Everything You Need to Know About 12 Point Star Rims Sourcing in 2025

Introduction: Navigating the Global Market for 12 point star rims

In today’s competitive automotive landscape, sourcing high-quality 12 point star rims poses a significant challenge for international B2B buyers. With the global market expanding, businesses must navigate various factors such as material quality, design specifications, and compliance with regional regulations. This comprehensive guide is designed to equip buyers with essential insights on the diverse types of 12 point star rims available, their applications across various vehicle models, and effective strategies for supplier vetting.

The guide delves into cost considerations, helping you understand pricing structures and potential value-adds from different suppliers. It also highlights market trends that could influence purchasing decisions, ensuring you stay ahead in a rapidly evolving marketplace. By focusing on the unique needs of B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—this resource empowers you to make informed decisions that align with your business objectives.

Through expert analysis and actionable recommendations, this guide not only simplifies the sourcing process but also enhances your ability to establish fruitful partnerships with reliable rim manufacturers. Whether you’re upgrading your inventory or seeking specialized designs, the insights provided will help you navigate the complexities of the global market for 12 point star rims effectively.

Understanding 12 point star rims Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 12 Point Star Rim | Classic design with 12 points around the rim | OEM replacements, standard vehicles | Pros: Widely available, cost-effective; Cons: Limited aesthetic options. |

| Machined Finish 12 Point Rim | Precision machined surface for enhanced aesthetics | Custom vehicles, performance upgrades | Pros: Attractive appearance, durable; Cons: Higher price point. |

| Lightweight Alloy 12 Point Rim | Made from lightweight aluminum alloys | Racing, off-road vehicles | Pros: Improved performance, fuel efficiency; Cons: May sacrifice durability. |

| Custom 12 Point Star Rim | Tailored designs with unique finishes | Specialty vehicles, show cars | Pros: Unique branding opportunities; Cons: Longer lead times, higher costs. |

| Directional 12 Point Star Rim | Designed for specific rotational direction | Performance vehicles, sports cars | Pros: Enhanced handling and stability; Cons: Requires careful installation. |

What Are the Characteristics of Standard 12 Point Star Rims?

Standard 12 point star rims are characterized by their classic design featuring twelve distinct points around the rim. These rims are typically made from steel or basic alloys, making them a cost-effective solution for OEM replacements. They are widely used in standard vehicles across various markets, providing a reliable option for B2B buyers looking to maintain or repair fleet vehicles. When sourcing these rims, buyers should consider availability and compatibility with specific vehicle models.

How Do Machined Finish 12 Point Rims Differ From Standard Options?

Machined finish 12 point rims offer a more refined aesthetic compared to standard options. The precision machining process enhances the visual appeal while maintaining durability. These rims are often sought after for custom vehicles and performance upgrades, appealing to businesses focused on aesthetics and brand image. Buyers should evaluate the balance between cost and visual impact, as these rims typically come at a premium price.

Why Choose Lightweight Alloy 12 Point Rims for Performance?

Lightweight alloy 12 point rims are engineered for performance, made from aluminum alloys that reduce overall vehicle weight. This design improves fuel efficiency and handling, making them popular in racing and off-road applications. B2B buyers should consider the specific performance needs of their clientele when selecting these rims. While they offer significant advantages in speed and agility, buyers must also account for potential trade-offs in durability.

What Are the Benefits of Custom 12 Point Star Rims?

Custom 12 point star rims allow businesses to create unique designs tailored to specific branding or aesthetic preferences. This customization can enhance the appeal of specialty vehicles or show cars, presenting a strong marketing opportunity. However, the lead times and costs associated with custom rims can be higher, requiring careful planning and budget considerations from B2B buyers.

How Do Directional 12 Point Star Rims Improve Vehicle Handling?

Directional 12 point star rims are specifically designed to rotate in one direction, optimizing handling and stability. This design is particularly beneficial for performance and sports cars, where precise handling is critical. B2B buyers should ensure proper installation and compatibility with the intended vehicle to maximize performance benefits. While these rims can enhance driving dynamics, they may require more meticulous maintenance and care.

Key Industrial Applications of 12 point star rims

| Industry/Sector | Specific Application of 12 point star rims | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Used in the production of various vehicle models, especially compact cars. | Enhances vehicle aesthetics and performance. | Quality certifications, compliance with local regulations, and availability of different sizes. |

| Heavy Machinery | Utilized in specialized equipment such as forklifts and construction vehicles. | Improves durability and load-bearing capacity. | Need for heavy-duty materials, custom sizes, and resistance to wear and tear. |

| Agricultural Equipment | Found in tractors and harvesters for enhanced mobility and efficiency. | Increases operational efficiency in fields. | Compatibility with various agricultural implements and resistance to environmental factors. |

| Specialty Vehicle Customization | Custom rims for off-road vehicles and racing cars. | Provides enhanced performance and customization options. | Availability of unique designs, materials, and compliance with performance standards. |

| Logistics and Transportation | Employed in trailers and transport vehicles for logistics companies. | Ensures reliable transportation and reduces downtime. | Need for bulk purchasing, cost-effectiveness, and durability under diverse conditions. |

In the automotive manufacturing sector, 12 point star rims are integral to the production of various vehicle models, particularly compact cars. These rims not only improve the aesthetic appeal but also contribute to the overall performance of vehicles, making them more attractive to consumers. Buyers in this sector should prioritize quality certifications and compliance with local regulations, as well as ensure that they can source different sizes to meet specific vehicle requirements.

