Hinge Boat Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for hinge boat

In the competitive landscape of marine equipment, sourcing high-quality boat hinges is a critical yet often challenging task for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, navigating the intricacies of hinge specifications, materials, and applications can be daunting. This guide is designed to simplify your journey by providing a comprehensive overview of hinge types—ranging from butt and piano hinges to specialty options—along with their specific applications in various marine contexts.

Throughout this guide, we delve into essential considerations for selecting the right boat hinge, including material durability, mounting styles, and cost factors. We also emphasize the importance of vetting suppliers to ensure reliability and quality, which can significantly impact the longevity and performance of your marine applications. By equipping you with actionable insights and detailed comparisons, this resource empowers you to make informed purchasing decisions that align with your operational needs and budget constraints.

As the marine industry continues to expand globally, understanding the nuances of hinge selection becomes increasingly vital. This guide serves as your strategic partner in sourcing the best boat hinges, enabling you to enhance functionality, safety, and aesthetic appeal in your marine projects. Let’s embark on this journey to unlock the potential of your marine operations with the right hinge solutions.

Understanding hinge boat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Butt Hinges | Simple design, commonly used, various materials available | Livewell lids, hatches | Pros: Easy to install; Cons: Limited weight capacity. |

| Piano Hinges | Long continuous hinge, available in friction styles | Console doors, storage center doors | Pros: Provides smooth operation; Cons: Requires precise installation. |

| Concealed Hinges | Hidden when door is closed, offers clean aesthetic | Cabinet doors, interior boat applications | Pros: Enhanced aesthetics; Cons: More complex installation. |

| Friction Hinges | Allows controlled movement, available in various sizes | Adjustable seat backs, storage compartments | Pros: Holds position without additional hardware; Cons: Potential for wear over time. |

| Specialty Hinges | Designed for unique applications, including bimini tops | Ratcheting seat backs, custom installations | Pros: Tailored solutions for specific needs; Cons: May be more expensive than standard options. |

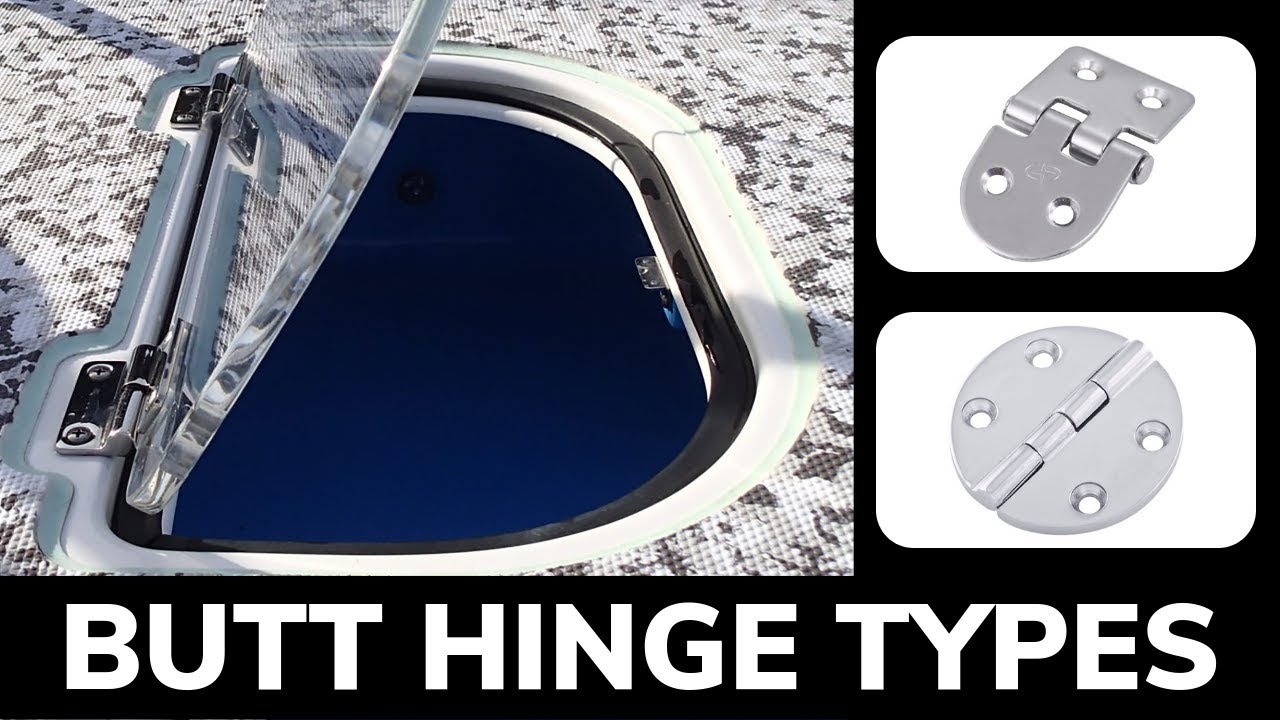

What Are the Key Characteristics of Butt Hinges for Marine Use?

Butt hinges are among the most common types of boat hinges, characterized by their straightforward design and versatile applications. Typically used on livewell lids and hatches, these hinges are available in various materials, including stainless steel and plastic. B2B buyers should consider the weight capacity and durability of the materials, as well as ease of installation, which is generally straightforward. However, buyers should note that while butt hinges are economical, they may not support heavier applications effectively.

