Is Your Nomenclature Plate Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for nomenclature plate

In the complex landscape of global trade, sourcing high-quality nomenclature plates can be a daunting challenge for B2B buyers. Whether you are looking to enhance workplace organization in your offices or provide clear identification for industrial equipment, understanding the nuances of nomenclature plates is essential. This guide is designed to navigate you through the various types, applications, and customization options available, ensuring that you make informed decisions that align with your specific business needs.

As international buyers from regions like Africa, South America, the Middle East, and Europe—particularly Germany and Saudi Arabia—you face unique challenges in supplier vetting, cost management, and compliance with local regulations. This comprehensive resource delves into the intricacies of nomenclature plates, covering everything from materials and design considerations to the most reliable suppliers in the market. By equipping you with actionable insights and practical tips, this guide empowers you to streamline your procurement process, mitigate risks, and ultimately enhance your brand’s visibility and professionalism.

In a world where first impressions matter, the right nomenclature plates can elevate your business’s image. Join us as we explore the essential elements that will help you make strategic purchasing decisions in the global market for nomenclature plates.

Understanding nomenclature plate Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Engraved Name Plates | Customizable text, durable materials like brass or plastic | Offices, reception areas, conference rooms | Pros: Professional appearance, high durability. Cons: May require longer lead times for customization. |

| Printed Name Plates | Full-color printing, lightweight materials like acrylic | Trade shows, promotional events | Pros: Cost-effective, vibrant designs. Cons: Less durable than engraved options. |

| Desk Name Plates | Designed for desktop use, often with stands or holders | Individual workstations, personal branding | Pros: Easy to personalize, enhances workspace aesthetics. Cons: Limited visibility compared to wall-mounted options. |

| Wall-Mounted Signs | Fixed installation, larger size, often includes logos | Building directories, office entrances | Pros: Highly visible, can convey more information. Cons: Permanent installation may limit flexibility. |

| Custom Logo Plates | Incorporates company logos, available in various materials | Branding, client-facing environments | Pros: Strengthens brand identity, professional look. Cons: Higher cost due to customization. |

What are the Characteristics of Engraved Name Plates?

Engraved name plates are crafted from durable materials such as brass, aluminum, or high-quality plastic. They feature customizable text that is etched into the surface, ensuring longevity and resistance to wear. These plates are ideal for corporate environments, particularly in offices and conference rooms, where a professional appearance is crucial. When considering an engraved name plate, buyers should evaluate their customization options, lead times, and the material’s durability to ensure it meets their branding needs.

How Do Printed Name Plates Differ from Other Types?

Printed name plates utilize full-color printing on lightweight materials like acrylic or plastic, making them visually appealing and cost-effective. They are particularly popular for trade shows and promotional events where vibrant designs can attract attention. Buyers should consider the trade-off between aesthetics and durability; while printed plates offer eye-catching designs, they may not withstand harsh environments as well as engraved options.

Why Choose Desk Name Plates for Your Business?

Desk name plates are specifically designed for individual workstations, often featuring stands or holders that allow for easy personalization. They enhance workspace aesthetics and provide a clear identification method for employees. When purchasing desk name plates, businesses should focus on customization options, including font styles and colors, as well as the ease of updating names as personnel changes occur.

What are the Advantages of Wall-Mounted Signs?

Wall-mounted signs are fixed installations that typically feature larger text and can include logos or additional information. They are highly visible, making them suitable for building directories or office entrances. However, buyers should be mindful of the installation process, as these signs are permanent and may require professional installation. Evaluating the location and intended message is essential for maximizing their effectiveness.

How Do Custom Logo Plates Enhance Brand Identity?

Custom logo plates incorporate company logos and branding elements into the design, available in various materials like metal or acrylic. They are essential for creating a professional image in client-facing environments, reinforcing brand identity. While these plates can significantly enhance a company’s visibility, buyers should consider the associated costs of customization and ensure that the materials used align with their brand’s quality standards.

Key Industrial Applications of nomenclature plate

| Industry/Sector | Specific Application of nomenclature plate | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Equipment identification and safety compliance | Enhances workplace safety and operational efficiency | Durability, resistance to environmental factors, customization options |

| Healthcare | Patient room signage and staff identification | Improves patient experience and staff organization | Compliance with health regulations, visibility, and readability |

| Construction | Project site signage and contractor identification | Ensures compliance with regulations and enhances brand visibility | Material durability, weather resistance, and customization capabilities |

| Education | Classroom and office nameplates | Facilitates communication and organization | Customization options, material durability, and design flexibility |

| Hospitality | Guest room identification and service area signage | Enhances guest experience and operational efficiency | Aesthetic appeal, material quality, and customization options |

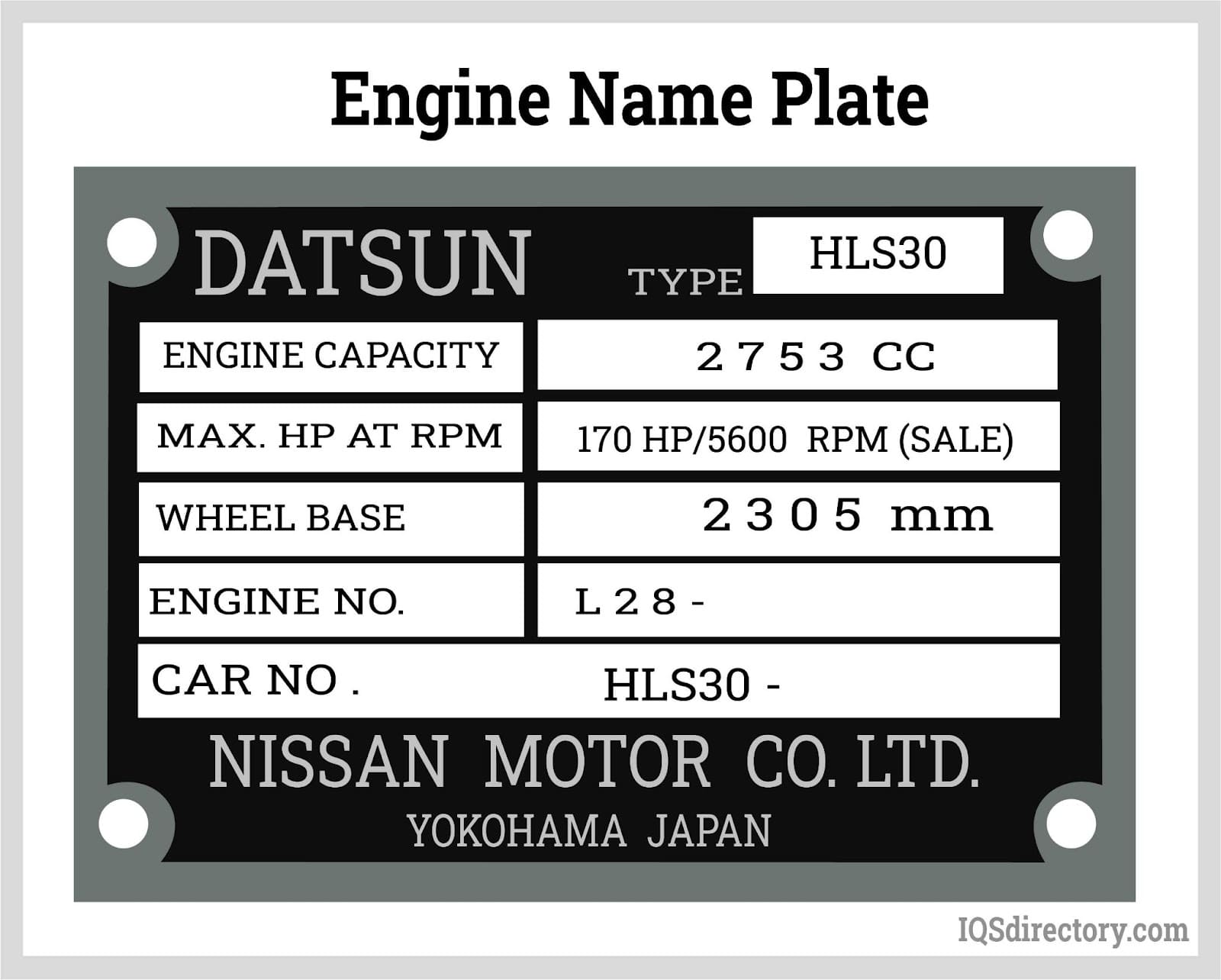

How is Nomenclature Plate Used in the Manufacturing Sector?

