The Definitive Guide to Galvanized Steel Trailer: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for galvanized steel trailer

In the ever-evolving landscape of international trade, sourcing a reliable galvanized steel trailer can be a daunting task for B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying quality suppliers but also in understanding the specific applications and benefits of galvanized steel trailers, which are renowned for their durability and corrosion resistance. This comprehensive guide aims to demystify the process by providing valuable insights into various types of galvanized steel trailers, their applications across industries, and essential factors for supplier vetting.

By addressing key aspects such as cost considerations, maintenance requirements, and regulatory compliance, this guide equips international B2B buyers with the knowledge necessary to make informed purchasing decisions. Whether you are in Brazil seeking trailers for agricultural use or in Saudi Arabia looking to enhance your logistics fleet, our resource serves as a strategic tool to navigate the complexities of the global market. With a focus on actionable insights and practical recommendations, this guide empowers you to optimize your procurement process, ensuring you secure the best value and quality for your galvanized steel trailer needs.

Understanding galvanized steel trailer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Utility Trailers | Versatile design, often with drop gates, and varying sizes | Landscaping, equipment transport, recreational use | Pros: High versatility, affordable. Cons: Limited load capacity compared to specialized trailers. |

| Dump Trailers | Hydraulic lift system for easy unloading, heavy-duty construction | Construction, waste management, agricultural use | Pros: Efficient unloading, high payload capacity. Cons: Higher maintenance due to hydraulic systems. |

| Enclosed Trailers | Fully enclosed with secure access, often insulated | Transporting sensitive equipment, tools, or goods | Pros: Enhanced security, protection from elements. Cons: Heavier and may require more powerful towing vehicles. |

| Car Haulers | Designed specifically for transporting vehicles, often with ramps | Auto transport, car dealerships, auctions | Pros: Safe transport of vehicles, specialized design. Cons: Limited use for other transport needs. |

| Flatbed Trailers | Open design with no sides or roof, easy loading/unloading | Heavy equipment transport, construction materials | Pros: Versatile for various loads, easy access. Cons: Less protection for cargo, may require tarps for weather. |

What are the Characteristics and Suitability of Utility Trailers?

Utility trailers are the most versatile option available, ideal for various applications such as landscaping, equipment transport, and recreational use. They typically feature drop gates for easy loading and unloading and come in multiple sizes to accommodate different needs. B2B buyers should consider payload capacity, which usually ranges from 1,000 to 3,000 pounds, depending on the model. They are an economical choice for businesses that require a reliable and adaptable transport solution.

How Do Dump Trailers Stand Out in the Market?

Dump trailers are characterized by their hydraulic lift systems, which allow for efficient unloading of heavy materials. They are particularly suited for construction, waste management, and agricultural applications where quick disposal of loads is essential. B2B buyers should evaluate the payload capacity and hydraulic system reliability, as these factors significantly influence operational efficiency. While they offer high capacity and ease of use, ongoing maintenance of the hydraulic components is a consideration.

What Makes Enclosed Trailers a Secure Choice for Businesses?

Enclosed trailers provide a secure environment for transporting sensitive equipment and goods, often featuring insulation for temperature control. Their design protects contents from theft and weather damage, making them ideal for businesses in sectors like logistics and construction. When purchasing, B2B buyers should assess the size and weight of the trailer to ensure compatibility with their towing vehicles. While they offer substantial security, enclosed trailers can be heavier and may require more powerful towing options.

Why Choose Car Haulers for Vehicle Transportation?

Car haulers are specifically designed to transport vehicles, featuring ramps for easy loading and unloading. They are commonly used by auto transport companies, dealerships, and during auctions. Buyers in the automotive sector should consider the trailer’s weight capacity and ramp design to ensure safe vehicle handling. While these trailers excel in transporting cars, their specialized design limits their versatility for other cargo types.

How Do Flatbed Trailers Provide Versatility in Transport?

Flatbed trailers are known for their open design, allowing for easy access and loading of various cargo types, including heavy equipment and construction materials. They are highly adaptable for multiple industries, making them a popular choice among B2B buyers. When considering a flatbed trailer, buyers should evaluate load capacity and the need for additional securing equipment like tarps. While they offer flexibility, the lack of sides means cargo is more exposed to environmental elements.

Key Industrial Applications of galvanized steel trailer

| Industry/Sector | Specific Application of galvanized steel trailer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Transporting heavy materials and equipment | Enhanced durability and resistance to corrosion | Ensure compliance with local regulations and standards |

| Agriculture | Hauling crops and agricultural equipment | Versatility and longevity in harsh environments | Evaluate load capacity and compatibility with machinery |

| Landscaping | Moving landscaping materials and tools | Increased efficiency in material transport | Consider size, weight capacity, and ease of loading |

| Oil and Gas | Carrying drilling equipment and supplies | Reliable performance in rugged terrains | Assess structural integrity and weather resistance |

| Waste Management | Transporting waste materials | Durability against corrosive waste | Look for features like easy cleaning and maintenance |

How Can Construction Companies Benefit from Galvanized Steel Trailers?

In the construction industry, galvanized steel trailers are essential for transporting heavy materials such as concrete, steel beams, and construction equipment. Their robust construction ensures they can withstand the rigors of job sites, while the galvanized finish protects against rust and corrosion, extending the trailer’s lifespan. International buyers should consider compliance with local regulations regarding load capacities and safety standards, as well as the availability of replacement parts for maintenance.

What Role Do Galvanized Steel Trailers Play in Agriculture?

Agriculture relies heavily on galvanized steel trailers for hauling crops, fertilizers, and farming equipment. The corrosion-resistant properties of galvanized steel make these trailers ideal for use in various weather conditions, ensuring that they maintain their integrity over time. Buyers in regions like South America and Africa should assess the trailer’s load capacity and compatibility with existing agricultural machinery to maximize efficiency and productivity.

