How to Source 55 Gallon Drum Dimensions Cm Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for 55 gallon drum dimensions cm

In today’s global marketplace, sourcing the right 55 gallon drum dimensions in centimeters can present a significant challenge for B2B buyers. With a variety of drum types—steel, plastic, and fiber—each possessing unique specifications and applications, understanding these dimensions is crucial for effective logistics, storage, and compliance with international shipping standards. This comprehensive guide aims to demystify the complexities surrounding 55-gallon drum dimensions by offering in-depth insights into their types, applications, and the vital considerations for supplier vetting.

By addressing key factors such as cost implications, compatibility with various products, and the regulatory requirements for transporting hazardous materials, this guide empowers international B2B buyers from regions like Africa, South America, the Middle East, and Europe—including Germany and Brazil—to make informed purchasing decisions. Whether you are looking to optimize your supply chain or ensure compliance with international standards, our guide is structured to provide actionable insights and best practices tailored to your specific market needs.

Navigating the nuances of 55-gallon drum dimensions is not just about selecting the right container; it’s about enhancing operational efficiency and ensuring product integrity. Equip yourself with the knowledge to confidently select the best drum solutions for your business needs and stay ahead in a competitive landscape.

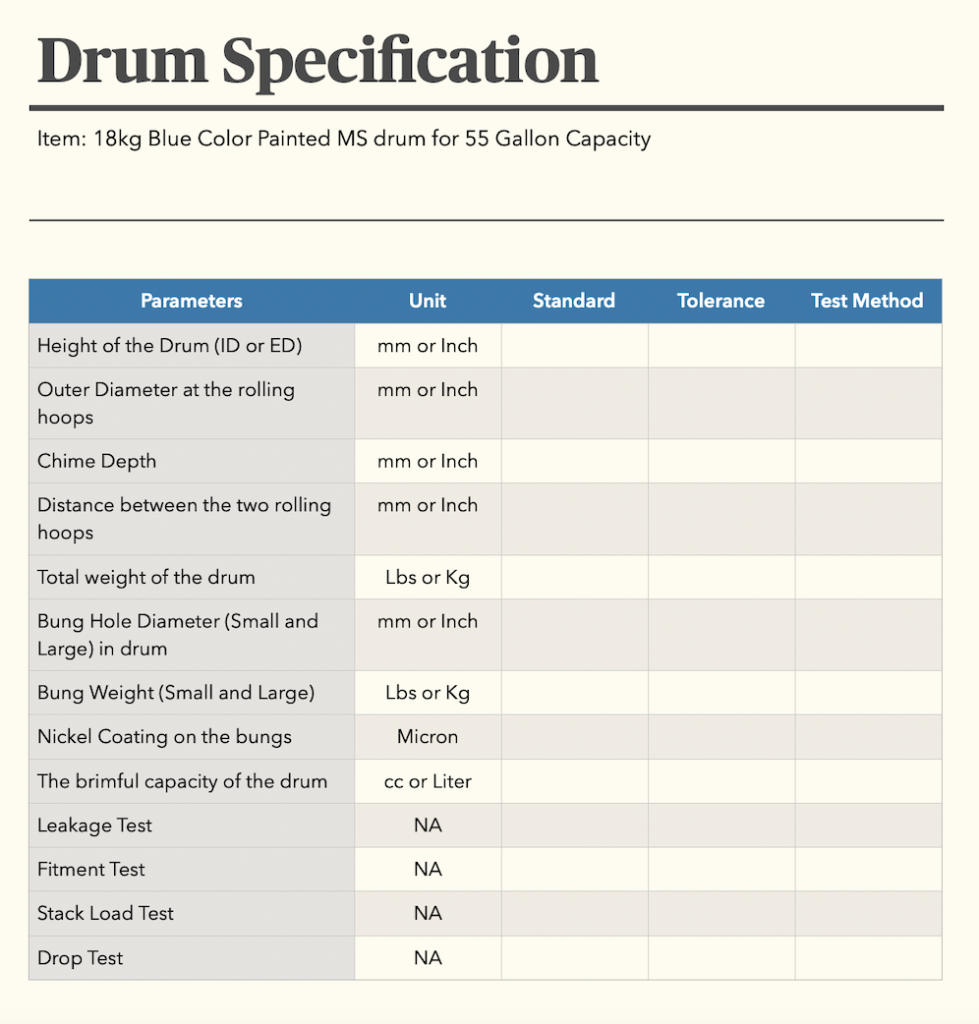

Understanding 55 gallon drum dimensions cm Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Tight-Head | Permanently attached top; robust construction | Transporting hazardous liquids, chemicals | Pros: Durable, reusable; Cons: Heavier, may corrode with certain contents. |

| Steel Open-Head | Removable lid with locking ring; versatile | Storage of thick liquids, adhesives | Pros: Easy access; Cons: Less secure for volatile materials. |

| Plastic Tight-Head | Lightweight, UV-resistant, high-density polyethylene (HDPE) | Safe storage of hazardous materials, bio waste | Pros: Lightweight, resistant to chemicals; Cons: Less durable than steel. |

| Plastic Open-Head | Lever-lock closure, lightweight design | Ideal for lab pack applications, non-leaking materials | Pros: Easy handling; Cons: Limited to less viscous products. |

| Fiber Drums | Made from layered kraft paper; customizable height | Storing powders, semi-solids, and dry materials | Pros: Lightweight, recyclable; Cons: Not suitable for liquids. |

What Are the Key Characteristics of Steel Tight-Head Drums?