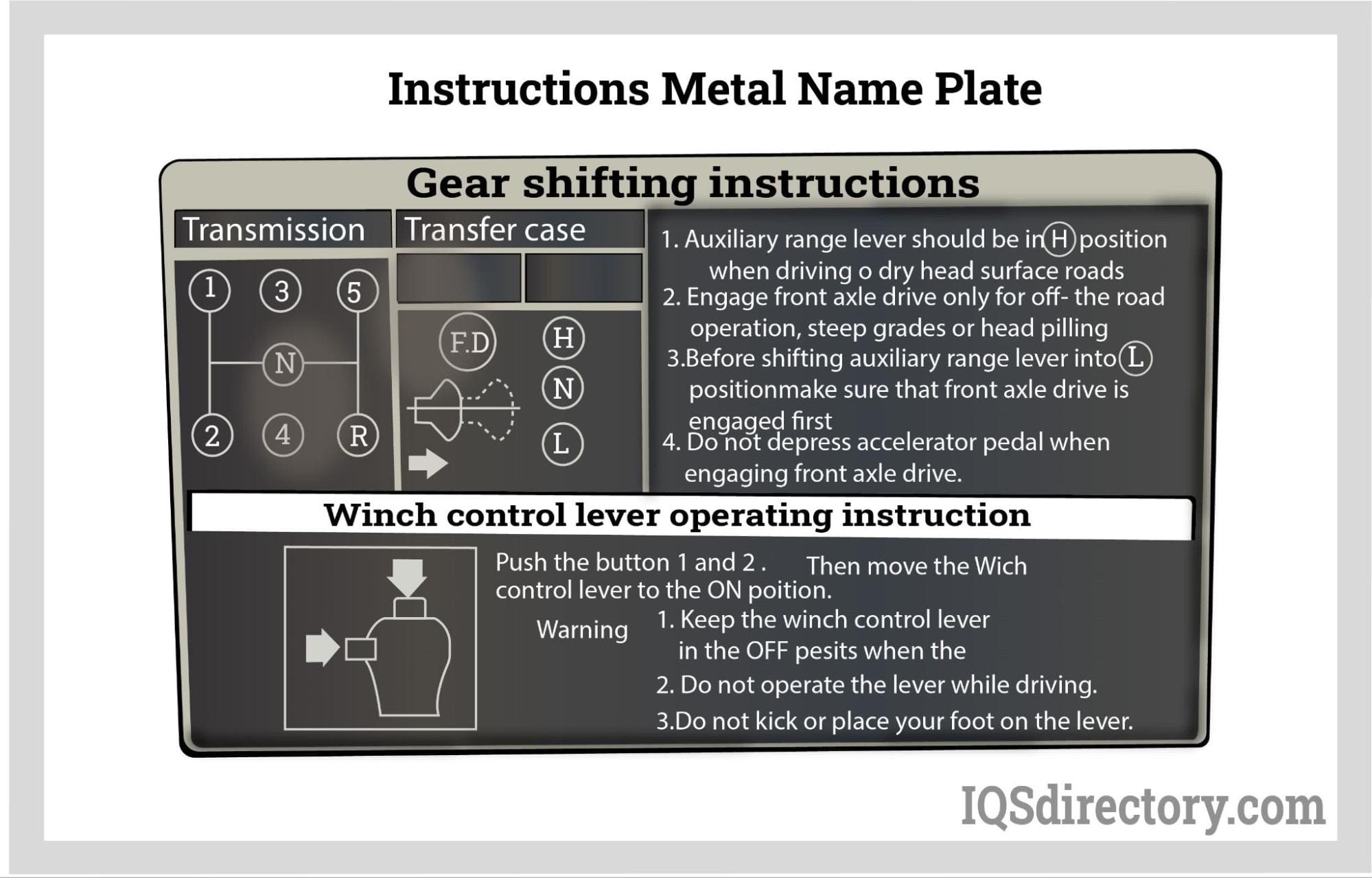

In manufacturing, nomenclature plates are vital for equipment identification and safety compliance. They provide essential information about machinery, such as operational instructions and safety warnings, which are crucial for maintaining workplace safety and efficiency. Buyers in this sector must prioritize durability and resistance to various environmental factors, ensuring that the plates withstand harsh conditions. Customization options are also important, as different machines may require specific information tailored to their functions.

What Role Does Nomenclature Plate Play in Healthcare?

In the healthcare industry, nomenclature plates are commonly used for patient room signage and staff identification. These plates enhance the patient experience by making it easy to identify rooms and services, thereby improving navigation within healthcare facilities. Additionally, clearly labeled staff identification fosters better communication among healthcare professionals. Buyers should consider compliance with health regulations, ensuring that the plates are visible and easily readable to facilitate quick identification.

How is Nomenclature Plate Applied in Construction Projects?

In construction, nomenclature plates serve as project site signage and contractor identification. They help ensure compliance with local regulations by clearly displaying necessary information, such as safety protocols and contractor details. This not only enhances brand visibility but also promotes a professional image to clients and visitors. When sourcing for this application, businesses should focus on material durability and weather resistance, as construction sites are often exposed to harsh environmental conditions.

Why are Nomenclature Plates Important in Educational Institutions?

Educational institutions utilize nomenclature plates for classroom and office nameplates, facilitating communication and organization within the facility. These plates help students and staff identify classrooms, offices, and other areas, promoting a more structured environment. Buyers should look for customization options that allow for unique designs and durability to withstand frequent handling. Material quality is also essential to ensure longevity and a professional appearance.

How Does Nomenclature Plate Enhance the Hospitality Experience?

In the hospitality sector, nomenclature plates are used for guest room identification and service area signage. They play a significant role in enhancing the guest experience by providing clear directions and information about services. This contributes to operational efficiency by helping staff locate areas quickly. When sourcing nomenclature plates for hospitality applications, businesses should consider aesthetic appeal, material quality, and customization options to reflect their brand identity effectively.

3 Common User Pain Points for ‘nomenclature plate’ & Their Solutions

Scenario 1: Navigating Customization Challenges in Nomenclature Plates

The Problem: Many B2B buyers face difficulties when trying to customize nomenclature plates to align with their branding needs. The challenge often lies in the limitations of available materials, colors, and sizes. For instance, a company may require plates that not only feature their logo but also adhere to specific color codes and dimensions that match their branding guidelines. If the nomenclature plates fail to meet these specifications, it can lead to a disjointed brand image and customer confusion. Additionally, buyers might feel overwhelmed by the customization options available, leading to decision fatigue.

