How to Source Soft Rubber Roller Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for soft rubber roller

In today’s competitive landscape, sourcing the right soft rubber roller can be a daunting challenge for international B2B buyers, especially when navigating a global market filled with diverse options and varying quality standards. This guide is designed to simplify the procurement process by providing comprehensive insights into the types, applications, and sourcing considerations of soft rubber rollers. From understanding the nuances of hardness ratings to identifying the best suppliers, this resource will equip businesses across Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—with the knowledge they need to make informed purchasing decisions.

Soft rubber rollers play a crucial role in various applications, including printmaking, engraving, and industrial uses. The effectiveness of these rollers can significantly impact the quality of the final product, making it essential for buyers to understand the differences in materials, sizes, and hardness levels. Furthermore, this guide delves into supplier vetting processes, cost considerations, and market trends, ensuring that you can navigate the complexities of the global market with confidence.

By leveraging the insights offered in this guide, B2B buyers will be empowered to select high-quality soft rubber rollers that meet their specific needs, ultimately enhancing their operational efficiency and product quality. Whether you are a small business or a large manufacturer, the information provided will serve as a valuable tool in your procurement strategy.

Understanding soft rubber roller Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Soft Rubber Brayer | Made from natural latex, available in various sizes (1.5″ to 6″) | Printmaking, scrapbooking, stamping | Pros: Excellent ink distribution; versatile. Cons: Can become sticky over time. |

| Professional Soft Roller | Medium hardness (30 Shore), robust construction | Engraving, lithography, collagraphs | Pros: Durable; suitable for detailed work. Cons: Higher price point than standard rollers. |

| Lino Printing Roller | Soft rubber designed for uneven surfaces, 25-70 Shore | Relief printing, fine art reproduction | Pros: Captures fine details; multiple sizes available. Cons: May require specific maintenance. |

| Pop-In Roller | Interchangeable roller heads for various textures | Crafting, mixed media projects | Pros: Flexibility to switch rollers; multipurpose. Cons: Initial investment in multiple heads. |

| Heavy-Duty Rubber Roller | Sturdy metal core, designed for heavy applications | Industrial printing, large-scale production | Pros: High durability; can handle thick inks. Cons: Bulkier and heavier, may require more effort to use. |

What Are the Characteristics of Soft Rubber Brayers?

Soft rubber brayers are crafted from natural latex and come in a range of sizes, typically from 1.5 inches to 6 inches in width. Their flexibility and soft texture make them ideal for evenly distributing ink across various surfaces, making them a staple in printmaking, scrapbooking, and stamping. When considering a purchase, buyers should evaluate the brayer’s size in relation to their projects, as a wider roller can cover more area efficiently. However, potential buyers should be aware that these rollers can become sticky over time and may require maintenance to ensure optimal performance.

How Do Professional Soft Rollers Differ from Standard Options?

Professional soft rollers are designed for more specialized applications, such as engraving and lithography. With a medium hardness rating of 30 Shore, these rollers provide a robust option for detailed inking tasks. Their construction typically features high-quality materials, ensuring durability under repeated use. B2B buyers should consider the specific needs of their projects; while these rollers offer precision and reliability, they often come at a higher price point compared to standard soft rollers.

What Makes Lino Printing Rollers Unique?

Lino printing rollers are specifically designed for relief printing techniques, featuring a soft rubber composition that allows for optimal ink transfer on uneven surfaces. They are available in various shore hardness ratings, from 25 to 70, which affects their flexibility and suitability for different applications. These rollers are particularly effective for capturing intricate details in fine art reproduction. When purchasing, businesses should assess the hardness level needed for their specific projects, as softer rollers may be better for detailed work while firmer options are suitable for broader applications.

Why Choose Pop-In Rollers for Versatility?

Pop-in rollers stand out due to their interchangeable heads, allowing users to switch between different textures and applications easily. This versatility makes them suitable for crafting and mixed media projects, where varying effects are desired. Buyers should consider the initial investment in multiple roller heads, as this can enhance their creative capabilities. While they offer flexibility, the need to manage various components may require additional organization.

What Are the Benefits of Heavy-Duty Rubber Rollers?

Heavy-duty rubber rollers are built with a sturdy metal core, making them ideal for industrial applications and large-scale printing projects. Their robust design allows them to handle thick inks and provide consistent results. B2B buyers should note that while these rollers are highly durable, their bulkier design may require more effort to maneuver. Businesses looking for reliable performance in demanding environments will find these rollers to be a worthwhile investment, despite the potential drawbacks in handling.

Key Industrial Applications of soft rubber roller

| Industry/Sector | Specific Application of soft rubber roller | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Printmaking | Inking blocks and plates for relief printing | Ensures even ink distribution for high-quality prints | Durability of materials, compatibility with inks, and size options |

| Packaging | Applying adhesive in label and packaging production | Enhances productivity and reduces waste | Roller size, softness, and resistance to adhesive buildup |

| Textile Manufacturing | Roller printing for fabric designs | Achieves precise patterns and consistent results | Material flexibility, ease of cleaning, and ink compatibility |

| Graphic Arts | Stamping and scrapbooking applications | Provides versatility in creative projects | Range of sizes, comfort grip, and weight for handling |

| Engraving and Lithography | Inking for various engraving techniques | Facilitates detailed applications in fine arts | Hardness levels, ease of use, and maintenance requirements |

How is a Soft Rubber Roller Used in Printmaking and What Problems Does It Solve?

