A Deep Dive into Planetary Gear Applications Solution

Introduction: Navigating the Global Market for planetary gear applications

In today’s competitive landscape, sourcing reliable planetary gear applications can pose significant challenges for international B2B buyers. With a diverse range of options available, organizations must navigate varying quality standards, supplier capabilities, and market conditions, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding these complexities is crucial for making informed purchasing decisions that align with operational needs and budget constraints.

This comprehensive guide serves as an essential resource for decision-makers seeking to optimize their procurement processes. It delves into the different types of planetary gears, their specific applications across various industries, and the critical factors to consider when vetting suppliers. By highlighting key performance metrics and cost considerations, this guide empowers B2B buyers to identify solutions that not only meet their technical requirements but also enhance overall productivity and efficiency.

Furthermore, as global supply chains continue to evolve, understanding regional market dynamics becomes increasingly important. Whether you’re based in Nigeria, Saudi Arabia, or any other part of the world, this guide equips you with the insights necessary to navigate the global market confidently. By leveraging the information presented, buyers can forge strategic partnerships that drive innovation and success in their respective fields.

Understanding planetary gear applications Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Planetary Gears | Central sun gear with multiple orbiting planet gears | CNC machinery, automotive, conveyor systems | Pros: High efficiency, compact design. Cons: Limited customization. |

| Custom Planetary Gears | Tailored designs for specific load requirements | Specialized machinery, aerospace, robotics | Pros: Optimized performance for unique applications. Cons: Higher cost and longer lead times. |

| High-Precision Planetary Gears | Exceptional accuracy and minimal backlash | Laser cutting, medical equipment | Pros: Superior positioning accuracy. Cons: More expensive due to precision manufacturing. |

| Compact Planetary Gears | Space-saving designs ideal for tight installations | Robotics, AGVs, portable machinery | Pros: Lightweight and efficient. Cons: May sacrifice durability for size. |

| Heavy-Duty Planetary Gears | Designed to handle high radial and axial loads | Construction equipment, industrial applications | Pros: Robust and reliable under stress. Cons: Bulkier and heavier, requiring more space. |

