The Definitive Guide to Exhaust Header Gasket Material: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for exhaust header gasket material

In the fast-paced world of automotive manufacturing and repair, sourcing high-quality exhaust header gasket materials is a critical challenge for international B2B buyers. The integrity of exhaust systems is paramount; any leaks can compromise performance, increase emissions, and lead to costly repairs. This comprehensive guide delves into the diverse range of exhaust header gasket materials available, including their types, applications, and the specific characteristics that define their performance.

By exploring the nuances of materials such as composite graphite, multi-layer steel, and flexible graphite, this guide equips buyers with the knowledge necessary to make informed purchasing decisions. Additionally, it addresses key considerations such as supplier vetting processes, cost analysis, and the importance of aligning gasket selection with regional manufacturing standards and environmental regulations.

Designed specifically for B2B buyers from regions including Africa, South America, the Middle East, and Europe—such as Brazil and Vietnam—this guide empowers stakeholders to navigate the complexities of the global market effectively. With a focus on actionable insights and strategic sourcing, it aims to enhance operational efficiency, minimize downtime, and foster long-term supplier relationships. Embrace the opportunity to optimize your exhaust system solutions and stay ahead in the competitive automotive landscape.

Understanding exhaust header gasket material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Composite Graphite | Lightweight, heat-resistant, and flexible | Automotive, marine, and industrial applications | Pros: Excellent sealing properties; withstands high temps. Cons: May not be reusable. |

| Multi-Layer Steel (MLS) | Comprises multiple sheets with sealing material | Heavy-duty engines, commercial vehicles | Pros: High durability and heat tolerance; reusable. Cons: Higher cost; installation complexity. |