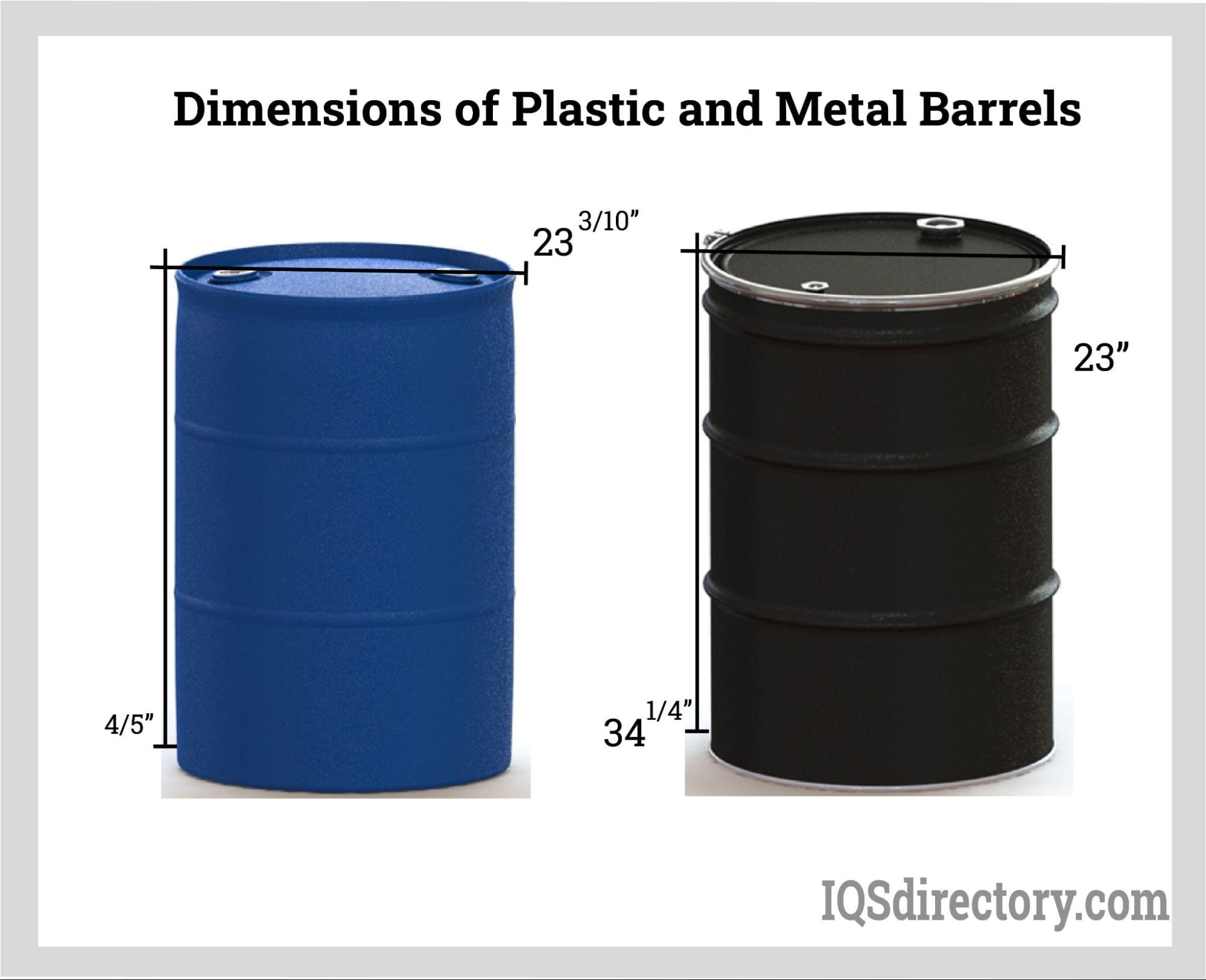

Steel tight-head drums are designed with a permanently attached top, making them ideal for transporting hazardous liquids and chemicals. Their robust construction ensures durability, allowing them to withstand rough handling during shipping. The standard dimensions typically include an outside height of approximately 84 cm and a diameter of around 58.4 cm. B2B buyers should consider their weight and potential for corrosion when selecting these drums, especially for long-term storage or transport of aggressive materials.

How Do Steel Open-Head Drums Differ from Tight-Head Variants?

Steel open-head drums feature a removable lid secured with a locking ring, making them versatile for storing thicker liquids and adhesives. They are slightly taller than tight-head drums, with dimensions generally around 88.3 cm in height. Their design allows for easy access, which is beneficial for businesses needing to frequently refill or dispense contents. However, buyers should weigh the benefits of easy access against the potential risks of leakage or contamination, particularly for volatile substances.

What Advantages Do Plastic Tight-Head Drums Offer?

Plastic tight-head drums are constructed from high-density polyethylene (HDPE), making them lightweight and resistant to UV rays and chemicals. They are commonly used for the safe storage of hazardous materials and bio waste, with dimensions similar to steel variants. The primary advantage lies in their lighter weight, which reduces shipping costs. However, buyers should note that while they are chemical-resistant, they may not offer the same level of durability as steel drums, particularly under extreme conditions.

Why Choose Plastic Open-Head Drums for Lab Applications?

Plastic open-head drums are designed with a lever-lock closure and are ideal for lab pack applications involving non-leaking materials. Their dimensions typically include a height of around 92.7 cm and a diameter of 53.3 cm, making them easy to handle. These drums are particularly beneficial for businesses that need to store smaller containers or bottles within a larger drum. However, they are best suited for less viscous products, and buyers should be cautious when considering their use for thicker substances.

What Makes Fiber Drums a Unique Option for B2B Buyers?

Fiber drums are crafted from layers of kraft paper, making them lightweight and customizable in height. They are particularly effective for storing powders and semi-solid materials. Their dimensions can vary based on customization, but they generally offer a more eco-friendly option due to their recyclability. While fiber drums are excellent for dry materials, they are not suitable for liquids, which is a critical consideration for buyers aiming to optimize their packaging solutions.

Key Industrial Applications of 55 gallon drum dimensions cm

| Industry/Sector | Specific Application of 55 gallon drum dimensions cm | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Manufacturing | Storage and transportation of bulk chemicals in tight-head drums | Ensures safe handling of hazardous materials while maximizing storage efficiency. | Compliance with UN ratings for hazardous materials; material compatibility. |

| Food and Beverage | Transport of liquid food products and ingredients in open-head drums | Maintains product integrity and prevents contamination during transport. | FDA compliance for food-grade materials; color coding for easy identification. |

| Waste Management | Collection and disposal of hazardous waste in fiber drums | Facilitates safe and efficient waste handling, reducing environmental impact. | Durability and reusability; appropriate linings for specific waste types. |

| Pharmaceuticals | High-purity storage of drugs and chemicals in stainless steel drums | Ensures product safety and integrity, crucial for regulatory compliance. | Quality certifications; specialized cleaning and maintenance procedures. |

| Agriculture | Transport of fertilizers and pesticides in plastic drums | Provides resistance to chemicals and UV light, ensuring long-term storage. | Environmental regulations for chemical storage; compatibility with various agrochemicals. |

How Are 55 Gallon Drums Used in Chemical Manufacturing?

In the chemical manufacturing sector, 55-gallon drums are often utilized for the storage and transportation of bulk chemicals. Tight-head drums are particularly favored for their ability to securely contain hazardous materials, minimizing the risk of spills and leaks during transit. International buyers must ensure that the drums meet UN standards for hazardous materials and are compatible with the chemicals being stored. The durability and strength of these drums provide businesses with a reliable solution for safe handling, which is critical in regions where regulatory compliance is strictly enforced.

What Role Do 55 Gallon Drums Play in Food and Beverage Industries?

In the food and beverage industry, open-head 55-gallon drums are commonly used for transporting liquid ingredients, such as oils and sauces. The dimensions of these drums facilitate efficient loading and unloading, while their design helps maintain product integrity. Buyers should prioritize sourcing drums that are FDA-compliant and made from food-grade materials to avoid contamination. Additionally, color coding can aid in quick identification, enhancing operational efficiency, especially in large-scale production environments.

Why Are 55 Gallon Drums Important for Waste Management?

55-gallon fiber drums are a staple in waste management, particularly for the collection and disposal of hazardous waste. These drums provide a practical solution for safely handling materials that may pose environmental risks. Their ability to be rinsed and reused makes them a sustainable choice for businesses looking to reduce waste. When sourcing these drums, companies must consider durability, the need for appropriate linings to accommodate different waste types, and adherence to local environmental regulations, especially in regions with strict waste management laws.

