Diafragma Valve: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for diafragma valve

In an increasingly interconnected world, sourcing reliable diaphragm valves can pose significant challenges for international B2B buyers. These essential components play a critical role in various industries, including pharmaceuticals, food and beverage, and wastewater management, where precision and hygiene are paramount. However, navigating the complexities of the global market—such as understanding diverse applications, evaluating supplier credibility, and managing cost considerations—can be daunting.

This comprehensive guide delves into the multifaceted landscape of diaphragm valves, offering insights into different types, their specific applications, and the key factors to consider when selecting the right valve for your needs. From understanding the materials used in manufacturing to assessing the performance metrics that matter most, we empower buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Saudi Arabia—to make informed purchasing decisions.

By providing actionable strategies for vetting suppliers and a clear breakdown of cost implications, this guide serves as a valuable resource for businesses aiming to enhance their operational efficiency and product quality. Equip yourself with the knowledge to navigate the global market for diaphragm valves, ensuring your procurement process is both strategic and effective.

Understanding diafragma valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pneumatic Diaphragm Valve | Operated by compressed air; quick actuation | Chemical processing, food & beverage | Pros: Fast response, precise control. Cons: Requires air supply, potential for air leaks. |

| Manual Diaphragm Valve | Operated by hand lever; simple mechanical design | Water treatment, HVAC systems | Pros: Low maintenance, cost-effective. Cons: Slower operation, less suitable for automated systems. |

| Electric Diaphragm Valve | Electrically actuated; offers automation capabilities | Pharmaceutical manufacturing, robotics | Pros: High precision, remote operation. Cons: Higher initial cost, requires electrical infrastructure. |

| Sanitary Diaphragm Valve | Designed for hygiene; smooth surfaces and materials | Food and beverage processing, biotech | Pros: Prevents contamination, easy to clean. Cons: More expensive, specific material requirements. |

| Tri-Clamp Diaphragm Valve | Features tri-clamp fittings for easy installation | Brewing, dairy applications | Pros: Quick assembly/disassembly, versatile. Cons: Limited to specific pipe sizes, may require additional fittings. |

What Are the Characteristics and Suitability of Pneumatic Diaphragm Valves?

Pneumatic diaphragm valves utilize compressed air for actuation, providing rapid response times ideal for dynamic processes in industries like chemical processing and food and beverage. Their design allows for precise flow control, making them suitable for applications where accuracy is critical. When considering procurement, buyers should assess the availability of compressed air systems and the potential for air leaks, which can impact operational efficiency.

How Do Manual Diaphragm Valves Function and What Are Their Applications?

Manual diaphragm valves operate via a hand lever, making them a straightforward and reliable choice for applications such as water treatment and HVAC systems. Their mechanical simplicity translates to low maintenance costs, appealing to budget-conscious buyers. However, they may not be suitable for automated systems due to their slower actuation speed, which should be a key consideration during the purchasing process.

What Advantages Do Electric Diaphragm Valves Offer for B2B Buyers?

Electric diaphragm valves are designed for automated environments, providing high precision and the ability to be operated remotely. They are particularly beneficial in pharmaceutical manufacturing and robotics, where accuracy and consistency are paramount. While the initial investment may be higher, the long-term savings in labor and increased operational efficiency can justify the cost for many businesses.

Why Are Sanitary Diaphragm Valves Essential in Certain Industries?

Sanitary diaphragm valves are engineered with hygiene in mind, featuring smooth surfaces that minimize contamination risks, making them essential in food, beverage, and biotechnology sectors. Their ease of cleaning and compliance with health regulations can significantly enhance product safety and quality. Buyers should consider the cost implications of these specialized materials, as they can be more expensive than standard options.

How Do Tri-Clamp Diaphragm Valves Enhance Operational Flexibility?

Tri-clamp diaphragm valves are designed with tri-clamp fittings, allowing for quick installation and removal, which is particularly advantageous in brewing and dairy applications. Their versatility in connecting with various pipe sizes can facilitate easy maintenance and adaptability in production lines. However, buyers should ensure compatibility with existing systems to avoid the need for additional fittings or modifications.

