The Definitive Guide to Car Vacuum Machine Station: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for car vacuum machine station

Navigating the complexities of sourcing car vacuum machine stations can be a daunting task for international B2B buyers, especially when considering the unique requirements and preferences across different regions such as Africa, South America, the Middle East, and Europe. With a growing emphasis on cleanliness and vehicle maintenance, understanding the diverse types and applications of car vacuum machines is essential for making informed purchasing decisions. This guide delves into the various models available, including stationary and portable options, and explores their suitability for car washes, auto dealerships, and gas stations.

In addition to providing a comprehensive overview of the product landscape, this guide addresses critical factors such as supplier vetting, cost analysis, and technological advancements in vacuum systems. By highlighting the importance of performance, durability, and customer engagement features—like coin-operated or free-use options—B2B buyers can better assess which solutions align with their business models.

Furthermore, insights into regional market trends and preferences will empower buyers from diverse markets, including Saudi Arabia and Brazil, to tailor their procurement strategies effectively. This resource serves not only as an informative catalog of available products but also as a strategic tool for enhancing customer satisfaction and operational efficiency in the competitive car care industry.

Understanding car vacuum machine station Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stationary Vacuum Systems | Permanent installation, high suction power, and durability | Car washes, auto dealerships, rental agencies | Pros: Long-lasting; Cons: Higher initial cost |

| Portable Vacuum Units | Lightweight, easy to transport, often battery-operated | Mobile detailing, small service providers | Pros: Flexibility; Cons: Limited power |

| Coin-Operated Vacuums | Integrated payment systems, user-friendly interfaces | Gas stations, car washes, convenience stores | Pros: Revenue generation; Cons: Maintenance costs |

| Industrial Vacuum Cleaners | Heavy-duty, designed for high volume and tough debris | Fleet services, body shops, large detailing operations | Pros: High efficiency; Cons: Requires space |

| Self-Service Vacuum Stations | User-operated, often with multiple vacuum points | High-traffic car washes, event venues | Pros: Customer convenience; Cons: Potential vandalism |

What are the Characteristics of Stationary Vacuum Systems?

Stationary vacuum systems are robust installations designed for high-volume cleaning. These units typically feature powerful motors and a durable construction, ensuring longevity and efficiency in demanding environments. Ideal for car washes, auto dealerships, and rental agencies, they provide consistent performance and can handle a variety of vehicles. Buyers should consider the initial investment against the long-term benefits of reduced maintenance and increased customer satisfaction.

How Do Portable Vacuum Units Stand Out?

Portable vacuum units offer the flexibility of mobility, making them suitable for mobile detailing services and small service providers. These lightweight vacuums often operate on batteries or have a compact design, allowing easy transport to various job sites. While they provide convenience, potential buyers should note that their suction power may not match that of stationary systems, making them less suitable for high-volume applications.

Why Choose Coin-Operated Vacuums for Your Business?

Coin-operated vacuums integrate payment systems, allowing businesses like gas stations and car washes to generate revenue while providing a valuable service. These user-friendly units often come with features that enhance the customer experience, such as clear instructions and ease of use. However, buyers should factor in the ongoing maintenance costs and the need for regular service to ensure optimal operation.

What Makes Industrial Vacuum Cleaners Necessary?

Industrial vacuum cleaners are engineered for heavy-duty applications, capable of managing tough debris and high volumes of waste. They are particularly beneficial for fleet services and body shops that require efficient cleaning solutions. While their performance is unmatched, the space required for installation and the higher price point may pose challenges for smaller operations.

How Do Self-Service Vacuum Stations Enhance Customer Experience?

Self-service vacuum stations allow customers to operate the equipment themselves, often featuring multiple vacuum points to accommodate high traffic. These stations are perfect for busy car washes and event venues, providing convenience and efficiency. However, potential buyers should be aware of the risk of vandalism and the need for regular maintenance to keep the equipment in good working order.

Key Industrial Applications of car vacuum machine station

| Industry/Sector | Specific Application of car vacuum machine station | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Dealerships | Self-service vacuum stations for customer use | Enhances customer experience and increases dealership visits | Durability, ease of use, payment options (coin/bill acceptors) |

| Car Wash Facilities | High-capacity vacuum systems for thorough cleaning | Reduces labor costs while boosting cleaning efficiency | Suction power, maintenance support, and installation services |

| Fleet Management Companies | Centralized vacuum stations for fleet vehicles | Streamlines cleaning process, improving vehicle turnover | Space requirements, power source, and service agreements |

| Rental Car Agencies | Integrated vacuum systems at rental locations | Provides added value to customers, enhancing satisfaction | Mobility, ease of use, and coin-operated features |

| Body Shops | Dedicated vacuums for vehicle detailing | Improves service quality and reduces time spent on cleaning | Compatibility with various vehicle types and suction capacity |

How Are Car Vacuum Machine Stations Used in Automotive Dealerships?

Automotive dealerships often integrate self-service vacuum stations to enhance customer satisfaction. These stations allow clients to clean their vehicles while waiting for service, promoting a positive experience that can lead to increased sales and repeat visits. For international buyers, sourcing durable equipment that can withstand diverse environmental conditions is crucial. Additionally, options for coin and bill acceptance can cater to various customer preferences, making the stations more appealing.

What Role Do Car Wash Facilities Play in Cleaning Efficiency?