In the heavy machinery industry, 12 point star rims are used in specialized equipment such as forklifts and construction vehicles. Their robust design enhances durability and load-bearing capacity, which is critical for machinery operating in demanding environments. Businesses should focus on sourcing rims made from heavy-duty materials that can withstand wear and tear, as well as any custom sizing needed for specific machinery applications.

In agricultural equipment, these rims are found on tractors and harvesters, significantly enhancing mobility and efficiency in the field. The unique design allows for better traction, which is essential for navigating uneven terrain. Buyers must consider compatibility with various agricultural implements and the rims’ resistance to environmental factors such as mud and corrosion when sourcing.

The specialty vehicle customization market employs 12 point star rims for off-road vehicles and racing cars, where performance and aesthetic customization are paramount. These rims provide enhanced performance characteristics and allow for personalized designs, appealing to a niche market of enthusiasts. Buyers should look for suppliers that offer a variety of unique designs and materials, ensuring compliance with relevant performance standards.

In the logistics and transportation sector, 12 point star rims are commonly used in trailers and transport vehicles. Their reliability is crucial for ensuring smooth operations and minimizing downtime in logistics operations. When sourcing, businesses should focus on bulk purchasing options, cost-effectiveness, and the rims’ ability to endure diverse transportation conditions, which can vary significantly across regions such as Africa, South America, and the Middle East.

3 Common User Pain Points for ’12 point star rims’ & Their Solutions

Scenario 1: Sourcing the Right Specifications for 12 Point Star Rims

The Problem: B2B buyers often face challenges when sourcing 12 point star rims due to the variety of specifications available. This can lead to confusion over which rim is compatible with their vehicles or applications. Inconsistent product descriptions, variations in lug patterns, sizes, and finishes can create a scenario where buyers end up purchasing rims that do not meet their needs, resulting in delays, additional costs, and inventory challenges.

The Solution: To effectively source the right 12 point star rims, buyers should start by gathering detailed specifications for their intended application. This includes measuring the existing rims for diameter, width, and bolt pattern. Utilize comprehensive databases or catalogs from reputable suppliers that provide clear images and specifications for each rim. When ordering, buyers should communicate directly with manufacturers or suppliers to confirm compatibility, specifying not only the vehicle make and model but also the intended use (e.g., racing, off-road, or daily driving). This proactive approach reduces the likelihood of mismatched orders and ensures that the rims meet performance and safety standards.

Scenario 2: Managing Inventory and Supply Chain Issues

The Problem: International B2B buyers, particularly those in regions like Africa and South America, may encounter significant supply chain issues, leading to delays in receiving 12 point star rims. Fluctuating demand, shipping delays, and customs regulations can result in stock shortages, which can hinder business operations and customer satisfaction.

The Solution: To mitigate inventory challenges, B2B buyers should adopt a strategic approach to inventory management. This involves establishing strong relationships with multiple suppliers to diversify the sourcing options and reduce dependency on a single source. Implementing an inventory management system can help track stock levels in real-time, allowing buyers to anticipate shortages before they occur. Additionally, consider negotiating contracts that include favorable terms for bulk purchasing or consignment agreements that allow for flexible stock management. By developing a responsive supply chain strategy and maintaining open communication with suppliers, buyers can better navigate potential disruptions and ensure a consistent supply of 12 point star rims.

Scenario 3: Ensuring Quality and Compliance with Standards

The Problem: Quality assurance is a critical concern for B2B buyers dealing with 12 point star rims, as poor-quality products can lead to safety issues and damage to vehicles. Buyers may struggle to determine the manufacturing standards and quality certifications associated with the rims, especially when sourcing from international suppliers.

The Solution: To ensure that the 12 point star rims meet the necessary quality and compliance standards, buyers should prioritize working with manufacturers who provide transparent information about their production processes and quality control measures. Request documentation that includes certifications such as ISO standards or compliance with local regulations. Conducting due diligence by reviewing supplier ratings and seeking testimonials from other B2B customers can also provide insights into product quality. Additionally, consider establishing a quality assurance protocol that includes inspections upon receipt of the rims, ensuring they meet specified standards before they are distributed or installed. By taking these steps, buyers can confidently select high-quality 12 point star rims that enhance vehicle safety and performance.

Strategic Material Selection Guide for 12 point star rims

What Are the Common Materials Used for 12 Point Star Rims?