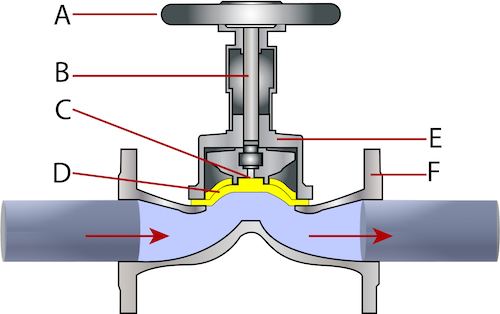

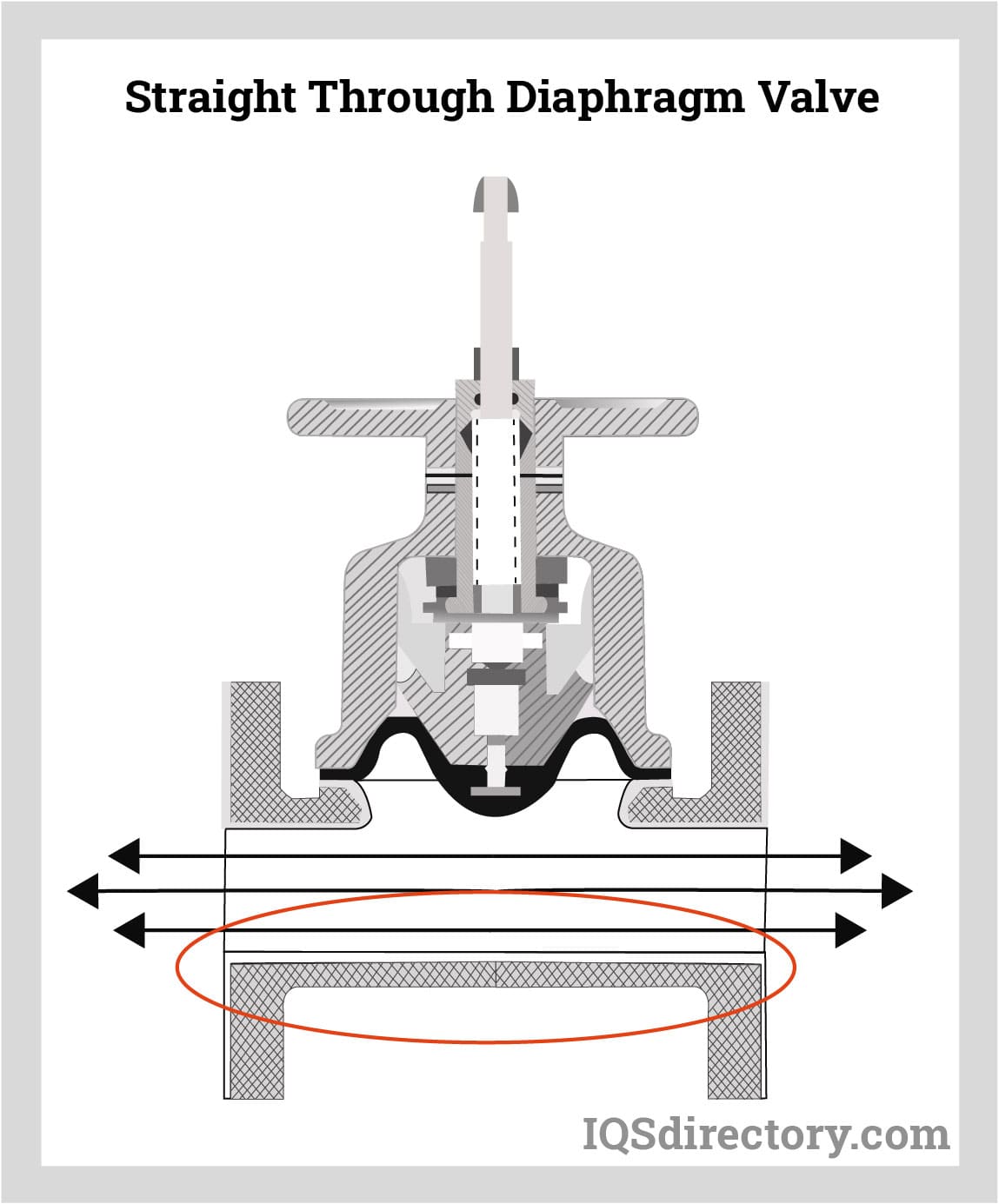

Illustrative image related to diafragma valve

Key Industrial Applications of diafragma valve

| Industry/Sector | Specific Application of diafragma valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceutical | Precise flow control in drug formulation processes | Ensures product quality and compliance with regulations | Material compatibility, FDA certification, cleanroom standards |

| Food and Beverage | Sanitary processing of liquids and gases | Maintains hygiene and prevents contamination | Certifications (e.g., FDA, NSF), ease of cleaning, durability |

| Water Treatment | Regulation of chemical dosing in water purification | Improves efficiency and effectiveness of treatment processes | Corrosion resistance, compatibility with various chemicals |

| Chemical Processing | Control of corrosive and viscous fluids | Enhances safety and operational reliability | Material selection, pressure rating, temperature tolerance |

| Biotechnology | Handling of sensitive biological fluids | Protects product integrity and minimizes contamination risks | Sterilization capability, biocompatibility, and flexibility in design |

How Are Diaphragm Valves Used in the Pharmaceutical Industry?

In the pharmaceutical sector, diaphragm valves are vital for maintaining precise flow control during drug formulation processes. These valves help ensure that the correct amount of active ingredients is mixed, thus guaranteeing product quality and compliance with stringent regulations. Buyers should prioritize valves made from materials that are FDA compliant and suitable for cleanroom environments, as contamination can lead to significant financial losses and regulatory issues.

What Role Do Diaphragm Valves Play in Food and Beverage Processing?

Diaphragm valves are extensively used in the food and beverage industry for the sanitary processing of liquids and gases. Their design facilitates smooth, obstruction-free flow paths, which are crucial for maintaining hygiene and preventing contamination. For international buyers, sourcing valves that meet certifications like FDA or NSF is essential, along with ensuring ease of cleaning and durability to withstand rigorous cleaning protocols.

How Are Diaphragm Valves Applied in Water Treatment?

In water treatment facilities, diaphragm valves regulate chemical dosing in purification processes. This application is critical for improving the efficiency and effectiveness of treatment systems, ensuring safe water supply. Buyers should consider sourcing valves that offer corrosion resistance and compatibility with various chemicals, as these factors significantly influence the longevity and reliability of the valves in harsh environments.

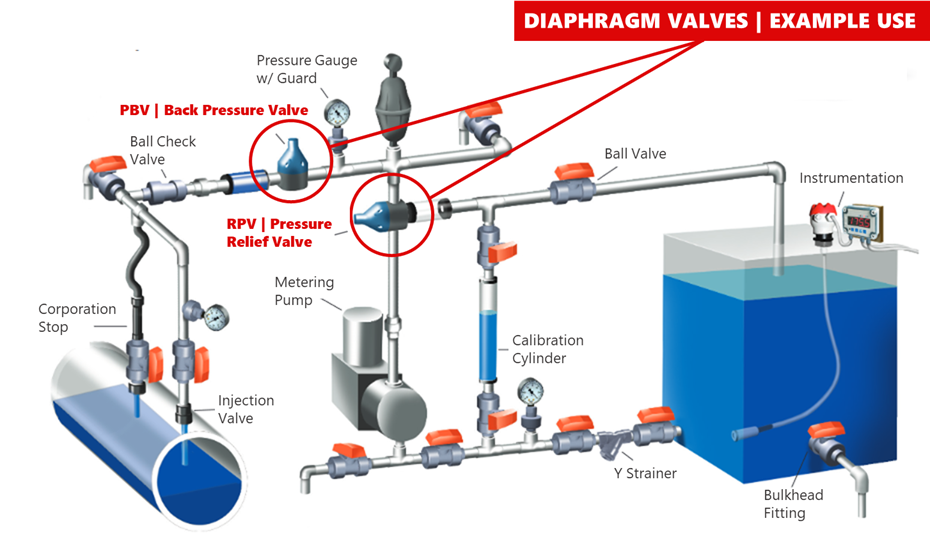

Illustrative image related to diafragma valve

Why Are Diaphragm Valves Important in Chemical Processing?

