How to Source Key Making Machine Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for key making machine

In the rapidly evolving landscape of global commerce, sourcing a reliable key making machine can present significant challenges for international B2B buyers. Whether you’re a locksmith in Brazil seeking efficient key duplication solutions or a security firm in the Middle East looking to expand your offerings, understanding the nuances of the key making machine market is crucial. This comprehensive guide addresses the diverse types of key cutting machines available, their applications across various industries, and the essential criteria for supplier vetting.

From manual duplicators to advanced automatic machines, each option comes with its own set of features and pricing, which can vary significantly based on regional availability and technological advancements. This guide not only outlines the cost implications of different machines but also provides insights into the potential return on investment, ensuring that buyers make informed decisions tailored to their specific needs.

By exploring the key making machine market, B2B buyers from regions such as Africa, South America, Europe, and beyond will gain valuable knowledge to navigate their purchasing processes effectively. Ultimately, this guide empowers businesses to select the right key making machine, enhancing their operational capabilities and service offerings in a competitive marketplace.

Understanding key making machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automatic Key Cutting Machines | Fast, precise cutting with minimal manual input; often features advanced technology for various key types. | High-volume locksmiths, automotive services | Pros: Efficient, reduces labor costs. Cons: Higher initial investment. |

| Manual Key Cutting Machines | Operated by hand, allowing for more control; typically more affordable. | Small locksmith shops, mobile services | Pros: Cost-effective, easy to repair. Cons: Slower production rate. |

| Key Copy Kiosks | Self-service kiosks that allow users to duplicate keys on-site. | Retail environments, convenience stores | Pros: Low overhead, attracts foot traffic. Cons: Limited to basic key types. |

| Electronic Key Machines | Integrates digital technology for precision; often includes software for key programming. | Automotive and security industries | Pros: High accuracy, versatile. Cons: Requires technical knowledge for operation. |

| Specialty Key Machines | Designed for specific key types, such as dimple or high-security keys. | Niche locksmith services, specialized industries | Pros: Tailored functionality, meets specific demands. Cons: Limited versatility for general key cutting. |

What Are the Key Characteristics of Automatic Key Cutting Machines?

Automatic key cutting machines are designed for speed and precision, making them ideal for high-volume operations. They often incorporate advanced technology, allowing them to cut a variety of key types with minimal manual intervention. This makes them particularly suitable for large locksmith businesses and automotive service centers that require rapid turnaround times. When considering a purchase, buyers should evaluate the machine’s compatibility with the types of keys they handle and assess the total cost of ownership, including maintenance and software updates.

How Do Manual Key Cutting Machines Fit into the Market?

Manual key cutting machines offer a hands-on approach to key duplication, providing users with greater control over the cutting process. They are generally more affordable than their automatic counterparts, making them an attractive option for smaller locksmith shops or mobile service providers. Buyers should consider their production needs; while manual machines can be slower, they are easier to maintain and repair, making them a practical choice for businesses with lower volumes of work.

What Advantages Do Key Copy Kiosks Provide for Retail Environments?

Key copy kiosks are self-service units that allow customers to duplicate keys quickly and conveniently. These kiosks are ideal for retail environments, such as convenience stores or hardware shops, where foot traffic is high. They require minimal staffing and can handle basic key types efficiently. However, businesses should evaluate the kiosk’s capabilities to ensure it meets the demands of their customer base, as they may not support specialized or high-security keys.

Why Invest in Electronic Key Machines?

Electronic key machines incorporate digital technology to enhance cutting accuracy and versatility. These machines are particularly beneficial for industries that require precision, such as automotive and security services. They often come with software that allows for key programming, making them a valuable asset for locksmiths who deal with electronic fobs and advanced locking systems. Buyers should consider the learning curve associated with operating these machines, as technical knowledge may be required for effective use.

What Are the Benefits of Specialty Key Machines?

Specialty key machines are engineered for specific key types, such as dimple or high-security keys, catering to niche markets. These machines can provide tailored functionality, allowing locksmiths to meet specific customer demands effectively. However, their limited versatility may restrict their use for general key cutting tasks. Buyers should assess the market demand for specialized keys in their area before investing, ensuring that the machine aligns with their business strategy.

Key Industrial Applications of key making machine

| Industry/Sector | Specific Application of Key Making Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Duplicating car keys and fobs | Reduces wait times and costs associated with dealership services | Availability of specialized key cutting machines for various vehicle models; compatibility with local key types. |

| Hospitality | Key duplication for hotel room keys | Enhances guest experience by providing quick access to rooms | Machines should accommodate a range of key types; durability for high-volume usage. |

| Security Services | Making keys for high-security locks | Ensures the integrity and safety of client properties | Machines must support advanced key designs and security features; reliability and precision are critical. |

| Retail | Self-service key duplication kiosks | Increases foot traffic and adds a new revenue stream | Kiosk design should be user-friendly; consider local regulations on self-service units. |

| Manufacturing | Creating keys for machinery and equipment | Minimizes downtime by providing quick access to replacement keys | Machines must be capable of cutting heavy-duty keys; sourcing should ensure quality and precision. |

How Are Key Making Machines Used in the Automotive Industry?

In the automotive sector, key making machines play a crucial role in duplicating car keys and fobs. With the growing complexity of vehicle security systems, businesses require machines that can handle various key types, including transponder keys and key fobs. This application not only reduces the wait times for customers but also significantly cuts costs compared to dealership services. International buyers should focus on sourcing machines that are compatible with local vehicle models and equipped with the latest technology for accurate key duplication.

Why Are Key Making Machines Essential for the Hospitality Sector?

In the hospitality industry, key making machines are vital for efficiently duplicating hotel room keys. This service enhances the guest experience by allowing quick access to rooms without long waiting periods. Additionally, with high guest turnover, having a reliable key duplication system can streamline operations. Buyers should consider machines that can accommodate a wide variety of key types and are durable enough to handle frequent use, especially in high-traffic hotels.

