications. | Simple to integrate but requires careful handling to prevent damage. | Can be complex to set up; may require specialized knowledge for proper alignment and calibration. |

| Maintenance | Minimal maintenance needed; robust design ensures longevity. | Low maintenance; however, exposure to dust and moisture can reduce lifespan. | Low maintenance if properly installed; however, environmental factors can affect performance. |

| Best Use Case | Ideal for applications requiring physical actuation, such as safety interlocks and mechanical linkages. | Best suited for low-power applications like alarm systems or simple control circuits. | Excellent for automation applications where non-contact detection is preferable, such as in assembly lines. |

What Are the Advantages and Disadvantages of Reed Switches Compared to Plunger Switches?

Reed switches are electromechanical devices that operate using a magnetic field to open or close an electrical circuit. Their primary advantage lies in their simplicity and cost-effectiveness, making them suitable for low-power applications. However, they are vulnerable to environmental factors such as humidity and dust, which can hinder their performance. Moreover, reed switches have limitations in terms of the power they can handle, making them less versatile compared to plunger switches.

How Do Proximity Sensors Compare to Plunger Switches in Industrial Applications?

Proximity sensors use electromagnetic fields or beams of electromagnetic radiation to detect the presence of nearby objects without physical contact. This feature allows for high-speed operation and increased durability. However, they generally come at a higher cost and require careful installation to ensure accurate sensing. While they excel in automation scenarios, their complexity can be a barrier for some users compared to the straightforward design of plunger switches.

Illustrative image related to plunger switches

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right switching technology depends on specific application requirements, including environmental conditions, power needs, and budget constraints. B2B buyers should consider the operational context of their projects—if reliability and robustness in harsh conditions are paramount, plunger switches may be the best choice. Alternatively, for applications that require non-contact detection and higher speed, proximity sensors could be more suitable. Ultimately, understanding the unique demands of their operations will guide buyers to make informed decisions that align with their strategic goals.

Essential Technical Properties and Trade Terminology for plunger switches

What Are the Key Technical Properties of Plunger Switches?

Understanding the technical specifications of plunger switches is essential for B2B buyers who need reliable and durable components for their applications. Here are some critical specifications that every buyer should consider:

1. Material Grade

Plunger switches are often constructed from materials such as stainless steel or brass. Stainless steel offers superior corrosion resistance, making it ideal for harsh environments, while brass is known for its excellent conductivity and durability. Choosing the right material ensures longevity and reliability, especially in demanding applications like outdoor machinery or industrial equipment.

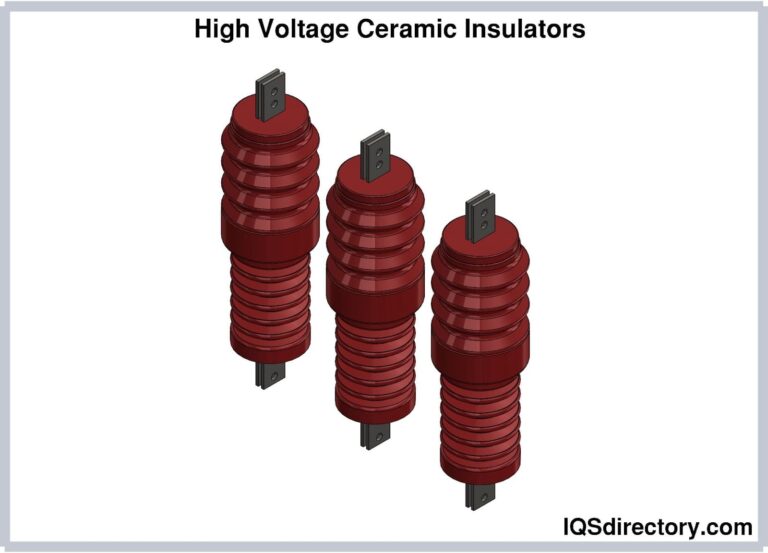

2. IP Rating (Ingress Protection)

The IP rating indicates the degree of protection provided against dust and moisture. For instance, an IP68 rating means the switch is fully dust-tight and can withstand continuous immersion in water. This property is particularly important for applications exposed to the elements, as it ensures the switch will function reliably despite environmental challenges.