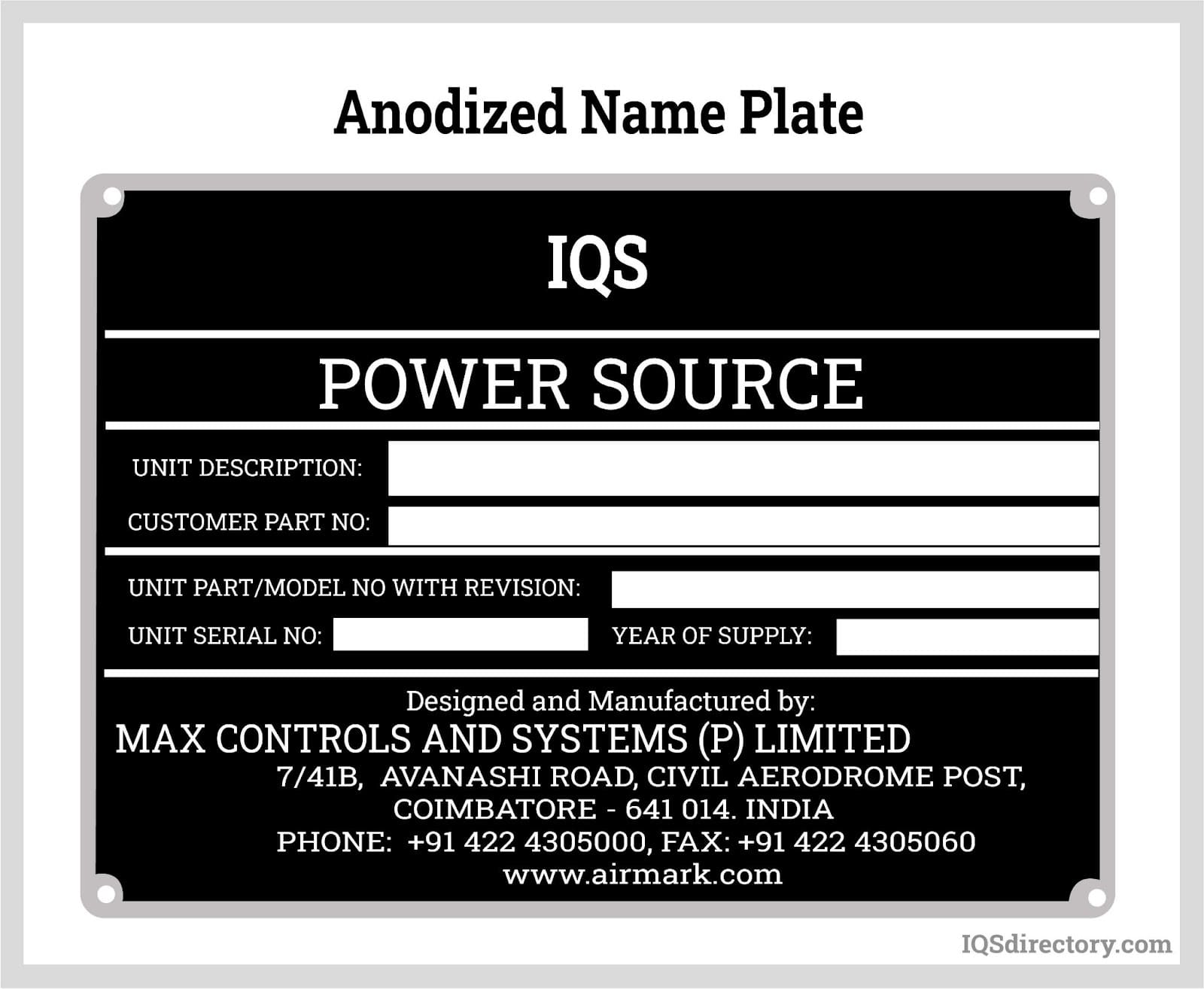

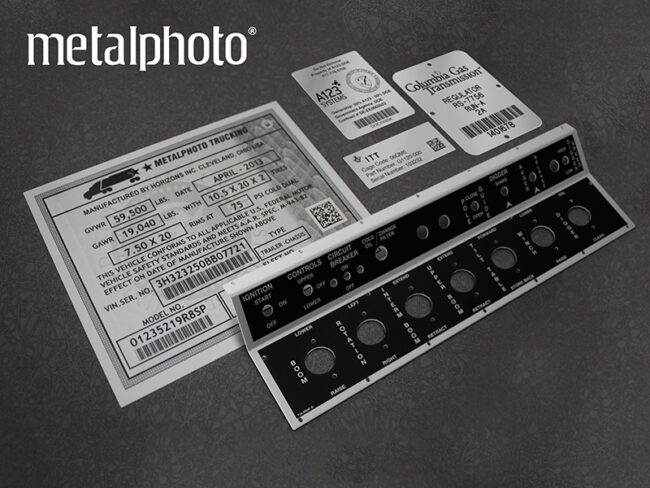

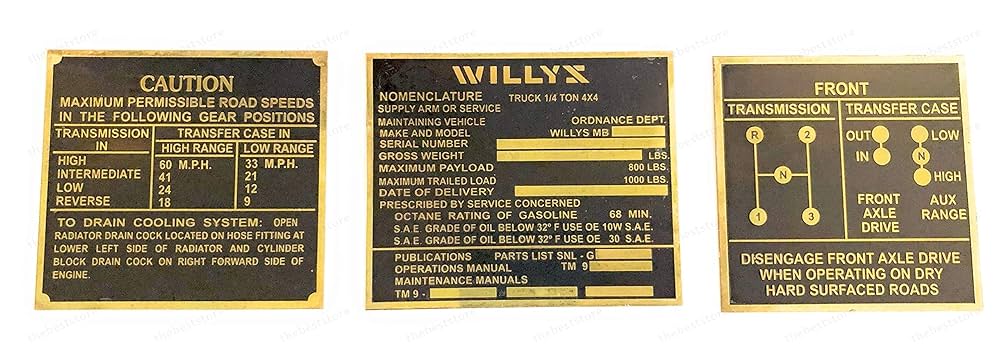

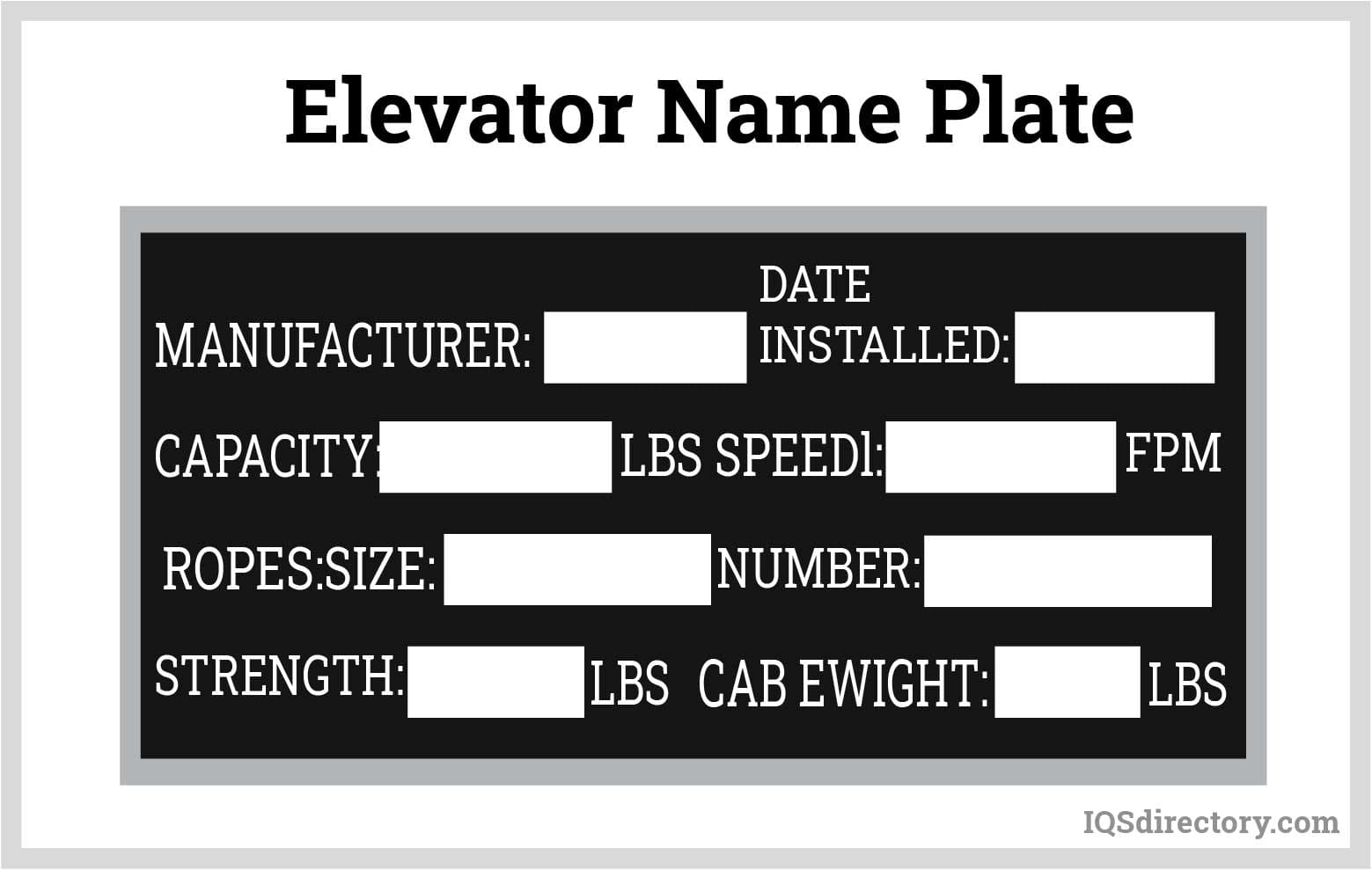

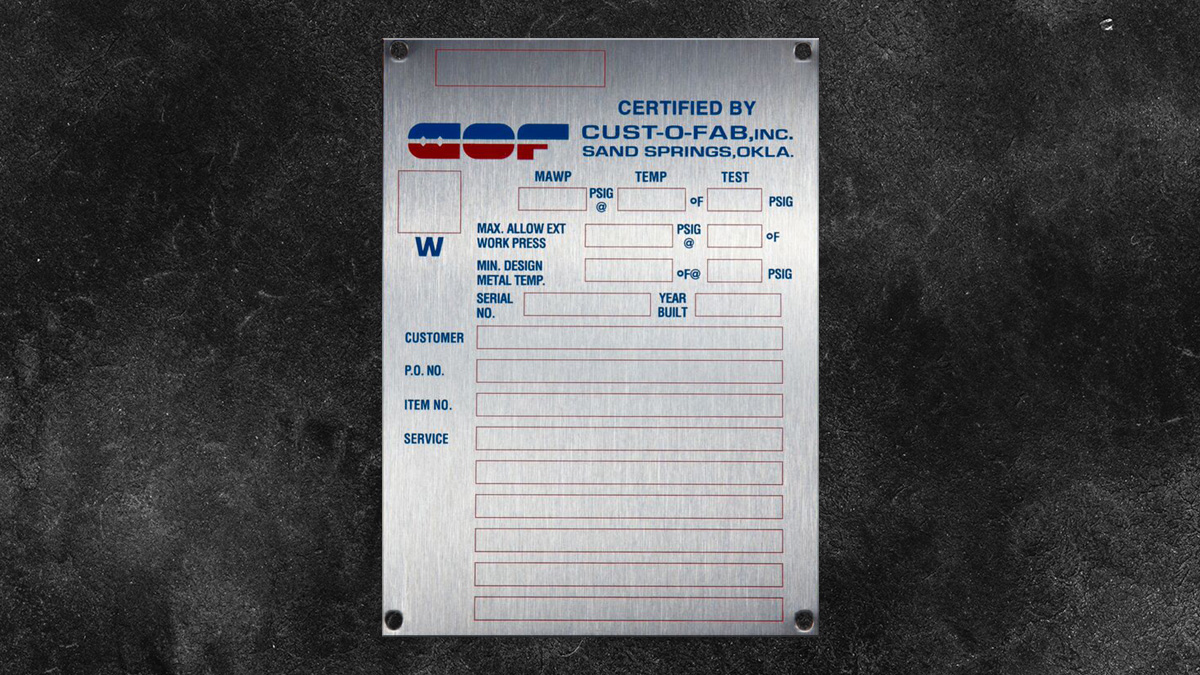

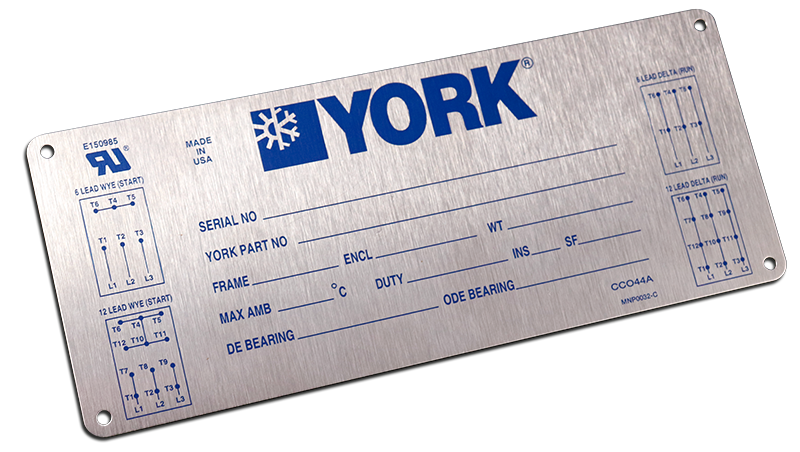

Illustrative image related to nomenclature plate

The Solution: To effectively navigate customization challenges, it’s crucial for buyers to partner with suppliers who offer a robust online design tool. This tool should allow for easy customization of text, fonts, colors, and logos, giving buyers a clear visual representation before finalizing their order. When sourcing nomenclature plates, look for vendors that provide a proofing process. This allows you to review and approve designs, ensuring that all specifications are met. Furthermore, establish clear communication with the supplier regarding your branding requirements, such as Pantone colors and logo placement. This proactive approach minimizes the chances of errors and ensures that the final product aligns perfectly with your brand identity.

Scenario 2: Addressing Durability and Environmental Suitability Concerns

The Problem: Buyers often encounter concerns regarding the durability of nomenclature plates, especially when they are intended for outdoor use or in high-traffic areas. Plates that fade, corrode, or break easily can lead to frequent replacements, resulting in increased costs and operational disruptions. Additionally, buyers must consider environmental factors, such as exposure to extreme weather conditions, which can compromise the longevity of the signage.

The Solution: To address durability concerns, it is essential to choose nomenclature plates made from high-quality, weather-resistant materials such as anodized aluminum or UV-resistant plastics. When sourcing, inquire about the manufacturer’s testing processes and warranties. A reputable supplier will provide information on the longevity of their products under various environmental conditions. Opt for plates that are treated with protective coatings to enhance resistance against fading and corrosion. Furthermore, consider implementing a regular maintenance schedule to inspect and clean the plates, ensuring they remain in optimal condition and prolonging their lifespan.

Scenario 3: Streamlining the Ordering Process for Bulk Purchases