Diaphragm valves are employed in chemical processing to control the flow of corrosive and viscous fluids safely. Their ability to handle aggressive substances while maintaining operational reliability enhances safety in industrial environments. When sourcing these valves, buyers must focus on material selection, pressure ratings, and temperature tolerances to ensure the valves can withstand the specific demands of their chemical processes.

How Do Diaphragm Valves Benefit Biotechnology Applications?

In biotechnology, diaphragm valves are crucial for the handling of sensitive biological fluids, where maintaining product integrity is paramount. These valves help minimize contamination risks, ensuring that the biological products meet quality standards. Buyers in this sector should prioritize valves that offer sterilization capabilities, biocompatibility, and flexibility in design to adapt to various applications and processes.

3 Common User Pain Points for ‘diafragma valve’ & Their Solutions

Scenario 1: Inconsistent Flow Control in Production Lines

The Problem: B2B buyers often encounter issues with maintaining consistent flow rates in production processes, particularly in industries such as pharmaceuticals and food and beverage. Inconsistent flow can lead to product quality variations, wasted materials, and increased operational costs. A diaphragm valve that doesn’t provide reliable sealing can cause fluctuations in pressure, resulting in either over-pressurization or inadequate flow, impacting overall efficiency.

The Solution: To address this challenge, it is crucial to select diaphragm valves designed for high precision and reliability. Buyers should look for valves with a robust construction, such as those made from FDA-approved materials like PTFE and stainless steel. Additionally, they should ensure that the diaphragm has the appropriate thickness and elasticity to maintain a tight seal under varying pressures. It is also advisable to work with suppliers who offer comprehensive technical support to help with installation and maintenance. Regularly scheduled inspections and maintenance can prevent wear and tear, ensuring that the valves operate smoothly and maintain consistent flow rates.

Scenario 2: Difficulty in Cleaning and Maintenance

The Problem: In industries requiring strict hygiene standards, such as food processing or pharmaceuticals, the challenge of cleaning diaphragm valves becomes a significant pain point. Residual materials can accumulate in the valve, leading to contamination risks and compliance issues. Buyers may find that certain valve designs are complicated to disassemble, making thorough cleaning a time-consuming and labor-intensive task.

The Solution: To alleviate cleaning issues, buyers should prioritize diaphragm valves that feature a simple, modular design, allowing for easy disassembly and reassembly. Opting for valves with smooth surfaces and minimal dead zones can facilitate effective cleaning. Additionally, investing in valves that support in-line cleaning methods, such as steam-in-place (SIP) or clean-in-place (CIP) systems, can enhance hygiene without extensive manual intervention. Collaborating with manufacturers who provide cleaning and maintenance guidelines can further ensure that best practices are followed, reducing downtime and maintaining compliance with industry standards.

Scenario 3: High Costs Due to Frequent Failures

The Problem: Frequent valve failures can lead to unplanned downtime, resulting in significant financial losses for businesses. Buyers often experience frustration with the high costs associated with replacing diaphragm valves that fail prematurely due to improper application or subpar materials. This scenario is especially prevalent in harsh environments where valves are subjected to extreme pressures or corrosive substances.

The Solution: To combat this issue, it’s essential to conduct a thorough application analysis before selecting diaphragm valves. Buyers should assess the specific conditions under which the valves will operate, including pressure, temperature, and the nature of the fluids being handled. Selecting valves made from high-quality materials suitable for the application can significantly reduce failure rates. Buyers should also consider investing in more advanced diaphragm valve technologies, such as those with built-in fail-safes or enhanced sealing mechanisms. Engaging with experienced suppliers who can provide tailored recommendations based on the unique operational environment can lead to better long-term performance and cost savings. Regular training for maintenance staff on the specific needs of diaphragm valves can also minimize the risk of damage and extend the lifespan of the equipment.

Strategic Material Selection Guide for diafragma valve

What Are the Most Common Materials Used in Diaphragm Valves?

When selecting diaphragm valves for various industrial applications, the choice of materials significantly impacts performance, durability, and compatibility with the intended media. Below, we analyze four common materials used in diaphragm valves, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. PTFE (Polytetrafluoroethylene)

Key Properties: PTFE is renowned for its excellent chemical resistance, high-temperature tolerance (up to 260°C), and low friction properties. It can withstand pressures of up to 15 bar, making it suitable for a variety of applications.

Pros & Cons: The primary advantage of PTFE is its exceptional resistance to corrosive chemicals, making it ideal for industries such as pharmaceuticals and food processing. However, PTFE can be more expensive than other materials and may require specialized manufacturing processes, increasing overall costs.

Impact on Application: PTFE is particularly effective for applications involving aggressive chemicals, such as acids and solvents. Its non-stick properties also facilitate easy cleaning, which is crucial in sanitary applications.

Illustrative image related to diafragma valve

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with international standards such as FDA regulations for food contact materials. Additionally, understanding local sourcing capabilities for PTFE can impact lead times and costs.

2. EPDM (Ethylene Propylene Diene Monomer)

Key Properties: EPDM is a synthetic rubber that exhibits excellent weather resistance, flexibility, and a temperature range of -40°C to 120°C. It also provides good resistance to steam and hot water.

Pros & Cons: EPDM is cost-effective and easy to manufacture, making it a popular choice for many applications. However, it has limited chemical resistance, particularly against hydrocarbons and oils, which can restrict its use in certain environments.