In car wash facilities, high-capacity vacuum systems are essential for providing thorough vehicle cleaning. These machines can handle a wide range of vehicles, from cars to larger trucks, significantly reducing the time and labor costs associated with manual cleaning. Buyers should consider the suction power and ease of maintenance when selecting a vacuum system, as these factors directly impact the efficiency and longevity of the equipment, especially in high-traffic locations.

How Can Fleet Management Companies Benefit from Vacuum Stations?

Fleet management companies utilize centralized vacuum stations to streamline the cleaning process for multiple vehicles. This setup allows for quick turnaround times, ensuring that vehicles are always ready for use. International buyers must assess the space requirements and power sources available at their facilities to ensure that the vacuum stations fit seamlessly into their operations. Additionally, service agreements for maintenance can be a valuable consideration to minimize downtime.

What Advantages Do Rental Car Agencies Gain from Integrated Vacuum Systems?

Rental car agencies can enhance customer experience by installing integrated vacuum systems at their locations. These systems provide added value, allowing customers to return clean vehicles, which can improve overall satisfaction and loyalty. Buyers should look for mobility features and ease of use, as these factors can significantly affect customer interactions. Coin-operated features are also advantageous, as they provide a self-service option that can reduce operational costs.

Why Are Dedicated Vacuums Important for Body Shops?

Dedicated vacuum systems in body shops are crucial for maintaining a clean environment during vehicle detailing. These machines facilitate quick and efficient cleaning, allowing technicians to focus on repairs rather than spending excessive time on cleanup. When sourcing vacuums, compatibility with various vehicle types and sufficient suction capacity are key considerations. Ensuring that the equipment meets the specific needs of the shop can lead to improved service quality and customer satisfaction.

3 Common User Pain Points for ‘car vacuum machine station’ & Their Solutions

Scenario 1: Inefficient Cleaning Performance Leading to Customer Dissatisfaction

The Problem: Many businesses that operate car vacuum machine stations, such as car washes or detail shops, face the challenge of providing an effective cleaning solution that meets customer expectations. Inefficient vacuums can lead to poor suction power, causing frustration among users who feel they are not receiving value for their money. This dissatisfaction can result in negative reviews and reduced customer loyalty, ultimately affecting profitability.

The Solution: To address this issue, B2B buyers should invest in high-performance car vacuum machines that are specifically designed for commercial use. When sourcing these machines, look for models with powerful motors and advanced filtration systems, such as HEPA filters, which enhance suction capabilities and maintain cleanliness. Brands like J.E. Adams and Tommy Car Wash Systems offer robust options that are built to withstand heavy use and ensure maximum performance. Additionally, consider implementing regular maintenance schedules to keep the machines in optimal working condition. Training staff to operate these machines effectively and assist customers can also enhance user experience and satisfaction.

Scenario 2: High Operational Costs Due to Frequent Breakdowns

The Problem: Frequent breakdowns of vacuum machines can lead to unexpected repair costs and downtime, significantly impacting service delivery. For B2B buyers, especially those operating in regions with challenging climates, such as the Middle East or Africa, the durability of equipment is critical. Constant repairs not only drain financial resources but also hinder the ability to serve customers efficiently, potentially pushing them towards competitors.

The Solution: To mitigate this pain point, buyers should prioritize sourcing industrial-grade car vacuum machines known for their durability and reliability. It is advisable to opt for units with a proven track record and warranties that cover parts and labor. Investing in high-quality components, such as stainless steel housings and reinforced hoses, can prevent common wear-and-tear issues. Additionally, establishing a relationship with reputable suppliers who offer installation and maintenance services can ensure prompt repairs and reduce downtime. Regularly scheduled preventive maintenance checks can also help identify potential issues before they escalate into costly repairs.

Scenario 3: Inadequate Payment Options Reducing Revenue Streams

The Problem: Many car vacuum machine stations face challenges related to payment processing, particularly when offering coin-operated or card payment systems. In regions where cashless transactions are becoming the norm, an inability to accommodate diverse payment methods can deter customers and limit revenue potential. B2B buyers may find themselves losing business to competitors who provide more flexible payment solutions.

The Solution: To enhance revenue opportunities, B2B buyers should invest in car vacuum machines equipped with versatile payment systems. Look for models that offer multiple payment options, including coins, credit cards, and mobile payment solutions. Brands like Cougar Chemical and D&S provide units with integrated payment systems that cater to various customer preferences. Additionally, consider customer feedback and market trends to identify the most popular payment methods in your region. By providing a seamless payment experience, businesses can attract more customers and encourage repeat visits, ultimately boosting profitability.

Strategic Material Selection Guide for car vacuum machine station

What Materials Are Commonly Used in Car Vacuum Machine Stations?

When selecting materials for car vacuum machine stations, it’s essential to consider their properties, advantages, and limitations. The right material can significantly influence the performance, durability, and cost-effectiveness of the vacuum systems. Below, we analyze four common materials used in the construction of these machines.

1. Stainless Steel

Key Properties:

Stainless steel is known for its high corrosion resistance, strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°F (427°C) and is resistant to rust, making it ideal for outdoor applications.

Pros & Cons:

The durability of stainless steel ensures a long lifespan, reducing the need for frequent replacements. However, it is more expensive than other materials and can be challenging to fabricate, leading to higher manufacturing costs.