How Do Piano Hinges Enhance Functionality in Marine Projects?

Piano hinges, also known as continuous hinges, offer a long, continuous design that provides stability and support across a larger area. They are particularly suitable for console doors and storage center doors, with friction variants gaining popularity for their ability to hold doors at various angles. For B2B buyers, the choice between standard and friction piano hinges will depend on the specific requirements of the installation, including the need for smooth operation versus fixed positioning. Installation precision is crucial to maximize their benefits.

What Advantages Do Concealed Hinges Offer in Boat Design?

Concealed hinges are designed to be invisible when the door is closed, providing a sleek and modern aesthetic that is particularly appealing in high-end boat designs. They are mainly used for cabinet doors and other interior applications where appearance matters. B2B buyers should consider the complexity of installation, as concealed hinges often require precise cutting and alignment. While they enhance the overall look of the vessel, the installation process can be more labor-intensive compared to simpler hinge types.

How Do Friction Hinges Support Adjustable Applications in Boats?

Friction hinges are unique in that they allow for controlled movement, maintaining the position of doors or lids without the need for additional hardware. These hinges are ideal for adjustable seat backs and storage compartments where stability is essential. When purchasing friction hinges, buyers must assess the force required to hold the hinge in place and ensure compatibility with the materials being used. While they offer significant operational advantages, friction hinges can experience wear over time, necessitating regular maintenance.

What Are the Unique Applications for Specialty Hinges in Marine Settings?

Specialty hinges cater to specific applications, such as securing bimini tops or providing ratcheting mechanisms for seat backs. These hinges are designed to meet unique requirements that standard hinges may not fulfill. B2B buyers should evaluate the cost versus the specific functionality needed for their projects. While specialty hinges can be more expensive than conventional options, their tailored solutions can enhance the overall functionality and user experience of the boat, making them a worthwhile investment in many cases.

Key Industrial Applications of hinge boat

| Industry/Sector | Specific Application of hinge boat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine Manufacturing | Installation of livewell lids and hatches | Enhances operational efficiency and user accessibility | Material durability, corrosion resistance, and load capacity |

| Recreational Vehicle | Console and storage center doors | Provides ease of access while ensuring safety and security | Hinge type (butt vs. piano), installation method, and size |

| Commercial Fishing | Access doors for storage compartments | Improves accessibility to critical equipment and supplies | Weather resistance, strength, and maintenance requirements |

| Marine Construction | Custom applications for specialty boats | Tailors functionality to specific needs, enhancing utility | Customization options, material choices, and compliance with marine standards |

| Boat Repair Services | Replacement of worn-out hinges | Reduces downtime and enhances boat longevity | Compatibility with existing structures and ease of installation |

How are hinge boats utilized in marine manufacturing?

In marine manufacturing, hinge boats are crucial for the installation of livewell lids and hatches. These components allow for efficient access to storage and operational areas, enhancing user accessibility. By utilizing durable materials like stainless steel, manufacturers ensure longevity and resistance to corrosion, which is vital for marine environments. International B2B buyers should prioritize sourcing hinges that meet specific load capacities and are compliant with marine standards to ensure safety and performance.

What role do hinge boats play in recreational vehicles?

Hinge boats are extensively used in recreational vehicles, particularly for console and storage center doors. These hinges allow for easy access while maintaining the safety and security of stored items. Buyers must consider the type of hinge—whether butt or piano—as well as the installation method, as these factors significantly impact functionality. Sourcing hinges that are weather-resistant and able to withstand the rigors of outdoor use is essential for ensuring long-term performance.

How do hinge boats benefit commercial fishing operations?

In the commercial fishing sector, hinge boats facilitate access to storage compartments, making it easier for crews to retrieve essential equipment and supplies. This accessibility is crucial for operational efficiency and can directly impact productivity. Buyers in this sector should focus on sourcing hinges that offer high weather resistance and strength to withstand harsh marine conditions. Additionally, maintenance requirements should be minimal to prevent operational downtime.

What custom applications exist for hinge boats in marine construction?

Marine construction often requires custom applications for specialty boats, where hinge boats can be tailored to meet specific functional needs. This customization enhances the utility of the boat, allowing for unique features that cater to different marine activities. Buyers should consider options for customization, material choices, and compliance with marine industry standards to ensure that the hinges will perform effectively in their intended applications.

Illustrative image related to hinge boat

Why is hinge replacement important for boat repair services?

For boat repair services, replacing worn-out hinges is critical to reducing downtime and enhancing the longevity of the vessel. Hinge boats play a vital role in maintaining the structural integrity of doors and access points. When sourcing replacements, compatibility with existing structures is essential, along with ease of installation to streamline the repair process. Buyers should also evaluate the durability of materials to ensure that new hinges can withstand the marine environment effectively.

3 Common User Pain Points for ‘hinge boat’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right Type of Hinge for Specific Applications

The Problem: B2B buyers often face challenges when selecting the appropriate hinge type for various marine applications. With numerous options available—like butt hinges, piano hinges, and friction hinges—buyers may feel overwhelmed. Each hinge type has distinct functionalities, and choosing incorrectly can lead to operational inefficiencies or even safety hazards. For instance, using a standard butt hinge on a console door instead of a friction hinge might result in the door swinging uncontrollably, posing risks to crew members and equipment.

