Choosing Your 316 Bar: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for 316 bar

In the competitive landscape of international manufacturing, sourcing high-quality 316 bar can pose significant challenges for B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. The need for durable and corrosion-resistant materials in various applications—from marine and chemical processing to architectural and industrial projects—makes understanding the nuances of 316 stainless steel critical. This guide is designed to provide a comprehensive overview of 316 bar, including its types, applications, and the factors influencing pricing.

As you navigate the global market, this resource will empower you to make informed purchasing decisions by offering insights into effective supplier vetting processes, cost considerations, and the latest industry trends. By understanding the specifications and performance characteristics of 316 bar, buyers can ensure they select the right materials for their projects, enhancing product longevity and operational efficiency.

Whether you’re looking to expand your supply chain or optimize material selection, this guide serves as an essential tool for international B2B buyers seeking to enhance their procurement strategies and drive business success in a globalized economy. Prepare to equip yourself with the knowledge needed to navigate the complexities of sourcing 316 bar and to forge strong partnerships with reliable suppliers worldwide.

Understanding 316 bar Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 316 Stainless Steel Bar | Excellent corrosion resistance, non-magnetic, high tensile strength | Marine, chemical processing, food industry | Pros: Durable, withstands harsh environments. Cons: Higher cost than lower grades. |

| 316L Stainless Steel Bar | Lower carbon content, improved weldability | Pharmaceutical, petrochemical | Pros: Reduced risk of carbide precipitation. Cons: Slightly lower strength than 316. |

| 316Ti Stainless Steel Bar | Titanium stabilized, excellent high-temperature performance | Aerospace, high-temperature applications | Pros: Enhanced stability in high heat. Cons: More expensive due to titanium alloying. |

| 316H Stainless Steel Bar | High carbon content for increased strength at elevated temperatures | Power generation, oil & gas | Pros: Retains strength under heat. Cons: May require careful handling due to carbon content. |

| 316F Stainless Steel Bar | Free-machining grade, enhanced machinability | Precision engineering, automotive | Pros: Easy to machine, reduces production time. Cons: Lower corrosion resistance compared to standard 316. |

What are the Characteristics and B2B Suitability of 316 Stainless Steel Bar?

The 316 stainless steel bar is renowned for its excellent corrosion resistance, making it ideal for applications in marine environments, chemical processing, and the food industry. Its non-magnetic properties and high tensile strength further enhance its suitability for various industrial applications. Buyers should consider the cost, as it is generally more expensive than lower grades, but the investment often pays off in durability and longevity.

How Does 316L Stainless Steel Bar Compare for Specific Applications?

The 316L variant features a lower carbon content, which significantly improves its weldability, making it particularly suitable for industries like pharmaceuticals and petrochemicals. This grade minimizes the risk of carbide precipitation during welding, which can lead to corrosion. Buyers should be aware that while 316L offers enhanced weldability, it may have slightly lower strength than standard 316, necessitating careful consideration of application requirements.

What Advantages Does 316Ti Stainless Steel Bar Offer in High-Temperature Environments?

316Ti stainless steel bars are titanium-stabilized, providing exceptional performance in high-temperature applications such as aerospace and power generation. The titanium content enhances the material’s stability and resistance to grain boundary precipitation. However, this grade is typically more expensive, which may be a consideration for buyers looking to balance budget with performance in demanding environments.

Why Choose 316H Stainless Steel Bar for Elevated Temperature Applications?

With a higher carbon content, the 316H stainless steel bar is designed to retain strength at elevated temperatures, making it ideal for use in the oil and gas industry and power generation sectors. While it offers significant strength benefits, buyers must handle this grade with care due to its carbon content, which can affect weldability and corrosion resistance compared to other 316 variants.

What is the Benefit of Using 316F Stainless Steel Bar in Precision Engineering?

The 316F stainless steel bar is a free-machining grade that enhances machinability, making it an excellent choice for precision engineering and automotive applications. This grade allows for quicker production times due to its ease of machining. However, it may sacrifice some corrosion resistance compared to standard 316, which buyers need to consider based on the environmental conditions of their applications.

Key Industrial Applications of 316 bar

| Industry/Sector | Specific Application of 316 bar | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine and Offshore | Structural components in ships and rigs | High corrosion resistance ensures longevity and reduces maintenance costs. | Verify certifications for marine-grade materials and compliance with international standards. |

| Chemical Processing | Equipment and piping systems | Resilience against harsh chemicals minimizes downtime and enhances safety. | Ensure compatibility with specific chemicals and obtain reliable supply chains. |

| Food and Beverage | Processing equipment and storage tanks | Non-reactive surface maintains product integrity and meets hygiene standards. | Confirm adherence to food safety regulations and certifications like FDA or EHEDG. |

| Pharmaceutical | Manufacturing equipment and containers | Prevents contamination, crucial for product safety and compliance. | Check for industry-specific certifications and traceability of materials. |

| Construction and Architecture | Reinforcement in high-stress environments | Provides strength and durability, essential for structural integrity. | Assess local sourcing capabilities and ensure compliance with building codes. |

How is 316 Bar Used in Marine and Offshore Applications?