Impact on Application:

Stainless steel is compatible with various media, including water and detergents, making it suitable for car wash environments.

Considerations for International Buyers:

Compliance with international standards such as ASTM for material quality is crucial. Buyers from regions like the Middle East and Europe may prefer stainless steel for its aesthetic appeal and durability.

2. Polypropylene

Key Properties:

Polypropylene is a lightweight thermoplastic with excellent chemical resistance and a temperature tolerance of around 180°F (82°C). It is also resistant to impact and abrasion.

Pros & Cons:

This material is cost-effective and easy to mold, making it suitable for complex designs. However, its lower temperature resistance compared to metals can limit its use in high-heat applications.

Impact on Application:

Polypropylene is ideal for vacuum parts that require flexibility and chemical resistance, such as hoses and containers for collecting debris.

Considerations for International Buyers:

Buyers should ensure that the polypropylene used meets local regulations regarding chemical safety and environmental impact, especially in regions with stringent regulations like Europe.

3. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with a temperature rating of around 600°F (316°C). It is also highly malleable, allowing for various shapes and designs.

Pros & Cons:

While aluminum offers a good balance of strength and weight, it can be more susceptible to denting and scratching compared to stainless steel. The cost is moderate, making it a popular choice for many applications.

Impact on Application:

Aluminum is suitable for components that require a lightweight design, such as vacuum frames and support structures.

Considerations for International Buyers:

It’s important for buyers to verify that the aluminum used complies with standards like JIS in Japan or DIN in Germany, particularly for structural components.

4. High-Density Polyethylene (HDPE)

Key Properties:

HDPE is a strong, durable plastic known for its high impact resistance and chemical stability, with a temperature tolerance of about 120°F (49°C).

Pros & Cons:

HDPE is relatively inexpensive and easy to manufacture, making it a popular choice for various applications. However, its lower temperature tolerance may limit its use in high-heat environments.

Impact on Application:

HDPE is often used for vacuum tanks and parts that require resistance to chemicals and moisture.

Considerations for International Buyers:

Buyers should ensure that HDPE products meet relevant safety and environmental standards, particularly in regions like Africa and South America, where regulations may vary.

Summary Table of Material Selection for Car Vacuum Machine Stations

| Material | Typical Use Case for car vacuum machine station | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Vacuum housings, frames | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Polypropylene | Hoses, debris containers | Cost-effective and easy to mold | Lower temperature resistance | Low |

| Aluminum | Structural components, frames | Lightweight and malleable | Susceptible to dents and scratches | Medium |

| High-Density Polyethylene (HDPE) | Vacuum tanks, chemical-resistant parts | Strong and chemical stable | Lower temperature tolerance | Low |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their car vacuum machine stations, ensuring they choose the right materials for their specific needs and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for car vacuum machine station

What Are the Main Stages in the Manufacturing Process of Car Vacuum Machine Stations?

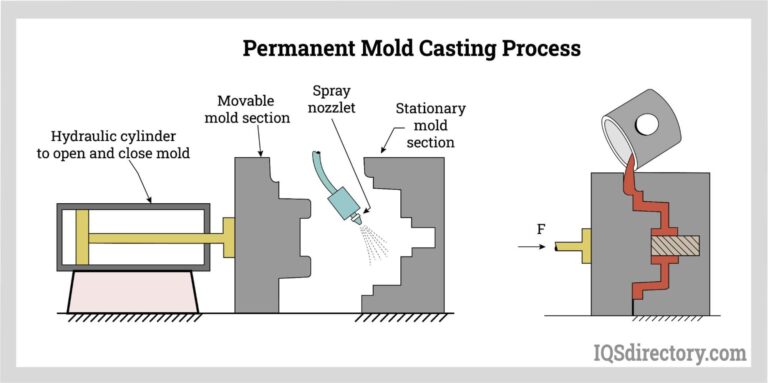

Manufacturing car vacuum machine stations is a multi-step process that requires precision and attention to detail. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials such as stainless steel for the body, durable plastics for the controls, and high-efficiency motors. Suppliers must provide materials that meet specific industry standards to ensure longevity and reliability.

-

Forming: In this phase, materials are shaped into the components of the vacuum machine. Techniques such as stamping, bending, and welding are employed to create the structure of the vacuum. Advanced manufacturing technologies like CNC machining may also be used to achieve precise dimensions, which are crucial for proper assembly and functionality.

-

Assembly: Once the components are formed, they are brought together in an assembly line. This stage involves fitting the motor, hoses, and filtration systems into the vacuum body. Automated systems may assist in this process to enhance speed and accuracy. Skilled technicians monitor the assembly to ensure that all parts fit correctly and function as intended.

-

Finishing: The final stage includes painting, coating, and quality checks. A protective finish is applied to enhance durability and aesthetics. This is also when detailed inspections are conducted to ensure that the vacuum stations meet design specifications and performance standards.

What Key Techniques Are Used in the Manufacturing of Car Vacuum Machines?

In the production of car vacuum machines, several key techniques are employed to ensure efficiency and quality. These include:

-

Robotic Automation: Many manufacturers use robotic systems for precision welding and assembly. This minimizes human error and increases production rates, making the process more cost-effective.

-

Quality Control Technology: Incorporating technology such as 3D scanning and laser measurement systems helps ensure that components meet strict tolerances before moving on to assembly.