What Role Do Key Making Machines Play in Security Services?

Security services utilize key making machines to create keys for high-security locks. This application is critical for maintaining the integrity and safety of client properties. The machines must support advanced key designs, ensuring that security features are not compromised during duplication. For B2B buyers in this sector, sourcing reliable and precise machines is essential to meet the specific security needs of their clients, particularly in regions with varying security standards.

How Do Retail Businesses Benefit from Self-Service Key Duplication Kiosks?

Retail businesses increasingly adopt self-service key duplication kiosks to enhance customer convenience and create new revenue streams. These kiosks allow customers to duplicate keys on-site, reducing the need for staff involvement and increasing efficiency. When sourcing these machines, businesses should prioritize user-friendly designs and compliance with local regulations governing self-service operations. This approach not only attracts foot traffic but also positions the retailer as a convenient solution for key duplication needs.

Why Are Key Making Machines Important for Manufacturing?

In the manufacturing sector, key making machines are essential for creating keys for machinery and equipment. Quick access to replacement keys minimizes downtime, which is critical for maintaining productivity. Buyers in this industry should focus on sourcing machines that can handle heavy-duty keys and ensure high precision in cutting. Additionally, understanding the specific requirements of their manufacturing processes will guide buyers in selecting the right key making machines to meet their operational needs.

3 Common User Pain Points for ‘key making machine’ & Their Solutions

Scenario 1: Difficulty in Finding Reliable Key Making Machines

The Problem: Many B2B buyers in regions such as Africa and South America encounter challenges in sourcing high-quality key making machines. They often face uncertainty regarding the reliability and performance of the machines available in their local markets. This uncertainty can stem from a lack of established distributors, insufficient product information, or varying quality standards. As a result, buyers risk investing in equipment that may not meet their operational needs, leading to financial loss and operational inefficiency.

The Solution: To navigate this challenge, B2B buyers should conduct thorough market research before making a purchase. They should seek out reputable manufacturers or distributors with a proven track record in the industry. Platforms like industry trade shows or online marketplaces can provide insights into the best-performing machines. Additionally, requesting product demonstrations or trial periods can help assess the machine’s performance and reliability firsthand. Buyers should also consider machines that come with robust warranties and after-sales support, ensuring they have recourse if issues arise.

Scenario 2: Complexity in Operating Key Making Machines

The Problem: Another common pain point for B2B buyers is the complexity involved in operating key making machines. Many machines come with intricate features and settings that can be overwhelming, especially for businesses that are new to key duplication. This complexity can lead to operational delays, increased training costs, and potential mistakes that compromise the quality of the keys produced.

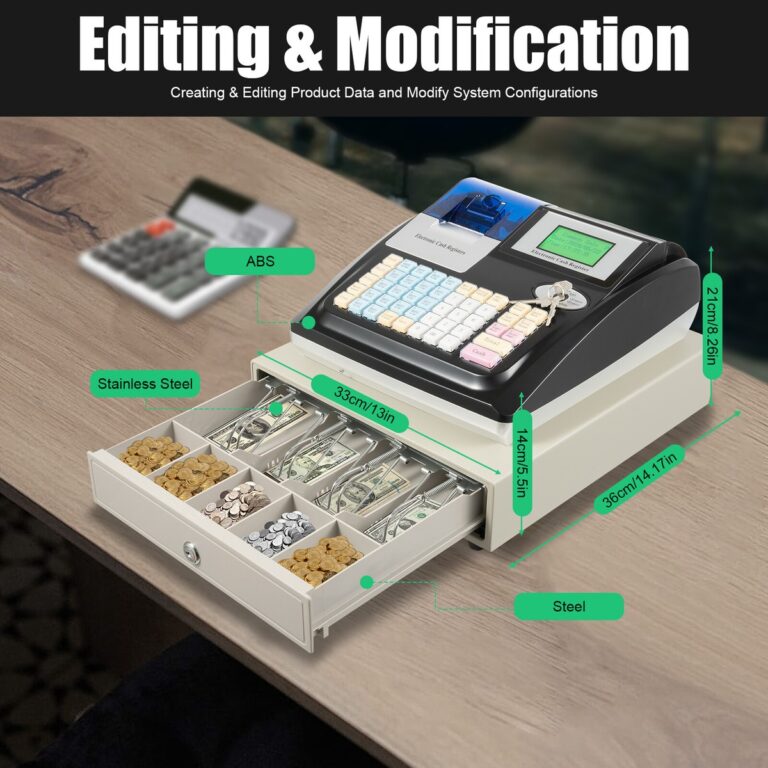

Illustrative image related to key making machine

The Solution: To address this issue, buyers should prioritize user-friendly machines that offer intuitive interfaces and clear operational guidelines. When sourcing equipment, it’s beneficial to ask for training sessions or instructional resources from the supplier. Comprehensive user manuals, online tutorials, and customer support can significantly ease the learning curve. Furthermore, investing in machines that integrate smart technology can simplify operations, as they often include automated features that reduce the manual input required, thereby minimizing the chance for error.

Scenario 3: High Operating Costs and Maintenance Issues

The Problem: B2B buyers frequently struggle with high operating costs associated with key making machines, particularly in terms of maintenance and consumables. Machines that require frequent repairs or have costly replacement parts can quickly erode profit margins. This issue is exacerbated in regions where access to affordable parts or skilled technicians is limited, leading to extended downtime and reduced service capacity.