In the marine and offshore sectors, 316 bar is commonly utilized for structural components in ships, oil rigs, and other marine equipment. Its high corrosion resistance against saltwater and harsh environments significantly reduces maintenance costs and extends the lifespan of critical components. For international buyers, particularly from regions like Africa and the Middle East, sourcing 316 bar must include verification of certifications for marine-grade materials to ensure compliance with international maritime standards.

What Role Does 316 Bar Play in Chemical Processing?

In chemical processing, 316 bar is essential for constructing equipment and piping systems that handle aggressive chemicals. Its resilience against corrosion and pitting ensures operational reliability, minimizing downtime and enhancing safety in hazardous environments. Buyers in South America and Europe should focus on the compatibility of 316 bar with specific chemicals and establish reliable supply chains to avoid disruptions in production.

Why is 316 Bar Critical for the Food and Beverage Industry?

The food and beverage industry relies on 316 bar for processing equipment and storage tanks due to its non-reactive surface, which maintains the integrity of food products and adheres to hygiene standards. This quality prevents contamination and ensures compliance with strict health regulations. B2B buyers, especially in Europe and Africa, must confirm that their suppliers meet food safety certifications like FDA or EHEDG to ensure compliance with local and international regulations.

How is 316 Bar Used in the Pharmaceutical Sector?

In the pharmaceutical industry, 316 bar is utilized for manufacturing equipment and containers that require high levels of cleanliness and resistance to contamination. This material is crucial for maintaining product safety and meeting regulatory compliance. Buyers need to check for industry-specific certifications and ensure traceability of materials, particularly when sourcing from international suppliers in regions such as South America and Europe.

What are the Construction Applications of 316 Bar?

In construction and architecture, 316 bar is used for reinforcement in high-stress environments, providing the necessary strength and durability for structural integrity. Its corrosion-resistant properties make it suitable for various applications, including bridges and high-rise buildings. When sourcing 316 bar, international buyers must assess local sourcing capabilities and ensure compliance with local building codes to meet project specifications.

3 Common User Pain Points for ‘316 bar’ & Their Solutions

Scenario 1: Sourcing Quality 316 Bar for Critical Applications

The Problem: A B2B buyer in the manufacturing sector is tasked with sourcing 316 stainless steel bar for a new project involving marine equipment. The challenge arises from the variety of suppliers available, each claiming to provide high-quality materials. However, the buyer is uncertain about the actual quality of the 316 bars offered, especially given the critical applications in corrosive environments. This uncertainty can lead to potential project delays and increased costs if subpar materials are used.

The Solution: To ensure the procurement of high-quality 316 bar, buyers should prioritize sourcing from reputable suppliers who provide certifications and detailed material test reports. It’s essential to request certificates of compliance with relevant standards such as ASTM A276 or ASTM A479, which specify the chemical composition and mechanical properties. Additionally, establishing a relationship with suppliers who offer traceability for their products can provide peace of mind. Buyers should also consider visiting suppliers’ facilities or requesting samples to assess the material firsthand before making a bulk purchase. By doing thorough due diligence and leveraging supplier relationships, buyers can mitigate the risk of receiving inferior products and ensure their project meets industry standards.

Scenario 2: Navigating Price Volatility in 316 Stainless Steel

The Problem: A buyer for a construction company faces the challenge of fluctuating prices for 316 stainless steel bars. With recent market trends indicating significant price spikes, the buyer must manage budget constraints while ensuring timely delivery of materials for ongoing projects. This unpredictability can jeopardize project timelines and profitability, as locked-in contracts may not account for sudden price increases.

The Solution: To navigate price volatility effectively, buyers should consider implementing a strategic purchasing approach that includes forward contracting or bulk purchasing agreements. By negotiating long-term contracts with fixed pricing, buyers can shield their projects from sudden market fluctuations. Additionally, maintaining open lines of communication with suppliers regarding market trends and price forecasts can provide valuable insights, allowing for better planning. Buyers might also explore alternative materials or grades for certain applications where permissible, potentially balancing cost and performance. Utilizing these strategies can help stabilize procurement costs and maintain project budgets.

Scenario 3: Ensuring Proper Specifications for 316 Bar Use

The Problem: An engineering firm is working on a project that requires precise specifications for 316 stainless steel bar, including dimensions, tolerances, and finish. However, the firm encounters difficulties due to inconsistent specifications from various suppliers, leading to compatibility issues with other components and potentially compromising the structural integrity of the final product.

The Solution: To avoid specification discrepancies, buyers should develop a comprehensive specification document that outlines exact requirements for dimensions, tolerances, and finishes. This document should be shared with potential suppliers to ensure they understand the project’s needs fully. Additionally, establishing a standardized approach to specifications across the organization can streamline the procurement process and reduce the risk of miscommunication. Buyers should also consider leveraging industry standards and guidelines, such as those from ASTM or ISO, to enhance clarity and ensure compliance. Regularly reviewing and updating these specifications in collaboration with engineers and suppliers can further enhance the alignment between product requirements and supplier offerings, ensuring successful project outcomes.