The Problem: Ordering nomenclature plates in bulk can be a complex process that often leads to logistical challenges. B2B buyers may struggle with ensuring consistency across orders, managing inventory, and meeting tight deadlines. This complexity is exacerbated when dealing with multiple locations or departments requiring unique signage, leading to potential miscommunication and errors.

The Solution: To streamline the ordering process for bulk nomenclature plates, establish a centralized ordering system within your organization. Designate a point person responsible for coordinating all signage needs, ensuring that branding guidelines and specifications are uniformly applied across different departments. When selecting a supplier, choose one that offers bulk order discounts and the ability to manage multiple order variations efficiently. A supplier with an intuitive online platform will allow for easy adjustments to orders, enabling you to make changes without starting from scratch. Additionally, utilizing a project management tool can help track orders, manage timelines, and maintain communication with the supplier, ensuring that all signage arrives on schedule and meets the required standards.

Strategic Material Selection Guide for nomenclature plate

What Are the Key Properties of Common Materials for Nomenclature Plates?

When selecting materials for nomenclature plates, it is essential to consider their properties, including durability, resistance to environmental factors, and suitability for specific applications. Here, we analyze four common materials: plastic, aluminum, brass, and stainless steel.

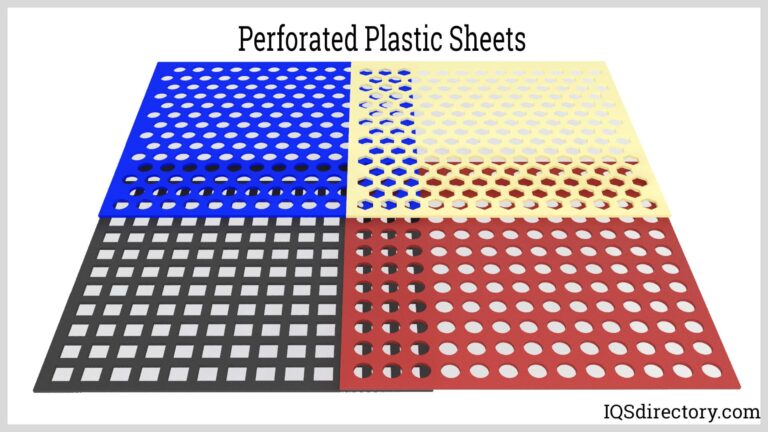

How Does Plastic Perform for Nomenclature Plates?

Plastic is a popular choice for nomenclature plates due to its lightweight nature and versatility. Common types include acrylic and polycarbonate, which offer good impact resistance and can be produced in various colors and finishes. However, plastic typically has a lower temperature tolerance and may degrade under prolonged exposure to UV light.

Pros: Plastic is cost-effective and easily customizable, making it suitable for high-volume production. It is also resistant to corrosion and can be manufactured with various printing techniques.

Cons: While affordable, plastic may not offer the same durability as metal options, especially in harsh environments. It can warp or discolor over time, particularly in extreme temperatures.