Illustrative image related to plunger switches

3. Electrical Ratings

These ratings specify the maximum voltage and current the switch can handle, typically measured in volts (V) and amperes (A). For example, a switch rated for 28VDC and 5A is suitable for various low-voltage applications. Understanding these ratings helps ensure the switch can safely handle the electrical demands of the specific application, preventing failures or malfunctions.

4. Endurance and Cycle Life

Endurance refers to the number of mechanical cycles a plunger switch can reliably perform before failure, often exceeding millions of cycles. This property is critical for applications requiring frequent operation, such as industrial machinery. A higher cycle life translates to reduced maintenance costs and downtime, making it a vital consideration for B2B buyers.

5. Actuation Force and Travel Distance

The actuation force is the amount of force required to activate the switch, while travel distance refers to how far the plunger moves during actuation. These parameters can be customized based on application requirements, ensuring optimal performance in various conditions. Understanding these specifications helps buyers select switches that align with their operational needs.

What Are Common Trade Terms Related to Plunger Switches?

Familiarizing yourself with industry jargon can enhance communication and negotiation processes. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of plunger switches, OEMs provide components that are integral to the final products of other companies, making them critical partners in supply chains.

Illustrative image related to plunger switches

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers, as it affects inventory management and cost-effectiveness. Suppliers may set MOQs to ensure profitability, especially for specialized or custom products.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. This term is commonly used in B2B transactions to initiate the procurement process. A well-prepared RFQ ensures clarity in specifications and pricing, facilitating better supplier responses.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms helps clarify who is responsible for shipping costs, insurance, and risk during transport, which is crucial for international B2B transactions.

Illustrative image related to plunger switches

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. In the context of plunger switches, lead time can impact project timelines and operational efficiency. Buyers should consider lead times when planning their procurement strategies to avoid delays in production or service delivery.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when selecting plunger switches, ensuring they meet the specific needs of their applications while fostering effective supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the plunger switches Sector

What Are the Current Market Dynamics and Key Trends in the Plunger Switches Sector?

The global plunger switches market is experiencing significant growth, driven by advancements in automation, increasing demand for reliable control systems, and the need for durable components in harsh environments. Key markets in Africa, South America, the Middle East, and Europe are witnessing a surge in applications across industries such as automotive, aerospace, and industrial machinery. This trend is propelled by the rapid adoption of electric vehicles and automation technologies, which require high-performance and resilient switching solutions.

Emerging technologies, including smart sensors and IoT integration, are reshaping the sourcing landscape. B2B buyers are increasingly seeking plunger switches that offer enhanced features such as electronic controls and remote monitoring capabilities. Additionally, customization options are becoming a critical factor for buyers, as they look for solutions tailored to their specific applications, whether for military vehicles, industrial equipment, or agricultural machinery. This demand for flexibility extends to electrical ratings, actuation force, and environmental resistance, catering to diverse operating conditions.

Sourcing trends indicate a shift towards local suppliers that can offer shorter lead times and better support. International buyers are also prioritizing suppliers with robust quality assurance processes and a commitment to meeting international standards, such as IP68 for water and dust resistance. This focus on quality, combined with the need for innovation, positions suppliers who can adapt quickly to market demands as leaders in the plunger switch sector.

Illustrative image related to plunger switches

How Are Sustainability and Ethical Sourcing Influencing the Plunger Switches Market?

Sustainability is becoming a cornerstone of procurement strategies in the plunger switches sector. As environmental regulations tighten and consumer awareness grows, B2B buyers are increasingly evaluating the ecological impact of their sourcing decisions. Suppliers that incorporate sustainable practices into their operations—such as using recyclable materials and reducing waste—are gaining a competitive edge.

Ethical sourcing is equally crucial, with buyers demanding transparency in supply chains. This includes ensuring that materials are sourced responsibly and that labor practices meet ethical standards. For instance, manufacturers of plunger switches are now more frequently obtaining certifications that demonstrate compliance with environmental and social governance criteria. This trend is particularly relevant for international buyers from regions like Africa and South America, where local regulations and community expectations can influence purchasing decisions.