The Solution: To effectively choose the right hinge, buyers should start by assessing the specific application requirements. For example, if the hinge is intended for a console door, opt for friction hinges that provide controlled movement. Detailed specifications such as weight capacity, corrosion resistance, and the environmental conditions (e.g., saltwater exposure) must be considered. Engaging directly with manufacturers or suppliers can provide insights into the best hinge types for particular projects. Additionally, consulting technical datasheets and installation guides can further clarify the best choices, ensuring that the selected hinges enhance functionality and safety.

Scenario 2: High Maintenance Costs Due to Corrosion

The Problem: In regions with high humidity or saltwater exposure, many businesses struggle with hinges that corrode quickly, leading to increased maintenance costs and operational downtime. Corroded hinges can impede the opening and closing of boat doors, lids, and hatches, which may interrupt service and result in lost revenue. Buyers often find themselves replacing hinges more frequently than anticipated, leading to frustration and additional expenses.

The Solution: To mitigate corrosion issues, B2B buyers should prioritize sourcing hinges made from high-grade stainless steel or other corrosion-resistant materials specifically designed for marine environments. It’s crucial to check for certifications and warranties that guarantee resistance to rust and wear. Furthermore, implementing a regular maintenance schedule that includes cleaning and inspecting hinges can help prolong their lifespan. Applying marine-grade lubricants periodically can also prevent rust formation and ensure smooth operation. Buyers should consider forming partnerships with reliable suppliers who understand the regional environmental challenges and can recommend suitable products.

Scenario 3: Installation Challenges Leading to Inefficiencies

The Problem: Installation difficulties are a common pain point for B2B buyers, particularly when dealing with complex hinge types or when retrofitting existing structures. Improper installation can lead to misalignment, which not only affects the functionality of the hinge but also poses safety risks. Buyers may experience frustration when their team lacks the necessary skills or tools for proper installation, resulting in wasted time and resources.

The Solution: To address installation challenges, buyers should invest in comprehensive training for their teams, focusing on the specific hinge types being used. Additionally, sourcing hinges that come with detailed installation instructions and support can significantly reduce errors. Utilizing hinges designed for ease of installation, such as top-mount or swaged hinges, can also simplify the process. When retrofitting, it’s essential to accurately measure existing hinge placements and consider hiring professional installers if the task exceeds in-house capabilities. Establishing a relationship with a supplier that offers technical support can further assist buyers in navigating complex installations, ultimately improving efficiency and reducing downtime.

Strategic Material Selection Guide for hinge boat

What Are the Key Properties of Common Materials Used for Boat Hinges?

When selecting materials for boat hinges, it’s essential to consider their properties, especially in marine environments where exposure to saltwater, humidity, and varying temperatures can significantly affect performance. The most common materials include stainless steel, aluminum, plastic, and bronze. Each material has unique characteristics that influence their suitability for specific applications.

How Does Stainless Steel Perform as a Material for Boat Hinges?

Stainless steel is widely regarded as the premium choice for marine hinges due to its excellent corrosion resistance and durability. It typically has a high tensile strength, making it suitable for high-stress applications. Stainless steel hinges can withstand extreme temperatures and pressures, which is essential for boats operating in diverse climates.

Pros: Exceptional durability, resistance to rust and corrosion, appealing aesthetic finish, and high strength.

Cons: Higher cost compared to other materials, potential for galvanic corrosion if not properly isolated from dissimilar metals.

Impact on Application: Stainless steel hinges are ideal for saltwater applications, such as on yachts and fishing boats, where exposure to harsh conditions is frequent.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is critical. Buyers from regions like Europe and the Middle East often prefer high-grade stainless steel (e.g., 316 grade) for its superior corrosion resistance.

What Role Does Aluminum Play in Boat Hinge Applications?

Aluminum is another popular material for boat hinges, known for its lightweight properties and resistance to corrosion. It is often used in smaller boats or applications where weight is a crucial factor, such as in racing or performance boats.

Pros: Lightweight, good corrosion resistance, and lower cost compared to stainless steel.

Cons: Less durable than stainless steel, can be prone to bending under heavy loads, and may require anodizing for enhanced corrosion resistance.

Impact on Application: Aluminum hinges are suitable for freshwater applications and lighter marine environments, making them ideal for smaller vessels and recreational boats.

Considerations for International Buyers: Buyers should ensure that aluminum hinges meet local standards for marine applications, particularly in regions like South America where regulations may vary.

How Do Plastic Hinges Compare in Terms of Performance and Cost?

Plastic hinges are often considered for budget-sensitive applications. They are lightweight and resistant to corrosion, making them a viable option for certain marine environments.

Pros: Cost-effective, lightweight, and resistant to corrosion.

Cons: Lower strength and durability compared to metal options, limited temperature resistance, and potential for cracking under stress.

Impact on Application: Best suited for non-structural applications, such as storage compartments and lightweight lids on boats.

Considerations for International Buyers: Buyers should be aware of the quality of plastic used, as not all plastics are suitable for marine environments. Compliance with local regulations and standards is also essential.

What Advantages Does Bronze Offer for Boat Hinges?

Bronze is a traditional material used in marine applications, known for its excellent corrosion resistance, especially in saltwater. It also has a high strength-to-weight ratio, making it suitable for various applications.

Pros: Superior corrosion resistance, durability, and aesthetic appeal.

Cons: Higher cost than aluminum and plastic, potential for discoloration over time.