Strategic Material Selection Guide for 316 bar

When selecting materials for 316 bars, international B2B buyers must consider several common materials that can influence performance, cost, and application suitability. This analysis focuses on key properties, advantages and disadvantages, and specific considerations relevant to buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

What Are the Key Properties of 316 Stainless Steel Bars?

316 Stainless Steel is known for its excellent corrosion resistance, particularly in chloride environments, making it ideal for marine applications and chemical processing. It can withstand temperatures up to 870°C (1600°F) in continuous service and 925°C (1700°F) for intermittent service. Its mechanical properties include high tensile strength and good ductility, which are crucial for structural applications.

Pros: The primary advantages of 316 stainless steel include its superior corrosion resistance, durability, and suitability for high-temperature applications. It is also relatively easy to machine and weld, making it a versatile choice for various manufacturing processes.

Cons: The main limitation is its cost, which is higher than that of other stainless steel grades like 304. Additionally, while it performs well in many environments, it is not suitable for prolonged exposure to highly acidic conditions.

Impact on Application: 316 stainless steel is particularly compatible with aggressive media such as seawater, chemicals, and high-pressure environments, making it a preferred choice in industries such as oil and gas, food processing, and pharmaceuticals.

How Do Other Materials Compare to 316 Bars?

Carbon Steel is another common alternative. It offers good strength and is cost-effective, but lacks the corrosion resistance of stainless steel. It is suitable for structural applications but may require protective coatings for longevity in corrosive environments.

Pros: Carbon steel is durable, widely available, and inexpensive, making it a popular choice for many construction and manufacturing applications.

Cons: The primary disadvantage is its susceptibility to rust and corrosion, especially in humid or saline environments. It also has lower heat resistance compared to stainless steel.

Impact on Application: Carbon steel is best suited for applications where exposure to moisture is minimal or where protective measures can be implemented.

Aluminum is another material that can be considered, especially for lightweight applications. It has excellent corrosion resistance and is easy to machine.

Pros: Aluminum is lightweight, has good corrosion resistance, and is relatively inexpensive compared to stainless steel.

Cons: Its lower strength and heat resistance can limit its use in high-stress applications, and it may not perform well in high-temperature environments.

Impact on Application: Aluminum is ideal for applications requiring lightweight materials, such as in the aerospace and automotive industries, but may not be suitable for heavy-duty structural applications.

Titanium is a premium alternative known for its exceptional strength-to-weight ratio and corrosion resistance.

Pros: Titanium offers outstanding durability and is highly resistant to corrosion, making it suitable for extreme environments.

Cons: The major drawback is its high cost and complexity in manufacturing, which can be prohibitive for many applications.

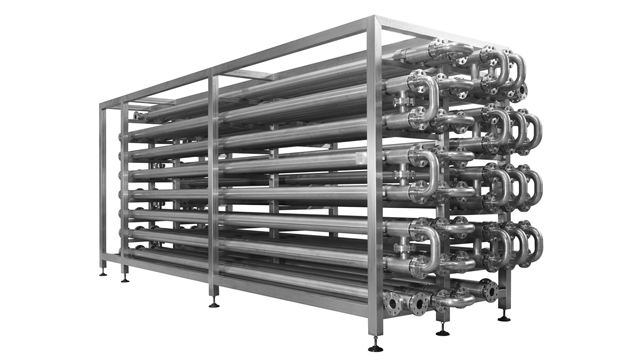

Illustrative image related to 316 bar

Impact on Application: Titanium is often used in aerospace, medical devices, and high-performance automotive applications where weight and strength are critical.

Summary of Material Comparisons

| Material | Typical Use Case for 316 bar | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 316 Stainless Steel | Marine, chemical processing | Excellent corrosion resistance | Higher cost compared to other steels | High |

| Carbon Steel | Structural applications | Durable and cost-effective | Susceptible to rust and corrosion | Low |

| Aluminum | Lightweight applications | Lightweight and easy to machine | Lower strength and heat resistance | Med |

| Titanium | Aerospace, medical devices | Outstanding strength-to-weight ratio | Very high cost and complex to manufacture | High |

In conclusion, the selection of materials for 316 bars involves a careful evaluation of properties, costs, and application suitability. Buyers should consider their specific needs and the environmental conditions in which the materials will be used, alongside compliance with international standards such as ASTM, DIN, and JIS, to ensure optimal performance and longevity.

In-depth Look: Manufacturing Processes and Quality Assurance for 316 bar

What are the Main Stages in the Manufacturing Process of 316 Bar?

The manufacturing process of 316 stainless steel bar involves several critical stages that ensure the final product meets the stringent requirements of various applications, particularly in industries such as construction, marine, and chemical processing.

Material Preparation: Sourcing and Melting

The first step in the manufacturing process is the careful selection of raw materials, primarily nickel, chromium, and molybdenum. These elements are sourced from reliable suppliers to ensure quality. The selected materials are then melted in an electric arc furnace (EAF) or a vacuum induction furnace (VIF). The melting process is crucial as it allows for precise control over the chemical composition, which directly influences the properties of the final product.