Buyers are encouraged to seek out suppliers who utilize “green” materials, such as bioplastics or metals that are recycled or sustainably sourced. By prioritizing these suppliers, businesses can not only enhance their corporate social responsibility profile but also tap into a growing market segment that values sustainability.

What Is the Brief Evolution and History of Plunger Switches?

The evolution of plunger switches has been marked by significant technological advancements since their inception. Initially designed for basic on-off applications, plunger switches have transformed into sophisticated devices capable of handling complex automation tasks. Early models were primarily mechanical, relying on simple actuation mechanisms, but with the rise of electronic controls in the late 20th century, manufacturers began integrating electronic components to enhance functionality.

The introduction of materials with superior durability, such as stainless steel and specialized plastics, has enabled plunger switches to operate in extreme conditions, thus expanding their applications across various industries. Today, plunger switches are integral to modern machinery, automotive systems, and military applications, reflecting a shift towards more advanced, reliable, and efficient control solutions. As the market continues to evolve, the focus on customization, sustainability, and technological integration will likely shape the future of plunger switches.

Frequently Asked Questions (FAQs) for B2B Buyers of plunger switches

-

How do I choose the right plunger switch for my application?

Selecting the appropriate plunger switch depends on various factors, including the operational environment, electrical ratings, and mechanical requirements. Assess the switch’s specifications, such as IP ratings for dust and water resistance, temperature tolerances, and endurance cycles. Consider the mounting style and actuator type that best fits your machinery or equipment. Additionally, evaluate the required electrical configuration, such as normally open (NO) or normally closed (NC) options. Consulting with manufacturers can provide insights tailored to your unique needs. -

What are the key features to look for in a plunger switch?

When sourcing plunger switches, prioritize features like durability, environmental sealing (IP ratings), and electrical specifications. Look for stainless steel or other robust materials that enhance longevity. Consider the switch’s actuation force, travel distance, and mechanical cycle rating, which indicate reliability in demanding applications. Also, assess customization options for mounting styles and electrical connections, ensuring compatibility with your systems. These factors collectively determine the switch’s performance and lifespan in your specific application. -

What customization options are typically available for plunger switches?

Many manufacturers offer customization options to meet specific operational requirements. Customizable features may include plunger length, actuator shape, mounting thread configurations, and termination types. You can also select between sealed or vented designs depending on exposure to environmental factors. Additionally, some suppliers may provide tailored electrical ratings or endurance specifications, allowing you to align the switch’s performance with your application needs. Always discuss your requirements with suppliers to explore available options. -

What is the minimum order quantity (MOQ) for plunger switches?

Minimum order quantities for plunger switches can vary significantly between manufacturers and product lines. Typically, MOQs can range from a small batch of 10-50 units for standard models to larger quantities for customized designs. It’s essential to confirm the MOQ with your chosen supplier, especially if you are considering a specific configuration or custom features. Additionally, some manufacturers may offer flexibility for new customers or bulk orders, so negotiating terms may yield favorable outcomes. -

How can I ensure the quality of plunger switches from international suppliers?

To ensure quality when sourcing plunger switches from international suppliers, conduct thorough due diligence. Request certifications and compliance documents, such as ISO 9001, to verify manufacturing standards. Review product samples and test them in your application to assess performance. Check supplier references and customer reviews to gauge reliability and service quality. Establishing a clear communication channel with the supplier will also help address any concerns and ensure adherence to your specifications. -

What payment terms should I expect when sourcing plunger switches internationally?

Payment terms for international purchases can vary widely among suppliers. Common arrangements include upfront payments, letters of credit, or net payment terms ranging from 30 to 90 days. Some suppliers may offer discounts for early payments or larger orders. It’s crucial to clarify these terms before placing an order and to understand any associated fees, such as currency exchange or transaction charges. Establishing a secure payment method that minimizes risk is also advisable. -

What logistics considerations should I keep in mind when importing plunger switches?