The Solution: To mitigate these costs, buyers should evaluate machines based on their long-term operational efficiency and maintenance requirements. Opting for machines that utilize durable materials and have a reputation for longevity can lead to significant savings. Additionally, establishing relationships with local suppliers for parts can reduce costs and improve turnaround times for repairs. Buyers should also consider machines that offer modular designs, allowing for easier and more cost-effective upgrades. Lastly, implementing a proactive maintenance schedule can help identify and address issues before they escalate, ensuring the machines remain in optimal working condition.

Strategic Material Selection Guide for key making machine

What Are the Common Materials Used in Key Making Machines?

When selecting materials for key making machines, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Here, we analyze four common materials: steel, aluminum, plastic, and brass, focusing on their performance and implications for international B2B buyers.

Illustrative image related to key making machine

How Does Steel Perform in Key Making Machines?

Steel is a widely used material in key making machines due to its high strength and durability. It typically exhibits excellent wear resistance and can withstand high temperatures and pressures, making it suitable for heavy-duty applications. However, steel is prone to corrosion if not properly treated or coated, which can impact its longevity.

Pros: Steel’s durability ensures a long lifespan for key making machines, reducing the frequency of replacements. It is also cost-effective when considering its performance over time.

Cons: The primary drawback is its susceptibility to rust, necessitating additional coatings or treatments. Manufacturing complexity can also increase due to the need for specialized machining processes.

For international buyers, compliance with standards such as ASTM A36 or DIN EN 10025 is crucial. Steel’s availability is generally good, but buyers should consider local sourcing to reduce costs.

What Role Does Aluminum Play in Key Making Machines?

Aluminum is another popular choice, particularly for portable or lightweight key making machines. It offers a good balance between strength and weight, making it easier to handle. Aluminum is also corrosion-resistant, which is advantageous in humid or coastal environments.

Pros: The lightweight nature of aluminum makes it ideal for mobile applications, and its resistance to corrosion enhances the machine’s durability.

Cons: While aluminum is strong, it is not as robust as steel, which may limit its use in high-stress applications. Additionally, it can be more expensive than steel, affecting overall project budgets.

International buyers should be aware of standards such as ASTM B221 for aluminum extrusions. The availability of aluminum may vary by region, particularly in developing markets in Africa and South America.

How Does Plastic Compare in Key Making Machines?

Plastic is often used in non-critical components of key making machines, such as housings or covers. It is lightweight, resistant to corrosion, and can be molded into complex shapes, which is advantageous for design flexibility.

Pros: The low cost and ease of manufacturing make plastic an attractive option for many applications. Its resistance to corrosion is particularly beneficial in various environments.

Cons: Plastic is generally less durable than metals, which may lead to wear and tear over time. It may also not withstand high temperatures as effectively as metals.

For international B2B buyers, compliance with standards like ISO 9001 for quality management can be critical. Understanding local regulations regarding plastic materials is also essential, especially in regions with strict environmental laws.

Why Is Brass Used in Key Making Machines?

Brass, an alloy of copper and zinc, is frequently used for key blanks and some machine components due to its excellent machinability and corrosion resistance. It is particularly suitable for applications requiring good electrical conductivity.

Pros: Brass offers a good combination of strength, corrosion resistance, and aesthetic appeal, making it ideal for high-quality key production.

Illustrative image related to key making machine

Cons: The primary limitation of brass is its higher cost compared to steel and aluminum. Additionally, it may not be suitable for high-stress applications.

International buyers should ensure compliance with standards such as ASTM B36 for brass materials. Brass is commonly available in many regions, but fluctuations in copper prices can impact costs.

Summary Table of Material Selection for Key Making Machines

| Material | Typical Use Case for key making machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Main structural components | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight, portable machines | Lightweight and corrosion-resistant | Less robust than steel | Medium-High |

| Plastic | Non-critical components | Low cost and design flexibility | Less durable than metals | Low |

| Brass | Key blanks and aesthetic components | Excellent machinability and corrosion resistance | Higher cost and not for high-stress use | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions when sourcing key making machines. Understanding the properties and implications of each material is crucial for optimizing performance and cost-effectiveness in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for key making machine

What Are the Main Stages in the Manufacturing Process of Key Making Machines?

The manufacturing process of key making machines involves several critical stages, each essential for producing high-quality equipment. Understanding these stages can help B2B buyers assess the capabilities and reliability of potential suppliers.

Material Preparation: What Materials Are Used in Key Making Machines?

The first stage of manufacturing involves selecting high-quality materials. Key making machines typically use durable metals such as steel and aluminum, which are essential for withstanding wear and tear during the key cutting process. Manufacturers may also utilize high-grade plastics for components that require lightweight or non-conductive properties. During this phase, materials are inspected for quality, ensuring they meet specific standards before moving to the next stage.

How Are Key Making Machines Formed?