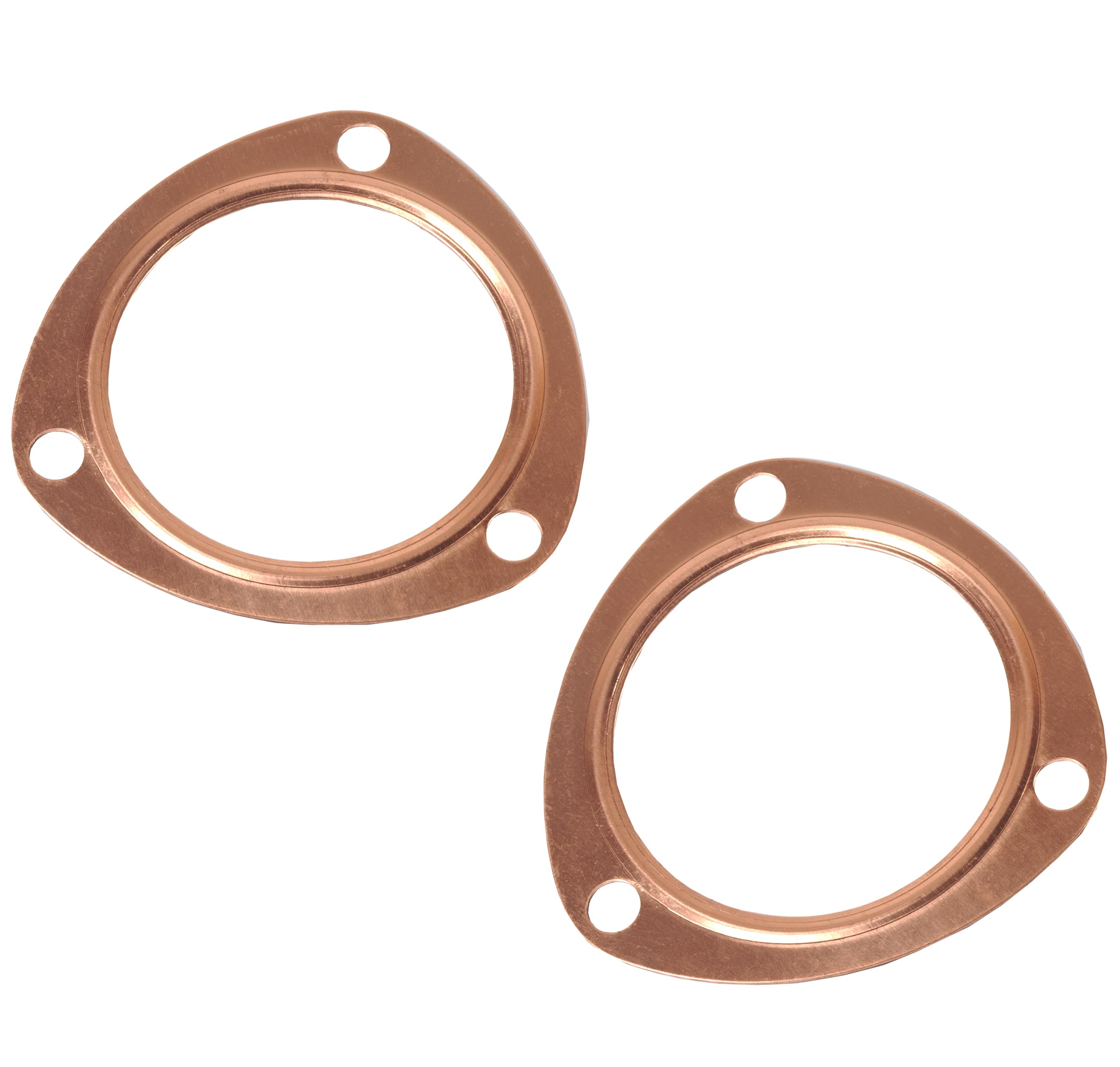

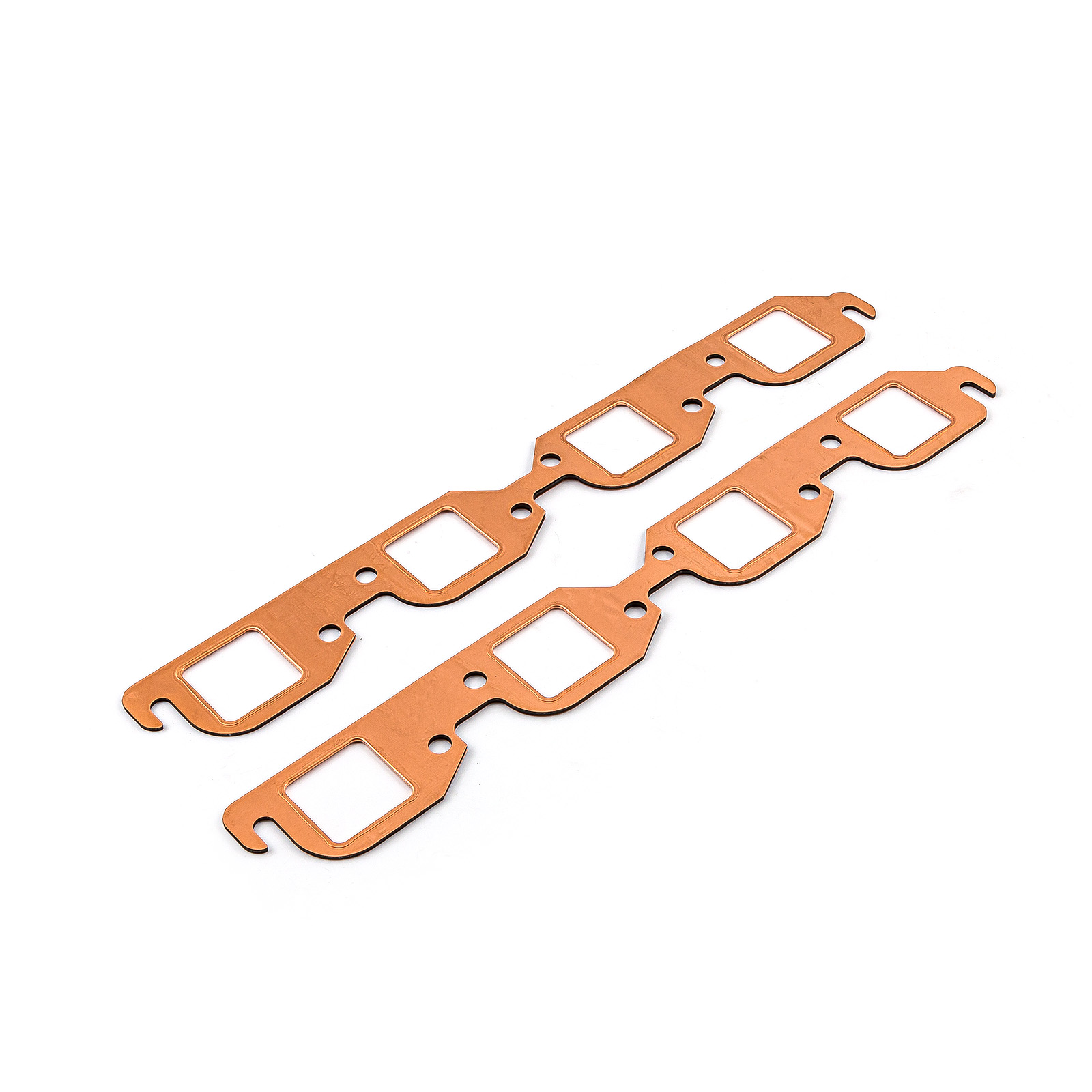

| Embossed Copper | High thermal conductivity and excellent sealing | Racing applications, high-performance engines | Pros: Reusable; great for high heat. Cons: Susceptible to corrosion; requires precise fit. |

| Carbon Composite | Combines carbon fibers with a resin matrix | Aerospace, automotive, and performance sectors | Pros: Lightweight; good thermal stability. Cons: Limited temperature range; can be expensive. |

| Flexible Graphite | 100% graphite construction, highly compressible | Custom headers, industrial applications | Pros: No re-torquing needed; withstands extreme heat. Cons: Limited to specific applications; can be costly. |

What Are the Characteristics of Composite Graphite Gaskets?

Composite graphite gaskets are highly regarded for their lightweight nature and exceptional heat resistance. They are particularly suitable for automotive and marine applications where performance and durability are critical. When considering B2B purchases, buyers should evaluate the specific temperature requirements of their application, as composite graphite gaskets are designed to withstand high temperatures without compromising integrity. However, they are typically not reusable, which could affect long-term cost efficiency.

How Does Multi-Layer Steel (MLS) Compare to Other Gasket Materials?

Multi-layer steel (MLS) gaskets are constructed from several layers of steel, providing superior durability and heat resistance. This makes them ideal for heavy-duty engines and commercial vehicles that experience extreme conditions. B2B buyers should assess the complexity of installation and the initial investment, as MLS gaskets tend to be pricier than other options. However, their reusability and longevity can justify the expense over time, particularly in high-use environments.

Why Choose Embossed Copper Gaskets for High-Performance Engines?

Embossed copper gaskets are favored in racing and high-performance applications due to their excellent thermal conductivity and sealing capabilities. They can withstand high temperatures and are reusable, which is a significant advantage for performance enthusiasts. However, B2B buyers must be cautious about the potential for corrosion and the need for precise fitting, as any misalignment can lead to performance issues.

What Are the Benefits and Drawbacks of Carbon Composite Gaskets?

Carbon composite gaskets blend carbon fibers with a resin matrix, offering a lightweight option with good thermal stability. These gaskets are suitable for aerospace and automotive applications where weight reduction is crucial. However, the limited temperature range and higher cost can be drawbacks for some buyers. When purchasing, it’s essential to consider the specific performance requirements and budget constraints.

Why Consider Flexible Graphite Gaskets for Custom Applications?