Forming: Casting and Hot Rolling

Once melted, the molten stainless steel is poured into molds to form semi-finished products such as billets or ingots. After solidifying, these billets undergo hot rolling, a process that involves heating them and then passing them through a series of rollers to achieve the desired shape and dimensions. This stage is vital for enhancing the mechanical properties of the steel, including its strength and ductility.

Finishing: Cold Drawing and Surface Treatment

After hot rolling, the bars may be subjected to cold drawing, which involves pulling the hot-rolled bars through a die to achieve tighter tolerances and improved surface finish. Following this, surface treatments such as pickling and passivation are applied to remove any oxides or contaminants, ensuring the bar’s corrosion resistance. This stage is essential for applications in harsh environments, where the integrity of the material is paramount.

Illustrative image related to 316 bar

What Quality Assurance Measures Are Typically Implemented?

Quality assurance (QA) in the manufacturing of 316 bars is essential to guarantee that the products meet both international standards and customer specifications.

What International Standards Apply to 316 Bar Production?

Manufacturers must adhere to various international standards, with ISO 9001 being the most recognized for quality management systems. This standard ensures that companies maintain consistent quality in their processes and products. Other industry-specific standards may include:

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

- API Spec Q1/Q2: Relevant for manufacturers supplying the oil and gas sector, ensuring that products meet rigorous quality and safety standards.

What are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure product integrity. These include:

- Incoming Quality Control (IQC): Raw materials are inspected upon receipt to verify compliance with specified standards.

- In-Process Quality Control (IPQC): During manufacturing, various parameters such as temperature, pressure, and dimensions are continuously monitored.

- Final Quality Control (FQC): Completed products undergo comprehensive testing to validate their performance against established specifications.

What Testing Methods Are Commonly Used for 316 Bars?

Several testing methods are employed to ensure the quality and performance of 316 bars:

- Chemical Analysis: Conducted to verify the composition of the steel, ensuring it meets the required standards for alloying elements.

- Mechanical Testing: Includes tensile testing, hardness testing, and impact testing to assess the material’s mechanical properties.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection are used to detect internal and surface defects without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some practical steps:

What Are the Best Practices for Conducting Supplier Audits?

Conducting on-site audits of suppliers can provide valuable insights into their manufacturing processes and QC practices. During an audit, buyers should evaluate:

- Quality Management Systems: Review documentation related to ISO certifications and quality policies.

- Production Processes: Observe manufacturing techniques and equipment used to ensure they meet industry standards.

- Employee Training: Assess the training programs in place to ensure that staff are knowledgeable about quality standards.

How Can Buyers Use Reports and Third-Party Inspections?

Buyers should request quality assurance reports, including material test reports (MTRs) and certificates of compliance, from suppliers. Additionally, third-party inspections can provide an unbiased assessment of the product quality. Engaging accredited inspection bodies can help verify that the products meet required specifications and standards.

What Nuances Should International B2B Buyers Consider Regarding QC and Certification?

International B2B buyers must be aware of the nuances in quality control and certification that may vary by region. For instance:

- Regulatory Compliance: Different countries may have specific regulations regarding material standards. Buyers should ensure that their suppliers are compliant with local and international regulations applicable to their market.

- Cultural Considerations: Understanding the cultural context can facilitate better communication with suppliers and improve the chances of successful collaboration.

In summary, the manufacturing processes and quality assurance for 316 bars are intricate and multifaceted. By understanding these processes, B2B buyers can make informed decisions, ensuring that they source high-quality materials that meet their specific needs and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘316 bar’

When sourcing 316 bar, a stainless steel alloy known for its corrosion resistance and strength, it’s essential to follow a structured approach. This guide will help international B2B buyers navigate the procurement process effectively, ensuring that they secure high-quality materials that meet their specific needs.

Step 1: Define Your Technical Specifications

Understanding the technical specifications for the 316 bar is critical. Determine the dimensions, tolerances, and any specific mechanical properties required for your applications. Consider factors such as environmental conditions and the intended use, which will influence your material choice.

- Dimensions: Specify diameter, length, and shape (round, square, etc.).

- Mechanical Properties: Consider yield strength, tensile strength, and elongation requirements.

Step 2: Research Market Trends and Pricing

Stay informed about current market trends and pricing fluctuations for 316 bar. This knowledge will help you make informed purchasing decisions and negotiate better terms with suppliers.

- Market Reports: Utilize industry reports and price indices to gauge average costs.

- Seasonal Variations: Recognize seasonal demand fluctuations that may impact pricing.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Look for companies with a strong reputation and experience in supplying 316 bar.

- Company Profiles: Request information about the supplier’s history, capabilities, and clientele.

- References: Ask for references from other businesses in your industry to validate their reliability and quality.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications that demonstrate compliance with industry standards, such as ISO 9001 or ASTM specifications. This step is crucial for maintaining quality assurance and meeting regulatory requirements.

- Documentation: Request copies of certifications and quality assurance processes.

- Inspection Procedures: Understand the supplier’s quality control measures and testing protocols.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the 316 bar for testing. This allows you to verify the material’s properties and ensure it meets your specifications.