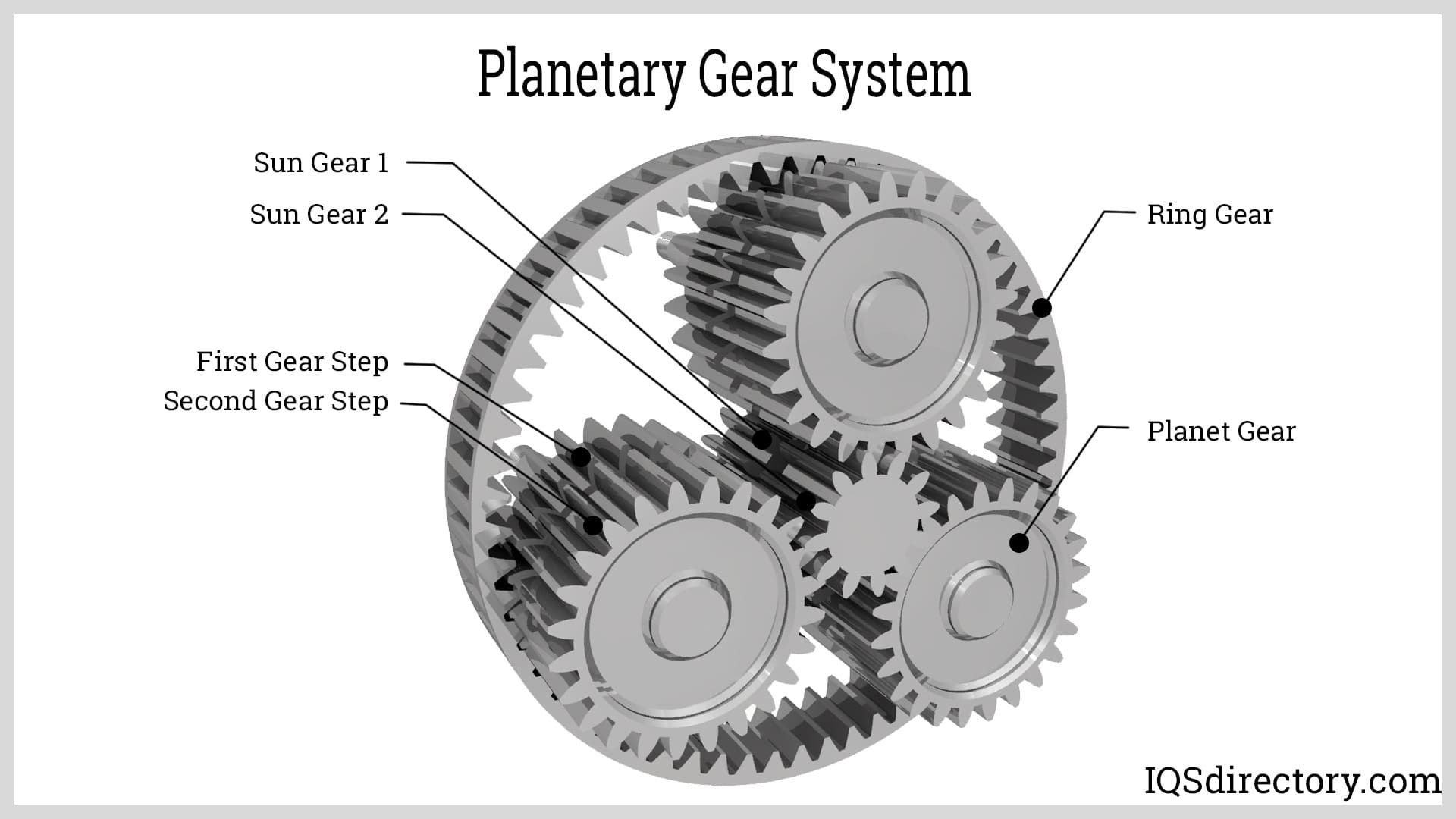

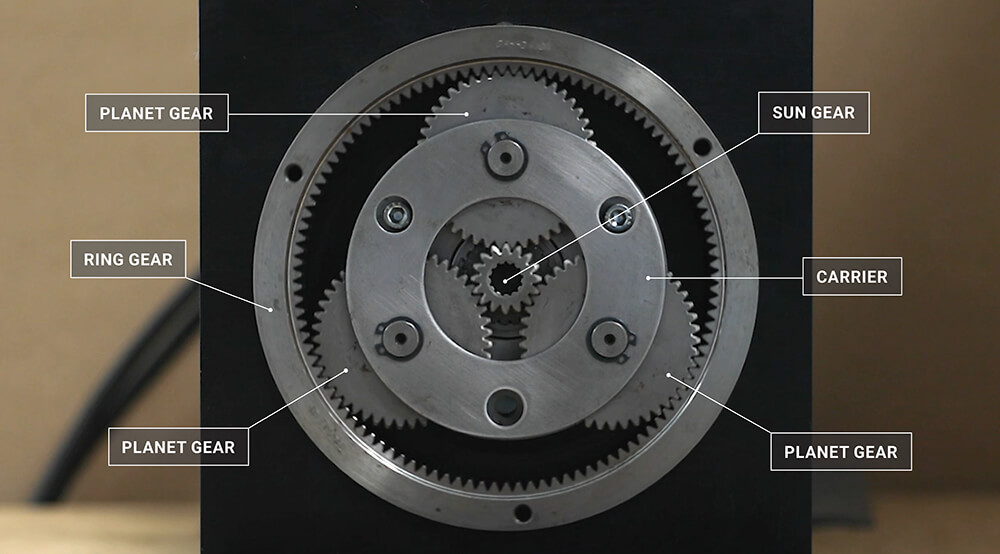

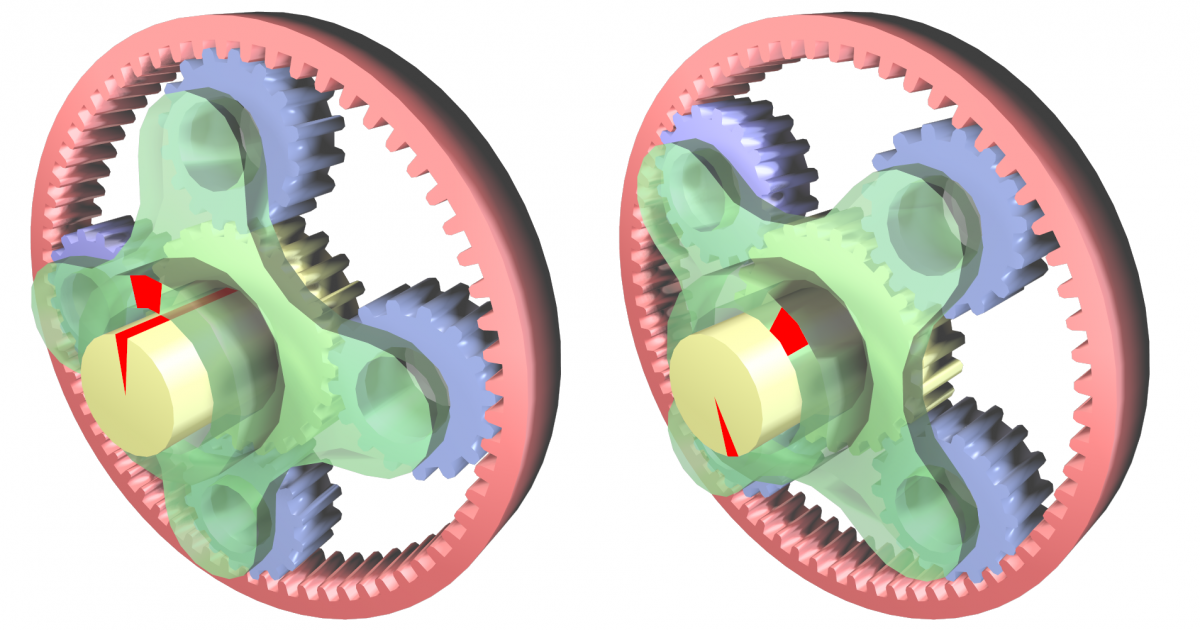

What Are the Key Characteristics of Standard Planetary Gears?

Standard planetary gears are characterized by their arrangement of a central sun gear, multiple planet gears, and a ring gear. This configuration allows for high torque transmission and compact design, making them suitable for various applications, including CNC machinery and automotive systems. Buyers should consider their efficiency and space-saving capabilities, while also noting that they may lack the customization options available in specialized designs.

How Do Custom Planetary Gears Meet Unique Application Needs?

Custom planetary gears are specifically designed to meet unique operational requirements, such as high radial loads or specific gear ratios. This flexibility makes them ideal for specialized machinery in sectors like aerospace and robotics. However, while they offer optimized performance, buyers should be aware of potentially higher costs and longer lead times associated with custom manufacturing.

What Makes High-Precision Planetary Gears Ideal for Certain Industries?

High-precision planetary gears are engineered for exceptional accuracy and minimal backlash, making them perfect for applications that demand precise motion control, such as laser cutting and medical equipment. Their advanced design ensures superior positioning accuracy, which is a significant advantage in high-stakes environments. However, the cost of these gears can be a consideration for budget-conscious buyers.

Why Choose Compact Planetary Gears for Space-Constrained Applications?

Compact planetary gears are designed to maximize efficiency in limited spaces, making them suitable for applications in robotics and automated guided vehicles (AGVs). Their lightweight and efficient nature allows for high performance without excessive bulk. Buyers should weigh the benefits of size and weight against potential durability concerns, as these gears may not withstand as much stress as larger counterparts.

What Are the Advantages of Heavy-Duty Planetary Gears in Industrial Settings?

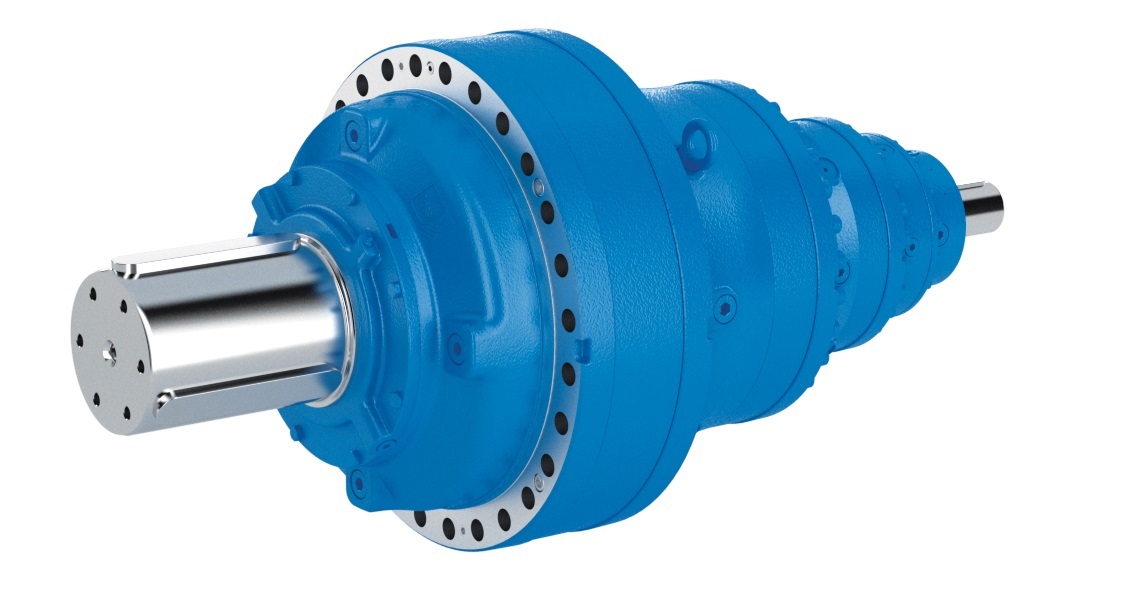

Heavy-duty planetary gears are built to handle high radial and axial loads, making them ideal for use in construction equipment and other industrial applications. Their robust construction ensures reliability and longevity under demanding conditions. However, buyers should consider their larger size and weight, which may necessitate more substantial installation space and support structures.

Illustrative image related to planetary gear applications

Key Industrial Applications of planetary gear applications

| Industry/Sector | Specific Application of planetary gear applications | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Press Brakes Drive | Enhanced precision in metal bending operations | Need for high torque and compact design |

| Robotics | In-Mould Labeling (IML) Robots | Improved efficiency and accuracy in labeling | Modular design and rapid availability are crucial |