How Do Stainless Steel Drums Benefit the Pharmaceutical Sector?

In the pharmaceutical industry, high-purity storage is critical, making stainless steel 55-gallon drums an excellent choice. These drums are designed to maintain the integrity of sensitive products, ensuring compliance with stringent health regulations. Buyers in this sector should focus on sourcing drums that meet quality certifications and are easy to clean, as the risk of contamination must be minimized. The investment in stainless steel drums not only protects valuable products but also enhances the overall safety and efficiency of pharmaceutical operations.

What Advantages Do 55 Gallon Drums Offer in Agriculture?

In agriculture, 55-gallon plastic drums are widely used for transporting fertilizers and pesticides. Their robust design offers resistance to chemicals and UV light, ensuring that products remain stable during storage. Businesses must ensure that the drums comply with environmental regulations regarding chemical storage and that they are compatible with the various agrochemicals being handled. The right dimensions and material properties can significantly enhance the efficiency of agricultural operations, making these drums a valuable asset for international buyers in the sector.

3 Common User Pain Points for ’55 gallon drum dimensions cm’ & Their Solutions

Scenario 1: Misalignment with Shipping Regulations for Hazardous Materials

The Problem: B2B buyers often face challenges when sourcing 55-gallon drums that meet international shipping regulations, especially for hazardous materials. The specifications, including dimensions in centimeters, must adhere to strict guidelines set by regulatory bodies such as the UN. Failure to comply can result in hefty fines, delays, and even damage to products during transit. Buyers may also struggle with understanding the different standards for various materials—plastic, steel, or fiber—leading to potential missteps in selecting the appropriate drum.

The Solution: To navigate these complex regulations effectively, it is crucial for buyers to familiarize themselves with UN ratings and the specific requirements for their intended materials. Sourcing from reputable suppliers who provide detailed product specifications—including dimensions in centimeters and compliance documentation—ensures that the drums meet necessary safety standards. Additionally, utilizing a checklist that includes factors such as drum material, closure types, and weight limits can streamline the selection process. Engaging with a logistics partner experienced in hazardous materials can also provide insights into local regulations and best practices for shipping, minimizing risk and ensuring compliance.

Scenario 2: Difficulty in Space Optimization for Drum Storage

The Problem: Many businesses encounter challenges when it comes to optimizing their storage space for 55-gallon drums. With varying dimensions, improper stacking can lead to inefficient use of warehouse space, safety hazards, or difficulty accessing specific drums when needed. International buyers, particularly in regions with limited warehouse space, may struggle to find solutions that maximize their storage capabilities while maintaining safety and compliance.

The Solution: To effectively optimize storage, buyers should first assess their available space and the dimensions of the drums they plan to use. Implementing a vertical storage solution is one effective approach; for example, stacking empty drums with appropriate stabilizing measures can free up valuable floor space. Additionally, using racks designed specifically for drum storage can enhance accessibility and safety. Utilizing software tools for inventory management can also aid in tracking drum locations, ensuring that the most frequently used items are easily accessible. Regular training for warehouse staff on safe handling and storage practices will further enhance operational efficiency and safety.

Scenario 3: Confusion Over Drum Types and Their Applications

The Problem: Buyers often experience confusion regarding the various types of 55-gallon drums and their specific applications, particularly when it comes to understanding the differences between tight-head and open-head drums. This lack of clarity can lead to purchasing the wrong type of drum for their needs, resulting in product damage, increased costs, and operational inefficiencies. For instance, a company may need to store a thick adhesive but mistakenly choose a tight-head drum, which could complicate access and dispensing.

The Solution: To mitigate this issue, buyers should invest time in understanding the unique characteristics and applications of each drum type. Resources such as supplier product guides, webinars, and industry publications can provide valuable insights into the best practices for drum selection based on intended use. Furthermore, collaborating with suppliers who offer consultations can help in identifying the right drum type for specific materials. Establishing a standard operating procedure (SOP) for selecting and using drums based on material characteristics can also streamline operations and reduce the likelihood of missteps in the future. By ensuring that all team members are educated about drum types and their applications, businesses can improve their overall efficiency and reduce costs associated with incorrect purchases.

Strategic Material Selection Guide for 55 gallon drum dimensions cm

What Are the Key Properties of Steel 55 Gallon Drums?

Steel drums, particularly those made from cold-rolled or stainless steel, are renowned for their strength and durability. They can withstand high temperatures and pressures, making them suitable for a wide range of applications, including hazardous materials. Steel has excellent corrosion resistance when treated or coated, which is essential for storing chemicals, oils, and other liquids. However, the weight of steel drums can be a drawback, especially in regions where transportation costs are a concern.

What Advantages and Disadvantages Do Plastic 55 Gallon Drums Offer?

Plastic drums, often constructed from high-density polyethylene (HDPE), are lightweight and resistant to many chemicals, making them ideal for various applications. They are less expensive than steel drums and can be produced in a variety of colors, which can be a factor in branding and compliance. However, they have lower temperature and pressure ratings compared to steel, which limits their use for certain materials. Additionally, while they are resistant to corrosion, they may not be suitable for all hazardous materials, particularly those that can permeate plastic.

How Do Fiber Drums Compare in Terms of Performance and Suitability?

Fiber drums are made from layers of kraft paper, providing a lightweight alternative for packaging dry goods and semi-solids. They are often used for products that require a breathable container, such as powders and certain chemicals. While fiber drums are recyclable and can be reused, they are less durable than steel or plastic options and may not withstand harsh environmental conditions. Their suitability for international shipping can also be limited due to moisture sensitivity, which is a critical consideration for buyers in humid regions.