When selecting materials for 12 point star rims, B2B buyers must consider the properties, advantages, and limitations of various materials. Here, we analyze four common materials: aluminum, steel, magnesium, and carbon fiber, focusing on their performance, cost implications, and suitability for specific applications.

How Does Aluminum Perform as a Material for 12 Point Star Rims?

Aluminum is a popular choice for 12 point star rims due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C and can withstand moderate pressure, making it suitable for various driving conditions. The primary advantage of aluminum rims is their ability to reduce overall vehicle weight, which can enhance fuel efficiency and handling.

However, aluminum rims can be prone to bending under high impact, which may affect durability. Additionally, while they are generally more affordable than other materials like carbon fiber, they can still be costly compared to steel. For international buyers, aluminum rims often comply with standards such as ASTM and are widely accepted in markets across Europe, Africa, and the Middle East.

What Are the Benefits and Drawbacks of Steel for 12 Point Star Rims?

Steel is another common material used for 12 point star rims, known for its strength and durability. Steel rims can handle higher pressures and are less likely to bend or crack under stress, making them ideal for off-road applications. They are also typically less expensive than aluminum, which can be a significant factor for cost-sensitive buyers.

On the downside, steel rims are heavier, which can negatively impact vehicle performance and fuel efficiency. They also have lower corrosion resistance compared to aluminum, requiring regular maintenance to prevent rust, especially in humid climates. Buyers in regions like Saudi Arabia and South America should consider the local climate and road conditions when opting for steel rims.

How Does Magnesium Compare for 12 Point Star Rims?

Magnesium is a lightweight alternative to aluminum, offering excellent performance in terms of strength-to-weight ratio. It has a high temperature rating, suitable for high-performance applications, and provides good corrosion resistance when properly treated. Magnesium rims can enhance vehicle performance, particularly in motorsports.

However, magnesium rims are typically more expensive and require specialized manufacturing processes, which can complicate production. They are also less common in standard automotive applications, making them a niche choice. For international buyers, compliance with specific standards like JIS may be necessary, and the availability of magnesium rims can vary by region.

What Are the Advantages of Carbon Fiber for 12 Point Star Rims?

Carbon fiber is the premium choice for high-performance 12 point star rims, known for its exceptional strength and lightweight properties. It can withstand high temperatures and offers excellent resistance to corrosion and fatigue. This material is ideal for racing applications where performance is critical.

The main disadvantages of carbon fiber include its high cost and manufacturing complexity. The production process is labor-intensive, which can lead to longer lead times. Additionally, carbon fiber rims may not be suitable for all driving conditions due to their susceptibility to impact damage. International buyers should ensure compliance with relevant standards and consider the market demand for carbon fiber products in their regions.

Summary Table of Material Selection for 12 Point Star Rims

| Material | Typical Use Case for 12 Point Star Rims | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General automotive applications | Lightweight, good corrosion resistance | Prone to bending under high impact | Medium |

| Steel | Off-road and heavy-duty applications | High strength and durability | Heavier, lower corrosion resistance | Low |

| Magnesium | High-performance and motorsport | Excellent strength-to-weight ratio | Expensive, specialized manufacturing | High |

| Carbon Fiber | Racing and high-performance vehicles | Exceptional performance and durability | High cost, susceptible to impact | High |

This comprehensive analysis of material selection for 12 point star rims provides B2B buyers with actionable insights to make informed purchasing decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 12 point star rims

What Are the Main Stages of Manufacturing 12 Point Star Rims?

The manufacturing process for 12 point star rims involves several critical stages that ensure both quality and performance. Understanding these stages can help B2B buyers make informed decisions when sourcing rims from international suppliers.

Material Preparation

The first step in the manufacturing process is material preparation. Typically, aluminum alloys are used due to their lightweight nature and strength. The raw materials undergo a rigorous selection process, where suppliers must ensure they meet specific standards. This may involve checking for impurities and verifying material properties against specifications. For international buyers, understanding the source of materials can be crucial for compliance with local regulations.

Forming Techniques: How Are 12 Point Star Rims Shaped?

Once the materials are prepared, the next stage is forming. Common techniques for shaping rims include casting, forging, and machining.

-

Casting: This involves pouring molten aluminum into a mold designed for the 12 point star shape. This method allows for intricate designs but requires careful temperature control to avoid defects.

-

Forging: Involves compressing the aluminum under high pressure to create a strong and durable rim. This technique enhances the mechanical properties of the material, making it ideal for performance applications.

-

Machining: After casting or forging, rims are often machined to achieve precise dimensions and finish. CNC (Computer Numerical Control) machines are commonly used to ensure accuracy in the final product.

Understanding these techniques helps buyers appreciate the craftsmanship and quality that goes into each rim.

What Happens During Assembly?

The assembly stage involves attaching components such as valve stems and wheel nuts to the rim. For 12 point star rims, this may also include additional features like decorative finishes or protective coatings.