-

Modular Design: A modular approach allows for easier upgrades and repairs, enhancing the lifecycle of the equipment. It also facilitates customization based on client specifications, which is particularly valuable for B2B buyers with unique needs.

How Is Quality Assurance Implemented in the Manufacturing of Car Vacuum Machine Stations?

Quality assurance (QA) is critical in ensuring that car vacuum machine stations perform reliably over time. Manufacturers typically adhere to international standards, such as ISO 9001, which provides a framework for consistent quality management.

-

International Standards: Compliance with ISO 9001 ensures that manufacturers implement effective quality management systems. Additionally, industry-specific certifications like CE (for European markets) and API (for petroleum-related applications) are often required to meet safety and performance benchmarks.

-

Quality Control Checkpoints: Quality control is integrated into various stages of manufacturing, which includes:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify compliance with specifications.

– In-Process Quality Control (IPQC): Regular checks during the manufacturing process ensure that all components are being produced to the required standards.

– Final Quality Control (FQC): Comprehensive testing of the assembled vacuum machines is conducted before shipping. This may include performance tests, durability assessments, and safety evaluations.

What Common Testing Methods Are Used in Quality Assurance?

Testing methods are crucial in validating the performance and safety of car vacuum machines. Some common methods include:

-

Performance Testing: Evaluating suction power, motor efficiency, and filtration effectiveness to ensure that the vacuum meets performance expectations.

-

Durability Testing: Subjecting the vacuum machine to stress tests simulating real-world usage, which helps identify potential failure points.

-

Safety Testing: Ensuring that all electrical components comply with safety regulations to prevent hazards such as electrical shocks or fires.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Here are actionable strategies:

-

Conduct Supplier Audits: Regular audits of the manufacturing facility can provide insights into their production processes and quality assurance measures. This includes reviewing their compliance with international standards.

-

Request Quality Reports: Suppliers should provide documentation on their quality control processes, including results from recent inspections and tests. This transparency helps buyers assess the reliability of the products.

-

Third-Party Inspections: Engaging independent third-party inspection services can further validate the quality of the vacuum machines before purchase. These inspections can be particularly useful for international transactions, ensuring compliance with local regulations.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

-

Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. Buyers should familiarize themselves with these regulations to ensure that the products they import comply with local laws.

-

Cultural Considerations: Communication styles and business practices may differ across regions, affecting negotiations and agreements. Building strong relationships with suppliers can foster better understanding and cooperation regarding quality expectations.

-

Logistics and Supply Chain Management: Consider the logistics involved in international shipping. Delays or damages during transport can affect product quality. Therefore, ensuring that suppliers have robust packaging and shipping practices is vital.

Conclusion

Understanding the manufacturing processes and quality assurance measures for car vacuum machine stations is crucial for B2B buyers. By focusing on the stages of production, key techniques, quality control standards, and verification methods, businesses can make informed purchasing decisions that ensure they receive high-quality equipment tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car vacuum machine station’

Introduction

Sourcing a car vacuum machine station is a critical investment for businesses in the automotive sector, including car washes, auto dealerships, and repair shops. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process, ensuring they select the right equipment that meets their operational needs while delivering value to their customers.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to outline the technical specifications required for your car vacuum machine station. Consider factors such as suction power, hose length, and motor capacity.

– Tip: Assess your customer volume to determine the necessary power and efficiency levels.

– Importance: Clear specifications help you filter options effectively, ensuring you invest in a machine that can handle your business demands.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends and innovations in car vacuum technologies. This includes advancements in energy efficiency, noise reduction, and integrated payment systems.

– Tip: Look for models that offer features like HEPA filters or eco-friendly options to attract environmentally conscious customers.

– Importance: Understanding market trends will position your business as a modern, customer-focused operation, enhancing your competitive edge.

Step 3: Evaluate Potential Suppliers

It’s crucial to vet suppliers thoroughly before making a commitment. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Tip: Prioritize suppliers that offer comprehensive support, including installation, maintenance, and warranty services.

– Importance: A reliable supplier can significantly impact your operational success, ensuring you receive quality equipment backed by dependable service.

Step 4: Assess Payment and Revenue Models

Determine whether you want to implement a free or coin-operated vacuum system. Assess the implications of each model on customer experience and revenue generation.

– Tip: Consider integrating modern payment methods such as mobile payment apps to enhance customer convenience.

– Importance: The right payment model can maximize your revenue potential while improving customer satisfaction.

Step 5: Check Compliance and Certifications

Ensure that the vacuum machines comply with local regulations and industry standards. Verify that suppliers provide certifications related to safety and environmental impact.

– Tip: Look for machines with energy efficiency certifications, which can reduce operational costs in the long run.

– Importance: Compliance not only mitigates legal risks but also enhances your brand’s reputation among eco-conscious consumers.

Step 6: Request Demonstrations and Trials

Before finalizing your purchase, request demonstrations or trial periods for the equipment. This allows you to evaluate performance firsthand and make informed decisions.

– Tip: Involve your staff in the evaluation process to gather insights on usability and functionality.

– Importance: Real-world testing ensures that the equipment meets your expectations and operational requirements.

Step 7: Finalize Negotiation and Purchase Terms

Once you’ve identified the right supplier and equipment, negotiate the purchase terms. Discuss pricing, delivery timelines, warranty coverage, and after-sales support.

– Tip: Don’t hesitate to ask for volume discounts or payment plans that suit your cash flow.