Flexible graphite gaskets, made entirely from graphite, are known for their ability to compress and conform to uneven surfaces, making them ideal for custom headers and industrial applications. They require no re-torquing, which simplifies maintenance and enhances reliability. However, B2B buyers should note that these gaskets are generally more specialized and can come with a higher price tag, making them best suited for specific high-performance scenarios.

Illustrative image related to exhaust header gasket material

Key Industrial Applications of exhaust header gasket material

| Industry/Sector | Specific Application of Exhaust Header Gasket Material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Sealing exhaust systems in passenger and commercial vehicles | Enhanced performance and reduced emissions | Compatibility with vehicle specifications and temperature tolerance |

| Heavy Equipment | Gaskets for diesel engines in construction machinery | Improved durability and reduced maintenance costs | Resistance to extreme heat and mechanical stress |

| Marine Engineering | Exhaust systems in ships and boats | Reliability in harsh marine environments | Corrosion resistance and compliance with maritime regulations |

| Power Generation | Gaskets for gas and diesel power generators | Increased efficiency and lower operational costs | High-temperature performance and longevity |

| Aerospace | Sealing exhaust systems in aircraft | Weight reduction and enhanced safety | Lightweight materials and compliance with aviation standards |

How is Exhaust Header Gasket Material Used in Automotive Manufacturing?

In the automotive manufacturing sector, exhaust header gasket material is crucial for sealing exhaust systems in both passenger and commercial vehicles. These gaskets prevent exhaust leaks, which can lead to performance issues and increased emissions. The material must withstand high temperatures and thermal cycling, making heat resistance a key consideration for buyers. For international buyers, particularly from regions like Africa and South America, sourcing gaskets that meet local vehicle specifications and environmental regulations is essential for compliance and performance.

What Role Does Exhaust Header Gasket Material Play in Heavy Equipment?

In heavy equipment, such as construction machinery, exhaust header gaskets are vital for ensuring the integrity of diesel engine exhaust systems. Given the extreme operating conditions, these gaskets must be durable and capable of withstanding significant mechanical stress and high temperatures. This application reduces maintenance costs and downtime for businesses, which is particularly important in fast-paced industries. Buyers from the Middle East and Europe should focus on sourcing materials that offer high-temperature performance and durability to meet the demands of heavy-duty operations.

How is Exhaust Header Gasket Material Utilized in Marine Engineering?

Marine engineering applications often require exhaust header gaskets for sealing exhaust systems in ships and boats. The harsh marine environment demands gaskets that are not only heat-resistant but also corrosion-resistant to withstand saltwater exposure. Reliable sealing is crucial to prevent exhaust leaks, which can affect engine performance and safety. Buyers in the maritime industry, especially in regions like Africa and South America, must prioritize sourcing materials that comply with maritime regulations and provide long-lasting performance under challenging conditions.

What is the Importance of Exhaust Header Gasket Material in Power Generation?

In the power generation sector, exhaust header gaskets are essential for sealing exhaust systems in gas and diesel power generators. The right gasket material can significantly enhance engine efficiency and reduce operational costs by preventing leaks that could lead to energy loss. For B2B buyers in Europe and the Middle East, it is crucial to consider the high-temperature performance and longevity of the gasket materials to ensure consistent operation in power generation facilities.

Illustrative image related to exhaust header gasket material

How is Exhaust Header Gasket Material Applied in Aerospace?

In the aerospace industry, exhaust header gaskets are used to seal exhaust systems in aircraft. These gaskets must be lightweight yet durable, as any additional weight can impact fuel efficiency and safety. Compliance with stringent aviation standards is critical, making the selection of the right gasket material vital for manufacturers. Buyers from international markets, including Brazil and Vietnam, should focus on sourcing gaskets that meet these regulations while providing the necessary performance characteristics for high-altitude operations.

3 Common User Pain Points for ‘exhaust header gasket material’ & Their Solutions

Scenario 1: The Challenge of Exhaust Leaks in High-Performance Applications

The Problem: B2B buyers, particularly those in sectors such as motorsports or heavy machinery, often face the critical issue of exhaust leaks caused by inadequate sealing of exhaust header gaskets. These leaks can severely compromise performance, leading to decreased efficiency and potential engine damage. In environments where performance is paramount, such as racing or industrial applications, even a minor leak can disrupt the entire operation, resulting in costly downtime and repairs.

The Solution: To mitigate this issue, buyers should consider sourcing high-quality gaskets specifically designed for high-temperature and high-pressure environments. Gaskets made from flexible graphite materials, like those offered by Remflex, can withstand extreme temperatures up to 3,000°F without degradation. When selecting a gasket, it is crucial to ensure that it features a built-in crush capability, allowing it to fill gaps and seal warped flanges effectively. Implementing a rigorous quality check during the procurement process can help ensure that the gaskets meet the specifications required for high-performance applications. Additionally, buyers should maintain a regular inspection schedule to identify any early signs of wear or leaks, thereby preventing more significant issues down the line.

Scenario 2: The Difficulty of Material Compatibility

The Problem: Many international buyers encounter challenges related to material compatibility when selecting exhaust header gaskets for their specific engine types. Different engines may have varying requirements for gasket materials, and a mismatch can lead to premature gasket failure, exhaust leaks, and costly repairs. This issue is often compounded by the lack of clear, standardized information across manufacturers, making it difficult for buyers to make informed decisions.

The Solution: To effectively address this challenge, buyers should invest time in understanding the specifications of their engine models and the corresponding gasket requirements. Utilizing resources such as manufacturer guidelines, technical datasheets, and expert consultations can provide valuable insights into the right gasket material for their specific applications. Multi-layer steel (MLS) gaskets, for instance, are known for their durability and ability to maintain a seal under varying thermal conditions, making them a reliable choice for many engine types. Additionally, engaging with suppliers who offer a diverse range of gasket materials and who can provide tailored recommendations based on specific engine requirements can streamline the selection process. Buyers should also consider investing in training for their procurement teams to enhance their understanding of material properties and compatibility.