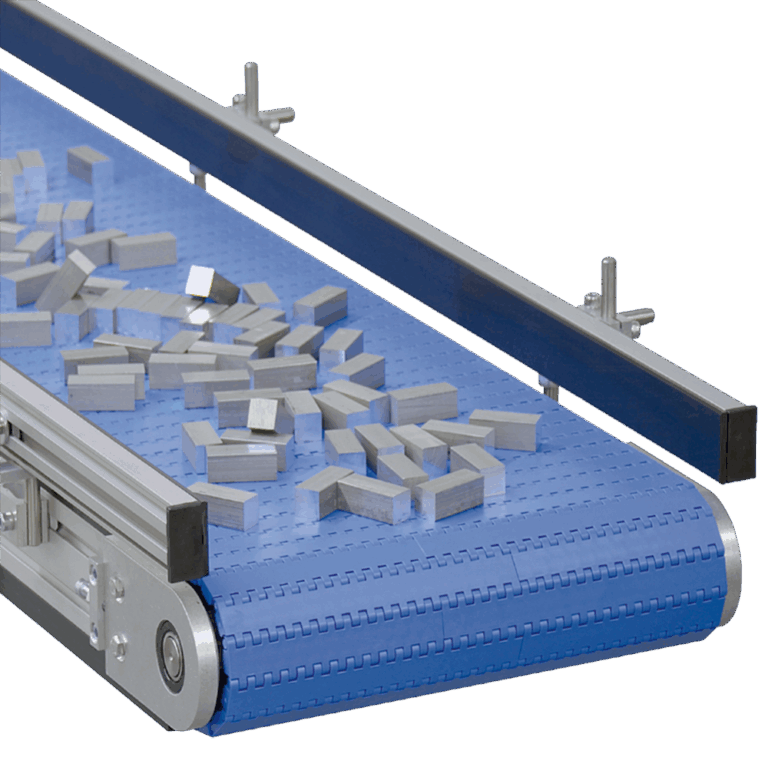

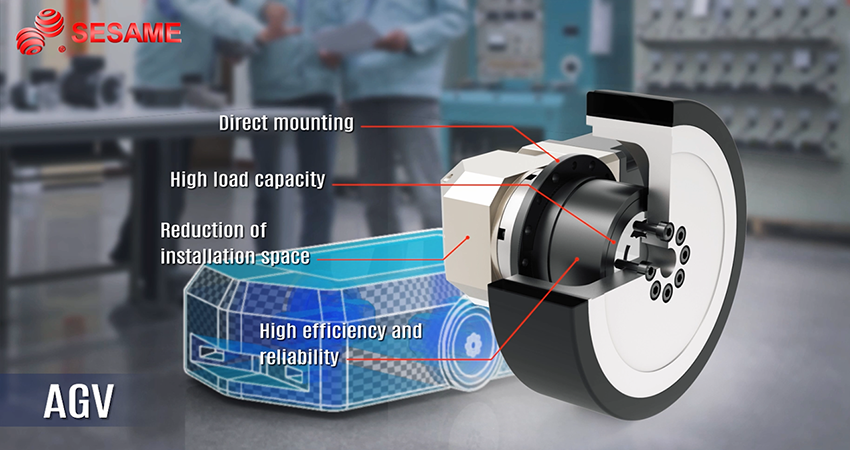

| Automation | Automated Guided Vehicles (AGVs) | Increased productivity and operational efficiency | Lightweight and compact construction for energy savings |

| Textile Production | Ring Spindle Machines | Long service life and reliability in textile processing | Cost-effectiveness and ability to handle high workloads |

| Food Processing | Cleaning Systems Drive | Reduced noise and improved hygiene standards | IP protection and durability in harsh environments |

How Are Planetary Gears Used in CNC Press Brakes Drive Applications?

In the manufacturing sector, planetary gears are integral to CNC press brakes, which bend metal sheets with high precision. The planetary gear system ensures accurate positioning of the back gauge, allowing for complex parts to be produced efficiently. International buyers, particularly in regions like Africa and the Middle East, should focus on sourcing gears that can handle high torque and offer compact designs to fit modern machinery requirements.

What Role Do Planetary Gears Play in Robotics for In-Mould Labeling?

In the robotics industry, particularly in the in-mould labeling (IML) process, planetary gears provide the necessary precision for handling pre-cut labels. By equipping IML robots with planetary gear systems, manufacturers can achieve high positioning accuracy and rapid cycle times, enhancing overall production efficiency. Buyers should prioritize modular designs that allow for quick adjustments and replacements, especially in fast-paced environments found in South America and Europe.

How Do Planetary Gears Enhance Productivity in Automated Guided Vehicles (AGVs)?

Automated guided vehicles (AGVs) utilize planetary gears to optimize their drive systems, ensuring efficient distribution of goods in warehouses. The compact design of these gears contributes to the lightweight nature of AGVs, allowing for longer operational periods without frequent recharging. International buyers in logistics and warehousing sectors should consider sourcing gears that offer high bending rigidity and can absorb axial and radial loads effectively.

Why Are Planetary Gears Essential for Ring Spindle Machines in Textile Production?

In the textile industry, planetary gears are used in ring spindle machines to ensure durability and efficiency. These gears are designed to withstand extensive operational hours, making them cost-effective over time. Buyers in this sector must seek gears that provide robust performance under high workloads, particularly in regions like Africa where textile manufacturing is growing rapidly.

How Do Planetary Gears Benefit Cleaning Systems in Food Processing?

Planetary gears are crucial in the food processing industry for the operation of cleaning systems, where hygiene and noise reduction are paramount. The IP65-rated planetary gears ensure protection against dust and water while maintaining quiet operation, which is essential in food environments. Buyers should focus on sourcing gears that meet these stringent requirements, ensuring compliance with international food safety standards, especially in markets like the Middle East where regulatory compliance is critical.

3 Common User Pain Points for ‘planetary gear applications’ & Their Solutions

Scenario 1: The Challenge of Precision and Speed in Automation Applications

The Problem: In sectors such as manufacturing and robotics, B2B buyers often face the dilemma of achieving both precision and speed in their automated systems. For instance, a company might be using planetary gears in a CNC machine for metal fabrication. However, they encounter issues with gear backlash and insufficient torque transmission, resulting in poor machining accuracy and decreased production efficiency. These problems can lead to costly delays and reduced competitiveness in a fast-paced market.

The Solution: To address these challenges, buyers should prioritize selecting high-precision planetary gear systems specifically designed for automation applications. When sourcing, look for gears that boast minimal backlash and high load capacity. For instance, the GSD series planetary gears are engineered to handle significant radial and axial loads while ensuring accurate positioning. Additionally, it’s essential to incorporate feedback mechanisms, such as encoders, that work in tandem with the planetary gear to provide real-time data on performance. Regular maintenance checks should also be scheduled to ensure optimal performance and longevity, helping prevent unexpected downtime and enhancing overall productivity.

Scenario 2: Addressing Gear Wear and Longevity in Harsh Environments

The Problem: B2B buyers in industries like mining or construction often operate in harsh environments where planetary gears face extreme conditions such as dust, moisture, and high temperatures. This can lead to accelerated wear and tear, resulting in frequent breakdowns and costly replacements. For example, a mining operation utilizing planetary gears in a conveyor system may find that their gearboxes fail prematurely, affecting the entire production line.

The Solution: To combat these issues, buyers should invest in planetary gear systems that are specifically designed for harsh operating conditions. Seek out gears that feature robust materials, such as hardened steel or corrosion-resistant coatings, which can withstand environmental stressors. Additionally, implementing a proactive maintenance schedule that includes regular inspections and lubrication can significantly extend the lifespan of the gears. It may also be beneficial to partner with suppliers who offer custom solutions tailored to specific environmental challenges, ensuring that the gear systems are optimized for longevity and reliability in demanding applications.

Illustrative image related to planetary gear applications

Scenario 3: Customization Needs for Unique Applications

The Problem: Many B2B buyers encounter situations where standard planetary gear solutions do not meet their specific application requirements. This is particularly common in industries like robotics and aerospace, where precise specifications are critical. For instance, a robotics company may need a lightweight yet high-torque planetary gearbox for a new robotic arm design but finds that off-the-shelf options do not deliver the necessary performance metrics.

The Solution: To effectively address the need for customization, buyers should engage with manufacturers that offer bespoke planetary gear solutions. Begin by conducting a thorough analysis of the application requirements, including torque, size, weight, and speed specifications. Once the parameters are clear, collaborate closely with the manufacturer’s engineering team to develop a tailored planetary gear system that meets these unique needs. This collaborative approach not only ensures that the solution fits perfectly but also allows for adjustments based on testing and feedback during the prototyping phase. Furthermore, establishing a long-term relationship with a reliable supplier can facilitate ongoing support and future customizations as the application evolves.

Strategic Material Selection Guide for planetary gear applications

What Are the Key Materials for Planetary Gear Applications?

When selecting materials for planetary gear applications, several factors must be considered, including mechanical properties, environmental conditions, and cost-effectiveness. Below is an analysis of four common materials used in the manufacturing of planetary gears, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Illustrative image related to planetary gear applications

How Do Steel Alloys Perform in Planetary Gear Applications?

Steel alloys, particularly those like carbon steel and alloy steel, are widely used in planetary gear applications due to their excellent strength and durability. Key properties include high tensile strength, good wear resistance, and the ability to withstand high temperatures and pressures. However, they may require additional treatments, such as heat treatment or surface hardening, to enhance their performance further.