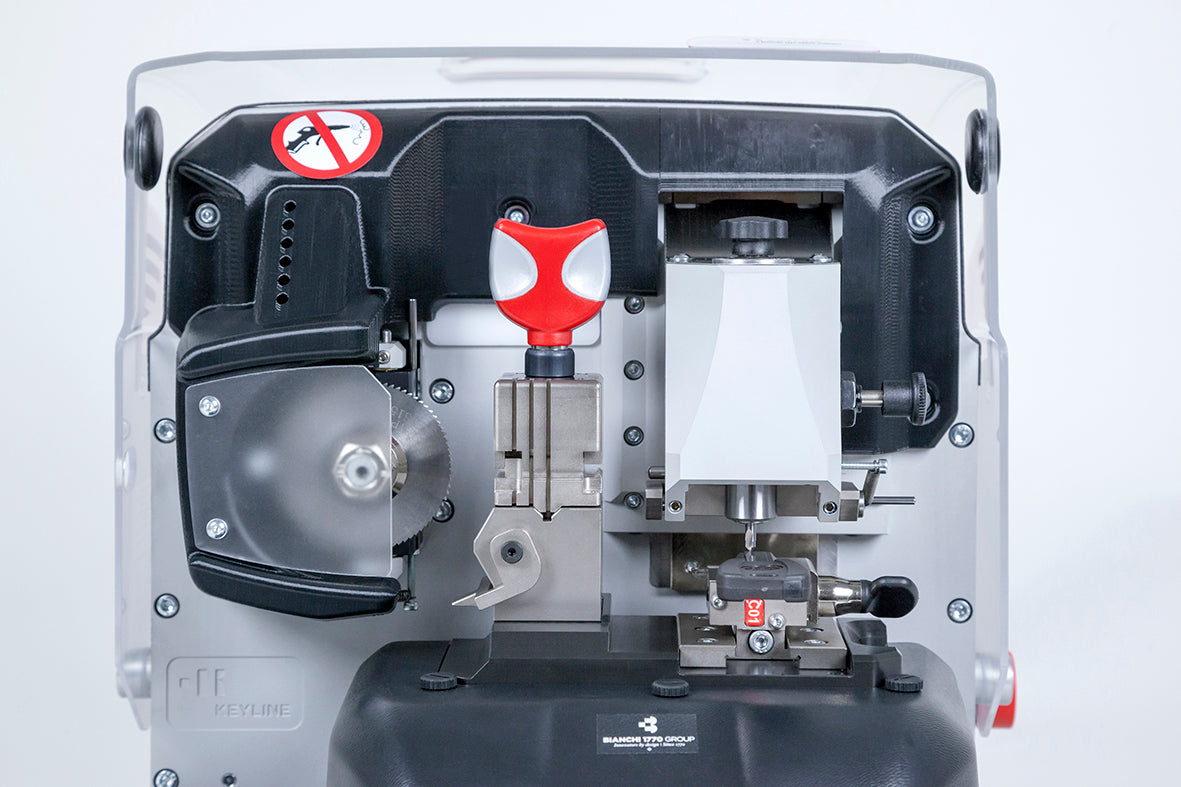

Once the materials are ready, they undergo various forming processes. Common techniques include:

- CNC Machining: Computer Numerical Control (CNC) machines are often employed to achieve precise cuts and shapes for components. This method ensures high accuracy and repeatability, which is crucial in key making machines.

- Stamping and Punching: For certain parts, stamping or punching is used to create shapes quickly and efficiently. This method is particularly useful for producing high volumes of similar components.

- Casting and Forging: Some parts may be cast or forged, providing strength and durability. These techniques are particularly valuable for components that endure high stress.

What Is Involved in the Assembly of Key Making Machines?

After forming, the components are assembled. This stage involves:

- Component Integration: Individual parts, such as motors, cutting blades, and control panels, are integrated into a cohesive unit. Skilled technicians ensure that each component fits correctly and operates as intended.

- Wiring and Electronics Installation: For automatic and semi-automatic machines, wiring and electronic components are installed. This may involve programming the machine to ensure it performs according to specifications.

What Finishing Techniques Are Used in Key Making Machine Production?

The final stage is finishing, where machines undergo several processes to enhance their functionality and aesthetic appeal:

- Surface Treatment: Techniques such as anodizing or powder coating are applied to protect against corrosion and wear. These treatments also improve the machine’s appearance, making it more appealing to end users.

- Quality Control Testing: Before packaging, machines are rigorously tested to ensure they meet performance standards. This can include operational tests and safety checks.

How Is Quality Assurance Implemented in Key Making Machines?

Quality assurance is a fundamental aspect of the manufacturing process, ensuring that key making machines meet international standards and customer expectations. B2B buyers should be aware of the quality assurance protocols that reputable manufacturers follow.

What International Standards Are Relevant for Key Making Machines?

Manufacturers of key making machines typically adhere to international standards such as:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For machines sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

What Are the Common Quality Control Checkpoints?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint assesses raw materials for quality and compliance with specifications before they enter production.

- In-Process Quality Control (IPQC): During assembly and manufacturing, ongoing inspections are conducted to ensure that each stage meets quality criteria.

- Final Quality Control (FQC): After assembly, the finished machines undergo comprehensive testing to ensure they function correctly and meet all performance standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures employed by their suppliers. Here are several strategies to ensure you are partnering with a reputable manufacturer:

Illustrative image related to key making machine

What Audits and Reports Should Buyers Request?

Buyers can request documentation that demonstrates compliance with international standards. This may include:

- Quality Management System Audits: Regular audits by external parties can provide insights into a manufacturer’s adherence to ISO standards.

- Quality Control Reports: These reports detail the results of various quality checks, providing transparency into the manufacturing process.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and quality control measures. These inspections can be particularly beneficial for international buyers, ensuring that machines meet specified standards before shipment.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, understanding the nuances of quality control is crucial:

- Cultural Differences: Quality expectations may vary across regions. Buyers should communicate their specific requirements clearly to avoid misunderstandings.

- Regulatory Compliance: Different countries have varying regulations regarding safety and quality. Buyers should ensure that the machines comply with the regulations of their home country.

- Logistics and Transportation: The condition of machines during transport can affect quality. Buyers should consider suppliers who have robust packaging and shipping protocols to protect equipment.

In summary, the manufacturing processes and quality assurance protocols for key making machines are vital for ensuring high-quality products. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to successful partnerships and satisfied customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘key making machine’

Introduction

When sourcing a key making machine, international B2B buyers must navigate a complex landscape of options, specifications, and supplier qualifications. This checklist provides a structured approach to ensure you make informed decisions that meet your business needs and market demands.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clearly outline the technical specifications of the key making machines you require. Consider the types of keys you need to duplicate, such as residential, automotive, or specialty keys. Additionally, assess whether you need manual or automatic machines, and the expected volume of key duplication to determine the appropriate machine capacity.