When importing plunger switches, consider logistics aspects such as shipping methods, customs regulations, and lead times. Evaluate the reliability of the shipping options offered by suppliers, including air versus sea freight, based on urgency and cost. Familiarize yourself with import duties, taxes, and compliance with local regulations in your country. Coordination with a freight forwarder can facilitate smooth customs clearance and delivery, ensuring that your plunger switches arrive in a timely manner. -

What are common applications for plunger switches in various industries?

Plunger switches are widely used across multiple sectors, including automotive, manufacturing, and military applications. Common uses include position sensing in hydraulic systems, control levers in outdoor power equipment, and interlock safety systems in industrial machinery. They are also prevalent in marine applications, where environmental resistance is crucial. Understanding the specific applications can help you identify the right switch features and configurations that best suit your industry’s demands.

Top 7 Plunger Switches Manufacturers & Suppliers List

1. CPI – Plunger Switch J4 Series

Domain: cpi-nj.com

Registered: 1996 (29 years)

Introduction: Product Name: Plunger Switch – J4 Series

Key Features:

– Stainless steel construction

– Completely submersible (meets IP68)

– Plunger seals, wiper seals, and hardened actuator configurations

– Ultra high-temperature capability

– Normally open and normally closed versions available

– Variable parameters: plunger length, actuator shape/size, mounting thread, terminations, actuation force, travel par…

2. McMaster – Plunger Switches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Plunger Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. TE – Shock Resistant Plunger Switches

Domain: te.com

Registered: 1992 (33 years)

Introduction: This company, TE – Shock Resistant Plunger Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Ttesports – Keyboard Inquiry

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Keyboard brand: Ttesports by Thermaltake; Type: Unknown switch (user inquiring if it’s a plunger or mechanical switch); Price: Approximately 45 euros; Duration of use: About 1 year.

5. Delta Systems – Plunger Switches

Domain: deltasystemsinc.com

Registered: 1997 (28 years)

Introduction: Delta Systems’ Plunger Switches are designed to sense the position of mechanical linkages and control levers. They feature a wiping action that cleans contacts during use, reducing contact resistance and extending switch life in rugged environments. Available configurations include one to three independent electrical circuits, with versatile mounting styles for various panel thicknesses and locati…

6. Littelfuse – Automotive Plunger Switches

Domain: littelfuse.com

Registered: 1996 (29 years)

Introduction: Automotive Plunger Switches for Commercial Vehicles; 5-volt DIN and 12-volt to 24-volt mechanical options; contact configurations: normally open, normally closed, normally open-normally closed; available with silver-plated and gold-plated contacts; used to signal situations such as power takeoff, idle and reverse gear, differential block, low gears brake failure, reduced gears, and handbrake failu…

7. AutomationDirect – Limit Switches with Plunger Actuators

Domain: automationdirect.com

Registered: 1999 (26 years)

Introduction: Limit switches with plunger actuators are designed for various applications in automation and control systems. They provide reliable and precise position sensing. Key features include a robust design for durability, various actuator styles, and compatibility with different mounting options. These switches are suitable for use in industrial environments, offering high performance and long service l…

Strategic Sourcing Conclusion and Outlook for plunger switches

In summary, strategic sourcing of plunger switches is essential for optimizing operational efficiency and ensuring reliability in various applications across industries. By focusing on high-performance options, such as waterproof and shock-resistant models, buyers can enhance their equipment’s durability and functionality. Additionally, understanding the diverse configurations and specifications available, from actuator designs to electrical ratings, allows for tailored solutions that meet specific business needs.

The global market presents unique opportunities, particularly for buyers in Africa, South America, the Middle East, and Europe. As industries continue to evolve, leveraging advanced sourcing strategies will enable businesses to stay competitive and responsive to market demands.

Investing in quality plunger switches not only improves product longevity but also enhances safety and operational performance. As you consider your sourcing strategy, engage with manufacturers and suppliers who offer comprehensive support and customization options. This proactive approach will position your business for success in an increasingly interconnected and dynamic marketplace. Take the next step by exploring partnerships that align with your goals and drive innovation within your operations.

Illustrative image related to plunger switches

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.