In the printmaking industry, soft rubber rollers are essential for inking blocks and plates. They provide an even distribution of ink, which is crucial for achieving high-quality prints with intricate details. These rollers are particularly effective on uneven surfaces, ensuring that every nook and cranny of the printing block is adequately covered. International buyers in regions such as Europe and South America should consider the durability of materials used in the rollers, as well as their compatibility with both oil-based and water-soluble inks.

What Role Does a Soft Rubber Roller Play in Packaging Applications?

In the packaging sector, soft rubber rollers are utilized for applying adhesives during the label and packaging production process. The softness of the roller allows for a gentle application, which minimizes waste and enhances productivity. This is especially important for businesses looking to streamline operations and reduce costs. Buyers from Africa and the Middle East should focus on sourcing rollers that are resistant to adhesive buildup and can be easily cleaned, ensuring consistent performance over time.

How Do Soft Rubber Rollers Enhance Textile Manufacturing Processes?

In textile manufacturing, soft rubber rollers are employed for roller printing, a method that applies designs onto fabrics. The flexibility and softness of these rollers allow for precise pattern application, resulting in vibrant and consistent designs. This application is vital for businesses that require high-quality fabric prints for garments and upholstery. Buyers should prioritize rollers that are compatible with various inks and can withstand the rigors of textile production, ensuring longevity and reliability.

What Benefits Do Soft Rubber Rollers Offer in Graphic Arts?

Within the graphic arts sector, soft rubber rollers are commonly used for stamping and scrapbooking. Their versatility allows artists to achieve diverse effects and patterns, making them a staple tool for creative projects. The ergonomic design of these rollers enhances usability, allowing for extended use without discomfort. When sourcing these tools, buyers should consider the range of sizes available, as well as the weight and balance of the roller for optimal handling.

How Are Soft Rubber Rollers Utilized in Engraving and Lithography?

In engraving and lithography, soft rubber rollers play a crucial role in inking various techniques. They enable artists to apply ink evenly across surfaces, facilitating intricate designs and detailed work. This application is particularly beneficial for fine arts, where precision is paramount. Buyers should take into account the hardness levels of the rollers, as well as their ease of maintenance, to ensure that they meet the specific demands of their artistic processes.

3 Common User Pain Points for ‘soft rubber roller’ & Their Solutions

Scenario 1: Difficulty Achieving Consistent Ink Distribution

The Problem: Many B2B buyers in the printing industry often struggle with achieving uniform ink distribution when using soft rubber rollers, especially when working with intricate designs or uneven surfaces. This inconsistency can lead to subpar print quality, wasted materials, and increased production times, ultimately affecting the bottom line. Buyers may find that the softness of the rubber roller causes excessive ink to be absorbed or leads to uneven application, which can be particularly problematic when using water-based or oil-based inks.

The Solution: To tackle this issue, it’s essential to select the right durometer rating for your specific application. A softer roller (around 25-30 Shore) is beneficial for uneven surfaces as it can conform to the contours, while a firmer roller (40-60 Shore) is more suited for flat surfaces or detailed work. Additionally, consider investing in rollers with a precision-ground finish, as these provide better ink distribution. Regular maintenance is also crucial; clean the roller thoroughly after each use to prevent ink build-up, which can affect performance. Finally, conduct tests with different sizes and types of rollers to identify the optimal combination for your specific printing needs.

Scenario 2: Roller Sticking or Becoming Too Tacky

The Problem: Another common pain point for B2B buyers is encountering soft rubber rollers that become sticky or tacky over time, particularly in humid conditions or after prolonged use. This stickiness can hinder the application process, causing frustration and inconsistency in prints. It may also lead to the roller pulling away from the substrate, resulting in misalignment or incomplete prints.

The Solution: To mitigate this issue, buyers should incorporate regular maintenance routines, such as applying a light dusting of corn starch or talc powder to the roller before and after use. This practice can significantly reduce tackiness without affecting ink performance. Additionally, it’s advisable to store rollers in a cool, dry place and to avoid exposure to direct sunlight or extreme temperatures. When sourcing rollers, consider options made from high-quality materials designed to withstand varied environmental conditions, ensuring they remain functional longer. Regularly assess the condition of the rollers and replace them when they start to lose their effectiveness.

Scenario 3: Incompatibility with Various Inks

The Problem: B2B buyers often face challenges when trying to find soft rubber rollers that are compatible with a range of inks, including water-based, oil-based, and specialty inks. This lack of versatility can limit operational efficiency and complicate the supply chain, as businesses may need to stock multiple types of rollers for different ink applications, leading to increased costs and inventory management challenges.

The Solution: To overcome this issue, buyers should prioritize sourcing soft rubber rollers that are explicitly labeled as compatible with various ink types. Look for rollers made from natural latex or synthetic rubber that can effectively handle both oil-based and water-soluble inks. Additionally, suppliers should provide detailed specifications on the roller’s compatibility to help buyers make informed decisions. Engaging with suppliers who offer a range of roller options and conducting trials can help determine which rollers perform best with specific inks. Establishing a long-term partnership with a reliable supplier can also streamline procurement and ensure consistent access to the right rollers for all printing needs.

Strategic Material Selection Guide for soft rubber roller

What Are the Key Materials Used in Soft Rubber Rollers?

When selecting soft rubber rollers for various applications, understanding the material composition is critical for optimizing performance and meeting specific operational requirements. Below, we analyze several common materials used in soft rubber rollers, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Natural Rubber in Soft Rubber Rollers?

Natural rubber is a highly elastic material derived from the sap of rubber trees. Its primary characteristics include excellent flexibility, high tensile strength, and a good resistance to wear and abrasion. Natural rubber rollers can typically withstand moderate temperatures and pressures, making them suitable for a variety of applications.