- Types of Keys: Identify if you need machines for basic house keys, car keys, or advanced RFID keys.

- Volume Needs: Determine your production needs to select a machine that can handle your expected output.

Step 2: Research Market Trends and Innovations

Stay updated on the latest trends and technological advancements in key making machines. Understanding current innovations can help you select machines that offer better efficiency, accuracy, and additional features.

- Emerging Technologies: Look for machines that incorporate digital technology for enhanced precision.

- Market Demand: Assess the demand in your target markets, such as Africa or South America, for specific types of key duplication.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your quality and service requirements. Request company profiles, product catalogs, and customer testimonials from businesses in similar industries or regions.

- Supplier Credentials: Verify certifications and experience in the key making industry.

- Case Studies: Ask for examples of previous successful implementations to gauge reliability.

Step 4: Request Samples and Product Demonstrations

Before finalizing a purchase, request samples or product demonstrations from suppliers. This allows you to evaluate the machine’s performance and suitability for your specific applications.

Illustrative image related to key making machine

- Hands-On Experience: Assess the ease of use, speed, and accuracy during a demo.

- Quality Assurance: Ensure that the machine meets your quality standards through firsthand testing.

Step 5: Verify Compliance with Local Regulations

Understand the regulatory requirements in your target market regarding key making machines. Compliance with local safety and operational standards is critical to avoid legal issues.

- Safety Standards: Check if the machines adhere to international safety regulations.

- Import Regulations: Familiarize yourself with any import/export restrictions or tariffs that may apply.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to finalize the purchase terms. This includes pricing, delivery schedules, warranty, and after-sales support.

- Pricing Strategy: Discuss bulk purchase discounts or financing options.

- Support Services: Ensure clarity on the terms of after-sales support, including maintenance and training.

Step 7: Establish a Long-Term Partnership

Consider establishing a long-term relationship with your chosen supplier. A reliable partnership can facilitate ongoing support, access to new technologies, and favorable pricing for future purchases.

- Communication: Maintain open lines of communication for feedback and support.

- Future Needs: Discuss potential future needs to ensure the supplier can accommodate your growth.

By following this structured checklist, B2B buyers can confidently navigate the sourcing process for key making machines, ensuring they select the right equipment for their operational needs.

Illustrative image related to key making machine

Comprehensive Cost and Pricing Analysis for key making machine Sourcing

What Are the Key Cost Components in Sourcing Key Making Machines?

When sourcing key making machines, understanding the cost structure is crucial for B2B buyers. The primary cost components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly influences the cost. Higher-grade metals and components can lead to increased durability and performance but will also raise the initial investment. Buyers should consider long-term benefits versus upfront costs when selecting materials.

-

Labor: Labor costs vary by region. In countries with higher wage standards, labor can constitute a significant portion of manufacturing costs. Understanding local labor markets can provide insights into potential savings or additional costs.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and administrative expenses. Efficient manufacturing processes can help mitigate these costs, making it essential for buyers to assess the supplier’s operational efficiency.

-

Tooling: Specialized tooling is often necessary for producing customized machines. This can be a substantial upfront cost but is essential for ensuring precision and quality.

-

Quality Control (QC): Effective QC processes are vital to ensure that machines meet specifications and standards. Investing in robust QC can prevent costly returns and repairs, adding to the overall cost structure.

-

Logistics: Shipping and handling costs can vary significantly based on the supplier’s location and the destination. It’s important to factor in these costs when evaluating total expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the market and typical margins can aid in negotiations.

How Do Price Influencers Affect the Cost of Key Making Machines?

Several factors can influence the pricing of key making machines. These include volume and minimum order quantity (MOQ), specifications and customization, materials and quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Purchasing in bulk can lead to significant cost reductions. Suppliers often offer discounts for larger orders, so understanding your needs can help negotiate better prices.

-

Specifications/Customization: Custom features or specifications may increase the price. Buyers should weigh the necessity of these features against their budget.

-

Materials and Quality Certifications: Machines made from high-quality materials or those that meet specific certifications may come at a premium. Buyers should assess whether these certifications are essential for their market.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms dictate shipping responsibilities and costs, impacting the total landed cost of the machines.

What Are the Best Buyer Tips for Negotiating Key Making Machine Prices?

International B2B buyers should adopt strategic approaches when negotiating prices for key making machines. Here are some actionable tips:

-

Negotiate Terms: Don’t just focus on price; consider negotiating payment terms, warranties, and service agreements. Flexible terms can improve cash flow and reduce risks.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the costs associated with operation, maintenance, and potential downtime. A higher initial investment might yield lower TCO in the long run.

-

Understand Pricing Nuances for International Buyers: Be aware of currency fluctuations and import duties that can affect pricing. These costs can vary widely depending on the buyer’s location.

-

Research Market Rates: Familiarize yourself with typical market rates for key making machines to have a benchmark for negotiations. This knowledge can empower you during discussions.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and terms over time. Suppliers are more likely to offer favorable terms to trusted partners.

In conclusion, understanding the cost structure, price influencers, and strategic negotiation techniques can significantly enhance the purchasing process for key making machines in international B2B markets. Buyers should approach sourcing with a comprehensive strategy that considers both immediate costs and long-term value.