How Are Galvanized Steel Trailers Used in Landscaping?

Landscaping businesses utilize galvanized steel trailers to transport materials such as soil, plants, and landscaping tools. Their durability and design allow for easy loading and unloading, which is crucial for maintaining project timelines. Buyers should focus on the trailer’s size and weight capacity to ensure it meets specific job requirements, particularly in urban areas where maneuverability can be a concern.

Why Are Galvanized Steel Trailers Important in the Oil and Gas Industry?

In the oil and gas sector, galvanized steel trailers are used to transport drilling equipment and supplies to remote locations. The trailers’ robust design ensures they can handle the harsh conditions often found in this industry, including exposure to chemicals and extreme weather. Buyers should prioritize sourcing trailers with a high structural integrity and protective coatings to withstand these challenges, especially in the Middle East where environmental conditions can be severe.

Illustrative image related to galvanized steel trailer

How Do Waste Management Companies Benefit from Galvanized Steel Trailers?

Waste management operations frequently utilize galvanized steel trailers for transporting waste materials. The corrosion resistance of galvanized steel is particularly beneficial when dealing with hazardous or corrosive waste, ensuring the trailer remains functional over time. When sourcing these trailers, businesses should consider features that facilitate easy cleaning and maintenance, as well as compliance with local environmental regulations to ensure safe and efficient operations.

3 Common User Pain Points for ‘galvanized steel trailer’ & Their Solutions

Scenario 1: Ensuring Longevity Against Corrosion

The Problem:

B2B buyers often face the challenge of corrosion when using steel trailers in harsh environments, especially in regions with high humidity, coastal proximity, or heavy rainfall. This can lead to significant long-term maintenance costs and shorten the lifespan of the trailers, resulting in financial strain and operational delays. Buyers might find themselves frequently repairing or replacing trailers, leading to unplanned expenditures and interruptions in their logistics operations.

The Solution:

To combat corrosion, it is essential to invest in galvanized steel trailers that feature hot-dipped galvanization. This process involves immersing steel in molten zinc, creating a protective coating that effectively shields the metal from moisture and corrosive elements. When sourcing trailers, buyers should look for manufacturers that guarantee a high-quality galvanization process, ensuring that the coating reaches all parts of the trailer, including hard-to-reach areas. Additionally, regular maintenance practices such as washing the trailer after exposure to saltwater or chemicals can further extend its lifespan. Establishing a routine inspection schedule will also help identify potential issues before they escalate, ensuring the trailer remains in optimal condition.

Scenario 2: Navigating Regulatory Compliance Challenges

The Problem:

International B2B buyers often encounter difficulties navigating different regulatory standards related to trailer construction and safety in their respective countries. In regions like Africa and the Middle East, where regulations may differ from those in Europe or South America, ensuring compliance can be complex. Buyers risk hefty fines or legal liabilities if they fail to meet local requirements, which can delay their operations and lead to costly modifications after purchase.

Illustrative image related to galvanized steel trailer

The Solution:

To mitigate these challenges, it is crucial for buyers to conduct thorough research on the specific regulations governing trailer use in their target markets. This includes understanding weight limits, lighting requirements, and other safety standards. Engaging with local industry experts or legal advisors can provide valuable insights into compliance requirements. Furthermore, selecting suppliers that provide trailers with all necessary documentation, including a Certificate of Origin and compliance certifications, can streamline the registration process. Ensuring that the supplier is familiar with international trade regulations can also provide buyers with the confidence that their trailers will meet all necessary standards upon delivery.

Scenario 3: Maximizing Payload Efficiency

The Problem:

B2B buyers often struggle with optimizing payload efficiency while using galvanized steel trailers, especially when transporting heavy materials. Overloading can lead to reduced fuel efficiency, increased wear and tear on vehicles, and potential safety hazards. This challenge is particularly pronounced in industries like construction or agriculture, where trailers are frequently loaded to capacity.

The Solution:

To maximize payload efficiency, buyers should first ensure that they are fully aware of their trailer’s payload capacity and Gross Vehicle Weight Rating (GVWR). When purchasing, look for galvanized steel trailers designed with high load-bearing capabilities, such as reinforced steel frames and appropriate axle configurations. It’s advisable to implement a weight management system that includes regular weighing of loads and utilizing load distribution techniques to avoid overloading any one axle. Additionally, investing in features such as a 2-position axle-mounted dump bed can facilitate easier loading and unloading, enhancing operational efficiency. Training staff on best practices for loading and securing materials can further optimize the use of the trailer, ensuring safety and compliance with weight regulations.

Strategic Material Selection Guide for galvanized steel trailer

What Are the Key Properties of Galvanized Steel for Trailers?

Galvanized steel is a popular choice for trailer manufacturing due to its excellent corrosion resistance and durability. The galvanization process involves coating steel with a layer of zinc, which significantly enhances its ability to withstand harsh environmental conditions. This material can endure high temperatures and pressures, making it suitable for various hauling applications. Its resistance to rust and corrosion is particularly advantageous in regions with high humidity or exposure to saltwater, such as coastal areas in Africa and South America.

What Are the Pros and Cons of Using Galvanized Steel in Trailer Construction?

The primary advantages of galvanized steel include its long lifespan and low maintenance requirements. The protective zinc layer prevents oxidation, which is crucial for trailers that may be exposed to moisture or corrosive substances. Additionally, galvanized steel is relatively cost-effective compared to other materials like stainless steel, making it an attractive option for B2B buyers looking for durable yet affordable solutions.

However, there are some limitations to consider. The manufacturing complexity of galvanized steel can be higher than that of untreated steel, as the galvanization process requires specialized equipment and handling. Furthermore, while galvanized steel is strong, it may not be as lightweight as aluminum, potentially affecting fuel efficiency during transportation.