Pros: Natural rubber is known for its superior grip and ink transfer capabilities, which is essential for printmaking and other applications requiring precision. It is also relatively cost-effective compared to synthetic alternatives.

Cons: However, natural rubber has limitations in terms of chemical resistance, particularly against oils and solvents. Its performance can degrade under extreme temperatures, which may be a concern for operations in hotter climates.

Impact on Application: Natural rubber is particularly compatible with water-based inks, making it ideal for environmentally conscious printing operations.

Considerations for International Buyers: Buyers in regions like Africa and South America should be aware of the availability of natural rubber and its compliance with local environmental regulations. Standards such as ASTM D2000 may apply for quality assurance.

How Does Synthetic Rubber Compare for Soft Rubber Rollers?

Synthetic rubber, such as styrene-butadiene rubber (SBR) or ethylene propylene diene monomer (EPDM), is engineered to enhance specific properties. These materials offer excellent durability, resistance to weathering, and better chemical stability compared to natural rubber.

Pros: Synthetic rubber rollers maintain their performance across a wider temperature range and are less susceptible to degradation from oils and solvents. This makes them versatile for various industrial applications.

Cons: The manufacturing process for synthetic rubber can be more complex and costly, which may affect the overall price point for buyers. Additionally, synthetic materials may not provide the same level of grip as natural rubber.

Impact on Application: Synthetic rubber is suitable for both oil-based and water-based inks, making it a versatile choice for diverse printing needs.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should ensure that synthetic rubber products comply with EU regulations regarding chemical safety and environmental impact, such as REACH.

What Role Does Foam Rubber Play in Soft Rubber Rollers?

Foam rubber is a lightweight alternative that is often used in applications requiring softer contact surfaces. It is characterized by its low density and high compressibility, which allows it to conform to uneven surfaces easily.

Pros: Foam rubber rollers are excellent for delicate applications, providing a gentle touch that minimizes damage to substrates. They are also cost-effective and lightweight, making them easier to handle.

Cons: However, foam rubber is generally less durable than solid rubber options and may wear out more quickly under heavy use. Its compressibility can also lead to inconsistent ink distribution if not managed properly.

Impact on Application: Foam rubber is particularly effective for applications requiring a soft touch, such as printing on sensitive materials or surfaces.

Considerations for International Buyers: Buyers in the Middle East should consider the temperature extremes that foam rubber may face, as high heat can cause it to degrade faster than other materials.

How Does Silicone Rubber Enhance Soft Rubber Rollers?

Silicone rubber is known for its exceptional heat resistance and flexibility. It can withstand high temperatures without degrading, making it ideal for applications that involve heat-sensitive materials.

Pros: Silicone rubber rollers provide excellent durability and can maintain their performance over extended periods. They are also resistant to UV light and ozone, making them suitable for outdoor applications.

Cons: The primary drawback is the higher cost associated with silicone rubber, which may not be justifiable for all applications. Additionally, it may not provide the same level of grip as natural rubber.

Impact on Application: Silicone rubber is compatible with a variety of inks, including both oil-based and water-based formulations, making it a versatile choice for industrial applications.

Considerations for International Buyers: Buyers in Europe should ensure that silicone rubber products meet relevant standards, such as DIN EN ISO 9001, to guarantee quality and safety.

Summary Table of Material Properties for Soft Rubber Rollers

| Material | Typical Use Case for Soft Rubber Roller | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Printmaking with water-based inks | Excellent grip and ink transfer | Poor chemical resistance | Low |

| Synthetic Rubber | Versatile industrial applications | Superior durability and chemical resistance | Higher manufacturing complexity | Medium |

| Foam Rubber | Sensitive surface applications | Gentle touch, cost-effective | Less durable, inconsistent ink distribution | Low |

| Silicone Rubber | High-temperature applications | Exceptional heat resistance | Higher cost, less grip | High |

This guide serves as a strategic resource for international B2B buyers to make informed decisions when selecting soft rubber rollers tailored to their specific needs and operational contexts.

In-depth Look: Manufacturing Processes and Quality Assurance for soft rubber roller

What Are the Key Stages in the Manufacturing Process of Soft Rubber Rollers?

The manufacturing of soft rubber rollers involves several critical stages that ensure the final product meets industry standards for quality and performance.

-

Material Preparation: The first step in manufacturing soft rubber rollers is the selection and preparation of raw materials. Typically, high-quality natural latex or synthetic rubber is chosen based on the desired properties, such as softness and durability. The rubber is mixed with various additives, including stabilizers and colorants, to enhance performance characteristics. This mixture is then subjected to rigorous quality checks to ensure consistency and compliance with specifications.

-

Forming: Once the material is prepared, it undergoes the forming process. This can be done using various techniques such as extrusion or molding. In extrusion, the rubber mixture is forced through a die to create a continuous shape, while molding involves pouring the rubber into a pre-designed mold. Both methods must ensure that the roller achieves the correct dimensions and surface finish. Precision is crucial here, as even minor discrepancies can affect the roller’s performance in applications.

-

Assembly: After forming, the rollers are assembled with their handles or cores. This is particularly important for brayers or rollers that require ergonomic handles for user comfort. The assembly process must be executed carefully to ensure that the components fit snugly together, which contributes to the roller’s overall stability and functionality.

-

Finishing: The finishing stage involves surface treatment and inspection. This may include polishing, grinding, or coating to enhance surface smoothness and reduce friction during use. Additionally, the rollers are subjected to a final quality inspection to identify any surface defects or imperfections. This stage is crucial for ensuring that the rollers can operate effectively across various surfaces and applications.

What Quality Assurance Standards Are Relevant for Soft Rubber Rollers?