- Testing Methods: Consider mechanical testing, corrosion resistance tests, and dimensional checks.

- Feedback Loop: Provide feedback to the supplier based on sample performance, which can help in final negotiations.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, it’s time to negotiate terms and conditions. This includes pricing, payment terms, delivery schedules, and warranties.

- Payment Terms: Discuss options such as upfront payments, net terms, or letters of credit.

- Delivery Guarantees: Ensure that the delivery timeline aligns with your project schedules to avoid delays.

Step 7: Establish a Long-Term Relationship

After successfully sourcing your 316 bar, focus on building a long-term relationship with your supplier. A strong partnership can lead to better pricing, priority service, and collaborative problem-solving in the future.

- Regular Communication: Keep an open line of communication to address any issues promptly.

- Feedback Mechanism: Establish a feedback mechanism to continuously improve the supplier’s service and product quality.

By following these steps, B2B buyers can ensure a systematic and effective sourcing process for 316 bar, ultimately leading to successful project outcomes and enhanced supplier relationships.

Comprehensive Cost and Pricing Analysis for 316 bar Sourcing

What Are the Key Cost Components in Sourcing 316 Bar?

When sourcing 316 stainless steel bars, it’s essential to understand the various cost components involved. The primary factors include:

-

Materials: The cost of raw 316 stainless steel is influenced by global market prices, which can fluctuate based on supply and demand dynamics. Buyers should keep an eye on commodity market trends to anticipate pricing changes.

-

Labor: Labor costs can vary significantly depending on the manufacturing location. Regions with higher labor costs, such as parts of Europe, may yield higher prices for the end product compared to countries in South America or Asia.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Factories with advanced manufacturing technologies may have lower overhead due to increased efficiency.

-

Tooling: The initial setup for tooling can be costly, especially for customized orders. However, once the tooling is established, the cost per unit can decrease with larger production runs.

-

Quality Control (QC): Implementing stringent QC measures ensures that the products meet required specifications, which may add to the overall cost. However, investing in quality can reduce long-term costs associated with defects and returns.

-

Logistics: Transportation costs are significant, especially for international shipments. Factors such as distance, shipping mode (air vs. sea), and fuel prices impact logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on competition, market demand, and the supplier’s positioning.

How Do Price Influencers Affect the Cost of 316 Bar?

Several factors influence the pricing of 316 bars, making it crucial for buyers to be aware of them:

-

Volume/MOQ: Purchasing in larger quantities can lead to significant discounts. Suppliers often have minimum order quantities (MOQs), and negotiating these can result in better pricing.

-

Specifications and Customization: Custom orders with specific dimensions, finishes, or certifications may incur additional costs. Standard sizes and specifications typically have more competitive pricing.

-

Materials: The grade and quality of the stainless steel used can affect pricing. Higher-quality materials will likely command a premium.

-

Quality and Certifications: Certifications such as ISO or ASTM standards can influence the price. Materials that meet rigorous quality standards may cost more but offer better long-term value.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge more for their products.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international buyers as they define the responsibilities of buyers and sellers concerning shipping, risk, and costs.

What Are the Best Tips for Negotiating Prices on 316 Bar?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, implementing effective negotiation strategies can lead to better pricing and terms:

-

Research and Benchmarking: Before negotiations, research market prices and supplier options to establish a baseline. Use this information to negotiate more effectively.

-

Focus on Total Cost of Ownership (TCO): When evaluating offers, consider not just the purchase price but also the total cost of ownership, which includes maintenance, operational costs, and potential downtime.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better deals. Long-term partnerships often yield favorable terms and pricing.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs or negotiate for future orders to secure lower prices.

-

Be Flexible: Consider alternative specifications or materials that could reduce costs without compromising quality.

-

Stay Informed: Keep abreast of industry trends, material availability, and geopolitical factors that could affect pricing.

Conclusion

Understanding the comprehensive cost and pricing landscape for 316 bar sourcing is crucial for making informed purchasing decisions. By considering cost components, price influencers, and effective negotiation strategies, B2B buyers can optimize their sourcing process and achieve better financial outcomes. Always remember to verify pricing with multiple suppliers and ensure that you’re getting the best value for your investment.

Alternatives Analysis: Comparing 316 bar With Other Solutions

Exploring Alternatives to 316 Bar: A Comparative Analysis

In the quest for optimal materials in manufacturing and construction, the 316 bar stands out due to its corrosion resistance and structural integrity. However, various alternative solutions may better fit specific operational needs or budget constraints. This analysis compares the 316 bar with two notable alternatives: 304 stainless steel and carbon steel, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | 316 Bar | 304 Stainless Steel | Carbon Steel |

|---|---|---|---|

| Performance | Excellent corrosion resistance, high strength at elevated temperatures | Good corrosion resistance, lower than 316 | High strength, but prone to corrosion |

| Cost | Higher cost due to alloying elements | More affordable, widely available | Generally the lowest cost option |

| Ease of Implementation | Requires specialized welding techniques | Easier to work with, can be welded using standard methods | Standard fabrication techniques applicable |

| Maintenance | Low maintenance due to durability | Moderate maintenance; may require protective coatings | High maintenance; prone to rust without treatment |

| Best Use Case | Marine, chemical processing, and high-temperature applications | Food processing, kitchen equipment, and general use | Construction, automotive, and heavy machinery |