– Importance: Effective negotiation can lead to significant cost savings and better overall terms, enhancing your investment’s value.

By following this checklist, B2B buyers can confidently navigate the procurement process for car vacuum machine stations, ensuring they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for car vacuum machine station Sourcing

What Are the Key Cost Components of Car Vacuum Machine Stations?

When sourcing car vacuum machine stations, understanding the cost structure is crucial for optimizing your procurement strategy. The main cost components include:

-

Materials: This includes the costs of high-quality components such as motors, hoses, and filtration systems. The choice of materials directly influences durability and performance, impacting long-term operational costs.

-

Labor: Labor costs encompass wages for skilled workers involved in the assembly and installation of the vacuum stations. In regions with higher labor costs, this can significantly affect the overall price.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Effective management of these costs can lead to more competitive pricing.

-

Tooling: The cost of specialized tools and equipment necessary for production can be significant, particularly for custom or high-specification machines.

-

Quality Control (QC): Investing in rigorous QC processes is essential to ensure reliability and compliance with international standards. This can add to initial costs but will minimize risks associated with defects and returns.

-

Logistics: Shipping and handling costs vary based on the destination, mode of transportation, and packaging requirements. For international buyers, understanding logistics can lead to substantial savings.

-

Margin: Suppliers typically include a margin in their pricing to cover business risks and ensure profitability. This margin can vary widely based on market conditions and supplier reputation.

How Do Price Influencers Impact Car Vacuum Machine Station Costs?

Several factors can influence the pricing of car vacuum machine stations:

-

Volume/MOQ: Larger orders often qualify for discounts, allowing buyers to negotiate better rates. Understanding minimum order quantities (MOQ) can facilitate bulk purchasing strategies.

-

Specifications and Customization: Custom features and specifications can increase costs. Buyers should balance the need for customization with budget constraints, ensuring they don’t overpay for unnecessary features.

-

Materials: The choice of materials can greatly affect pricing. Higher-quality materials may lead to higher initial costs but can offer lower maintenance and replacement expenses over time.

-

Quality and Certifications: Equipment that meets specific industry standards or certifications may carry a premium price. However, this can enhance customer trust and potentially lead to increased sales.

-

Supplier Factors: Supplier reputation, experience, and geographic location can affect pricing. Established suppliers may charge more due to perceived reliability, while emerging suppliers may offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms is essential for international transactions, as they define the responsibilities of buyers and sellers in terms of shipping costs, risks, and insurance. This can significantly affect the total landed cost of the equipment.

What Are the Best Buyer Tips for Cost-Efficiency in Car Vacuum Machine Sourcing?

To maximize cost-efficiency when sourcing car vacuum machine stations, consider these strategies:

-

Negotiation: Engage suppliers in discussions about pricing, terms, and potential discounts. Building relationships can often lead to better deals and favorable terms.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs, including maintenance, energy consumption, and potential downtime. This holistic view can reveal the true cost-effectiveness of different models.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that may affect pricing. Working with suppliers who understand the local market dynamics in regions like Africa, South America, the Middle East, and Europe can provide a competitive edge.

-

Research and Comparison: Conduct thorough market research to compare different suppliers and models. Utilize online platforms and trade shows to gather information and assess options.

-

Pilot Programs: Consider initiating a pilot program with a new supplier to test the performance and reliability of their equipment before committing to larger orders. This reduces the risk of investing in subpar products.

Disclaimer for Indicative Prices

Prices for car vacuum machine stations can vary widely based on specifications, suppliers, and market conditions. The figures mentioned in this analysis are indicative and should be validated through direct supplier inquiries and market research to ensure accuracy and relevance to your specific sourcing needs.

Alternatives Analysis: Comparing car vacuum machine station With Other Solutions

Introduction: Evaluating Alternatives to Car Vacuum Machine Stations

In the competitive landscape of automotive cleaning solutions, B2B buyers must consider various alternatives to car vacuum machine stations. While these stations offer convenience and efficiency for car washes and service centers, other viable options may better suit specific operational needs or budgets. This analysis will compare car vacuum machine stations with two alternative solutions: handheld vacuum cleaners and stationary vacuum systems, providing insights into their performance, cost, ease of implementation, maintenance, and ideal use cases.

Comparison Table

| Comparison Aspect | Car Vacuum Machine Station | Handheld Vacuum Cleaners | Stationary Vacuum Systems |

|---|---|---|---|

| Performance | High suction power, tailored for vehicles | Moderate suction, limited by battery life | High suction power, designed for continuous use |

| Cost | Moderate to high initial investment | Low to moderate, depending on brand and model | Moderate to high, depending on features |

| Ease of Implementation | Requires installation and setup | Ready to use, minimal setup | Installation needed, but often less complex than car stations |

| Maintenance | Regular maintenance required; durable | Low maintenance; easy to clean | Moderate, requires occasional servicing |

| Best Use Case | Car washes, service stations | Quick clean-ups, personal use | Commercial settings, high-volume operations |

Detailed Breakdown of Alternatives

Handheld Vacuum Cleaners

Handheld vacuum cleaners are compact, portable devices ideal for quick clean-ups. Their primary advantage is ease of use and portability, making them suitable for smaller facilities or personal use. However, their suction power is often limited compared to car vacuum machine stations, and they may require frequent recharging if cordless. Handheld vacuums can be an economical choice for businesses that do not require extensive cleaning capabilities or have limited space.