Scenario 3: The Cost of Frequent Gasket Failures

The Problem: Frequent gasket failures not only lead to operational inefficiencies but also result in significant financial losses for businesses. Buyers often find themselves in a cycle of replacing gaskets due to subpar material choices or improper installation, which can escalate costs associated with labor and replacement parts. This issue is particularly pronounced in industries such as automotive and construction, where reliability and cost-effectiveness are critical.

The Solution: To break this cycle, it is essential for buyers to focus on sourcing high-quality, durable gasket materials that can withstand the harsh conditions of exhaust systems. Investing in gaskets made from advanced materials, such as graphite or multi-layer steel, can significantly reduce the frequency of failures. Moreover, buyers should ensure that their installation processes follow best practices, including proper torque specifications and surface preparation to avoid common pitfalls that lead to gasket failure. Implementing a comprehensive training program for maintenance teams on the correct installation and maintenance of exhaust gaskets can enhance their longevity. Additionally, establishing relationships with reputable suppliers who provide warranties and guarantees on their products can offer peace of mind and protect against unexpected costs related to gasket failures.

Strategic Material Selection Guide for exhaust header gasket material

What Are the Key Properties of Common Exhaust Header Gasket Materials?

When selecting exhaust header gasket materials, it is essential to consider their key properties, which directly influence performance in demanding environments. The most common materials include composite graphite, multi-layer steel (MLS), embossed copper, and carbon composite. Each material has unique attributes that cater to specific applications and operational conditions.

How Does Composite Graphite Perform in Exhaust Header Applications?

Composite graphite gaskets are renowned for their excellent heat tolerance, capable of withstanding temperatures up to 3,000°F. This high thermal resistance helps prevent premature wear and failure, making them suitable for high-performance applications. Additionally, their flexibility allows them to conform to surface imperfections, ensuring a tight seal.

Pros: Composite graphite gaskets are durable and do not require re-torquing, which simplifies maintenance. They are also lightweight and can handle significant thermal cycling without losing their sealing properties.

Cons: The primary limitation is their cost, which can be higher than traditional materials. Additionally, they may not be suitable for all exhaust environments, particularly those with extreme mechanical stress.

What Advantages Do Multi-Layer Steel (MLS) Gaskets Offer?

Multi-layer steel gaskets consist of several layers of steel with a sealing material in between, providing exceptional durability and strength. They can handle high pressure and temperature variations, making them ideal for heavy-duty applications.

Pros: MLS gaskets maintain their integrity under extreme conditions, reducing the risk of leaks. They also offer excellent mechanical stability and can be reused, which is a significant advantage for maintenance.

Cons: The complexity of manufacturing MLS gaskets can lead to higher costs. Additionally, they require precise installation to ensure proper sealing, which may necessitate skilled labor.

Why Choose Embossed Copper Gaskets for High-Performance Engines?

Embossed copper gaskets are known for their excellent thermal conductivity and ability to withstand high temperatures. They are often used in racing and high-performance applications where reliability is critical.

Pros: The primary advantage of copper gaskets is their ability to create a strong, reliable seal that can withstand extreme conditions. They are also reusable, which can reduce costs over time.

Illustrative image related to exhaust header gasket material

Cons: However, copper gaskets can be prone to corrosion if not properly maintained, and they may require additional sealing materials to enhance their performance. Their cost can also be relatively high compared to other materials.

How Do Carbon Composite Gaskets Compare in Terms of Performance?

Carbon composite gaskets are designed to withstand high temperatures and pressures, making them a versatile option for various applications. They often incorporate a blend of carbon fibers and other materials to enhance durability.

Pros: These gaskets are lightweight and resistant to thermal expansion, which helps maintain a consistent seal. They are also less prone to burnout compared to traditional materials.

Cons: The main drawback is that carbon composite gaskets may not be as effective in extreme thermal cycling environments as graphite or MLS options. Additionally, they can be more expensive than conventional gaskets.

Summary Table of Exhaust Header Gasket Materials

| Material | Typical Use Case for exhaust header gasket material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Composite Graphite | High-performance automotive applications | Excellent heat tolerance and flexibility | Higher cost than traditional materials | High |

| Multi-Layer Steel (MLS) | Heavy-duty industrial and automotive applications | Exceptional durability and reusability | Higher manufacturing complexity | High |

| Embossed Copper | Racing and high-performance engines | Strong, reliable seal and reusability | Prone to corrosion without maintenance | High |

| Carbon Composite | Versatile applications in various exhaust systems | Lightweight and resistant to thermal expansion | Less effective in extreme thermal cycling | Medium |

This strategic material selection guide provides insights into the properties, advantages, and limitations of various exhaust header gasket materials. By understanding these factors, international B2B buyers can make informed decisions that align with their specific application requirements and operational conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for exhaust header gasket material

What Are the Main Stages of Manufacturing Exhaust Header Gasket Material?

The manufacturing of exhaust header gasket material is a multi-step process that combines various techniques to produce gaskets capable of withstanding high temperatures and pressures. The main stages of manufacturing include material preparation, forming, assembly, and finishing.

Illustrative image related to exhaust header gasket material

How Is Material Prepared for Exhaust Gasket Production?

The first stage involves selecting the appropriate materials, which typically include composites, graphite, metal reinforcements, and specialty fillers. Quality assurance begins at this stage, as materials must meet specific performance criteria, such as heat tolerance and durability. Suppliers often conduct incoming quality control (IQC) checks to ensure that materials conform to specifications. This may involve visual inspections, physical property tests, and chemical composition analyses.

What Techniques Are Used in Forming Exhaust Gaskets?

Once the materials are prepared, the forming stage begins. This process involves cutting, stamping, or molding the material into the desired shapes. Advanced techniques such as laser cutting or water jet cutting are often employed to achieve precise dimensions. For composite gaskets, layers may be bonded together using heat and pressure techniques, which enhance their structural integrity.