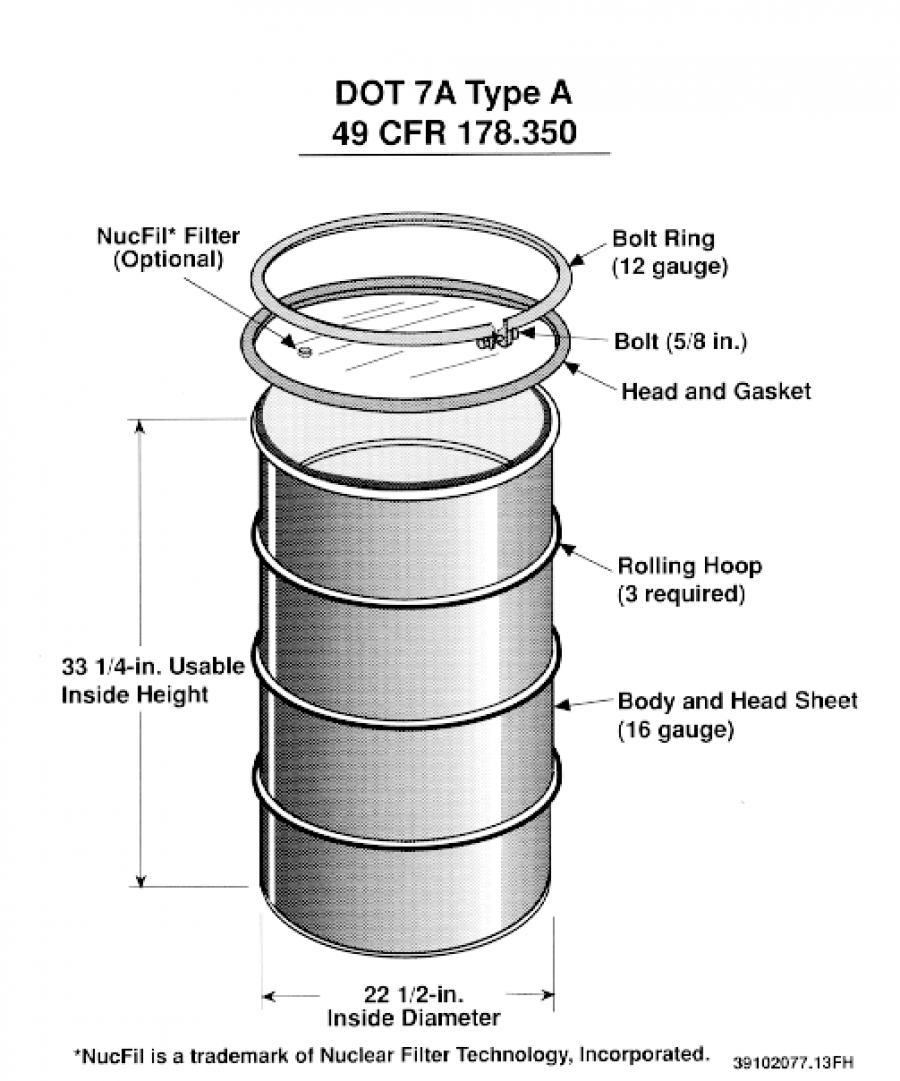

Illustrative image related to 55 gallon drum dimensions cm

What Should International B2B Buyers Consider When Selecting Drum Materials?

International buyers, especially from Africa, South America, the Middle East, and Europe, must consider compliance with local and international standards such as ASTM, DIN, and JIS. The choice of material can impact shipping costs, regulatory compliance, and product integrity. For example, UN-rated drums are crucial for transporting hazardous materials, and buyers should ensure that the selected drum meets the necessary performance standards. Additionally, regional preferences may dictate the choice of material based on availability, cost, and specific application needs.

| Material | Typical Use Case for 55 gallon drum dimensions cm | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Storing and transporting hazardous liquids and chemicals | High durability and strength | Heavy and may require special handling | High |

| Plastic | Storing non-hazardous liquids and chemicals | Lightweight and resistant to many chemicals | Lower temperature/pressure ratings | Medium |

| Fiber | Packaging dry goods and semi-solids | Recyclable and lightweight | Not suitable for wet or hazardous materials | Low |

| Stainless Steel | Storing high-purity products like pharmaceuticals | Excellent corrosion resistance and durability | Higher cost and weight | High |

This guide provides a comprehensive overview of the materials used in 55-gallon drums, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 55 gallon drum dimensions cm

What Are the Key Stages in the Manufacturing Process of 55 Gallon Drums?

The manufacturing of 55-gallon drums involves several critical stages, each designed to ensure the final product meets the stringent demands of various industries. The process typically includes material preparation, forming, assembly, and finishing.

How Is Material Prepared for Drum Production?

The first step in drum manufacturing is material preparation. For steel drums, low-carbon or stainless steel sheets are sourced based on the intended use of the drum. These sheets undergo cutting into precise dimensions that correspond to the required specifications. For plastic drums, high-density polyethylene (HDPE) is used, which is also prepared by melting and shaping into molds.