Impact on Application: Ideal for high-end marine applications, such as on luxury yachts and boats exposed to harsh marine environments.

Considerations for International Buyers: Buyers should ensure that bronze hinges comply with relevant marine standards, particularly in regions like Europe where quality and durability are prioritized.

Summary Table of Material Selection for Boat Hinges

| Material | Typical Use Case for hinge boat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-stress applications on yachts | Exceptional durability and corrosion resistance | Higher cost, risk of galvanic corrosion | High |

| Aluminum | Lightweight applications on smaller boats | Lightweight and cost-effective | Less durable, prone to bending | Medium |

| Plastic | Non-structural applications | Cost-effective and lightweight | Lower strength and durability | Low |

| Bronze | High-end marine applications | Superior corrosion resistance | Higher cost, potential discoloration | High |

This guide provides a comprehensive overview of material selection for boat hinges, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hinge boat

What Are the Main Stages of Manufacturing Boat Hinges?

The manufacturing process of boat hinges encompasses several critical stages that ensure the final product meets both functional and aesthetic requirements. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Prepared?

The choice of material is paramount in the production of boat hinges. Typically, stainless steel, aluminum, and high-grade plastics are utilized due to their resistance to corrosion and durability in marine environments. During material preparation, raw materials undergo thorough inspection to verify their quality and suitability. This includes checking for impurities, measuring thickness, and ensuring compliance with international standards such as ASTM or ISO specifications.

Once approved, the materials are cut to size using precision cutting methods like laser cutting or waterjet cutting, which provide clean edges and minimize waste.

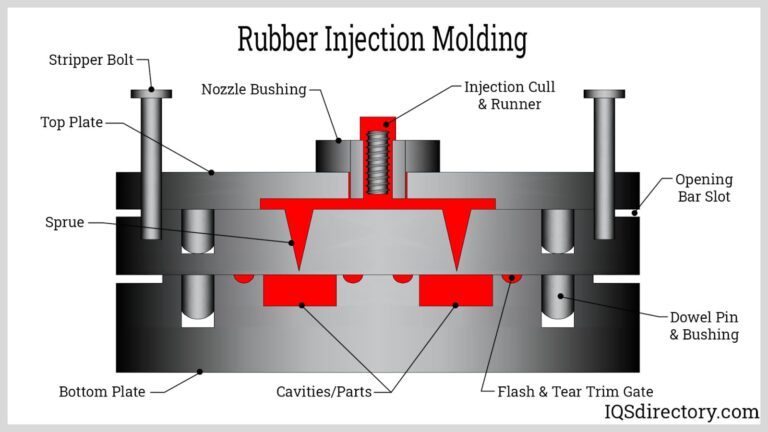

How Are Boat Hinges Formed?

The forming stage involves shaping the cut materials into the desired hinge components. Techniques such as stamping, forging, and machining are commonly employed. Stamping is particularly effective for producing high volumes of identical parts, while forging enhances the strength of the hinge through deformation under heat and pressure.

For more intricate designs, CNC machining is utilized to achieve precise tolerances and complex geometries. This technology allows manufacturers to create custom hinges tailored to specific customer needs, which is especially important for B2B buyers seeking unique solutions.

What Happens During the Assembly Process?

After individual components are formed, the assembly process begins. This stage often involves welding, riveting, or using fasteners to join parts together. For friction hinges, careful calibration is crucial to ensure the correct amount of resistance is achieved. Assembly may also include the installation of additional features like gaskets or seals, which enhance water resistance and longevity.

Quality control measures are implemented at this stage to ensure all components fit together properly and function as intended. Any defects identified during assembly are addressed immediately to prevent further complications.

What Finishing Techniques Are Commonly Used?

The finishing stage enhances both the appearance and performance of the boat hinges. Common techniques include polishing, anodizing, and powder coating. Polishing provides a smooth, reflective surface that is visually appealing, while anodizing offers added protection against corrosion, particularly for aluminum hinges.

Powder coating can be applied to create a durable, weather-resistant finish in various colors, catering to the aesthetic preferences of boat manufacturers and owners. This finishing touch is essential for B2B buyers who prioritize both form and function in their procurement decisions.

How Is Quality Assurance Integrated Into the Manufacturing Process?

Quality assurance (QA) is a critical component of hinge manufacturing, ensuring that products meet rigorous international standards and customer expectations.

What International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems, emphasizing continuous improvement and customer satisfaction. For boat hinges, industry-specific certifications like CE marking (for compliance with European safety standards) and API (American Petroleum Institute) standards may also apply, depending on the intended use.

These certifications not only assure product quality but also enhance marketability in global trade, making them essential for B2B buyers looking to establish credibility in their respective markets.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that defects are identified and rectified early. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before processing begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, random sampling and testing of components are conducted to monitor quality continuously.

-

Final Quality Control (FQC): Before shipping, each batch of finished hinges undergoes a final inspection, where functionality tests, dimensional checks, and surface quality evaluations are performed.

What Common Testing Methods Are Employed?

Testing methods vary based on the hinge type and its application. Common tests include:

- Load Testing: Ensures that hinges can withstand operational loads without failure.

- Corrosion Resistance Testing: Subjects hinges to harsh environmental conditions to evaluate their durability against saltwater and humidity.

- Dimensional Inspection: Utilizes calipers and gauges to verify that hinges conform to specified dimensions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures of potential suppliers.