Illustrative image related to galvanized steel trailer

How Does Material Selection Impact Application in Different Regions?

When selecting materials for galvanized steel trailers, it’s essential to consider the specific applications and environmental conditions in the target market. For instance, in regions like the Middle East, where temperatures can soar, the heat resistance of galvanized steel is beneficial. Conversely, in areas prone to heavy rainfall, the corrosion resistance of the material becomes paramount.

International buyers must also be aware of compliance with local standards. For example, ASTM standards in the U.S. or DIN standards in Europe dictate specific requirements for material properties and performance. Understanding these regulations is crucial for ensuring that the trailers meet safety and quality benchmarks in their respective markets.

What Specific Considerations Should International Buyers Keep in Mind?

B2B buyers from Africa, South America, the Middle East, and Europe should consider logistics and supply chain factors when selecting galvanized steel trailers. Import tariffs, transportation costs, and local manufacturing capabilities can significantly affect the overall cost and feasibility of purchasing trailers. Additionally, buyers should be aware of any specific certifications required for trailers in their region, which can impact resale value and marketability.

Summary Table of Material Selection for Galvanized Steel Trailers

| Material | Typical Use Case for galvanized steel trailer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Utility trailers for equipment and materials | Excellent corrosion resistance | Heavier than aluminum, complex mfg | Medium |

| Hot-Dip Galvanized | Trailers exposed to harsh environments | Long lifespan with minimal maintenance | Higher initial cost than untreated steel | Medium |

| Stainless Steel | Premium trailers for high-end markets | Superior corrosion resistance and aesthetics | Very high cost, less common in trailers | High |

| Aluminum | Lightweight trailers for specific applications | Lightweight, good for fuel efficiency | Lower strength compared to steel | Medium |

This analysis provides a comprehensive overview of the materials commonly used in galvanized steel trailers, offering valuable insights for international B2B buyers. Understanding the properties, pros and cons, and regional considerations can aid in making informed purchasing decisions that align with operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for galvanized steel trailer

What Are the Key Stages in the Manufacturing Process of Galvanized Steel Trailers?

The manufacturing process of galvanized steel trailers involves several critical stages that ensure durability, strength, and corrosion resistance. Understanding these stages can help B2B buyers assess the quality and reliability of their suppliers.

Material Preparation: How Are Raw Materials Selected and Processed?

The journey begins with the selection of high-quality steel, typically hot-rolled or cold-rolled, which is vital for the structural integrity of the trailer. The steel is then cut to size according to the specifications of the trailer design. This preparation phase often includes stress-relieving processes, such as heating or annealing, to enhance the material’s ductility and reduce the risk of cracking during forming.

Forming: What Techniques Are Used to Shape the Trailer Components?

Once the materials are prepared, the next step is forming the trailer components. This usually involves several techniques, including:

- Hydraulic Pressing: Used for bending and shaping the steel into the desired frame and body parts.

- Welding: Essential for joining different steel components, ensuring a robust structure. Techniques like MIG or TIG welding are often employed for precision.

- Roll Forming: This technique is utilized for producing continuous profiles like side rails and cross members, ensuring uniformity and strength.

These processes not only shape the steel but also enhance its structural properties, making the trailer more resilient under load.

Assembly: How Are the Components Brought Together?

The assembly stage is where individual components are brought together to form the complete trailer. This includes:

Illustrative image related to galvanized steel trailer

- Joining Components: Using bolts, welds, or rivets to secure the frame, axles, and other parts.

- Installation of Features: Adding essential elements such as lighting systems, brakes, and dump mechanisms.

During this phase, attention to detail is crucial, as the integrity of the assembly directly affects the trailer’s performance and safety.

Finishing: What Treatments Are Applied to Ensure Durability?

After assembly, trailers undergo a finishing process that includes hot-dip galvanizing. This involves submerging the assembled trailer frame in molten zinc at temperatures exceeding 800 degrees Fahrenheit. This process creates a protective layer that offers superior corrosion resistance, especially important for trailers exposed to harsh environments.

What Quality Assurance Measures Are Implemented During Manufacturing?

Quality assurance is a critical aspect of the manufacturing process, ensuring that every galvanized steel trailer meets international standards and customer expectations.

Which International Standards Guide the Quality Assurance Process?

Manufacturers often adhere to recognized international standards such as ISO 9001, which outlines the criteria for a quality management system. Additionally, specific industry certifications like CE (European Conformity) and API (American Petroleum Institute) may apply depending on the trailer’s intended use.

What Are the Key Quality Control Checkpoints in Production?

Quality control (QC) checkpoints are established at various stages of production to ensure compliance with standards:

Illustrative image related to galvanized steel trailer

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify their quality and specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to monitor processes and detect any deviations from standards.

- Final Quality Control (FQC): A thorough inspection of the finished trailer, including functional tests and visual inspections, to ensure that it meets all specifications and is free from defects.

What Common Testing Methods Are Used to Validate Quality?

Common testing methods include:

- Visual Inspections: Checking for surface defects and ensuring correct assembly.

- Load Testing: Assessing the trailer’s performance under maximum load conditions to evaluate structural integrity.

- Corrosion Resistance Testing: Exposing the galvanized surface to various environmental conditions to ensure durability.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

What Steps Can Buyers Take to Ensure Supplier Compliance with Quality Standards?

- Conduct Supplier Audits: Regularly auditing suppliers can provide insights into their manufacturing processes and quality assurance measures.

- Request Quality Reports: Buyers should ask for documentation related to quality checks, certifications, and test results to assess compliance with international standards.

- Engage Third-Party Inspectors: Hiring independent inspectors can provide an unbiased evaluation of the manufacturing and quality assurance processes.