Pros: Steel alloys offer high durability and are suitable for heavy-duty applications. They can be manufactured with relative ease and are compatible with various machining processes.

Cons: The primary downside is their susceptibility to corrosion if not properly coated or treated, which can be a significant concern in humid or corrosive environments. Additionally, the cost can be higher than other materials, especially if advanced treatments are required.

Impact on Application: Steel alloys are well-suited for applications involving high loads and dynamic stresses, such as in automotive and industrial machinery.

Illustrative image related to planetary gear applications

Considerations for International Buyers: Compliance with standards like ASTM or DIN is crucial. Buyers from regions like Africa and the Middle East should ensure the materials can withstand local environmental conditions, including humidity and temperature variations.

What Role Do Engineering Plastics Play in Planetary Gear Design?

Engineering plastics, such as polyamide (Nylon) and polyoxymethylene (POM), are increasingly popular in planetary gear applications due to their lightweight and corrosion-resistant properties. They can operate effectively at lower temperatures and are less prone to rust compared to metals.

Pros: The primary advantages of engineering plastics include reduced weight, lower noise during operation, and resistance to chemical exposure. They are also cost-effective for low-load applications.

Illustrative image related to planetary gear applications

Cons: However, engineering plastics may not be suitable for high-load or high-temperature applications, as they can deform under stress. Their manufacturing complexity can also increase costs if precision is required.

Impact on Application: These materials are ideal for applications in the food and beverage industry or environments where corrosion is a concern.

Considerations for International Buyers: Buyers should verify compliance with food safety standards and ensure that the selected plastics can withstand local operating conditions, particularly in humid climates.

How Do Aluminum Alloys Compare for Planetary Gears?

Aluminum alloys are known for their lightweight characteristics and good strength-to-weight ratio, making them an attractive option for planetary gears, especially in applications requiring reduced weight, such as in aerospace and automotive sectors.

Pros: Aluminum alloys are resistant to corrosion and have excellent machinability, which can lower manufacturing costs. They also provide good thermal conductivity, which can be beneficial in heat dissipation applications.

Cons: The main limitation is their lower strength compared to steel, which may restrict their use in high-load applications. They can also be more expensive than some traditional materials.

Impact on Application: Aluminum alloys are particularly useful in applications where weight savings are critical, such as in electric vehicles or drones.

Considerations for International Buyers: Buyers should ensure that the aluminum grades comply with relevant international standards and are suitable for the intended operational environment.

Illustrative image related to planetary gear applications

What Advantages Do Composite Materials Offer for Planetary Gears?

Composite materials, such as carbon-fiber-reinforced polymers, are gaining traction in high-performance planetary gear applications. They offer unique properties, including high strength, low weight, and excellent fatigue resistance.

Pros: Composites can significantly reduce weight while maintaining strength, making them ideal for advanced engineering applications. They also exhibit excellent resistance to corrosion and wear.

Cons: The main drawback is the higher cost of production and the complexity of manufacturing processes, which can make them less accessible for some manufacturers.

Impact on Application: Composites are suitable for high-performance applications in aerospace and specialized machinery where weight and performance are critical.

Considerations for International Buyers: Buyers should consider the availability of these materials in their regions and ensure compliance with industry-specific standards.

Summary Table of Material Selection for Planetary Gears

| Material | Typical Use Case for planetary gear applications | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel Alloys | Heavy-duty machinery, automotive applications | High durability and strength | Susceptible to corrosion | High |

| Engineering Plastics | Food and beverage processing equipment | Lightweight and corrosion-resistant | Not suitable for high-load applications | Medium |

| Aluminum Alloys | Aerospace, automotive sectors | Lightweight and good thermal conductivity | Lower strength compared to steel | Medium |

| Composite Materials | High-performance aerospace applications | High strength-to-weight ratio | Higher production costs | High |

This guide provides a foundational understanding of material selection for planetary gears, ensuring that international B2B buyers can make informed decisions tailored to their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for planetary gear applications

What Are the Main Stages in the Manufacturing Process of Planetary Gears?

The manufacturing process of planetary gears is intricate and involves several critical stages to ensure high performance and durability. Understanding these stages is essential for B2B buyers looking to procure reliable gear solutions.

1. Material Preparation

The first step in manufacturing planetary gears involves selecting high-quality raw materials, typically alloy steels or other metal alloys. The choice of material is crucial as it directly affects the gear’s strength, wear resistance, and overall performance. The raw materials undergo rigorous quality checks to verify their composition and properties. This can include tensile strength tests and hardness measurements to ensure they meet industry standards.

2. Forming Techniques

Once the materials are prepared, they undergo forming processes to shape them into gear components. Common techniques include:

- Machining: Precision machining is employed to create the intricate tooth profiles of planetary gears. CNC (Computer Numerical Control) machines are often used for their accuracy and repeatability.

- Forging: This process involves shaping the metal using compressive forces, which can enhance the material’s grain structure and improve mechanical properties.

- Powder Metallurgy: This method involves compacting powdered metal and sintering it to form solid components, offering benefits like reduced waste and enhanced material properties.

These techniques ensure that the components are not only shaped accurately but also possess the required strength and durability for their applications.

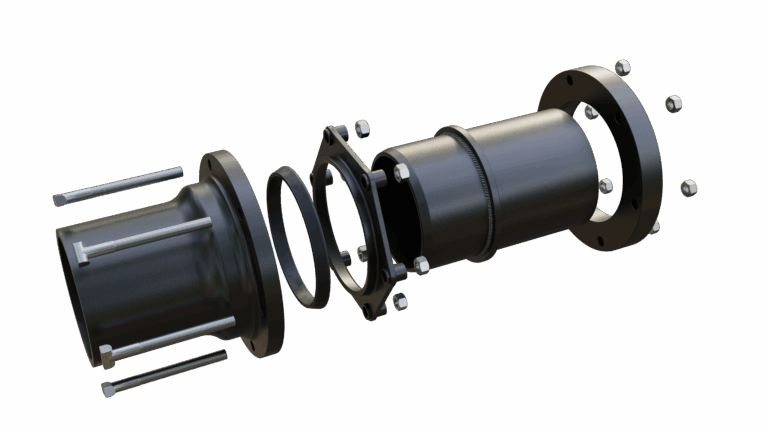

3. Assembly Process

The assembly of planetary gears is a critical stage where precision is paramount. The assembly typically includes:

- Sun Gear, Planet Gears, and Ring Gear Assembly: These components are meticulously aligned and assembled. The arrangement must maintain the correct gear mesh to ensure efficient power transmission.

- Bearing Installation: Bearings are installed to support the rotating elements, minimizing friction and wear during operation. Their placement must be precise to ensure optimal performance.

- Lubrication: Appropriate lubrication is applied to reduce friction and enhance the lifespan of the gears.

Quality control during assembly is crucial, as any misalignment or improper installation can lead to premature failure.

4. Finishing Processes

The final stage involves finishing processes that enhance the performance and appearance of the planetary gears. This may include:

- Heat Treatment: This process alters the physical and sometimes chemical properties of the material, improving hardness and strength.

- Surface Treatment: Techniques such as grinding, honing, or coating may be applied to enhance wear resistance and reduce friction.

- Inspection and Testing: Each finished gear undergoes rigorous inspection, including dimensional checks and surface quality assessments, to ensure they meet specifications.

How is Quality Assurance Maintained in Planetary Gear Manufacturing?

Quality assurance (QA) is critical in the manufacturing of planetary gears, ensuring that products meet both international standards and customer expectations.

Relevant International and Industry-Specific Standards

For planetary gear manufacturers, compliance with international standards such as ISO 9001 is fundamental. This standard focuses on quality management systems and is applicable across industries, ensuring that manufacturers have processes in place for consistent quality. Additionally, industry-specific certifications such as CE for safety, API for oil and gas applications, and others may be required depending on the target market and application.

Key Quality Control Checkpoints

Quality control in planetary gear manufacturing typically involves several checkpoints, including:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early. This can include checks on machining accuracy, assembly alignment, and lubrication application.