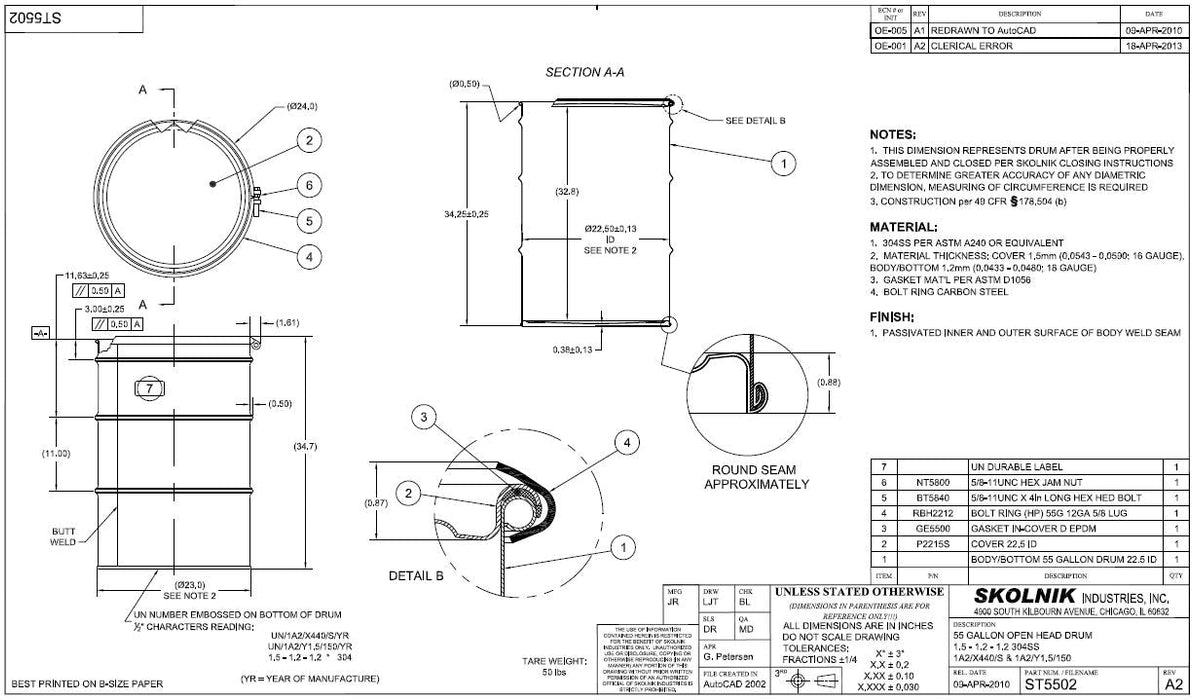

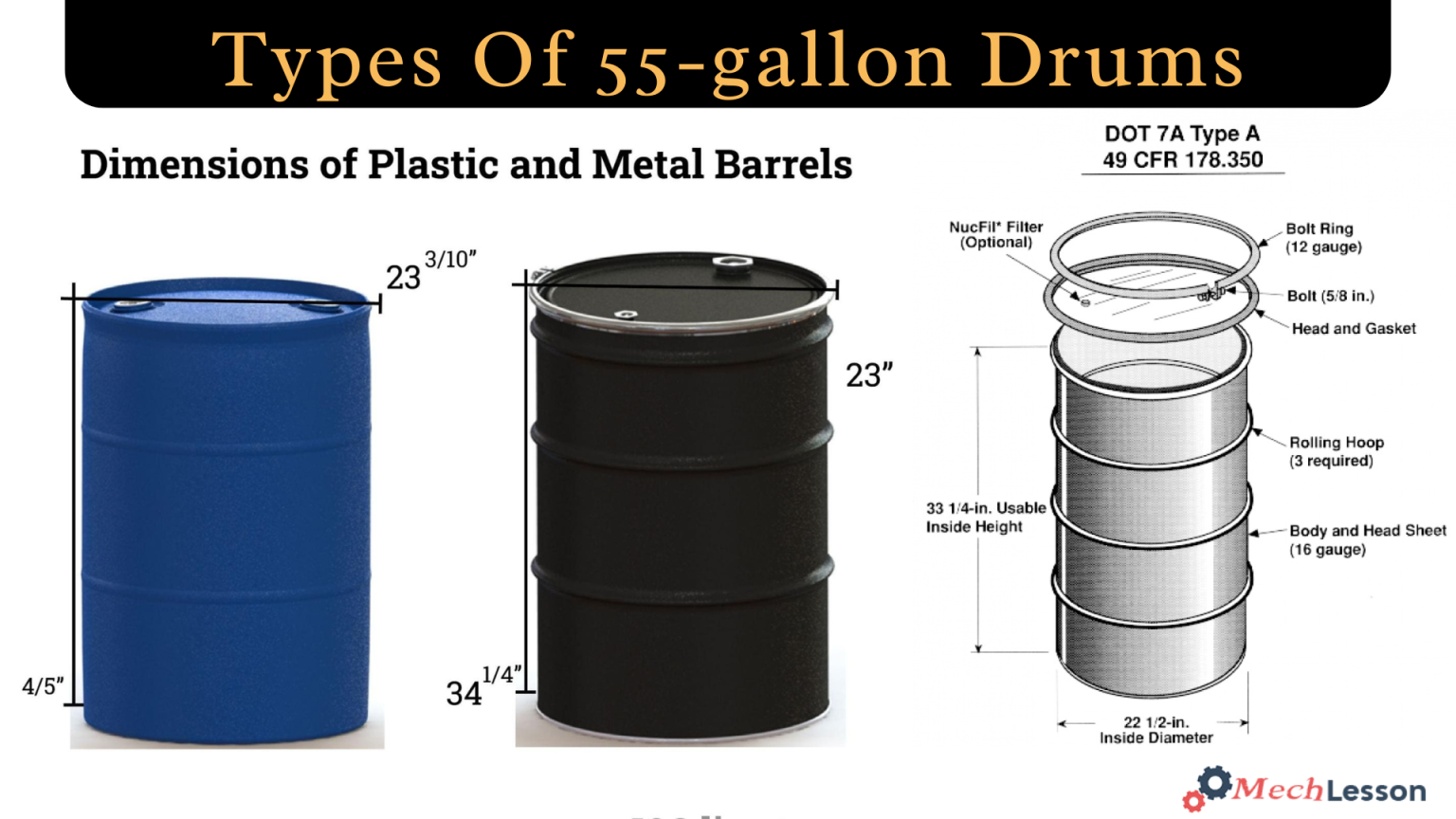

What Forming Techniques Are Used in Drum Manufacturing?

Forming is where the material is shaped into its final cylindrical form. In the case of steel drums, the cut sheets are rolled into cylinders and welded along the seam to create a sturdy structure. The bottom and top parts are then mechanically seamed to the body, enhancing the drum’s vertical crush strength. For plastic drums, the blow-molding technique is employed, where the melted plastic is expanded into a mold using compressed air, resulting in a seamless drum.

How Is Assembly Conducted in Drum Production?

The assembly stage involves adding features that enhance the drum’s functionality. For open-head drums, removable lids are secured with locking rings, while tight-head drums utilize threaded closures for filling and emptying. Additionally, any necessary internal linings, such as coatings for chemical resistance, are applied during this stage. Fiber drums are assembled by layering kraft paper and securing them with adhesives or mechanical fasteners.

What Finishing Touches Are Applied to 55 Gallon Drums?

The finishing stage includes painting, decorating, and adding any branding required by customers. For steel drums, protective coatings are often applied to prevent corrosion, while plastic drums may be molded in specific colors for branding purposes. All drums are subjected to a thorough cleaning process to ensure they are free from contaminants before being shipped.

What Quality Assurance Measures Are Essential for 55 Gallon Drums?

Quality assurance (QA) is paramount in the production of 55-gallon drums, ensuring they comply with international safety and performance standards. Various quality control checkpoints are established throughout the manufacturing process.

Illustrative image related to 55 gallon drum dimensions cm

Which International Standards Govern Drum Quality Assurance?

International standards such as ISO 9001 are widely adopted in the manufacturing of 55-gallon drums. ISO 9001 outlines the requirements for a quality management system, ensuring consistency in product quality. Additionally, industry-specific standards like CE marking for European markets and API (American Petroleum Institute) standards for oil and gas applications provide further guidelines for safety and quality.

What Are the Key Quality Control Checkpoints in Drum Manufacturing?

Quality control checkpoints are integrated at various stages of production:

- Incoming Quality Control (IQC): This checkpoint verifies the quality of raw materials, ensuring they meet specified standards before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to identify any deviations from quality standards. This includes inspections of welding integrity, dimensional accuracy, and assembly quality.

- Final Quality Control (FQC): Once production is complete, drums undergo final inspections to ensure they meet all specifications. Common tests include hydrostatic testing for leaks, dimensional checks, and weight assessments.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers, especially those sourcing internationally, should take proactive steps to verify the quality control processes of their suppliers. Here are several strategies:

What Auditing Practices Should Buyers Employ?

Conducting audits of potential suppliers is essential. Buyers can request third-party audits or certifications that demonstrate compliance with international standards. These audits can provide insights into the supplier’s manufacturing practices and quality management systems.

Illustrative image related to 55 gallon drum dimensions cm

How Important Are Quality Control Reports?

Requesting detailed quality control reports from suppliers can provide transparency regarding their QA processes. These reports should outline test results, adherence to standards, and any corrective actions taken in response to quality issues.

What Role Does Third-Party Inspection Play in Ensuring Drum Quality?

Engaging third-party inspection services can further bolster confidence in the quality of 55-gallon drums. These inspectors can conduct independent assessments during various manufacturing stages, ensuring that products meet the specified standards before they are shipped.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality control:

Illustrative image related to 55 gallon drum dimensions cm

- Understanding Regional Regulations: Different regions may have varying regulatory requirements for drum manufacturing. Buyers should familiarize themselves with these regulations to ensure compliance.

- Language Barriers and Documentation: Language differences can pose challenges in understanding quality documentation. Buyers should ensure that all quality documents are available in a language they understand.

- Cultural Differences in Quality Expectations: Quality expectations can differ between cultures. B2B buyers should communicate clearly with suppliers about their quality standards and ensure mutual understanding.