Impact on Application: EPDM is commonly used in water treatment and HVAC applications due to its excellent sealing properties. However, its limitations in chemical compatibility must be considered when selecting it for specific media.

Considerations for International Buyers: Buyers should verify compliance with local standards, such as ASTM D2000, especially in industries requiring stringent quality controls. Understanding the local market for EPDM can also provide insights into cost variations.

3. Stainless Steel (316L)

Key Properties: Stainless steel, particularly 316L, offers excellent corrosion resistance, high strength, and the ability to withstand temperatures up to 870°C. It is also capable of handling high-pressure applications.

Pros & Cons: The durability and strength of stainless steel make it suitable for harsh environments, including chemical processing and food production. However, it is more expensive than plastic alternatives and can be heavier, which may affect installation.

Impact on Application: Stainless steel is ideal for applications involving corrosive fluids and high-pressure systems. Its hygienic properties make it a preferred choice in the food and beverage industries.

Considerations for International Buyers: Compliance with standards such as ASTM A312 is essential for buyers in regions like Europe and South America. Additionally, understanding local regulations regarding food safety can impact the selection of stainless steel components.

4. Polypropylene (PP)

Key Properties: Polypropylene is a lightweight thermoplastic that offers good chemical resistance and a temperature range of -10°C to 100°C. It is suitable for moderate-pressure applications.

Pros & Cons: Polypropylene is cost-effective and easy to mold, making it a popular choice for various applications. However, it has lower temperature and pressure ratings compared to metals and can be less durable in harsh environments.

Impact on Application: PP is commonly used in water treatment and chemical handling applications. Its limitations in extreme conditions must be considered when selecting it for specific uses.

Considerations for International Buyers: Buyers should ensure that polypropylene meets relevant industry standards, such as ISO 9001, particularly in regions with strict compliance requirements. Understanding local availability can also influence procurement strategies.

Summary Table of Material Selection for Diaphragm Valves

| Material | Typical Use Case for diafragma valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PTFE | Chemical processing, food industry | Excellent chemical resistance | Higher cost and manufacturing complexity | High |

| EPDM | Water treatment, HVAC | Cost-effective and flexible | Limited chemical resistance | Low |

| Stainless Steel (316L) | Food production, chemical processing | High strength and corrosion resistance | Higher cost and weight | High |

| Polypropylene | Water treatment, chemical handling | Lightweight and cost-effective | Lower temperature and pressure ratings | Medium |

This strategic material selection guide provides critical insights for B2B buyers in various regions, helping them make informed decisions based on the specific requirements of their applications.

Illustrative image related to diafragma valve

In-depth Look: Manufacturing Processes and Quality Assurance for diafragma valve

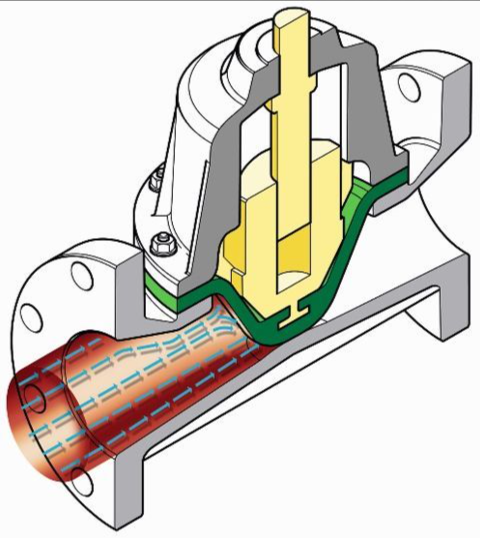

What Are the Main Stages in the Manufacturing Process of Diaphragm Valves?

The manufacturing process of diaphragm valves involves several critical stages, each essential for ensuring the final product meets the required specifications and standards. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in the manufacturing process is selecting appropriate materials, often stainless steel, plastic, or specialized elastomers for the diaphragm. The materials must be compatible with the fluids the valve will handle, ensuring durability and resistance to corrosion. These materials undergo rigorous quality checks before use, including chemical composition analysis and mechanical property testing.

-

Forming: During the forming stage, the prepared materials are shaped into the required components. This may involve machining, injection molding, or stamping processes to create the valve body, diaphragm, and other essential parts. Precision is crucial here, as any deviation from specifications can affect the valve’s performance. Advanced techniques like CNC machining and 3D printing are increasingly utilized for their accuracy and efficiency.

-

Assembly: Once the individual components are formed, they are assembled into a complete diaphragm valve. This stage requires careful handling to prevent contamination and ensure that each component fits correctly. Assemblers typically follow standardized procedures to maintain consistency, and the assembly area is often kept clean and organized to uphold hygiene standards.

-

Finishing: The final stage involves surface finishing treatments, such as polishing or coating, to enhance the valve’s performance and appearance. This may include applying protective coatings to prevent corrosion or improving the surface finish to reduce friction. Finishing processes are critical, especially for valves used in sanitary applications, where hygiene is paramount.

What Quality Assurance Standards Are Relevant for Diaphragm Valves?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that diaphragm valves meet international and industry-specific standards. For B2B buyers, understanding these standards can help in selecting reliable suppliers.

-

ISO 9001: This is a widely recognized international standard for quality management systems (QMS). Compliance with ISO 9001 indicates that a manufacturer has established processes for consistently delivering products that meet customer and regulatory requirements. B2B buyers should look for suppliers with ISO 9001 certification as a baseline for quality assurance.

-

CE Marking: In the European market, CE marking is mandatory for products that comply with EU safety, health, and environmental protection standards. Diaphragm valves intended for use in Europe must be CE marked, ensuring they meet essential requirements.

-

API Standards: The American Petroleum Institute (API) sets standards for equipment used in the oil and gas industry. For diaphragm valves used in these sectors, compliance with relevant API specifications is crucial for safety and reliability.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is typically integrated at various checkpoints throughout the manufacturing process to ensure that any defects are identified and addressed promptly.