Alternatives Analysis: Comparing key making machine With Other Solutions

Understanding Alternative Solutions for Key Making

In the realm of key duplication and creation, businesses often face a choice between various technologies and methods. Selecting the right solution can significantly impact operational efficiency, cost management, and customer satisfaction. This section compares traditional key making machines with alternative solutions such as key copy kiosks and manual key duplication methods, providing B2B buyers with critical insights for informed decision-making.

| Comparison Aspect | Key Making Machine | Key Copy Kiosk | Manual Key Duplication |

|---|---|---|---|

| Performance | High accuracy and speed | Moderate speed, variable accuracy | Variable speed, high accuracy |

| Cost | $500 – $10,250 depending on model | Low initial investment; pay-per-use | Low equipment cost; labor costs |

| Ease of Implementation | Requires installation and training | Easy to find and use; no training needed | Requires skilled personnel |

| Maintenance | Regular maintenance needed | Minimal maintenance required | Low maintenance; depends on tools |

| Best Use Case | High-volume key cutting | Quick, on-demand key duplication | Specialty or low-volume needs |

Key Copy Kiosks: What Are Their Advantages and Disadvantages?

Key copy kiosks, such as those offered by Minute Key and KeyMe, provide a convenient alternative for quick key duplication. These self-service machines are strategically placed in public areas, enabling users to duplicate keys for homes, offices, and vehicles with minimal wait times. One of the significant advantages of kiosks is their low initial investment; businesses can pay per transaction rather than purchase expensive machinery. However, the trade-off is that kiosks may not achieve the same level of accuracy as a dedicated key making machine, particularly for intricate or specialty keys.

Manual Key Duplication: Is It Still a Viable Option?

Manual key duplication remains a time-tested method for creating keys, especially in scenarios where precision and craftsmanship are paramount. This approach typically involves skilled personnel using hand-operated tools to replicate keys. The advantages of manual duplication include the ability to handle complex keys and a lower initial investment in equipment. However, the reliance on skilled labor can lead to increased operational costs, and the process can be time-consuming compared to automated machines or kiosks, making it less suitable for high-volume environments.

Making the Right Choice for Your Business

Choosing the right key making solution depends on your business’s specific needs. If your operations require high-volume key cutting with consistent accuracy, investing in a key making machine may be the best option. For businesses that prioritize convenience and lower upfront costs, key copy kiosks can offer a practical alternative. Conversely, manual key duplication may serve niche markets or specialized services effectively but could lead to higher labor costs and slower processing times. Assessing your operational requirements, budget, and target customer base will guide you in selecting the most suitable solution for your key-making needs.

Essential Technical Properties and Trade Terminology for key making machine

What Are the Essential Technical Properties of Key Making Machines?

Understanding the technical properties of key making machines is crucial for B2B buyers, as these specifications directly impact performance, reliability, and cost-efficiency. Here are several critical specifications to consider:

Illustrative image related to key making machine

-

Material Grade

– The durability and longevity of a key making machine are significantly influenced by its construction materials. Machines made from high-grade steel or aluminum alloys are preferred for their strength and resistance to wear. This is essential for maintaining precision and reducing maintenance costs, particularly in high-volume environments. -

Cutting Tolerance

– Cutting tolerance refers to the precision with which a machine can cut a key. A tighter tolerance (typically measured in microns) ensures that the duplicated keys fit smoothly into locks without jamming or failing. This is critical for businesses that prioritize quality service, as poor tolerances can lead to customer dissatisfaction and increased returns. -

Power Source

– Key making machines can be manual, semi-automatic, or fully automatic, with power sources varying from electric to battery-operated. The choice of power source affects the machine’s mobility and usability in different environments, such as workshops or mobile locksmith applications. Understanding power requirements is essential for ensuring the machine can operate effectively in the buyer’s intended setting. -

Operational Speed

– The speed at which a key making machine can duplicate keys is a vital metric for B2B buyers. Faster machines can significantly increase productivity, allowing businesses to serve more customers in a shorter time. This is particularly important in retail environments or during peak seasons when demand surges. -

Key Compatibility

– Different machines are designed to cut various types of keys, including standard, dimple, and automotive keys. Buyers should assess the machine’s compatibility with the types of keys they plan to duplicate to ensure they meet their service offerings. Machines with broad compatibility can serve a wider range of customers, enhancing business flexibility. -

Warranty and Support

– A robust warranty and reliable customer support are essential considerations. They provide assurance regarding the machine’s quality and the manufacturer’s commitment to service. Understanding warranty terms can help buyers avoid unexpected costs related to repairs or replacements.

What Are Common Trade Terms in the Key Making Machine Industry?

Familiarity with industry jargon can enhance communication and negotiation for B2B buyers. Here are several essential trade terms:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of key making machines, understanding OEM relationships can provide insights into quality standards and compatibility of parts. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for buyers to assess inventory needs and manage cash flow effectively, particularly when investing in multiple machines or components. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. Crafting an effective RFQ can help buyers obtain competitive pricing and better understand suppliers’ offerings. -

Incoterms (International Commercial Terms)

– These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery obligations, which is critical in international transactions. -

Lead Time

– This term refers to the amount of time from placing an order to receiving the product. Understanding lead times is essential for inventory planning and ensuring that businesses can meet customer demands promptly. -

Service Level Agreement (SLA)

– An SLA is a contract that outlines the expected level of service between a service provider and a customer. In the key making machine industry, an SLA may include performance metrics, response times, and support availability, which are vital for maintaining operational efficiency.

Incorporating these technical properties and industry terms into purchasing discussions can empower B2B buyers to make informed decisions, ultimately enhancing their business operations and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the key making machine Sector

What Are the Current Market Dynamics and Key Trends in the Key Making Machine Sector?

The global key making machine market is witnessing significant transformation driven by technological advancements and changing consumer preferences. Key trends include the growing popularity of self-service kiosks, which offer convenience and speed for key duplication, appealing particularly to urban consumers in regions like Africa and South America. Innovations in automation and smart technology are enhancing the efficiency of key cutting machines, allowing businesses to reduce operational costs while improving service delivery. Additionally, the rise of e-commerce platforms is reshaping sourcing practices, enabling international B2B buyers to access a broader range of products and suppliers, thus facilitating competitive pricing and better negotiation terms.