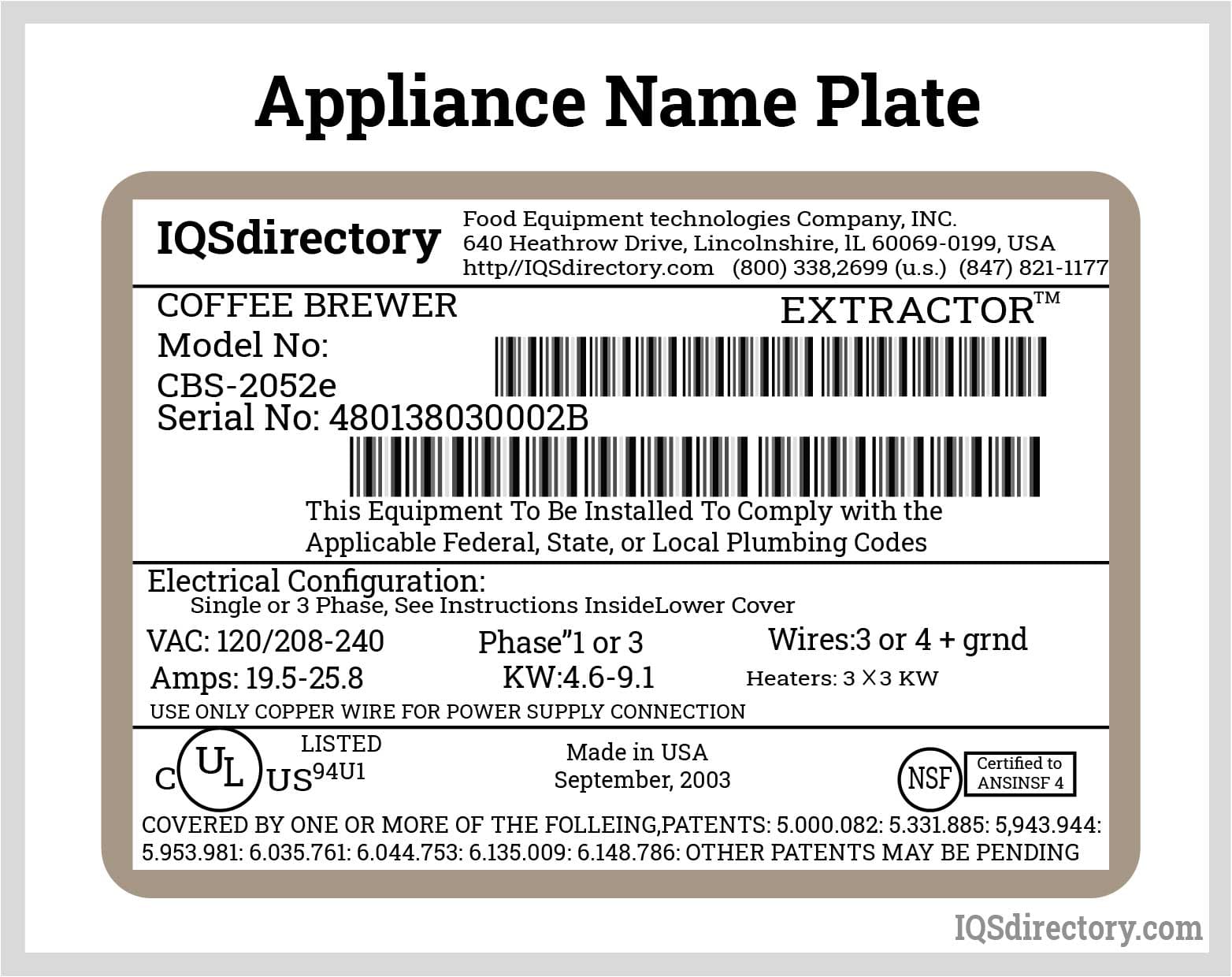

Illustrative image related to nomenclature plate

Impact on Application: Plastic nomenclature plates are ideal for indoor environments or low-stress applications. They may not be suitable for outdoor use unless specifically treated for UV resistance.

Considerations for International Buyers: Ensure compliance with local regulations regarding plastic materials, especially in regions with strict environmental laws. Buyers should also check for certifications like REACH in Europe.

What Are the Advantages of Aluminum for Nomenclature Plates?

Aluminum is favored for its lightweight yet strong characteristics. It offers excellent corrosion resistance, making it suitable for outdoor applications. Aluminum plates can be anodized or painted to enhance aesthetics and durability.

Pros: Aluminum is durable and can withstand a range of temperatures and environmental conditions. It is also relatively easy to machine and engrave, allowing for high-quality finishes.

Cons: While aluminum is more robust than plastic, it can be more expensive. Additionally, it may require protective coatings to prevent scratching and wear.

Illustrative image related to nomenclature plate

Impact on Application: Aluminum is well-suited for both indoor and outdoor environments, particularly in industrial settings where exposure to moisture is common.

Considerations for International Buyers: Verify compliance with standards such as ASTM or DIN for aluminum products, especially in regions like Germany or Saudi Arabia, where quality standards are stringent.

Why Choose Brass for Nomenclature Plates?

Brass is a traditional material known for its aesthetic appeal and durability. It offers excellent corrosion resistance and can withstand high temperatures, making it suitable for various applications.

Pros: Brass provides a classic look that is often preferred for formal settings. It is durable and can be easily engraved, allowing for intricate designs.

Cons: Brass can be more expensive than both plastic and aluminum. It may also tarnish over time, requiring regular maintenance to preserve its appearance.

Impact on Application: Brass is ideal for high-end office environments, reception areas, or luxury settings where aesthetics are paramount.

Considerations for International Buyers: Ensure compliance with local regulations regarding metal use, particularly in regions with specific environmental standards. Buyers should also consider the availability of brass in their local markets.

What Makes Stainless Steel a Reliable Choice for Nomenclature Plates?

Stainless steel is renowned for its strength and resistance to corrosion and heat. It is often used in industrial and outdoor applications due to its durability and low maintenance requirements.

Pros: Stainless steel is incredibly robust and can withstand harsh environmental conditions. It is also aesthetically pleasing, offering a modern look that suits various applications.

Cons: The primary drawback of stainless steel is its higher cost compared to other materials. It can also be heavier, which may be a consideration for certain applications.

Impact on Application: Stainless steel is suitable for environments that require high durability, such as factories, laboratories, and outdoor settings.

Considerations for International Buyers: Verify compliance with international standards such as JIS or ASTM for stainless steel products. Ensure that the grade of stainless steel meets the specific requirements of the intended application.

Summary Table of Material Selection for Nomenclature Plates

| Material | Typical Use Case for nomenclature plate | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Indoor signage, low-stress applications | Lightweight and cost-effective | Lower durability, UV degradation | Low |

| Aluminum | Outdoor and industrial environments | Excellent corrosion resistance | Higher cost, may require coatings | Medium |

| Brass | High-end offices, luxury settings | Aesthetic appeal and durability | Expensive, requires maintenance | High |

| Stainless Steel | Industrial and outdoor applications | High strength and low maintenance | Higher cost, heavier weight | High |

This guide provides a comprehensive overview of material options for nomenclature plates, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for nomenclature plate

What Are the Key Stages in the Manufacturing Process of Nomenclature Plates?

The manufacturing process of nomenclature plates involves several crucial stages, each designed to ensure the final product meets the high standards expected by B2B buyers.

Illustrative image related to nomenclature plate

Material Preparation: What Materials Are Typically Used?

The first step in manufacturing nomenclature plates is material selection and preparation. Common materials include metals like brass, aluminum, and stainless steel, as well as durable plastics and acrylics. The choice of material affects not only the durability and aesthetics of the plate but also its application. For instance, metal plates are often preferred for their robustness in industrial settings, while acrylic may be chosen for its versatility and cost-effectiveness in office environments.

Once the material is selected, it undergoes processes such as cutting and surface treatment to prepare it for the next steps. This may involve cleaning, deburring, and surface polishing to ensure that the material is free from contaminants and defects, which could impact the quality of the final product.