Quality assurance in the manufacturing of soft rubber rollers is essential to meet both customer expectations and regulatory requirements. Several international and industry-specific standards apply.

-

ISO 9001 Certification: This is a globally recognized standard for quality management systems (QMS). Manufacturers with ISO 9001 certification demonstrate their commitment to maintaining high-quality processes and continuous improvement. For B2B buyers, sourcing from ISO-certified suppliers can provide assurance of consistent product quality.

-

CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards. This is particularly relevant for buyers in Europe, as it ensures that the products meet stringent EU regulations.

-

API Standards: For manufacturers supplying to the oil and gas sector, compliance with American Petroleum Institute (API) standards may be necessary. This includes specific performance criteria for products used in harsh environments.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) is integrated at multiple checkpoints during the manufacturing process to ensure that each soft rubber roller meets the required specifications.

-

Incoming Quality Control (IQC): This initial inspection phase evaluates the quality of raw materials before production begins. Suppliers of rubber and additives are scrutinized to ensure they meet quality standards. Proper documentation and certifications from suppliers are vital for this phase.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators monitor various parameters, including temperature, pressure, and material consistency. This real-time monitoring helps identify and rectify any deviations from the established quality benchmarks before they escalate into larger issues.

-

Final Quality Control (FQC): Once the rollers are manufactured and assembled, they undergo comprehensive testing to assess their performance characteristics. This includes checking for hardness (measured in Shore durometer), flexibility, and surface quality. Any rollers that do not meet the specified criteria are rejected or reworked.

What Testing Methods Are Commonly Used to Ensure Quality?

To guarantee that soft rubber rollers perform as expected, manufacturers employ various testing methods:

-

Durometer Testing: This method measures the hardness of the rubber, which is critical for determining its suitability for specific applications. Different applications may require rollers with varying hardness levels, and this test ensures compliance with those requirements.

-

Adhesion Testing: For rollers designed for printing and coating applications, adhesion testing is performed to ensure that the ink or coating adheres properly to the roller surface. This is crucial for achieving consistent quality in printed materials.

-

Durability Testing: Rollers may be subjected to wear and tear tests to assess their longevity. This can include repeated use cycles under different conditions to simulate real-world applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to mitigate risks and ensure product reliability.

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards. Buyers can assess whether the supplier adheres to best practices in manufacturing and quality assurance.

-

Quality Reports and Certifications: Requesting documentation of quality certifications, such as ISO 9001 or CE marking, can help verify a supplier’s commitment to quality. Regular quality reports detailing performance metrics and testing results can also be valuable.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing and quality control processes. This is especially useful for buyers unfamiliar with local suppliers or those entering new markets.

What Are the Specific QC Considerations for International Buyers?

B2B buyers operating in diverse international markets must be aware of specific quality control considerations that can vary by region:

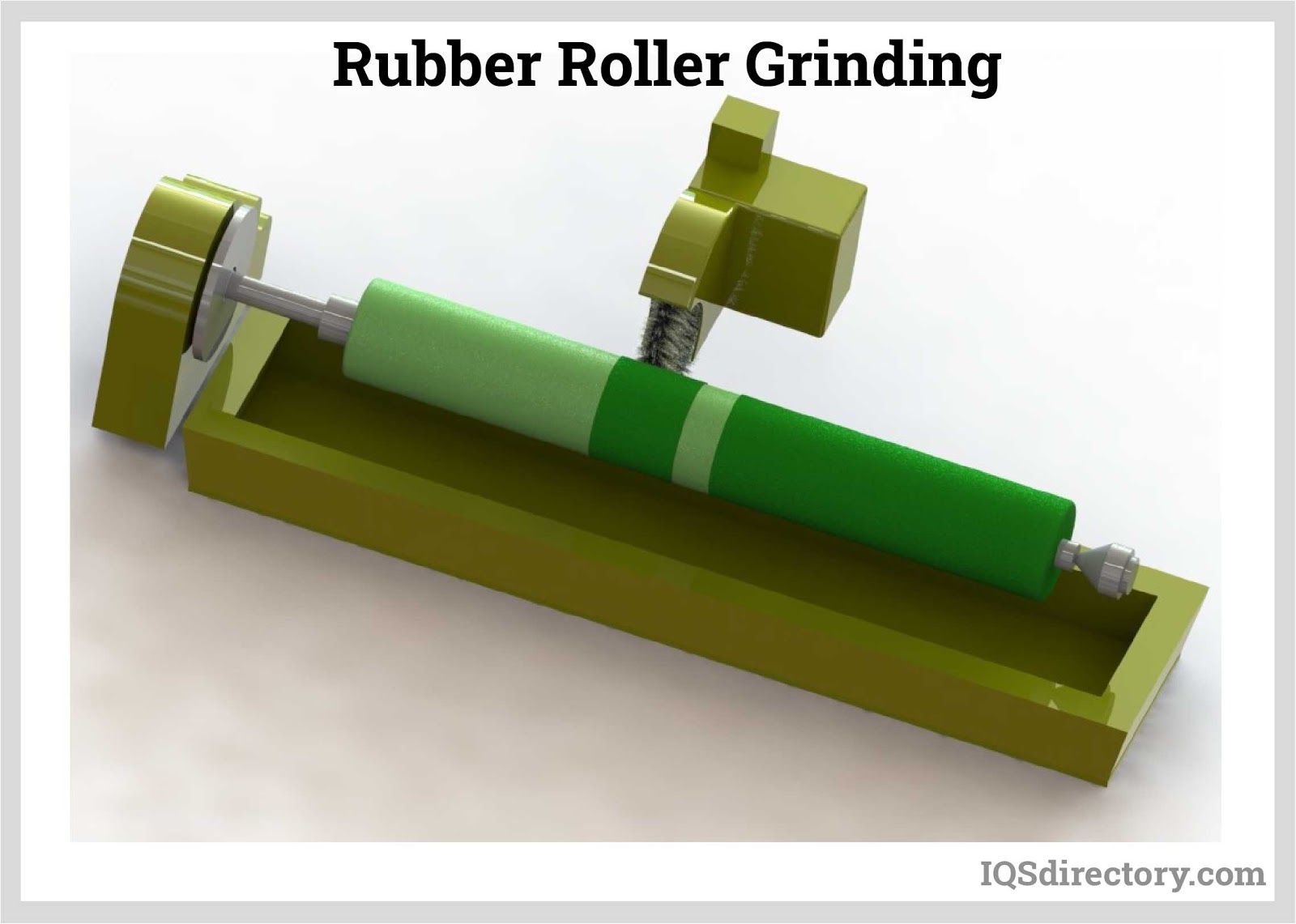

Illustrative image related to soft rubber roller

-

Regulatory Compliance: Different countries may have distinct regulations regarding product safety and quality. For example, products exported to the EU must comply with CE marking requirements, while those for the U.S. market may need to meet specific API standards.

-

Cultural Differences in Quality Expectations: Buyers should consider cultural differences that may affect quality expectations. For instance, European buyers may prioritize stringent quality controls, while other regions might have more flexible standards.

-

Logistics and Supply Chain Management: International buyers must also consider the implications of shipping and logistics on product quality. Ensuring that products are handled correctly during transport and storage is vital to maintain quality upon arrival.

By understanding the manufacturing processes and quality assurance practices associated with soft rubber rollers, B2B buyers can make informed decisions and select suppliers that align with their quality standards and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘soft rubber roller’

When sourcing soft rubber rollers, it is essential to take a structured approach that ensures quality, suitability, and cost-effectiveness. This checklist serves as a practical guide for B2B buyers looking to procure soft rubber rollers tailored to their specific needs.

Step 1: Define Your Technical Specifications

Begin by determining the specific requirements for your soft rubber rollers. Consider factors such as the hardness (measured in Shore), size, and intended application (e.g., printmaking, engraving). Understanding these parameters will help you select the right product for your manufacturing or artistic processes.

- Hardness: Softer rollers (e.g., 25-40 Shore) are ideal for uneven surfaces, while firmer rollers (e.g., 60-80 Shore) suit precise applications.

- Size: Ensure the roller size aligns with your work dimensions; a slightly wider roller than the surface to be inked is often recommended.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify potential suppliers. Look for manufacturers and distributors with a solid reputation in the industry, particularly those that specialize in printing and engraving tools.

- Certifications: Check for quality certifications like ISO or relevant industry standards.

- Reviews and Testimonials: Seek feedback from other businesses regarding their experiences with the suppliers.

Step 3: Evaluate Product Quality

Assess the quality of the soft rubber rollers offered by potential suppliers. Request samples if possible to evaluate the material, durability, and performance firsthand.

- Material Composition: Ensure that the rubber used is of high quality, such as natural latex or synthetic alternatives, suitable for your specific application.

- Performance Testing: Inquire if the rollers have been tested for even ink distribution and ease of use.

Step 4: Compare Pricing Structures

Once you have shortlisted suppliers, compare their pricing models. While it’s essential to find competitive pricing, ensure that it reflects the quality and service provided.

- Bulk Discounts: Inquire about pricing tiers for larger orders, which can significantly reduce costs.

- Hidden Costs: Be wary of additional fees such as shipping, handling, and potential import duties, especially when sourcing from international suppliers.

Step 5: Verify Supplier Certifications

Before finalizing your order, confirm that the supplier holds all necessary certifications and complies with safety and quality standards.

- Quality Assurance: Look for suppliers with a clear quality assurance process in place.

- Sustainability Practices: Consider suppliers that adhere to environmentally friendly practices, as this can reflect on your brand’s commitment to sustainability.

Step 6: Establish Clear Communication

Effective communication is vital throughout the sourcing process. Ensure you have direct lines of contact with suppliers for timely responses to inquiries and concerns.

- Language Proficiency: Given the international nature of sourcing, ensure that communication is clear and effective, ideally in a common language.

- Regular Updates: Request regular updates on order status, especially for larger or custom orders.

Step 7: Finalize Terms and Conditions

Before placing your order, review and agree upon all terms and conditions with your supplier. This includes delivery timelines, payment terms, and return policies.

- Contract Review: Consider having a legal expert review the contract to protect your interests.

- Flexibility in Terms: Ensure there is room for negotiation regarding terms to accommodate any future changes in order size or delivery needs.

By following this checklist, B2B buyers can navigate the sourcing process for soft rubber rollers with confidence, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for soft rubber roller Sourcing

What Are the Key Cost Components in Sourcing Soft Rubber Rollers?

When sourcing soft rubber rollers, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

- Materials: The type of rubber used (natural versus synthetic) significantly impacts the cost. Higher-quality rubbers that provide better durability and performance, such as those with specific shore hardness ratings, tend to be more expensive.

- Labor: Skilled labor is necessary for the production of high-quality rollers, especially when intricate designs or customizations are involved. Labor costs can vary widely based on geographical location and local wage standards.

- Manufacturing Overhead: This encompasses utilities, factory maintenance, and administrative costs. Efficient manufacturing processes can reduce overhead, ultimately affecting pricing.