What Are the Specific QC and Certification Nuances for International Buyers?

International buyers should be aware of specific regulations that may apply in their regions. For instance, in Europe, compliance with CE marking is often mandatory for trailers, while buyers in the Middle East may require adherence to local standards. Understanding these nuances can help buyers navigate the complexities of international trade and ensure they receive compliant products.

Conclusion: Why Is Understanding Manufacturing and QC Important for Buyers?

For B2B buyers looking to procure galvanized steel trailers, a thorough understanding of the manufacturing processes and quality assurance measures is essential. By focusing on the key stages of manufacturing and the associated quality control standards, buyers can make informed decisions and select suppliers that meet their operational needs and quality expectations. This knowledge not only aids in reducing risks but also fosters long-term partnerships with reliable manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘galvanized steel trailer’

Introduction

Sourcing a galvanized steel trailer requires careful consideration to ensure that you select a product that meets your operational needs and quality standards. This checklist serves as a practical guide for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By following these steps, you can streamline the procurement process and make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of successful sourcing. Consider factors such as payload capacity, dimensions, axle configurations, and intended uses (e.g., hauling equipment, landscaping materials). This clarity helps you communicate your requirements effectively to suppliers and ensures that the trailer will meet your operational demands.

- Payload Capacity: Determine the maximum weight the trailer must carry.

- Dimensions: Specify the length and width of the trailer bed.

- Features: Identify any specific functionalities, such as dump mechanisms or reinforced floors.

Step 2: Research Galvanizing Techniques

Understanding the galvanizing process is essential for assessing the durability of the trailer. Hot-dip galvanizing is the most effective method, providing a robust protective layer against corrosion that extends the lifespan of the steel. Investigate suppliers that utilize high-quality galvanizing processes to ensure superior protection.

- Quality Assurance: Look for suppliers that adhere to industry standards for galvanizing.

- Finish Quality: Ensure the finish is hard and permanent, resistant to peeling or chipping.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their reputation and reliability by checking reviews and ratings on independent platforms.

- Experience: Choose suppliers with extensive experience in manufacturing galvanized trailers.

- Certifications: Verify any relevant industry certifications or quality assurance protocols.

Step 4: Assess Pricing and Payment Terms

Understanding the cost structure and payment terms is vital for budget management. Compare quotes from multiple suppliers, ensuring that you consider all associated costs, such as shipping and tariffs. Look for transparent pricing to avoid unexpected expenses.

Illustrative image related to galvanized steel trailer

- Bulk Discounts: Inquire about discounts for large orders.

- Payment Flexibility: Assess payment terms to facilitate cash flow.

Step 5: Request Samples or Prototypes

If possible, request samples or prototypes to evaluate the quality of the trailer before making a bulk purchase. This step allows you to inspect the materials and construction firsthand, ensuring they meet your expectations and requirements.

- Quality Inspection: Look for signs of craftsmanship and durability.

- Performance Testing: Consider running tests for functionality if applicable.

Step 6: Confirm Compliance with Local Regulations

Ensure that the galvanized steel trailer complies with local regulations and standards in your region. This is particularly important for transportation safety and environmental regulations that may differ across countries.

- Documentation: Request all necessary paperwork for registration and compliance.

- Local Standards: Familiarize yourself with regional requirements to avoid legal issues.

Step 7: Establish After-Sales Support and Warranty Terms

Finally, confirm the availability of after-sales support and warranty terms. A reliable supplier should offer a warranty that covers manufacturing defects and provide support for maintenance and repairs.

- Duration of Warranty: Understand what is covered and for how long.

- Customer Service: Assess the supplier’s responsiveness and support channels.

By following this checklist, you can effectively navigate the sourcing process for galvanized steel trailers, ensuring that you make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for galvanized steel trailer Sourcing

What Are the Key Cost Components of Sourcing a Galvanized Steel Trailer?

When sourcing galvanized steel trailers, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Illustrative image related to galvanized steel trailer

-

Materials: The main expense is the galvanized steel itself, which is treated to resist corrosion. Prices fluctuate based on global steel market trends and zinc coating processes. For instance, hot-dip galvanizing, while more expensive than conventional painting, offers superior durability.

-

Labor: Labor costs can vary significantly by region. Skilled workers are needed for welding and assembly, impacting the overall pricing. For instance, labor in South America might be cheaper compared to Europe, but this could affect the quality and speed of production.

-

Manufacturing Overhead: This includes costs related to machinery maintenance, facility operations, and administrative expenses. Efficient production processes can lower overhead, influencing final pricing.

-

Tooling: For custom trailers, tooling costs can be substantial. These costs are amortized over production runs, so larger orders tend to lower the per-unit price.

-

Quality Control (QC): Implementing stringent QC measures incurs additional costs but ensures the trailers meet safety and performance standards. Certifications may also be required, particularly for international markets.

-

Logistics: Shipping costs can vary based on distance and mode of transport. International shipping may involve customs duties and insurance, which should be factored into the total cost.

-

Margin: Suppliers typically apply a markup to cover their costs and profit. Understanding the supplier’s margin can help in negotiations.

How Do Price Influencers Affect the Cost of Galvanized Steel Trailers?

Several factors influence the pricing of galvanized steel trailers, particularly in international markets:

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts. Many suppliers have a Minimum Order Quantity (MOQ) that can affect pricing structures.

-

Specifications/Customization: Custom features increase costs. Buyers should clearly define their needs upfront to avoid unexpected charges.

-

Materials: The choice of materials, such as the grade of steel and the thickness of the galvanization, can substantially impact pricing. Higher-quality materials typically come at a premium.

-

Quality/Certifications: Compliance with international standards may necessitate additional testing and certification, raising costs. Buyers should verify whether the supplier’s products meet local regulations.