- Final Quality Control (FQC): After assembly and finishing, final inspections are conducted. This includes functional testing, dimensional verification, and performance assessments to ensure the product meets all specifications.

Common Testing Methods for Planetary Gears

Several testing methods are commonly employed to validate the performance and reliability of planetary gears:

- Load Testing: Gears are subjected to operational loads to assess their performance under stress.

- Vibration Analysis: This technique detects any abnormal vibrations that could indicate misalignment or imbalance, which can lead to failure.

- Noise Testing: Measuring the operational noise helps ensure that the gears operate smoothly and within acceptable limits.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

Conducting Supplier Audits

One effective way to assess a supplier’s quality control is through supplier audits. These audits allow buyers to evaluate the manufacturing processes, quality control measures, and adherence to international standards directly. During an audit, buyers should look for evidence of certifications, inspection reports, and records of compliance with quality standards.

Requesting Quality Reports

Buyers can also request quality reports that document testing results, inspection outcomes, and any corrective actions taken in response to quality issues. These reports should provide insights into the supplier’s commitment to maintaining high standards.

Engaging Third-Party Inspection Services

Another option is to engage third-party inspection services. These independent organizations can conduct thorough evaluations of the manufacturing processes and quality control practices, providing an unbiased assessment of the supplier’s capabilities.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances related to quality control when sourcing planetary gears. This includes understanding regional standards, potential language barriers, and logistical challenges in quality assurance.

- Regional Standards: Different countries may have varying requirements for quality standards. Buyers should familiarize themselves with these standards to ensure compliance.

- Language Barriers: Communication with suppliers in different regions may pose challenges. Clear documentation and specifications can help mitigate misunderstandings.

- Logistical Challenges: Ensuring consistent quality across different manufacturing locations can be complex. Buyers should consider suppliers with centralized quality control processes to maintain consistency.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing planetary gears, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘planetary gear applications’

Introduction

This practical sourcing guide is designed for B2B buyers seeking to procure planetary gear applications. Whether you are operating in industries like automation, robotics, or manufacturing, understanding the essential steps in the sourcing process can significantly enhance your procurement efficiency and ensure you select the most suitable solutions for your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. This includes parameters such as gear ratios, load capacities, dimensions, and operational environments. Specificity in your requirements helps suppliers tailor their offerings to meet your needs precisely.

- Consider application context: Identify whether the planetary gears will be used in robotics, conveyor systems, or other machinery.

- Account for environmental factors: Consider temperature, humidity, and potential exposure to corrosive elements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a proven track record in planetary gear applications. Look for companies that specialize in your industry and have experience with similar projects.

- Check their portfolio: Review case studies and past projects to assess their capability.

- Read customer testimonials: Genuine feedback can provide insights into their reliability and service quality.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers have the necessary certifications and standards compliance. This step is vital to ensure that the products meet industry regulations and quality benchmarks.

- Look for ISO certifications: Such certifications often indicate adherence to international quality standards.

- Check for industry-specific certifications: Depending on your sector, additional certifications may be relevant, such as those for food safety or automotive components.

Step 4: Request Quotes and Compare Pricing

After narrowing down your list of suppliers, request detailed quotes that outline pricing, delivery timelines, and payment terms. Comparing these quotes will help you find the best value.

- Ensure transparency: Quotes should include all potential costs, including shipping, taxes, and duties.

- Factor in quality and service: The cheapest option may not always be the best; consider the overall value, including warranty and after-sales support.

Step 5: Conduct a Supplier Capability Assessment

Before finalizing your choice, assess the supplier’s capability to deliver as per your specifications. This may involve site visits or virtual meetings to understand their manufacturing processes and quality control measures.

- Evaluate production capacity: Ensure they can handle your order volume and delivery schedule.

- Inquire about quality control practices: Understanding how they monitor and maintain quality can mitigate future risks.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate terms that are favorable for both parties. This includes delivery schedules, payment terms, and warranty conditions.

Illustrative image related to planetary gear applications

- Discuss potential for future collaboration: Establishing a long-term relationship can lead to better pricing and priority service.

- Clarify dispute resolution processes: Having clear terms can save both parties from potential conflicts later on.

Step 7: Finalize the Purchase Order

After negotiations, finalize the purchase order with clear documentation. Ensure that all agreed-upon terms are included in the contract to avoid misunderstandings.

- Include delivery and payment terms: Specify timelines and methods for both delivery and payments.

- Document quality assurance expectations: Outline what quality checks will be performed upon delivery to ensure compliance with your specifications.

By following these steps, B2B buyers can enhance their procurement process for planetary gear applications, ensuring they secure reliable, high-quality products tailored to their operational needs.

Comprehensive Cost and Pricing Analysis for planetary gear applications Sourcing

What Are the Key Cost Components in Sourcing Planetary Gear Applications?

When sourcing planetary gear applications, understanding the cost structure is essential for B2B buyers to make informed decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include high-strength steel, aluminum, and engineering plastics. Specialty materials, such as those providing corrosion resistance or higher strength, can drive costs higher but may offer performance benefits in demanding applications.

-

Labor: Labor costs vary by region and depend on the complexity of the manufacturing process. Skilled labor is often required for precision machining and assembly, which can elevate labor costs.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient production processes can minimize these overheads, making suppliers with optimized operations more appealing.

-

Tooling: Custom tooling can be a significant upfront investment, especially for bespoke gear solutions. However, this cost can be amortized over high-volume orders, making it vital to consider long-term procurement strategies.

-

Quality Control: Rigorous QC processes ensure that the gears meet the necessary specifications. The costs associated with QC can vary based on the certifications required (e.g., ISO, CE), which can add to the initial price.

-

Logistics: Transportation and warehousing costs must be factored in, especially for international shipments where tariffs and customs duties can affect pricing.

-

Margin: Supplier profit margins vary based on market conditions, competition, and the perceived value of their products. Understanding typical margins in the industry can help buyers negotiate effectively.

How Do Price Influencers Affect Planetary Gear Costs?

Several factors influence the pricing of planetary gears, including volume, specifications, materials, quality certifications, supplier dynamics, and Incoterms.

-

Volume/MOQ: Minimum order quantities (MOQs) can impact the unit cost. Higher volumes generally lead to lower per-unit prices due to economies of scale. Buyers should assess their needs against supplier MOQs to negotiate better pricing.

-

Specs/Customization: Custom gear solutions designed for specific applications can significantly increase costs. Buyers should clearly define their requirements to avoid unnecessary modifications that could inflate prices.

-

Materials: As previously mentioned, the choice of materials directly affects costs. Higher-quality or specialized materials increase initial expenditures but can lead to lower maintenance and replacement costs over time.

-

Quality/Certifications: Suppliers offering certified products may charge higher prices due to the assurance of quality and performance. Buyers in regulated industries may need to prioritize certified suppliers, even if it means higher upfront costs.

-

Supplier Factors: The supplier’s reputation, reliability, and geographical location can influence pricing. Established suppliers with proven track records may command higher prices, but they often provide better service and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for international buyers, as they dictate the responsibilities for shipping, insurance, and tariffs. Different terms can lead to varied overall costs, impacting the total cost of ownership.

What Buyer Tips Can Help Optimize Costs for Planetary Gear Sourcing?

B2B buyers can employ several strategies to optimize costs when sourcing planetary gears.

-

Negotiation: Leverage competitive quotes from multiple suppliers to negotiate better terms. Highlighting long-term partnerships can also incentivize suppliers to provide discounts.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. Consider factors such as operational efficiency, durability, and maintenance costs, which may lead to significant savings in the long run.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and shipping costs. Building relationships with local distributors can mitigate some of these challenges.

-

Understand Market Trends: Staying informed about industry trends, material availability, and technological advancements can provide leverage in negotiations and help identify cost-effective solutions.

Disclaimer on Indicative Prices

Prices for planetary gear applications can vary significantly based on the factors discussed. It is essential for buyers to conduct thorough market research and engage directly with suppliers to obtain accurate quotes tailored to their specific needs.