What Steps Can Buyers Take for Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control processes. Audits can be performed by the buyer or through a third-party organization specializing in quality assessments. During an audit, buyers should evaluate:

- Quality Management Systems: Review documentation related to ISO certifications and other relevant standards.

- Production Processes: Observe manufacturing processes to ensure compliance with stated practices.

- Quality Records: Examine records of previous inspections and testing results for consistency and reliability.

How Important Are Reports and Third-Party Inspections?

Requesting quality control reports from suppliers can provide insight into their production capabilities and reliability. Additionally, third-party inspections serve as an unbiased evaluation of the supplier’s quality assurance processes. This is particularly important for international B2B buyers who may face language barriers or differences in regulatory standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances. Differences in regional standards and practices can impact the procurement process.

For instance, European buyers may place a higher emphasis on CE marking compliance, while buyers in other regions might prioritize cost-effectiveness over certification. Understanding these regional preferences is crucial for effective negotiation and supplier selection.

Furthermore, establishing clear communication channels and expectations regarding quality standards can mitigate misunderstandings and ensure a smoother procurement experience.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for boat hinges is essential for B2B buyers. By focusing on material selection, production techniques, and rigorous quality control, buyers can make informed decisions that align with their operational requirements and market standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hinge boat’

In the competitive landscape of marine hardware procurement, sourcing the right hinges for boats is essential for ensuring functionality, durability, and overall performance. This guide offers a structured approach for B2B buyers looking to source high-quality boat hinges, providing actionable steps that will facilitate informed decision-making.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for aligning your needs with the right product. Determine the type of hinge required—be it butt hinges, piano hinges, or specialty hinges—based on the application, such as lids, doors, or hatches. Pay attention to dimensions, weight capacities, and material requirements, as these factors will significantly impact the hinge’s performance in a marine environment.

Step 2: Research Material Options

The choice of material is crucial for longevity and resistance to marine conditions. Stainless steel is often preferred for its strength and resistance to corrosion, while plastic hinges may offer cost savings for less demanding applications. Consider the environmental factors your hinges will face, such as saltwater exposure and temperature fluctuations, to ensure you select the most suitable material.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, a thorough evaluation is essential. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a proven track record in marine hardware and check for certifications that affirm their adherence to quality standards, such as ISO or ASTM.

Step 4: Assess Product Range and Customization Options

Not all projects are alike, and having access to a diverse product range can be a significant advantage. Review suppliers’ catalogs to understand their offering and ensure they can meet your specific requirements. Additionally, inquire about customization options, as tailored solutions can enhance functionality and fit.

Step 5: Verify Compliance with Industry Standards

Ensure that the hinges comply with relevant marine industry standards and regulations. This is critical not just for safety, but also for ensuring that the products will perform as expected in demanding marine environments. Suppliers should provide documentation that verifies compliance, including test results and certifications.

Step 6: Evaluate Pricing and Payment Terms

Once you’ve shortlisted potential suppliers, compare pricing structures and payment terms. Be cautious of prices that seem too good to be true, as they may indicate inferior quality. Look for transparent pricing that includes details on shipping, taxes, and potential discounts for bulk purchases.

Step 7: Establish a Quality Assurance Process

Finally, develop a quality assurance process to evaluate the hinges upon receipt. This should include inspections for material integrity, functionality, and compatibility with your specifications. Establishing this process will help mitigate risks associated with defective products and ensure that the hinges meet your operational standards.

By following this structured checklist, B2B buyers can make informed decisions when sourcing boat hinges, ensuring they select products that meet their technical needs while partnering with reputable suppliers.

Comprehensive Cost and Pricing Analysis for hinge boat Sourcing

What Are the Key Cost Components in Sourcing Boat Hinges?

When sourcing boat hinges, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The most significant portion of the cost is attributed to materials. Stainless steel is often preferred for its durability and resistance to corrosion, particularly in marine environments. However, options like plastic may provide a cost-effective alternative for less demanding applications.

-

Labor: Labor costs can vary significantly based on the manufacturing location. Countries with lower labor costs, such as Vietnam, may offer competitive pricing, while European manufacturers may have higher labor costs, impacting overall pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, equipment maintenance, and utilities. Efficient manufacturing processes can reduce overhead costs, which is essential for pricing competitiveness.

-

Tooling: Custom tooling can be a substantial initial investment, particularly for specialized hinge designs. The cost will also depend on the complexity of the hinge and the volume of production.

-

Quality Control (QC): Rigorous QC processes ensure that the hinges meet industry standards and customer specifications. These costs can vary based on the supplier’s quality assurance practices and certifications.

-

Logistics: Transportation costs can be significant, especially for international shipments. Factors such as distance, shipping method, and customs duties play vital roles in determining logistics costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and generate revenue. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Impact Boat Hinge Costs?

Several factors influence the pricing of boat hinges, particularly for B2B buyers in diverse regions:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Negotiating favorable MOQs can significantly affect pricing, especially for smaller buyers.

-

Specifications and Customization: Customized hinges that meet specific project requirements may incur additional costs. Buyers should weigh the need for customization against budget constraints.

-

Materials: The choice between stainless steel, plastic, or other materials will greatly influence the price. While stainless steel hinges offer longevity, they come at a premium.

-

Quality and Certifications: Higher-quality hinges that comply with international standards may cost more but can lead to reduced maintenance and longer lifespans, ultimately lowering the Total Cost of Ownership (TCO).