-

Supplier Factors: Established suppliers with a reputation for quality may command higher prices. However, they may also offer better after-sales support and warranty options.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) will influence shipping costs and responsibilities, impacting the overall pricing strategy. Understanding these terms is crucial for international transactions.

What Are the Best Negotiation Tips for B2B Buyers of Galvanized Steel Trailers?

When negotiating prices, B2B buyers should consider the following strategies to enhance cost-efficiency:

-

Research Market Prices: Familiarize yourself with market rates to establish a baseline for negotiations. Utilize multiple suppliers to gauge competitive pricing.

-

Leverage Relationships: Building a good rapport with suppliers can lead to better deals. Long-term partnerships often yield favorable pricing and terms.

-

Discuss Total Cost of Ownership (TCO): Highlight the benefits of investing in higher-quality trailers with better durability and lower maintenance costs over time, justifying a potentially higher upfront cost.

-

Be Clear About Specifications: Clearly communicate your requirements to avoid miscommunication and ensure the supplier can meet your needs without incurring additional costs.

-

Explore Payment Terms: Flexibility in payment terms can sometimes lead to discounts. Suppliers may offer reduced prices for upfront payments or larger orders.

What Are the Pricing Nuances for International Buyers in Emerging Markets?

International buyers, particularly from Africa, South America, and the Middle East, should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can impact the final cost. Consider hedging against currency risk for large purchases.

-

Import Tariffs and Taxes: Research local import duties that may apply to galvanized steel trailers. Understanding these costs upfront can prevent budget overruns.

-

Cultural Considerations: Different regions may have varying expectations regarding pricing negotiations. Being culturally aware can enhance communication and lead to better outcomes.

Disclaimer on Indicative Prices

Prices for galvanized steel trailers can vary widely based on the factors discussed. The indicative price for a basic model may start around $2,200, but customization, quality, and logistics can significantly alter this figure. Always seek detailed quotes from multiple suppliers to ensure a comprehensive understanding of the costs involved.

Illustrative image related to galvanized steel trailer

Alternatives Analysis: Comparing galvanized steel trailer With Other Solutions

Exploring Alternative Solutions to Galvanized Steel Trailers

When considering the best solution for transportation needs in various industries, galvanized steel trailers are a popular choice due to their durability and resistance to corrosion. However, there are several alternatives available, each with its own set of advantages and disadvantages. This analysis will compare galvanized steel trailers against aluminum trailers and wood trailers, providing B2B buyers with insights to make informed decisions.

| Comparison Aspect | Galvanized Steel Trailer | Aluminum Trailer | Wood Trailer |

|---|---|---|---|

| Performance | High load capacity, corrosion-resistant | Lightweight, good load capacity | Lower load capacity, durable under specific conditions |

| Cost | Moderate ($2,200) | Higher initial cost ($3,000+) | Lower initial cost ($1,500) |

| Ease of Implementation | Moderate, requires proper towing equipment | Easy to tow, lightweight | Requires maintenance and proper treatment |

| Maintenance | Low, resistant to rust and wear | Low, but can dent easily | High, prone to rot and insect damage |

| Best Use Case | Versatile for heavy-duty tasks | Ideal for lightweight cargo and frequent use | Suitable for specific applications like farming |

In-Depth Analysis of Alternatives

Aluminum Trailers

Aluminum trailers are known for their lightweight properties, making them easier to tow and maneuver. They typically offer good load capacities and are resistant to corrosion, similar to galvanized steel trailers. However, their initial cost is usually higher, and while they require less maintenance than wood, they can be prone to dents and scratches. Aluminum trailers are best suited for industries that prioritize weight savings, such as recreational vehicle transportation or those that frequently move lighter loads.

Wood Trailers

Wooden trailers present a cost-effective alternative, often appealing to budget-conscious buyers. While they can be sturdy and effective for specific applications, such as agriculture or landscaping, they require regular maintenance to prevent rot and insect damage. Their lower load capacity compared to galvanized steel and aluminum options limits their use in heavy-duty applications. Wooden trailers are ideal for users who have specialized needs and can commit to regular upkeep.

Making the Right Choice for Your Needs

When selecting the right trailer solution for your business, consider factors such as the type of cargo you will transport, the frequency of use, and your maintenance capabilities. Galvanized steel trailers offer robust performance and low maintenance, making them ideal for heavy-duty and diverse applications. In contrast, aluminum trailers provide a lightweight option for frequent haulers, while wood trailers serve niche markets with specific cost and weight considerations.

Ultimately, the best choice will depend on a comprehensive analysis of your operational needs, budget constraints, and long-term usage plans. By weighing these factors, B2B buyers can ensure they invest in a trailer solution that aligns with their business objectives and operational requirements.

Essential Technical Properties and Trade Terminology for galvanized steel trailer

What Are the Key Technical Properties of a Galvanized Steel Trailer?

When sourcing galvanized steel trailers, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

-

Material Grade

The material grade, typically classified as ASTM A123 for hot-dipped galvanized steel, indicates the quality and durability of the steel used. This specification ensures that the steel can withstand corrosion, making it suitable for harsh environments. For B2B buyers, selecting a trailer with a recognized material grade guarantees longevity and reduced maintenance costs. -

Payload Capacity

This specification defines the maximum weight a trailer can safely transport. For instance, a trailer with a payload capacity of 1,637 lbs (742.5 kg) is designed for moderate hauling tasks. Understanding payload capacity is vital for businesses to ensure compliance with transportation regulations and to avoid overloading, which can lead to safety hazards and legal issues. -

Gross Vehicle Weight Rating (GVWR)

GVWR indicates the total weight the trailer can safely carry, including its own weight and the load. For example, a trailer with a GVWR of 2,090 lbs (948 kg) allows businesses to calculate the maximum load they can transport. This figure helps buyers assess the suitability of a trailer for specific operations and ensures compliance with weight limits on roads. -

Flooring Material and Design

The flooring of a trailer, often made from reinforced corrugated steel, provides structural integrity and supports heavy loads. The design, such as a 20″ ground clearance, enhances maneuverability over rough terrain. For B2B buyers, selecting a trailer with durable flooring reduces the risk of damage during transport and prolongs the trailer’s lifespan. -

Axle Configuration

The axle configuration, such as a solid square tubular steel cambered axle, influences the trailer’s stability and handling. A well-designed axle system improves load distribution and enhances safety during transport. Understanding axle specifications is crucial for businesses that require reliable performance under varying load conditions.