Alternatives Analysis: Comparing planetary gear applications With Other Solutions

Understanding Alternative Solutions for Gear Applications

When evaluating gear applications, it’s crucial to consider various technologies that can achieve similar objectives. Planetary gear systems are widely recognized for their efficiency and compact design. However, other alternatives can also meet specific needs depending on factors such as performance, cost, and application suitability. This analysis compares planetary gear applications with bevel gears and worm gears, providing insights for B2B buyers.

Comparison Table

| Comparison Aspect | Planetary Gear Applications | Bevel Gears | Worm Gears |

|---|---|---|---|

| Performance | High torque density, compact size, excellent efficiency | Good for angular motion, limited torque capacity | High torque reduction, limited efficiency at high speeds |

| Cost | Higher initial investment, but cost-effective in long-term applications | Moderate cost, varies with complexity | Generally lower cost, but can have higher wear rates |

| Ease of Implementation | Requires precise engineering, more complex | Easier to install, standard designs available | Simple design, easy to implement |

| Maintenance | Low maintenance due to enclosed design | Moderate maintenance, depends on load | Higher maintenance due to wear on threads |

| Best Use Case | Robotics, automation, and applications requiring high precision | Automotive applications, right-angle drives | Conveyors, lifting applications, and low-speed operations |

Detailed Breakdown of Alternatives

Bevel Gears

Bevel gears are designed to transmit power between shafts that are not parallel, typically at right angles. They are simpler to install and have a lower initial cost compared to planetary gears. However, bevel gears generally have a lower torque capacity, which may limit their use in high-load applications. Additionally, they can experience more wear over time, requiring periodic maintenance to ensure optimal performance. Bevel gears are best suited for automotive applications and situations where space constraints and angular motion are critical.

Worm Gears

Worm gears consist of a worm (a screw-like gear) and a worm wheel (similar to a spur gear) and are known for their ability to provide high torque reduction in a compact setup. They are generally less expensive than planetary gears and are straightforward to implement, making them attractive for various applications. However, worm gears have lower efficiency, particularly at higher speeds, and they tend to experience greater wear due to the sliding contact between the worm and the wheel. They excel in applications requiring significant speed reduction, such as conveyors and lifting mechanisms.

Conclusion: How to Choose the Right Gear Solution

Selecting the appropriate gear solution for a B2B application involves analyzing specific operational requirements, budget constraints, and performance expectations. Planetary gears offer superior efficiency and compactness for high-precision applications, whereas bevel and worm gears may provide cost-effective alternatives for less demanding scenarios. Buyers should consider factors such as torque requirements, space limitations, and maintenance capabilities when making their decision. A thorough evaluation will ensure that the chosen gear technology aligns well with the operational goals and long-term performance of the machinery or system in question.

Illustrative image related to planetary gear applications

Essential Technical Properties and Trade Terminology for planetary gear applications

What Are the Key Technical Properties of Planetary Gears for B2B Buyers?

In the realm of planetary gears, understanding critical technical specifications is essential for making informed purchasing decisions. Here are several key properties that should be on your radar:

-

Material Grade

– The material used in planetary gear construction significantly impacts durability and performance. Common materials include steel, aluminum, and engineering plastics. Steel gears, for instance, offer superior strength and wear resistance, making them suitable for high-load applications. In contrast, plastic gears can be advantageous in environments requiring noise reduction or corrosion resistance. Selecting the right material grade can influence the longevity and reliability of your gear system. -

Gear Ratio

– The gear ratio defines the relationship between the input speed and output speed of a planetary gear system. It is calculated by comparing the number of teeth on the gears. A higher gear ratio typically means increased torque and decreased speed, which is crucial for applications such as robotics or heavy machinery. Understanding gear ratios helps buyers select the appropriate configuration for their specific operational needs. -

Backlash

– Backlash refers to the amount of play between the teeth of the gears when they are engaged. It is a critical specification that affects precision and accuracy in motion control applications. Low backlash is essential in high-precision systems, such as CNC machines, where minute inaccuracies can lead to significant operational issues. Buyers should assess the acceptable backlash levels for their applications to ensure optimal performance. -

Tolerance

– Tolerance indicates the permissible limit of variation in a physical dimension. In planetary gears, this affects how well the components fit together, impacting efficiency and noise levels. Tight tolerances are crucial for high-performance applications, as they minimize wear and enhance overall system reliability. Understanding tolerance requirements can guide buyers in selecting manufacturers who meet their specifications. -

Load Capacity

– Load capacity defines the maximum load that a planetary gear can handle without failure. This includes both radial and axial loads. Knowing the load capacity is vital for ensuring that the gear system will operate effectively within the intended application, particularly in industries like automotive or aerospace where safety is paramount.

What Are the Common Trade Terms Used in Planetary Gear Applications?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B environment. Here are some common terms that are frequently encountered:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of planetary gears, buyers often engage with OEMs to obtain custom solutions tailored to specific applications. Understanding OEM relationships can help buyers navigate their supply chain more effectively. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, especially smaller businesses or those testing new products. Knowing the MOQ can influence purchasing decisions and inventory management strategies. -

RFQ (Request for Quotation)

– An RFQ is a document that a buyer sends to suppliers to request pricing and other terms for specified goods or services. This is an essential step in the procurement process, allowing buyers to compare costs and terms from multiple vendors. A well-crafted RFQ can lead to better pricing and service agreements. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers operating across borders, as they dictate who is responsible for shipping, insurance, and tariffs. -

Lead Time

– Lead time is the amount of time it takes for a supplier to fulfill an order after it has been placed. Understanding lead times is essential for effective supply chain management and inventory control. Buyers should consider lead times when planning production schedules or project timelines.

By grasping these essential technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring that their planetary gear applications meet both performance and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the planetary gear applications Sector

What Are the Current Market Dynamics and Key Trends in Planetary Gear Applications?

The planetary gear applications sector is experiencing a transformative phase, driven by the increasing demand for automation and precision in various industries such as automotive, aerospace, and manufacturing. Key market drivers include the shift towards electric vehicles (EVs) and robotics, which require compact and efficient gear systems. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe look to enhance operational efficiency, the adoption of advanced planetary gear technologies is becoming crucial.

Emerging trends indicate a growing preference for customizable and modular gear solutions. Manufacturers are increasingly offering tailored planetary gear systems that can be easily integrated into existing machinery, thereby reducing downtime and enhancing productivity. Furthermore, the rise of Industry 4.0 is pushing companies to invest in smart gear solutions equipped with IoT capabilities for real-time monitoring and predictive maintenance. This trend is particularly relevant for buyers in regions like Nigeria and Saudi Arabia, where the push for modernization in industrial sectors is gaining momentum.

Another notable trend is the increasing focus on lightweight materials and designs that improve energy efficiency. As businesses aim to reduce their carbon footprints, the demand for materials that facilitate high performance while minimizing weight is on the rise. This shift is particularly beneficial for applications in automotive and aerospace, where weight reduction can lead to significant efficiency gains.

How Can Sustainability and Ethical Sourcing Impact B2B in Planetary Gear Applications?

Sustainability is becoming a non-negotiable aspect of the procurement process for B2B buyers in the planetary gear applications sector. The environmental impact of manufacturing processes and materials is under scrutiny, prompting companies to prioritize ethical sourcing and sustainable practices. Buyers from Africa, South America, and the Middle East are increasingly looking for suppliers that adhere to environmentally friendly practices and can provide certifications that validate their commitment to sustainability.

The use of ‘green’ materials, such as recycled metals and bio-based composites, is gaining traction in the production of planetary gears. These materials not only reduce environmental impact but also appeal to customers who are environmentally conscious. Additionally, certifications like ISO 14001, which focuses on effective environmental management systems, are becoming essential for suppliers aiming to do business in more stringent markets, particularly in Europe.

Ethical supply chains are not just about environmental concerns; they also encompass social responsibility. Buyers are now more inclined to work with manufacturers who ensure fair labor practices and transparency throughout their supply chain. By prioritizing suppliers that align with these values, businesses can enhance their brand reputation and foster customer loyalty.