Illustrative image related to diafragma valve

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components before they enter the production line. Tests may include material verification, dimensional checks, and compliance with specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections ensure that production remains within specified tolerances. This may involve monitoring machinery performance, conducting in-line measurements, and performing spot checks on assembled components.

-

Final Quality Control (FQC): Once the diaphragm valves are fully assembled, they undergo rigorous testing to verify their functionality and safety. Common tests include pressure testing, leak testing, and functional testing to ensure the valves operate as intended under specified conditions.

What Testing Methods Are Commonly Used for Diaphragm Valves?

Testing methods play a crucial role in verifying the performance and reliability of diaphragm valves. Here are some common testing techniques used:

-

Pressure Testing: This method assesses the valve’s ability to withstand operational pressures without leaking. The valve is subjected to pressures exceeding its operational limit to identify weaknesses or potential failure points.

-

Leak Testing: Various techniques, such as bubble testing or vacuum testing, are employed to detect leaks in the valve assembly. Ensuring a leak-free design is critical, particularly in applications where fluid contamination could have severe consequences.

-

Functional Testing: This involves simulating actual operating conditions to ensure the valve opens and closes correctly, and that flow rates meet specifications. Functional testing helps identify any operational issues that could arise during use.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability and compliance with industry standards.

-

Supplier Audits: Conducting regular audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures. During audits, buyers can assess the effectiveness of the supplier’s QMS and identify areas for improvement.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the QC measures implemented throughout the manufacturing process. These reports should include data on IQC, IPQC, and FQC results, along with any corrective actions taken in response to defects.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These inspections can verify compliance with relevant standards and ensure that the products meet the buyer’s specifications.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing diaphragm valves internationally, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should consider several nuances related to quality control:

Illustrative image related to diafragma valve

-

Regulatory Compliance: Different regions have varying regulatory requirements. Buyers must ensure that suppliers comply with local standards, such as CE marking in Europe or specific certifications in the Middle East.

-

Cultural and Communication Barriers: Language differences and cultural practices may affect the quality assurance process. Establishing clear communication channels and understanding local business practices can facilitate smoother transactions.

-

Logistical Considerations: International shipping can introduce challenges related to product integrity during transport. Buyers should discuss packaging and handling procedures with suppliers to ensure that products arrive in optimal condition.

In conclusion, understanding the manufacturing processes and quality assurance standards for diaphragm valves is crucial for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they select reliable suppliers that meet their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diafragma valve’

In the competitive landscape of industrial procurement, sourcing diaphragm valves requires careful consideration and strategic planning. This guide serves as a practical checklist for B2B buyers, ensuring that you make informed decisions tailored to your specific operational needs.

Step 1: Define Your Technical Specifications

Understanding your operational requirements is the first step in sourcing diaphragm valves. This includes specifying the size, material, and type of diaphragm valve you need, based on the fluids or gases being controlled. Look for details such as pressure ratings, temperature tolerances, and compatibility with your systems to ensure optimal performance.

Step 2: Research Industry Standards and Regulations

Familiarize yourself with the relevant industry standards that diaphragm valves must meet. This includes compliance with FDA regulations for food and beverage applications or specific certifications for pharmaceutical use. Ensuring that the valves meet these standards can prevent costly compliance issues down the line.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct thorough due diligence. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their track record for quality, delivery times, and customer service to ensure they align with your expectations.

Illustrative image related to diafragma valve

Step 4: Request Samples and Technical Data Sheets

Obtaining samples of the diaphragm valves you are considering is essential for testing compatibility with your systems. Additionally, request technical data sheets that provide insights into the valve’s specifications, materials, and maintenance requirements. This information is vital for evaluating performance and longevity.

Step 5: Compare Pricing and Total Cost of Ownership

While price is a critical factor, it’s essential to consider the total cost of ownership, which includes installation, maintenance, and potential downtime. Compare quotes from multiple suppliers, but also assess the value each supplier offers in terms of quality and service. The cheapest option may not always be the most cost-effective in the long run.

Step 6: Verify Supplier Certifications

Ensure that your chosen suppliers have the necessary certifications, such as ISO 9001 for quality management or other industry-specific certifications. This verification process is crucial in ensuring that the products meet high-quality standards and that the supplier is committed to continuous improvement.

Step 7: Establish Clear Communication Channels

Finally, establish clear communication channels with your suppliers. Discuss expectations regarding lead times, order processes, and after-sales support. A reliable supplier should be responsive and willing to provide ongoing assistance, ensuring a smooth procurement process and long-term partnership.

Illustrative image related to diafragma valve

By following this checklist, you can enhance your procurement strategy for diaphragm valves, ensuring that you select products that meet your operational needs while fostering successful supplier relationships.

Comprehensive Cost and Pricing Analysis for diafragma valve Sourcing

What Are the Key Cost Components in Diaphragm Valve Manufacturing?

When sourcing diaphragm valves, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials like stainless steel, PTFE, and EPDM are often used for their durability and resistance to corrosion. High-quality materials may incur higher initial costs but can lead to lower maintenance and replacement expenses over time.

-

Labor: Labor costs depend on the manufacturing location and the complexity of the valve design. Skilled labor is essential for precise machining and assembly, particularly in regions with higher wage standards.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can minimize overhead costs.

-

Tooling: The initial investment in tooling for custom valve designs can be substantial. However, reusable tooling can spread these costs over multiple units, reducing the per-unit cost in larger production runs.

-

Quality Control (QC): Rigorous QC processes ensure that valves meet industry standards and specifications, which can add to the overall cost. However, investing in quality control can prevent costly returns and warranty claims.

-

Logistics: Shipping costs vary based on distance, shipping method, and the weight of the valves. Understanding the logistics involved is crucial for accurate cost predictions.

-

Margin: Suppliers typically apply a margin to cover their costs and ensure profitability. This margin can vary widely based on competition and market demand.

What Factors Influence Pricing for Diaphragm Valves?