During this phase, manufacturers should maintain strict adherence to international standards, such as ISO 9001, which outlines criteria for a quality management system. This ensures that the forming processes are consistent and capable of delivering high-quality products.

How Are Exhaust Gaskets Assembled and Finished?

The assembly stage involves joining different components of the gasket, such as metal reinforcements or additional sealing layers. This may require adhesives or mechanical fasteners, depending on the design. Once assembled, gaskets undergo finishing processes, including surface treatments and coatings, to enhance their resistance to wear and chemical exposure.

Quality checkpoints during assembly and finishing, known as in-process quality control (IPQC), are critical. These checks may include dimensional inspections, surface roughness measurements, and adhesion tests to verify that the gaskets meet required specifications before they are packaged for shipping.

What Quality Assurance Practices Are Essential for Exhaust Header Gasket Manufacturers?

Quality assurance (QA) is a crucial component of the manufacturing process for exhaust header gaskets. Manufacturers often implement a series of quality control checkpoints to ensure that the final products meet both international and industry-specific standards.

Which International Standards Should Buyers Be Aware Of?

For B2B buyers, understanding relevant international standards is essential. ISO 9001 certification indicates that a manufacturer adheres to a quality management system that emphasizes continuous improvement and customer satisfaction. Additionally, certifications like CE mark for products sold in Europe and API standards for oil and gas applications can provide buyers with confidence in the manufacturer’s commitment to quality.

What Are the Key QC Checkpoints in Gasket Manufacturing?

Quality checkpoints include:

- Incoming Quality Control (IQC): Verification of raw materials upon arrival.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of finished gaskets for performance and reliability.

Common testing methods include pressure testing, thermal cycling tests, and dimensional checks to ensure that the gaskets can withstand operational conditions without failure.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to ensure the quality of exhaust header gaskets from their suppliers. Conducting audits is one of the most effective methods. An audit can provide insights into the manufacturer’s processes, adherence to quality standards, and overall operational efficiency.

What Should Buyers Look for During Supplier Audits?

During supplier audits, buyers should assess the following:

- Quality Management Systems: Review documentation related to ISO certifications and QA protocols.

- Testing Facilities: Inspect whether the manufacturer has in-house capabilities for testing materials and finished products.

- Traceability: Ensure that there is a system in place to trace materials back to their sources, which is critical for accountability.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection agencies can provide an unbiased assessment of a manufacturer’s quality practices. These agencies can conduct random sampling of products, perform independent testing, and provide detailed reports on compliance with specified standards.

What Quality Control Nuances Should International Buyers Consider?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, there are specific nuances to consider in quality control.

Illustrative image related to exhaust header gasket material

How Do Regulatory Requirements Vary by Region?

Different regions have varying regulatory requirements that manufacturers must meet. For example, products sold in Europe must comply with CE marking regulations, while those in the Middle East may require specific local certifications. Buyers should ensure that suppliers are aware of and compliant with these regional regulations.

Why Is Communication with Suppliers Important?

Effective communication is essential when dealing with international suppliers. Buyers should establish clear expectations regarding quality standards, delivery timelines, and material specifications upfront. Regular updates and open lines of communication can help mitigate misunderstandings and enhance the overall quality of the partnership.

Conclusion

In summary, understanding the manufacturing processes and quality assurance practices for exhaust header gasket materials is critical for B2B buyers looking to ensure product reliability and performance. By paying close attention to the stages of manufacturing, relevant quality standards, and effective verification methods, buyers can make informed decisions when selecting suppliers in the competitive international market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘exhaust header gasket material’

Introduction

When sourcing exhaust header gasket materials, it’s essential to follow a structured approach to ensure that you select high-quality products that meet your specific needs. This checklist provides actionable steps for B2B buyers, helping you navigate the complexities of material selection, supplier evaluation, and compliance with industry standards.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications of the exhaust header gaskets you need. This includes the size, shape, and material requirements. Understanding these parameters is crucial as they directly affect the gasket’s performance and durability in high-temperature environments.

- Consider bolt patterns: Ensure compatibility with your existing headers and cylinder heads.

- Identify required heat tolerance: Look for materials that can withstand extreme temperatures without degrading.

Step 2: Research Available Gasket Materials

Various gasket materials offer different benefits, so it’s essential to understand your options. Common materials include graphite, composite, and multi-layer steel gaskets, each with unique properties.

Illustrative image related to exhaust header gasket material

- Graphite: Known for high heat tolerance and flexibility.

- Multi-layer steel: Offers durability and is suitable for applications with varying thermal expansion.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request detailed company profiles, product samples, and case studies from buyers within your industry.

- Check references: Speak with other companies that have purchased similar products to gauge supplier reliability.

- Assess manufacturing capabilities: Ensure the supplier can produce gaskets that meet your specifications and volume requirements.

Step 4: Verify Compliance with Industry Standards

Ensure that the gasket materials you are considering comply with relevant industry standards and regulations. This is vital for maintaining quality and ensuring safety in applications.

- Request certifications: Look for ISO certifications or other industry-specific quality assurances.

- Review material safety data sheets (MSDS): These documents provide crucial information about the properties and handling of the materials.

Step 5: Consider Long-Term Performance

Select gaskets that offer longevity and reliability. Evaluate the expected lifespan and performance characteristics of the materials under real-world conditions.

- Assess resistance to thermal cycling: This is crucial as exhaust systems undergo constant temperature fluctuations.

- Review warranties: A strong warranty can be indicative of the manufacturer’s confidence in their product’s durability.

Step 6: Negotiate Terms and Conditions

Once you have identified potential suppliers, it’s time to negotiate terms. This includes price, delivery schedules, and payment terms.

- Discuss bulk purchasing discounts: Leverage your order size for better pricing.