- Tooling: Initial costs for molds and equipment can be substantial but are amortized over production runs. Custom tooling for unique specifications can increase costs, which should be factored into the final pricing.

- Quality Control: Ensuring that each batch of rollers meets industry standards requires investment in testing and quality assurance processes, contributing to overall costs.

- Logistics: Transportation and warehousing costs can vary depending on the supplier’s location and the destination market. International shipping may involve additional tariffs and duties, which should be considered in the total cost.

- Margin: Suppliers will add a profit margin to cover their costs and ensure business sustainability. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect the Cost of Soft Rubber Rollers?

Several factors can influence the pricing of soft rubber rollers, particularly for international buyers:

- Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce per-unit costs due to economies of scale. Negotiating favorable terms based on volume can lead to significant savings.

- Specifications and Customization: Custom rollers tailored to specific applications or designs may incur additional costs. Standardized sizes and specifications are generally more cost-effective.

- Materials and Quality Certifications: Rollers made from premium materials or those that meet specific certifications (such as ISO) may command higher prices. Buyers should weigh the long-term benefits of quality against initial costs.

- Supplier Factors: Established suppliers with a strong reputation may charge more due to perceived quality and reliability. Conversely, emerging suppliers might offer competitive pricing to enter the market.

- Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, influencing overall costs.

What Are Essential Buyer Tips for Negotiating Soft Rubber Roller Prices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing and cost management:

- Conduct Thorough Research: Familiarize yourself with market prices, supplier capabilities, and industry standards. This knowledge empowers you during negotiations.

- Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with each roller, including maintenance, replacement, and potential downtime. Sometimes, a higher upfront cost can lead to lower TCO.

- Negotiate Payment Terms: Flexible payment options can ease cash flow issues, especially for larger orders. Discussing terms upfront can lead to more favorable arrangements.

- Utilize Multiple Suppliers: Engaging with multiple suppliers can create competitive pressure, resulting in better pricing. However, ensure that quality is not compromised for cost savings.

- Be Aware of Currency Fluctuations: International buyers should consider how currency exchange rates can affect pricing. Locking in rates at favorable times can lead to cost savings.

Conclusion: Understanding Cost and Pricing Dynamics

The sourcing of soft rubber rollers involves a complex interplay of various cost components and price influencers. By grasping these dynamics, B2B buyers can make informed decisions that align with their operational needs and budget constraints. While indicative pricing can provide a baseline, it’s essential to consider the broader context of quality, service, and total cost in making sourcing decisions.

Alternatives Analysis: Comparing soft rubber roller With Other Solutions

Exploring Alternatives to Soft Rubber Rollers for Printmaking Solutions

When considering tools for printmaking, soft rubber rollers are a popular choice due to their versatility and effectiveness. However, there are alternative solutions that can also achieve similar results, each with unique characteristics and applications. This section provides a detailed comparison of soft rubber rollers against other viable options, helping B2B buyers make informed decisions based on their specific needs.

| Comparison Aspect | Soft Rubber Roller | Hard Rubber Roller | Foam Roller |

|---|---|---|---|

| Performance | Excellent for inking uneven surfaces; offers good ink distribution | Ideal for fine details; less flexible | Provides a unique texture; limited ink coverage |

| Cost | Generally affordable, varying by brand and size | Typically higher due to material quality | Usually low-cost, but quality can vary |

| Ease of Implementation | Easy to use; versatile across different inks | Requires more technique for best results | Simple application; best for specific effects |

| Maintenance | Requires basic cleaning; can become sticky if not maintained | Durable, minimal maintenance required | Limited care needed, but can wear out quickly |

| Best Use Case | Great for linoleum, soft block, and woodcut printing | Best for detailed block printing and fine lines | Suitable for texture effects and craft projects |

In-Depth Analysis of Alternatives

1. Hard Rubber Roller

Hard rubber rollers are constructed from a firmer synthetic material, making them ideal for detailed printmaking applications. They offer precise ink application on flat surfaces, ensuring that fine lines are well-defined without excess ink bleeding. However, their rigidity means they may not be suitable for uneven surfaces, which can limit their versatility compared to soft rubber rollers. Additionally, these rollers tend to be more expensive, which could be a consideration for budget-conscious buyers.

2. Foam Roller

Foam rollers are a cost-effective alternative, particularly favored for their ability to create unique textures and patterns in printmaking. They are lightweight and easy to handle, making them an excellent choice for quick projects or craft applications. However, they provide less control over ink distribution, which may not be suitable for detailed work. Foam rollers can also wear out quickly, necessitating more frequent replacements, which can add to long-term costs.

Making the Right Choice for Your Printmaking Needs

Choosing the right roller for your printmaking projects ultimately depends on your specific applications and desired outcomes. If you prioritize versatility and the ability to work on uneven surfaces, a soft rubber roller is likely your best option. However, if your focus is on detailed work with fine lines, a hard rubber roller may provide the precision you need. For those exploring creative textures, a foam roller offers an economical solution, albeit with some trade-offs in terms of control and durability.

By assessing the performance, cost, ease of implementation, maintenance requirements, and best use cases of each option, B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for soft rubber roller

What Are the Key Technical Properties of Soft Rubber Rollers?

Soft rubber rollers are essential tools in various applications, particularly in printing and coating processes. Understanding their technical properties can significantly impact purchasing decisions for B2B buyers.