What Is the Brief Evolution and History of Planetary Gear Applications in B2B?

The evolution of planetary gear applications can be traced back to the early 19th century, where they were first utilized in steam engines and early mechanical systems. Initially, their complex design was a significant challenge, but advancements in materials and manufacturing processes have led to widespread adoption across various sectors.

As industries evolved, so did the applications of planetary gears. The introduction of computer-aided design (CAD) and manufacturing technologies in the late 20th century allowed for more precise and efficient designs, leading to the development of compact, high-performance gear systems. Today, planetary gears are integral to modern machinery, from automated guided vehicles (AGVs) to advanced robotics, reflecting a continuous trend towards efficiency and precision.

In conclusion, the planetary gear applications sector presents numerous opportunities for international B2B buyers seeking innovative and sustainable solutions. By understanding market dynamics, prioritizing ethical sourcing, and recognizing the historical context, buyers can make informed decisions that drive their business success.

Frequently Asked Questions (FAQs) for B2B Buyers of planetary gear applications

-

How do I solve issues related to planetary gear failure?

To address planetary gear failure, first conduct a thorough inspection to identify the root cause, which may include wear, misalignment, or lubrication issues. Implement a regular maintenance schedule that includes cleaning, lubrication, and alignment checks to extend the lifespan of the gears. Additionally, consult with your supplier for potential upgrades or replacements that can enhance performance and reliability, especially in high-stress applications. Engaging in proactive communication with your gear supplier can also provide insights into common failure modes and preventative measures tailored to your specific use case. -

What is the best planetary gear type for industrial automation?

The best planetary gear type for industrial automation often depends on the specific application requirements, such as load capacity, speed, and precision. Generally, high-efficiency planetary gears with low backlash are preferred for their ability to handle dynamic loads while maintaining accuracy. For applications like robotic arms or conveyor systems, consider gears with robust construction and high torque ratings. Engaging with experienced manufacturers can help you identify a suitable gear type that meets your technical specifications and operational needs. -

How can I ensure the quality of planetary gears sourced from international suppliers?

To ensure the quality of planetary gears from international suppliers, conduct comprehensive due diligence before placing an order. Look for suppliers with ISO certifications or industry-specific quality standards. Request samples and technical documentation to assess their manufacturing processes and materials. Additionally, consider visiting the supplier’s facility if possible, or utilize third-party inspection services to verify product quality before shipment. Establishing clear quality assurance protocols, including testing and inspection criteria, can further safeguard your investment. -

What customization options are available for planetary gears?

Customization options for planetary gears can vary significantly among manufacturers. Common modifications include adjustments to gear ratios, size, and materials to suit specific operational environments. Many suppliers offer custom designs for specialized applications, such as enhanced load capacity or unique mounting configurations. To explore customization, provide detailed specifications and application requirements to your supplier. Collaborating closely with their engineering team can lead to tailored solutions that optimize performance in your specific context. -

What are typical minimum order quantities (MOQs) for planetary gears?

Minimum order quantities for planetary gears can vary widely based on the manufacturer and the complexity of the gear design. Standard products may have lower MOQs, while custom gears typically require larger orders to offset production costs. It’s advisable to discuss your needs directly with suppliers to negotiate MOQs that align with your project scale and budget. Some manufacturers may also offer flexibility for first-time buyers or smaller-scale projects, so open communication is key to finding a suitable arrangement. -

What payment terms should I expect when sourcing planetary gears internationally?

Payment terms for international gear sourcing generally depend on the supplier’s policies and your business relationship. Common terms include upfront deposits, letters of credit, or payment upon delivery. It’s important to negotiate terms that provide adequate security for both parties, especially for large orders. Additionally, consider the implications of currency exchange rates and potential transaction fees. Establishing a clear agreement on payment terms in advance can help avoid misunderstandings and ensure a smoother procurement process. -

How can I assess the reliability of a planetary gear supplier?

To assess the reliability of a planetary gear supplier, start by reviewing their industry reputation through customer testimonials, case studies, and online reviews. Consider their experience in your specific industry and the range of applications they support. Evaluate their production capabilities, quality assurance processes, and certifications. Establishing direct communication with the supplier and asking for references from past clients can also provide valuable insights into their reliability and commitment to customer satisfaction. -

What logistics considerations should I keep in mind when importing planetary gears?

When importing planetary gears, consider logistics aspects such as shipping methods, lead times, and customs regulations. Choose a shipping method that balances cost and delivery speed, and factor in potential delays at customs. Ensure that all documentation, including invoices and certificates of origin, is in order to facilitate smooth customs clearance. Additionally, consider working with logistics partners who specialize in international trade to navigate any complexities and ensure timely delivery to your location.

Top 5 Planetary Gear Applications Manufacturers & Suppliers List

1. IQS Directory – Planetary Gears

Domain: iqsdirectory.com

Registered: 2004 (21 years)