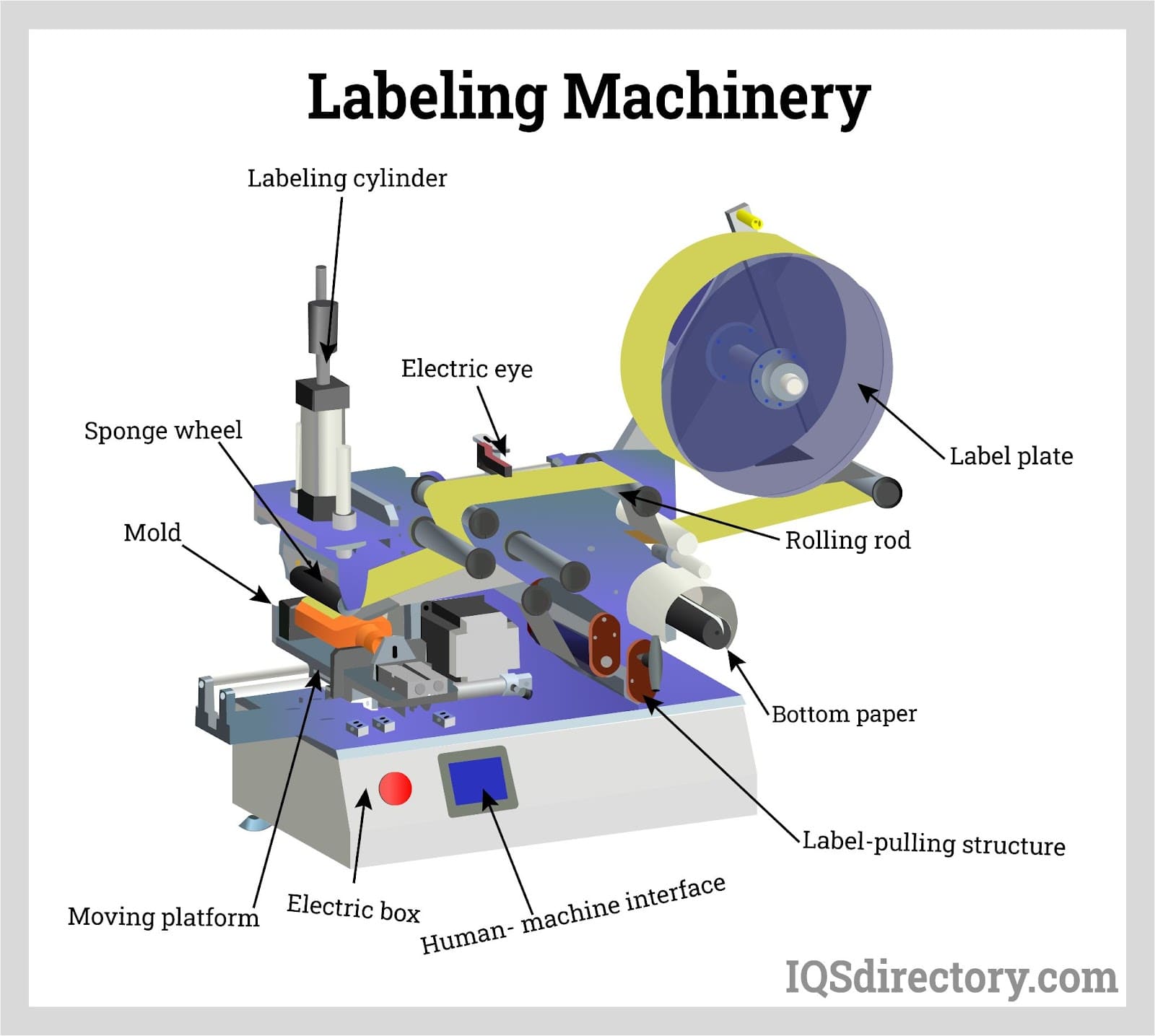

How Are Nomenclature Plates Formed and Assembled?

The forming stage typically involves techniques such as engraving, laser cutting, or stamping. Each technique has its unique advantages; for instance, laser cutting allows for intricate designs and high precision, making it ideal for custom nameplates that require detailed logos or text.

After the initial forming, the assembly stage may come into play, especially if the nomenclature plate includes multiple components, such as mounting hardware or additional decorative elements. This stage ensures that all parts fit together seamlessly, contributing to the overall integrity and functionality of the product.

Illustrative image related to nomenclature plate

What Finishing Techniques Are Applied to Enhance Quality?

Finishing is a critical stage that enhances both the aesthetic appeal and durability of nomenclature plates. Techniques such as anodizing, powder coating, or applying protective films are common. Anodizing, for example, increases corrosion resistance in aluminum plates, while powder coating provides a durable finish that can withstand harsh environments.

This stage may also include quality checks to ensure that the finishes applied meet the required specifications, which is vital for ensuring longevity and performance in various applications.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is essential in the manufacturing of nomenclature plates, as it ensures that the products meet international standards and customer expectations.

What Are the Relevant International Standards for Nomenclature Plates?

International standards such as ISO 9001 are critical for ensuring consistent quality in manufacturing processes. ISO 9001 outlines the requirements for a quality management system (QMS) that organizations must follow to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) standards for industrial applications may also be relevant.

Illustrative image related to nomenclature plate

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify and rectify any issues that may arise. Key checkpoints include:

- Incoming Quality Control (IQC): This is performed on raw materials to ensure they meet specified standards before they enter the production process.

- In-Process Quality Control (IPQC): Conducted during manufacturing, IPQC involves monitoring various stages of production to catch defects early.

- Final Quality Control (FQC): This takes place after production is complete and includes thorough inspections and testing of the finished products to ensure they meet quality standards.

Common testing methods may include dimensional checks, surface finish assessments, and corrosion resistance tests, depending on the materials used and the intended application of the nomenclature plates.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, especially those operating in international markets such as Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control practices of potential suppliers.

What Steps Can Buyers Take to Ensure Supplier Compliance with Quality Standards?

- Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control systems, and adherence to international standards firsthand.

- Requesting Quality Reports: Buyers should request detailed QC reports that document the results of inspections and tests conducted at various checkpoints. These reports provide insight into the supplier’s commitment to quality.

- Third-party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s products and processes, ensuring they comply with the required standards.

What Are the Unique QC and Certification Nuances for International B2B Buyers?

International buyers must be aware of the nuances in quality control and certification requirements that may vary by region. For instance, buyers in Europe may place a higher emphasis on CE certification, while those in the Middle East might prioritize compliance with local standards. Understanding these regional differences is crucial for ensuring that nomenclature plates meet both local and international requirements.

In summary, the manufacturing processes and quality assurance measures for nomenclature plates are integral to ensuring product reliability and performance. B2B buyers should prioritize suppliers with robust QC practices and a commitment to quality standards to ensure they receive products that meet their specific needs and applications.

Illustrative image related to nomenclature plate

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nomenclature plate’

In today’s competitive business landscape, sourcing high-quality nomenclature plates is essential for effective branding and communication within your organization. This guide provides a step-by-step checklist designed for international B2B buyers, helping you navigate the procurement process efficiently.

Step 1: Identify Your Requirements

Before you begin sourcing, clearly define your needs. Consider the type of nomenclature plates required, such as desk plates, wall-mounted signs, or door plaques. Additionally, specify the materials (e.g., metal, plastic, wood) and any design elements like logos or color schemes. This clarity will streamline your search and ensure you communicate effectively with potential suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for manufacturers with a strong reputation in the industry, particularly those with experience serving markets in Africa, South America, the Middle East, and Europe. Utilize online directories, trade shows, and industry forums to gather information. Pay attention to customer reviews and testimonials to gauge reliability and quality.

Illustrative image related to nomenclature plate

Step 3: Evaluate Supplier Capabilities

Once you have a list of suppliers, assess their capabilities. Inquire about their production capacity, lead times, and customization options. A supplier’s ability to meet your volume requirements and deadlines is crucial, especially if you need large quantities or have tight timelines. Also, consider their technological capabilities for engraving or printing, as this can affect the final product quality.

Step 4: Request Samples

Before placing a bulk order, request samples of the nomenclature plates. This step allows you to evaluate the quality of materials, craftsmanship, and finish. When reviewing samples, pay attention to durability, color accuracy, and overall aesthetics. Ensure the samples align with your branding standards to avoid discrepancies in the final order.

Step 5: Verify Certifications and Compliance

Ensure that potential suppliers comply with relevant industry standards and certifications. This is particularly important when sourcing from international suppliers, as regulations can vary significantly. Check for certifications such as ISO for quality management or environmental compliance. This verification helps mitigate risks associated with subpar products and ensures adherence to safety standards.

Step 6: Negotiate Terms and Pricing

Once you’ve selected a preferred supplier, negotiate pricing and terms. Discuss volume discounts, payment terms, and shipping options. It’s essential to clarify all costs upfront to avoid unexpected expenses later. A transparent negotiation process builds a solid foundation for a long-term partnership.

Step 7: Establish a Communication Plan

Effective communication is vital throughout the sourcing process. Set up regular check-ins with your supplier to discuss order progress, potential issues, and any adjustments needed. A clear communication plan fosters collaboration and ensures that both parties are aligned on expectations and timelines.

Illustrative image related to nomenclature plate

By following this checklist, B2B buyers can streamline their sourcing process for nomenclature plates, ensuring they choose the right suppliers and obtain high-quality products that meet their organizational needs.

Comprehensive Cost and Pricing Analysis for nomenclature plate Sourcing

What Are the Key Cost Components in Sourcing Nomenclature Plates?