In regions such as Europe and the Middle East, there is a marked shift towards high-security keys and specialized key types, including those for automotive and electronic access systems. This trend is creating demand for advanced key making machines that can accommodate complex key profiles and coding requirements. Furthermore, the market is increasingly influenced by sustainability concerns, with buyers seeking equipment that aligns with environmental standards, which is leading manufacturers to explore eco-friendly materials and processes.

How Is Sustainability and Ethical Sourcing Impacting the Key Making Machine Sector?

Sustainability is becoming a critical consideration in the key making machine sector, with both manufacturers and buyers recognizing the environmental impact of their operations. As global awareness of climate change grows, businesses are under pressure to adopt sustainable practices and materials in their production processes. This includes the use of recycled metals and environmentally friendly coatings for key making machines, which not only reduce waste but also appeal to an environmentally conscious customer base.

Illustrative image related to key making machine

Ethical sourcing is equally important, especially for B2B buyers operating in regions with varying regulatory standards. Companies are increasingly scrutinizing their supply chains to ensure compliance with ethical labor practices and environmental regulations. By sourcing from manufacturers who prioritize sustainability and ethical labor, businesses can enhance their brand reputation and appeal to a growing demographic of eco-conscious consumers. Certifications such as ISO 14001 for environmental management and Fair Trade practices can serve as benchmarks for evaluating suppliers, ensuring that buyers are aligned with global sustainability goals.

What Is the Evolution of Key Making Machines in the B2B Context?

The evolution of key making machines has significantly shaped the B2B landscape, transforming from manual duplicators to sophisticated automated systems. Early key cutting methods relied heavily on manual labor, which limited efficiency and accuracy. The introduction of electric key machines in the mid-20th century marked a pivotal shift, allowing for quicker and more precise key duplication.

Over the past two decades, the industry has embraced digital technology, with machines now featuring computer numerical control (CNC) capabilities that enhance cutting accuracy and reduce human error. The rise of self-service kiosks and mobile key-making solutions reflects the ongoing trend towards automation and convenience, allowing businesses to meet consumer demands efficiently. This historical progression underscores the importance of staying abreast of technological advancements, as they play a crucial role in shaping sourcing strategies and operational capabilities in the key making sector.

Frequently Asked Questions (FAQs) for B2B Buyers of key making machine

-

How do I choose the right key making machine for my business needs?

Choosing the right key making machine involves evaluating your specific requirements, such as the types of keys you plan to duplicate (e.g., residential, automotive, commercial) and your production volume. Consider machines with features like automatic vs. manual operation, portability, and the ability to handle different key profiles. Research brands that are known for reliability and customer support. Additionally, consult with suppliers to understand the machine’s capabilities and maintenance needs. -

What are the common types of key making machines available in the market?

The market offers several types of key making machines, including manual key duplicators, automatic machines, and high-security key cutting machines. Manual machines are typically cost-effective and suitable for low-volume needs, while automatic machines are designed for higher efficiency and precision. High-security key machines cater to specialized keys, requiring advanced technology. Assess your business model to determine which type aligns best with your operational goals. -

What is the typical lead time for ordering key making machines from international suppliers?

Lead times can vary significantly based on the supplier’s location, production capacity, and shipping methods. Generally, you can expect a lead time ranging from 4 to 12 weeks for machines sourced from overseas. Factors such as customs clearance and logistics can also affect delivery times. To ensure timely receipt, it’s advisable to communicate clearly with suppliers about your deadlines and consider expedited shipping options if necessary. -

What are the minimum order quantities (MOQs) for key making machines?

Minimum order quantities (MOQs) for key making machines can differ between suppliers and are often influenced by the machine’s price and production costs. Many manufacturers may require an MOQ of 1-5 units for individual machines, while bulk orders can lead to lower MOQs. It’s essential to clarify these terms upfront to ensure that your order aligns with your budget and business needs. -

How can I assess the quality and reliability of a key making machine supplier?

To assess the quality and reliability of a key making machine supplier, start by reviewing their industry reputation, customer testimonials, and case studies. Request references from other clients and inquire about their experiences with the supplier’s products and support. Additionally, check for certifications that demonstrate compliance with international quality standards. Engaging in direct communication can also provide insights into their responsiveness and customer service approach. -

What payment terms are typically offered by suppliers for key making machines?

Payment terms for key making machines can vary widely among suppliers. Common terms include upfront payment, partial payment with the balance due upon delivery, or net payment terms (e.g., net 30 days). It’s crucial to negotiate terms that protect your interests and ensure that you are comfortable with the payment schedule. Always request a pro forma invoice to clarify costs and payment expectations before finalizing the agreement. -

How do I ensure compliance with international trade regulations when importing key making machines?

To ensure compliance with international trade regulations, familiarize yourself with the import laws and tariffs of your country. Work closely with your supplier to obtain all necessary documentation, such as commercial invoices, certificates of origin, and any required permits. Engaging a customs broker can also streamline the process, helping you navigate complex regulations and avoid potential delays or penalties during customs clearance. -

What are the best practices for shipping and logistics when sourcing key making machines internationally?

Best practices for international shipping include selecting a reliable freight forwarder with experience in handling machinery. Consider using Incoterms to define responsibilities between you and the supplier regarding shipping costs and risks. Ensure that the machines are packaged securely to prevent damage during transit. Lastly, keep open lines of communication with your logistics provider to track shipments and address any potential issues proactively.

Top 4 Key Making Machine Manufacturers & Suppliers List

1. Minute Key – Key Copy Kiosks

Domain: minutekey.com

Registered: 2007 (18 years)

Introduction: Key Copy Kiosks allow users to duplicate keys for homes, offices, and padlocks quickly and easily. The kiosks are self-service and can copy keys within minutes. Additional services include key fobs and car keys. Locations can be found by entering a ZIP code, city, or state.