Stationary Vacuum Systems

Stationary vacuum systems provide a robust cleaning solution designed for continuous use in commercial environments. They typically feature high suction power and can be integrated into various cleaning setups, making them suitable for auto dealerships, car rental agencies, and high-volume detail shops. While the initial investment may be similar to that of car vacuum machine stations, stationary vacuums often have lower long-term maintenance costs. However, they do require installation, which could be a consideration for some businesses.

Conclusion: How to Choose the Right Solution for Your Business

When selecting the right cleaning solution, B2B buyers must assess their specific operational needs, budget constraints, and the expected volume of use. Car vacuum machine stations are ideal for businesses focused on providing dedicated car cleaning services, while handheld vacuums serve well for quick, less frequent tasks. Stationary vacuum systems offer a balance of power and efficiency for commercial settings. By weighing the pros and cons of each option, buyers can make informed decisions that align with their business objectives and enhance their service offerings.

Essential Technical Properties and Trade Terminology for car vacuum machine station

What Are the Key Technical Properties of Car Vacuum Machine Stations?

When considering car vacuum machine stations, understanding their technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

-

Suction Power (Airflow Rate)

– Defined as the volume of air the vacuum can move, measured in cubic feet per minute (CFM). Higher CFM indicates stronger suction, which is crucial for effectively cleaning various vehicle types. For B2B buyers, opting for vacuums with robust suction power ensures that your customers can achieve thorough cleaning, thus enhancing customer satisfaction and repeat business. -

Motor Configuration

– This refers to the number of motors integrated into the vacuum system. Units with multiple motors typically offer greater suction and reliability. For businesses, investing in a vacuum with a dual or multi-motor setup can lead to reduced downtime and maintenance costs, ensuring consistent service for customers. -

Material Durability

– The construction materials of the vacuum casing (e.g., stainless steel, high-grade plastic) impact its longevity and resistance to wear and tear. Durable materials are vital for high-traffic environments like car washes or service stations, as they minimize the need for frequent replacements, thereby reducing operational costs. -

Filtration System

– This includes the type of filters used, such as HEPA or cartridge filters, which capture fine particles and allergens. A high-quality filtration system is not only essential for maintaining air quality but also for preventing clogging, which can affect performance. For businesses, a reliable filtration system translates to lower maintenance and operational disruptions. -

Payment Options

– Many car vacuum stations come equipped with various payment systems, such as coin-operated, card readers, or built-in bill acceptors. Offering multiple payment methods can increase customer convenience and maximize usage, making it a critical feature for B2B buyers looking to enhance customer experience and revenue potential. -

Hose Length and Flexibility

– The length and flexibility of the vacuum hoses determine how easily customers can access hard-to-reach areas within their vehicles. Longer, flexible hoses improve usability and customer satisfaction, making this a vital consideration for businesses aiming to provide exceptional service.

What Are Common Trade Terms in the Car Vacuum Machine Industry?

Understanding industry jargon is vital for effective communication and negotiation. Here are some common terms related to car vacuum machine stations:

-

OEM (Original Equipment Manufacturer)

– Refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of car vacuums, OEM products ensure compatibility and reliability, which is crucial for businesses looking to maintain consistent quality in their offerings. -

MOQ (Minimum Order Quantity)

– The smallest number of units a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, especially for B2B buyers looking to optimize their purchasing strategy without overcommitting resources. -

RFQ (Request for Quotation)

– A formal process where buyers solicit quotes from suppliers for specific products or services. This process is critical for B2B transactions as it enables buyers to compare prices and terms, ensuring they make informed decisions. -

Incoterms (International Commercial Terms)

– A set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps businesses navigate shipping, insurance, and risk management more effectively. -

Lead Time

– The amount of time it takes from placing an order to receiving the goods. Understanding lead time is crucial for effective inventory management and ensuring that your operations run smoothly without delays. -

Aftermarket Support

– Refers to services provided after the purchase of equipment, including maintenance, repairs, and spare parts. For B2B buyers, understanding the level of aftermarket support available can influence purchasing decisions, ensuring that they choose suppliers who can assist with ongoing service needs.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed choices that enhance their operations and meet customer expectations in the competitive car vacuum market.

Navigating Market Dynamics and Sourcing Trends in the car vacuum machine station Sector

What Are the Key Trends Influencing the Car Vacuum Machine Station Market?

The car vacuum machine station market is experiencing dynamic shifts influenced by several global drivers. One significant trend is the increasing consumer demand for convenience and quality in car care services. As more consumers seek quick and efficient cleaning solutions, businesses in Africa, South America, the Middle East, and Europe are investing in advanced vacuum systems that offer superior suction power and user-friendly interfaces. Additionally, the rise of self-service car washes is expanding the market for stationary and coin-operated vacuums, making it easier for businesses to cater to a diverse clientele.

Emerging technologies are also reshaping sourcing strategies within the sector. For instance, the integration of IoT (Internet of Things) in vacuum systems allows for real-time monitoring and maintenance, enhancing operational efficiency and reducing downtime. Buyers are increasingly seeking suppliers that provide not only high-quality equipment but also innovative features that can drive customer engagement, such as built-in payment systems and multi-functional units.