Quality assurance during assembly is critical. Each component must be checked for compatibility and fit, ensuring that the final product meets design specifications. For B2B buyers, it’s essential to verify that suppliers have strict assembly protocols to maintain quality standards.

How Is the Finishing Process Executed?

The finishing stage includes several processes that enhance the aesthetic appeal and durability of the rims. Common finishing techniques include:

-

Anodizing: This electrochemical process increases corrosion resistance and allows for various color options.

-

Painting: High-quality paints are used to provide a protective layer against environmental factors while also allowing for branding or custom designs.

-

Polishing: This step is crucial for achieving a mirror-like finish, which is often desired for aesthetic reasons.

Understanding these finishing techniques can help B2B buyers identify suppliers who can meet specific design and durability requirements.

What International Standards Should B2B Buyers Consider for Quality Assurance?

Quality assurance is paramount in the manufacturing of 12 point star rims. International standards play a significant role in ensuring that rims meet safety and performance requirements.

ISO 9001 Certification: Why Is It Important?

ISO 9001 is a widely recognized quality management standard that outlines the requirements for a quality management system (QMS). Suppliers with ISO 9001 certification demonstrate their commitment to quality processes, which can be crucial for B2B buyers seeking reliable suppliers. This certification ensures that the supplier is continuously improving their processes, which ultimately leads to better products.

What Other Industry-Specific Certifications Are Relevant?

In addition to ISO 9001, B2B buyers should be aware of industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for products used in the oil and gas sector. These certifications ensure that the rims meet specific safety and performance criteria, which can be particularly important in regions with stringent regulatory requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is an integral part of the manufacturing process for 12 point star rims. Key checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials before they enter the production line. Ensuring that materials meet specifications is critical for the overall quality of the rims.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checks are performed to monitor critical parameters. This includes monitoring temperature during casting or pressure during forging.

-

Final Quality Control (FQC): After the rims are manufactured, a final inspection is conducted to ensure that they meet all specifications. This may include dimensional checks, visual inspections, and performance testing.

For B2B buyers, understanding these checkpoints can help assess the reliability of a supplier’s quality assurance processes.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control measures is essential for B2B buyers, especially when sourcing from international markets. Here are several methods to ensure supplier reliability:

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is a proactive approach to verify quality control processes. Buyers should establish a checklist that includes:

- Compliance with international standards (ISO, CE, etc.)

- Availability of quality control documentation

- Evidence of past performance and quality issues

Regular audits not only help in maintaining quality but also build a stronger relationship between buyers and suppliers.

How Can Buyers Utilize Reports and Third-Party Inspections?

Buyers should request quality control reports that detail inspection results and any corrective actions taken. Third-party inspections can also be beneficial, providing an unbiased assessment of the supplier’s quality practices. Engaging a reputable inspection agency can help mitigate risks associated with international sourcing.

What Are the Nuances of Quality Control for International Buyers?

For B2B buyers from diverse regions, understanding the nuances of quality control is essential. Different regions may have varying expectations regarding quality standards, and being aware of these can facilitate smoother transactions.

-

Regional Regulations: Buyers should familiarize themselves with local regulations that may impact the import of rims, such as safety standards in Europe or environmental regulations in South America.

-

Cultural Differences: Understanding cultural attitudes towards quality and customer service can enhance communication and expectations with suppliers.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for 12 point star rims empowers B2B buyers to make informed decisions, ensuring they source high-quality products that meet their specific needs. By considering material preparation, forming techniques, quality control checkpoints, and international standards, buyers can effectively navigate the complexities of the global rim market.

Practical Sourcing Guide: A Step-by-Step Checklist for ’12 point star rims’

To effectively source 12 point star rims for your business, it’s crucial to follow a structured approach. This guide provides a practical checklist to ensure you make informed decisions while procuring these specialized rims. By adhering to these steps, you can streamline your sourcing process and mitigate potential risks.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications of the 12 point star rims you require. Consider factors such as size, material (e.g., aluminum or steel), weight capacity, and design features.

– Why it matters: Accurate specifications help ensure compatibility with your vehicles or equipment, reducing the likelihood of returns or modifications later.

Step 2: Research Market Trends and Pricing

Conduct thorough research on current market trends and pricing for 12 point star rims. Compare prices from various suppliers and analyze the demand for specific styles or designs in your target regions.

– Why it matters: Understanding the market landscape enables you to negotiate better prices and identify potential suppliers who offer competitive rates.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct a comprehensive evaluation. Request company profiles, relevant certifications, and case studies demonstrating their experience in providing 12 point star rims.

– Why it matters: Vetting suppliers helps ensure they meet your quality and service expectations. Look for suppliers with positive reviews and a solid track record in your industry.

Step 4: Verify Quality Assurance Processes

Inquire about the quality assurance measures that suppliers have in place for their products. This includes testing standards, material sourcing, and adherence to international quality certifications such as ISO.

– Why it matters: Quality assurance processes are vital for ensuring that the rims meet safety and performance standards. This step can prevent costly defects and enhance customer satisfaction.