-

Material Grade

The primary material used in soft rubber rollers is natural latex or synthetic rubber, which affects flexibility, durability, and ink adhesion. Higher quality materials can withstand repeated use without degrading, ensuring consistent performance. For B2B buyers, investing in high-grade rollers means reduced replacement costs and improved print quality. -

Durometer Hardness

Measured on the Shore A scale, durometer hardness indicates the roller’s softness or firmness. Common durometer ratings for soft rubber rollers range from 25 to 60 Shore. Softer rollers (lower numbers) are ideal for uneven surfaces, while firmer rollers (higher numbers) provide better ink distribution on flat surfaces. Selecting the right hardness is crucial for achieving the desired print quality and efficiency in production. -

Roller Width and Diameter

Roller width typically ranges from 1.5 inches to 12 inches, while diameter can vary based on application needs. A wider roller can cover more area and distribute ink more efficiently, reducing the time required for printing tasks. B2B buyers should match roller dimensions to their specific application requirements to optimize productivity. -

Core Material

The core of a soft rubber roller can be made from metal or plastic, affecting durability and performance. Metal cores tend to offer greater strength and stability, especially in high-pressure applications, while plastic cores are lighter and may reduce costs. Understanding the core material helps buyers choose a roller that balances performance and budget. -

Tolerance and Precision

Tolerance refers to the allowable deviation in roller dimensions, which is critical for ensuring consistent contact with the printing surface. High precision in manufacturing allows for better performance, especially in intricate printing tasks. Buyers should consider tolerance specifications to ensure compatibility with their equipment and desired output. -

Ink Compatibility

Soft rubber rollers must be compatible with different types of inks, such as oil-based or water-soluble inks. Certain materials may perform better with specific ink types, affecting the quality of prints. Buyers should inquire about ink compatibility to avoid issues during production and ensure optimal results.

What Are Common Trade Terms in the Soft Rubber Roller Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to soft rubber rollers:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products or components that are used in another company’s end product. In the context of soft rubber rollers, buyers might source rollers from OEMs to ensure compatibility with their machinery, ensuring optimal performance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and minimize costs. Suppliers often set MOQs to ensure profitability, so negotiating this term can be vital for bulk purchases. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Buyers should prepare detailed RFQs that outline specifications for soft rubber rollers to receive accurate quotes and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping, including delivery points and risk transfer. Familiarity with these terms can help B2B buyers negotiate better shipping agreements and understand their liabilities during transit. -

Lead Time

This term refers to the amount of time required from placing an order to receiving the product. Understanding lead times for soft rubber rollers is critical for inventory planning and ensuring that production schedules remain on track. -

Durability Rating

A durability rating assesses how well a roller can withstand wear and tear over time. This rating can help buyers gauge the longevity of a product and its overall value, making it a key consideration in the purchasing process.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing soft rubber rollers, ensuring they select products that meet their operational needs while optimizing cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the soft rubber roller Sector

What Are the Key Trends and Market Dynamics in the Soft Rubber Roller Sector?

The global soft rubber roller market is experiencing significant growth, driven by increasing demand across various industries, including printmaking, packaging, and textiles. Key trends include the adoption of advanced manufacturing technologies, such as automation and precision engineering, which enhance product quality and reduce production costs. As international buyers, particularly from Africa, South America, the Middle East, and Europe, explore sourcing opportunities, they should consider the growing trend towards customization. Tailored solutions that meet specific application needs are becoming increasingly popular, allowing manufacturers to differentiate their offerings in a competitive landscape.

Illustrative image related to soft rubber roller

Additionally, the rise of e-commerce has transformed the sourcing process, enabling buyers to access a wider range of suppliers and products. This shift emphasizes the importance of digital tools and platforms for efficient procurement. Buyers are encouraged to leverage online marketplaces and supplier networks to identify reliable vendors and compare prices and specifications. Moreover, understanding regional market dynamics is crucial; for instance, European buyers may prioritize quality and durability, while South American buyers might focus on cost-effectiveness and availability.

How Does Sustainability Influence Sourcing Trends for Soft Rubber Rollers?

As global awareness of environmental issues grows, sustainability has become a central concern in the soft rubber roller sector. Buyers are increasingly scrutinizing the environmental impact of their sourcing decisions, pushing manufacturers to adopt greener practices. This includes utilizing sustainable materials, such as natural rubber or recycled compounds, and minimizing waste through efficient manufacturing processes.

Ethical sourcing is also gaining traction, with buyers seeking suppliers that adhere to fair labor practices and transparent supply chains. Certifications like ISO 14001 for environmental management and Fair Trade can signal a commitment to sustainability and ethical practices, making these attributes essential for buyers looking to enhance their brand reputation.

Furthermore, incorporating ‘green’ materials not only aligns with consumer expectations but can also lead to cost savings in the long run, as regulatory pressures increase. Buyers should prioritize suppliers who demonstrate a clear commitment to sustainability, as this can significantly influence market positioning and customer loyalty.

How Has the Soft Rubber Roller Market Evolved Over Time?

The evolution of the soft rubber roller market reflects broader technological advancements and changing consumer preferences. Initially, these rollers were primarily crafted from natural rubber, which offered flexibility and excellent ink distribution. However, as industries evolved, so did the materials and manufacturing techniques used in roller production.

The introduction of synthetic rubbers has expanded the functional capabilities of rollers, allowing for variations in hardness and durability. This diversification has enabled the production of rollers suitable for specific applications, from fine art printing to industrial applications. Moreover, the rise of digital printing technologies has prompted manufacturers to innovate, leading to the development of specialized rollers that cater to new printing methods.

Today, the soft rubber roller market is characterized by a blend of traditional craftsmanship and modern technology, ensuring that it continues to meet the diverse needs of international B2B buyers. As buyers navigate this dynamic landscape, understanding the historical context can provide valuable insights into current trends and future developments.

Frequently Asked Questions (FAQs) for B2B Buyers of soft rubber roller

-

How do I solve issues with my soft rubber roller becoming sticky?