-

Supplier Factors: Relationships with suppliers can impact pricing. Established suppliers may offer better terms, while new entrants might provide lower prices to penetrate the market.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international buyers. Terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can affect overall costs and risk management.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Boat Hinges?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, implementing strategic sourcing practices can lead to cost savings:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for larger orders. Explore opportunities for discounts based on volume or long-term contracts.

-

Focus on Total Cost of Ownership: Evaluate not just the initial purchase price but also maintenance costs, expected lifespan, and performance when assessing hinge options. This holistic view can lead to better long-term investments.

-

Consider Regional Suppliers: Sourcing from local or regional manufacturers can reduce logistics costs and import duties, making the total cost more manageable.

-

Stay Informed About Market Trends: Understanding industry trends, such as material price fluctuations or technological advancements in hinge design, can provide leverage during negotiations.

-

Be Aware of Pricing Nuances: International buyers should consider currency fluctuations, trade tariffs, and political stability in supplier countries, as these factors can affect pricing and delivery timelines.

In conclusion, a thorough understanding of cost components, pricing influencers, and strategic sourcing tips can empower B2B buyers to make informed decisions when sourcing boat hinges. By leveraging these insights, businesses can optimize their procurement processes and enhance overall profitability.

Alternatives Analysis: Comparing hinge boat With Other Solutions

Introduction to Alternative Solutions in Marine Applications

When considering the best solutions for marine applications, particularly in the context of boat hinges, it’s essential to explore alternatives that can achieve similar functionality. The right choice will depend on various factors, including performance, cost, ease of implementation, maintenance, and specific use cases. This analysis will compare the traditional hinge boat solution with other viable alternatives, enabling international B2B buyers to make informed decisions tailored to their unique operational needs.

Comparison Table

| Comparison Aspect | Hinge Boat | Friction Hinges | Piano Hinges |

|---|---|---|---|

| Performance | Reliable for heavy use; supports significant weight | Provides controlled movement; adjustable resistance | Smooth operation; good for long spans |

| Cost | Moderate to high; varies with material | Generally lower; varies with design | Affordable; widely available |

| Ease of Implementation | Requires specific installation skills | Easy to install; may need precise adjustments | Simple installation; minimal tools required |

| Maintenance | Low maintenance; corrosion-resistant options available | Requires periodic checks for wear | Low maintenance; durable materials available |

| Best Use Case | Ideal for heavy-duty applications like hatches and doors | Suitable for applications needing variable resistance | Best for longer spans, like console doors |

Detailed Breakdown of Alternatives

Friction Hinges

Friction hinges are designed to hold doors and hatches in place at various angles, providing adjustable resistance. They are particularly advantageous in applications where controlled movement is required, such as on smaller boats or for lightweight access points. The primary benefits include lower cost and ease of installation. However, they may require more frequent maintenance checks to ensure the friction mechanism does not wear down over time, which can affect performance.

Illustrative image related to hinge boat

Piano Hinges

Piano hinges, also known as continuous hinges, are ideal for longer spans and are often used on storage compartments and console doors. They offer smooth operation and distribute weight evenly, which minimizes stress on the mounting surfaces. The affordability and availability of piano hinges make them a popular choice. However, they may not be suitable for heavy-duty applications where additional strength is required, as their design might not support significant weight without additional reinforcements.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right hinge solution is crucial for operational efficiency and longevity in marine applications. When evaluating options, consider the specific demands of your project, including weight capacity, environmental conditions, and installation complexity. For heavy-duty applications, the hinge boat remains a robust choice, while friction and piano hinges can provide effective alternatives for lighter or more specialized uses. By aligning your choice with the unique requirements of your operations, you can ensure optimal performance and cost-effectiveness in your marine applications.

Essential Technical Properties and Trade Terminology for hinge boat

What Are the Essential Technical Properties of Boat Hinges?

Understanding the critical specifications of boat hinges is vital for B2B buyers, particularly when sourcing components for marine applications. Below are some essential technical properties that influence performance, longevity, and overall suitability for specific projects.

1. Material Grade: Why Is It Important?

The material grade of boat hinges primarily determines their strength, corrosion resistance, and suitability for marine environments. Stainless steel is a popular choice due to its durability and resistance to rust and corrosion, making it ideal for saltwater applications. Buyers should also consider the grade of stainless steel; for example, 316 stainless steel offers superior corrosion resistance compared to 304, which may be sufficient for freshwater applications. Understanding material grades helps in selecting hinges that will withstand environmental stresses, thereby reducing maintenance costs and increasing longevity.

2. Load Capacity: How Much Weight Can It Handle?

Load capacity is a crucial specification that defines how much weight a hinge can support without failure. It is essential for applications like boat doors, hatches, and livewell lids. Buyers should ensure that the hinges selected can accommodate not just the weight of the door but also any additional loads that may be applied during use. Overlooking this specification could lead to premature failure and costly repairs.

3. Tolerance: What Is the Significance of Precision?

Tolerance refers to the allowable deviation from a specified dimension. In the context of boat hinges, precise tolerances are critical for ensuring proper fit and function. If hinges are not manufactured within specified tolerances, they may not align correctly, leading to operational issues or mechanical failure. Understanding tolerance specifications allows buyers to ensure compatibility with other components in their marine projects.