When sourcing nomenclature plates, understanding the cost structure is crucial for effective budgeting and procurement strategies. The primary cost components typically include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include plastic, brass, aluminum, and wood. Each material varies in cost, durability, and aesthetic appeal, which can influence the final pricing.

-

Labor: Labor costs encompass the expenses associated with the workforce involved in the design, manufacturing, and finishing processes. Skilled labor is often required for tasks like engraving or custom design, which can drive costs up.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Specialized tools and molds are often necessary for custom designs, adding to initial setup costs. These costs can be amortized over larger production runs, making them more manageable for bulk orders.

-

Quality Control (QC): Ensuring that nomenclature plates meet quality standards requires investment in quality control measures, which can include inspections and testing. This is particularly important for international buyers who may face stricter compliance regulations.

-

Logistics: Shipping costs can vary widely based on the supplier’s location, the destination, and the shipping method. Understanding logistics costs is crucial, especially for international shipments where duties and tariffs may apply.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on market competition and the supplier’s pricing strategy.

How Do Price Influencers Affect the Cost of Nomenclature Plates?

Several factors influence the pricing of nomenclature plates, making it essential for buyers to be aware of these elements:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often result in lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk orders, making it beneficial for buyers to consolidate their needs.

-

Specifications and Customization: Custom designs or specific material requirements can lead to increased costs. Buyers should clearly communicate their specifications to receive accurate quotes.

-

Material Quality and Certifications: High-quality materials and industry certifications can drive up costs but may be necessary for compliance with local regulations or industry standards.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: The chosen Incoterms can significantly affect logistics costs and responsibilities. Buyers should carefully consider terms like FOB (Free On Board) or CIF (Cost Insurance and Freight) when negotiating contracts.

What Are the Best Tips for Negotiating Nomenclature Plate Prices?

To maximize value in sourcing nomenclature plates, B2B buyers should consider the following strategies:

-

Negotiate Effectively: Understand the cost structure and leverage it during negotiations. Highlighting your potential for repeat business can also provide leverage.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, handling, and potential maintenance costs over the product’s lifespan.

-

Explore Pricing Nuances for International Purchases: Be aware of currency fluctuations and international shipping costs that can affect pricing. Establishing relationships with local suppliers in Africa, South America, the Middle East, or Europe can also mitigate some of these costs.

-

Request Samples: Before committing to large orders, request samples to assess quality. This can prevent costly mistakes and ensure that the final product meets expectations.

-

Stay Informed About Market Trends: Understanding market conditions can help buyers anticipate price changes and make informed purchasing decisions.

Disclaimer on Pricing

Prices for nomenclature plates can vary significantly based on the aforementioned factors. It is advisable to obtain multiple quotes and conduct thorough market research to ensure competitive pricing. This analysis serves as a guideline; actual prices may differ based on specific requirements and market conditions.

Alternatives Analysis: Comparing nomenclature plate With Other Solutions

Exploring Alternatives to Nomenclature Plates

In the world of business signage and identification solutions, nomenclature plates serve a specific purpose in labeling and branding. However, various alternatives exist that can meet similar needs, each with its own set of advantages and drawbacks. This analysis will compare nomenclature plates against two prominent alternatives: custom desk nameplates and electronic display boards.

Comparison Table

| Comparison Aspect | Nomenclature Plate | Custom Desk Nameplates | Electronic Display Boards |

|---|---|---|---|

| Performance | High durability and clarity | Good visibility, customizable | Dynamic content display |

| Cost | Moderate ($30-$100) | Low to moderate ($10-$50) | High ($200+) |

| Ease of Implementation | Simple installation | Easy online design and order | Requires technical setup |

| Maintenance | Minimal upkeep | Rarely needs maintenance | Regular updates required |

| Best Use Case | Permanent signage in offices | Personalized office spaces | Interactive environments or events |

Detailed Breakdown of Alternatives

Custom Desk Nameplates

Custom desk nameplates are popular for personalizing office spaces. They are typically made from materials like plastic, wood, or metal, offering a professional appearance. One of the significant advantages of custom nameplates is their affordability and ease of ordering, often available through online platforms with quick turnaround times. However, they may lack the durability of nomenclature plates, particularly in high-traffic areas, and are generally not suitable for outdoor use. Additionally, customization options can be limited compared to more advanced solutions.

Electronic Display Boards

Electronic display boards represent a modern alternative, allowing businesses to showcase dynamic content, including names, schedules, and announcements. These boards are particularly effective in environments where information needs to be updated frequently, such as conferences or reception areas. The primary advantage lies in their versatility and ability to engage audiences with multimedia content. However, electronic display boards come with a higher initial investment and require regular maintenance and updates, which can be a drawback for businesses looking for a low-maintenance solution.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate solution for your business needs, consider factors such as the environment, budget, and the type of information you wish to convey. Nomenclature plates are an excellent choice for permanent, durable signage, particularly in formal office settings. If personalization and cost-efficiency are your priorities, custom desk nameplates may be the best fit. Conversely, if you need a flexible, interactive solution for frequently changing information, electronic display boards are worth the investment. By assessing these alternatives against your specific requirements, you can make an informed decision that aligns with your organizational goals.

Illustrative image related to nomenclature plate

Essential Technical Properties and Trade Terminology for nomenclature plate

What Are the Key Technical Properties of Nomenclature Plates?

When selecting nomenclature plates, understanding their technical specifications is vital for ensuring they meet your operational needs. Here are some critical properties to consider:

-

Material Grade

Nomenclature plates are commonly made from materials such as brass, aluminum, plastic, or acrylic. The choice of material affects durability, aesthetic appeal, and the environment in which the plate will be used. For example, brass is known for its corrosion resistance and elegant appearance, making it suitable for high-end office environments, whereas plastic might be preferred for cost-effective solutions in less demanding applications. -

Thickness

The thickness of a nomenclature plate impacts its rigidity and resistance to wear. Typical thicknesses range from 1mm to 5mm. A thicker plate may offer greater durability and longevity, especially in high-traffic areas. It’s essential to choose a thickness that aligns with the intended use and mounting method. -

Tolerance

Tolerance refers to the allowable deviation from specified dimensions. For nomenclature plates, maintaining tight tolerances is crucial for ensuring that the plates fit properly within designated spaces, especially when integrated with other components. This precision is particularly important in industrial settings where misalignment can cause operational issues. -

Finish Type

The finish of a nomenclature plate can vary from matte to glossy, which not only affects its aesthetic but also its functionality. A matte finish may reduce glare, making it easier to read under bright lighting conditions, while a glossy finish can enhance visibility and aesthetic appeal. Choosing the right finish is important for both branding and user experience. -

Mounting Style

Nomenclature plates can be designed for various mounting styles, including wall-mounted, desk-mounted, or freestanding options. Understanding the mounting requirements is crucial for ensuring ease of installation and optimal visibility. The selected mounting style should align with the intended use and location of the nomenclature plate. -

Customization Options

Many manufacturers offer customization options, including engraved text, logos, and color choices. Customization is essential for branding and personalizing office spaces. Businesses should consider their branding guidelines when selecting colors and fonts to ensure consistency across all signage.

What Are the Common Trade Terms Associated with Nomenclature Plates?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers for nomenclature plates that fit seamlessly into existing systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. This is particularly important for businesses looking to manage inventory costs. Knowing the MOQ helps in planning purchases and avoiding overstocking or shortages. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products, including nomenclature plates. This process helps businesses compare suppliers based on price, quality, and delivery timelines, ensuring informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding these terms is crucial for international buyers to avoid unexpected costs and delays in receiving nomenclature plates. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. Knowing the lead time for nomenclature plates is critical for project planning and ensuring that signage is available when needed. -

Customization Lead Time

This term specifically refers to the additional time required for customized orders, such as engraved or printed nomenclature plates. Being aware of this timeframe is essential for meeting deadlines, especially in project-based environments where timing is crucial.

Understanding these properties and terms will enhance your purchasing strategy and ensure that your organization selects the most appropriate nomenclature plates for its needs.

Navigating Market Dynamics and Sourcing Trends in the nomenclature plate Sector

Market Overview & Key Trends in the Nomenclature Plate Sector

The nomenclature plate market is experiencing a dynamic shift driven by globalization, customization, and technological advancements. International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking personalized solutions that reflect their unique branding and operational needs. The trend towards customization is not just about aesthetics; businesses recognize that personalized nameplates enhance brand identity and foster employee engagement.