Conclusion: Ensuring Quality in 55 Gallon Drum Sourcing

In summary, the manufacturing and quality assurance processes for 55-gallon drums are intricate and vital for ensuring safety and functionality. B2B buyers should prioritize understanding these processes, verifying supplier practices, and ensuring compliance with international standards. By doing so, they can make informed purchasing decisions that align with their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ’55 gallon drum dimensions cm’

This guide aims to equip international B2B buyers with a structured approach to procuring 55-gallon drums, specifically focusing on their dimensions in centimeters. Understanding the specifications of these drums is crucial for ensuring compatibility with your storage and transportation needs, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

Step 1: Determine Your Required Drum Type

Identifying the type of drum you need is the first step in the sourcing process. There are three primary materials: steel, plastic, and fiber, each with distinct properties and uses.

– Steel Drums: Ideal for hazardous materials due to their durability.

– Plastic Drums: Lightweight and resistant to chemicals, suitable for a variety of liquids.

– Fiber Drums: Best for dry goods and powders.

Step 2: Define Your Technical Specifications

Clearly outline the dimensions you need in centimeters, as well as any specific features such as tight-head or open-head designs.

– Height and Diameter: Standard steel drums typically have an approximate height of 84 cm and a diameter of 58 cm. Knowing these details ensures you select a drum that fits your operational requirements.

– Weight Capacity: Consider the weight of the contents, as a filled 55-gallon drum can weigh around 227 kg.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct thorough evaluations. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Certifications: Ensure the supplier has the necessary certifications, especially if you are dealing with hazardous materials.

– Reputation: Look for reviews or testimonials that can provide insight into their reliability and product quality.

Illustrative image related to 55 gallon drum dimensions cm

Step 4: Verify Compliance with International Standards

Check that the drums meet the necessary international safety and performance standards, particularly if you are shipping hazardous materials.

– UN Rating: Drums should have a UN rating indicating they are suitable for transporting dangerous goods. This is crucial for compliance with local regulations.

– Material Specifications: Confirm that the drum material aligns with your intended use, such as food-grade compliance for food products.

Step 5: Assess Pricing and Total Cost of Ownership

Gather quotes from multiple suppliers and consider not just the initial purchase price, but also the total cost of ownership.

– Shipping Costs: Factor in shipping, especially if sourcing from international suppliers.

– Lifecycle Costs: Consider durability and reuse potential; investing in high-quality drums can save costs in the long run.

Step 6: Plan for Logistics and Storage

Ensure that your logistics and storage capabilities can accommodate the drums you intend to purchase.

– Palletization: Understand how many drums fit on a standard pallet (typically four filled drums) and ensure your storage space can handle this configuration.

– Accessibility: Plan for easy access to drums for both receiving and dispatching, especially in high-turnover environments.

Step 7: Finalize the Purchase Agreement

Once you’ve selected a supplier, it’s time to negotiate and finalize the purchase agreement.

– Terms and Conditions: Clearly outline payment terms, delivery schedules, and return policies.

– After-Sales Support: Confirm what support is available post-purchase, including warranty and service options.

By following these steps, B2B buyers can ensure a well-informed procurement process for 55-gallon drums, tailored to meet their specific business needs.

Comprehensive Cost and Pricing Analysis for 55 gallon drum dimensions cm Sourcing

What Are the Key Cost Components in Sourcing 55 Gallon Drums?

When sourcing 55-gallon drums, understanding the breakdown of costs is crucial for effective budgeting and procurement. The primary cost components include:

-

Materials: The type of drum—steel, plastic, or fiber—significantly impacts material costs. Steel drums are generally more expensive due to raw material prices and durability, while plastic drums may offer a lower upfront cost but can vary based on UV resistance and compliance standards.

-

Labor: Labor costs encompass the manufacturing processes, including welding for steel drums or blow-molding for plastic. The complexity of the drum’s design and the level of automation in the manufacturing process will also affect labor expenses.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. A manufacturer’s location can influence overhead costs, particularly in regions with higher operational costs.

-

Tooling: Specific tooling is required for different drum types, particularly for custom designs. This upfront investment can be significant, especially for specialized or custom orders.

-

Quality Control (QC): Ensuring that drums meet safety and quality standards incurs additional costs. UN-rated drums, for instance, require rigorous testing and certification, impacting overall pricing.

-

Logistics: Transportation costs vary based on the supplier’s location, shipping method, and destination. International shipping can add layers of complexity and cost due to tariffs and customs fees.

-

Margin: Suppliers will add a profit margin to their costs, which can vary widely depending on market competition, demand, and the supplier’s positioning strategy.

How Do Price Influencers Impact 55 Gallon Drum Sourcing?

Several factors can influence the pricing of 55-gallon drums:

-

Volume/MOQ: Bulk purchasing typically leads to lower per-unit costs. Suppliers often have minimum order quantities (MOQ) that can affect pricing. Negotiating for larger orders can yield better discounts.

-

Specifications and Customization: Custom designs or specifications—like unique sizes or additional features—can increase costs. Understanding your requirements clearly can help in obtaining accurate quotes.

-

Materials: As mentioned, the choice of material significantly influences price. For instance, stainless steel drums, while more expensive, may offer long-term savings through durability and reusability.

-

Quality and Certifications: Drums that meet specific industry standards (e.g., UN-rated for hazardous materials) may come with a higher price tag but are crucial for compliance and safety.

-

Supplier Factors: The supplier’s reputation, reliability, and service levels can affect pricing. Established suppliers may charge a premium for quality assurance and service.

-

Incoterms: The agreed terms for shipping and delivery can impact costs. Options like FOB (Free on Board) or CIF (Cost, Insurance, Freight) can lead to different total landed costs.

What Are the Best Buyer Tips for Cost-Efficiency in 55 Gallon Drum Sourcing?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Always negotiate pricing and terms. Suppliers may have flexibility in pricing based on your relationship and order size.

-

Total Cost of Ownership (TCO): Consider the TCO, which includes purchase price, maintenance, and disposal costs. A cheaper drum might incur higher disposal costs if not recyclable.

-

Pricing Nuances: Be aware of regional pricing variations. For instance, European suppliers may have higher standards and costs due to stricter regulations, while suppliers in South America may offer competitive pricing but could lack certain certifications.

-

Shipping Considerations: Factor in shipping costs and times. Sometimes, a slightly higher price from a local supplier can save significantly on logistics.

-

Supplier Diversification: Don’t rely on a single supplier. Exploring multiple vendors can provide better pricing options and reduce risk.

Conclusion

In summary, understanding the cost structure and pricing dynamics of 55-gallon drums is vital for international B2B buyers. By analyzing cost components, recognizing price influencers, and employing strategic purchasing tips, businesses can optimize their sourcing processes, ensuring both cost-effectiveness and compliance with industry standards. As always, indicative prices should be validated with suppliers to ensure accuracy and alignment with current market conditions.