4. Mounting Style: What Options Are Available?

The mounting style of a hinge impacts its installation and usability. Common styles include top mount, flush mount, and swaged mount. Each style has its own set of advantages and disadvantages. For instance, flush mount hinges offer a sleek appearance and minimize snag hazards, while top mount hinges are easier to install. Choosing the appropriate mounting style can enhance both aesthetics and functionality.

Illustrative image related to hinge boat

What Common Trade Terminology Should B2B Buyers Know?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are some key terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of boat hinges, understanding OEM specifications can help buyers source high-quality components that meet the original design requirements, ensuring compatibility and performance.

2. MOQ (Minimum Order Quantity)

MOQ represents the minimum number of units a supplier is willing to sell. This term is crucial for buyers looking to optimize costs; understanding MOQ can help in budgeting and inventory management. It’s important to negotiate MOQs that align with your project needs without incurring excess costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a price estimate for specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process by allowing them to compare prices and terms from multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers engaged in cross-border trade, as they clarify who is responsible for shipping, insurance, and tariffs, thereby minimizing the risk of disputes.

Illustrative image related to hinge boat

5. Friction vs. Non-Friction Hinges: What’s the Difference?

Friction hinges provide resistance to movement, allowing them to hold a position without additional support. This feature can be advantageous for applications where stability is required. Non-friction hinges, on the other hand, are designed for free movement. Knowing the differences helps buyers select the right type for their specific needs.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions, optimizing their sourcing strategy for boat hinges and enhancing overall project success.

Navigating Market Dynamics and Sourcing Trends in the hinge boat Sector

What Are the Key Market Dynamics and Trends Influencing the Hinge Boat Sector?

The hinge boat sector is experiencing notable growth driven by several global factors. Increased recreational boating activities, particularly in regions like Africa and South America, have led to a rising demand for durable and efficient hinge solutions. Innovations in materials, such as the use of corrosion-resistant stainless steel and advanced polymers, are shaping product offerings, making them more appealing to international B2B buyers. Additionally, the shift towards electric and hybrid boats is prompting manufacturers to adapt their hinge designs to meet new operational requirements, influencing sourcing decisions.

Emerging technologies, such as digital sourcing platforms and supply chain analytics, are revolutionizing how businesses procure hinges. These platforms enable buyers to compare products, assess supplier reliability, and streamline purchasing processes. Moreover, the rise of e-commerce in the marine industry allows for easier access to a wider range of products, including specialty hinges that cater to specific applications such as livewell lids and console doors. Buyers from Europe, like Germany, are increasingly leveraging these platforms to ensure they get the best value and quality.

How Are Sustainability and Ethical Sourcing Practices Shaping the Hinge Boat Industry?

Sustainability has become a critical consideration in the hinge boat sector, with environmental impact increasingly influencing purchasing decisions. B2B buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recyclable materials and minimizing waste in production processes. The demand for hinges made from environmentally friendly materials, such as recycled plastics or sustainably sourced metals, is on the rise.

Ethical sourcing is equally important, as international buyers are becoming more vigilant about the origins of their products. Companies that can provide transparency in their supply chains and demonstrate compliance with environmental and labor standards are gaining a competitive edge. Certifications such as ISO 14001 (Environmental Management) and other ‘green’ labels are increasingly sought after, as they assure buyers of a product’s sustainability credentials. As the hinge boat market continues to evolve, integrating sustainability into sourcing strategies will be essential for long-term success.

What Is the Historical Context of Hinge Development in the Marine Sector?

The evolution of hinges in the marine sector can be traced back to the early days of boat construction, where simple wooden pivots were used for door and hatch operations. As boating technology advanced, the demand for more durable and efficient hinges led to the introduction of metal options. The transition from traditional materials to stainless steel and specialized alloys marked a significant milestone, enhancing the longevity and reliability of hinges in harsh marine environments.

In recent years, the focus has shifted towards innovation, with manufacturers developing friction hinges and concealed designs that offer improved functionality and aesthetics. This evolution reflects the broader trends within the marine industry, where performance and sustainability are becoming paramount. Understanding this historical context allows international B2B buyers to appreciate the advancements in hinge technology and make informed decisions that align with current market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of hinge boat

-

How do I select the right hinge for my boat project?

Selecting the right hinge involves considering several factors such as the type of hinge (butt, piano, or friction), the intended use, and the mounting style. For instance, butt hinges are commonly used for lids and hatches, while piano hinges are better for doors requiring continuous support. Assess the material compatibility—stainless steel is durable but pricier, whereas plastic may suffice for less demanding applications. Finally, ensure the hinge can handle environmental factors like saltwater exposure, which can accelerate corrosion. -

What is the best material for marine hinges?

Stainless steel is generally regarded as the best material for marine hinges due to its resistance to corrosion and durability. It provides a polished look that enhances the aesthetic of any boat. However, plastic hinges can be a cost-effective alternative for applications that don’t require high durability. Consider the specific environmental conditions your hinges will face, as factors like humidity and exposure to seawater can influence your choice. -

What customization options are available for boat hinges?

Many suppliers offer customization options, such as specific dimensions, finishes, and even custom designs to meet your unique needs. You can specify the mounting style, whether top-mount, flush-mount, or offset, to ensure optimal fit and functionality. When discussing customization, it’s essential to communicate your requirements clearly to the supplier and inquire about any additional costs or lead times associated with bespoke orders. -

What are the minimum order quantities (MOQs) for marine hinges?