Detailed Breakdown of Alternatives

304 Stainless Steel: A Viable Option

304 stainless steel is a popular alternative to 316 bar, known for its good corrosion resistance and excellent formability. It is often used in applications where exposure to corrosive environments is limited. The primary advantage of 304 is its cost-effectiveness; it typically costs less than 316 due to its simpler alloy composition. However, its lower resistance to chlorides means it may not be suitable for marine environments or highly corrosive applications. Its ease of welding and machining makes it a go-to choice for many manufacturers.

Carbon Steel: Cost-Effective but Maintenance-Intensive

Carbon steel is another alternative that offers significant strength at a lower price point. It is widely used in construction and manufacturing due to its high tensile strength and durability. However, carbon steel is susceptible to rust and corrosion, requiring regular maintenance and protective coatings to ensure longevity. This makes it less ideal for environments where moisture or corrosive substances are present. While it can be implemented using standard fabrication techniques, the need for protective measures can increase overall lifecycle costs.

Conclusion: Choosing the Right Material for Your Needs

When selecting the right material for your project, it is essential to consider the specific requirements of your application, including environmental conditions, budget constraints, and maintenance capabilities. The 316 bar is unparalleled in corrosive environments but comes at a premium. In contrast, 304 stainless steel provides a balanced approach for less demanding applications, while carbon steel offers a budget-friendly option with higher maintenance demands. By analyzing these factors, B2B buyers can make informed decisions that align with their operational needs and financial objectives.

Essential Technical Properties and Trade Terminology for 316 bar

What Are the Key Technical Properties of 316 Bar?

Understanding the technical properties of 316 stainless steel bar is crucial for businesses looking to utilize this material in various applications, particularly in industries like marine, chemical processing, and food production. Below are the essential specifications:

-

Material Grade

– The 316 bar is categorized as an austenitic stainless steel, primarily composed of iron, chromium (16-18%), nickel (10-14%), and molybdenum (2-3%). This composition enhances its corrosion resistance, especially in chloride environments, making it ideal for marine applications. -

Tensile Strength

– 316 stainless steel typically exhibits a tensile strength of around 70,000 psi (pounds per square inch). This property is critical for applications requiring materials that can withstand significant stress without deforming, ensuring durability and longevity in structural applications. -

Yield Strength

– The yield strength of 316 bar is generally about 30,000 psi. This value indicates the maximum stress that the material can withstand without yielding, making it a vital factor for engineers when designing components that must resist deformation under load. -

Corrosion Resistance

– One of the standout features of 316 stainless steel is its excellent resistance to corrosion, especially from chlorides and other harsh environments. This property is essential for applications in chemical processing and marine environments, where exposure to corrosive substances is common. -

Dimensional Tolerance

– The dimensional tolerance of 316 bar typically adheres to ASTM standards, ensuring uniformity and precision in manufacturing. Tolerances are crucial for ensuring that components fit together correctly, reducing the risk of mechanical failure in assemblies. -

Thermal Conductivity

– 316 stainless steel has moderate thermal conductivity, which is important for applications involving heat exchange. Understanding this property helps in selecting the right material for components that will experience temperature fluctuations.

What Trade Terms Should B2B Buyers Know About 316 Bar?

Navigating the procurement of 316 bar requires familiarity with specific trade terminology. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term helps buyers identify suppliers who provide components that meet their specific requirements. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest amount of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand, as it impacts inventory management and cost-efficiency when sourcing 316 bars. -

RFQ (Request for Quote)

– An RFQ is a standard business process where buyers invite suppliers to submit price quotes for specific products. Issuing an RFQ for 316 bar allows buyers to compare prices and services, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for B2B buyers to understand their obligations regarding shipping, insurance, and risk transfer when sourcing 316 bars globally. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order until the goods are delivered. Understanding lead time is vital for effective supply chain management, particularly when dealing with international suppliers. -

Certification

– Certification refers to the documentation that verifies that a product meets specific standards or regulations. For 316 bars, certifications such as ASTM or ISO can assure buyers of the quality and compliance of the material, which is crucial for industries with stringent safety requirements.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing 316 bars, ensuring they select the right materials for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the 316 bar Sector

What Are the Current Market Dynamics and Key Trends Influencing the 316 Bar Sector?

The 316 bar sector is experiencing robust growth, driven by increasing demand across various industries, including construction, automotive, and manufacturing. This material, known for its corrosion resistance and durability, is particularly favored in marine and chemical applications. Global drivers such as urbanization, infrastructure development, and advancements in manufacturing technologies are propelling the market. In emerging markets across Africa, South America, and the Middle East, there is a notable trend toward modernization, leading to higher consumption of stainless steel products, including 316 bars.