- Clarify return policies: Ensure there are clear guidelines in place for defective products or unsatisfactory orders.

Step 7: Finalize the Purchase Order

After agreeing on terms, finalize your purchase order with the selected supplier. Include all specifications, quantities, and agreed-upon terms to avoid any misunderstandings.

- Double-check details: Ensure that all aspects of the order are clearly documented.

- Maintain communication: Keep the lines of communication open for updates on order status and delivery timelines.

By following these steps, B2B buyers can make informed decisions when sourcing exhaust header gasket materials, ensuring that they select products that meet their technical and performance needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for exhaust header gasket material Sourcing

What Are the Key Cost Components in Exhaust Header Gasket Material Sourcing?

When sourcing exhaust header gasket materials, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of material significantly affects pricing. Options range from inexpensive compressed fibers to high-performance multi-layer steel and flexible graphite gaskets. Each material offers different durability and heat resistance, influencing the overall cost.

-

Labor: Labor costs encompass the expenses associated with the workforce involved in the manufacturing process. This includes skilled labor for assembly and quality control checks, which may vary based on geographical location and labor laws.

-

Manufacturing Overhead: These costs cover utilities, equipment maintenance, and factory operations. Efficient production methods and technology can reduce overhead, allowing for competitive pricing.

-

Tooling: Initial tooling investments for custom gasket designs can be substantial. Buyers should consider whether the tooling costs are factored into the unit price or charged separately.

-

Quality Control (QC): Ensuring that the gaskets meet specified performance standards is critical, especially for applications in high-stress environments. QC processes add to the cost but are essential for maintaining product integrity.

-

Logistics: Shipping and handling costs can vary significantly based on the supplier’s location and the destination market. International buyers should factor in freight costs, customs duties, and potential tariffs.

-

Margin: Suppliers typically include a profit margin that reflects their operational costs and market conditions. Understanding the typical margins in your specific region can aid in negotiations.

How Do Price Influencers Impact Exhaust Header Gasket Material Costs?

Several factors influence the pricing of exhaust header gaskets, particularly for international buyers:

Illustrative image related to exhaust header gasket material

-

Volume/MOQ: Bulk purchasing often leads to reduced per-unit costs. Negotiating minimum order quantities (MOQ) can yield better pricing, especially for high-demand items.

-

Specifications and Customization: Custom gaskets tailored to specific applications may incur additional costs. Be clear about your requirements to avoid unexpected charges.

-

Material Quality and Certifications: Gaskets with certifications for high-performance standards typically command higher prices. International buyers should evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: The supplier’s reputation, production capabilities, and geographical location can significantly affect pricing. Established suppliers may offer reliability but at a premium.

-

Incoterms: The agreed terms of shipment (Incoterms) can impact total costs. Understanding whether costs cover insurance, duties, or shipping can help buyers make informed decisions.

What Are Effective Buyer Tips for Sourcing Exhaust Header Gaskets Internationally?

International B2B buyers should adopt several strategies to enhance cost-efficiency:

-

Negotiation: Leverage your purchasing power to negotiate better terms. Discuss volume discounts and payment terms upfront to minimize costs.

-

Total Cost of Ownership (TCO): Consider not only the initial purchase price but also long-term costs such as installation, maintenance, and potential downtime from gasket failures. Investing in higher-quality materials can lead to lower TCO.

-

Pricing Nuances: Be aware of regional pricing variations. Factors like currency fluctuations, local demand, and supply chain issues can affect costs. Buyers in regions like Africa, South America, and the Middle East should be particularly vigilant about these aspects.

-

Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Regular communication can also ensure that you are informed about new products and pricing changes.

-

Research and Compare: Utilize online platforms to compare prices and product specifications. This can provide insights into market trends and help identify the best options for your needs.

Conclusion

Navigating the complex cost structure and pricing dynamics of exhaust header gasket materials requires careful consideration of multiple factors. By understanding the cost components, price influencers, and effective sourcing strategies, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that prices may vary, and it’s essential to engage in thorough research and negotiation to secure the best value.

Alternatives Analysis: Comparing exhaust header gasket material With Other Solutions

Introduction: Understanding Alternatives to Exhaust Header Gasket Material

In the realm of exhaust systems, selecting the right sealing solution is paramount for ensuring optimal performance and longevity. While traditional exhaust header gasket materials are widely used, various alternative technologies and methods can achieve similar sealing objectives. This analysis aims to compare exhaust header gasket materials with other viable solutions, providing B2B buyers with a comprehensive understanding of their options.

Comparison Table

| Comparison Aspect | Exhaust Header Gasket Material | Flexible Graphite Gaskets | Multi-Layer Steel Gaskets |

|---|---|---|---|

| Performance | Effective in sealing gaps; suitable for high temperatures | Excellent thermal resistance; can fill gaps | High durability; maintains seal under extreme conditions |

| Cost | Moderate pricing | Higher than composites | Premium pricing |

| Ease of Implementation | Straightforward installation | Requires careful handling | Requires precision alignment |

| Maintenance | May require re-torquing | No re-torquing needed | Typically no maintenance needed |

| Best Use Case | General automotive applications | High-performance racing, custom builds | Heavy-duty vehicles, industrial applications |

Detailed Breakdown of Alternatives

Flexible Graphite Gaskets

Flexible graphite gaskets are constructed entirely from graphite, providing superior thermal resistance and flexibility. They are particularly effective in high-temperature environments, making them ideal for racing and performance applications where exhaust temperatures can exceed standard limits. The ability to fill significant gaps due to their compressibility is a distinct advantage. However, their cost is generally higher than traditional gasket materials, which may deter budget-conscious buyers. Additionally, these gaskets require careful handling during installation to avoid damage.