What Common Trade Terms Should B2B Buyers Know When Purchasing Galvanized Steel Trailers?

Familiarity with industry jargon can streamline communication and negotiations between buyers and manufacturers. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to the company that manufactures the original product or component. In the context of trailers, OEMs often provide warranties and support for their products. Understanding OEM relationships can help buyers ensure they are purchasing genuine, high-quality trailers with reliable backing. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. For B2B buyers, knowing the MOQ can influence purchasing decisions, especially for businesses looking to maintain inventory without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers. It typically includes detailed specifications and quantities. For businesses, issuing an RFQ can foster competitive bidding and help secure the best price for galvanized steel trailers. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers manage logistics and reduce risks associated with international transactions. -

Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. Understanding lead times is essential for businesses to plan their operations and manage inventory effectively, especially when dealing with international suppliers.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the galvanized steel trailer Sector

What are the Key Market Dynamics and Trends Influencing the Galvanized Steel Trailer Sector?

The galvanized steel trailer sector is witnessing robust growth, driven by increasing demand for durable and corrosion-resistant transport solutions across various industries. Key global drivers include the rising construction and infrastructure projects, particularly in emerging markets in Africa, South America, and the Middle East. These regions are experiencing a construction boom that necessitates reliable transportation for heavy equipment and materials, thereby boosting the demand for galvanized steel trailers.

Emerging B2B technologies are transforming sourcing strategies within this sector. Digital platforms for procurement are becoming prevalent, allowing buyers to compare suppliers, assess product specifications, and streamline purchasing processes. Additionally, the integration of advanced manufacturing techniques, such as automation and robotics, is enhancing production efficiency and quality control, leading to better products at competitive prices. Furthermore, the ongoing trend toward customization is prompting manufacturers to offer tailored solutions, meeting specific needs of diverse industries, from agriculture to logistics.

In Europe, regulatory compliance and safety standards are becoming more stringent, compelling manufacturers to innovate and improve product specifications. International buyers must stay informed about these regulations to ensure their sourcing decisions align with compliance requirements. As galvanized steel trailers are increasingly utilized in logistics and transportation, understanding the market dynamics will enable B2B buyers to make informed procurement choices that align with their operational needs.

Illustrative image related to galvanized steel trailer

How Does Sustainability and Ethical Sourcing Impact the Galvanized Steel Trailer Industry?

Sustainability is becoming a cornerstone of B2B sourcing strategies in the galvanized steel trailer sector. The environmental impact of production processes and the end-of-life disposal of trailers are critical considerations for buyers today. Galvanization, which involves coating steel with a layer of zinc, not only extends the lifespan of trailers but also reduces the frequency of replacements, thus minimizing waste. This longevity is essential for buyers looking to invest in sustainable solutions that align with corporate social responsibility goals.

Ethical sourcing is increasingly important, especially in markets where environmental regulations are evolving. Buyers are urged to vet suppliers for their adherence to ethical practices, which includes responsible sourcing of raw materials and minimizing environmental footprints. Certifications such as ISO 14001 for environmental management systems can serve as indicators of a manufacturer’s commitment to sustainability.

The demand for ‘green’ certifications is on the rise, with buyers increasingly looking for products made from recycled materials or those that contribute to a circular economy. For galvanized steel trailers, sourcing from suppliers who engage in environmentally friendly galvanization processes and utilize recycled steel can enhance a buyer’s sustainability profile while supporting ethical supply chains.

What is the Historical Context of the Galvanized Steel Trailer Market?

The evolution of the galvanized steel trailer market can be traced back to the early 20th century when the need for durable and corrosion-resistant materials became apparent in various industries. Galvanization emerged as a revolutionary process, providing steel with a protective layer that significantly improved its longevity and resistance to environmental factors.

Initially, galvanized steel trailers were primarily used in agricultural applications, where they offered a reliable solution for transporting goods across challenging terrains. Over the decades, advancements in galvanization techniques and manufacturing processes expanded their use into diverse sectors such as construction, logistics, and recreational activities. The versatility and durability of galvanized steel trailers have made them a staple in many industries, adapting to the evolving demands of B2B buyers across the globe.

Illustrative image related to galvanized steel trailer

Today, the galvanized steel trailer market continues to thrive, driven by technological advancements and a growing emphasis on sustainability, positioning it as a vital component in the transportation and logistics landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of galvanized steel trailer

-

How do I select the right galvanized steel trailer for my business needs?

Choosing the right galvanized steel trailer depends on your specific requirements, such as payload capacity, intended use, and terrain. Evaluate your needs against the trailer specifications, including dimensions, weight limits, and durability features. Consider factors like the type of materials you will transport, frequency of use, and whether you require customization options. It’s advisable to consult with suppliers for recommendations based on your business activities and to ensure compliance with local regulations in your region. -

What are the advantages of galvanized steel trailers over standard steel trailers?