Moreover, the market is influenced by a growing emphasis on sustainability and energy efficiency. B2B buyers are looking for products that not only meet their operational needs but also align with eco-friendly practices, reflecting the broader global commitment to reducing carbon footprints.

How Important Is Sustainability and Ethical Sourcing in the Car Vacuum Machine Sector?

Sustainability is becoming a critical factor in the purchasing decisions of B2B buyers in the car vacuum machine station sector. The environmental impact of manufacturing and operating these machines is under scrutiny, prompting businesses to seek suppliers that prioritize eco-friendly practices. This includes the use of energy-efficient motors, recyclable materials, and sustainable manufacturing processes, which not only help in reducing operational costs but also appeal to the environmentally conscious consumer base.

Ethical sourcing is equally important. Buyers are increasingly demanding transparency in supply chains, seeking partners who adhere to ethical labor practices and sustainable sourcing of materials. Certifications such as Green Seal and Energy Star are becoming vital indicators of a supplier’s commitment to sustainability. By choosing products that meet these standards, businesses not only enhance their brand reputation but also contribute positively to their communities and the environment.

Investing in ‘green’ technologies can also yield long-term financial benefits. Eco-friendly machines often come with lower energy consumption rates, leading to reduced utility costs and a smaller carbon footprint. This positions businesses as leaders in sustainability, attracting a customer base that values environmentally responsible practices.

How Has the Car Vacuum Machine Station Market Evolved Over Time?

The evolution of the car vacuum machine station market reflects broader changes in consumer behavior and technological advancements. Initially, car washes relied on basic, portable vacuum systems that offered limited functionality. However, as the automotive service industry grew, so did the demand for more robust solutions capable of handling various vehicle types and sizes.

In recent decades, the introduction of stationary vacuum systems has revolutionized the market. These systems not only provide enhanced suction power but also incorporate advanced features such as coin-operated mechanisms and integrated payment systems. The shift towards self-service models has further driven innovation, leading to the development of user-friendly designs that cater to the needs of both consumers and operators.

Today, the market is characterized by a focus on durability, efficiency, and sustainability, with an increasing number of manufacturers prioritizing eco-friendly practices and technologies. This evolution reflects the growing importance of customer experience and environmental responsibility in the automotive service industry.

Frequently Asked Questions (FAQs) for B2B Buyers of car vacuum machine station

-

How do I choose the right car vacuum machine for my business needs?

Choosing the right car vacuum machine involves assessing the specific requirements of your business. Consider factors such as the volume of vehicles serviced, the types of vehicles (cars, trucks, etc.), and the desired features like coin operation or built-in bill acceptors. Additionally, evaluate the vacuum’s power, durability, and ease of use. Research various brands and models, paying attention to customer reviews and testimonials, which can provide insights into performance and reliability. -

What are the key benefits of investing in a commercial car vacuum station?

Investing in a commercial car vacuum station can significantly enhance customer satisfaction and retention. These machines offer powerful suction that outperforms standard household vacuums, making them ideal for thorough cleaning. They can be customized with payment options, which can increase revenue streams. Moreover, a high-quality vacuum station can reduce maintenance costs in the long run, as they are built to last and require less frequent replacements than consumer-grade models. -

What is the typical lead time for ordering a car vacuum machine station?

Lead times for car vacuum machine stations can vary depending on the manufacturer and the specific model. Generally, you can expect a lead time of 4 to 8 weeks for standard orders. However, custom configurations or large orders may take longer. It’s advisable to communicate directly with suppliers to get accurate timelines and ensure your needs align with their production schedules, particularly if you have a specific launch date in mind. -

What payment terms should I expect when purchasing car vacuum machines internationally?

Payment terms can differ widely among suppliers, but common practices include a deposit (usually 30-50%) upfront, with the balance due before shipping or upon delivery. Some suppliers may offer credit terms based on your business history. Be sure to clarify these terms before finalizing your order. Additionally, consider discussing payment methods that protect both parties, such as letters of credit or escrow services, especially for larger transactions. -

How can I vet suppliers for car vacuum machines to ensure quality and reliability?

Vetting suppliers requires a multi-faceted approach. Start by checking their business credentials, such as registration and certifications. Look for reviews and testimonials from other B2B clients to assess their reputation. Request references and follow up with past customers to inquire about their experiences. Additionally, consider visiting the supplier’s manufacturing facility if possible, and ask for product samples to evaluate the quality firsthand. -

Are customization options available for car vacuum machine stations?

Yes, many manufacturers offer customization options for car vacuum machine stations. This can include variations in size, color, features (such as payment systems), and branding elements. Customization allows you to tailor the vacuum to your specific business needs and customer preferences. When discussing options with suppliers, clearly outline your requirements and ask for examples of past custom projects they have completed. -

What are the logistics considerations for importing car vacuum machines?

When importing car vacuum machines, consider the logistics of shipping, customs clearance, and local regulations. Ensure you understand the shipping terms, such as Incoterms, which dictate responsibilities for shipping costs and risks. Additionally, research local import duties and taxes that may apply to your shipment. Collaborating with a logistics provider experienced in international trade can streamline the process and mitigate potential issues. -

What quality assurance measures should I look for in car vacuum machines?