Illustrative image related to exhaust header gasket material

Multi-Layer Steel Gaskets

Multi-layer steel gaskets (MLS) are engineered with multiple layers of steel, often interspersed with sealing materials. This design enhances durability and allows for effective sealing under extreme pressure and temperature conditions. MLS gaskets excel in heavy-duty applications, such as commercial vehicles and industrial machinery, where reliability is critical. They do not require maintenance or re-torquing, which is a significant advantage for users seeking a low-maintenance solution. However, the initial investment can be steep, making them less appealing for smaller businesses or less demanding applications.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating exhaust header gasket materials and their alternatives, B2B buyers should consider several key factors, including performance requirements, budget constraints, and the specific application environment. While traditional exhaust header gasket materials are suitable for general applications, alternatives like flexible graphite and multi-layer steel gaskets offer unique advantages for high-performance and heavy-duty needs. Ultimately, the best choice will align with the operational demands of the vehicle or machinery, ensuring optimal performance and cost-effectiveness in the long term. By understanding the strengths and weaknesses of each option, buyers can make informed decisions that enhance the efficiency and reliability of their exhaust systems.

Essential Technical Properties and Trade Terminology for exhaust header gasket material

What Are the Key Technical Properties of Exhaust Header Gasket Materials?

When selecting exhaust header gasket materials, understanding their technical properties is vital for ensuring optimal performance and longevity. Here are some critical specifications that B2B buyers should consider:

1. Material Composition

The composition of the gasket significantly affects its performance. Common materials include composite graphite, multi-layer steel, and flexible graphite. Each material offers unique advantages in terms of heat resistance, durability, and sealing capabilities. For example, flexible graphite can withstand extreme temperatures (up to 3,000°F) without burning out, making it ideal for high-performance applications.

2. Temperature Tolerance

Temperature tolerance is a measure of how well a gasket can withstand the heat generated by exhaust systems. Gaskets must maintain their integrity under high temperatures to prevent leaks. Choosing a gasket with a high temperature tolerance ensures reliability and reduces maintenance costs over time.

3. Compression Set and Recovery

This property measures how much a gasket compresses under pressure and its ability to return to its original thickness once the pressure is removed. A gasket with a low compression set maintains its sealing ability over time, which is crucial for preventing exhaust leaks. This characteristic is particularly important for applications subject to thermal cycling, where materials expand and contract with temperature changes.

4. Creep Relaxation

Creep relaxation refers to the tendency of a material to deform under constant load over time. Gaskets with low creep relaxation maintain consistent sealing pressure, which is essential for avoiding leaks. This property is particularly vital in exhaust systems where varying temperatures can lead to uneven expansion and contraction.

5. Durability and Abrasion Resistance

Durability indicates how well a gasket can withstand physical wear and tear, while abrasion resistance measures its ability to resist damage from friction. Selecting a durable gasket is essential for long-term applications, especially in environments with high thermal motion and dissimilar metals.

What Are Common Trade Terms in the Exhaust Gasket Industry?

Understanding industry terminology is crucial for effective communication and decision-making in B2B transactions. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the manufacturing of vehicles or machinery. In the context of exhaust gaskets, OEM parts are designed to meet specific standards and specifications set by vehicle manufacturers, ensuring compatibility and reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to determine their purchasing strategy and to ensure they meet supplier requirements without overcommitting to inventory.

Illustrative image related to exhaust header gasket material

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. Crafting a clear RFQ can help businesses receive accurate pricing and terms, facilitating better negotiation and decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that delineate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is critical for B2B buyers engaging in international transactions, as they clarify risk and cost allocation.

5. Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. Understanding lead times is crucial for buyers to manage inventory levels and plan production schedules effectively.

Illustrative image related to exhaust header gasket material

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make informed decisions regarding exhaust header gasket materials, ensuring compatibility, performance, and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the exhaust header gasket material Sector

What Are the Current Market Dynamics and Key Trends Influencing the Exhaust Header Gasket Material Sector?

The global exhaust header gasket material market is experiencing significant growth driven by several factors. Rising vehicle production, particularly in emerging markets such as Brazil and Vietnam, is increasing the demand for high-quality exhaust systems. Moreover, the automotive sector is shifting towards more efficient and durable materials that can withstand extreme conditions, thereby prompting a shift from traditional composite materials to advanced options like multi-layer steel (MLS) and flexible graphite. International B2B buyers should also be aware of technological advancements in manufacturing processes that enhance the performance and longevity of gaskets. These innovations allow for better sealing capabilities, reduced weight, and improved thermal resistance, making them particularly appealing for high-performance applications.

Sourcing trends are evolving, with B2B buyers increasingly favoring suppliers who can offer customized solutions tailored to specific applications. This trend is especially prevalent among buyers in the Middle East and Europe, where there is a growing emphasis on precision engineering. Additionally, digital transformation in procurement processes, facilitated by platforms that connect suppliers and buyers, is streamlining sourcing operations. Buyers are also looking for transparency in supply chains, especially regarding the sourcing of raw materials and manufacturing practices.

How Can Sustainability and Ethical Sourcing Impact Exhaust Header Gasket Material Procurement?

Sustainability has emerged as a critical consideration in the procurement of exhaust header gasket materials. The environmental impact of manufacturing processes and materials used in gaskets is under scrutiny, leading to a demand for eco-friendly alternatives. Buyers are increasingly prioritizing suppliers who adopt sustainable practices, such as using recycled materials or implementing energy-efficient manufacturing techniques. For instance, gaskets made from composite graphite or multi-layer steel with minimal environmental footprint are gaining traction.

Ethical sourcing is equally important, as buyers are more inclined to partner with suppliers who demonstrate responsibility in their supply chains. This includes compliance with labor laws and fair trade practices. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming prerequisites for suppliers aiming to enter international markets. These certifications not only enhance the credibility of suppliers but also provide assurance to buyers that they are making responsible choices.

How Has the Exhaust Header Gasket Material Sector Evolved Over Time?