Step 5: Assess Logistics and Supply Chain Capabilities

Examine the logistics and supply chain capabilities of potential suppliers. Consider their shipping times, inventory management practices, and ability to handle international orders, especially if you’re sourcing from different continents.

– Why it matters: A reliable supply chain is crucial for timely delivery and maintaining your production schedules. Understanding these capabilities can help you avoid delays and ensure a consistent supply.

Step 6: Request Samples for Testing

Before placing a large order, request samples of the 12 point star rims for testing. This allows you to evaluate the rims in real-world conditions and verify that they meet your specifications.

– Why it matters: Testing samples ensures that the product performs as expected and fits your application requirements. It also helps you identify any potential issues before making a significant financial commitment.

Step 7: Negotiate Terms and Finalize Contracts

Once you’ve identified a suitable supplier, negotiate the terms of your contract, including pricing, payment terms, warranty provisions, and delivery schedules. Ensure that all agreements are documented clearly.

– Why it matters: Clear contracts protect your interests and set expectations for both parties. Thorough negotiations can lead to better terms, enhancing your overall purchasing strategy.

By following this checklist, you can navigate the complexities of sourcing 12 point star rims more effectively, ensuring a successful procurement process that meets your business needs.

Comprehensive Cost and Pricing Analysis for 12 point star rims Sourcing

What Are the Key Cost Components Involved in Sourcing 12 Point Star Rims?

When sourcing 12 point star rims, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Aluminum alloys are commonly used due to their lightweight and corrosion-resistant properties, while steel options may be more affordable but heavier. The quality and source of these materials can vary, affecting both price and performance.

-

Labor: Labor costs vary by region and production method. In countries with lower labor costs, such as some in Africa and South America, the overall production cost can be reduced. However, skilled labor for precision manufacturing is often required, especially for high-quality rims.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: The initial investment in tooling for rim production can be significant, especially for custom designs. Buyers should inquire about tooling costs upfront, as these can influence the per-unit price.

-

Quality Control (QC): Implementing stringent QC measures ensures that rims meet safety and performance standards. This can involve additional costs but is crucial for maintaining product integrity.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and volume. It’s important to factor in these costs, especially for international buyers who may face customs duties and tariffs.

-

Margin: Suppliers typically add a markup to cover their costs and profit. Understanding the standard margins in the industry can help buyers negotiate better pricing.

How Do Price Influencers Affect the Cost of 12 Point Star Rims?

Several factors influence the pricing of 12 point star rims, making it essential for buyers to consider these when sourcing:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to lower per-unit costs. Suppliers may offer discounts for larger quantities, so negotiating MOQs can yield significant savings.

-

Specifications and Customization: Custom designs or specific specifications can drive up costs. Buyers should clarify their requirements to avoid unexpected charges.

-

Material Choices: Higher-grade materials can increase costs but may provide better durability and performance. Buyers should weigh the benefits against the additional expense.

-

Quality and Certifications: Rims that meet international safety standards or certifications may come at a premium. However, investing in certified products can reduce liability risks.

-

Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Suppliers with established quality control processes may charge more but offer better assurance of product consistency.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the total cost.

What Are Essential Buyer Tips for Sourcing 12 Point Star Rims?

When navigating the sourcing process for 12 point star rims, international buyers should keep the following tips in mind:

-

Negotiate Effectively: Engage in discussions with suppliers about pricing, especially for bulk orders. Be prepared to discuss your needs and expectations to find a mutually beneficial agreement.

-

Focus on Cost-Efficiency: Look beyond the initial price. Consider the Total Cost of Ownership (TCO), which includes maintenance, potential repairs, and replacement costs over time.

-

Understand Pricing Nuances: Be aware that pricing can vary significantly between regions. For example, buyers in Europe may encounter different pricing structures compared to those in the Middle East or Africa, influenced by local economic factors and shipping costs.

-

Build Long-Term Relationships: Establishing a reliable relationship with suppliers can lead to better pricing, priority service, and improved product quality over time.

-

Stay Informed About Market Trends: Keeping abreast of trends in the wheel and rim market can help you anticipate changes in pricing and availability, allowing for more strategic sourcing decisions.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and may vary based on market fluctuations, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing 12 point star rims With Other Solutions

Introduction: Evaluating Alternative Wheel Solutions

In the realm of automotive wheels, choosing the right rim is crucial for performance, aesthetics, and cost-effectiveness. While 12 point star rims offer unique benefits, various alternatives exist that may better suit specific applications or preferences. This analysis provides a comparative overview of 12 point star rims against other viable options, helping B2B buyers make informed decisions based on their unique operational needs.