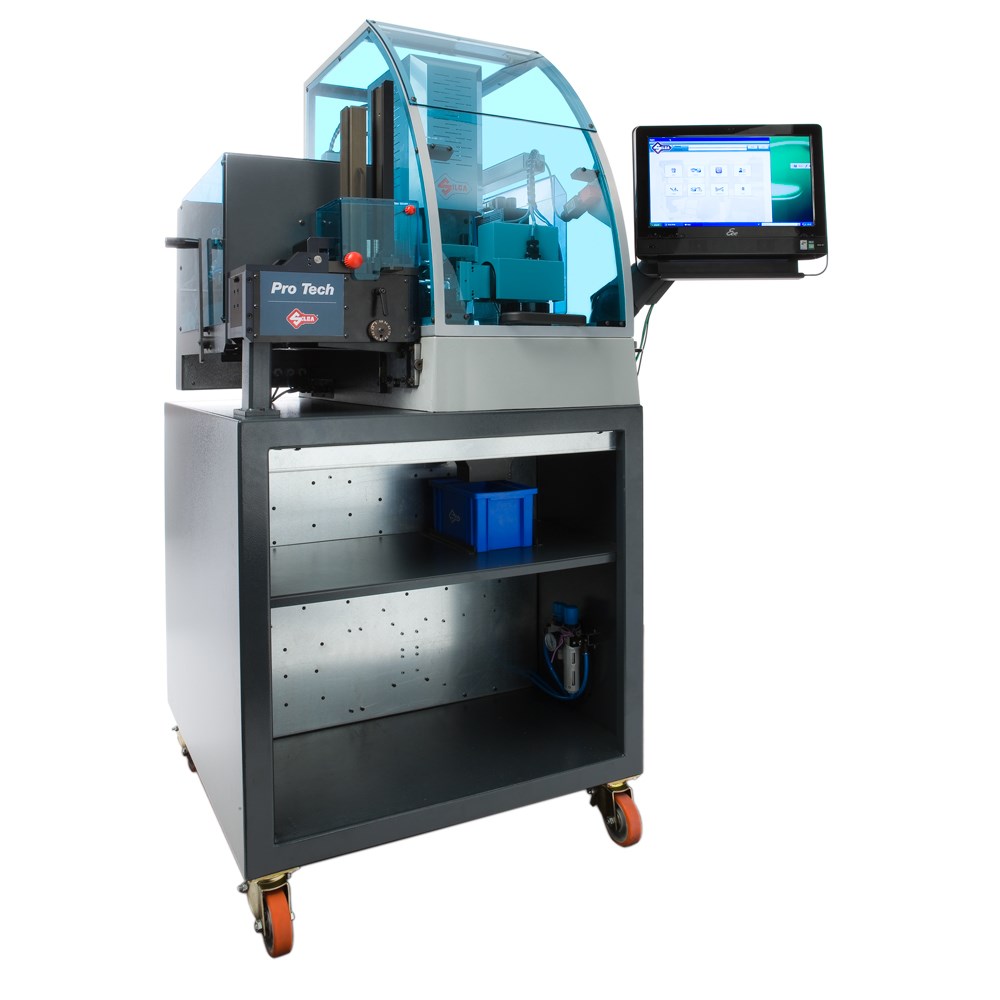

2. WENXING – Automatic Key Duplicator

Domain: lockpicks.com

Registered: 1997 (28 years)

Introduction: Key Cutting Machines available at LockPicks.com include various types such as Automatic Key Duplicators, Manual Key Duplicators, and Semi-Automatic Key Duplicators. Notable brands include WENXING, JMA, PRO-LOK, SILCA, and HPC. Prices range from $495.04 to $10,250.00. Some featured products are: WENXING Automatic Key Machine ($899.00), WENXING W288E Automatic Key Machine ($799.00), JMA NOMAD Key Du…

3. HPC – Mini Speedex Manual Key Machine

Domain: clksupplies.com

Registered: 2004 (21 years)

Introduction: {“products”:[{“name”:”HPC Mini Speedex Manual Key Machine”,”price”:”$495.04″,”description”:”A lightweight, industrial-grade duplicator, and is one of the most accurate key duplicators available.”},{“name”:”Ilco Flash 008 Key Machine 120V”,”price”:”$1,122.05″,”description”:”Easily duplicates most edge cut cylinder, cruciform, large bow and long blade keys.”},{“name”:”Nomad Key Machine by JMA -110V”…

4. ILCO – Key-Cutting Machines & Accessories

Domain: locksmithkeyless.com

Registered: 2015 (10 years)

Introduction: ILCO Key-Cutting Machines & Accessories are high-quality locksmith equipment designed for businesses and professionals. The collection includes various key-cutting machines and accessories tailored for efficient key duplication and locksmith tasks.

Strategic Sourcing Conclusion and Outlook for key making machine

As the demand for key making machines continues to rise globally, strategic sourcing becomes paramount for international B2B buyers. The diverse range of products—from manual to automatic key cutting machines—offers businesses the flexibility to cater to various customer needs, enhancing service offerings. By prioritizing quality and reliability in sourcing, companies can ensure they remain competitive in their markets across Africa, South America, the Middle East, and Europe.

Investing in advanced technology, such as self-service kiosks and high-precision machines, allows businesses to streamline operations and reduce turnaround times. Moreover, building relationships with reputable suppliers ensures access to the latest innovations and cost-effective solutions, which can significantly enhance profitability.

Looking ahead, the key making machine market is poised for growth, driven by technological advancements and increasing consumer demand for efficient key duplication services. B2B buyers are encouraged to actively explore partnerships with manufacturers and distributors that align with their strategic goals. Now is the time to leverage these insights to optimize sourcing strategies and position your business for success in an evolving landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.