Illustrative image related to 316 bar

International B2B buyers are increasingly leveraging technology to enhance sourcing strategies. The rise of digital marketplaces and e-commerce platforms has simplified procurement processes, allowing buyers from regions like Vietnam and Germany to access a broader range of suppliers. Additionally, data analytics is gaining traction, enabling companies to forecast demand more accurately and optimize inventory management. Sustainability trends are also shaping sourcing decisions, with buyers seeking suppliers that demonstrate commitment to ethical practices and environmental stewardship.

Another emerging trend is the customization of products. Manufacturers are responding to the unique requirements of clients by offering tailored solutions that align with specific project needs. This is particularly relevant for sectors that require specific grades or dimensions of 316 bars. As the market evolves, adaptability and responsiveness will be crucial for suppliers aiming to capture the interest of international buyers.

How Is Sustainability and Ethical Sourcing Impacting the 316 Bar Sector?

Sustainability has become a cornerstone of sourcing strategies for B2B buyers in the 316 bar sector. The environmental impact of production processes, particularly in metallurgy, has led to heightened scrutiny. Buyers are increasingly prioritizing suppliers who implement sustainable practices, such as energy-efficient manufacturing and waste reduction initiatives. This shift is not only beneficial for the environment but also enhances the reputation of companies committed to corporate social responsibility.

Ethical sourcing is also gaining prominence, with buyers seeking assurance that their materials are sourced from suppliers who adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and the ResponsibleSteel certification for sustainable steel production are becoming important criteria in supplier evaluation. These certifications not only provide transparency but also mitigate risks associated with supply chain disruptions and reputational damage.

Furthermore, the use of recycled materials in the production of 316 bars is gaining traction. By incorporating recycled steel, manufacturers can significantly reduce their carbon footprint and resource consumption. This aligns with global sustainability goals and appeals to environmentally conscious buyers, particularly in markets like Europe, where regulatory frameworks are increasingly stringent.

What Is the Brief Evolution and History of the 316 Bar Sector?

The 316 bar sector has evolved significantly since the introduction of stainless steel in the early 20th century. Initially developed for its corrosion resistance, 316 stainless steel quickly gained recognition in various applications, particularly in marine environments where exposure to saltwater is a concern. Over the decades, advancements in metallurgy and processing techniques have led to the widespread use of 316 bars in diverse industries, including food processing, pharmaceuticals, and aerospace.

The globalization of trade has further accelerated the growth of the 316 bar market, enabling suppliers to reach international buyers and establish competitive pricing. As technology continues to advance, the future of the 316 bar sector will likely see innovations in production methods, enhancing both efficiency and sustainability. This evolution reflects the industry’s adaptability to changing market demands and the increasing importance of ethical sourcing and environmental responsibility in B2B transactions.

Frequently Asked Questions (FAQs) for B2B Buyers of 316 bar

-

How do I ensure the quality of 316 bar from suppliers?

To ensure the quality of 316 bar, start by requesting material certifications, such as ASTM or ISO standards. Look for suppliers who conduct regular quality control tests and can provide test reports for the specific batch you are purchasing. Consider asking for samples to evaluate the material’s properties before placing a large order. Additionally, check reviews and references from other clients to gauge the supplier’s reliability and quality history. -

What is the minimum order quantity (MOQ) for 316 bar?

Minimum order quantities (MOQ) for 316 bar can vary significantly between suppliers and regions. Typically, MOQs range from a few hundred kilograms to several tons. It’s crucial to communicate directly with potential suppliers to understand their specific MOQ policies and whether they can accommodate smaller orders, especially for new buyers or trial runs. -

What are the payment terms commonly offered for international purchases of 316 bar?

Payment terms for international purchases of 316 bar often include options like letters of credit, advance payments, or payment upon delivery. Suppliers may require a deposit upfront, especially for large orders. Discussing payment terms early in negotiations is vital to ensure both parties are comfortable and to avoid potential cash flow issues. -

How do I vet suppliers for 316 bar effectively?

Vetting suppliers for 316 bar involves several steps. Start by checking their business credentials, such as registration and certifications. Look for online reviews and testimonials from other clients. Engage in direct communication to assess their responsiveness and willingness to provide necessary documentation. Additionally, consider visiting their manufacturing facilities if feasible, or request third-party audits to ensure compliance with quality standards. -

What customization options are available for 316 bar?

Many suppliers offer customization options for 316 bar, including specific dimensions, finishes, and lengths. Discuss your requirements with potential suppliers to see if they can accommodate your needs. Customization may also extend to surface treatments or specific chemical compositions. Be prepared to provide detailed specifications to ensure the final product meets your expectations. -

What is the typical lead time for ordering 316 bar internationally?

Lead times for ordering 316 bar can vary based on the supplier’s location, inventory levels, and production capabilities. Generally, expect a lead time ranging from 2 to 8 weeks for international shipments. Factors such as customs clearance and logistics can also impact delivery times. Always confirm lead times with the supplier before placing an order to align your project timelines accordingly. -

What are the best practices for shipping 316 bar internationally?