If your soft rubber roller has become sticky, it can still be used effectively. A simple solution is to lightly dust the roller with corn starch or talc powder. This prevents the surface from becoming tacky and allows for smooth application of inks without impacting performance. Regular maintenance, including cleaning the roller after use and storing it in a cool, dry place, can also help prolong its lifespan and maintain optimal performance. -

What is the best type of soft rubber roller for block printing?

The best soft rubber roller for block printing depends on your specific project requirements. For detailed designs, a softer roller (around 30-40 Shore hardness) is ideal as it adapts to uneven surfaces, ensuring even ink distribution. Conversely, for firmer surfaces or intricate lines, a slightly harder roller (60 Shore) may be preferable. Additionally, consider the size of the roller; a width slightly larger than your block will enhance coverage and efficiency. -

How can I ensure quality when sourcing soft rubber rollers internationally?

To ensure quality, start by vetting suppliers through certifications and customer reviews. Request samples before placing a large order to assess the roller’s performance and durability. Additionally, consider suppliers who provide detailed product specifications and quality assurance processes. It’s also beneficial to inquire about their manufacturing standards and whether they adhere to international quality norms, especially if you’re sourcing from regions with varying quality standards. -

What are the common minimum order quantities (MOQs) for soft rubber rollers?

Minimum order quantities (MOQs) can vary significantly among suppliers, typically ranging from 50 to several hundred units. It is advisable to discuss MOQs with potential suppliers to find a balance between your needs and their production capabilities. Some suppliers may offer flexible MOQs for new customers or bulk discounts, which can be advantageous for smaller businesses looking to test the market before committing to larger orders. -

What payment terms should I expect when purchasing soft rubber rollers?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upon order confirmation, with the balance due before shipping. Some suppliers may offer net terms, allowing payment within 30 to 90 days post-delivery, especially for repeat customers. It is essential to clarify these terms upfront to avoid misunderstandings and ensure smooth transactions, particularly when dealing with international suppliers. -

How can I customize soft rubber rollers for my specific needs?

Most manufacturers offer customization options for soft rubber rollers, including size, hardness, and even branding. To initiate customization, communicate your specific requirements to the supplier, including dimensions, material hardness, and intended use. Be prepared to discuss potential costs and lead times, as customized products may require longer production times. Ensure you receive a prototype or sample for approval before full-scale production begins. -

What logistics considerations should I keep in mind when importing soft rubber rollers?

When importing soft rubber rollers, consider shipping methods, customs duties, and import regulations specific to your country. Evaluate the total landed cost, which includes shipping, taxes, and fees, to avoid unexpected expenses. Collaborating with a logistics partner experienced in international trade can streamline the process, ensuring compliance with regulations and timely delivery. It’s also wise to track your shipments to address any issues that may arise during transit. -

What quality assurance practices should I look for in suppliers of soft rubber rollers?

When evaluating suppliers, inquire about their quality assurance (QA) practices, such as regular testing of raw materials and finished products. Look for suppliers who implement ISO standards or equivalent quality management systems. Request documentation that outlines their QA processes, including inspections and testing protocols. Understanding these practices will help ensure that the rollers you receive meet the required performance and durability standards for your applications.

Top 3 Soft Rubber Roller Manufacturers & Suppliers List

1. Jackson’s Art – Synthetic Rollers & Brayers

Domain: jacksonsart.com

Registered: 2000 (25 years)

Introduction: This company, Jackson’s Art – Synthetic Rollers & Brayers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Speedball – Soft Rubber Brayers

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Soft rubber Speedball brayers work better with Speedball screenprinting ink for printing on fabrics. Hard rubber brayers struggle to pick up ink. The user is considering switching to oil-based Speedball block printing inks, which may be more opaque. Softer brayers pick up more chatter and noise, which can be desirable for uneven matrices. Hard brayers are better suited for oil-based inks, while wa…

3. Rittagraf – Professional Soft Printmaking Roller

Domain: rittagraf.com

Registered: 2021 (4 years)

Introduction: {“name”: “Professional Soft Printmaking Roller”, “brand”: “Rittagraf”, “price”: “€78.00”, “sku”: “31102378”, “width”: “15 cm”, “diameter”: “5 cm”, “hardness”: “30 shores”, “material”: “NBR rubber, varnished wooden handle, steel structure”, “features”: [“one-hand professional roller”, “soft rubber for engraving”, “robust construction”, “good resistance to oils and cleaning products”, “2 support leg…

Strategic Sourcing Conclusion and Outlook for soft rubber roller

In the evolving landscape of printmaking and industrial applications, the strategic sourcing of soft rubber rollers presents significant opportunities for international B2B buyers. By prioritizing quality and compatibility with various inks and substrates, businesses can enhance their production efficiency and output quality. Investing in soft rubber rollers tailored to specific applications—be it for relief printing or other uses—ensures optimal performance, leading to reduced waste and higher customer satisfaction.

Moreover, the demand for soft rubber rollers is on the rise, particularly in diverse markets across Africa, South America, the Middle East, and Europe. This growth underscores the importance of establishing reliable supplier relationships that prioritize both quality and cost-effectiveness. As buyers navigate this competitive landscape, leveraging data-driven sourcing strategies can yield substantial benefits, including improved pricing structures and supply chain resilience.

Looking ahead, the global market for soft rubber rollers is poised for expansion. Now is the time for B2B buyers to evaluate their sourcing strategies and align with manufacturers that offer innovative solutions and exceptional service. Embrace the opportunity to enhance your production capabilities—partner with leading suppliers and secure your position in the market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.