Comparison Table

| Comparison Aspect | 12 Point Star Rims | Alloy Wheels | Steel Wheels |

|---|---|---|---|

| Performance | Excellent grip and stability; lightweight | High performance; better heat dissipation | Durable; good for heavy loads |

| Cost | Moderate ($140 – $185) | High ($200 – $500) | Low ($80 – $150) |

| Ease of Implementation | Simple installation | Requires specialized tools for fitting | Easy to install |

| Maintenance | Low maintenance required | Moderate; may need polishing | Low; rust-proof options available |

| Best Use Case | Sporty vehicles, aesthetics | Performance vehicles, racing | Heavy-duty applications, fleet vehicles |

Detailed Breakdown of Alternatives

Alloy Wheels

Alloy wheels are a popular alternative, especially in performance applications. They are made from a combination of metals, which enhances their strength while maintaining a lightweight profile. This results in better acceleration and handling compared to traditional steel wheels. However, alloy wheels can be significantly more expensive and may require more maintenance to keep them looking pristine. They are ideal for high-performance vehicles or where aesthetics play a crucial role.

Steel Wheels

Steel wheels are known for their durability and cost-effectiveness, making them a common choice for commercial fleets and heavy-duty vehicles. They can withstand rough conditions and are less likely to bend or crack under stress. However, they are heavier than alloy or 12 point star rims, which can affect vehicle performance negatively. While they are generally less expensive and easier to replace, their aesthetic appeal may not match that of alloy or specialized rims like the 12 point star design.

Conclusion: Making the Right Choice for Your Needs

Choosing the right wheel solution involves assessing your specific requirements, including performance expectations, budget constraints, and the types of vehicles in your fleet. For buyers focused on aesthetics and enhanced handling, 12 point star rims may be the most suitable choice. In contrast, those prioritizing cost-effectiveness and durability might lean towards steel wheels. Alloy wheels can serve as a middle ground, offering performance benefits but at a higher price point. By carefully evaluating these options, B2B buyers can select the optimal rim solution that aligns with their operational goals and enhances their vehicles’ overall performance.

Essential Technical Properties and Trade Terminology for 12 point star rims

What Are the Key Technical Properties of 12 Point Star Rims?

When considering 12 point star rims, several critical technical properties are essential for B2B buyers to understand. These specifications directly influence the performance, compatibility, and longevity of the rims in various applications.

1. Material Grade

The material used in manufacturing rims significantly affects durability and performance. Common materials include aluminum alloys and steel. Aluminum is lightweight, enhancing fuel efficiency and performance, while steel offers greater strength and resistance to bending. Understanding material grade helps buyers choose rims that meet specific vehicle requirements and environmental conditions.

2. Lug Pattern

The lug pattern refers to the arrangement of the bolt holes on the rim. For 12 point star rims, this is typically a 5-lug configuration, but variations exist. Buyers must ensure that the lug pattern matches the vehicle’s specifications to ensure proper fitment and safety. A mismatch can lead to installation issues and compromise vehicle performance.

3. Offset

Offset is the distance between the wheel’s centerline and the mounting surface of the hub. It can be positive, negative, or zero. A correct offset is crucial for vehicle handling, stability, and brake clearance. Buyers should understand the offset requirements for their vehicles to avoid issues such as tire rubbing or compromised suspension geometry.

4. Backspacing

Backspacing measures the distance from the mounting surface to the back edge of the rim. This specification is vital for ensuring that the wheel fits within the wheel arch without interfering with suspension components or brake calipers. Buyers need to consider backspacing to achieve optimal performance and safety.

5. Load Rating

The load rating indicates the maximum weight a rim can safely support. This specification is particularly important for commercial vehicles that carry heavy loads. Understanding the load rating helps buyers select rims that can withstand the demands of their specific applications, ensuring safety and reliability.

6. Finish

The finish of a rim, such as machined, painted, or polished, affects both aesthetics and protection against environmental factors. A high-quality finish can prevent corrosion and enhance the lifespan of the rims. Buyers should consider the finish that best suits their vehicles and operating conditions.

What Are Common Trade Terminology and Jargon Related to 12 Point Star Rims?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are several key terms relevant to 12 point star rims:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the vehicle manufacturer or authorized suppliers. These parts are often preferred for their guaranteed compatibility and quality. Understanding OEM specifications helps buyers avoid aftermarket products that may not meet performance standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of products a supplier is willing to sell. It is essential for buyers to know the MOQ to plan their inventory and budget effectively. Understanding MOQ can also help in negotiating better pricing and terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits pricing and terms from suppliers for specific products. This process is vital for B2B buyers to compare options and make informed purchasing decisions. A well-prepared RFQ can streamline procurement and ensure competitive pricing.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in global trade. Understanding Incoterms helps buyers manage shipping costs, risk, and delivery timelines effectively. Familiarity with these terms is crucial for international transactions, especially in regions like Africa, South America, and the Middle East.

5. Tire Compatibility

This term refers to the ability of a rim to fit specific tire sizes and types. Buyers must ensure that the selected rims are compatible with their tires to maintain vehicle safety and performance. Understanding tire compatibility is essential for optimal vehicle operation.