Alternatives Analysis: Comparing 55 gallon drum dimensions cm With Other Solutions

Exploring Alternative Solutions to 55 Gallon Drums

In the realm of bulk storage and transportation, 55-gallon drums (approximately 208 liters) are a longstanding favorite due to their versatility and ease of handling. However, there are alternative solutions that may better suit specific needs or applications, especially for international B2B buyers. This section explores two viable alternatives: Intermediate Bulk Containers (IBCs) and Bulk Bags, comparing their dimensions, performance, and practicality against standard 55-gallon drums.

| Comparison Aspect | 55 Gallon Drum Dimensions Cm | Intermediate Bulk Container (IBC) | Bulk Bag (FIBC) |

|---|---|---|---|

| Performance | Standard height: 85.1 cm, diameter: 58.4 cm | Capacity: 1000 liters, dimensions vary (typically 120 cm x 100 cm x 116 cm) | Capacity: Up to 2000 kg, dimensions vary widely (typically 90 cm x 90 cm x 110 cm) |

| Cost | Moderate ($50 – $150) | Higher ($200 – $500) | Lower ($50 – $150) |

| Ease of Implementation | Easily moved by hand or pallet jack | Requires forklift for movement | Manual handling or forklift needed |

| Maintenance | Reusable, but must be cleaned for different uses | Durable, requires less frequent cleaning | Often single-use; can be recycled |

| Best Use Case | Liquids and solids; versatile storage | Ideal for bulk liquids and chemicals | Best for dry bulk materials like grains or powders |

What are the Advantages and Disadvantages of Intermediate Bulk Containers (IBCs)?

Intermediate Bulk Containers (IBCs) are large containers that can hold up to 1000 liters (approximately 264 gallons). They are particularly useful for transporting and storing bulk liquids and chemicals. The advantages of IBCs include a larger capacity, which reduces the number of containers needed for shipping, and their stackability, making them space-efficient. However, IBCs are typically more expensive than 55-gallon drums and require a forklift for handling, which may not be practical for all operations, particularly in regions with limited access to such equipment.

How do Bulk Bags Compare to 55 Gallon Drums?

Bulk Bags, or Flexible Intermediate Bulk Containers (FIBCs), are designed for storing dry bulk materials, with capacities ranging from 500 kg to 2000 kg. They are lightweight and often more cost-effective than both 55-gallon drums and IBCs. Bulk bags can be easily transported and stored, as they take up less space when empty. However, they are not suitable for liquids and require careful handling to prevent spillage or contamination. Additionally, while some bulk bags can be reused, many are single-use, which may contribute to waste concerns in sustainability-focused operations.

Making the Right Choice for Your Business Needs

When choosing between 55-gallon drums, IBCs, and bulk bags, B2B buyers should consider their specific storage and transportation requirements. For businesses dealing primarily with liquids, the versatility of 55-gallon drums may be advantageous. Conversely, if bulk quantities are needed and handling equipment is available, IBCs offer a more efficient solution. Bulk bags are ideal for companies focused on dry goods, providing a cost-effective and space-saving option. Ultimately, the right choice will depend on the type of material being stored, handling logistics, and budget constraints. Careful consideration of these factors will lead to more efficient operations and optimized supply chain management.

Essential Technical Properties and Trade Terminology for 55 gallon drum dimensions cm

What Are the Key Technical Properties of 55 Gallon Drums in Centimeters?

When sourcing 55-gallon drums, understanding their technical properties is essential for making informed purchasing decisions. Below are critical specifications that impact usability, safety, and compliance in various industries.

-

Material Grade

– Definition: Refers to the type of material used in manufacturing the drum, such as steel, stainless steel, plastic (HDPE), or fiber.

– Importance: The material grade affects the drum’s durability, resistance to chemicals, and suitability for specific applications. For instance, stainless steel drums are ideal for high-purity products, while HDPE is preferred for corrosive substances. -

Capacity and Dimensions

– Definition: The nominal volume of the drum (55 gallons or 208 liters) and its physical dimensions, typically around 85.1 cm in height and 58.4 cm in diameter for steel drums.

– Importance: Accurate dimensions ensure compatibility with storage and transportation methods. Understanding these metrics helps optimize space in warehouses and shipping containers, allowing for efficient logistics. -

Weight Specifications

– Definition: The net weight of the empty drum, which varies by material; for example, a steel drum may weigh around 22 kg, while a plastic one can weigh approximately 10.7 kg.

– Importance: Knowing the weight is crucial for planning transportation and handling. Heavier drums may require additional equipment for safe movement, impacting logistics costs. -

Closure Type

– Definition: Refers to how the drum is sealed, such as tight-head (permanently attached top) or open-head (removable lid).

– Importance: The closure type affects the ease of filling and dispensing contents. Tight-head drums are generally more secure for hazardous liquids, while open-head drums offer easier access for bulk solids or viscous materials. -

UN Rating

– Definition: A designation indicating that the drum meets international safety standards for the transport of hazardous materials.

– Importance: Compliance with UN standards is crucial for legal shipping and storage of dangerous goods. B2B buyers must ensure their chosen drums have the appropriate ratings to avoid regulatory issues.

What Are Common Trade Terms Related to 55 Gallon Drums?

Familiarity with industry jargon is vital for effective communication with suppliers and partners. Here are several key terms related to 55-gallon drums.

-

OEM (Original Equipment Manufacturer)

– Definition: A company that manufactures products or components that are sold under another company’s brand name.

– Relevance: When sourcing drums, knowing if a supplier is an OEM can provide insights into product quality and reliability. -

MOQ (Minimum Order Quantity)

– Definition: The smallest order size that a supplier will accept.

– Relevance: Understanding MOQ is essential for budgeting and inventory management, especially for businesses with varying storage capacities. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price quotes from suppliers.

– Relevance: Submitting an RFQ can help buyers obtain competitive pricing and understand the market rate for specific drum types. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions.

– Relevance: Knowing relevant Incoterms (e.g., FOB, CIF) helps in understanding shipping responsibilities, costs, and risks associated with transporting 55-gallon drums. -

Pallet Quantity

– Definition: The number of drums that can be safely stacked on a standard shipping pallet.

– Relevance: This specification impacts shipping costs and efficiency. For example, four drums typically fit on a 48” x 48” pallet, which is vital for logistics planning.

By comprehensively understanding these properties and terms, B2B buyers can make more informed decisions when sourcing 55-gallon drums, ensuring they meet their operational needs while remaining compliant with industry regulations.

Navigating Market Dynamics and Sourcing Trends in the 55 gallon drum dimensions cm Sector

What Are the Current Market Dynamics and Key Trends in the 55 Gallon Drum Sector?

The global market for 55-gallon drums, or 208-liter drums, is witnessing significant growth driven by increasing demand for bulk packaging solutions across various industries, including chemicals, pharmaceuticals, food and beverage, and waste management. The versatility of these drums, which can accommodate diverse materials such as liquids, solids, and powders, positions them as an essential component in logistics and supply chain management. Furthermore, the ease of handling—where one person can manage a full drum—adds to their popularity among international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

Emerging trends in sourcing technology include the adoption of digital platforms for procurement and inventory management. B2B buyers are increasingly leveraging e-commerce solutions to streamline their purchasing processes, ensuring real-time visibility of inventory levels and pricing. Additionally, the rise of automation in manufacturing processes for drums is enhancing production efficiency and reducing lead times, making it easier for suppliers to meet the fluctuating demands of international clients. This dynamic marketplace also sees a growing focus on customization, where manufacturers offer tailored solutions to meet specific industry requirements, such as UN-rated drums for hazardous materials.