Galvanized steel trailers offer superior corrosion resistance due to the hot-dip galvanization process, which protects the steel from environmental factors. This makes them ideal for regions with high humidity or exposure to chemicals, ensuring longevity and lower maintenance costs. Additionally, galvanized trailers maintain structural integrity, providing reliable performance over time. For businesses operating in diverse climates, investing in galvanized steel trailers can lead to significant savings on repairs and replacements. -

What payment terms should I expect when purchasing galvanized steel trailers internationally?

Payment terms for international purchases can vary significantly among suppliers. Common arrangements include letters of credit, advance payments, or net terms. It’s essential to clarify these terms upfront, considering factors like currency fluctuations and transaction fees. Additionally, inquire about any discounts for bulk purchases or long-term contracts. Establishing a solid payment agreement protects both parties and ensures a smooth transaction process. -

What is the typical minimum order quantity (MOQ) for galvanized steel trailers?

The MOQ for galvanized steel trailers can vary by supplier and depends on factors such as production capacity and customization requirements. Some manufacturers may offer flexibility for smaller orders, while others may have stricter MOQs to cover production costs. It’s advisable to discuss your needs with potential suppliers to determine if they can accommodate your order volume and to explore options for bulk pricing if you’re looking to purchase multiple units. -

How can I verify the credibility of a supplier for galvanized steel trailers?

To ensure you’re partnering with a reliable supplier, conduct thorough research including checking their business credentials, certifications, and customer reviews. Request references from previous clients and inquire about their manufacturing processes and quality control measures. Additionally, it may be beneficial to visit the supplier’s facility if possible or engage in virtual meetings to assess their operations. A trustworthy supplier will be transparent about their capabilities and will provide detailed information about their products. -

What are the shipping options for international orders of galvanized steel trailers?

Shipping options for international orders typically include sea freight, air freight, and, in some cases, rail transport. Sea freight is often the most cost-effective choice for larger shipments, while air freight offers quicker delivery times at a higher cost. Ensure that your supplier provides comprehensive logistics support, including documentation for customs clearance and insurance options. It’s crucial to discuss shipping timelines and costs upfront to avoid unexpected delays and expenses. -

Can I customize my galvanized steel trailer?

Many suppliers offer customization options for galvanized steel trailers to meet specific business needs. Customizations may include alterations in size, payload capacity, and additional features such as ramps or specialized fittings. Be sure to communicate your requirements clearly to the supplier and inquire about any additional costs or lead times associated with custom orders. Understanding the customization process helps you align your expectations with the supplier’s capabilities. -

What quality assurance processes should I expect from a reputable supplier?

A reputable supplier of galvanized steel trailers should have robust quality assurance processes in place. This typically includes inspections at various stages of production, adherence to industry standards, and certifications from relevant regulatory bodies. Ask about their testing methods for durability, safety, and corrosion resistance. Additionally, inquire about warranty terms and support for any issues that may arise post-purchase, ensuring that you receive a product that meets your quality expectations.

Top 6 Galvanized Steel Trailer Manufacturers & Suppliers List

1. DK2 – Galvanized Utility Trailer

Domain: detailk2.com

Registered: 2012 (13 years)

Introduction: {‘name’: ‘DK2 by Marlon MMT5X7G’, ‘type’: ‘Galvanized Utility Trailer’, ‘dimensions’: ‘4.5 ft. x 7.5 ft.’, ‘capacity’: ‘1,637 lb’, ‘price’: ‘$2,200.00’, ‘material’: ‘Hot-Dip Galvanized Steel’, ‘color’: ‘Silver’, ‘wheels’: ‘D.O.T. 5.30-12 bias’, ‘coupler’: ‘2 in (5.08 cm) ball’, ‘GVWR’: ‘2,090 lbs (948 kg)’, ‘bed_dimensions’: ’88 in x 52 in (223.5 cm x 132.1 cm)’, ‘side_panels’: ‘Solid corrugated s…

2. D&K Trailers – Galvanized Trailers

Domain: dktrailers.com

Registered: 2002 (23 years)

Introduction: Galvanized Trailers by D&K Trailers Inc. are designed to protect steel from corrosion through a hot-dip galvanizing process. Valmont Galvanizing offers one of the deepest and widest kettles in the area, capable of dipping full trailer frames up to 30 feet in length. The hot zinc coating is applied at over 800 degrees, providing a hard, permanent finish that reaches areas inaccessible to paint, suc…

3. Load Rite – Galvanized Frame Utility Trailers

Domain: loadrite.com

Registered: 1996 (29 years)

Introduction: Utility Trailers | Load Rite Trailers

– Galvanized Frame Utility Trailers

– Features:

– Welded tubular steel frame

– Hot-dipped galvanized frame structure

– Pressure treated 2x deck

– Spring assisted 5’ fold-flat ramp

– LED lighting

– Radial tires

– Dexter Leaf-spring axle with E-Z Lube® hubs

– Aluminum diamondplate and skirted fenders

– Footed top-wind tongue jack

– Integrated…

4. Silver Mountain – 2025 82×22′ Galvanized Steel Equipment Trailer

Domain: centraltrailers.com

Registered: 2003 (22 years)

Introduction: {“Model”:”2025 Silver Mountain Trailers 82×22′ Galvanized Steel Equipment Trailer”,”GVWR”:”16,000 lb”,”Dry Weight”:”3,858 lb”,”Payload Capacity”:”12,142 lb”,”Axles”:”2 (8000# Axles)”,”Tires”:”ST215/75R17.5 16Ply Tire, Black Mod Wheels”,”Suspension”:”Multi-Leaf Slipper Spring Suspension w/Equalizer”,”Frame”:”6” Channel Frame, 3” Channel, 16” On Center Crossmembers”,”Tongue”:”6” Channel Tongue”,”Dov…

5. BWise Trailers – Galvanized Steel Solutions

Domain: bwisetrailers.com

Registered: 2012 (13 years)