Several key factors influence the pricing of diaphragm valves, particularly in international B2B transactions:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes usually lead to lower per-unit costs due to economies of scale. Understanding a supplier’s MOQ is essential for budgeting.

-

Specifications and Customization: Customized valves often come with higher costs due to the additional design and manufacturing requirements. Off-the-shelf solutions may offer cost savings for standard applications.

-

Materials and Quality Certifications: Valves made from premium materials or those that meet specific certifications (like FDA or ISO) can command higher prices. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record and reliability.

-

Incoterms: The agreed-upon Incoterms affect the final price by determining who is responsible for shipping costs, insurance, and risks. Understanding these terms can help buyers negotiate better deals.

What Are Effective Buyer Tips for Negotiating Diaphragm Valve Prices?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management are vital:

Illustrative image related to diafragma valve

-

Negotiate for Better Terms: Leverage volume discounts and payment terms to reduce upfront costs. Establishing a long-term relationship with suppliers can lead to better pricing over time.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes not only the purchase price but also maintenance, downtime, and replacement costs. A higher initial investment in quality valves may yield savings in the long run.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, import duties, and taxes can affect the final price. Buyers should factor these elements into their budgeting and negotiations.

-

Request Multiple Quotes: Gathering quotes from different suppliers allows buyers to compare pricing and terms, providing leverage in negotiations.

-

Stay Informed on Market Trends: Keeping abreast of industry trends and material costs can help buyers make informed decisions and negotiate effectively.

Conclusion: Why Is It Important to Understand Diaphragm Valve Pricing?

Understanding the comprehensive cost and pricing analysis for diaphragm valves is crucial for making informed purchasing decisions. By recognizing the various cost components and pricing influencers, B2B buyers can negotiate better terms, optimize their budgets, and ultimately enhance their procurement strategies. As prices can vary significantly based on multiple factors, it’s essential to approach sourcing with a well-rounded perspective and a focus on long-term value.

Alternatives Analysis: Comparing diafragma valve With Other Solutions

Understanding Alternatives to Diaphragm Valves

In the pursuit of effective fluid control solutions, diaphragm valves stand out due to their precision and reliability. However, various alternatives exist that may better suit specific applications or operational requirements. This analysis compares diaphragm valves against two notable alternatives: Ball Valves and Pinch Valves. By examining performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | Diafragma Valve | Ball Valve | Pinch Valve |

|---|---|---|---|

| Performance | Excellent for precise flow control; effective with viscous fluids | Quick on/off operation; less precise for flow regulation | Good for slurries; can handle solids |

| Cost | Moderate initial cost; low long-term maintenance | Generally lower initial cost; good longevity | Lower initial cost; potential for higher maintenance |

| Ease of Implementation | Requires careful installation; can be complex | Easy to install; straightforward design | Simple installation; fewer components |

| Maintenance | Requires periodic checks; diaphragm replacements needed | Low maintenance; durable design | Requires regular inspections; susceptible to wear |

| Best Use Case | Ideal for pharmaceutical and food applications requiring hygiene | Suitable for water supply and gas applications | Effective for handling solids and slurries in wastewater management |

Detailed Breakdown of Alternatives

Ball Valves

Ball valves are widely recognized for their simplicity and durability. They operate by rotating a ball with a hole through it, allowing for quick and effective flow control. The main advantage of ball valves is their ability to provide a tight seal and quick shut-off, making them ideal for applications like water supply and gas distribution. However, they may not offer the same level of precision in flow control as diaphragm valves, particularly in applications requiring fine adjustments. Their lower initial cost and ease of installation make them a popular choice for various industrial applications.

Pinch Valves

Pinch valves utilize a flexible tube that can be pinched closed to control fluid flow. They are particularly well-suited for handling slurries and fluids with solid particles, as their design minimizes the risk of clogging. The main advantage of pinch valves is their ability to handle a wide range of fluids, including those containing solids. However, they may require more frequent maintenance due to wear on the tubing, and their flow control is less precise compared to diaphragm valves. Pinch valves can be an economical choice for applications in wastewater treatment and other industries where solids are prevalent.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between diaphragm valves and their alternatives, it is essential for B2B buyers to consider the specific requirements of their applications. Diaphragm valves excel in environments demanding high precision and hygiene, making them ideal for pharmaceuticals and food processing. In contrast, ball valves provide a cost-effective and straightforward solution for general fluid control, while pinch valves offer versatility in handling solids and slurries. Evaluating factors such as performance, cost, ease of implementation, and maintenance will help buyers make informed decisions, ensuring they choose the best valve solution for their operational needs.

Illustrative image related to diafragma valve

Essential Technical Properties and Trade Terminology for diafragma valve

What Are the Key Technical Properties of Diaphragm Valves and Why Are They Important in B2B Transactions?

When selecting diaphragm valves for industrial applications, understanding their critical specifications is essential. Here are several key technical properties that should be evaluated:

1. Material Grade

Diaphragm valves are commonly made from materials such as stainless steel, plastic, or elastomers. Stainless steel (e.g., 316L) is preferred for its corrosion resistance and durability in harsh environments. The choice of material impacts the valve’s longevity and ability to handle specific fluids, making it crucial for industries such as pharmaceuticals, food and beverage, and chemicals. Choosing the right material can prevent costly downtime and maintenance.

2. Pressure Rating

The pressure rating, often measured in psi (pounds per square inch), indicates the maximum pressure the valve can withstand without failure. A higher pressure rating allows for greater flexibility in application, particularly in high-pressure systems. Understanding the pressure requirements ensures that the valve can safely operate within the intended environment, preventing leaks and system failures.

3. Orifice Size

Orifice size, typically measured in millimeters, determines the flow capacity of the valve. A larger orifice allows for higher flow rates, which can be critical in applications requiring rapid fluid transfer. Selecting the appropriate orifice size is essential for maintaining system efficiency and meeting production demands, especially in high-volume industries.