The evolution of exhaust header gasket materials reflects broader trends in automotive technology and materials science. Initially, gaskets were predominantly made from compressed fiber materials, which offered limited performance and durability. Over time, advancements in materials science have led to the introduction of more resilient options like graphite and multi-layer steel, which can withstand higher temperatures and offer superior sealing capabilities.

The shift towards high-performance materials has been driven by the increasing demands of modern engines, which operate at higher temperatures and pressures than ever before. As a result, manufacturers have focused on developing gaskets that not only improve performance but also extend the lifespan of exhaust systems. This evolution is crucial for B2B buyers, as the right gasket material can significantly impact engine efficiency and overall vehicle performance, making informed procurement decisions essential in today’s competitive market.

Frequently Asked Questions (FAQs) for B2B Buyers of exhaust header gasket material

-

How do I solve exhaust leaks in my system?

To effectively solve exhaust leaks, first, inspect the entire exhaust system for visible cracks or damaged gaskets. If the gasket is compromised, consider using high-quality exhaust header gaskets that can withstand extreme heat and pressure, such as multi-layer steel or flexible graphite options. Ensure that the gaskets you choose are compatible with your specific engine type and header design. Proper installation is crucial; use a torque wrench to apply the correct tension to avoid future leaks. -

What is the best gasket material for high-performance exhaust systems?

For high-performance exhaust systems, flexible graphite gaskets are often the best choice due to their ability to withstand temperatures up to 3,000°F without burning out or shrinking. Multi-layer steel gaskets also provide excellent sealing capabilities and durability. When selecting a gasket, consider factors such as the thermal cycling of your application and the potential for flange warping, as these can significantly impact performance. -

How can I vet suppliers of exhaust header gasket materials?

When vetting suppliers, consider their experience and reputation in the industry. Look for suppliers who provide detailed product specifications, certifications, and customer testimonials. Request samples to evaluate the quality of their materials firsthand. Additionally, check their compliance with international standards and regulations, especially if you are importing to regions with stringent quality control measures. -

What are the typical minimum order quantities (MOQ) for exhaust header gaskets?

Minimum order quantities for exhaust header gaskets can vary widely depending on the supplier and the type of material. Generally, MOQs can range from as low as 50 units for standard gaskets to 500 units for custom-made options. It’s essential to communicate your specific requirements to the supplier to negotiate favorable terms that suit your purchasing needs. -

What payment terms should I expect when ordering internationally?

Payment terms for international orders typically vary by supplier but often include options like advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, especially for custom orders. It’s advisable to clarify payment terms before placing an order to avoid any misunderstandings and ensure a smooth transaction. -

How do I ensure quality assurance for exhaust header gaskets?

To ensure quality assurance, request product certifications and test results from the supplier. Many reputable manufacturers conduct rigorous testing for heat resistance, durability, and sealing performance. Additionally, establish a clear quality control process, including inspection upon receipt of goods and regular evaluations during production for larger orders. -

What logistics considerations should I keep in mind when sourcing internationally?

When sourcing exhaust header gasket materials internationally, consider shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with your destination’s import requirements. Factor in potential delays due to customs clearance and ensure that all necessary documentation, such as invoices and certificates of origin, is prepared to facilitate smooth logistics. -

Can I customize exhaust header gaskets for my specific application?

Yes, many suppliers offer customization options for exhaust header gaskets, allowing you to specify dimensions, materials, and designs tailored to your application. Custom gaskets can be particularly beneficial for unique engine configurations or specialized performance needs. Discuss your requirements with the supplier early in the sourcing process to explore available customization options and associated costs.

Top 3 Exhaust Header Gasket Material Manufacturers & Suppliers List

1. Remflex – Checker Exhaust Header Gasket

Domain: catalog.remflex.com

Registered: 2004 (21 years)

Introduction: Checker – Remflex Exhaust Header / Manifold Gasket

Key Features:

– Material: 100% flexible graphite

– Thickness: Standard 1/8-inch, designed to crush 50%

– Temperature Resistance: Up to 3,000 degrees F

– No re-torquing necessary due to 30% rebound

– Seals warped flanges, filling gaps up to 1/16-inch

Product Numbers and Sizes:

– PN GS16511: 6-1/2″ Wide x 11″ Long, MSRP $41.39

– PN GS16024: 6″ Wid…

2. Steiner Tractor – Exhaust Manifold Gasket ABC448

Domain: steinertractor.com

Registered: 1997 (28 years)

Introduction: Exhaust Manifold Gasket Material, part number ABC448, designed for use in various tractor models, provides a reliable seal for exhaust manifolds, ensuring optimal performance and durability.

3. Reddit – BGA Gaskets & Custom Fabrication

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: BGA metal gasket material, high temp silicone sealant, paper gasket material (possibly carbon-based), custom downpipe, laser cut flanges from 10mm mild steel.

Strategic Sourcing Conclusion and Outlook for exhaust header gasket material

In navigating the complex landscape of exhaust header gasket materials, strategic sourcing emerges as a critical factor for international B2B buyers. Understanding the unique properties of various gasket materials—such as composite graphite, multi-layer steel, and flexible graphite—enables companies to select products that not only withstand extreme conditions but also enhance performance and longevity. By prioritizing quality and compatibility with specific applications, businesses can mitigate risks associated with exhaust leaks, improve operational efficiency, and ultimately reduce maintenance costs.

For buyers in Africa, South America, the Middle East, and Europe, the ability to source high-performance gasket materials tailored to regional requirements is paramount. Engaging with reputable suppliers who offer innovative solutions can position your business for success in a competitive market.

As we look ahead, it is essential to stay informed about advancements in gasket technology and material science. Embrace the opportunities to enhance your procurement strategies and ensure that your exhaust systems operate at peak efficiency. Connect with trusted manufacturers and distributors to explore the best options available, securing your supply chain and driving your business forward.

Illustrative image related to exhaust header gasket material

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.