Introduction: Galvanized Steel – BWise Trailers offers long-term performance and protection through a hot-dip galvanization process that adds a layer of zinc to steel, providing three layers of protection: Barrier Protection, Cathodic Protection, and Zinc Patina. Key benefits include resistance to corrosion at 1/30th the rate of bare steel, reduced upkeep, and durability in harsh conditions. BWise trailers are …

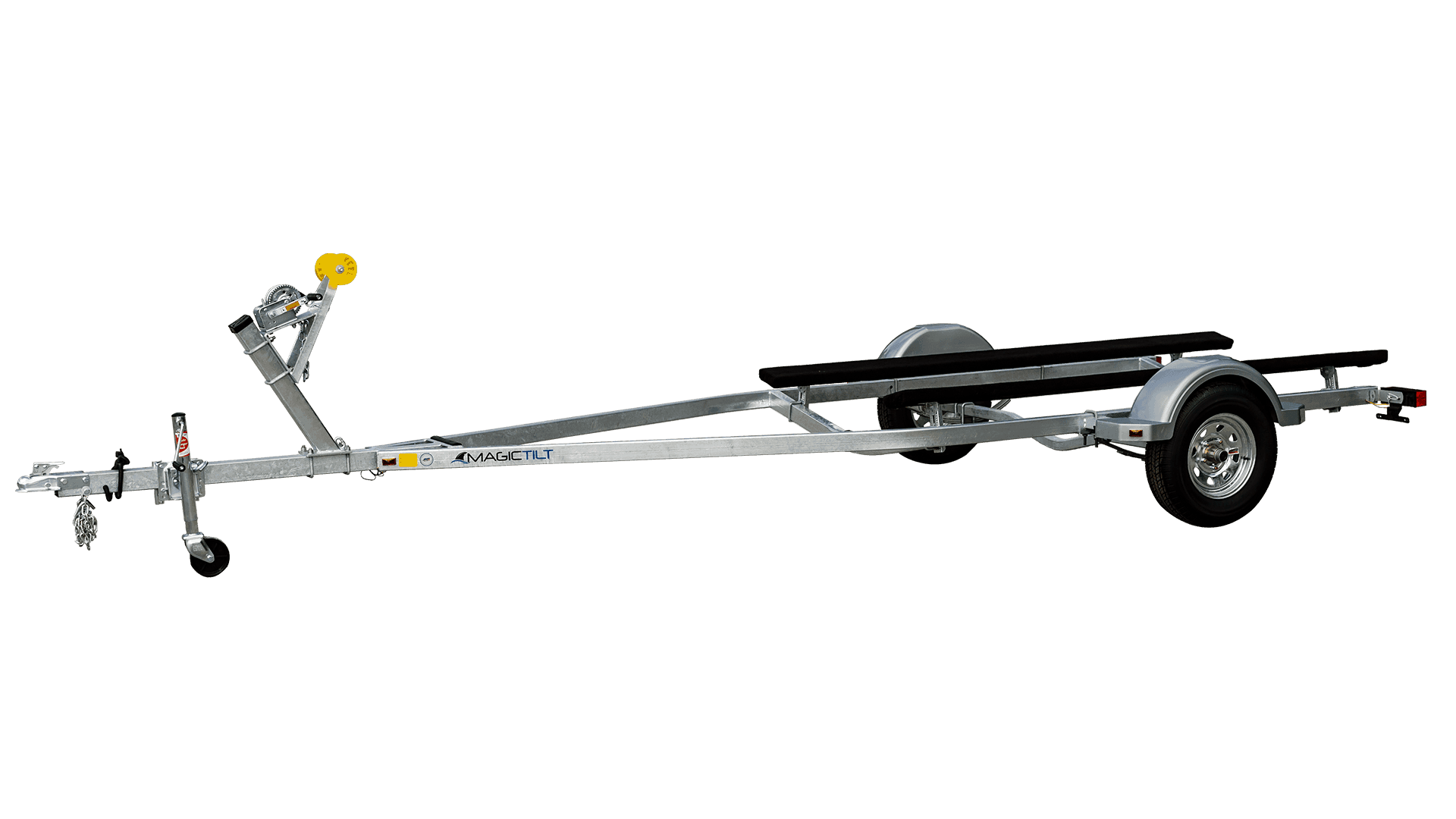

6. Magic Tilt – Galvanized Trailers

Domain: magictilt.com

Registered: 1996 (29 years)

Introduction: Galvanized Trailers by Magic Tilt offer a complete line of trailers designed for various boating conditions. Key benefits include excellent corrosion resistance, hot dipped steel frames, welded or bolted construction, and great value. The construction is divided into three parts: frame (structural strength and appearance), boat support (for easy loading and unloading), and under-carriage (weight c…

Strategic Sourcing Conclusion and Outlook for galvanized steel trailer

In the evolving landscape of industrial transport solutions, galvanized steel trailers stand out as a robust choice for international buyers. Their superior corrosion resistance, achieved through hot-dip galvanizing, ensures longevity and reduced maintenance costs—key factors for businesses operating in diverse climates, particularly in Africa, South America, the Middle East, and Europe. As you consider strategic sourcing, focus on suppliers who provide high-quality materials and comprehensive warranties, ensuring that your investment delivers long-term value.

Moreover, the versatility of galvanized trailers makes them suitable for various applications, from transporting heavy equipment to recreational use. Understanding the specifications and benefits of these trailers will empower you to make informed purchasing decisions that align with your operational needs.

Illustrative image related to galvanized steel trailer

As you navigate the global market, prioritize partnerships with reputable manufacturers and distributors that offer not only quality products but also exceptional customer support. The future of your logistics and transportation strategy depends on it. Embrace the opportunity to enhance your fleet with galvanized steel trailers and position your business for success in an increasingly competitive environment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.