Quality assurance measures vary by manufacturer but should include certifications like ISO standards, which indicate adherence to quality management systems. Look for warranties or guarantees that protect your investment and demonstrate the manufacturer’s confidence in their products. Additionally, inquire about the testing processes used for the machines before they reach the market, such as performance testing and durability assessments, to ensure you are purchasing reliable equipment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Car Vacuum Machine Station Manufacturers & Suppliers List

1. Dultmeier – Car Wash Vacuums

Domain: dultmeier.com

Registered: 1996 (29 years)

Introduction: This company, Dultmeier – Car Wash Vacuums, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Tommy Car Wash – Tommy Vacuums

Domain: tommycarwash.com

Registered: 2002 (23 years)

Introduction: Tommy Vacuums: Robust self-serve interior cleaning with colorful coverage provided by triangular canopies. Features include dual drop design for easy handling, durable stainless steel construction, and peak performance with powerful producers, cartridge filters, and tapered hoses. Options for vacuum producers include stanchion-mounted turbine producers, central vacuum producers, or onboard caniste…

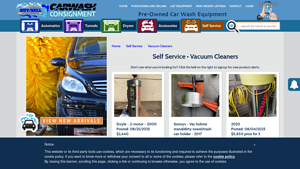

3. Doyle – 2-Motor Vacuum Cleaner

Domain: carwashconsignment.com

Registered: 2000 (25 years)

Introduction: Self Service Car Wash Vacuum Cleaners for Sale: 1. Doyle – 2-motor – 2000, Price: $2,640, Product # 5330. 2. Sonnys – Vac holster stand/dirty towel/trash can holder – 2017, Price: $2,999 (negotiable), Product # 5447, sold as set – 20 units. 3. 2020, Price: $5,850 for 5, Product # 3728, 7 Push/Start Vacs, Lighted Dome, 3 min timer. 4. J. E. Adams Industries – 9200 – 2015, Price: $1,920, Product # 5…

4. Reddit – Car Wash Vacuum Stations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Vacuum stations at car washes typically require coins (quarters) to operate, and they may be timed. Users should clean out any garbage from their vehicle before inserting coins to avoid wasting time. It is advisable to remove floor mats and open all doors and the trunk for easier access. Some car washes include vacuum usage with the car wash service, indicated by the vacuum being already on. Users…

5. Ultimate Washer – Self Vacuum Car Wash

Domain: ultimatewasher.com

Registered: 2003 (22 years)

Introduction: {“products”:[{“product_name”:”Self Vacuum Car Wash”,”product_number”:”11000VR”,”power_source”:”Electric”,”price”:”$4,118.68″},{“product_name”:”Vacuum At Car Wash”,”product_number”:”12000″,”power_source”:”Electric”,”price”:”Call for Pricing”},{“product_name”:”Car Vacuum Car Wash”,”product_number”:”12000VR”,”power_source”:”Electric”,”price”:”$5,836.44″},{“product_name”:”Self Vacuum Car Wash, 110V”,”…

6. Vacutech – Car Wash Vacuum Systems

Domain: vacutechllc.com

Registered: 1999 (26 years)

Introduction: Car Wash Vacuum Systems by Vacutech offer customizable solutions for various car wash configurations including Express Exterior, Flex Service, Full Service, Vehicle Detailing, In Bay Automatic, and Self Service. Key features include:

– Central vacuum systems designed for efficiency and customer satisfaction.

– Options for free and paid vacuum services.

– Equipment includes arches (booms), stanchio…

7. ESTA – Central Car Cleaning System (CCCS 2.0)

Domain: esta.com

Registered: 1996 (29 years)

Introduction: Vacuum systems for car washes include options for free or chargeable vacuuming, with choices between self-service and central vacuum systems. Central vacuum systems, such as the ESTA Central Car Cleaning System (CCCS 2.0), are weatherproof, compact, and can connect up to eight vacuum units. They offer benefits like better vacuuming results, automatic suction power control, integrated cyclone separ…

8. Tough Guy – Car Wash Vacuum Cleaners

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Car wash vacuum products for sale on eBay include various types such as car wash vacuum cleaners, car vacuums, and wet/dry car wash machines. Popular brands include Tough Guy and RIDGID. Products are available in new and used conditions, with prices ranging from under $500 to over $2,000. Shipping options include free shipping and local pickup within 25 miles. There are 760 results available for c…

9. Hertz – Car Cleaning Service

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Hertz – Car Cleaning Service, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for car vacuum machine station

How Can Strategic Sourcing Enhance Your Car Vacuum Machine Station Business?

In the competitive landscape of car vacuum machine stations, strategic sourcing is not just beneficial; it is essential. By partnering with reliable manufacturers, businesses can secure high-quality equipment that meets the demands of their customers, particularly in high-volume settings like car washes and service stations. Understanding the nuances of different models—such as coin-operated versus free-use vacuums—can enhance customer satisfaction and drive repeat business.

Moreover, sourcing from reputable suppliers can lead to long-term cost savings through better pricing structures and maintenance support. As markets in Africa, South America, the Middle East, and Europe continue to grow, aligning with innovative providers ensures access to advanced technologies and features that enhance operational efficiency.

Looking ahead, now is the time for international B2B buyers to capitalize on these opportunities. Investing in state-of-the-art car vacuum systems will not only elevate service offerings but also position your business for sustainable growth in a rapidly evolving market. Engage with top suppliers today to explore the best options for your unique operational needs and customer base. The future of car cleaning solutions is bright, and your strategic sourcing decisions can pave the way for success.