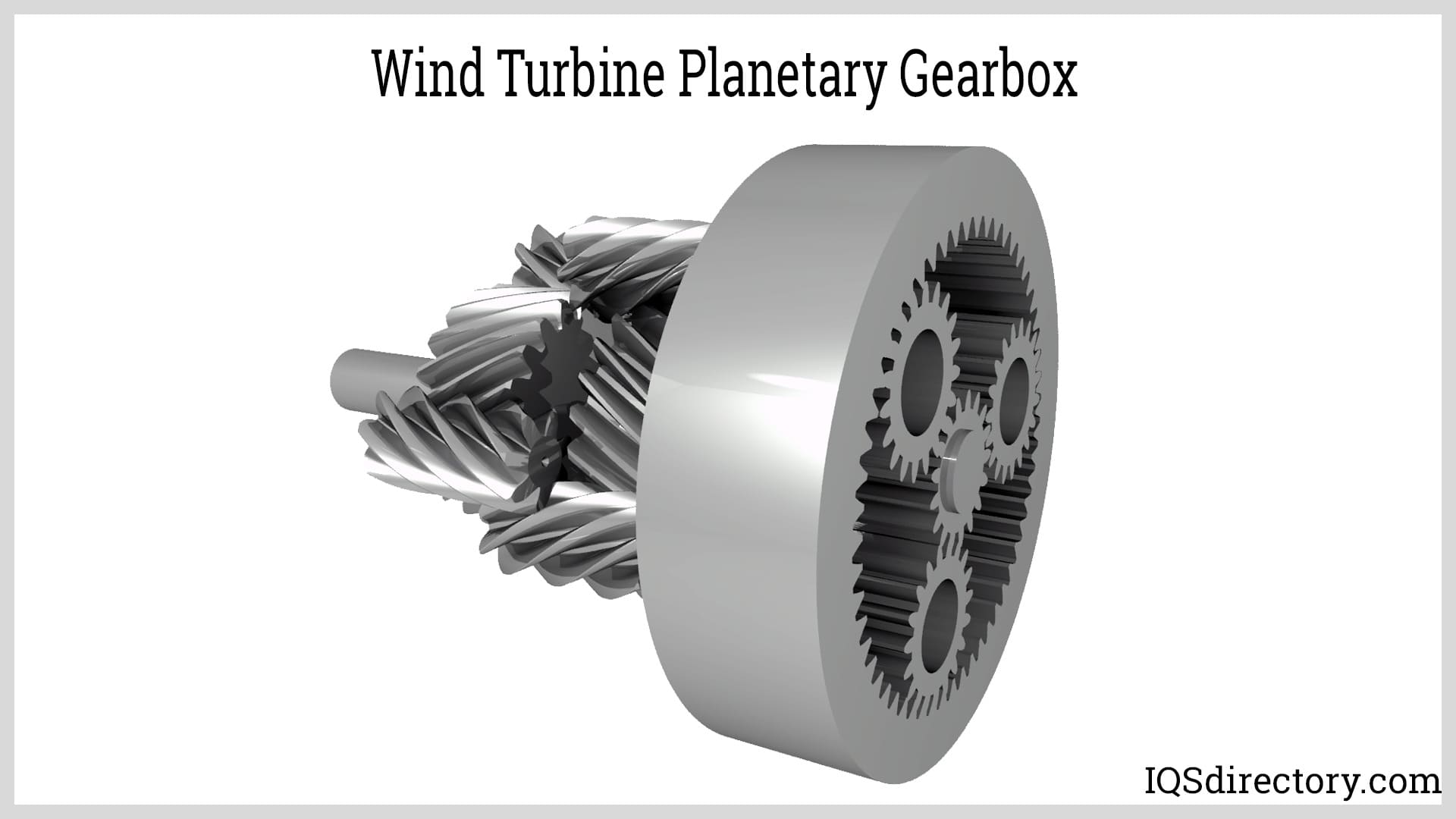

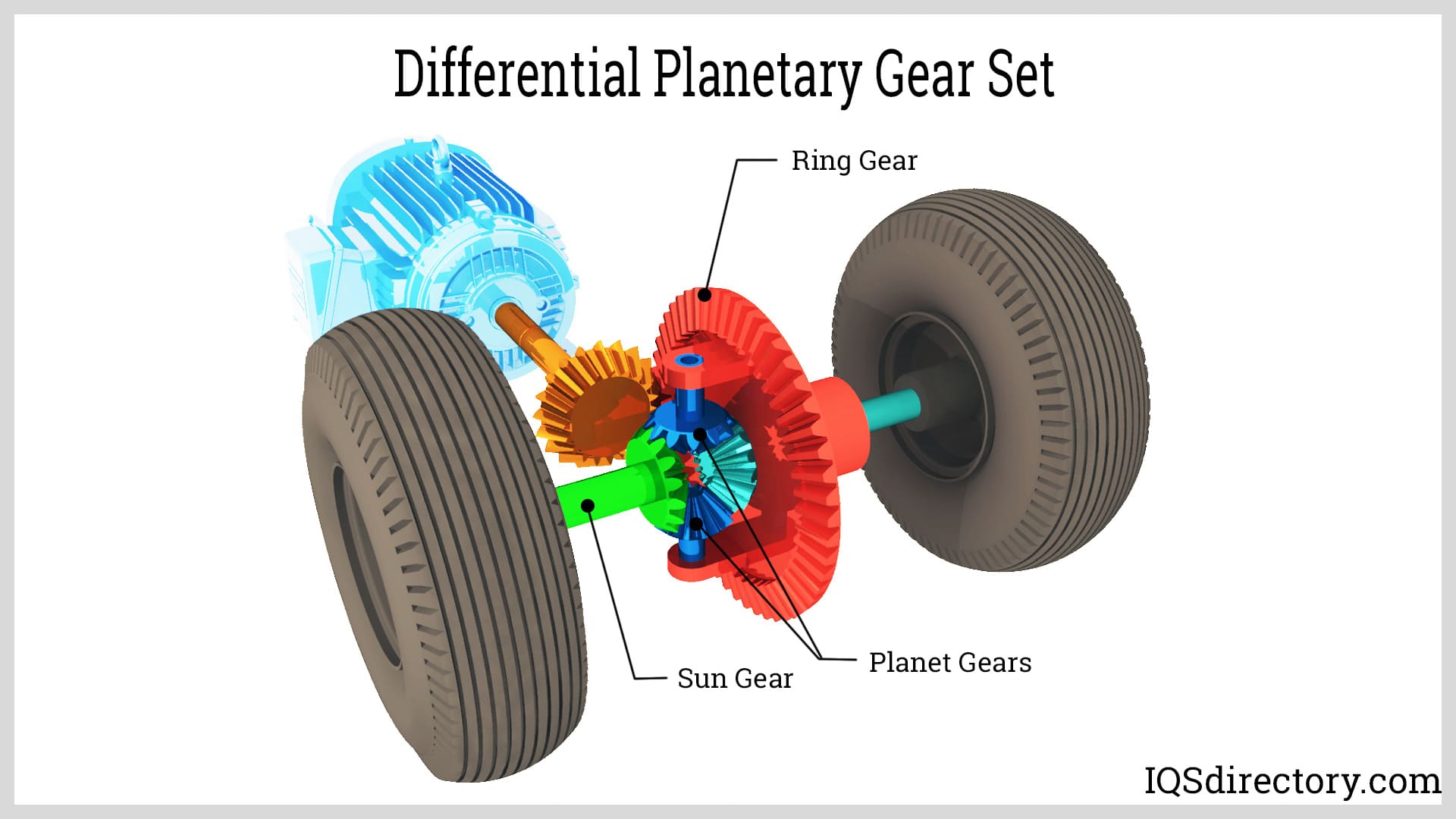

Introduction: Planetary gears, also known as epicyclic gear systems, consist of a central sun gear, multiple planet gears, and a surrounding ring gear. They are designed for efficient speed reduction and torque multiplication in various applications, including automotive transmissions, industrial machinery, electric vehicles, wind turbines, and robotics. Key components include:

1. **Sun Gear**: Central gear th…

2. Sesame Motor – Planetary Gearboxes

Domain: sesamemotor.com

Registered: 2007 (18 years)

Introduction: Planetary gearboxes are used in various industries including machine tools, semiconductor, packaging, medical, food and beverage, and aerospace. They consist of a sun gear, planet gears, and a ring gear, allowing for high torque density, economy, high precision (up to 1 arcmin), low noise (as low as 55 decibels), high efficiency (up to 97%), and high reduction ratios. Types include Output Shaft, F…

3. Rotalink – Planetary Gear Systems

Domain: rotalink.com

Registered: 1999 (26 years)

Introduction: Planetary gears are compact gear systems that provide high torque and efficiency, ideal for applications in medical devices, robotics, and optics. Key components include a sun gear, planet gears, and a ring gear. Advantages include high torque density, compact design, high efficiency, greater durability, and high reduction ratios. Applications include medical devices (infusion pumps, robotic surgi…

4. Matex Gears – Planetary Gear Systems

Domain: matexgears.com

Registered: 1997 (28 years)

Introduction: Planetary gears are used for speed reduction and torque increase in various industries. Matex Gears offers patented systems with design flexibility in size, ratio, and material. Key applications include motorized wheels, winches, automatic door openers, conveyors, medical devices, fluid transfer, appliances, tools, and robotics. The efficiency of Matex planetary gears is 98% at single reduction, 9…

5. KHK Gears – Gear Systems & Solutions

Domain: khkgears.net

Registered: 2015 (10 years)

Introduction: Product Category: Gear Systems

Types of Gears: Spur Gears, Worm Gears, Bevel Gears, Gear Rack, Helical Gears, Miter Gears, Plastic Gears, Screw Gears, Internal Gears, Bevel Gearbox

Key Features: Compact size, high reduction ratio

Special Gear Systems: Planetary Gear Systems, Hypocycloid Mechanisms, Constrained Gear Systems

Planetary Gear System Components: Sun Gear (A), Planet Gears (B), Internal …

Strategic Sourcing Conclusion and Outlook for planetary gear applications

As industries across Africa, South America, the Middle East, and Europe continue to evolve, the strategic sourcing of planetary gears has become increasingly vital. These components not only enhance the efficiency and performance of various applications, such as automation, manufacturing, and robotics, but they also contribute significantly to reducing operational costs and increasing productivity. Buyers are encouraged to consider the full spectrum of planetary gear solutions, from standard to custom designs, that meet specific operational requirements.

Illustrative image related to planetary gear applications

Moreover, fostering relationships with experienced suppliers can provide access to innovative technologies and customized solutions that align with unique business needs. Engaging with manufacturers who understand regional market demands will facilitate the acquisition of high-quality components that can withstand diverse environmental conditions.

Looking ahead, the demand for advanced gear systems is poised to grow, driven by technological advancements and the need for precision in various sectors. International B2B buyers should seize this opportunity to enhance their sourcing strategies, ensuring they are well-equipped to meet future challenges. By prioritizing strategic partnerships and investing in quality gear solutions, companies can position themselves for sustained success in a competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.