6. Warranty Terms

Warranty terms outline the conditions under which a manufacturer will replace or repair a defective product. Buyers should review these terms to ensure they are protected against manufacturing defects and to understand the expected lifespan of the rims.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing 12 point star rims, ultimately enhancing their operational efficiency and product performance.

Navigating Market Dynamics and Sourcing Trends in the 12 point star rims Sector

What Are the Current Market Dynamics and Key Trends in the 12 Point Star Rims Sector?

The 12 point star rims sector is experiencing significant growth driven by several global factors. Increasing vehicle ownership in emerging markets such as Africa and South America is propelling demand for aftermarket wheels, including the popular 12 point star design. In regions like the Middle East and Europe, the trend is leaning towards customization, where buyers seek unique aesthetic enhancements for their vehicles. B2B buyers should note that the market is increasingly influenced by technological advancements, such as 3D printing and CNC machining, which enable manufacturers to produce highly customized and lightweight rims more efficiently.

Moreover, digital sourcing platforms are transforming how international buyers engage with suppliers. The rise of e-commerce and B2B marketplaces allows buyers from diverse regions to connect with manufacturers directly, streamlining the procurement process. This shift is particularly significant in Europe and the Middle East, where buyers are looking for quality assurance and competitive pricing. Additionally, the use of data analytics in inventory management is helping suppliers predict trends and optimize their offerings, ensuring that they meet the evolving preferences of B2B buyers.

How Is Sustainability and Ethical Sourcing Influencing the 12 Point Star Rims Market?

Sustainability has become a crucial consideration for B2B buyers in the 12 point star rims sector. The environmental impact of manufacturing processes and materials is under scrutiny, prompting companies to adopt greener practices. This includes sourcing aluminum from recycled materials and ensuring that production facilities adhere to stringent environmental regulations. B2B buyers should prioritize suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001 or those utilizing green materials.

Ethical sourcing is also gaining traction as buyers seek to ensure that their supply chains are free from exploitation and environmental harm. Transparency in sourcing practices, such as providing information about the origin of materials and labor conditions, is becoming essential. By choosing suppliers who are committed to ethical practices, B2B buyers not only contribute to global sustainability efforts but also enhance their brand reputation in increasingly eco-conscious markets.

What Is the Brief Evolution of 12 Point Star Rims and Its Importance for B2B Buyers?

The 12 point star rim design has its roots in the automotive industry’s quest for both aesthetics and performance. Initially popularized in the mid-20th century, these rims were favored for their distinctive look and lightweight properties, which contributed to better vehicle handling and fuel efficiency. Over the years, the design has evolved with advancements in materials and manufacturing technologies, making them more accessible to the aftermarket sector.

For B2B buyers, understanding this evolution is crucial as it highlights the ongoing innovation within the industry. The transition from heavy, traditional materials to lighter, more durable alternatives reflects broader trends in automotive engineering. Buyers should be aware of these developments to make informed purchasing decisions that align with the latest performance standards and consumer preferences. Additionally, recognizing the historical significance of rim designs can aid in marketing strategies aimed at tapping into nostalgia while appealing to modern sensibilities.

Frequently Asked Questions (FAQs) for B2B Buyers of 12 point star rims

1. How do I ensure the quality of 12 point star rims from suppliers?

To ensure quality when sourcing 12 point star rims, start by vetting suppliers through third-party audits and certifications such as ISO 9001. Request detailed product specifications, including material types and manufacturing processes. It’s also beneficial to ask for samples before placing a large order. Establish a quality assurance protocol that includes inspecting rims upon delivery and setting up a feedback loop with your suppliers to address any quality issues promptly. This proactive approach can significantly mitigate risks associated with poor-quality products.

2. What are the typical minimum order quantities (MOQs) for 12 point star rims?

Minimum order quantities can vary significantly among suppliers, typically ranging from 50 to 500 units depending on the manufacturer’s capacity and the specific design of the rims. Always clarify MOQs before entering negotiations to avoid potential misunderstandings. Some suppliers may offer lower MOQs for customized designs, so it’s wise to discuss your specific needs and explore options for smaller pilot orders that can lead to larger future purchases.

3. What payment terms are commonly offered by suppliers of 12 point star rims?

Payment terms can vary widely, but many suppliers offer options such as 30% upfront and 70% upon delivery. Other common arrangements include net 30 or net 60 terms, allowing buyers to pay after receiving the goods. It’s crucial to discuss and negotiate payment terms upfront to align with your cash flow needs and risk tolerance. Using secure payment methods, such as letters of credit, can also provide added protection in international transactions.

4. How can I customize 12 point star rims for my market?

Customization options for 12 point star rims typically include alterations in design, size, finish, and lug patterns. When working with suppliers, provide detailed specifications and any design mockups to ensure alignment. Inquire about the supplier’s capabilities for custom manufacturing and whether they can accommodate smaller production runs for unique designs. Establishing a collaborative relationship with the supplier can facilitate the customization process and lead to innovative product offerings tailored to your market’s demands.