Minimum order quantities can vary significantly between suppliers. Some may require a MOQ of 100 units, while others might offer smaller quantities for trial orders. When sourcing hinges, it’s beneficial to confirm the MOQ upfront, especially if you’re testing a new product line. Additionally, consider negotiating terms if you foresee larger orders in the future, as suppliers may be more flexible for long-term partnerships. -

How can I vet suppliers for boat hinges?

To vet suppliers effectively, start by researching their reputation in the industry. Look for customer reviews, testimonials, and case studies to gauge reliability. Request samples to evaluate product quality firsthand and inquire about certifications related to quality assurance and environmental standards. Establish direct communication to assess their responsiveness and willingness to accommodate your needs, which can indicate their level of professionalism. -

What payment terms are typically offered by hinge suppliers?

Payment terms can vary widely depending on the supplier and the size of the order. Common options include upfront payment, partial payment upon order confirmation, and the balance due upon delivery. Some suppliers may offer net 30 or net 60 terms for larger orders, especially for established relationships. Always clarify payment conditions before finalizing your order to avoid any misunderstandings. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have established quality assurance protocols in place, including material inspections, dimensional checks, and testing for corrosion resistance. Ask suppliers about their quality control processes and if they have certifications like ISO 9001, which signifies adherence to international quality management standards. Request documentation or reports from recent quality audits to ensure their compliance with industry standards. -

How do logistics and shipping work for international orders of boat hinges?

When ordering internationally, logistics can be complex and should be discussed upfront with your supplier. Inquire about their shipping methods, estimated delivery times, and responsibilities for customs clearance. It’s crucial to understand incoterms (like FOB, CIF) that dictate who bears shipping costs and risks during transit. Additionally, ensure that the supplier can provide tracking information for your order, so you can monitor its progress until it reaches your location.

Top 6 Hinge Boat Manufacturers & Suppliers List

1. Gemlux – Marine Hinges

Domain: gemlux.com

Registered: 1995 (30 years)

Introduction: This company, Gemlux – Marine Hinges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

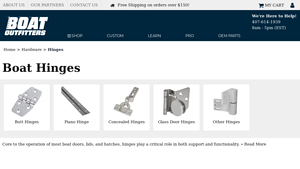

2. Boat Outfitters – Marine Hinges

Domain: boatoutfitters.com

Registered: 2002 (23 years)

Introduction: Boat Hinges – Best Marine Hinges | Boat Outfitters. Types of Hinges: Butt Hinges (common for livewell lids and hatches), Piano Hinges (used on console and storage center doors, available in standard and friction styles), Concealed Hinges (hidden look for cabinet doors), Glass Door Hinges (hold glass without drilling), Specialty Hinges (for applications like ratcheting seat backs and securing bimin…

3. Hinge Outlet – Stainless Steel Hinges

Domain: hingeoutlet.com

Registered: 2004 (21 years)

Introduction: This company, Hinge Outlet – Stainless Steel Hinges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Hodges Marine – Marine Door Hardware

Domain: hodgesmarine.com

Registered: 2006 (19 years)

Introduction: Marine Door Hardware – Hatch Hinges, Deck Hinges, Seat Hinges & More. Types of hinges available: stainless steel (304 or 316 SS), nylon (black or white), polished brass, chrome-plated Zamac. Options include strap, butt, T-strap, flush-mount, standard, heavy-duty bearing style, or offset hinges. Products include Taco Command Ratchet Hinges, Whitecap Door Hinges, Southco Adjustable Torque Position C…

5. Roca Industry – Boat Hinges

Domain: rocaindustry.com

Registered: 1997 (28 years)

Introduction: Boat hinges: Friction hinges, Lift-off hinges, Hatch hinges, Butt hinges, Piano hinges, Table hinges, Glass hinges, Heavy Duty Hatch hinges.

6. Eddie Marine – Custom Hatch Hinges

Domain: eddiemarine.com

Registered: 1997 (28 years)

Introduction: Hatch Hinges: Custom hinges popular with boat builders for a smooth finish. Products include: Long Reach Hatch Hinge – Replacement Pin and Keeper ($7.00), Long Reach Hatch Hinges ($72.00), Super Duty Offshore Hatch Hinges ($90.00), Hidden Hatch Hinge Aluminum Short (Pair) starting at $95.00, Hidden Hatch Hinges Aluminum Long starting at $95.00, Heavy Duty Blind Hole Hinge Billet Aluminum ($141.00)…

Strategic Sourcing Conclusion and Outlook for hinge boat

In conclusion, strategic sourcing of marine hinges is essential for optimizing operational efficiency and enhancing the durability of boat components. Buyers should prioritize quality materials, such as stainless steel, to ensure longevity and resilience against harsh marine environments. Understanding the different types of hinges—such as butt, piano, and friction hinges—allows companies to make informed decisions that align with their specific applications and performance requirements.

Moreover, evaluating factors like mounting styles and compatibility with existing materials can significantly affect installation ease and functionality. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, engaging with reliable suppliers who offer comprehensive product knowledge and superior customer service is vital for securing the best deals.

As the marine industry continues to evolve, staying abreast of emerging trends and technological advancements in hinge design will be crucial. We encourage buyers to take proactive steps in their sourcing strategies, ensuring they are well-equipped to meet the demands of an increasingly competitive marketplace. Investing in high-quality marine hinges today will pave the way for enhanced performance and customer satisfaction tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to hinge boat

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.