How Is Sustainability Influencing the Sourcing of 55 Gallon Drums?

Sustainability has become a pivotal factor in the sourcing of 55-gallon drums, influencing the purchasing decisions of B2B buyers globally. The environmental impact of packaging materials is under scrutiny, and companies are increasingly prioritizing ethical sourcing practices. This shift is leading to an emphasis on reusable and recyclable materials, particularly in regions where regulatory frameworks are stringent regarding waste management.

Buyers are also looking for suppliers that offer ‘green’ certifications, such as ISO 14001, which denotes a commitment to environmental management. The use of high-density polyethylene (HDPE) for plastic drums, for instance, is favored for its recyclability and lower environmental footprint compared to other materials. Moreover, the market is seeing innovations in the production of drums that utilize recycled content, which not only reduces waste but also appeals to eco-conscious buyers. Emphasizing sustainability in sourcing not only aligns with corporate social responsibility goals but also enhances brand reputation in a competitive global market.

What Is the Historical Context of 55 Gallon Drums and Their Evolution?

The 55-gallon drum has a rich history that dates back to the early 1900s when it was first used for transporting oil and other liquids. Originally made from wood, the design evolved to incorporate steel and, later, plastic materials, which offered increased durability and versatility. The standard dimensions of the 55-gallon drum emerged due to its optimal capacity for handling bulk materials while still being manageable by an individual.

Over the decades, the drum has adapted to meet the changing needs of various industries. Today, manufacturers produce drums in multiple configurations—tight-head, open-head, and in various materials—to accommodate a wide array of products, from hazardous chemicals to food-grade materials. This evolution reflects the drum’s critical role in modern logistics and supply chains, solidifying its status as a staple in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of 55 gallon drum dimensions cm

-

What are the standard dimensions of a 55-gallon drum in centimeters?

The standard dimensions for a 55-gallon drum vary based on the type of material. For steel drums, the typical dimensions are approximately 85 cm in height and 58.4 cm in diameter. Plastic drums often have similar height but may have a diameter of around 57.4 cm. Fiber drums may vary more significantly, and customization options are often available depending on the supplier. It’s essential to confirm the exact dimensions with your supplier as they may vary slightly from manufacturer to manufacturer. -

How much does a filled 55-gallon drum weigh?

A filled 55-gallon drum can weigh significantly depending on the contents. For example, a drum filled with water weighs approximately 208.6 kg (459 lbs). However, the total weight will vary based on the density of the liquid or material inside. When sourcing drums, consider the overall weight for logistics, including handling and transportation, to ensure compliance with local regulations and shipping standards. -

What types of materials are available for 55-gallon drums?

55-gallon drums are commonly made from three materials: steel, plastic (polyethylene), and fiber. Steel drums are durable and suitable for hazardous materials, while plastic drums are lighter, chemical-resistant, and often used for liquids. Fiber drums are ideal for powders and semi-solids. Understanding the material types can help buyers select the right drum based on their specific application needs and regulatory requirements. -

What is the minimum order quantity (MOQ) for 55-gallon drums?

The MOQ for 55-gallon drums can vary significantly depending on the supplier and the type of drum. Generally, suppliers may require a minimum order of 50 to 100 units for standard sizes. However, for customized or specialized drums, the MOQ might be higher. It is advisable to discuss your needs with potential suppliers to negotiate terms that suit your business requirements, especially for international orders. -

How do I verify the quality of 55-gallon drums from suppliers?

To ensure the quality of 55-gallon drums, request product certifications and compliance documents from suppliers. Look for UN ratings if the drums will be used for hazardous materials, as this indicates adherence to international safety standards. Additionally, consider requesting samples for inspection and testing. Engaging in third-party audits can also provide assurance regarding the supplier’s manufacturing processes and product quality. -

What are the payment terms typically offered by suppliers for international orders?

Payment terms for international orders can vary widely among suppliers. Common terms include advance payment, letter of credit, or net 30/60 days after delivery. It’s crucial to discuss and agree upon payment terms before finalizing the order to avoid any misunderstandings. Additionally, consider the implications of currency exchange rates and potential transaction fees when dealing with international suppliers. -

How can I ensure safe shipping and handling of 55-gallon drums?

To ensure safe shipping and handling, choose suppliers who comply with international shipping regulations. Packaging should be robust, and drums should be secured on pallets to prevent movement during transport. It’s also advisable to use stretch wrap or straps for added stability. Finally, ensure that all handling personnel are trained in the proper techniques for lifting and moving heavy drums to minimize accidents and damage. -

Can I customize the dimensions or features of 55-gallon drums?

Many suppliers offer customization options for 55-gallon drums, including dimensions, colors, and closure types. Customization can be particularly useful for specific applications or branding purposes. When considering customization, discuss your requirements with suppliers early in the procurement process to ensure they can meet your specifications and to understand any potential impact on pricing and lead times.

Top 2 55 Gallon Drum Dimensions Cm Manufacturers & Suppliers List

1. Eagle – 1656B Blue High-Density Polyethylene Container

Domain: eagle.justrite.com

Registered: 1997 (28 years)

Introduction: {“Model No”:”1656B”,”Color”:”Blue”,”Brand”:”Eagle”,”Material”:”High-Density Polyethylene (HDPE)”,”Net Weight (lbs)”:”23.5″,”Net Weight (kgs)”:”10.66″,”UN/DOT Rating”:”1H2/X100/S, 1H2/Y100/S”,”Exterior Dimensions (inches)”:”21D x 36.375H”,”Interior Dimensions (Top)”:”20.06″ (31cm)”,”Interior Dimensions (Bottom)”:”22.13″ (56.2cm)”,”Interior Dimensions (Height)”:”35.8″ (91cm)”,”Gallon Capacity”:”55″,…

2. Big Dipper – 55-Gallon Drum with Lid

Strategic Sourcing Conclusion and Outlook for 55 gallon drum dimensions cm

In conclusion, understanding the dimensions and specifications of 55-gallon drums is crucial for international B2B buyers aiming to optimize their supply chain operations. These drums, available in various materials such as steel, plastic, and fiber, offer flexibility in storage and transport across diverse industries. The standard dimensions typically provide a balance of capacity and ease of handling, making them an ideal choice for transporting liquids, solids, and hazardous materials.

Illustrative image related to 55 gallon drum dimensions cm

Strategic sourcing of these drums can lead to significant cost savings and improved efficiency. By aligning with reliable suppliers, businesses can ensure product compatibility, compliance with safety standards, and sustainability practices. As markets evolve, the demand for high-quality, durable packaging solutions will continue to rise, particularly in regions like Africa, South America, the Middle East, and Europe.

As you consider your sourcing options, prioritize suppliers who demonstrate a commitment to quality and customer service. Embrace the future of packaging by leveraging innovative solutions that enhance your operational capabilities. Connect with trusted manufacturers to secure your supply of 55-gallon drums and stay ahead in a competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to 55 gallon drum dimensions cm

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.