5. What logistics considerations should I keep in mind when importing 12 point star rims?

When importing 12 point star rims, it’s essential to consider shipping methods, customs regulations, and associated costs. Choose a reliable freight forwarder experienced in handling automotive parts to navigate complexities. Ensure compliance with local import regulations, tariffs, and duties in your region, as these can impact your overall cost. Additionally, factor in lead times for production and shipping to align with your inventory needs, allowing for any unexpected delays in the supply chain.

6. How do I assess the reliability of a supplier for 12 point star rims?

To assess a supplier’s reliability, check their industry reputation through reviews and testimonials from other B2B buyers. Look for suppliers with a solid track record in delivering quality products on time. Request references and conduct background checks on their business practices. Engaging in initial smaller transactions can also help gauge their responsiveness and service quality before committing to larger orders.

7. What are the common finishes available for 12 point star rims?

12 point star rims are available in various finishes, including chrome, matte, glossy, and powder-coated options. Each finish offers different aesthetics and durability levels, catering to diverse consumer preferences. When sourcing, consider the target market’s preferences for style and functionality, as well as the environmental conditions in which the rims will be used. Discuss available finishes with suppliers and request samples to ensure alignment with your branding strategy.

8. How do I handle disputes with suppliers of 12 point star rims?

Handling disputes with suppliers requires a clear and documented communication process. Start by addressing the issue directly with the supplier, presenting any relevant documentation or evidence. If the dispute cannot be resolved amicably, refer to the terms outlined in your purchase agreement regarding dispute resolution mechanisms, such as mediation or arbitration. Maintaining a professional demeanor throughout the process can help preserve the business relationship while working toward a satisfactory resolution.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 12 Point Star Rims Manufacturers & Suppliers List

1. Wheel Collision – 13×5 12 Point Star Wheel

Domain: wheelcollision.com

Registered: 1996 (29 years)

Introduction: This company, Wheel Collision – 13×5 12 Point Star Wheel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

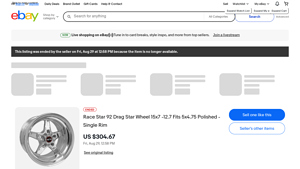

2. Race Star – 92 Drag Star Wheel

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “Race Star 92 Drag Star Wheel”, “size”: “15×7”, “offset”: “-12.7”, “bolt_pattern”: “5×4.75”, “finish”: “Polished”, “type”: “Single Rim”, “price”: “$304.67”, “list_price”: “$510.95”, “discount”: “40% off”, “condition”: “New”, “seller”: “m maperformance”, “seller_feedback”: “98.5% positive feedback”, “quantity_available”: “1”}

3. Weld – Weldstar Beadlock Wheels

Domain: weldwheels.com

Introduction: Weldstar Beadlock Wheels are designed for maximum grip and performance. Key features include: 3-piece forged aluminum construction, polished shell with black machined or polished center, black anodized forged aluminum beadlock rings, and 12-point coated beadlock hardware. They are compatible with a 5/8″ drive stud or short shank mag style lug. Available sizes include 15″, 17″, and 18″ with matchin…

4. Fastenal – Stainless Steel Solutions

Domain: bimmerforums.com

Registered: 2000 (25 years)

Introduction: This company, Fastenal – Stainless Steel Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. CRAGAR – STAR WIRE WHEELS

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: CRAGAR STAR WIRE WHEELS 30&50 SPOKES ONLY, timeless, classic design, enhances the appearance of any car.

6. JBugs – 5×205 5 Spoke VW Aluminum Wheel

Domain: jbugs.com

Registered: 1999 (26 years)

Introduction: {“product_id”: “520515-STAR”, “wheel_type”: “5×205 5 Spoke VW Aluminum Wheel”, “offset”: “Off Road Offset”, “made_in”: “USA”, “discount”: “15% off sitewide and 20% off orders over $1800”, “coupon_conditions”: “Must be logged into a customer account to redeem coupon. Limit 1 use per customer.”}

Strategic Sourcing Conclusion and Outlook for 12 point star rims

In the dynamic landscape of automotive components, the strategic sourcing of 12 point star rims presents unique opportunities for international buyers. The demand for these rims, driven by both aesthetic appeal and functional performance, underscores the importance of selecting reliable suppliers who can provide high-quality products at competitive prices. By leveraging data-driven insights, businesses can optimize their procurement strategies, ensuring that they remain responsive to market trends and customer preferences.

Additionally, understanding regional market nuances, such as regulatory requirements and cultural preferences in Africa, South America, the Middle East, and Europe, is essential. This knowledge not only facilitates smoother transactions but also fosters long-term partnerships with suppliers.

As we look to the future, the importance of adaptability in sourcing strategies cannot be overstated. International buyers are encouraged to explore innovative sourcing channels, embrace digital platforms for procurement, and prioritize sustainable practices. By doing so, they can position themselves for growth and competitiveness in an ever-evolving market. Embrace the potential of strategic sourcing for 12 point star rims today and ensure your business remains at the forefront of the automotive industry.