Illustrative image related to diafragma valve

4. Temperature Range

The temperature range specifies the limits within which the valve can operate effectively. This property is particularly important in applications involving hot or cold fluids. Selecting a valve with an appropriate temperature rating ensures reliable performance and reduces the risk of material degradation or failure.

5. Actuation Type

Diaphragm valves can be actuated manually, pneumatically, or electrically. The choice of actuation impacts operational efficiency and control precision. For example, pneumatic actuation is preferred in automated systems for its speed and reliability, while manual actuation may suffice for smaller operations. Understanding the operational needs will help in selecting the most suitable actuation method.

6. Flow Characteristics

Flow characteristics describe how the valve affects fluid dynamics, including factors like flow coefficient (Cv) and flow pattern (linear or equal percentage). These characteristics are vital for ensuring that the valve performs as needed under varying conditions. A proper understanding of flow characteristics helps in optimizing system design and achieving desired process outcomes.

What Are Common Trade Terms Related to Diaphragm Valves in B2B Transactions?

Navigating the procurement of diaphragm valves requires familiarity with industry-specific terminology. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of diaphragm valves, working with OEMs can ensure that you receive components that meet specific quality standards and are compatible with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory levels and costs effectively. It can also influence purchasing decisions, especially when dealing with specialized components like diaphragm valves.

3. RFQ (Request for Quotation)

An RFQ is a standard business process in which a company invites suppliers to bid on providing specific goods or services. When purchasing diaphragm valves, issuing an RFQ allows buyers to compare pricing, terms, and specifications from various suppliers, leading to informed purchasing decisions.

4. Incoterms

Incoterms (International Commercial Terms) are international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for understanding shipping, insurance, and delivery responsibilities, ensuring smooth logistics and compliance.

Illustrative image related to diafragma valve

5. CIP (Carriage and Insurance Paid To)

CIP is an Incoterm that indicates the seller is responsible for the cost of transportation and insurance to a specified destination. This term is particularly relevant for B2B buyers who need clarity on shipping costs and risk management when importing diaphragm valves.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product reliability in their respective industries.

Navigating Market Dynamics and Sourcing Trends in the diafragma valve Sector

What Are the Current Market Dynamics Impacting the Diaphragm Valve Sector?

The diaphragm valve market is currently driven by several global factors, including the increasing demand for reliable fluid control solutions in various industries such as pharmaceuticals, food and beverage, and chemical processing. Key trends include the rise of automation technologies and Industry 4.0, which enhance operational efficiency and reduce manual errors. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to optimize their operations, there is a growing interest in smart diaphragm valve systems equipped with IoT capabilities for real-time monitoring and predictive maintenance.

Emerging sourcing trends highlight the importance of supplier reliability and advanced manufacturing capabilities. Buyers are increasingly favoring manufacturers that employ precision engineering and offer customizable solutions tailored to specific applications. Moreover, as global supply chains adapt to geopolitical shifts, companies are prioritizing local sourcing to mitigate risks associated with international logistics. This shift allows B2B buyers to maintain a steady supply of diaphragm valves while also reducing lead times.

How Is Sustainability Shaping the Diaphragm Valve Supply Chain?

Sustainability has become a cornerstone of modern procurement strategies, particularly for B2B buyers concerned about environmental impacts. The diaphragm valve industry is no exception, with manufacturers increasingly adopting eco-friendly practices and materials. For instance, valves made from recyclable materials and those that conform to FDA standards for food safety are gaining traction.

Ethical sourcing is critical for maintaining brand integrity and consumer trust. Companies are now scrutinizing their supply chains to ensure that all materials are sourced responsibly, minimizing environmental impact and ensuring fair labor practices. Certifications such as ISO 14001 (Environmental Management) and EcoLabel are becoming essential benchmarks for buyers looking to make sustainable choices. By prioritizing suppliers with these certifications, B2B buyers not only contribute to environmental conservation but also enhance their own brand reputation in an increasingly eco-conscious market.

What Is the Historical Context of Diaphragm Valves in Industrial Applications?

Diaphragm valves have evolved significantly since their inception in the early 20th century. Initially designed for basic fluid control, advancements in materials and manufacturing processes have transformed them into versatile components suitable for a wide range of applications. The introduction of elastomeric diaphragms and corrosion-resistant materials has enhanced their performance, particularly in industries requiring high hygiene standards, such as pharmaceuticals and food processing.

As industries have become more complex, the diaphragm valve’s design has adapted to meet new challenges, such as the need for precise flow control in automated systems. This evolution underscores the valve’s role as a critical element in modern industrial applications, making it a focal point for international B2B buyers seeking reliable and efficient fluid management solutions.

In summary, understanding the current market dynamics, embracing sustainability, and recognizing the historical evolution of diaphragm valves are essential for B2B buyers aiming to navigate this sector effectively. By leveraging these insights, businesses can make informed decisions that align with their operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of diafragma valve

-

How do I solve issues with diaphragm valve leaks?

Leaks in diaphragm valves can often be traced back to worn or damaged diaphragms, improper installation, or unsuitable materials. To address these problems, first, inspect the diaphragm for any signs of wear or tears. If damaged, replace the diaphragm with a compatible part made from materials suitable for the fluids being handled. Ensure that all seals and fittings are tight and correctly installed. Additionally, consider the operating pressure and temperature to ensure they align with the diaphragm’s specifications. -

What is the best diaphragm valve for high-viscosity fluids?

For high-viscosity fluids, a diaphragm valve with a larger orifice size and a robust design is recommended. Look for valves specifically designed to handle thick materials, such as those made from PTFE or other chemical-resistant materials. Additionally, valves with a pneumatic actuator may provide better control over flow rates, essential for managing viscous fluids. Always consult the manufacturer’s specifications to ensure compatibility with your fluid’s viscosity and composition. -

How can I ensure quality assurance when sourcing diaphragm valves?