When shipping 316 bar internationally, ensure that all documentation is complete, including customs declarations and shipping invoices. Utilize reputable freight forwarders who are familiar with international regulations and can handle customs clearance efficiently. Consider insurance for high-value shipments to mitigate potential losses. Additionally, discuss packaging options with your supplier to ensure the material is protected during transit. -

How can I assess the total cost of purchasing 316 bar?

To assess the total cost of purchasing 316 bar, consider not just the unit price but also shipping costs, customs duties, and any additional fees related to handling or storage. Request a detailed quote from suppliers that includes all associated costs. Additionally, factor in potential currency exchange rates and payment fees if applicable. This comprehensive approach will give you a clearer picture of the overall investment required.

Top 6 316 Bar Manufacturers & Suppliers List

1. Bar 316 – Weekly Events & Entertainment

Domain: bar316.com

Registered: 2015 (10 years)

Introduction: The Bar at 316 offers various events throughout the week: Monday Movie Night, Tuesday Karaoke at 10pm, Wednesday Game Show Night at 8pm, Thursday DJ Bryson Rider starting at 10pm, Friday Video Dance Night starting at 10pm, Saturday BIG FUN Drag Show with Buff Faye & Patti ‘O Furniture at Midnight, and Sunday Karaoke from 8pm to Midnight. Seasonal Kickball Afterparty is also available. Location: 31…

2. Metals Depot – 316 Stainless Steel Round

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: 316 Stainless Steel Round is an austenitic chromium nickel steel round bar containing molybdenum, providing superior corrosion resistance and increased strength at elevated temperatures compared to 304 Stainless. It is known as food grade or marine grade, suitable for applications in food production, pharmaceutical equipment, furnace parts, heat exchangers, valves and pumps, chemical equipment, an…

3. 316 Oyster Bar – Seafood Grill

Domain: 316oysterbar.com

Registered: 2008 (17 years)

Introduction: 316 Oyster Bar is a local bar and seafood grill located at 316 Owen Drive, Fayetteville, NC 28304. The establishment offers a menu featuring seafood dishes and is available for private events. Customers can contact them at 910-481-0530 for inquiries.

4. Fast Metals – Stainless Steel Flat Bar 316/316L

Domain: fastmetals.com

Registered: 2013 (12 years)

Introduction: Stainless Steel Flat/Rectangle Bar 316/316L (True Bar) 20% Off Purchases Over $200! Use Code FASTMETALS20

5. Midwest Steel Supply – 316 Stainless Steel Round Bar

Domain: midweststeelsupply.com

Registered: 2005 (20 years)

Introduction: {“product_name”: “316 Stainless Steel Round Bar”, “sizes_available”: [“1/8”, “1/4”, “5/16”, “3/8”, “7/16”, “1/2”, “9/16”, “5/8”, “3/4”, “7/8”, “1”, “1-1/8”, “1-1/4”, “1-3/8”, “1-1/2”, “1-5/8”, “1-3/4”, “1-7/8”, “2”, “2-1/8”, “2-1/4”, “2-3/8”, “2-1/2”, “2-5/8”, “2-3/4”, “2-7/8”, “3”, “3-1/8”, “3-1/4”, “3-1/2”, “3-5/8”, “3-3/4”, “3-7/8”, “4”, “4-1/4”, “4-1/2”, “4-3/4”, “5”, “5-1/4”, “5-1/2”, “5-3/4″…

6. Castle Metals – Stainless Steel 316/316L Round Bar

Domain: castlemetals.com

Registered: 1996 (29 years)

Introduction: {“item_number”: “6249”, “material”: “Stainless Steel 316/316L”, “shape”: “Round”, “diameter”: “6.5 IN”, “length_range”: “132.0000-156.0000 IN”, “specifications”: [“AMS.5653”, “AMS.5648”, “AMS.QQ-S-763”, “ASME.SA182”, “ASME.SA479”, “ASME.SA193”, “ASTM.A276”, “ASTM.A479”, “UNS.S31600”, “UNS.S31603”, “ASTM.A182”, “ASTM.A193”], “lbs_per_ft”: “117.18”, “tolerance”: {“length_tolerance”: {“positive”: “0….

Strategic Sourcing Conclusion and Outlook for 316 bar

In conclusion, the strategic sourcing of 316 stainless steel bars is essential for international B2B buyers seeking durable and versatile materials for various applications. The unique properties of 316 stainless steel, including its corrosion resistance and strength, make it an ideal choice for industries such as marine, chemical processing, and construction. By fostering relationships with reliable suppliers, buyers can ensure a consistent quality and supply chain stability, which are crucial for meeting production deadlines and maintaining operational efficiency.

As the global demand for 316 bars continues to rise, particularly in emerging markets across Africa, South America, the Middle East, and Europe, it is imperative for businesses to adopt a proactive approach in their sourcing strategies. Engaging with suppliers who understand regional market dynamics and can provide tailored solutions will enhance competitiveness and drive innovation.

Looking ahead, B2B buyers should prioritize building strategic partnerships that leverage technological advancements and sustainable practices. By doing so, they can not only secure high-quality materials but also contribute to a more sustainable future. Start exploring your sourcing options today to stay ahead in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.