Emerging B2B technologies are revolutionizing the sourcing landscape. Online platforms that offer rapid design and ordering processes, such as customizable nameplate services, are becoming essential. These platforms enable businesses to create tailored products with minimal lead time, catering to the fast-paced demands of modern enterprises. Furthermore, advancements in manufacturing technologies, such as laser engraving and digital printing, are allowing for high-quality, durable nameplates at competitive prices.

Sustainability is another key driver in the nomenclature plate sector. As global awareness of environmental issues rises, buyers are increasingly prioritizing suppliers who demonstrate a commitment to eco-friendly practices. This includes sourcing materials that are sustainable and ensuring that manufacturing processes minimize waste and pollution. In regions like Europe, stringent regulations around sustainability are pushing businesses to adapt quickly, making it vital for suppliers to align their offerings with these expectations.

How Does Sustainability & Ethical Sourcing Impact the Nomenclature Plate Market?

Sustainability and ethical sourcing have become central themes for B2B buyers in the nomenclature plate sector. Environmental impacts associated with production processes, such as waste generation and energy consumption, are under scrutiny. Buyers are increasingly seeking suppliers who can demonstrate a commitment to reducing their carbon footprint and employing sustainable practices.

To meet these demands, suppliers are turning to eco-friendly materials for nameplate production, including recycled plastics and sustainably sourced wood. Certifications like Forest Stewardship Council (FSC) for wood products and ISO 14001 for environmental management systems are becoming essential criteria for buyers when evaluating suppliers. Such certifications not only enhance brand reputation but also ensure compliance with increasingly stringent regulations.

Moreover, the demand for transparency in supply chains is rising. Buyers are looking for partners who can provide clear information about the sourcing of materials and the labor conditions under which products are manufactured. This focus on ethical sourcing not only helps mitigate risks associated with supply chain disruptions but also aligns with the values of socially conscious consumers.

What is the Evolution of the Nomenclature Plate Sector?

The nomenclature plate sector has evolved significantly over the years, transitioning from simple identification tags to sophisticated branding tools. Historically, nameplates were primarily functional, serving the basic purpose of identifying individuals and roles within organizations. However, as the importance of branding and personalization has grown, so too has the sophistication of nameplates.

In the early 20th century, materials were limited to basic metals and plastics, with designs largely dictated by practicality. The introduction of digital technologies in the late 20th century revolutionized this space, allowing for intricate designs and personalized options. Today, the market is characterized by a diverse range of materials, including eco-friendly options, and an emphasis on custom designs that reflect the values and identity of the business.

Illustrative image related to nomenclature plate

This evolution reflects broader trends in consumer behavior, where personalization and sustainability are no longer just preferences but expectations. For B2B buyers, understanding this history is crucial as it informs current sourcing strategies and highlights the importance of aligning with suppliers who are forward-thinking and adaptable to market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of nomenclature plate

-

How do I select the right nomenclature plate supplier for my business needs?

When selecting a supplier for nomenclature plates, consider their experience in the industry, production capabilities, and customization options. Look for suppliers that offer a range of materials (such as metal, plastic, and acrylic) and finishes to meet your specific requirements. Additionally, check their lead times and reliability by seeking reviews or testimonials from other businesses. Engaging in direct communication can also help clarify their understanding of your needs and their ability to meet them. -

What customization options are available for nomenclature plates?

Customization options for nomenclature plates can include size, material, font, color, and the ability to incorporate logos or specific designs. Many suppliers offer online design tools that allow you to preview your plate before finalizing the order. It’s essential to discuss your vision with the supplier to ensure they can accommodate your requests, including any unique specifications related to branding or corporate identity. -

What is the typical minimum order quantity (MOQ) for nomenclature plates?

Minimum order quantities for nomenclature plates can vary significantly between suppliers. Some may have a MOQ of as low as 10 plates, while others may require orders in the hundreds or thousands to achieve cost-effective pricing. Always inquire about MOQs during your initial discussions with potential suppliers, as this can impact your budgeting and planning processes. -

What payment terms should I expect when ordering nomenclature plates internationally?

Payment terms can differ widely among suppliers. Common practices include upfront payment, partial payment upon order confirmation, or payment upon delivery. For international transactions, suppliers may require a Letter of Credit or other secure payment methods to mitigate risk. It’s crucial to clarify payment terms before placing an order to avoid unexpected costs or delays. -

How do I ensure quality assurance for my nomenclature plates?

To ensure quality assurance, request samples before finalizing your order. Many reputable suppliers will provide prototypes or samples of their work. Additionally, inquire about their quality control processes, such as inspections and testing protocols, to ensure that the final products meet your specifications. Establishing clear communication regarding your quality expectations from the outset is also key. -

What are the shipping options and logistics for nomenclature plates?

Shipping options can vary based on the supplier’s location and your destination. Inquire about available logistics solutions, including express shipping, standard delivery, and tracking capabilities. Many suppliers offer free shipping for larger orders, while others may partner with logistics companies for international shipments. Understanding the shipping costs and estimated delivery timelines will help you plan better. -

What should I consider regarding compliance and regulations for nomenclature plates in different regions?

When sourcing nomenclature plates for international use, consider local regulations regarding materials and labeling requirements. For example, certain regions may have restrictions on specific materials or mandates for environmental compliance. Researching these regulations or consulting with your supplier can help ensure that your products adhere to local laws, avoiding potential legal issues. -

How can I assess the reliability of a nomenclature plate supplier?

Assessing the reliability of a supplier involves researching their reputation within the industry. Check for certifications, industry affiliations, and their history of on-time delivery and product quality. Engaging with previous clients through testimonials or case studies can provide insights into their service levels. Furthermore, consider visiting their facilities if possible, or arranging a virtual meeting to discuss their operations and capabilities in detail.

Top 5 Nomenclature Plate Manufacturers & Suppliers List

1. MyNamePlates – Custom Desk Nameplates

Domain: mynameplates.com

Registered: 2006 (19 years)

Introduction: Custom Desk Nameplates, Office Nameplates, Engraved Sign Custom Plates. Fast, Affordable, Durable for Desks, Doors & Office Spaces. Ships in 1-2 days. Engraved or Printed Options. No Setup Fees. Available in Brass, Aluminum & Plastic. Sizes include 2″ x 10″, 2″ x 8″, 1.75″ x 8.5″, and 2.25″ x 10″. Customizable with text, fonts, colors, and logos. Made in the USA. Trusted by 30,000+ customers. Free…

2. Office Depot – Customizable Name Plates

Domain: officedepot.com

Registered: 1995 (30 years)

Introduction: Name Plates available at Office Depot include customizable options made from various materials such as plastic, metal, wood, and stone. Key features include different holder lengths (1 in., 2 in., 3 in., 4 in., 6 in.) and various product types like desk signs and wall signs. Notable products include Custom Engraved Plastic Desk Signs with Slide-in Metal Holder (2″ x 10″), Custom Create Your Own En…

3. An American Craftsman – Personalized Name Plate

Domain: anamericancraftsman.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Personalized Name Plate”, “price”: “$36.00”, “materials”: [“Cherry”, “Maple”, “Walnut”], “customization”: {“cost_per_letter”: “$12.00”, “max_letters”: 18, “min_order”: 3}, “shipping”: “All items are handmade and subject to availability. Shipping times will vary.”, “features”: [“Handmade name plate”, “Makes a perfect gift”], “font_options”: “Enter the font and name of your choice …

4. Nomenclature Plate – Military Equipment Identifier

Domain: encyclopedia2.thefreedictionary.com

Registered: 2003 (22 years)

Introduction: Nomenclature plate is a plate, usually made of metal, that is conspicuously mounted on military equipment. It provides model letters, symbols, and numbers, along with other pertinent information.

5. Etsy – Unique Name Plates

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Unique Name Plates, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for nomenclature plate

In today’s competitive landscape, the strategic sourcing of nomenclature plates presents a unique opportunity for international B2B buyers to enhance branding and operational efficiency. Prioritizing high-quality materials, such as brass, aluminum, and durable plastics, ensures longevity and a professional appearance that resonates with clients and employees alike. By leveraging custom solutions—ranging from engraved designs to logo incorporation—businesses can convey their identity and values effectively.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for personalized and functional office decor is on the rise. Strategic sourcing not only fosters supplier relationships but also allows companies to adapt quickly to changing market needs while maintaining cost-effectiveness.

Looking ahead, it is crucial for B2B buyers to stay informed about emerging trends in customization and sustainable materials. Engaging with reliable suppliers who offer fast turnaround times and quality assurance will position your business for success. Take the initiative to explore innovative nomenclature plate solutions today—your brand’s identity and operational excellence depend on it.

Illustrative image related to nomenclature plate

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.