To ensure quality assurance when sourcing diaphragm valves, request documentation from suppliers, including certifications, product specifications, and test results. Consider suppliers who adhere to international quality standards such as ISO 9001. Conduct factory audits if possible, and seek references from other clients. Additionally, inquire about the supplier’s warranty and return policy, which can provide insight into their commitment to quality. -

What should I consider when customizing diaphragm valves for specific applications?

When customizing diaphragm valves, consider factors such as the fluid type, temperature, pressure, and flow requirements. Discuss material options with the supplier to ensure chemical compatibility and durability. Additionally, think about the valve’s size and configuration to fit your system. A detailed specification sheet can help communicate your needs effectively to the manufacturer, ensuring the final product meets your operational requirements. -

What are the minimum order quantities (MOQs) for diaphragm valves?

Minimum order quantities (MOQs) for diaphragm valves can vary significantly based on the manufacturer and the specific valve type. Typically, MOQs can range from a few pieces to hundreds, especially for customized valves. It’s advisable to clarify MOQs upfront with potential suppliers to understand their policies. Some manufacturers may be willing to negotiate MOQs for first-time buyers or larger contracts. -

What payment terms should I expect when purchasing diaphragm valves internationally?

Payment terms for international purchases of diaphragm valves often vary by supplier and the size of the order. Common arrangements include upfront payment, a deposit with the balance due upon shipment, or net payment terms (e.g., 30, 60, or 90 days). Ensure to discuss and agree upon payment methods, such as wire transfers, letters of credit, or PayPal, to find a secure option that works for both parties. Always review the terms thoroughly to avoid misunderstandings. -

How can I vet suppliers of diaphragm valves effectively?

To effectively vet suppliers of diaphragm valves, start by researching their reputation in the industry. Look for reviews, case studies, and testimonials from existing customers. Assess their experience and expertise in producing the specific type of diaphragm valve you need. Additionally, verify their certifications, production capabilities, and after-sales support. Engaging in direct communication can also provide insights into their responsiveness and willingness to collaborate. -

What logistics considerations should I keep in mind when importing diaphragm valves?

When importing diaphragm valves, consider logistics factors such as shipping methods, lead times, and customs regulations in your country. Choose a reliable freight forwarder who understands the complexities of international shipping. Be aware of any tariffs, duties, or taxes that may apply to your import. Additionally, ensure that the supplier provides the necessary documentation for customs clearance, such as invoices and packing lists, to prevent delays in delivery.

Top 5 Diafragma Valve Manufacturers & Suppliers List

1. Bürkert – Diaphragm Control Valves

Domain: burkert.com

Registered: 1995 (30 years)

Introduction: Diaphragm Control Valves from Bürkert are designed for precise control of fluid and gas flow in various industrial applications. They are suitable for a wide range of industries and solutions, providing individual solutions tailored to customer needs. The product line includes features such as high reliability, durability, and the ability to handle different media types. Bürkert also offers additi…

2. GW Kent – Diaphragm Valve

Domain: gwkent.com

Registered: 1999 (26 years)

Introduction: Diaphragm Valve – Various Sizes, In stock, Catalog 905-G. Manual diaphragm valve in 316L stainless steel, sanitary design with complete drainage. Can be sanitized in line with steam (SIP or CIP) or autoclave. Allows precise control of fluid flow rate with low turbulence and minimal back pressure. Diaphragms conform to FDA standards. Surface is mirror polished to prevent contamination, PFA diaphrag…

3. ITT Engineered Valves – Dia-Flo® Diaphragm Valves

Domain: engvalves.com

Registered: 1997 (28 years)

Introduction: ITT Engineered Valves manufactures diaphragm valves, including Dia-Flo® diaphragm valves, which are dependable, cost-effective, and versatile. They are suitable for various chemical applications such as sulfuric acid, hydrochloric acid, hydrofluoric acid, and sodium hydroxide. The valves can handle pressures up to 200 psi (13.8 bar) and temperatures up to 350° F (177° C). Available in weir and str…

4. GEMÜ – Diaphragm Valves

Domain: gemu-group.com

Registered: 2011 (14 years)

Introduction: GEMÜ diaphragm valves are available in various designs including metal aseptic, single-use, and plastic options. They are suitable for sterile processes, pharmaceutical applications, and numerous industrial processes. Key features include:

– Hermetic separation between medium and actuator.

– Stainless steel actuator with gamma-sterilizable diaphragm valve body for single-use valves.

– High-grade p…

5. Alfa Laval – Diaphragm Valves for Ultra-Hygienic Processes

Domain: alfalaval.us

Registered: 2002 (23 years)

Introduction: Diaphragm valves for ultra-hygienic processes, modular design, configurable to specific requirements, ideal for sterile and ultra-hygienic processes, supplied with comprehensive documentation package (Alfa Laval Q-doc) for transparency in sourcing, production, supply chains, and traceability of material changes, manufacturing procedures, or spare parts.

Strategic Sourcing Conclusion and Outlook for diafragma valve

In the competitive landscape of industrial manufacturing, effective strategic sourcing of diaphragm valves is paramount for optimizing operational efficiency and ensuring product quality. These valves are integral across multiple sectors, including pharmaceuticals, food and beverage, and chemical processing, thanks to their ability to deliver precise flow control and maintain hygiene standards. By prioritizing suppliers that offer durable, customizable options tailored to specific industry needs, businesses can significantly enhance their production processes and minimize downtime.

Moreover, understanding the technical specifications and advantages of various diaphragm valve types—such as those with PTFE diaphragms for chemical resistance or those designed for easy cleaning—will empower international buyers to make informed decisions. This diligence not only fosters stronger supplier relationships but also leads to more cost-effective procurement strategies.

Looking ahead, as global markets continue to evolve, the demand for reliable diaphragm valves will only increase. Buyers from regions such as Africa, South America, the Middle East, and Europe should seize this opportunity to engage with manufacturers and distributors who can provide innovative solutions. By doing so, they can position themselves at the forefront of industry advancements and drive sustainable growth. Embrace strategic sourcing today to ensure your operations remain competitive tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to diafragma valve

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.